Patents

Literature

183results about "Veneer drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

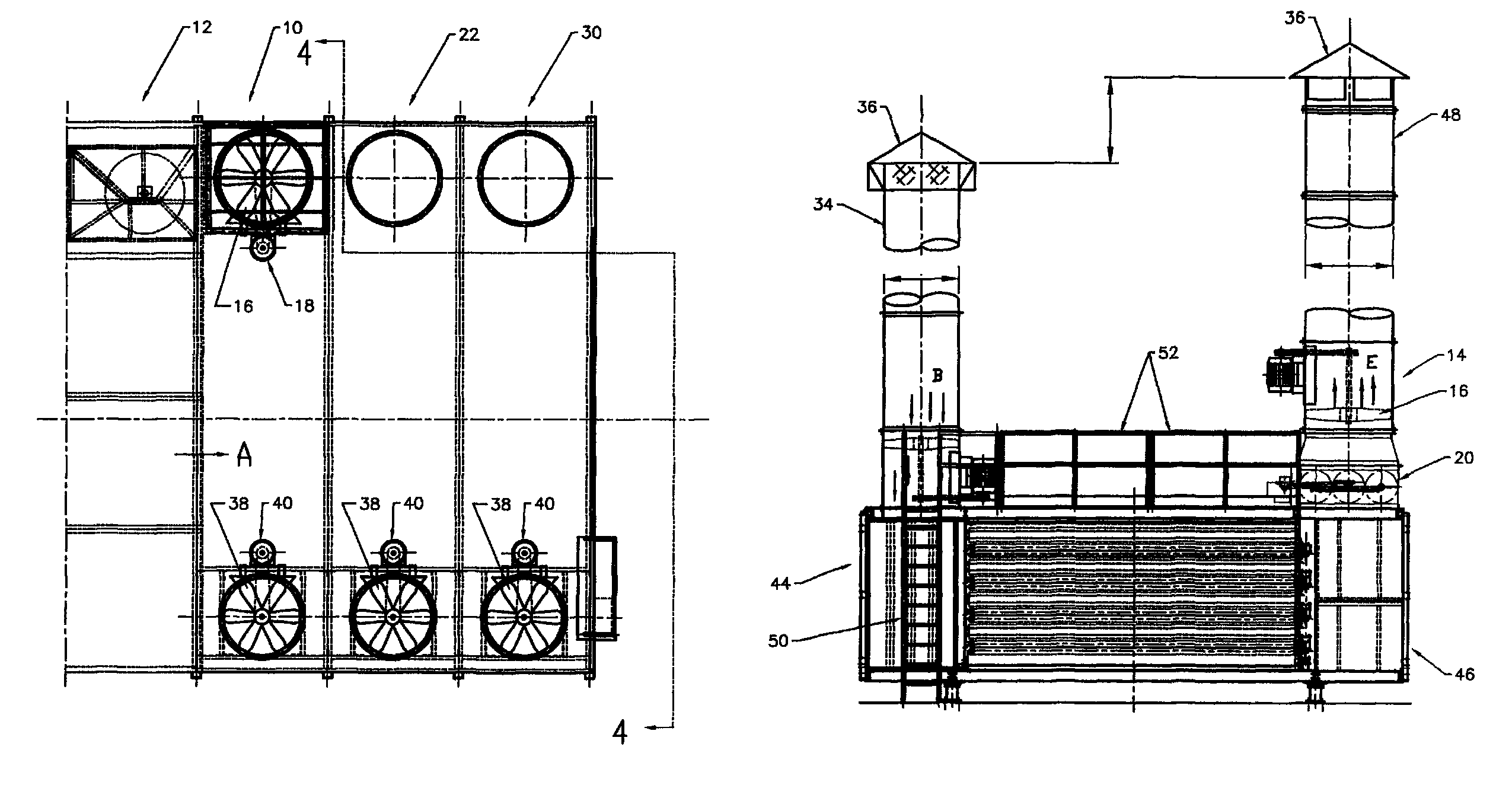

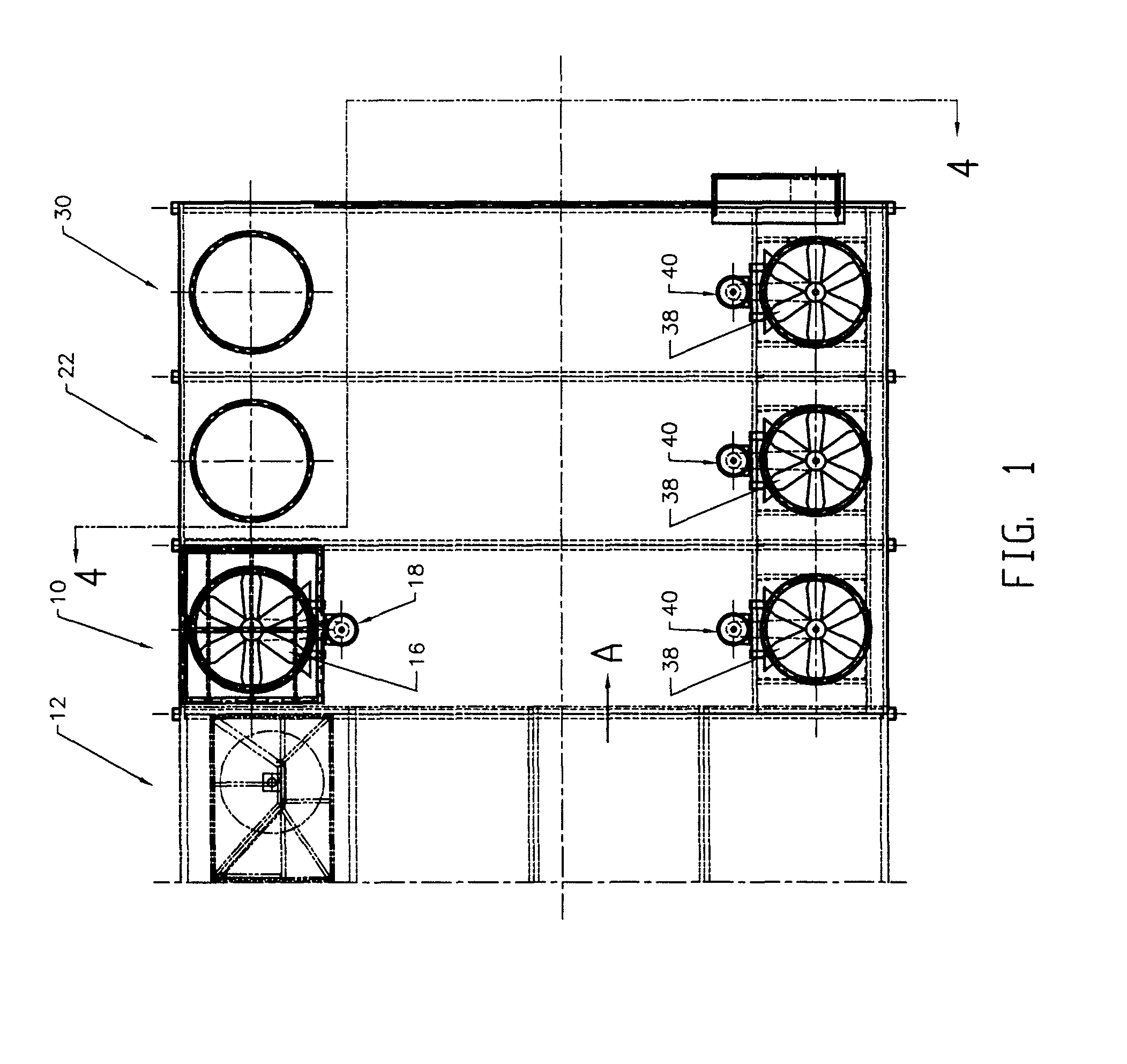

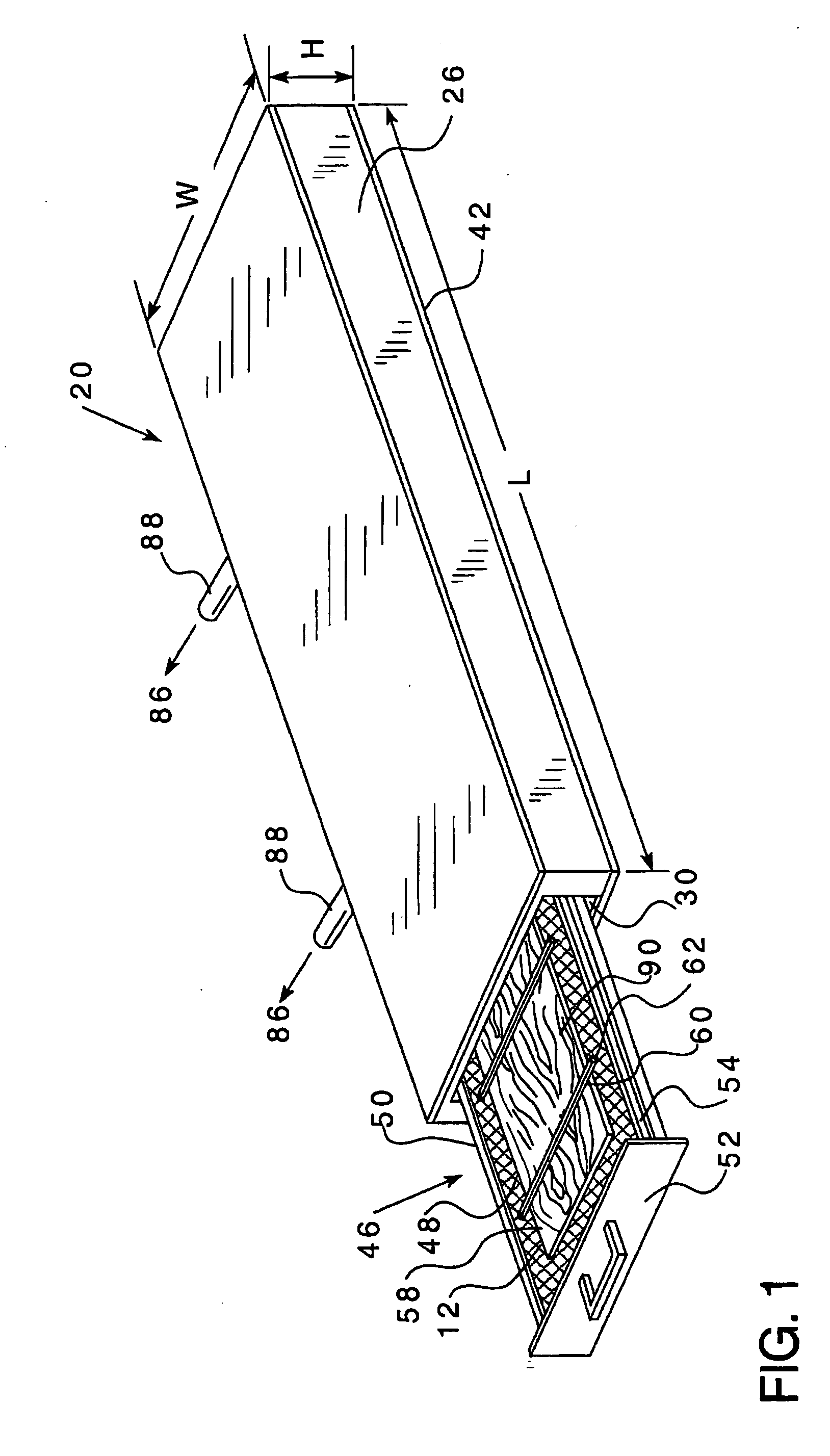

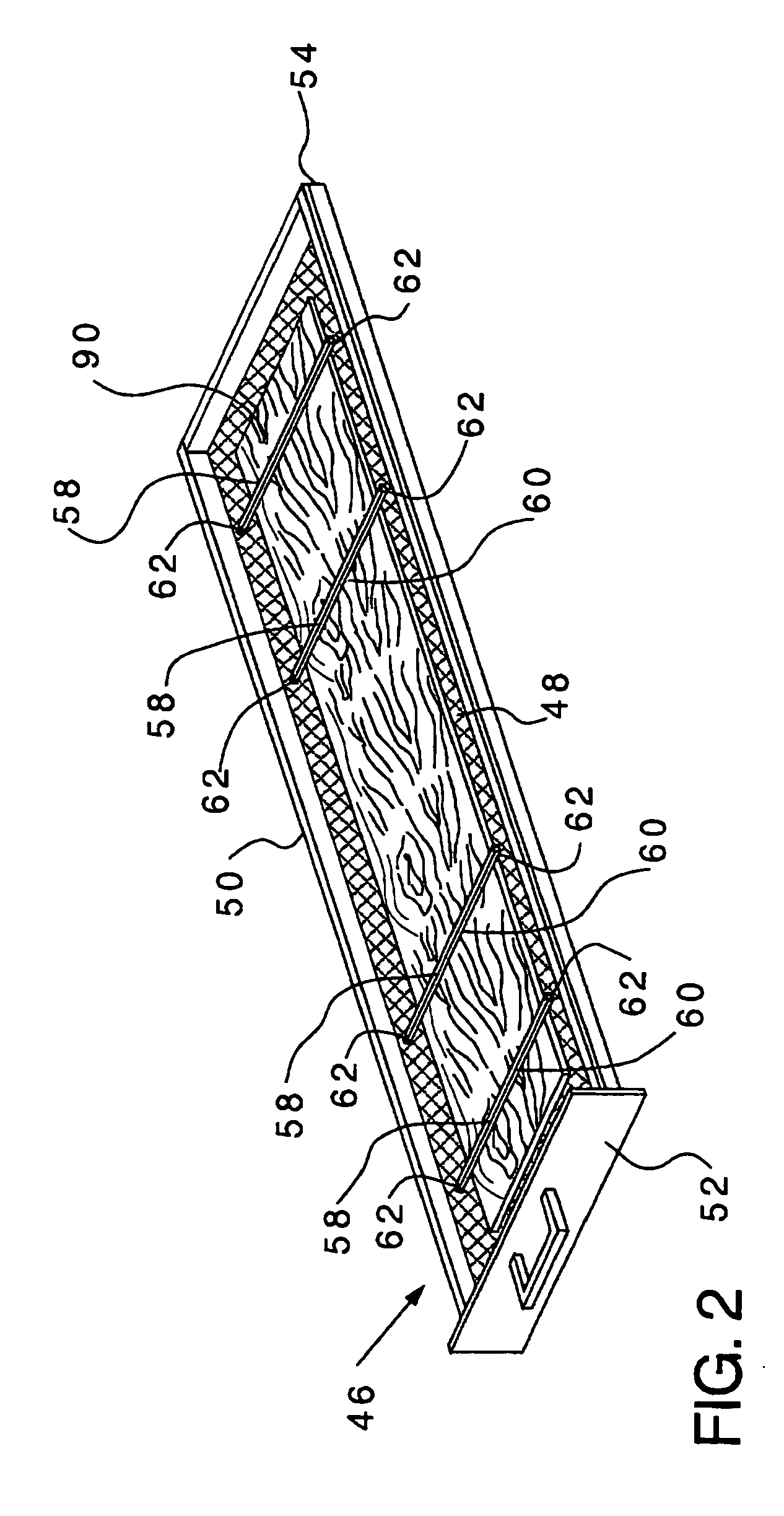

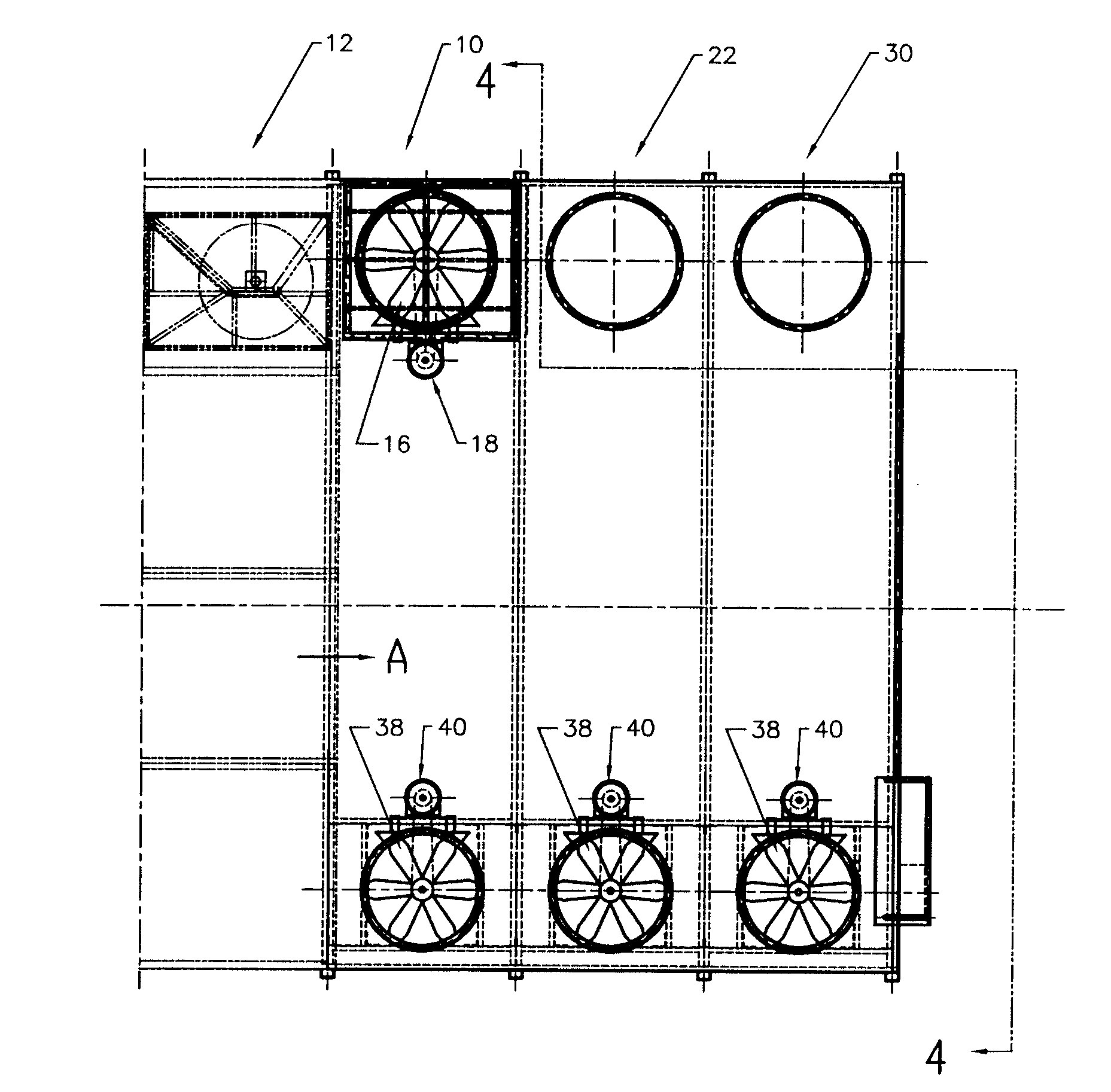

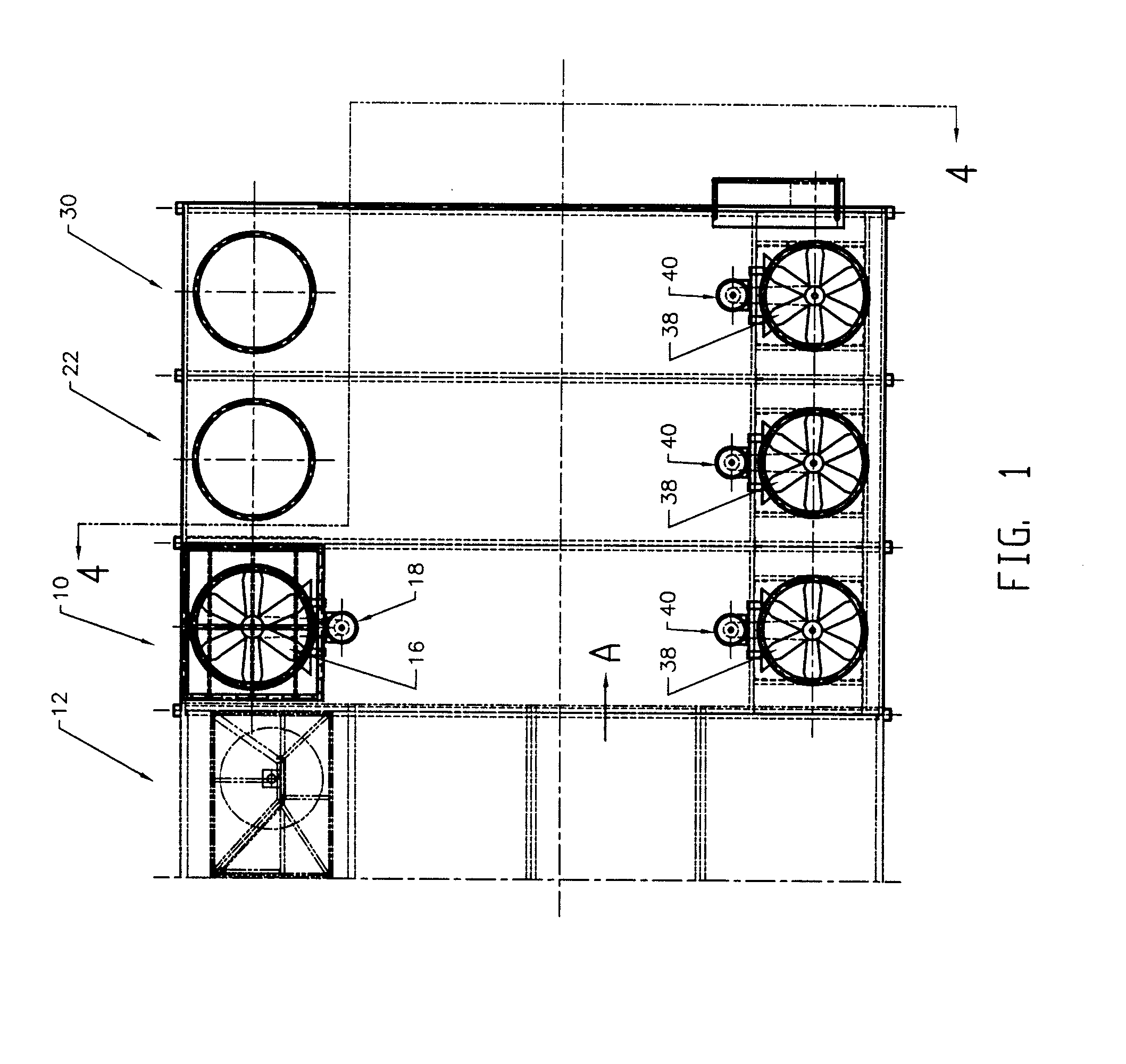

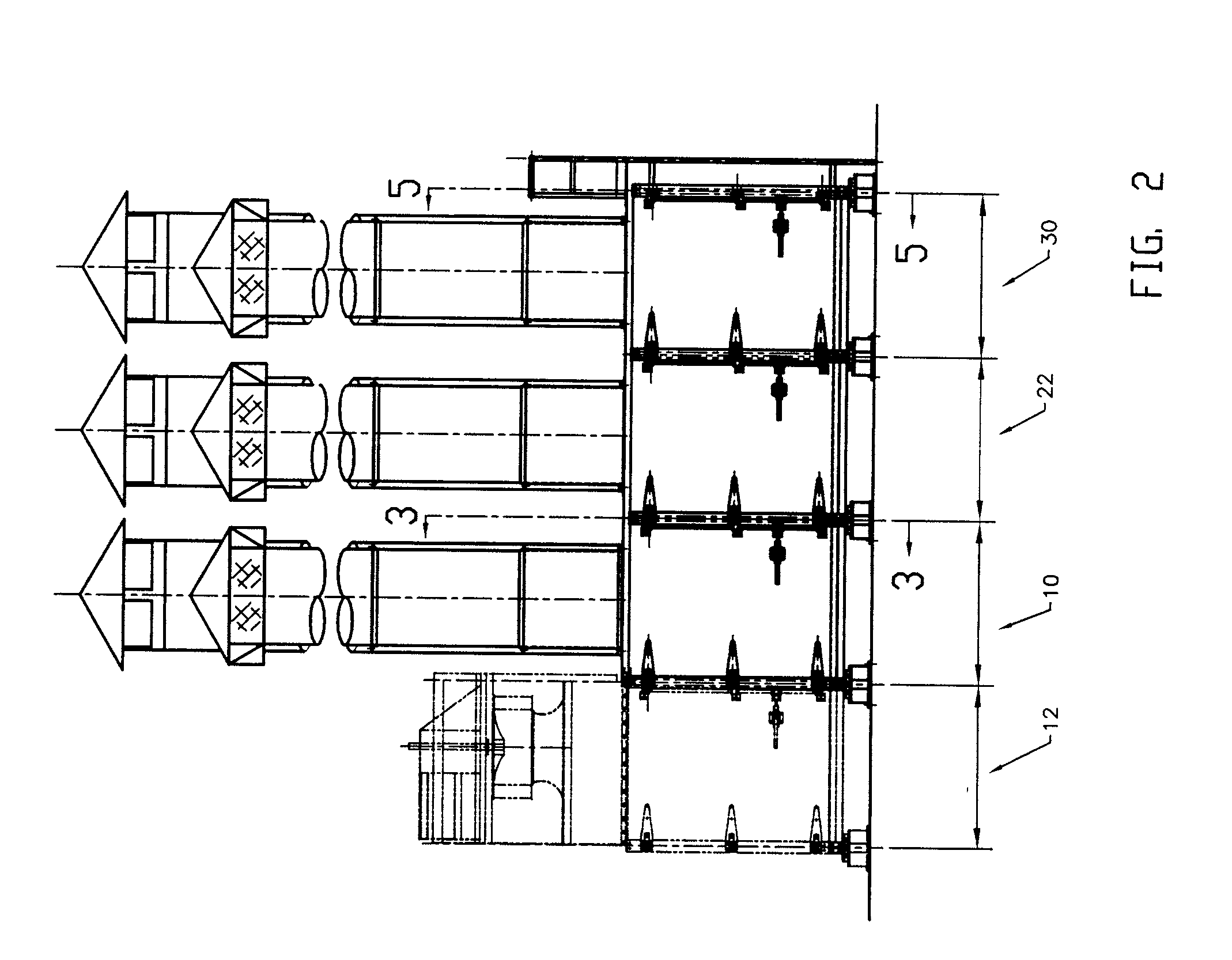

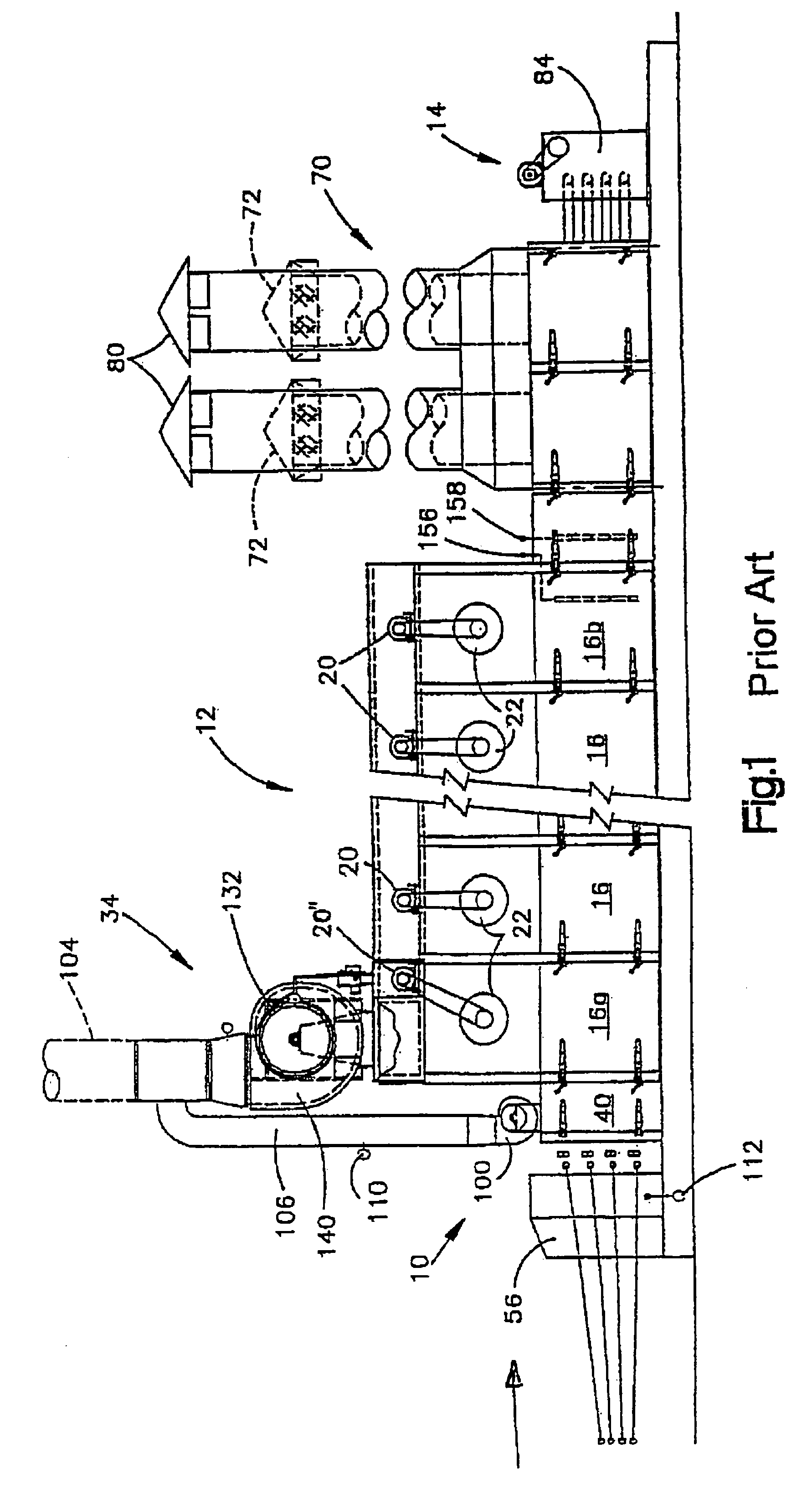

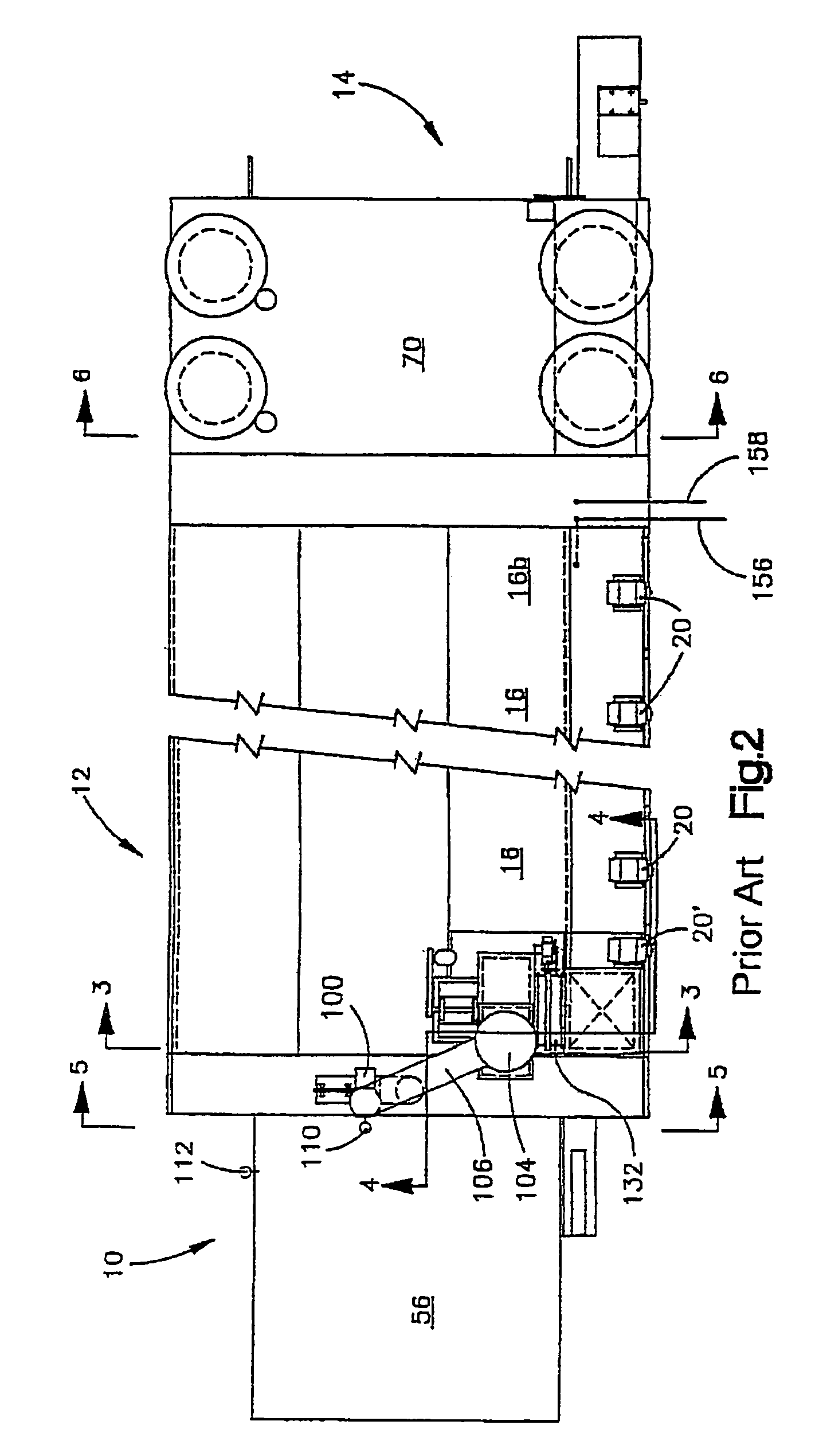

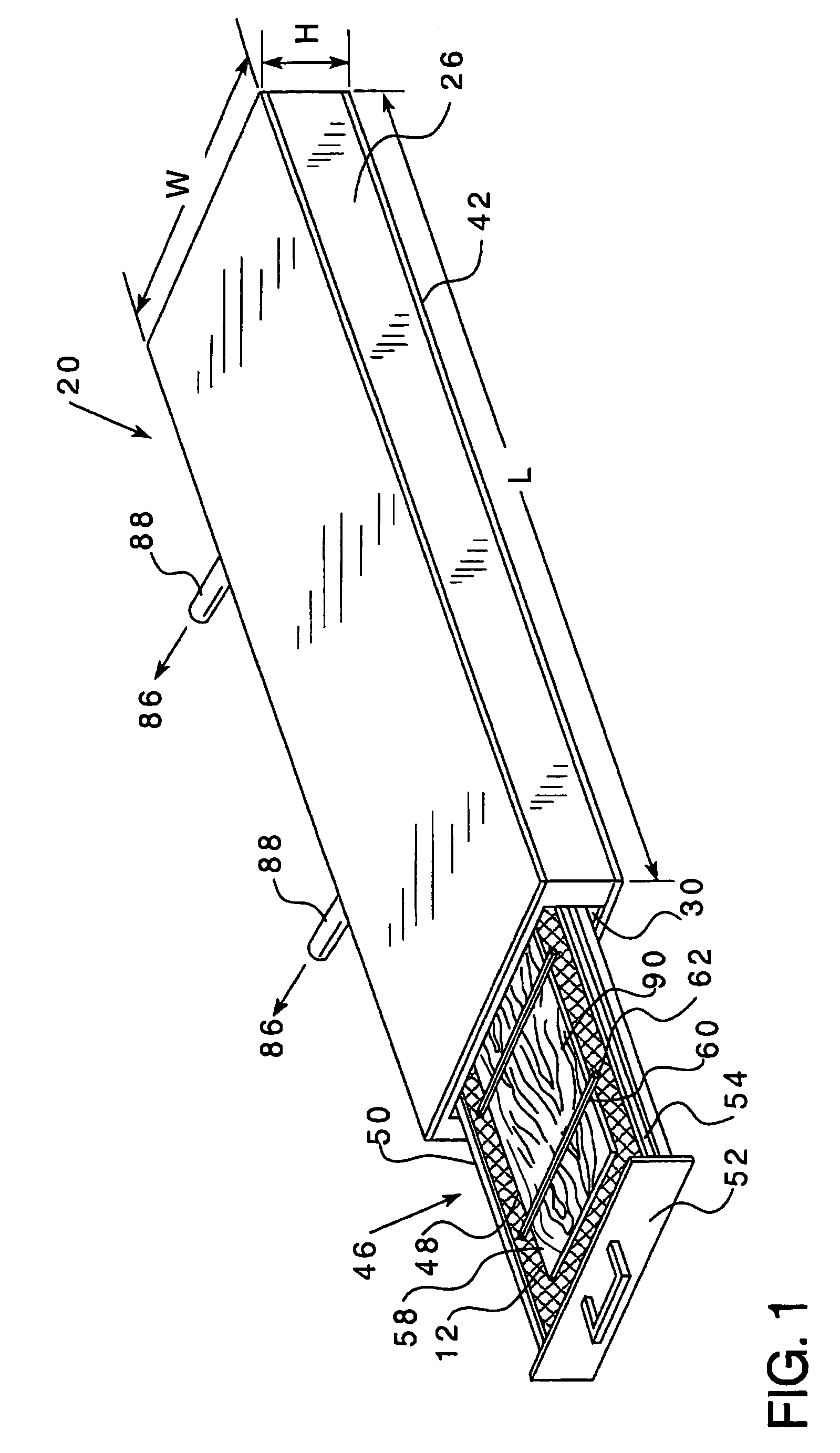

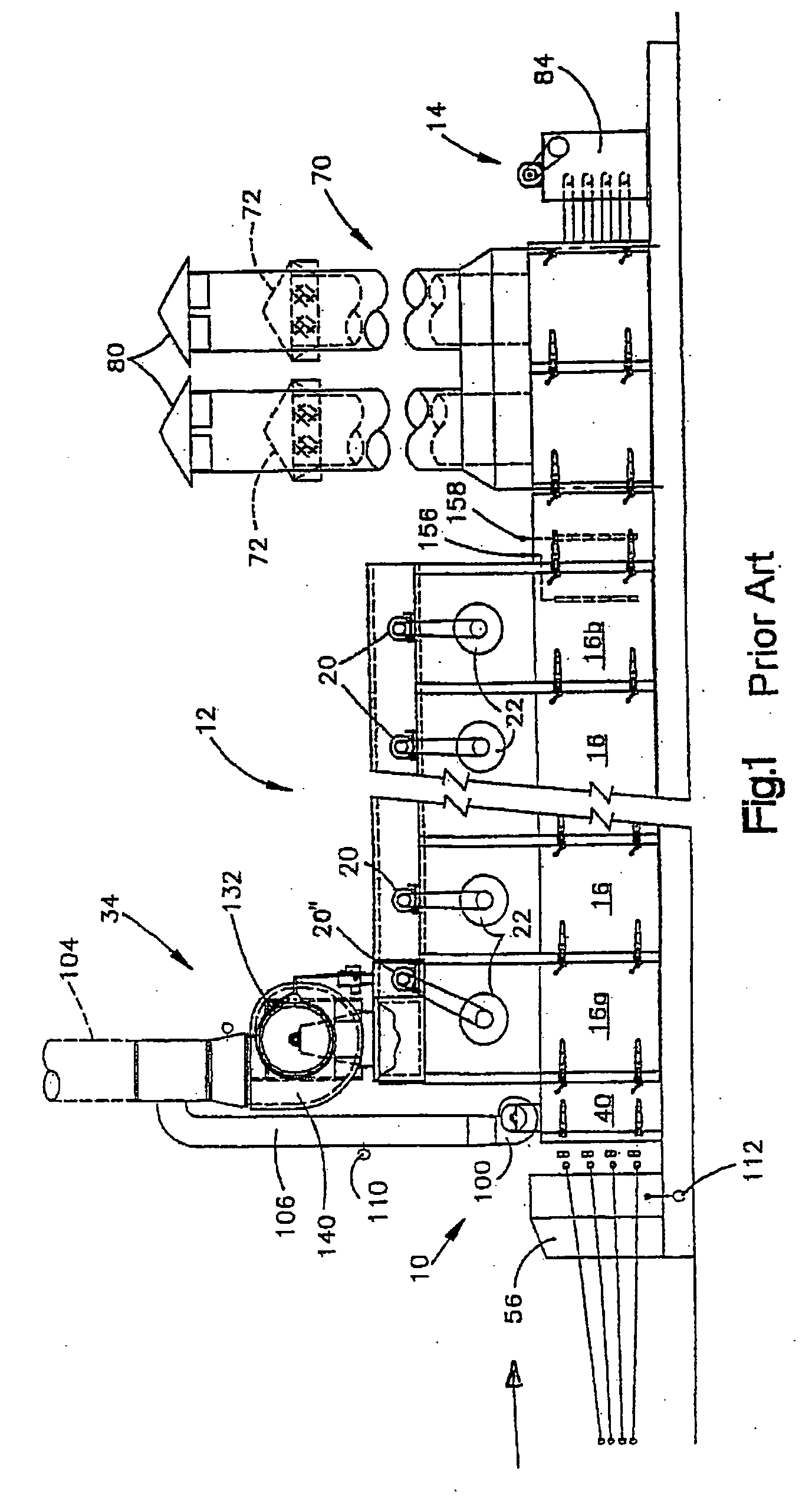

Method and apparatus for controlling cooling temperature and pressure in wood veneer jet dryers

ActiveUS8196310B2Minimize flowRestrict movementAdhesive processesDrying solid materials with heatWood veneerPressure difference

An apparatus for drying wood veneer includes an elongate drying chamber including a conveyor for conveying material to be dried from an input end to an output end; and a cooling section for cooling veneer leaving the output end of the drying chamber, the cooling section including a pressure controller for maintaining a pressure in the cooling section that is slightly higher than pressure in the drying chamber while maintaining a near-zero pressure differential between the drying chamber and the cooling section.

