Preparation method of tungsten-copper functional gradient material

A functionally graded material, tungsten-copper technology, applied in the field of materials engineering, can solve the problems of low preparation efficiency, easy introduction of impurities, and difficulty in controlling the particle size of tungsten-copper composite powder, achieving good uniformity, high purity, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

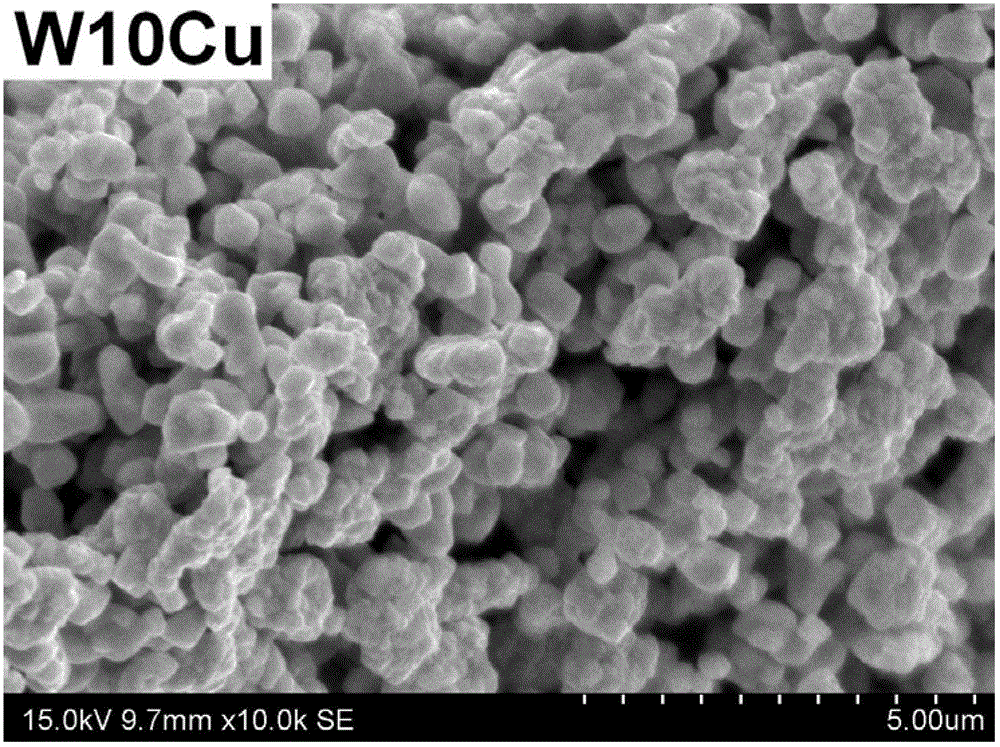

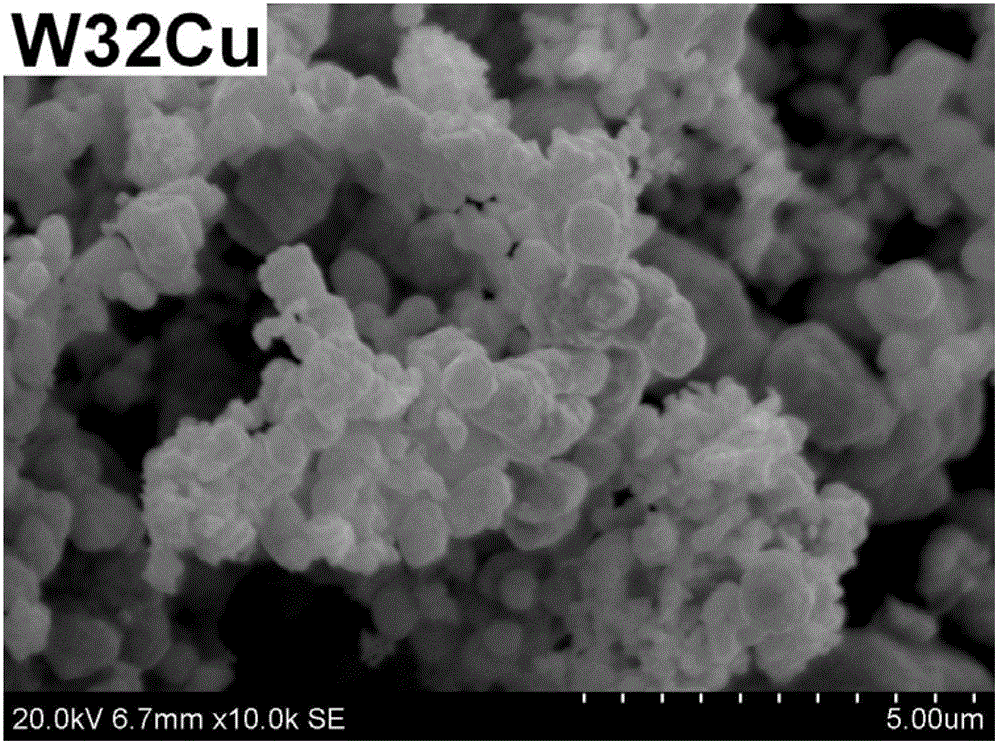

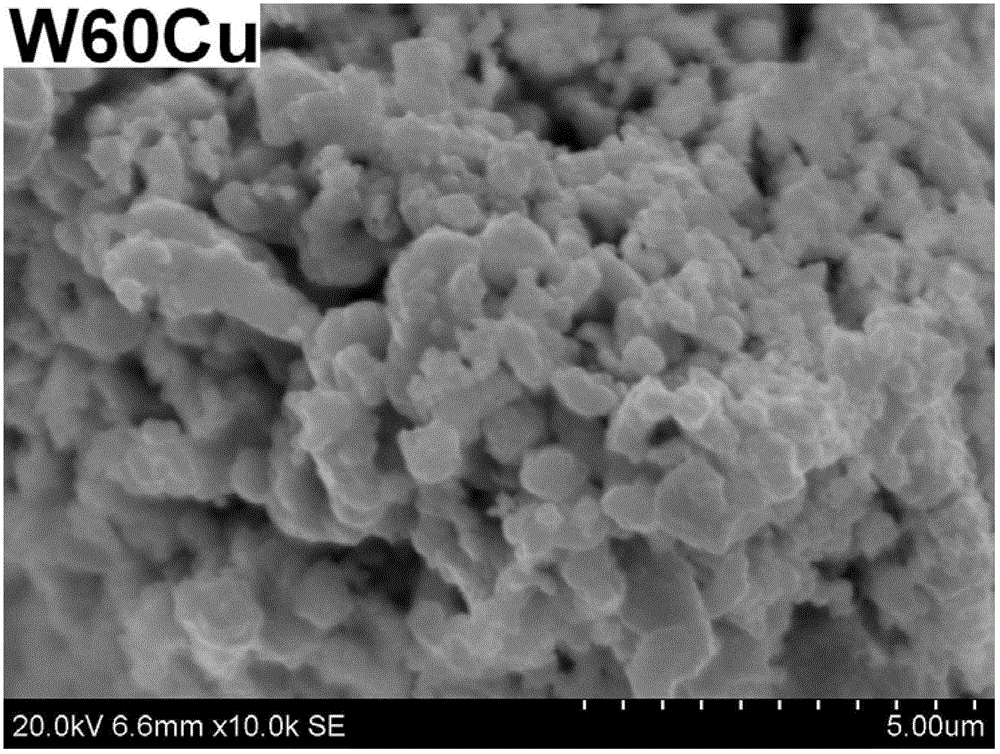

[0036] This embodiment is used to prepare a three-layer tungsten-copper functionally graded material, and the copper contents of the three layers are 10%, 32%, and 60% respectively. The specific implementation steps are as follows:

[0037] (1) Mix ammonium metatungstate, copper nitrate, and water into three kinds of solutions according to the mass ratio of 16:5:21, 10:13:23, and 1:4:5, and form a transparent sol after uniform stirring for 30 minutes system, the above sol was spray-dried at 140°C to obtain tungsten-copper composite precursor powders with three different tungsten-copper ratios.

[0038] (2) Calcining the above three kinds of tungsten-copper composite precursor powders in the air, the calcination temperature is 600°C, and the calcination time is 120 minutes, to obtain the corresponding three oxide composite powders.

[0039] (3) The above three oxide composite powders were mixed in H 2 Medium reduction, the reduction temperature is 700 ℃, respectively to obtai...

Embodiment 2

[0045] This embodiment is used to prepare a 4-layer tungsten-copper functionally graded material, and the copper contents of the 4 layers are 10%, 20%, 40%, and 80% respectively. The specific implementation steps are as follows:

