Light-weight wallboard drying equipment

A technology of lightweight wallboard and drying equipment, which is used in veneer drying, drying of solid materials, drying chambers/containers, etc. The effect of improving drying speed, shortening drying cycle and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

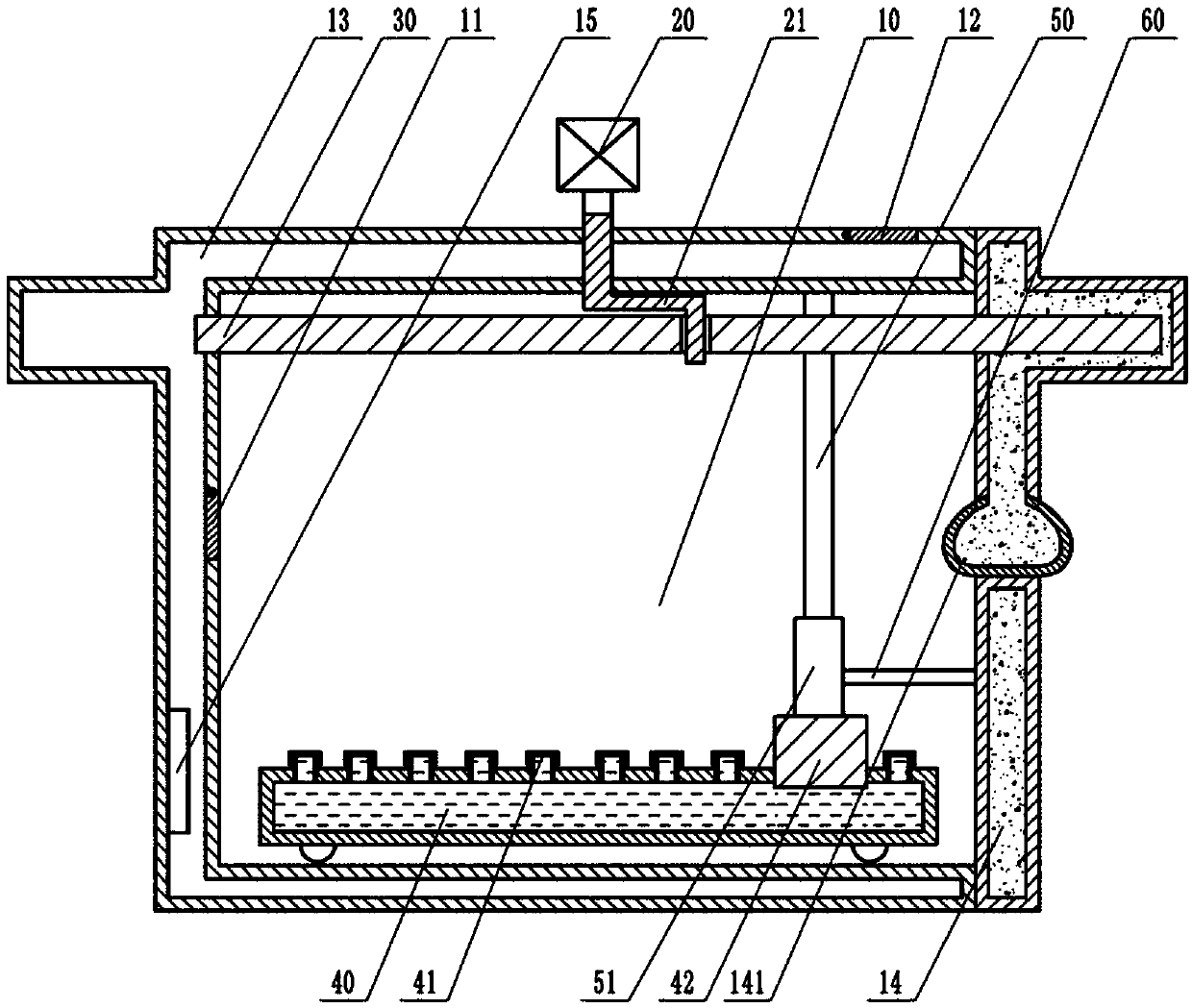

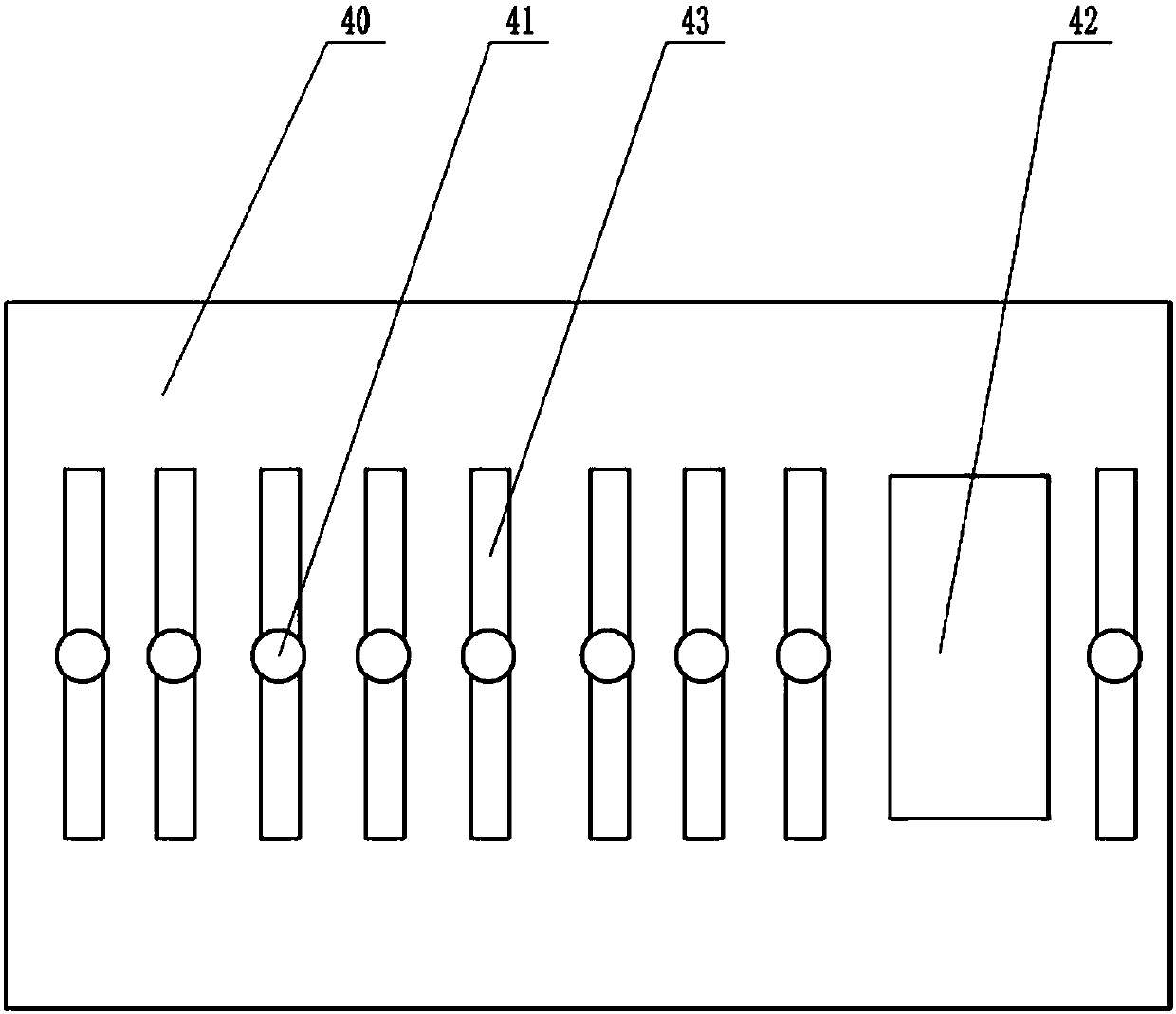

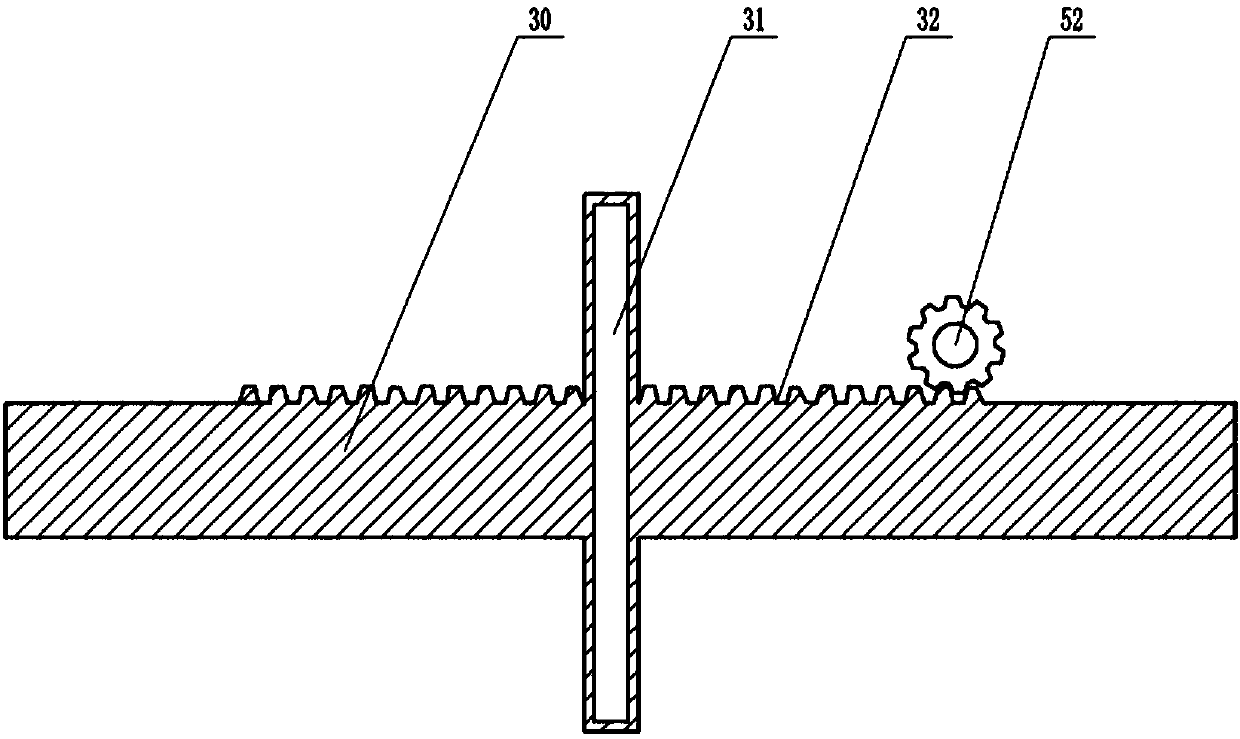

[0020] Instructions attached Figures 1 to 3 The reference signs in include: drying chamber 10, second one-way door 11, first one-way door 12, cavity 13, oil chamber 14, rubber sleeve 141, heating device 15, motor 20, Z-shaped rod 21, cross Slide bar 30, bar-shaped through hole 31, rack 32, conveying trolley 40, telescopic post 41, pressure post 42, support plate 43, telescopic bar 50, push post 51, gear 52, stop bar 60.

[0021] Such as Figure 1-Figure 3 As shown, the lightweight wallboard drying equipment includes a conveying trolley 40, a drying chamber 10 and a motor 20 located on the upper surface of the drying chamber 10. The output shaft of the motor 20 is connected with a Z-shaped rod 21, and the lower end of the Z-shaped rod 21 is located in the drying chamber. In the upper part of the chamber 10, start the motor 20 to make the Z-shaped bar 21 rotate around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com