Owner:USNRKOCKUMS CANCAR

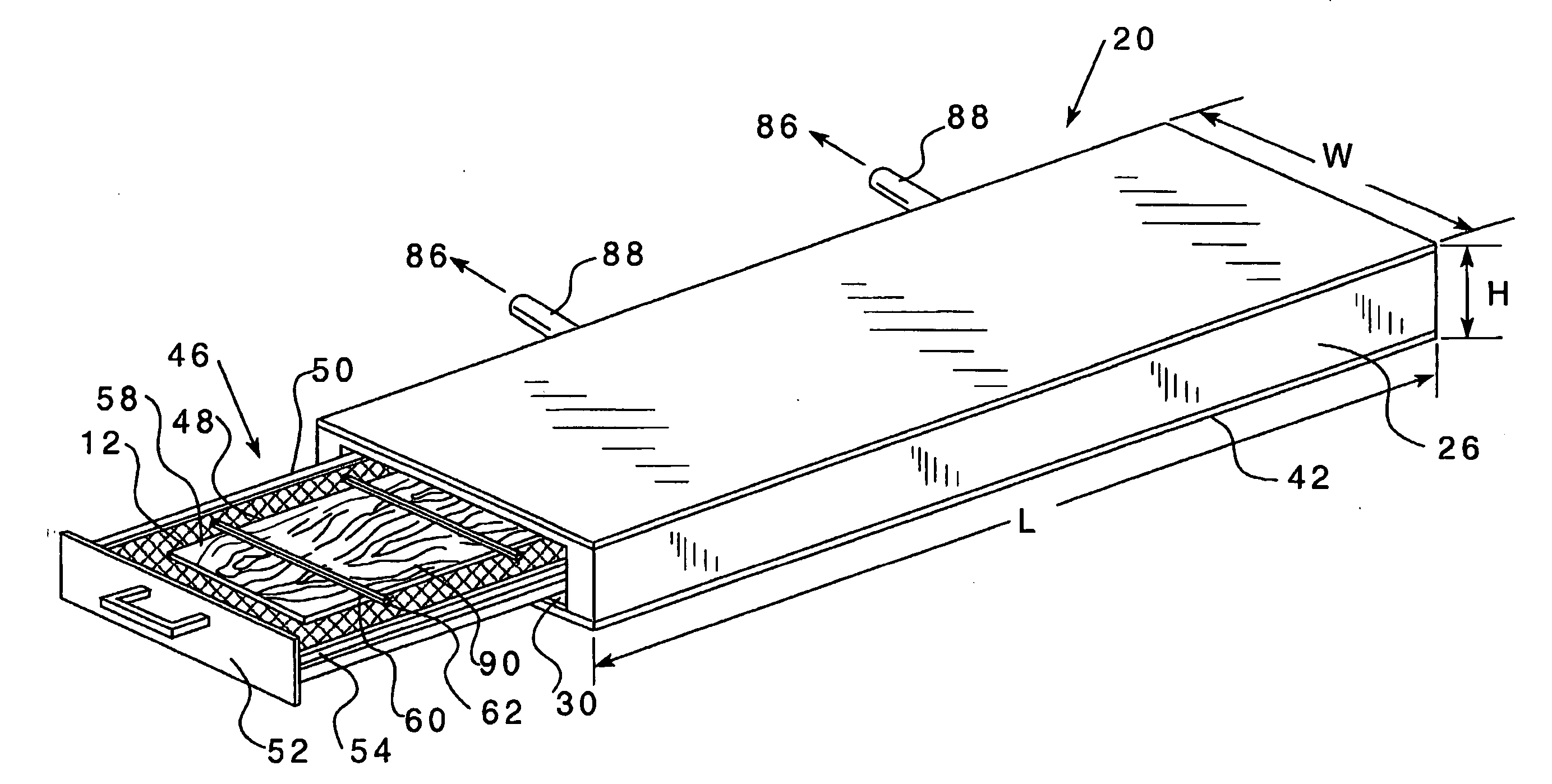

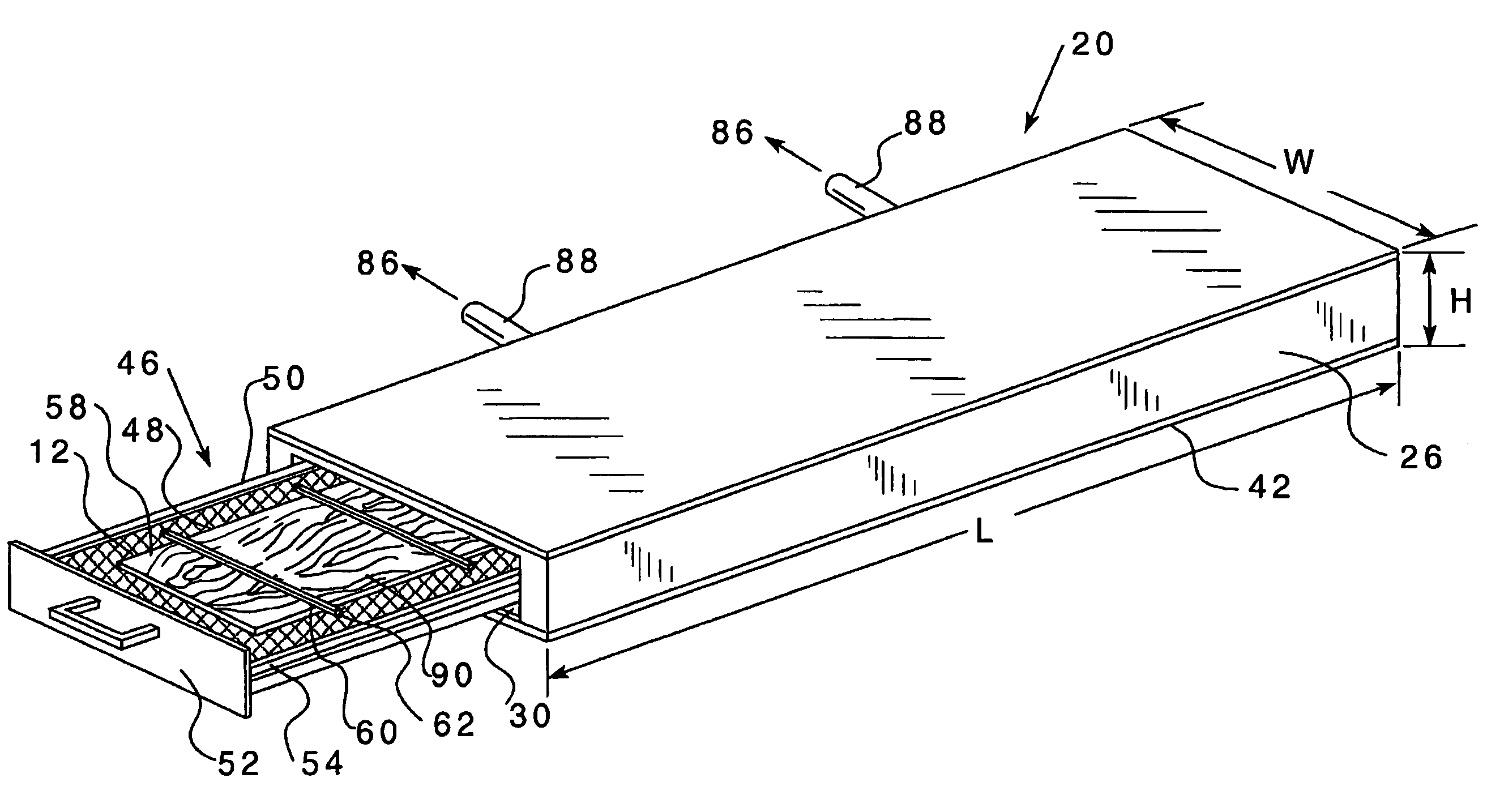

Method and apparatus for drying materials including veneers

InactiveUS20050217136A1Uniform porosityImproved control and monitoringDrying solid materials without heatDrying machines with progressive movementsHermetic sealEngineering

An apparatus and method is provided to dry veneer or other items by vaporization of moisture in the item. Apparatus has an insulated chamber with a frame and a drawer with a door. A mesh surface of the drawer supports item for drying with a heater at sub-atmospheric pressure inside of the chamber. Item is placed on the layer of mesh of the drawer of the apparatus and secured with fasteners such as another layer of mesh. The drawer with fastened item is placed into the chamber of the apparatus. With the drawer fully engaged within the chamber, the drying apparatus is closed with an airtight seal. A pump draws a vacuum in the chamber and heat is directed at the item to raise the temperature of the item to less than 160° F., particularly between 120° F. to 150° F. Apparatus can dry veneer in less than five minutes.