[0046](1) Mix ammonium metatungstate, copper nitrate and water into 4 kinds of solutions according to the mass ratio of 16:5:21, 29:20:50, 5:9:15 and 1:11:12, and stir evenly for 30 A transparent sol system was formed after a few minutes. The above sol was spray-dried at 160°C to obtain four kinds of tungsten-copper composite precursor powders with different tungsten-copper ratios.

[0047] (2) The above four kinds of tungsten-copper composite precursor powders were calcined in air at a calcination temperature of 650°C and a calcination time of 90 minutes to obtain the corresponding four kinds of oxide composite powders.

[0048] (3) The above four kinds of oxide composite powders were mixed in H 2 Medium reduction, the reduction temperature is 60...

Embodiment 3

[0052] (1) Mix ammonium paratungstate, copper chloride, water, citric acid, and polyethylene glycol in proportions of 50:32:130:25:1, 21:31:80:15:1 and 9:31:70:12:1 The mass ratio of the solution was formulated into three kinds of solutions, and a transparent sol system was formed after uniform stirring for 30 minutes. The above sol was spray-dried at 120°C to obtain tungsten-copper composite precursor powders with three different tungsten-copper ratios.

[0053] (2) The above three kinds of tungsten-copper composite precursor powders were calcined in air at a calcination temperature of 500°C and a calcination time of 180 minutes to obtain the corresponding three oxide composite powders.

[0054] (3) The above three kinds of oxide composite powders were mixed in H 2 Medium reduction at a reduction temperature of 500°C, ultrafine tungsten-copper composite powders W30Cu (30% Cu content), W50Cu (50% Cu content) and W70Cu (70% Cu content) were obtained respectively.

[0055] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com