Owner:BASE POINT

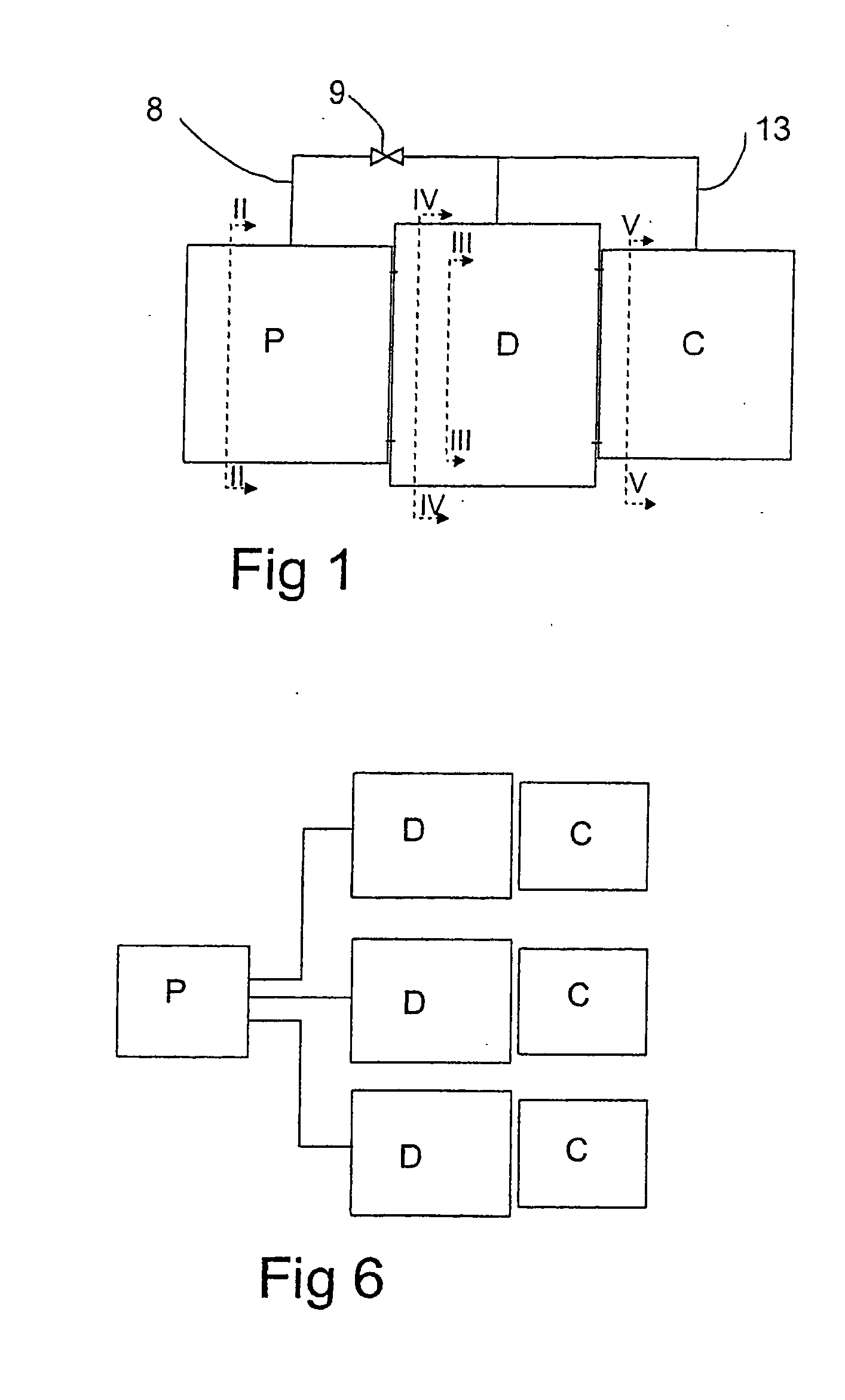

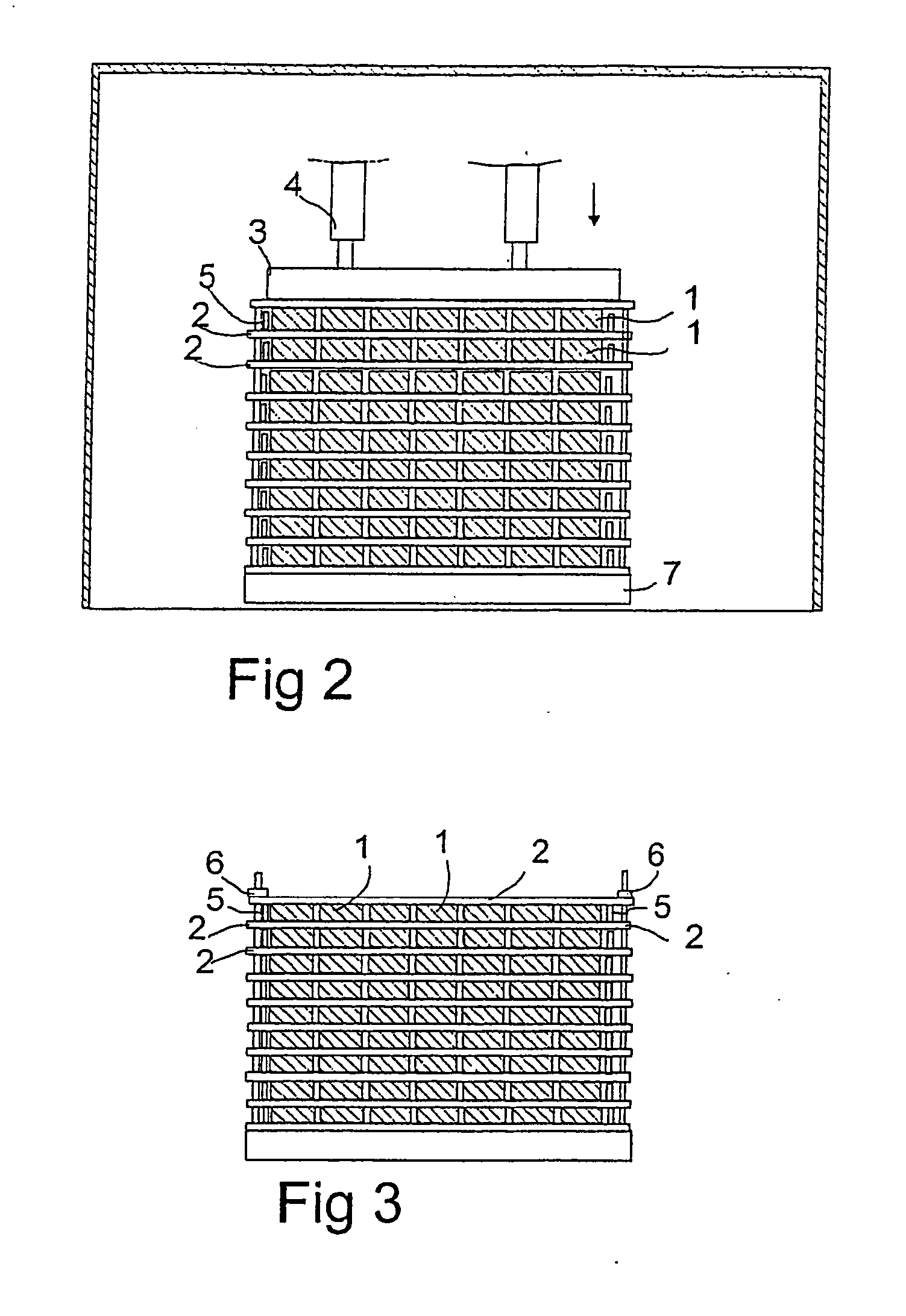

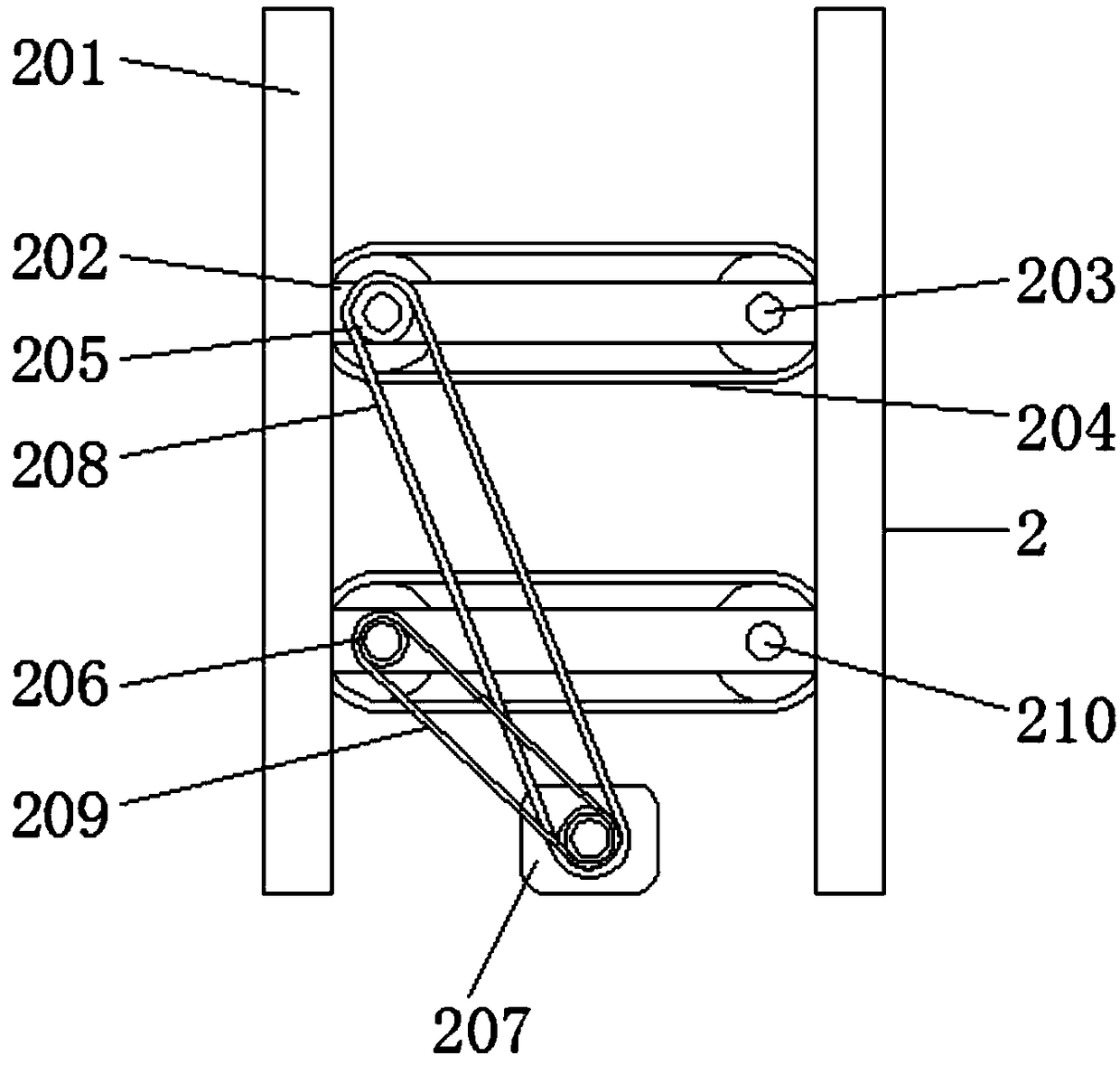

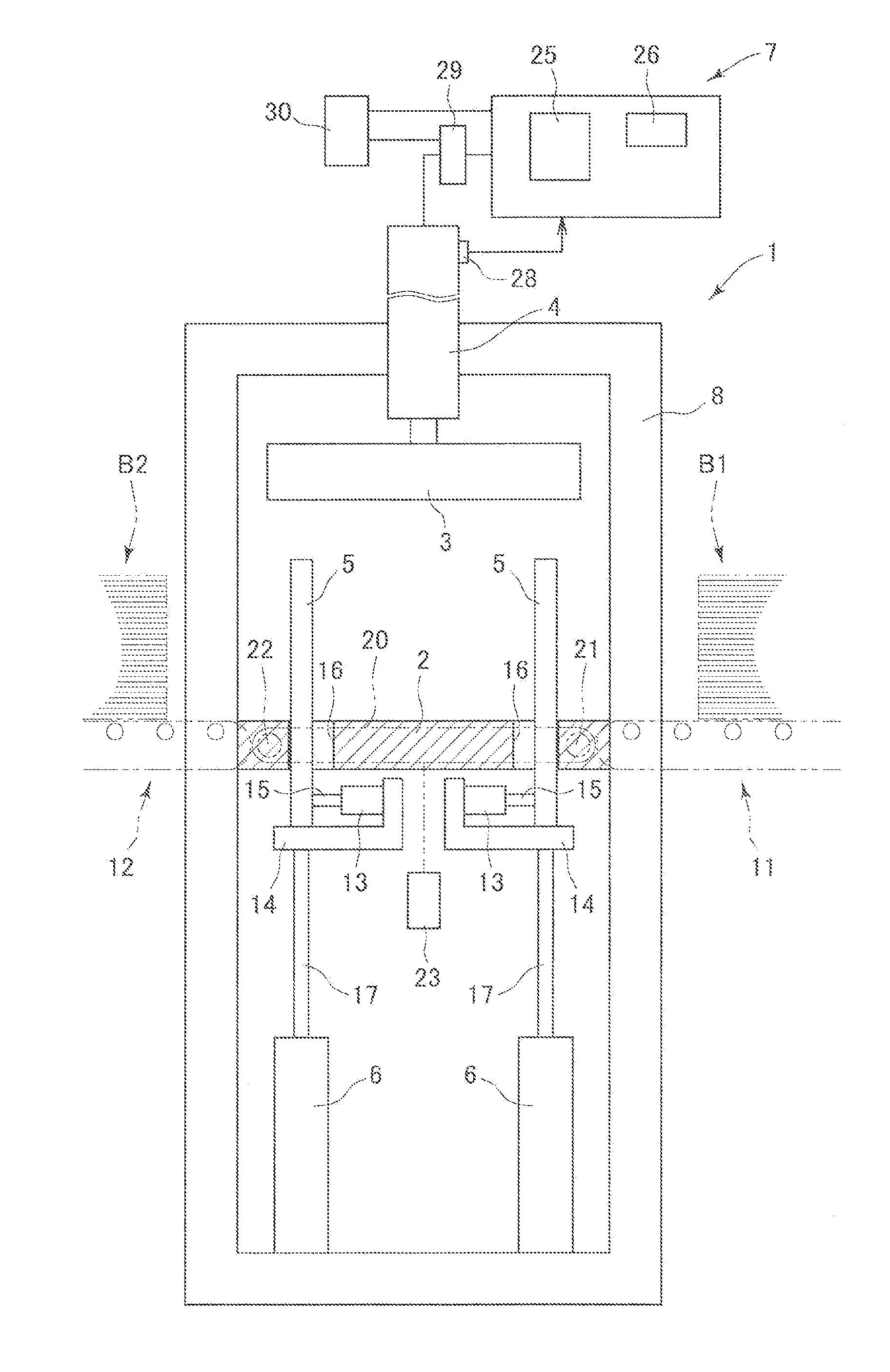

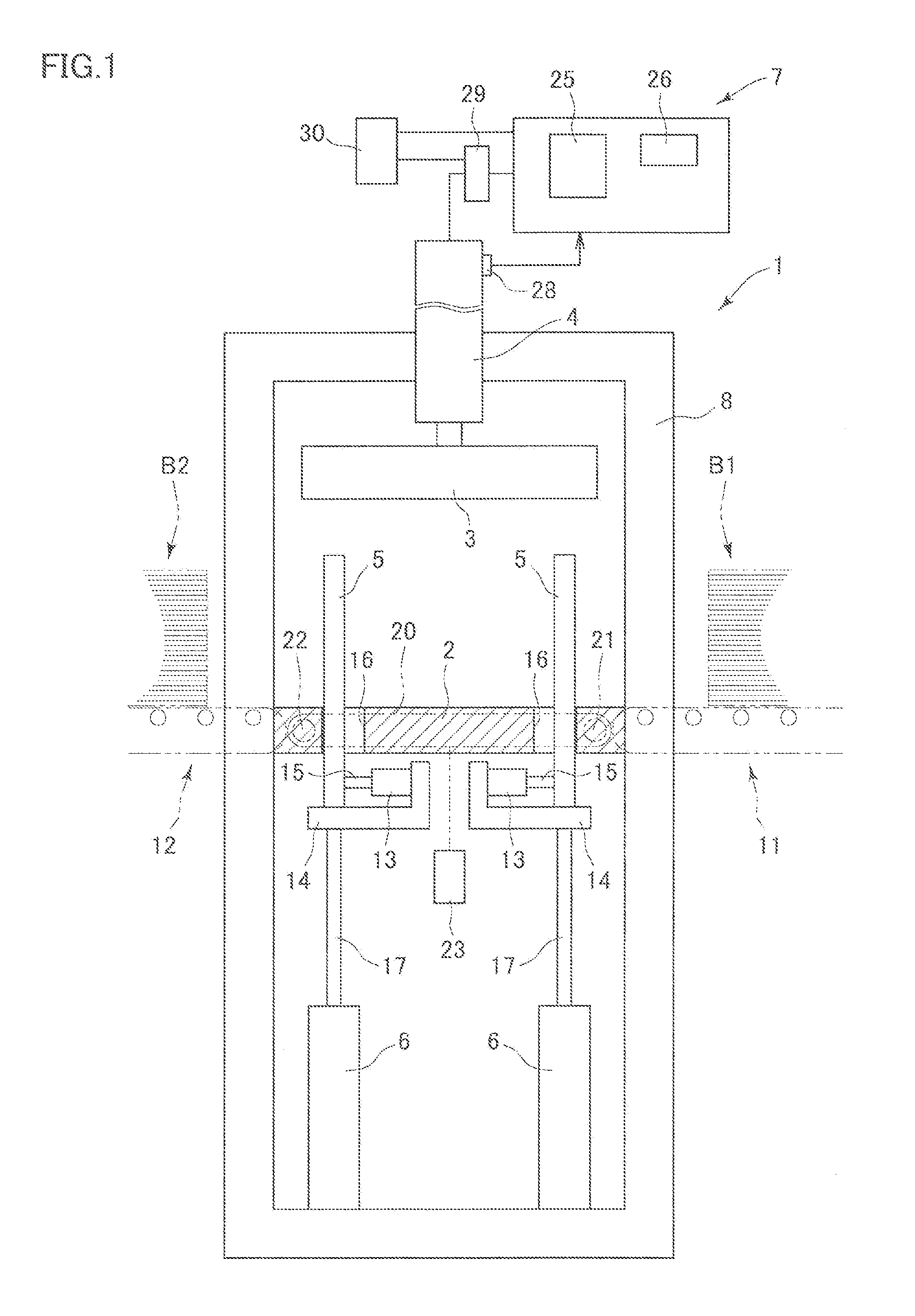

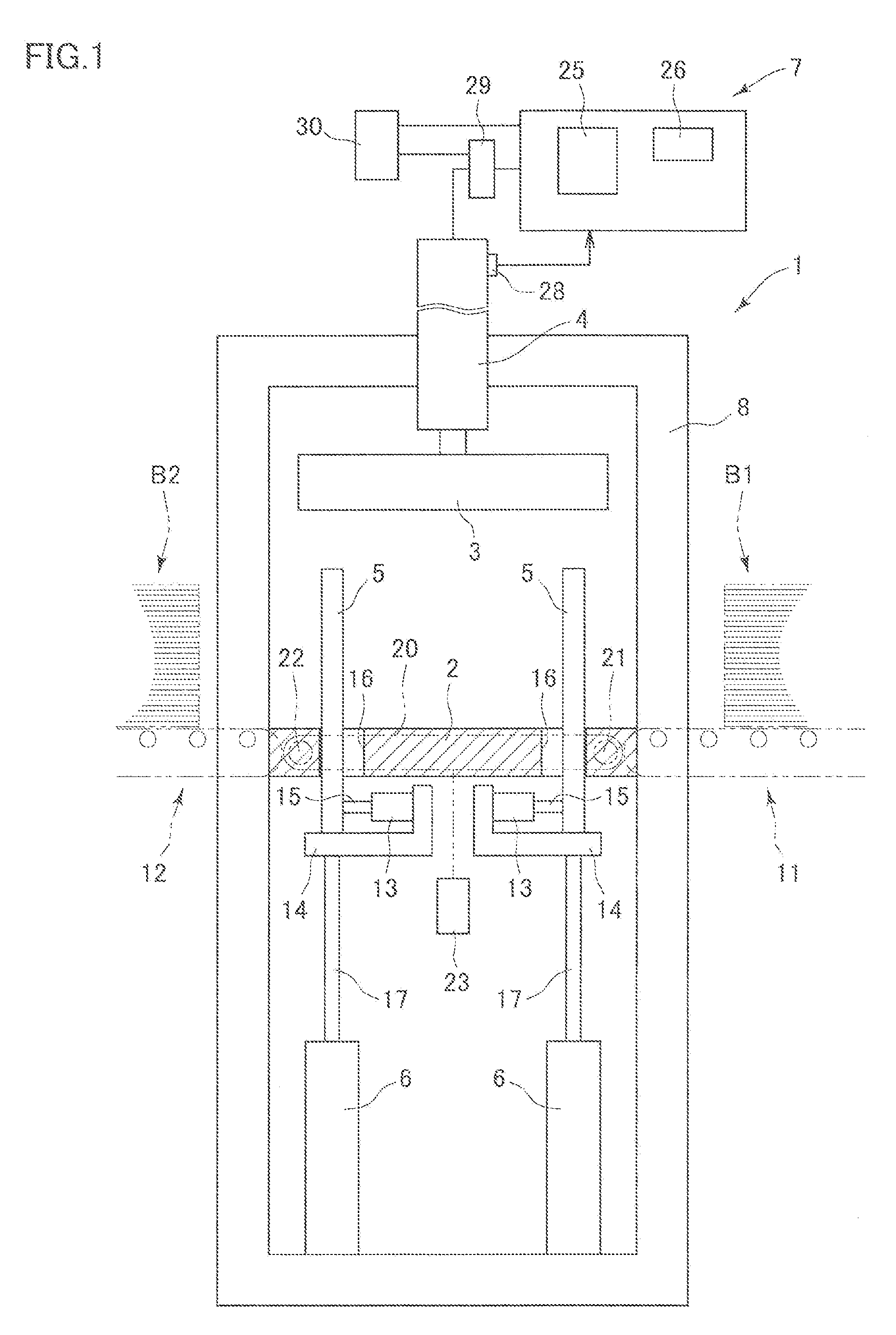

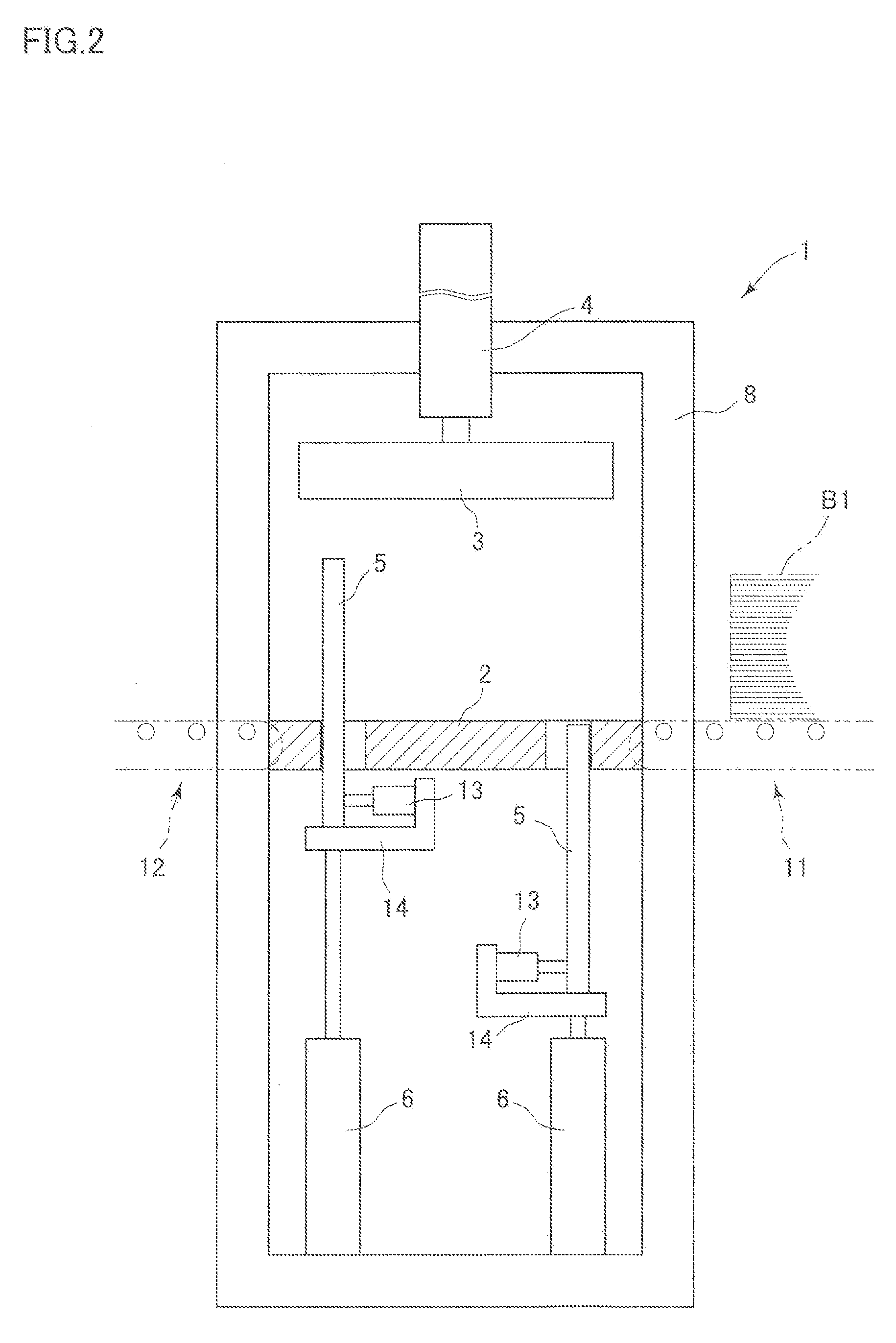

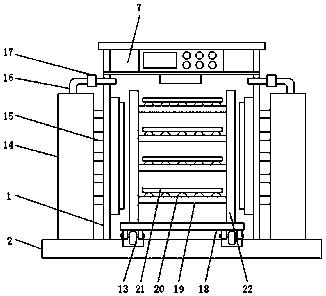

Method and apparatus for the treatment of wood or wood products

InactiveUS20060278336A1Avoid large amounts of heatSave energyDrying using combination processesPlywood pressesPulp and paper industryWood product

A method for the treatment of wood or wood products, in which method moist wood or wood products (1) are dried by first pressing and further by heating so that a desired degree of dryness is reached. In a first stage, the wood or wood products (1) arranged between treating elements (2) are pressed between the treating elements (2) so that a considerable amount of water is removed from the wood being treated, next the treating elements (2) are locked so that the wood or wood products (1) remain compressed between the treating elements (2), and the combination of treating elements (2) and wood or wood products (1) between them thus formed is moved into a drying chamber (D), where the wood or wood products are dried further by applying heat. The invention also relates to an apparatus.

Owner:TEKNOCOMP

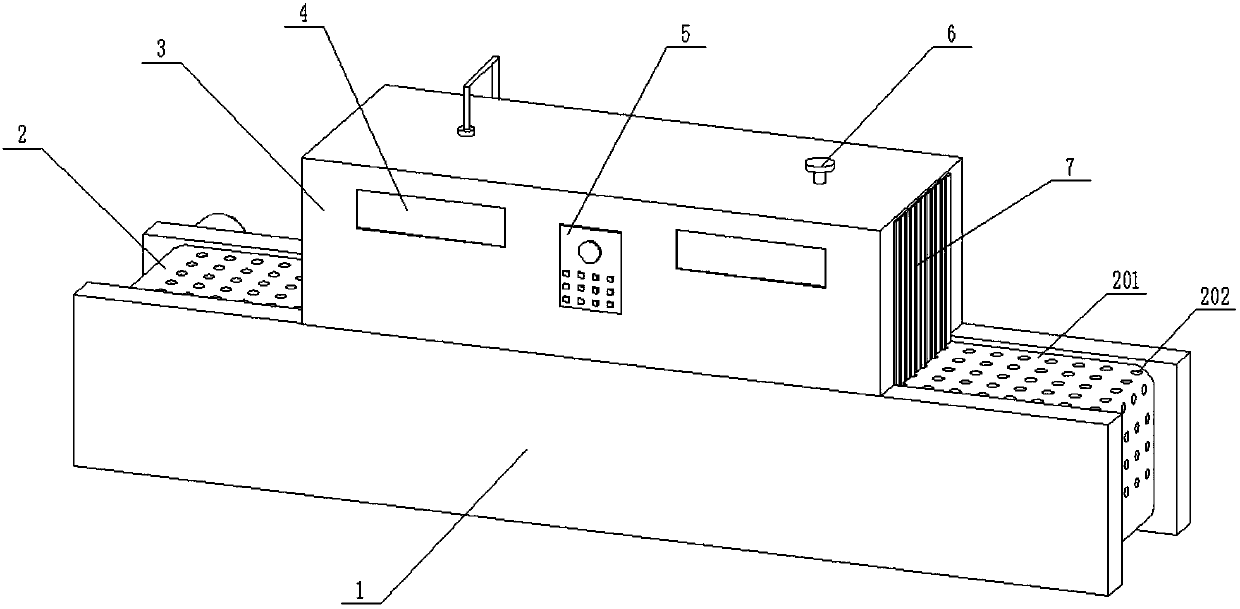

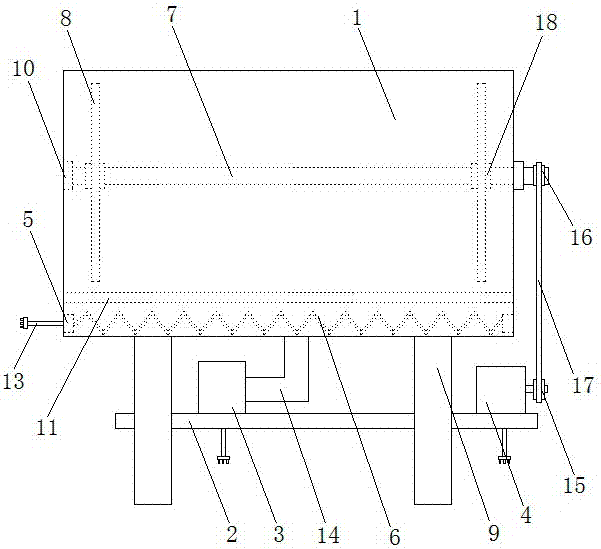

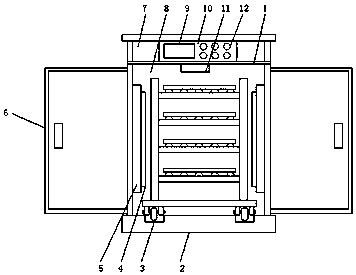

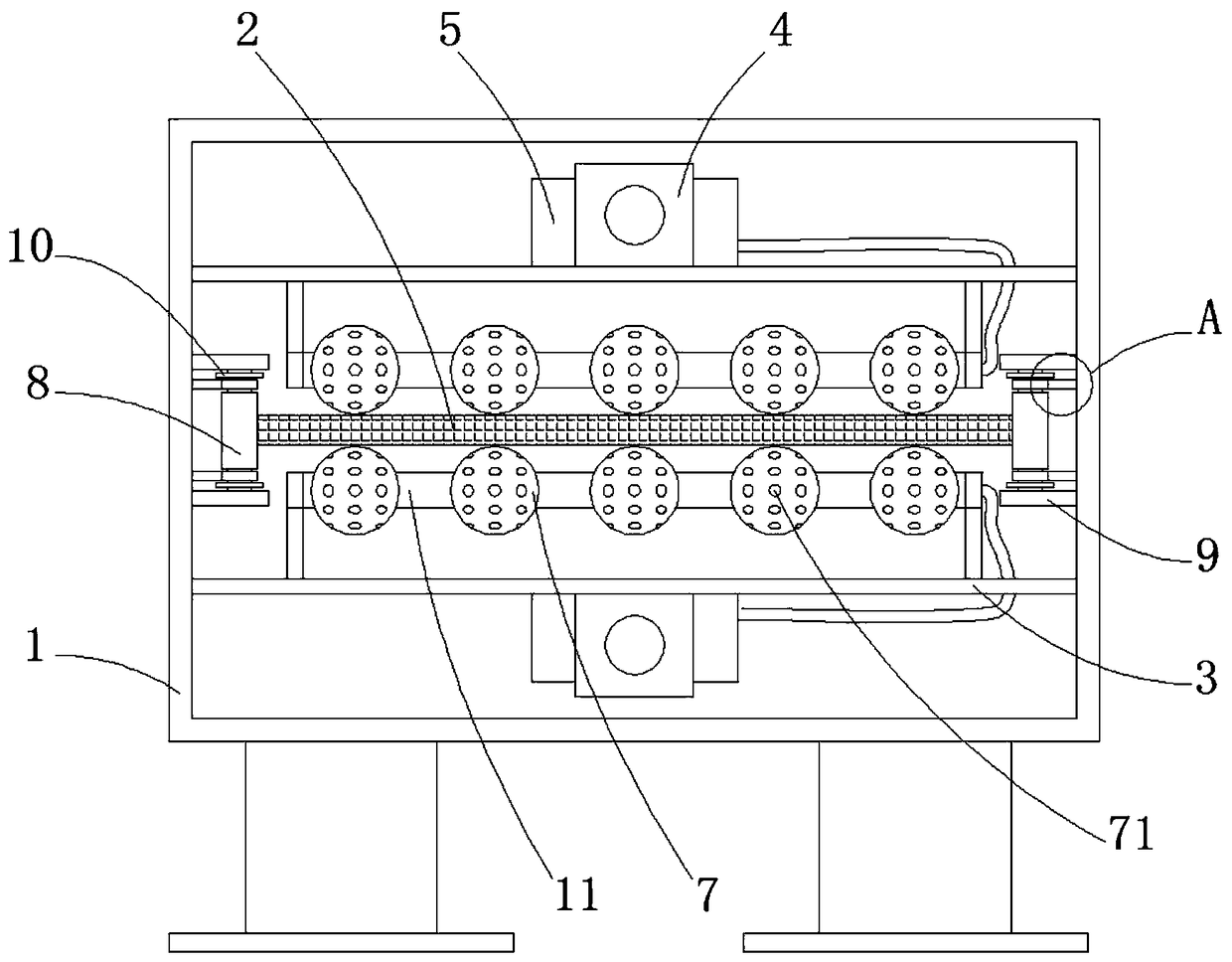

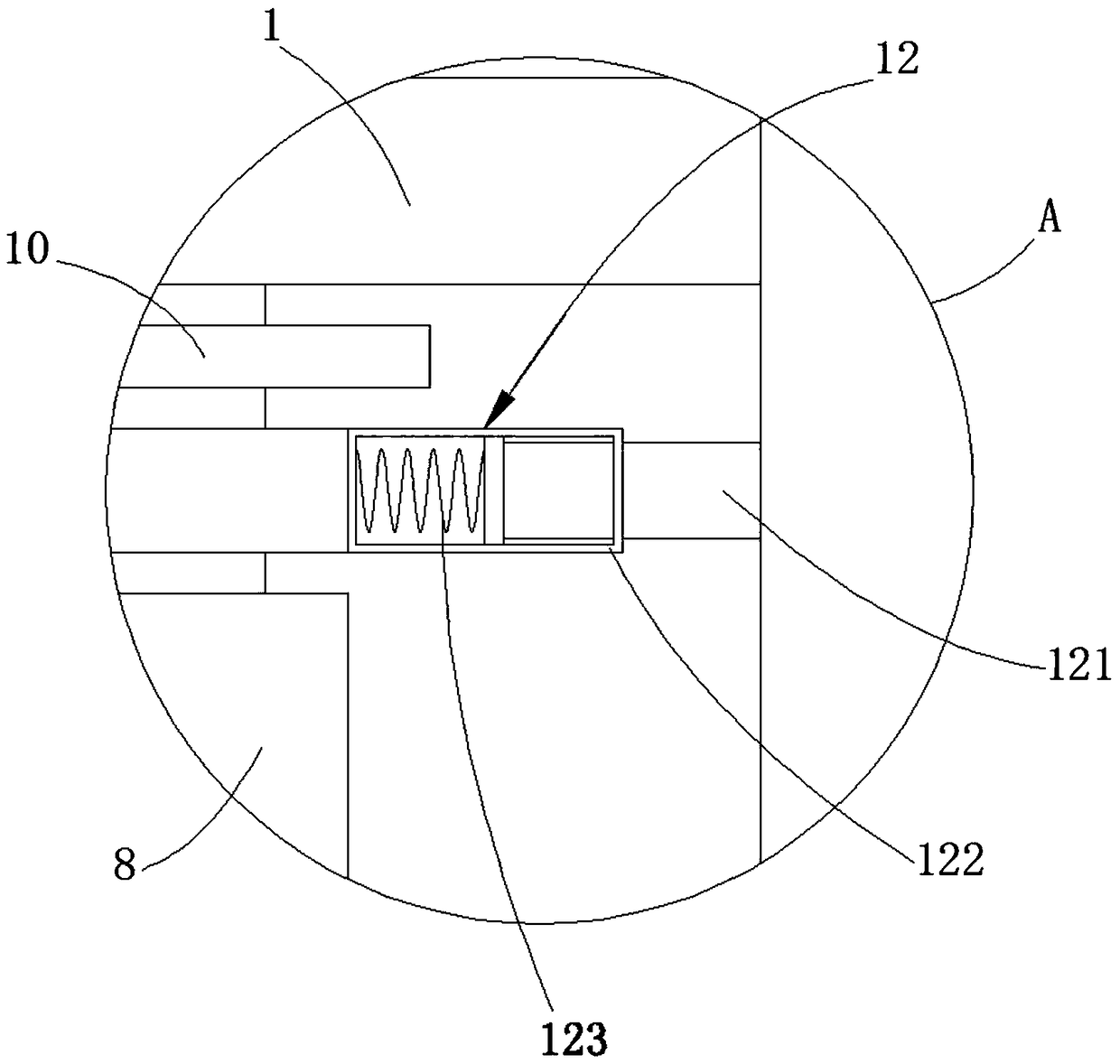

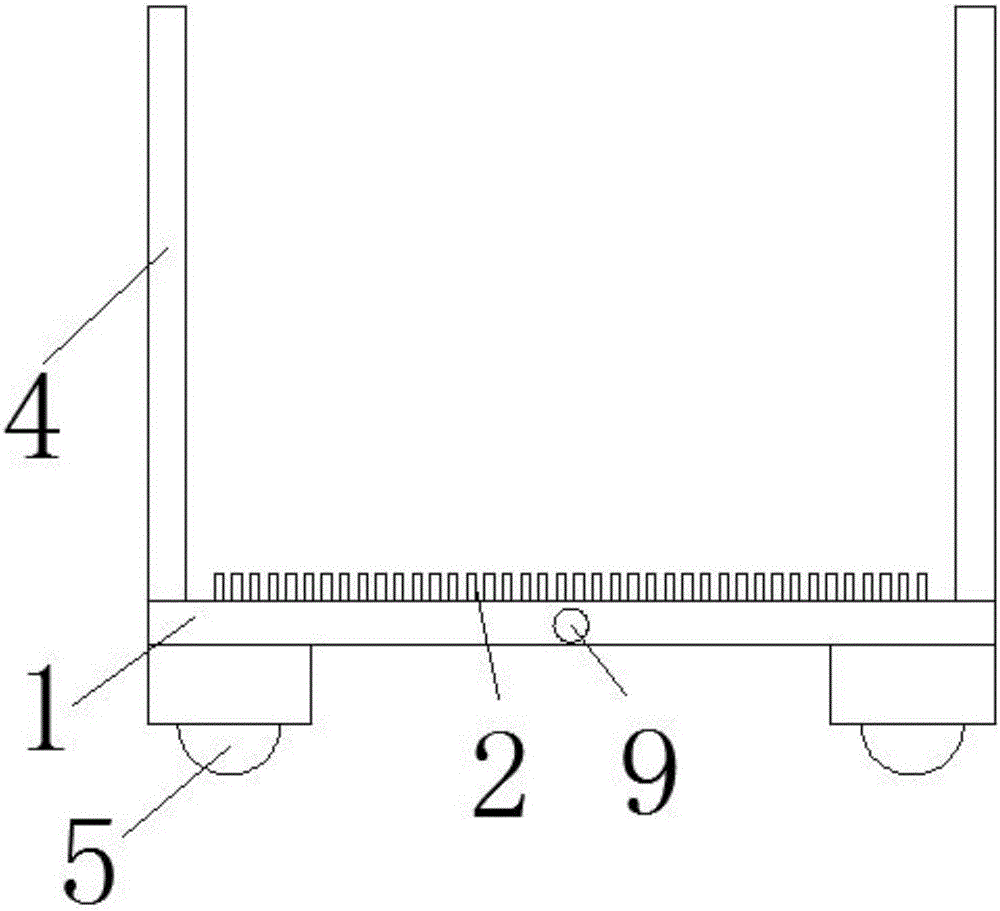

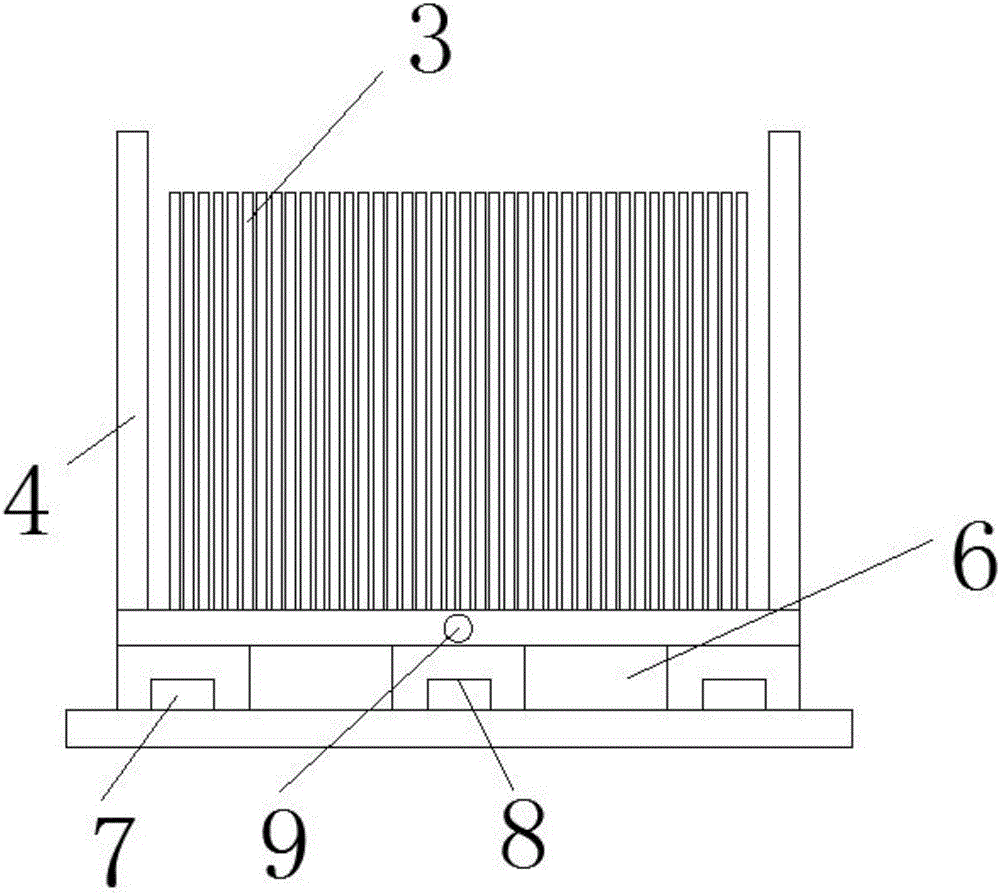

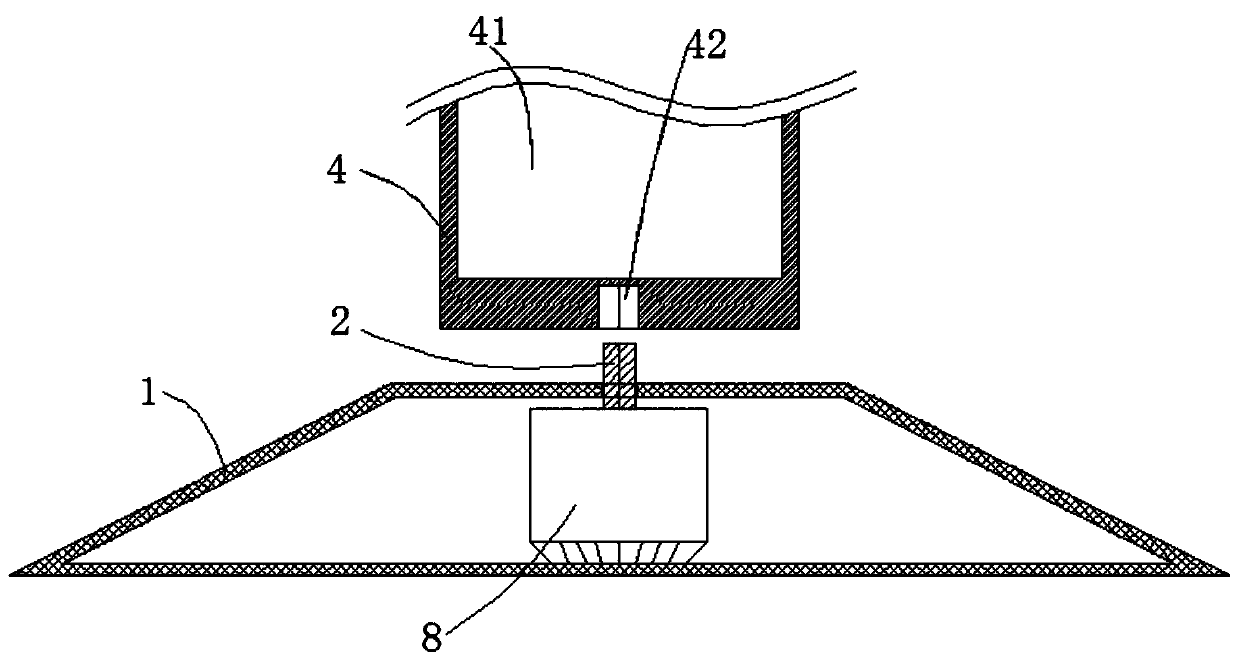

Aluminum veneer washing and drying device

InactiveCN107677091AAchieve cleaningAchieve dryingDrying gas arrangementsDrying machines with progressive movementsExhaust valveAir pump

The invention discloses an aluminum veneer washing and drying device. The aluminum veneer washing and drying device comprises a machine frame. The upper end of the machine frame is provided with a box. The front side of the box is provided with a controller. A gas exhausting valve is arranged at the upper end of the box. A conveying device and a drying device are arranged in the machine frame. A washing device is installed in the box. The aluminum veneer washing and drying device has the beneficial effects that aluminum veneers are automatically washed and dried in an assembly line mode through the conveying device, the washing device and the drying device; the aluminum veneers are supported through a guiding plate, and the aluminum veneers are sent between an upper washing roller and a lower washing roller by being combined with the conveying device; a washing motor is in transmission with a driven gear through a driving gear, so that the upper washing roller and the lower washing roller are driven to wash the aluminum veneers in a double-sided mode; the upper surfaces of the aluminum veneers are dried through a drying heater; and the small surfaces of the aluminum veneers are dried through an air pump and an air drying heater, the drying efficiency is high, the effect is good, and the aluminum veneers cannot be over-temperature.

Owner:JIANGSU HAIDEMAN BUILDING MATERIALS IND

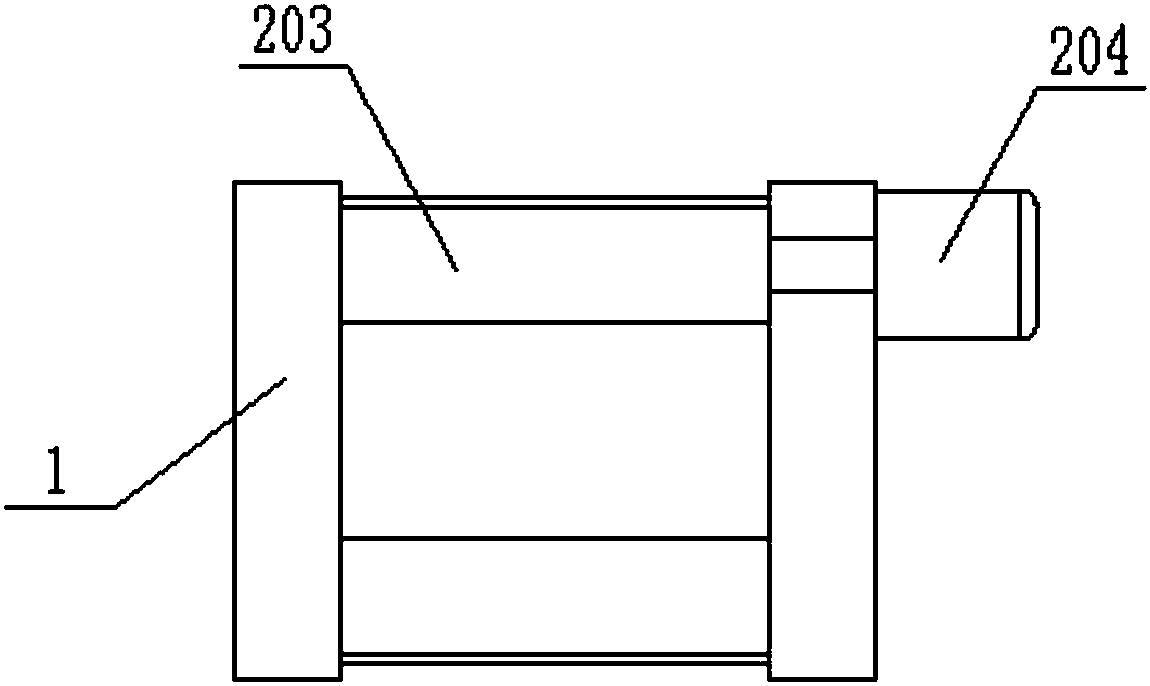

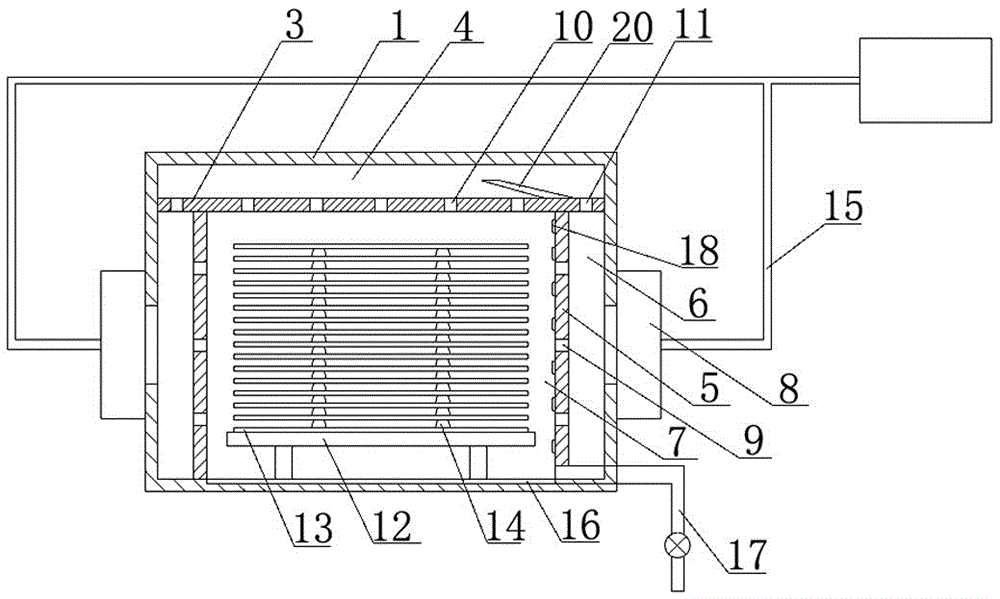

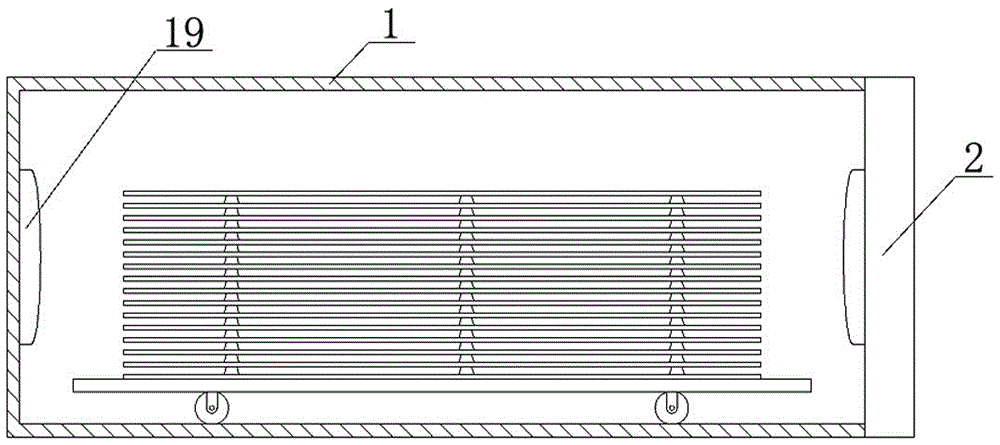

Drying device for wood boards for furniture

InactiveCN107401904AAchieve dryingImprove drying efficiencyDrying gas arrangementsDrying chambers/containersRotational axisDrive wheel

The invention discloses a drying device for wood boards for furniture. The drying device comprises a drying cylinder, a fixed plate, a blower, a motor, heating blocks, a heating wire, a rotary shaft and a bearing plate. The drying device is characterized in that the drying cylinder is arranged on brackets, the fixed plate is arranged between the brackets, the blower is arranged on the fixed plate, the motor is arranged on the fixed plate, a power line and a driving wheel are arranged on the motor, the heating blocks are arranged in the drying cylinder, power lines are arranged on the heating blocks, the heating wire is arranged between the heating blocks, one end of the rotary shaft is arranged in a bearing, the other end of the rotary shaft passes through the bearing, a driven wheel is arranged on the rotary shaft, and the bearing plate is arranged on the rotary shaft by virtue of an installation ring. According to the drying device, the heating wire is arranged between the heating blocks in the drying cylinder, and heat can be supplied to a drying chamber by virtue of the heating wire, so that the wood boards in the drying cylinder are dried.

Owner:李琪

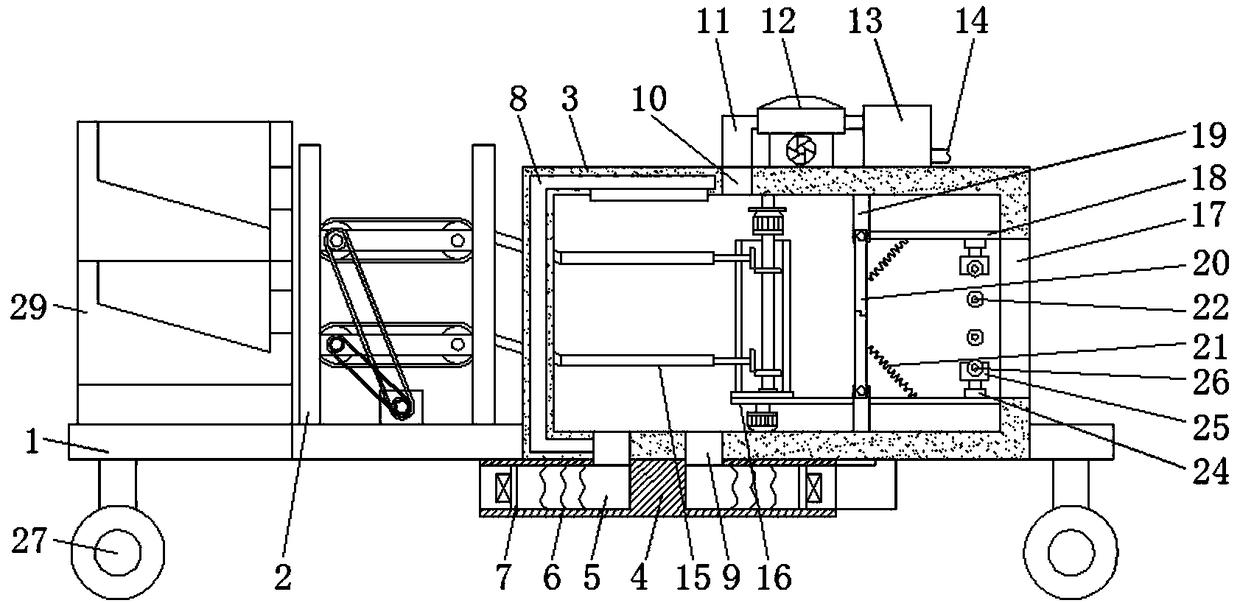

Working method of efficient plate drying treatment device

ActiveCN109059435AReduce labor intensityImprove work efficiencyDrying solid materials with heatDrying gas arrangementsInlet channelPulp and paper industry

The invention relates to the technical field of plate machining, in particular to a working method of an efficient plate drying treatment device. The efficient plate drying treatment device comprisesa base; a feeding device, a loading device and a drying box are sequentially arranged at the upper end of the base; air inlet channels are symmetrically formed in the two sides of the bottom plate; anelectric heating net and a fan are arranged in the air inlet channels; an air outlet is formed in the middle part of the upper end of the drying box; the right side of a circulating pump is connectedwith a filter device through a connecting pipeline; transverse plates are symmetrically arranged on the right side of an inner cavity of the drying box; a turnover device is arranged on the left sideof a connecting plate located below; and the outer side of the turnover device is connected with a fixing device matched with the feed port in use. The efficient plate drying treatment device is reasonable in structural design and convenient and quick to use, loading and unloading of a plate can be completed automatically, the labor intensity of a worker is lowered greatly, and the working efficiency is improved. Furthermore, the drying effect of the plate is good, and the plate efficient plate drying treatment device is more environmentally friendly and deserves popularization.

Owner:扶绥县千百林木业有限公司

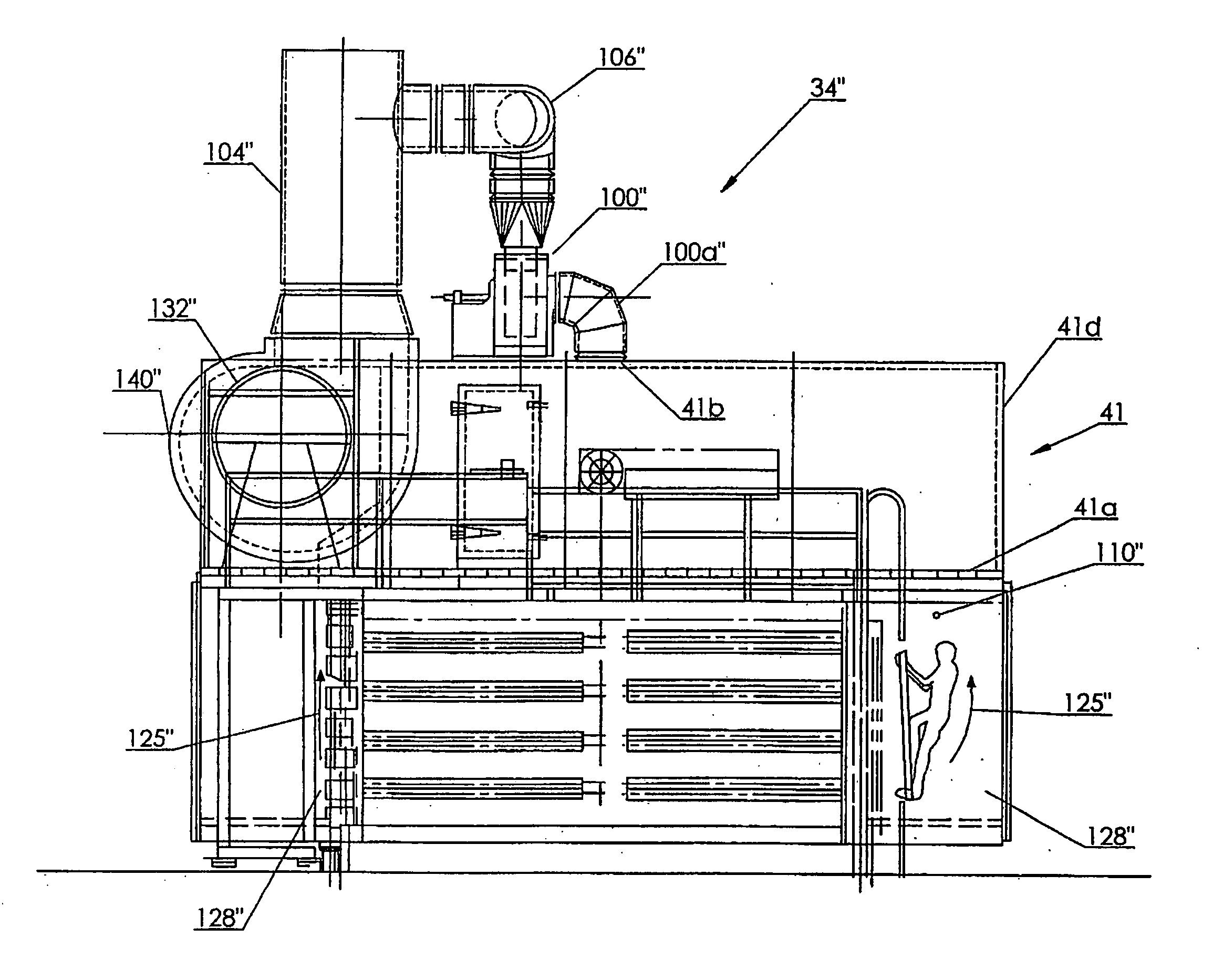

Method and apparatus for controlling cooling temperature and pressure in wood veneer jet dryers

ActiveUS20080307669A1Minimize flowRestrict movementAdhesive processesDrying solid materials with heatWood veneerEngineering

An apparatus for drying wood veneer includes an elongate drying chamber including a conveyor for conveying material to be dried from an input end to an output end; and a cooling section for cooling veneer leaving the output end of the drying chamber, the cooling section including a pressure controller for maintaining a pressure in the cooling section that is slightly higher than pressure in the drying chamber while maintaining a near-zero pressure differential between the drying chamber and the cooling section.

Owner:USNRKOCKUMS CANCAR

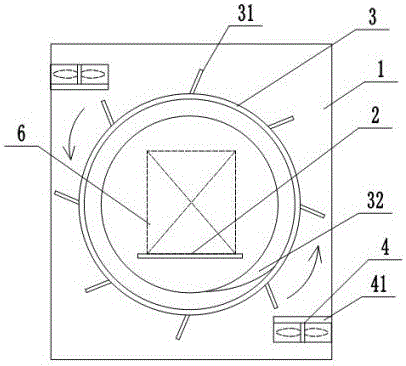

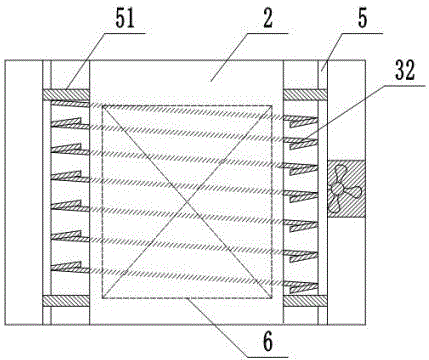

Wind-heat type wood drying box

InactiveCN106595248AAvoid uneven drying and partial crackingEvenly distributedDrying gas arrangementsDrying chambers/containersHelical bladePulp and paper industry

The invention relates to the technical field of drying solid materials and particularly discloses a wind-heat type wood drying box which comprises a box, hot-wind blowers, a supporting plate and a roller. The roller is connected into the box in a rotating manner. The inner wall of the roller is provided with spiral vanes. The outer wall of the roller is provided with a plurality of wind plates. The two ends of the supporting plate are connected to the inner wall of the box. The supporting plate penetrates the roller to enable wood on the supporting plate to be located in the roller. The two hot-wind blowers are arranged at the upper end and the lower end of the box correspondingly. The hot-wind blowers face the outer edge direction of the roller. According to the above technical scheme, the hot-wind blowers carry out wind-heat drying without facing the wood, the roller rotates so that the wind plates on the surface of the roller can achieve heat circulation in the box, axial circulation of heat in the box is achieved through the spiral vanes in the roller, then the heat in the whole box is distributed more uniformly, and the phenomenon that the wood is dried unevenly and cracked partially is avoided.

Owner:重庆金华兴门业有限公司

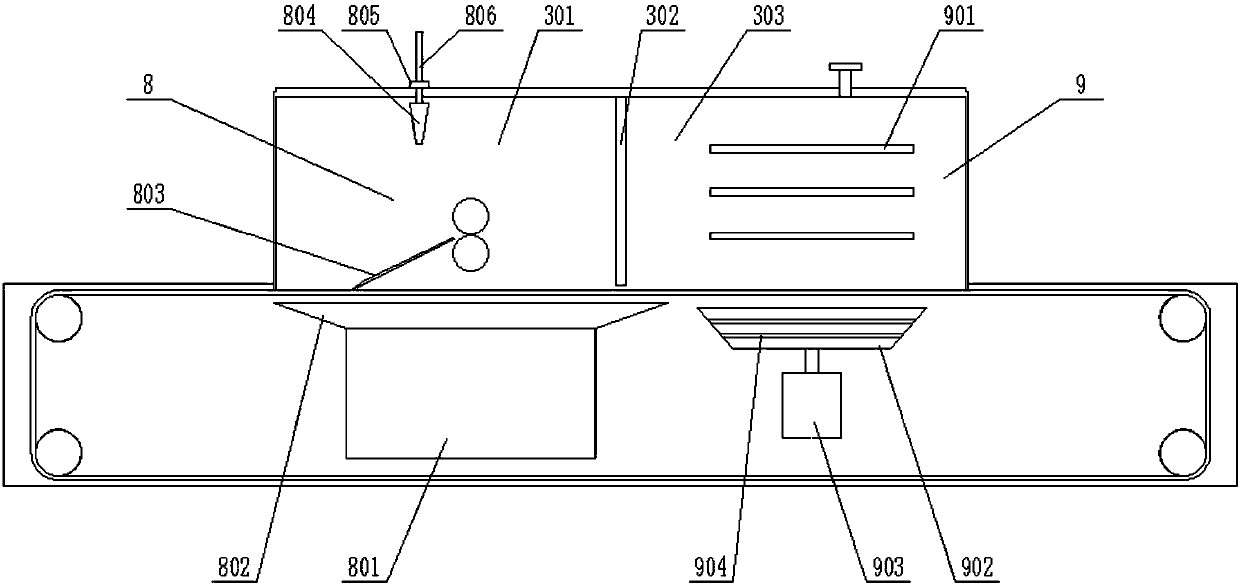

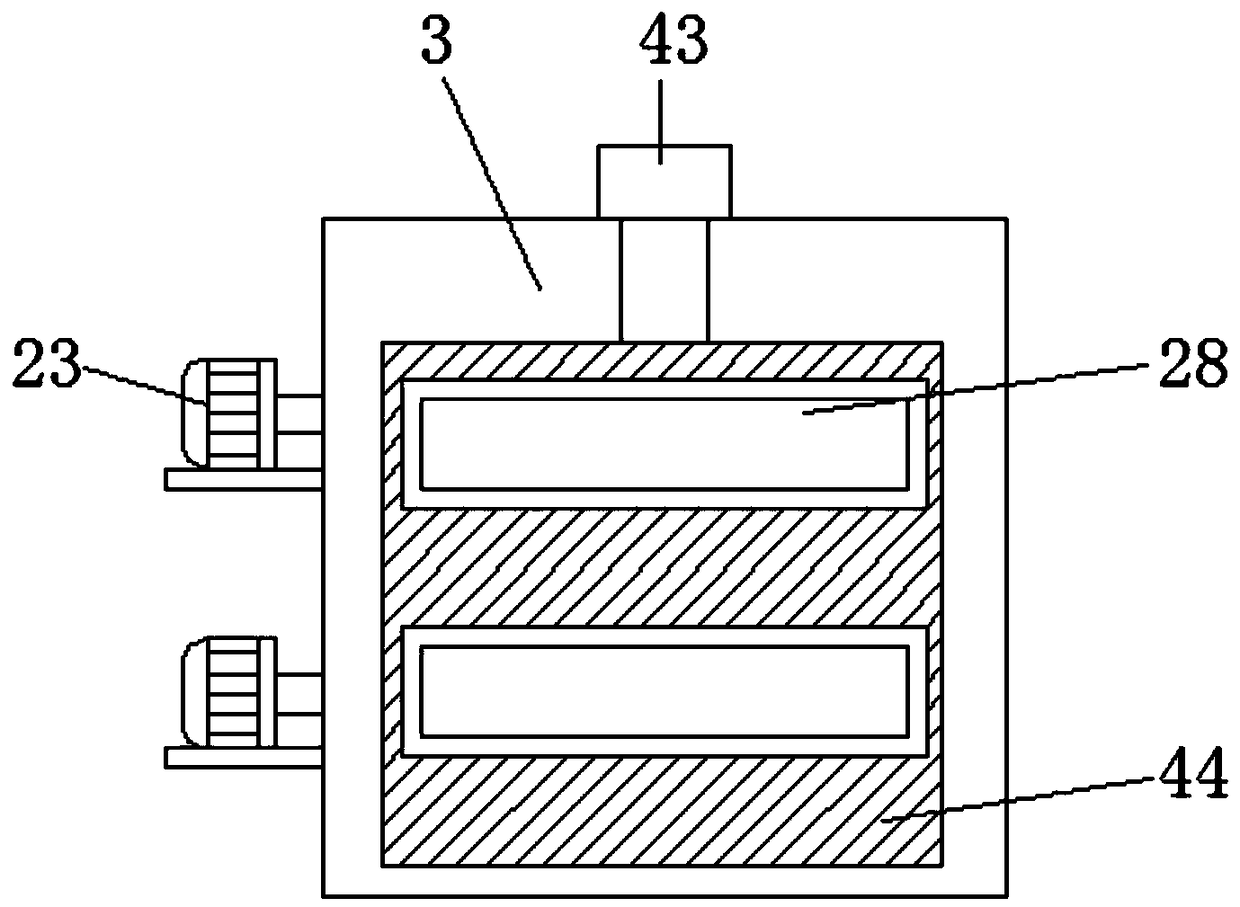

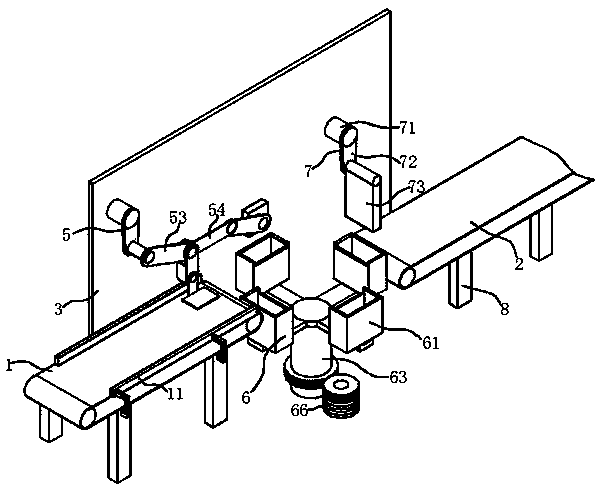

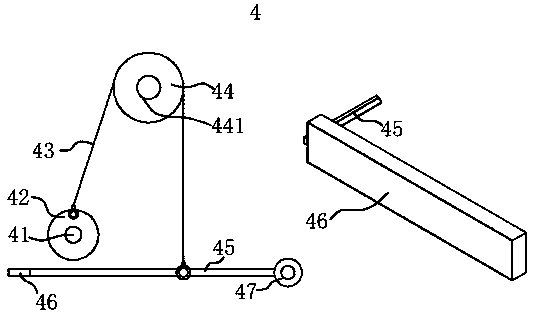

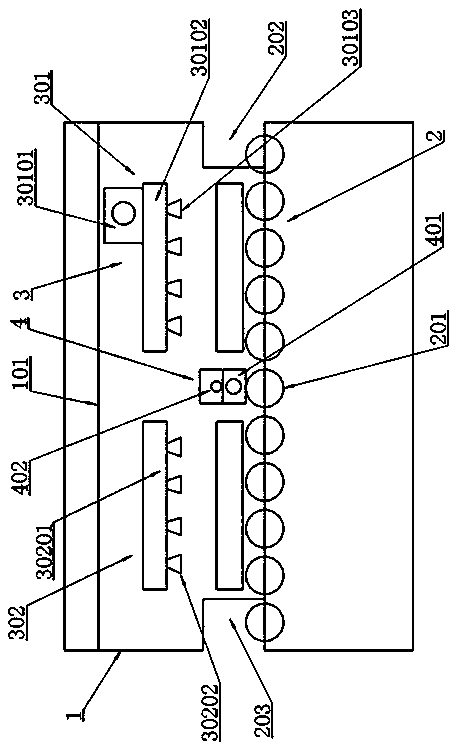

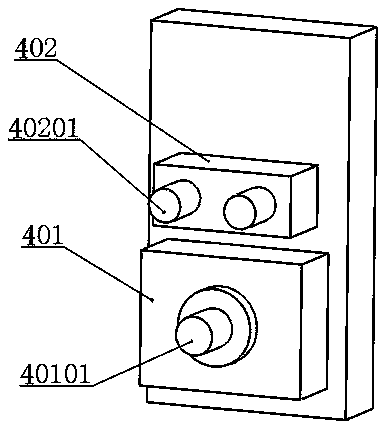

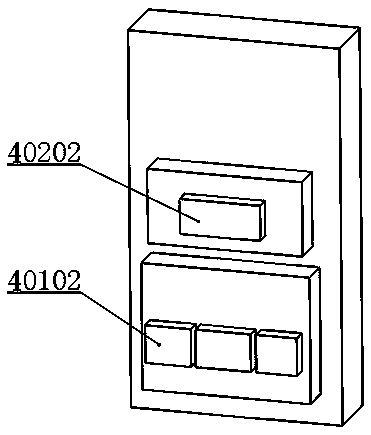

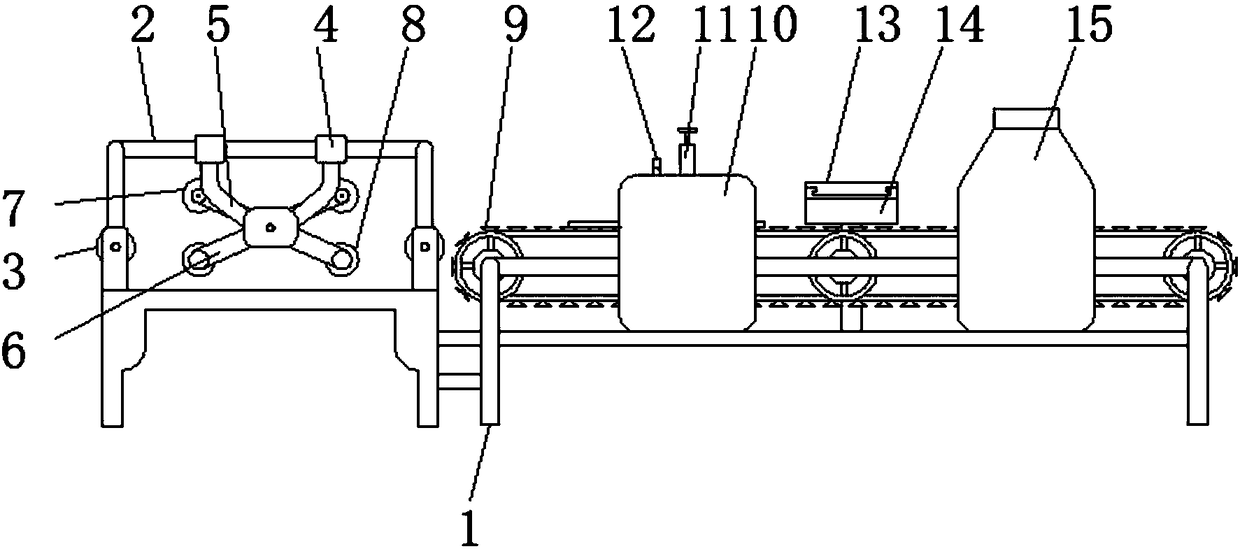

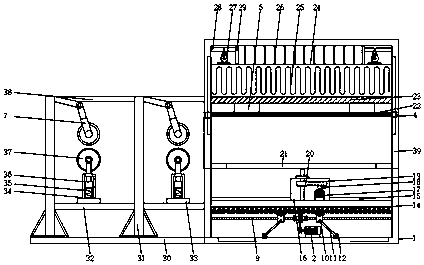

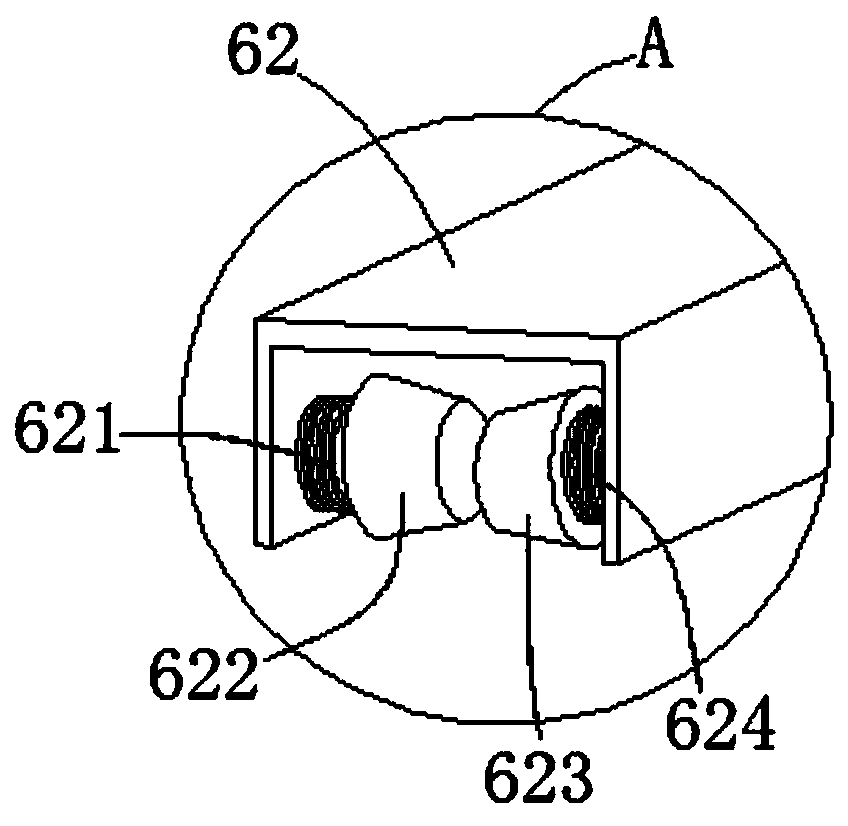

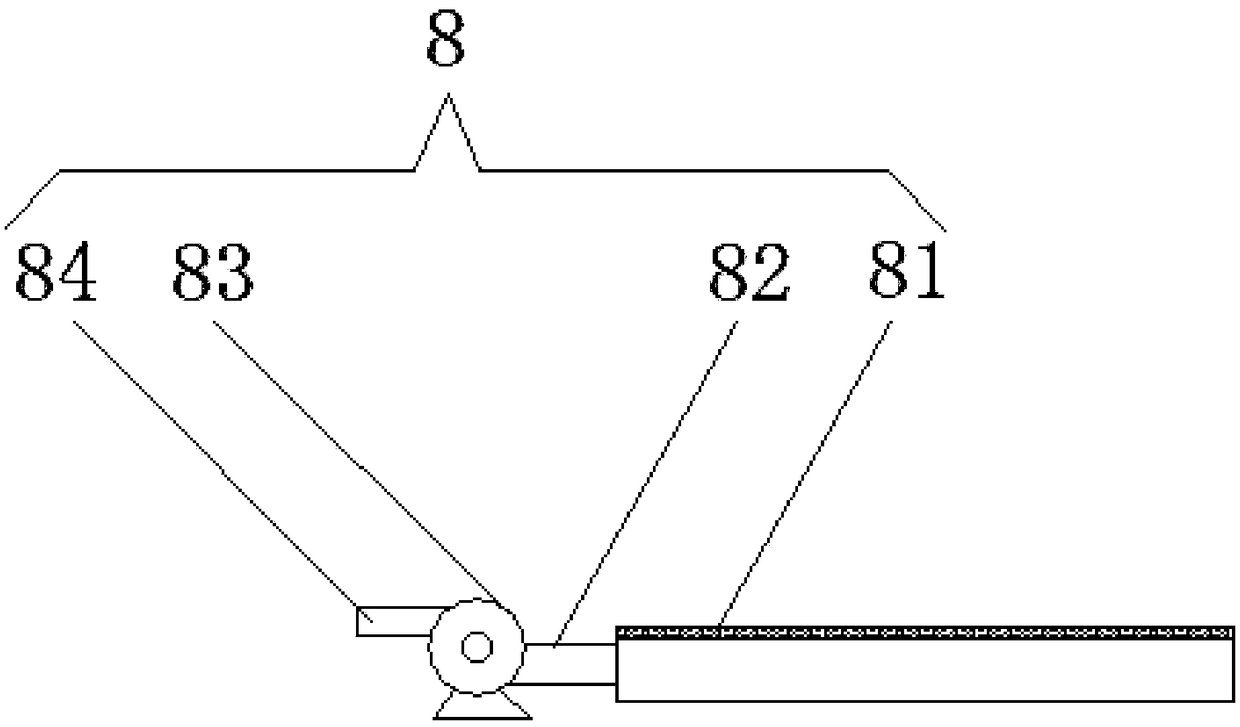

Plate conveying and drying system

ActiveCN110595190AReasonable structural designDrying machines with progressive movementsDrying solid materialsEngineeringMechanical engineering

The invention provides a plate conveying and drying system. The system comprises a first conveying belt and a second conveying belt, wherein a drying box is arranged between the first conveying belt and the second conveying belt; a pressing structure is arranged on the inner wall of one side of the drying box; a first turning structure is arranged on the inner wall of the other side of the dryingbox; a drying structure is arranged on the bottom surface of the drying box on one side of the first turning structure; and a second turning structure is arranged on the inner wall of the drying box on the other side of the drying structure. The system has reasonable structural design, the pressing structure, the first turning structure, the drying structure, the second turning structure and the conveying belts are arranged to complete drying and conveying of plates, and hence, the system has high flexibility and uniform drying, improves drying efficiency and is convenient to use.

Owner:安徽科林新材料科技有限公司

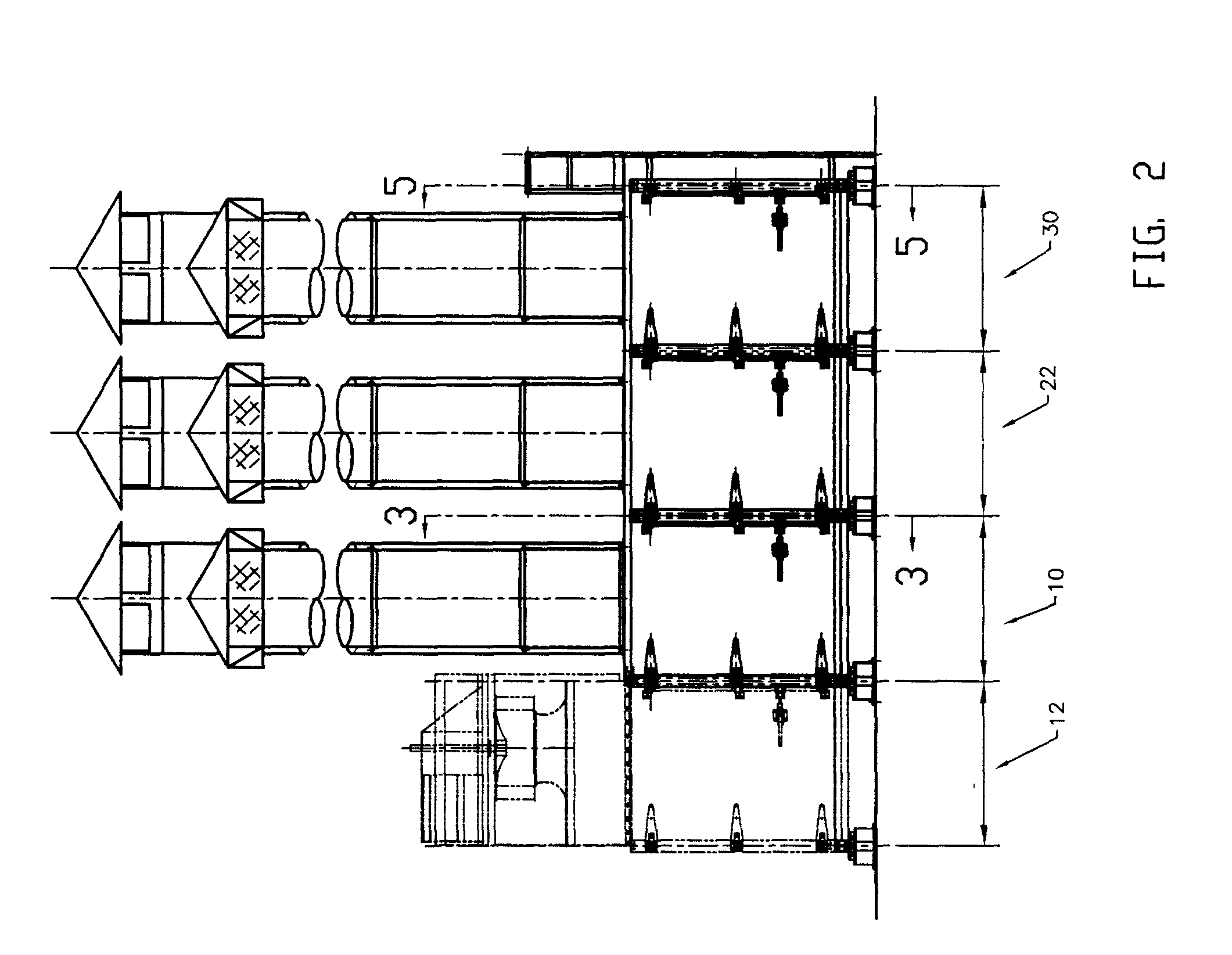

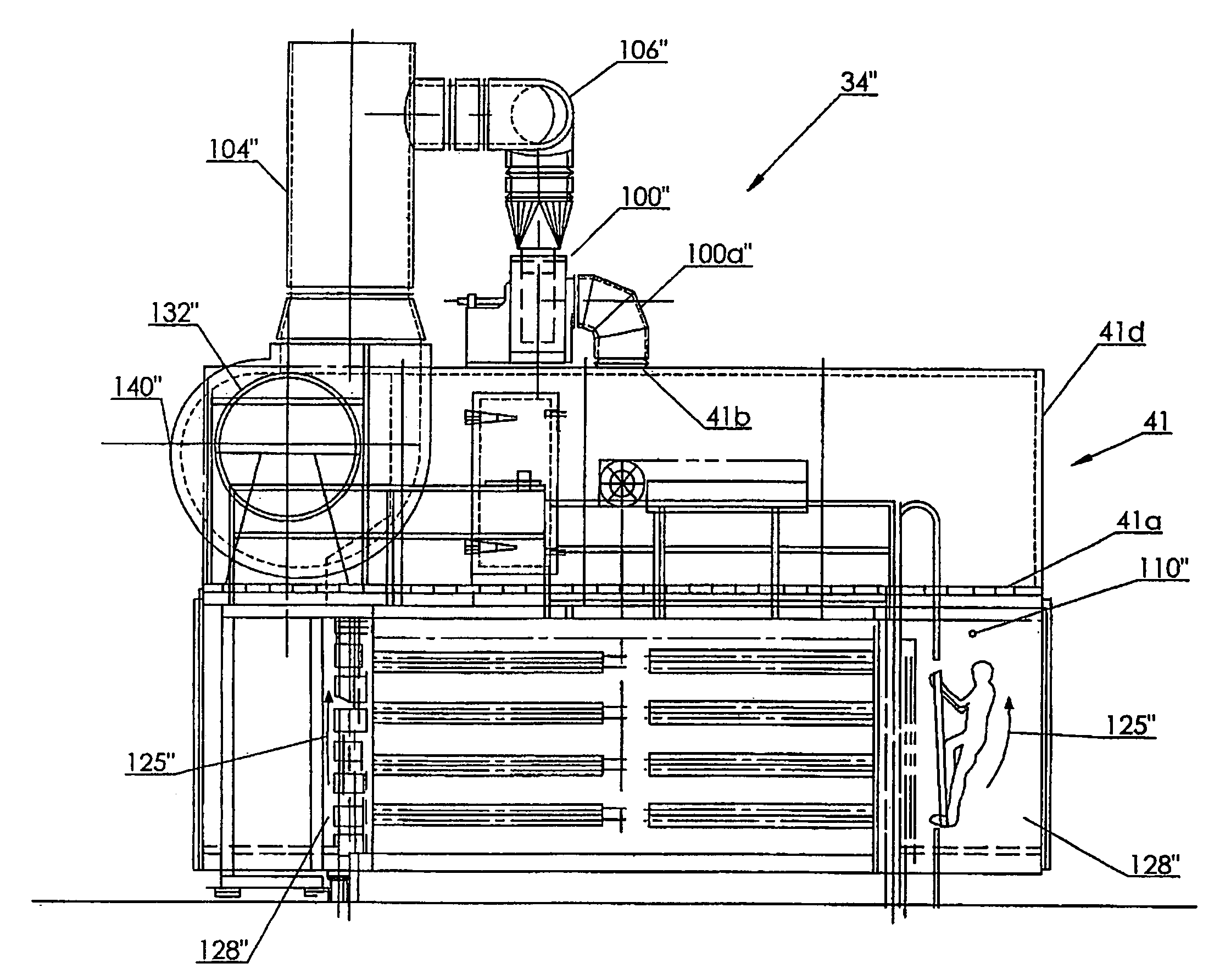

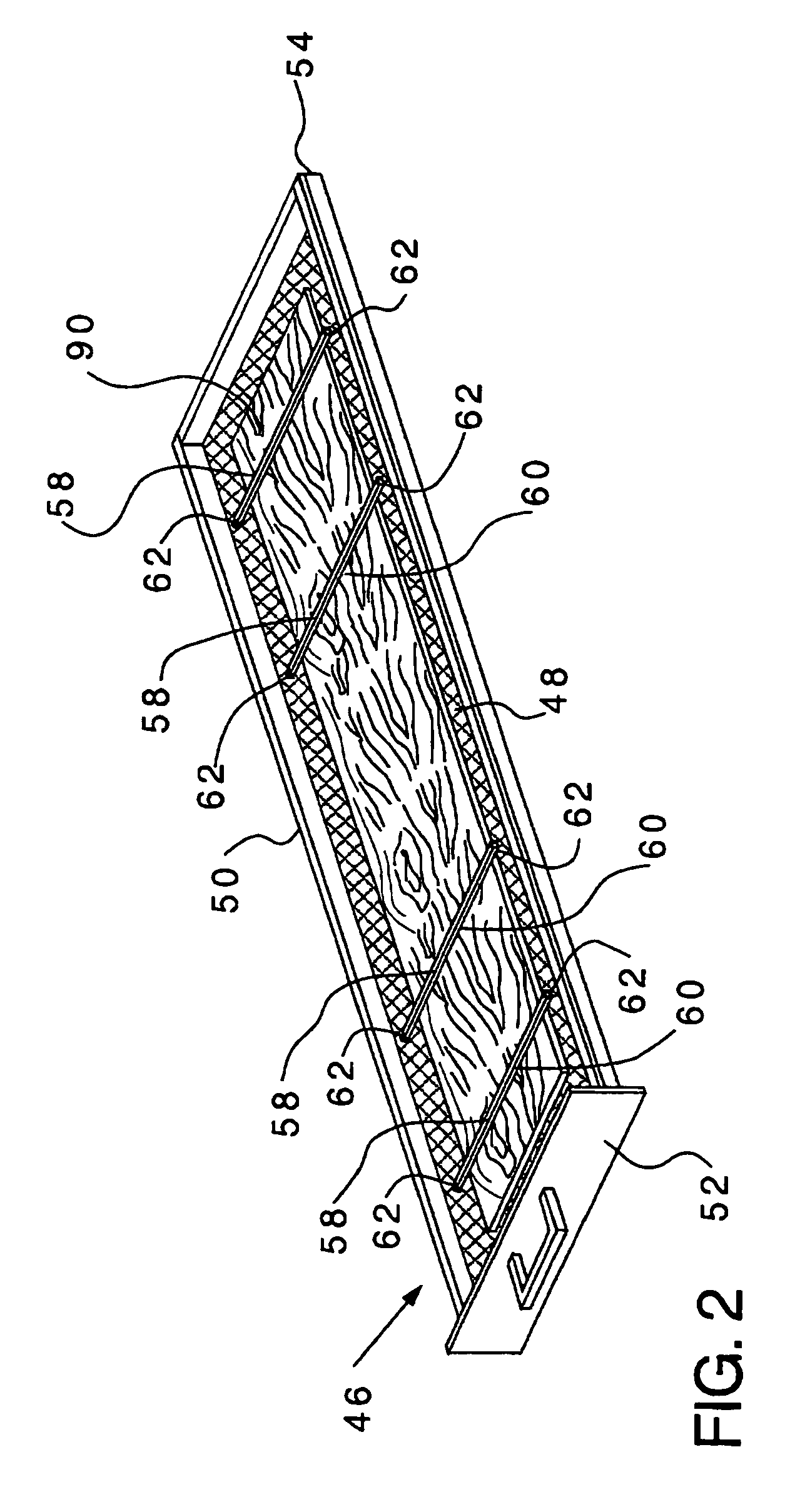

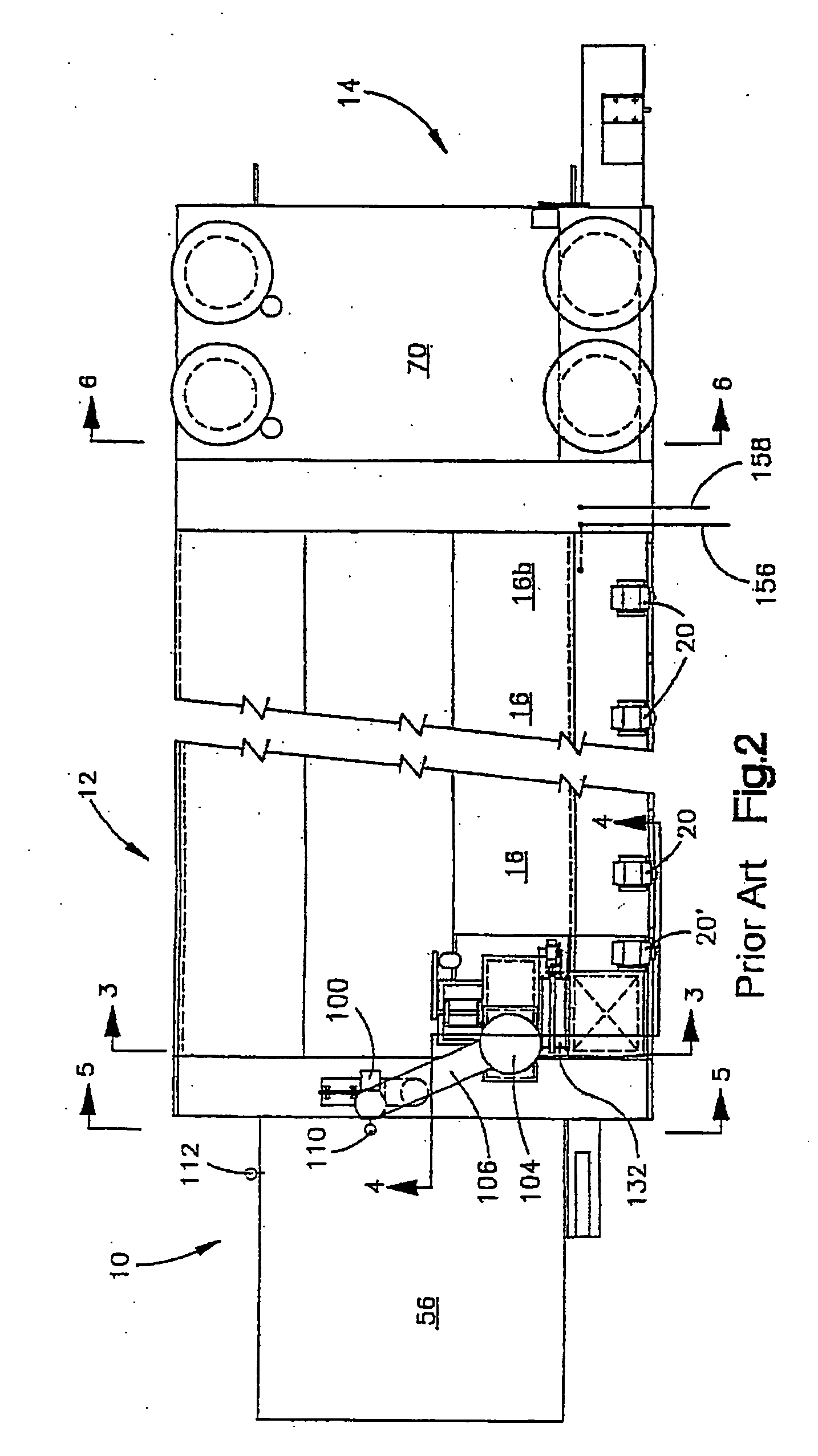

Method and apparatus for inhibiting pitch formation in the wet seal exhaust duct of a veneer dryer

ActiveUS8046932B2Reduce moisture contentReduce and increase rateDrying solid materials with heatDrying gas arrangementsCondensation temperatureEngineering

A method and apparatus for operating a dryer used to reduce the moisture content of sheet material. A drying chamber is provided and includes a plurality of drying sections and a single point exhaust system. A seal section located at the input end of the dryer includes an exhaust passage through which a gas sample is drawn by a sampling fan. Gases within the seal section are a combination of ambient air drawn through restricted passages at the entry to the seal section and exhaust gas that bleeds into the seal section from the drying chamber. A controller monitors the temperature of the sampled gases and ambient air and adjusts the rate of exhaust flow from the main exhaust system as a function of the temperature differential. A heating system is also provided for heating the seal exhaust gases above the pitch condensation temperature for the flow.

Owner:USNRKOCKUMS CANCAR +1

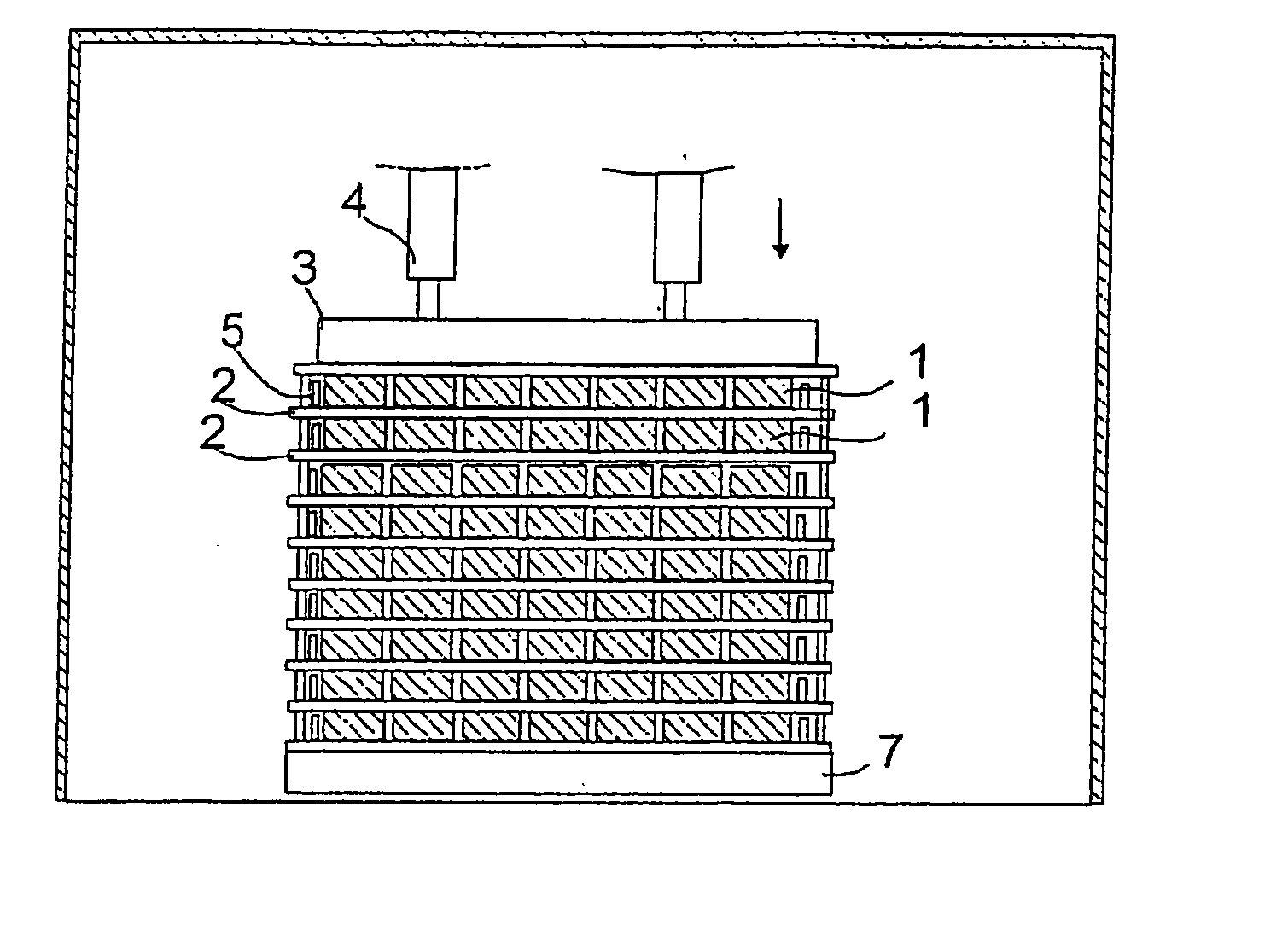

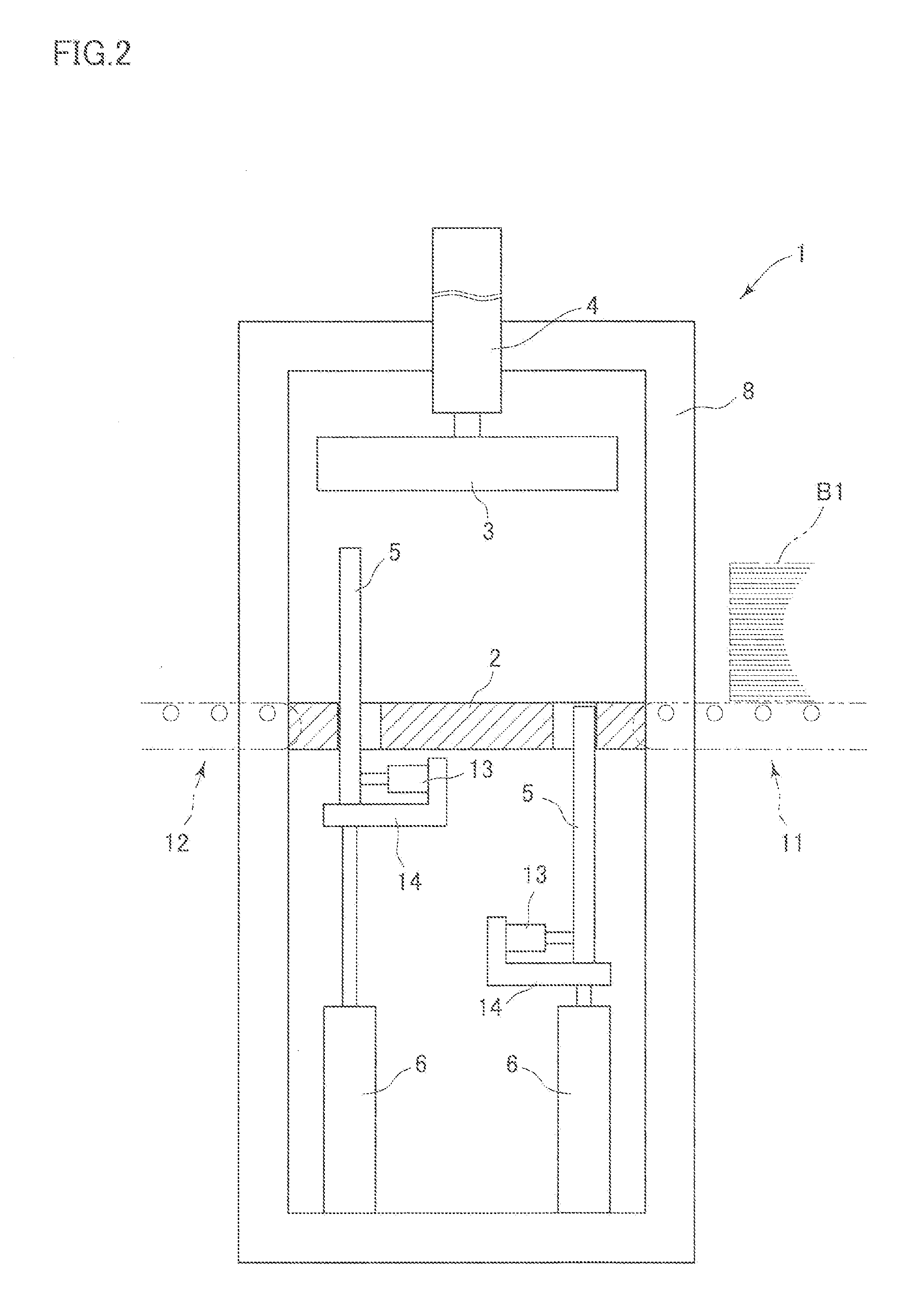

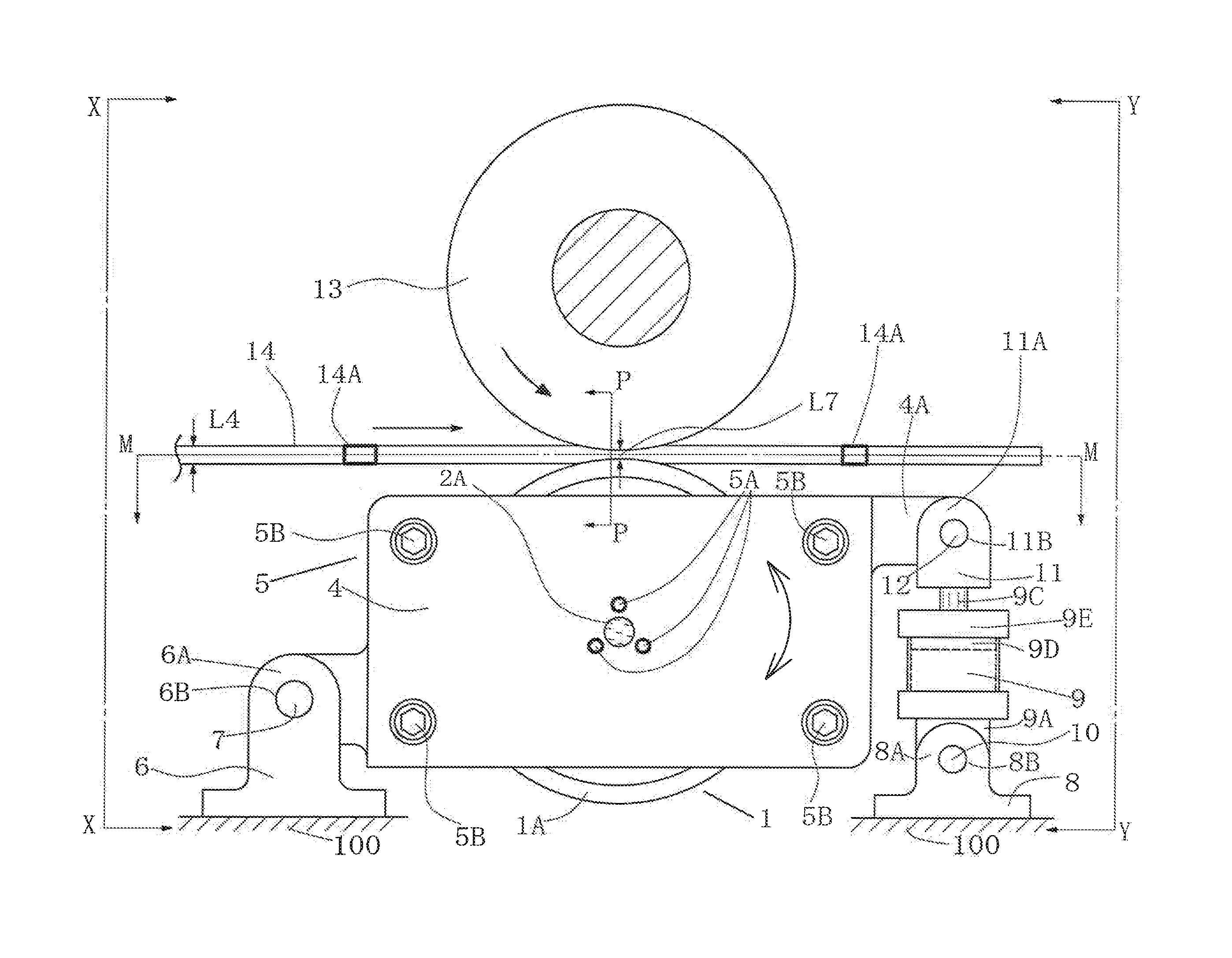

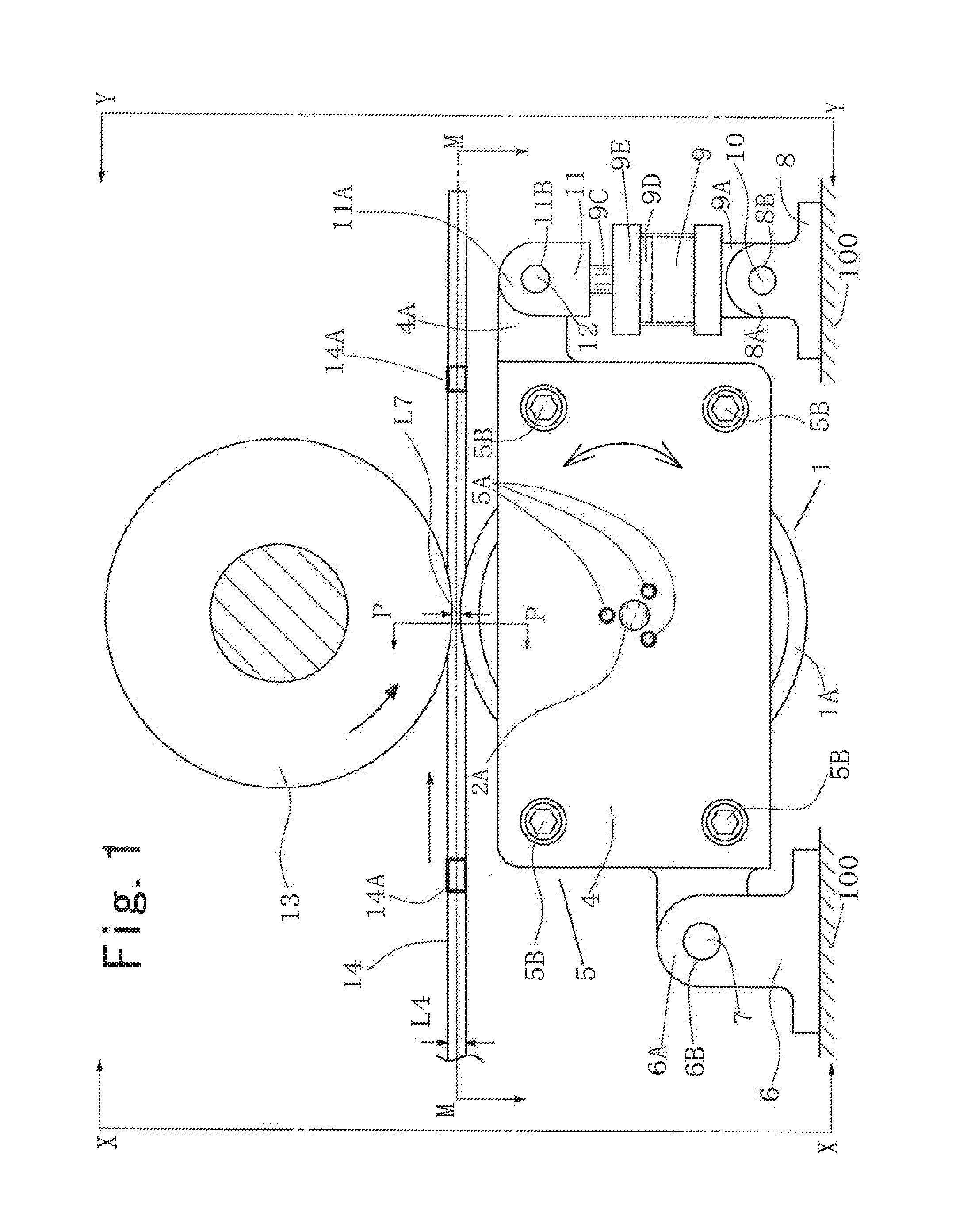

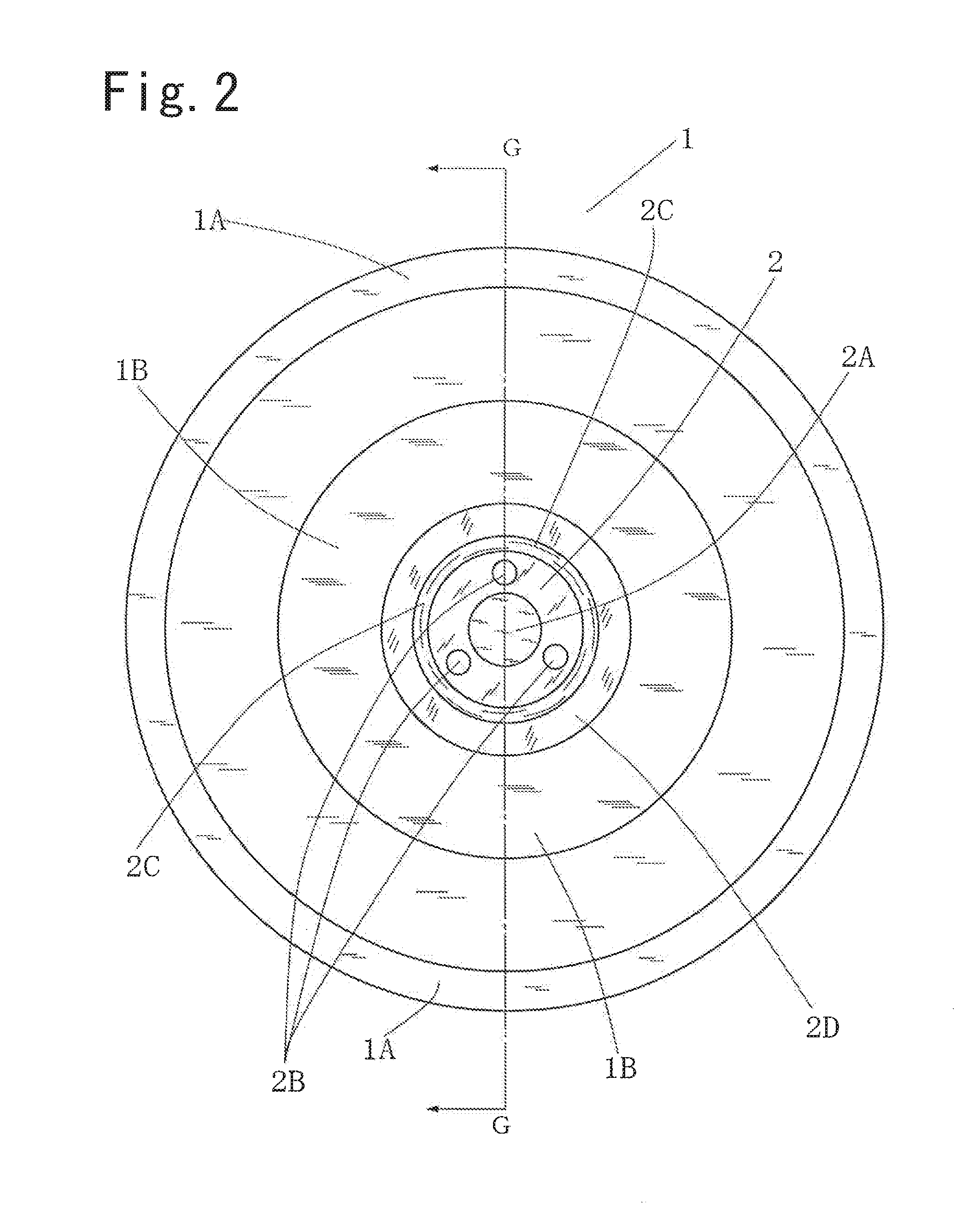

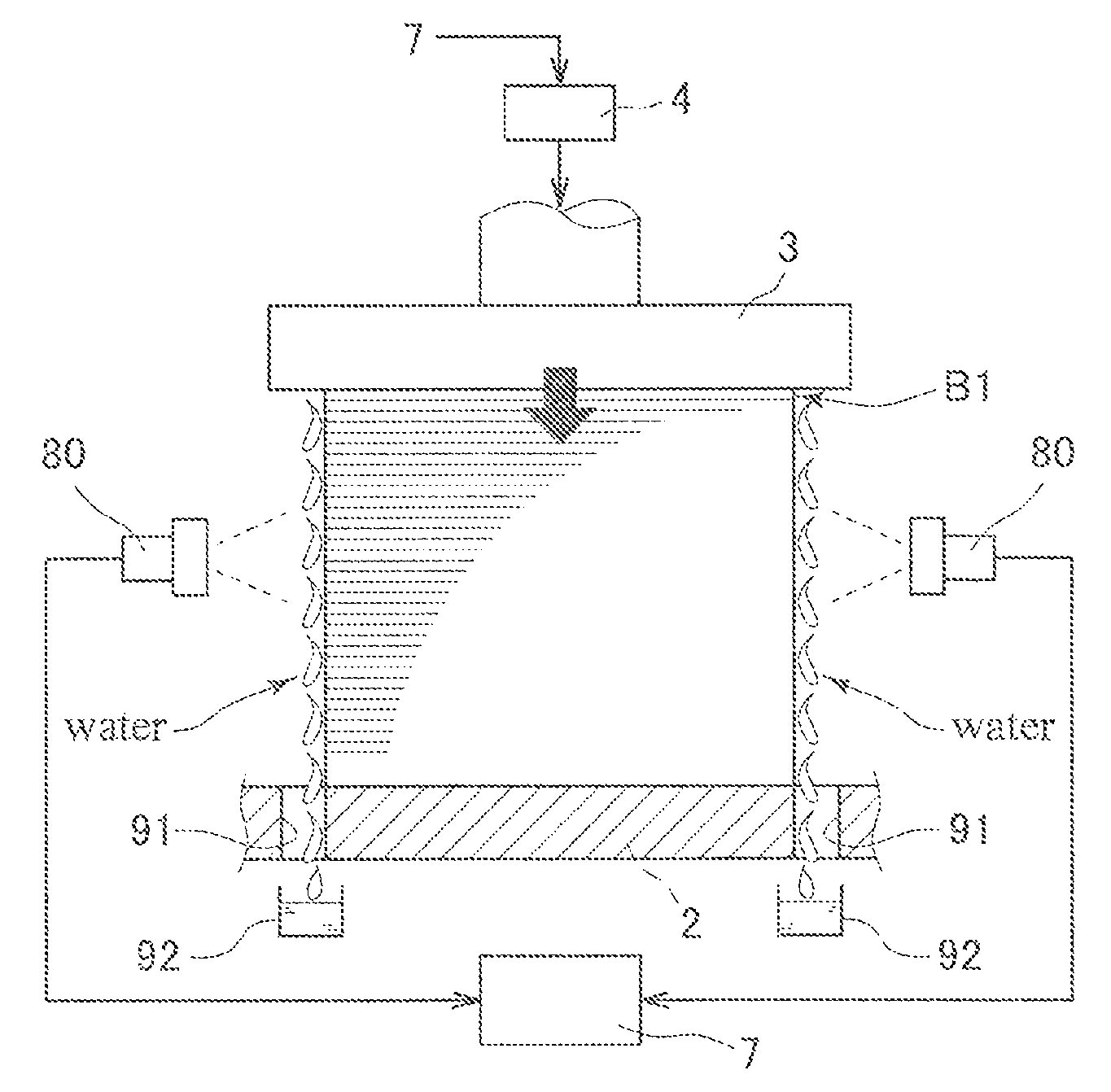

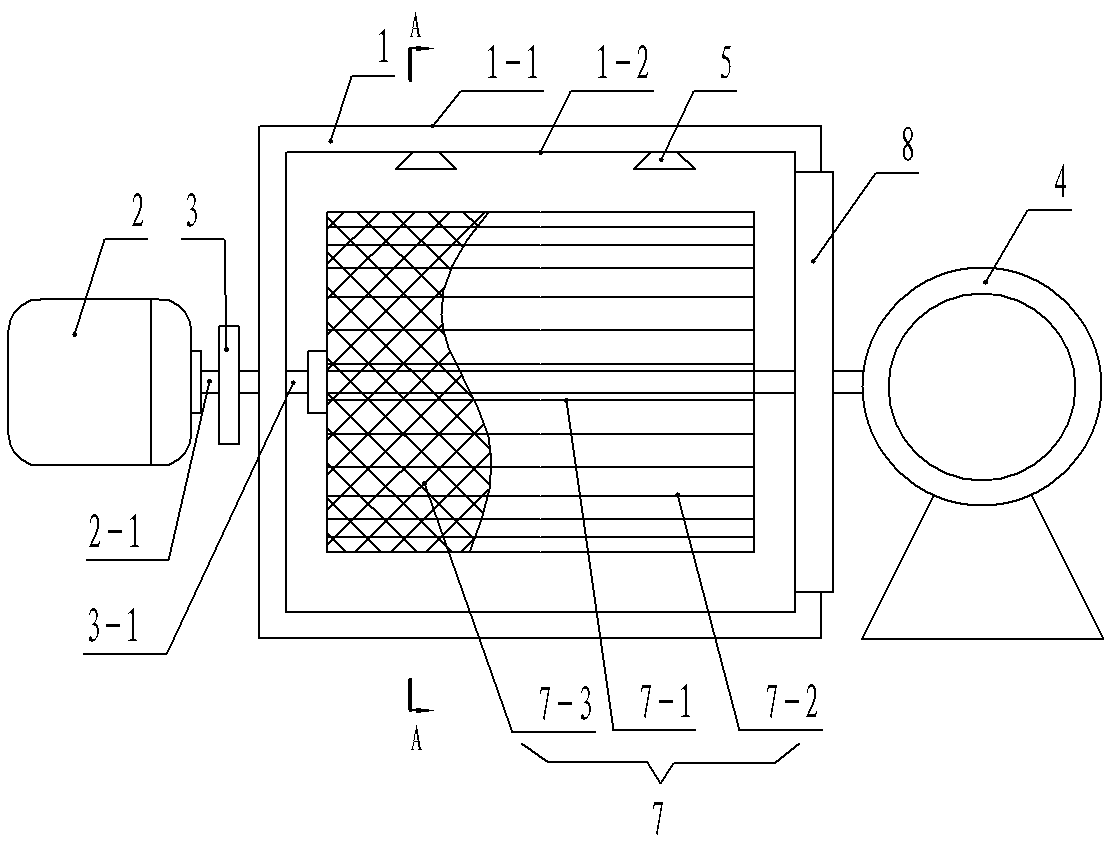

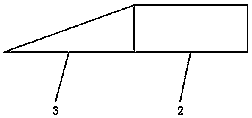

Dewatering Method for Correcting Water Content of Green Veneer for Plywood and Apparatus for Dewatering the Green Veneer

ActiveUS20140000464A1Unnecessary drivingSave energyPlywood pressesLamination ancillary operationsEngineeringHigh water content

A large number of green veneers for plywood respectively having high water contents and formed in a rectangular shape are vertically laminated to obtain a veneer laminate having a quadrangular prismatic shape. The veneer laminate is located between upper and lower platen members so that two opposite side faces of the veneer laminate vertically form cut face gathering planes. The upper and lower platen members are moved toward each other to apply a pressing force to the veneer laminate. The pressing force applied to the veneer laminate is released or weakened while the water drawn through the cut face gathering planes by the pressing force is dripping downward along the cut face gathering planes of the veneer laminate vertically formed.

Owner:TAIHEI SEISAKUSHO AKA TAIHEI MACHINERY WORKS

Drying treatment technology of wood sheets

InactiveCN106288688AGood removal effectPromote sheddingDrying solid materials without heatDrying gas arrangementsEngineeringDrying time

The invention discloses a drying treatment technology of wood sheets, and belongs to the technical field of wood processing. The technology comprises the following steps of 1, sheet processing; 2, primary sheet drying treatment; 3, secondary sheet drying treatment; 4, tertiary sheet drying treatment; 5, sheet drying post-treatment. The phenomenon that wood sheets deform, crack and bend in the drying process can be well prevented, the drying time is shortened by 40-60%, the wood sheet cracking probability is lowered by 2 times or more, the surface of the dried wood sheet is more smooth, and the good application and popularization value is achieved.

Owner:阜南县环宇柳木工艺制品有限公司

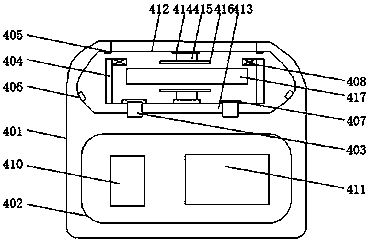

Novel wood floor drying plant

ActiveCN105509446AImprove drying effectRaise countMeasurement devicesDrying gas arrangementsManufacturing technologyPulp and paper industry

The invention belongs to the technical field of wood floor manufacturing, and particularly relates to a novel wood floor drying plant which comprises a machine frame, a delivering unit arranged in the machine frame, a drying unit arranged above the delivering unit, and a photoelectric detection unit arranged between the delivering unit and the drying unit, wherein the photoelectric detection unit comprises a counting photoelectric part and a flat detection photoelectric part; and the drying unit comprises a hot air quick drying unit and a common drying unit. The novel wood floor drying plant is used for carrying out drying operation on the floor, has the functions of drying, counting and flatness detection, and has the advantages of favorable drying effect and high counting and detection precision.

Owner:蚌埠格识知识产权运营有限公司

Method for drying veneers

InactiveUS7383643B2Uniform porosityImproved control and monitoringDrying solid materials without heatDrying machines with progressive movementsHermetic sealVaporization

An apparatus and method is provided to dry veneer or other items by vaporization of moisture in the item. Apparatus has an insulated chamber with a frame and a drawer with a door. A mesh surface of the drawer supports item for drying with a heater at sub-atmospheric pressure inside of the chamber. Item is placed on the layer of mesh of the drawer of the apparatus and secured with fasteners such as another layer of mesh. The drawer with fastened item is placed into the chamber of the apparatus. With the drawer fully engaged within the chamber, the drying apparatus is closed with an airtight seal. A pump draws a vacuum in the chamber and heat is directed at the item to raise the temperature of the item to less than 160° F., particularly between 120° F. to 150° F. Apparatus can dry veneer in less than five minutes.

Owner:BASE POINT

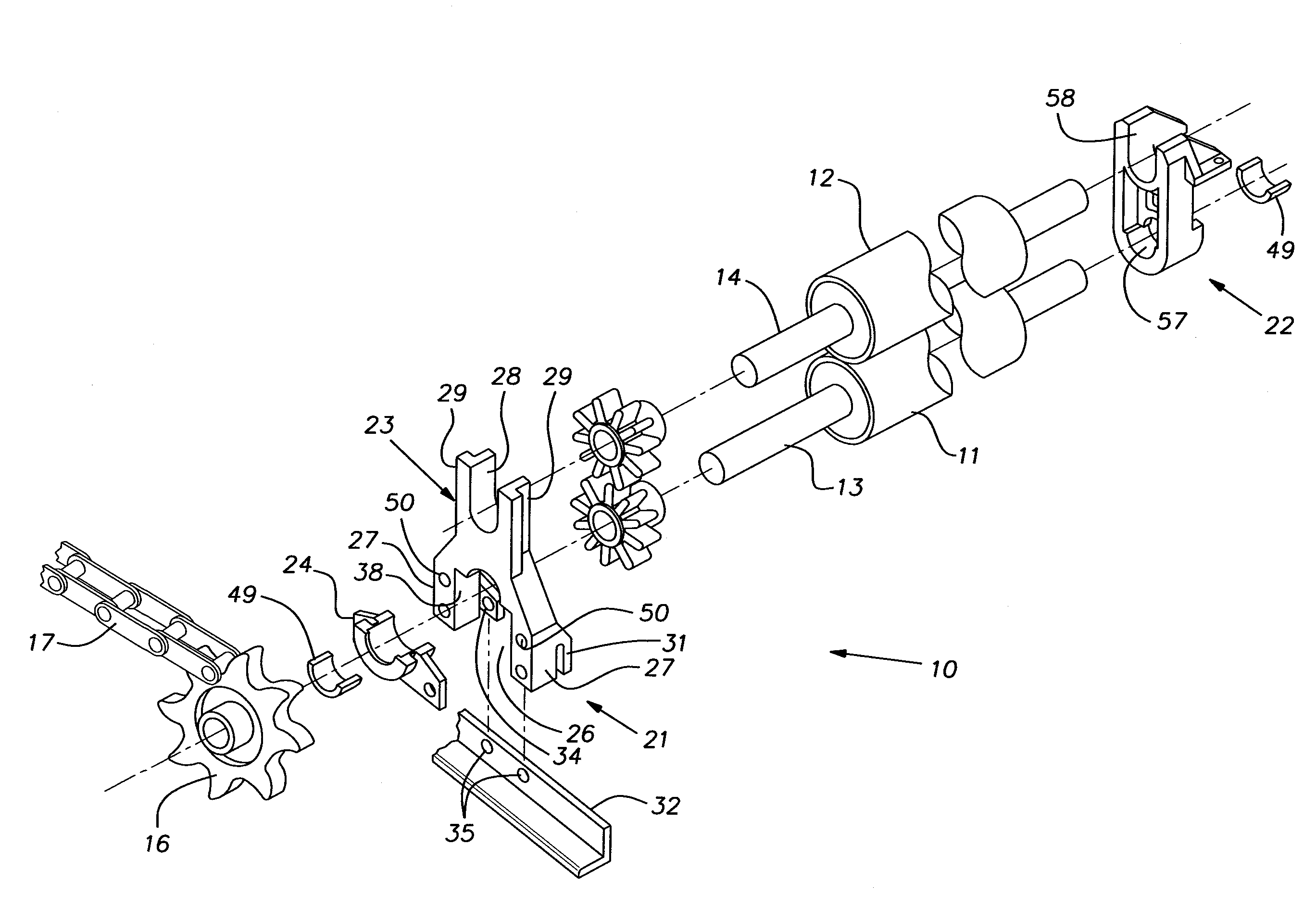

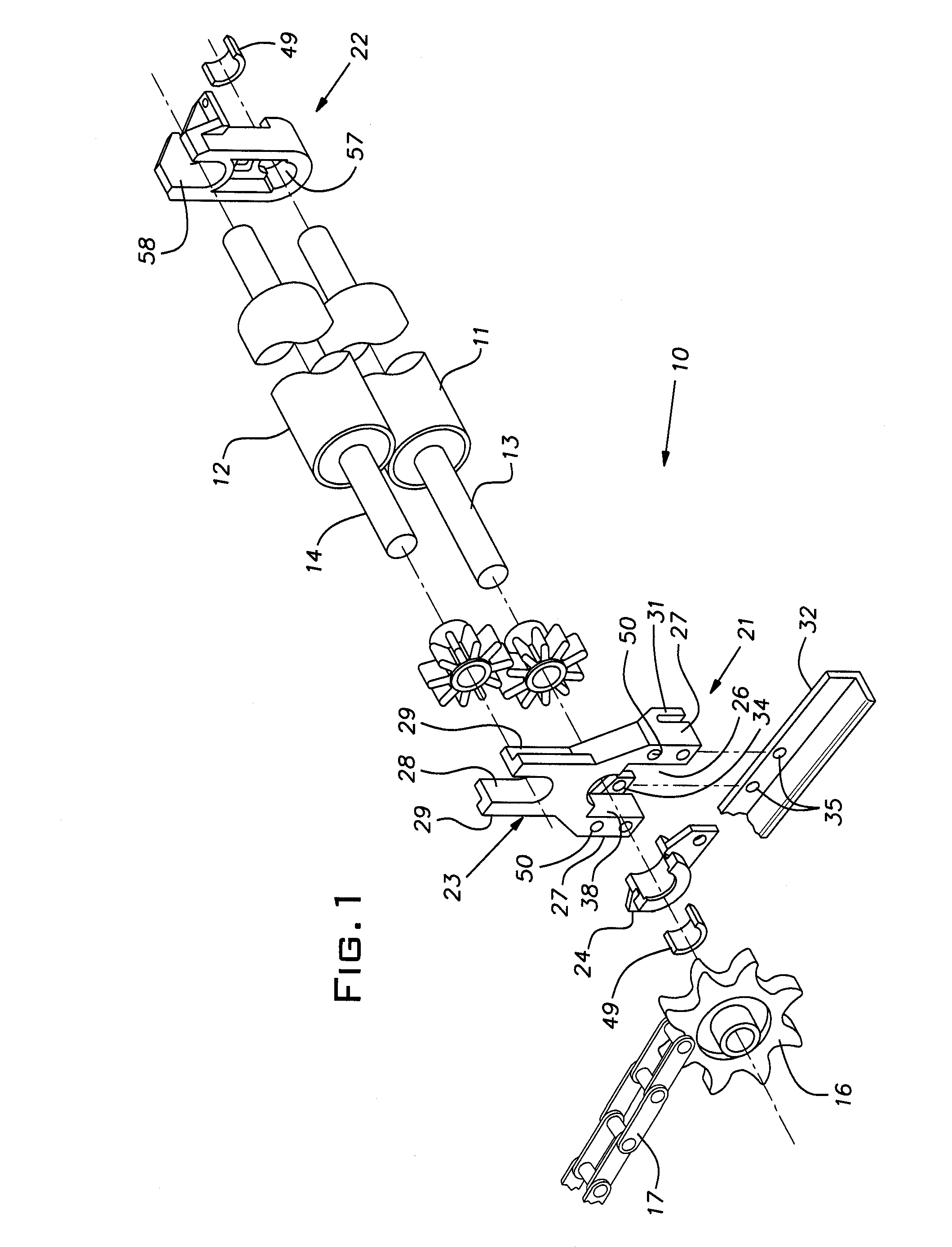

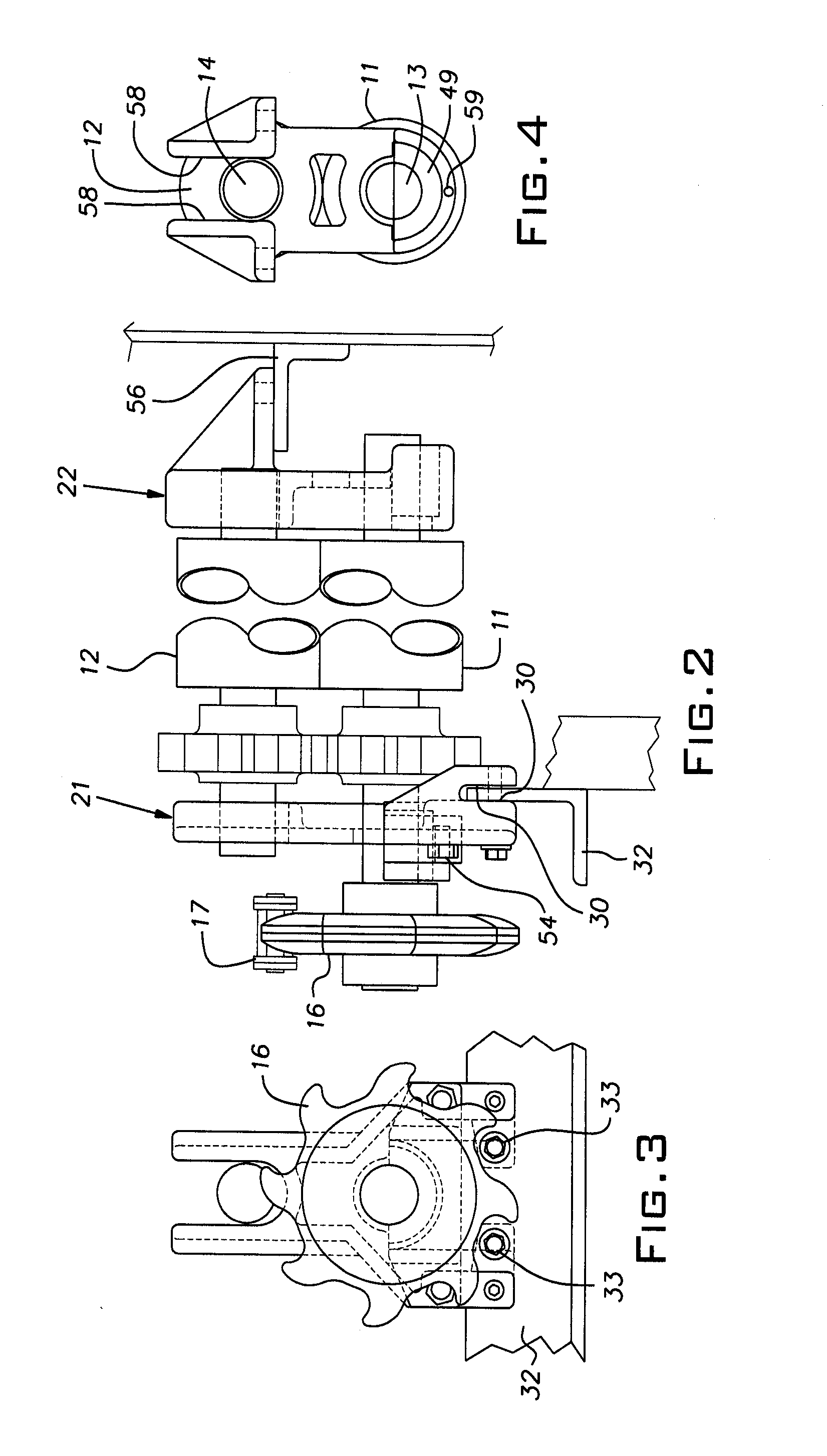

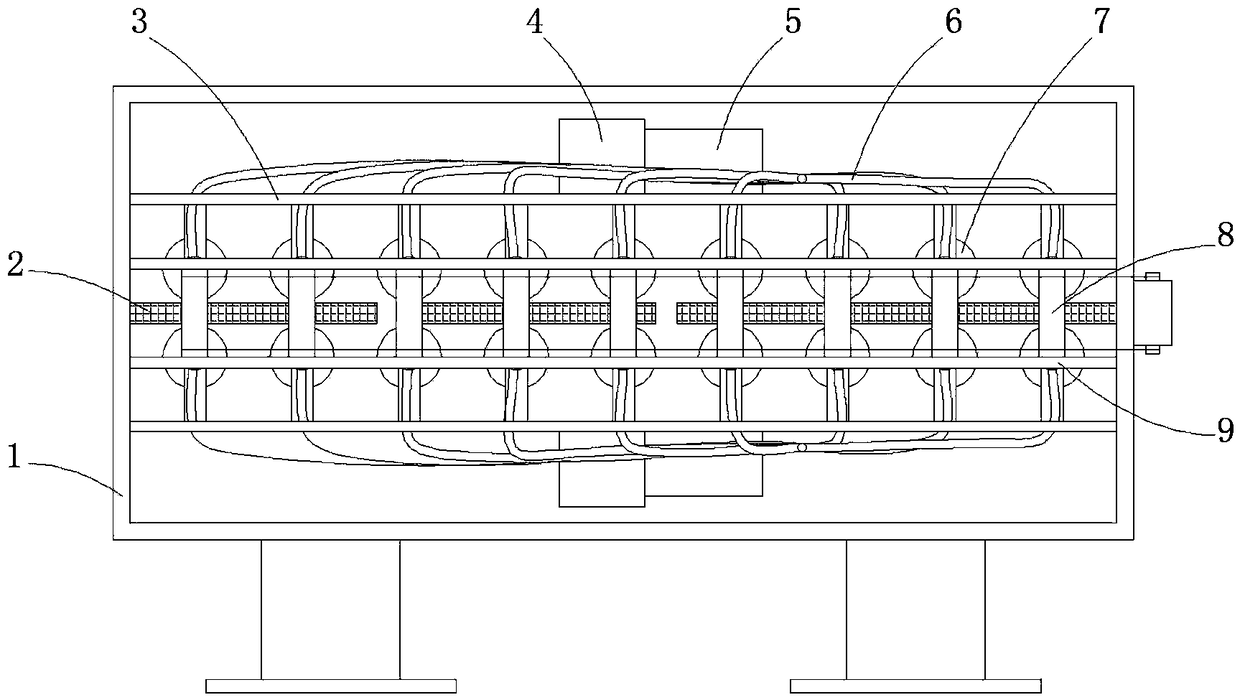

Method and apparatus for dehydrating veneer

ActiveUS20150135975A1Control flowDrying solid materials without heatWood veneer joiningEngineeringStops device

Method and apparatus for dehydration of veneer sheet having therein a knot are disclosed. Veneer dehydration apparatus includes a first stationary single dehydrating roller and a plurality of second movable sectional dehydrating rollers, which rollers are disposed one above the other so that a nip through which a veneer sheet for dehydration is moved is formed between the first and second rollers. A stop device determines the initial position of each second roller relative to the first roller where a predetermined spaced distance is formed between the first and the second rollers. An urging device yieldably urges each second roller to the initial position. The second roller is movable away from the initial position against the urging force of the urging device independently of the other second rollers by a knot present in the veneer sheet and just moving through the nip between the second roller and the first roller.

Owner:MEINAN MASCH WORKS INC

Plate material polishing and cleaning integrated machine

ActiveCN108581668AImprove grinding efficiencyIncrease frictionDrying gas arrangementsCleaning using toolsRubber materialDrive shaft

The invention relates to a plate material polishing and cleaning integrated machine. The plate material polishing and cleaning integrated machine comprises a machine frame, a fixed sleeve, an electricconveying belt, a fixed frame and a drying chamber; a supporting frame is arranged above the machine frame; rolling shafts are arranged on the two sides of the supporting frame; the fixed sleeve is arranged on the supporting frame; the part below the fixed sleeve is connected with a mounting frame; a first servo motor is arranged at the top of the drying chamber; an electric heating wire is arranged below the first servo motor; the mounting frame and a polishing frame are mutually connected through a fixed clip; and tension springs are arranged on the two sides of the polishing frame. The plate material polishing and cleaning integrated machine are provided with two polishing shafts, so that the polishing efficiency of the plate material is higher and polishing is conducted completely; inaddition, the surface of an electric transmission shaft is a rubber material, so that the friction force of the plate material can be enhanced and the plate material can be conveyed conveniently; andthe plate material is subjected to scrubbing, water-removing and drying integrated treatment through a cleaning box, a sponge brush and the drying chamber, so that the working efficiency of the device is higher.

Owner:临沂普润机械有限公司

Method and apparatus for inhibiting pitch formation in the wet seal exhaust duct of a veneer dryer

ActiveUS20080104859A1Reduce moisture contentDrying solid materials with heatDrying solid materials without heatCondensation temperatureProduct gas

Owner:USNRKOCKUMS CANCAR +1

Wood chip drying process

InactiveCN106766708AFast dryingIncrease temperatureDrying solid materials without heatDrying machines with local agitationMicrowaveEngineering

The invention discloses a wood chip drying process. The wood chip drying process comprises the following steps of (1) pretreating, (2) preheating, (3) accelerating drying, (4) baking, and (5) cooling. In the wood chip drying process, heat is not transferred from the surface of a wood chip, but penetrates through the interior of the wood chip through microwaves and is absorbed by contained moisture and the wood chip for direct heating, so that the drying speed is high. The wood chip is heated fully and thoroughly before drying, the temperature and the moisture containing ratio of the wood chip are increased firstly in the drying process, original moisture in the wood chip is easier to volatilize, and meanwhile, harmful bacteria in the wood chip can further be killed and the possibility of the corrosion of the wood chip is reduced. Compared with the prior art, the wood chip is dried through the process, therefore, the defects such as shrinkage, bending, crinkling, collapsing and deforming are not liable to occur, and the wood chip damage rate caused by improper drying is greatly decreased.

Owner:张松波

Dewatering method for correcting water content of green veneer for plywood and apparatus for dewatering the green veneer

ActiveUS9259890B2Increase moisture contentReduce water contentPlywood pressesLamination ancillary operationsEngineeringHigh water content

A large number of green veneers for plywood respectively having high water contents and formed in a rectangular shape are vertically laminated to obtain a veneer laminate having a quadrangular prismatic shape. The veneer laminate is located between upper and lower platen members so that two opposite side faces of the veneer laminate vertically form cut face gathering planes. The upper and lower platen members are moved toward each other to apply a pressing force to the veneer laminate. The pressing force applied to the veneer laminate is released or weakened while the water drawn through the cut face gathering planes by the pressing force is dripping downward along the cut face gathering planes of the veneer laminate vertically formed.

Owner:TAIHEI SEISAKUSHO AKA TAIHEI MACHINERY WORKS

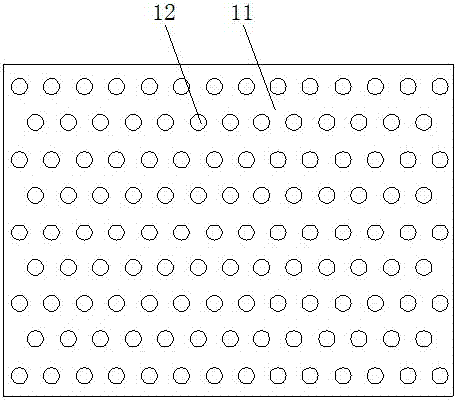

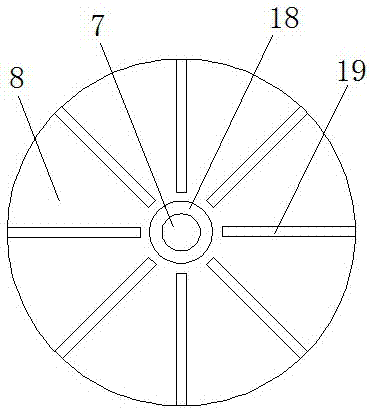

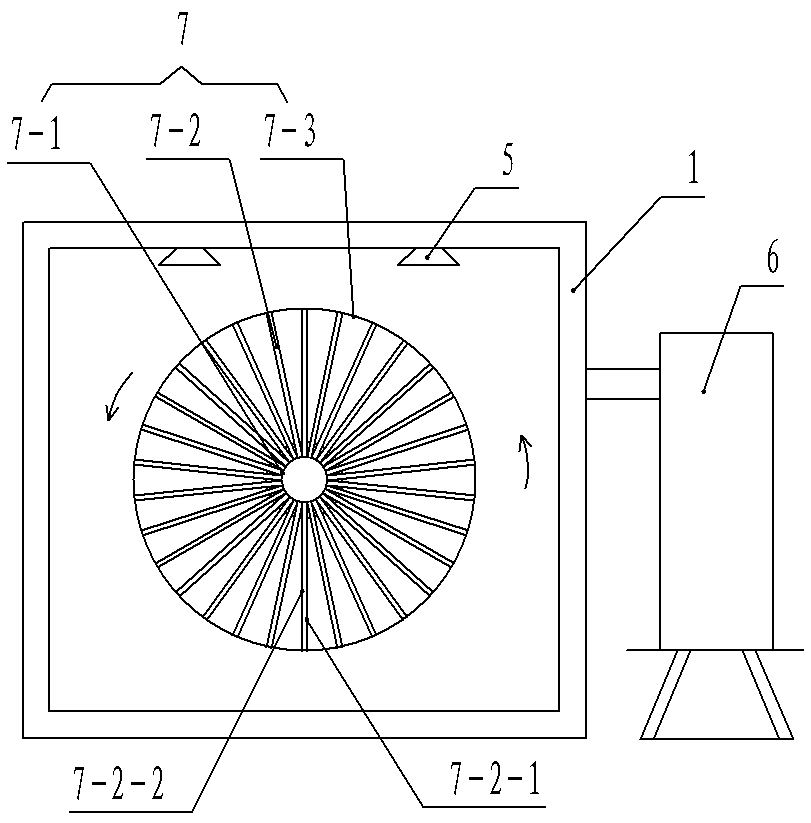

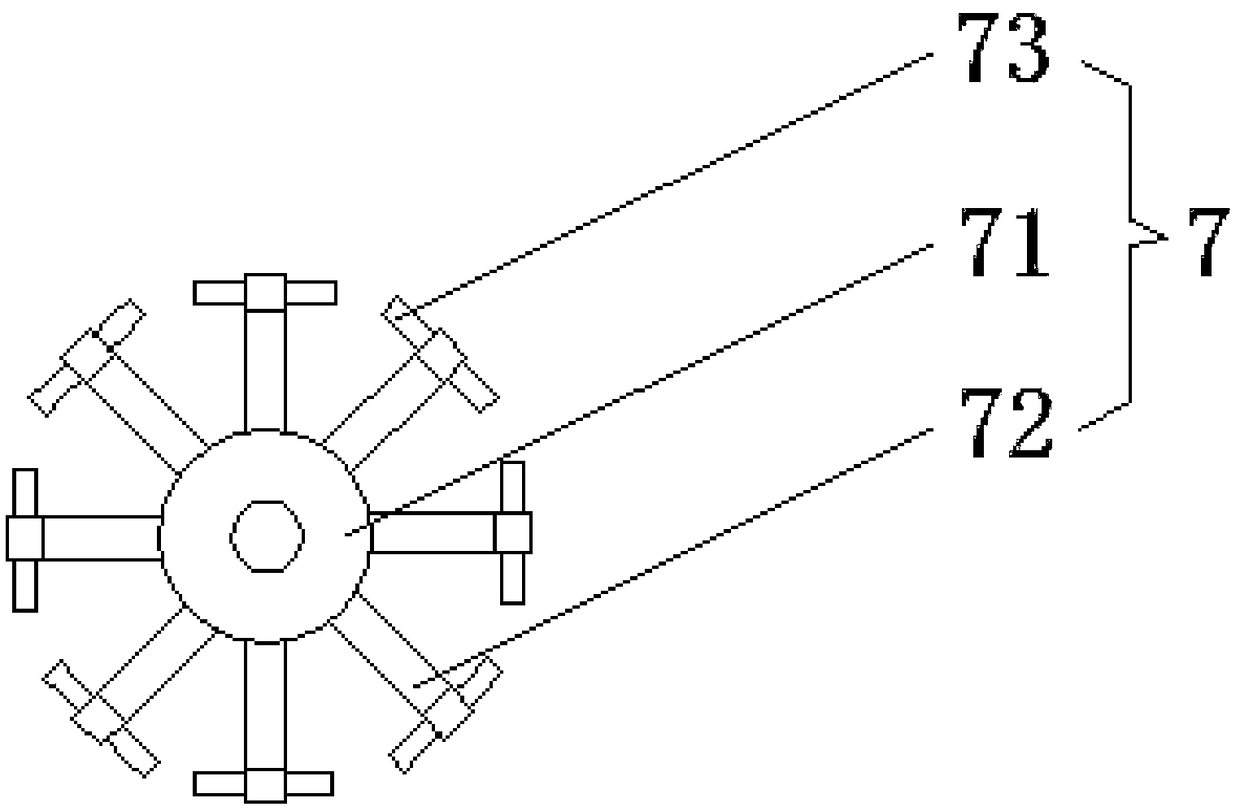

Wood dryer

PendingCN107764011AAvoid crackingAvoid curlDrying gas arrangementsDrying machines with non-progressive movementsWood veneerPulp and paper industry

The invention discloses a wood dryer and belongs to the technical field of wood processing equipment. The wood dryer comprises a drying chamber surrounded by a shell, a door used for opening or closing a feed inlet is arranged on one side of the shell, a plate containing frame which is driven by a power machine to rotate is arranged in the shell and comprises a core tube, multiple support fin plates and a supporting net plate, the core tube faces the door transversely, the support fin plates stretch out of the surface of the core tube in the radial direction, and the outer ends of the supportfin plates are covered with the supporting net plate. A draught fan is arranged outside the shell. Each support fin plate is provided with two opposite panels which are respectively provided with multiple air outlet holes, and an air channel is arranged between the two panels. An air outlet of the draught fan communicates with the air outlet holes through the core tube and the air channels. The wood dryer can solve the problems that an existing wood dryer has uneven air supply, wood veneers piled on the surface are prone to crazing or curling, while wood veneers piled in the middle and at thebottom are difficult to dry, and as a result, energy consumption is high, and the energy utilization rate is low.

Owner:柳州市鸿联木业有限公司

Bearing arrangement for veneer dryer

InactiveUS20090161999A1Significant in costSignificant in laborDrying machines with progressive movementsRollersEngineeringMechanical engineering

A bearing mount assembly for a powered roller conveyor of the type used in veneer dryers comprising a bearing mount base and a bearing holder, the base having a lower part with a vertical surface adapted to abut a cage angle and apertures for fastening it to a vertical face of the cage angle, an upper end of the base being in the shape of a yoke open at the top for locating the shaft of an upper roller, the bearing holder having a pocket for holding an arcuate section of a sleeve bearing, the base and holder having mating surfaces capable of locating the holder in a position where it supports the bearing in registry with the desired axis of rotation of the shaft of a lower roller.

Owner:CROOKS WAYNE

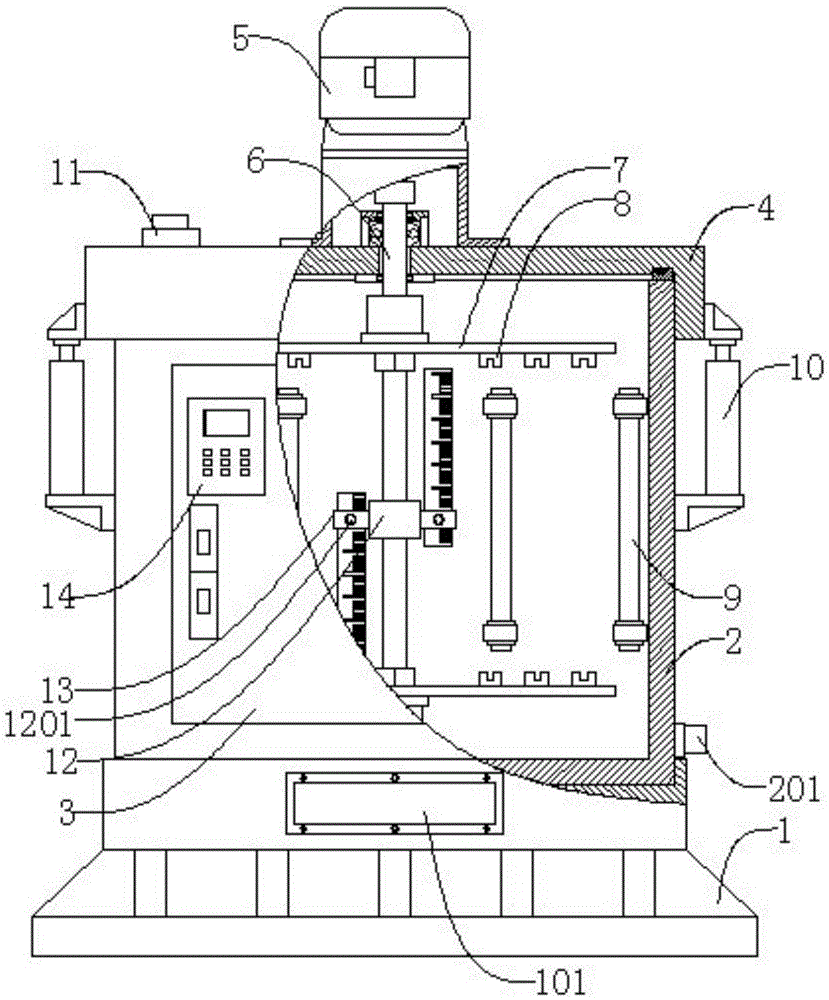

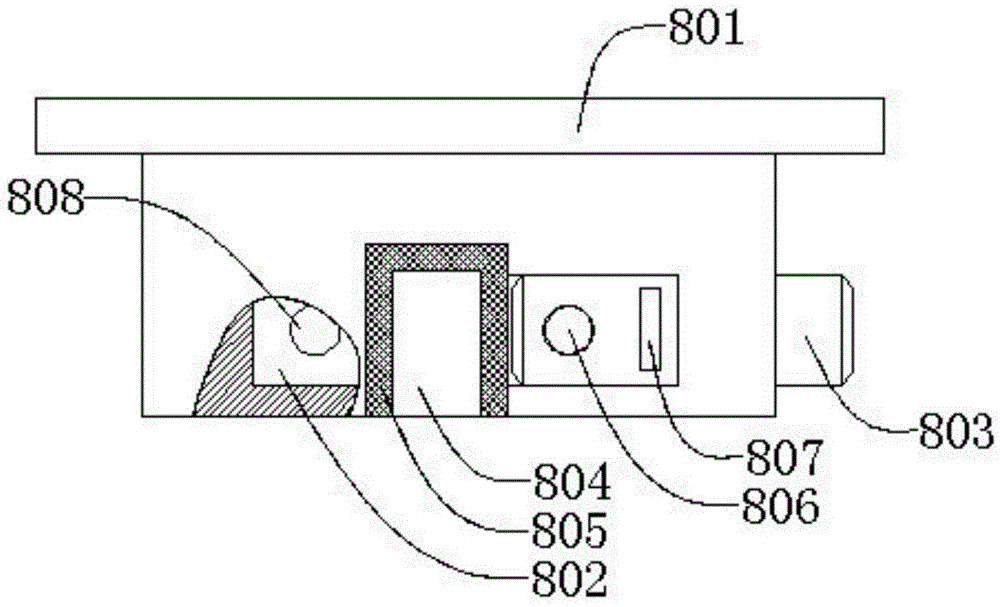

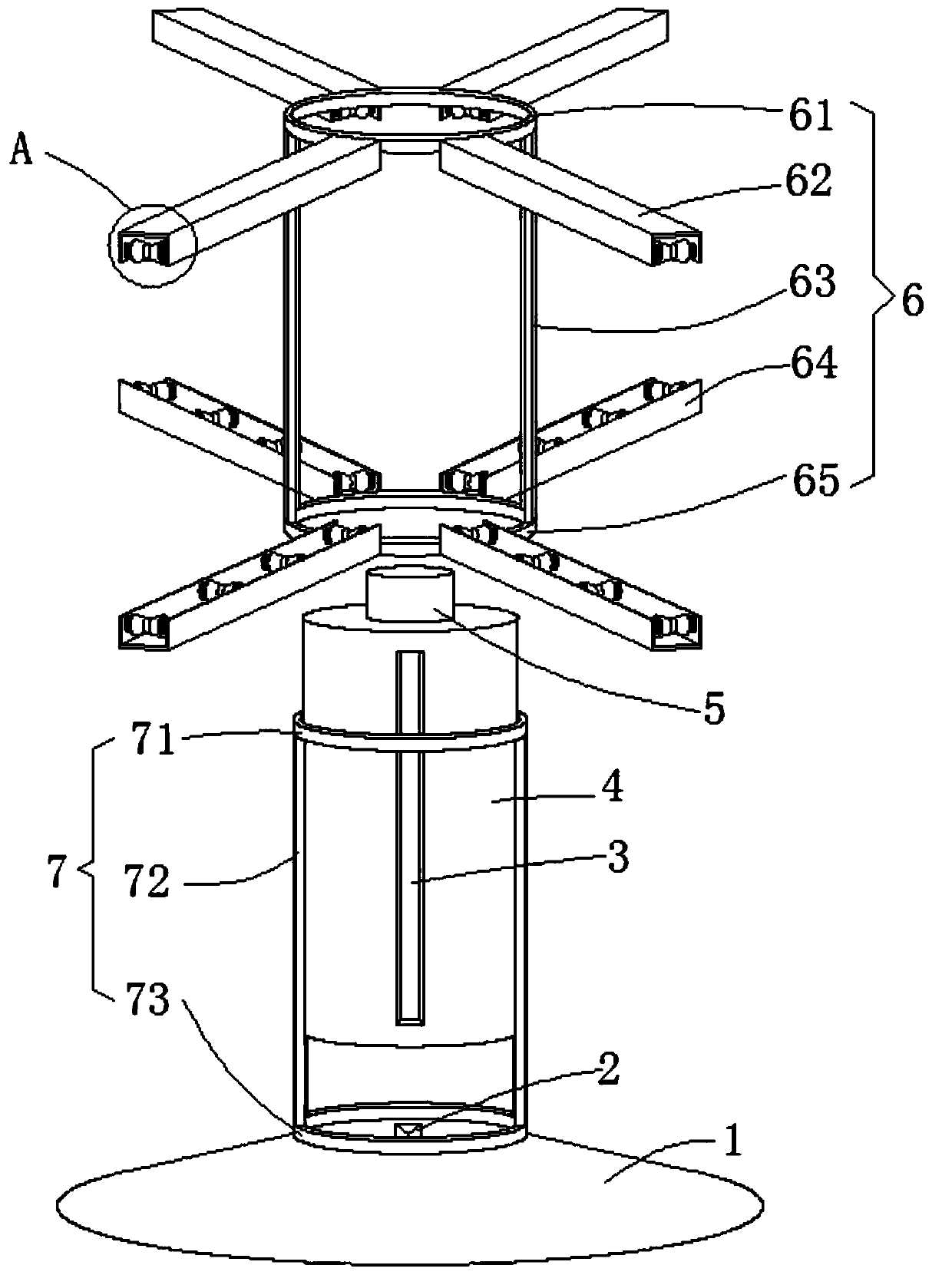

Centrifugal PCB plate automatic drying device

ActiveCN105546939AReduce consumptionSimple structureDrying solid materials without heatDrying machines with non-progressive movementsWastewaterEngineering

The invention discloses a centrifugal PCB plate automatic drying device which comprises a base, a drying barrel, a front door, a cover plate, a motor, a main shaft, wheel plates symmetrically arranged along the main shaft, limiting seats, heating tubes, air cylinders, a temperature sensor, a sliding seat, scaleplates and a controller. When in operation, the front door is manually opened, PCB plates to be processed are placed in the limiting seats, the front door is closed, and the controller controls the motor to drive the wheel plates to rotate at high speed through the main shaft, so that the PCB plates are driven to rotate at high speed, moisture attached in the surface and holes of the PCB plates are spin-dried, and wastewater is discharged through a water discharging connector; meanwhile, the heating tubes work until the temperature reaches the preset temperature of the temperature sensor, so that the temperature in the drying barrel keeps constant; the intervals of the wheel plates can be adjusted through cooperative use of the sliding seat and the scaleplates, so that the PCB plates with different height sizes can be adapted. The device is simple in structure, moisture in the surface and holes of the PCB plates are removed by adopting the high-speed centrifugal dewatering principle, energy consumption is greatly saved, and the production cost is reduced.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

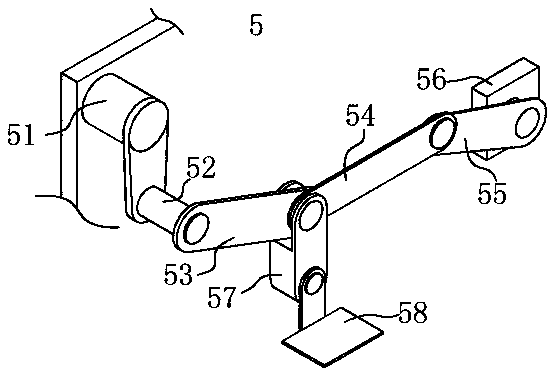

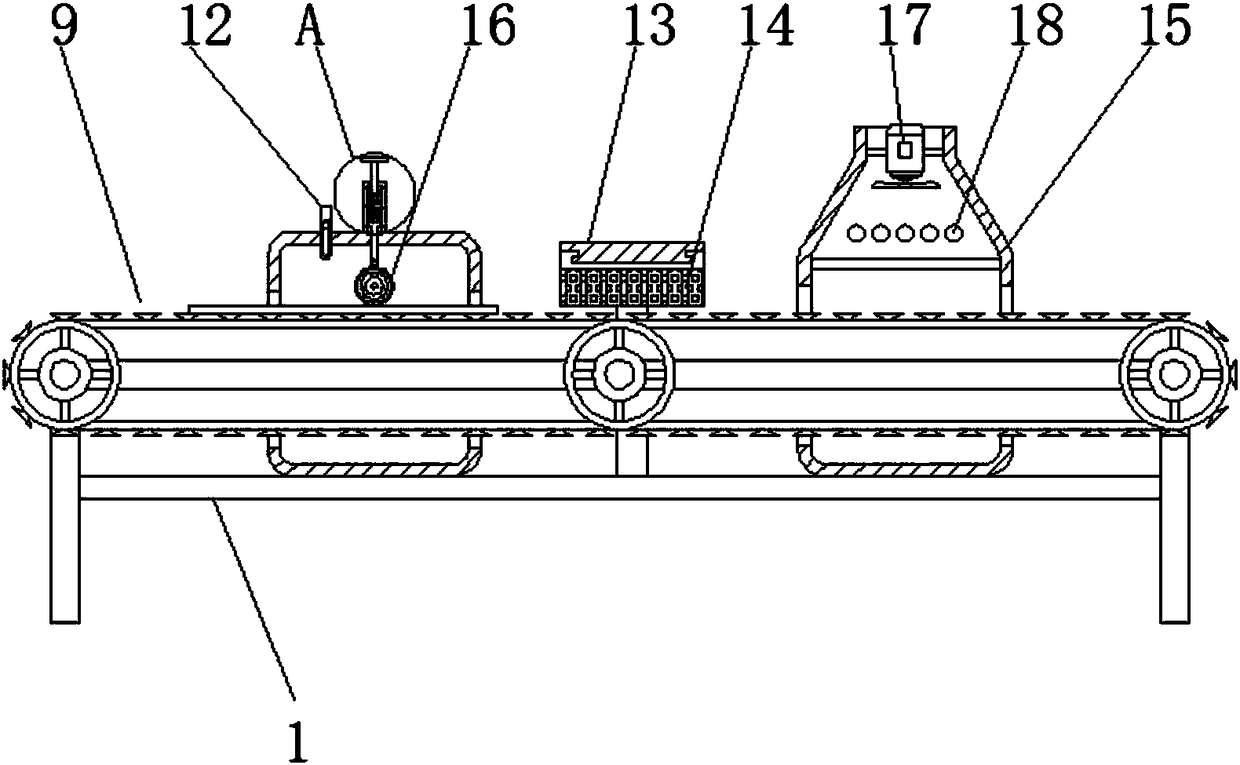

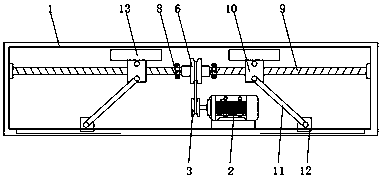

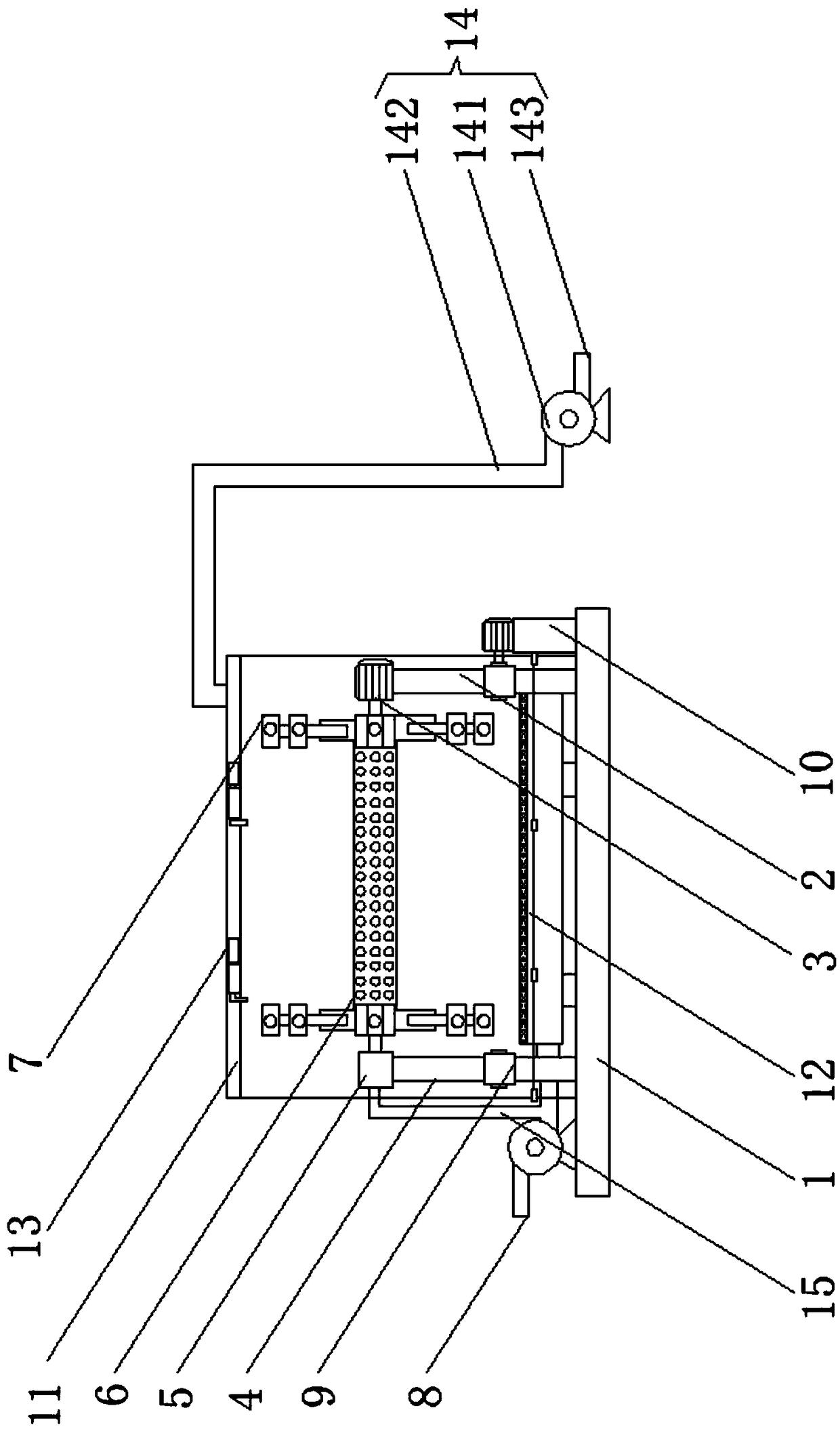

Automatic feeding and drying device for cutting plates of mahogany furniture

InactiveCN107655313ADry evenlyReduce workloadDrying machine combinationsDrying gas arrangementsCouplingEngineering

The invention discloses an automatic feeding and drying device for mahogany furniture cutting boards. There is a first pulley, the first pulley is rotatably connected to a second pulley through a belt, the second pulley is fixedly connected with a coupling through a flat key, and both ends of the coupling are fixedly connected with threaded rods, the The outer wall of the threaded rod is sleeved with a sliding block, the bottom of the sliding block is rotatably connected with a rotating rod through a pin shaft, and the invention relates to the technical field of mahogany furniture cutting board processing. The automatic feeding and drying device for mahogany furniture cutting boards solves the problem of uniform drying of mahogany furniture cutting boards and stable transmission of mahogany furniture cutting boards, ensuring drying quality and drying efficiency, reducing the workload of workers and reducing Labor costs and production costs, the efficiency of faster production and transfer, and the adaptability of different workpieces.

Owner:湖州南浔雷欧木制品厂

Wood drying box for furniture production

InactiveCN107655272AEasy to placeEasy accessDrying gas arrangementsDrying chambers/containersPulp and paper industryDrying time

Owner:湖州南浔雷欧木制品厂

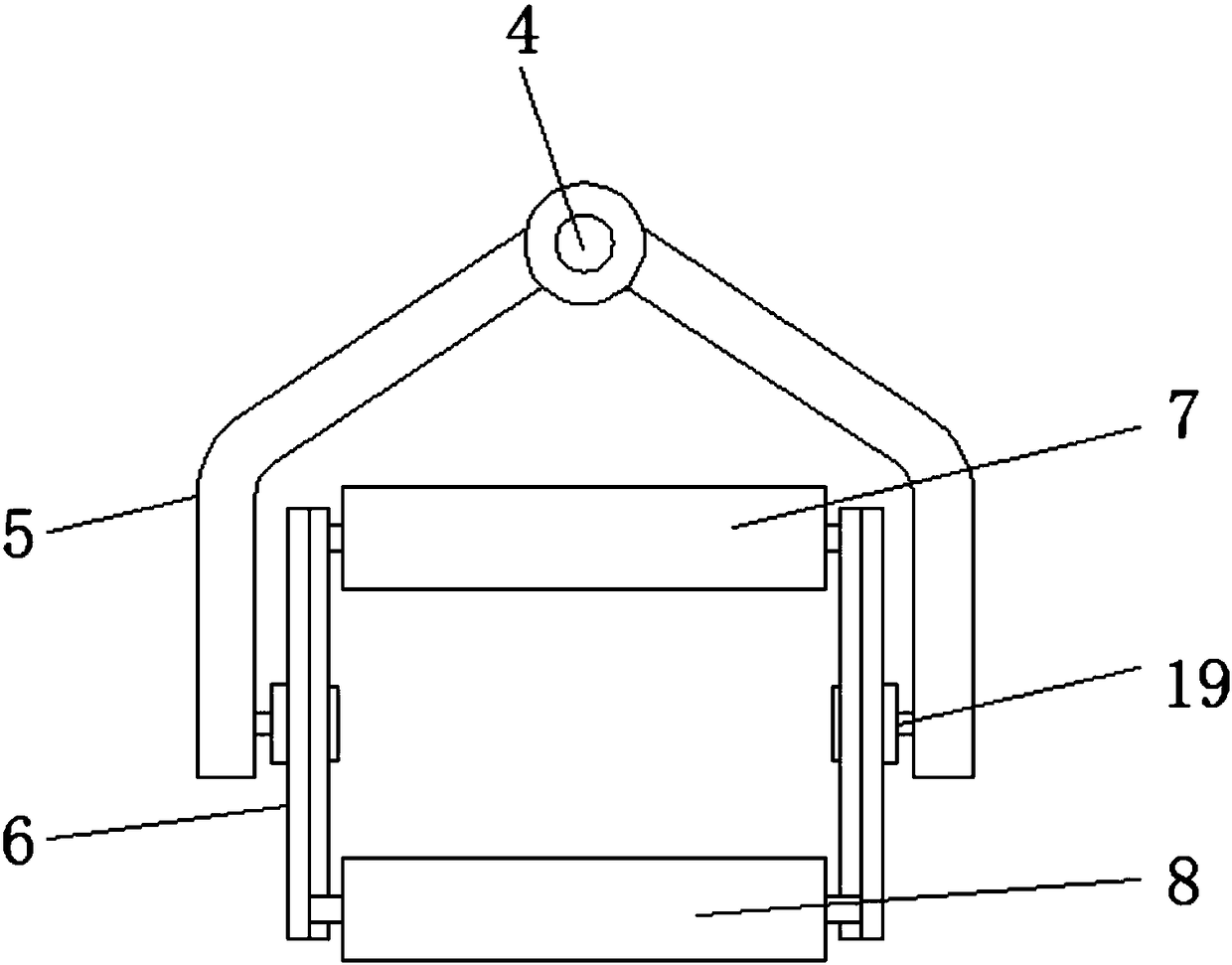

Plate drying device for furniture production

InactiveCN109470044AReduce the clamping partImprove drying efficiencyDrying gas arrangementsDrying machines with progressive movementsAir pumpSprocket

The invention discloses a plate drying device for furniture production, and relates to the field of furniture production. The plate drying device for furniture production comprises a machine body, wherein openings are formed at two ends of the machine body, a plurality of drying pieces are arranged in the machine body, the drying pieces are of hollow structures, a plurality of through holes are formed in each drying piece, one end of a connecting rod is hermetically connected with a hose, one end of the hose is hermetically connected with the output end of an air pump, the input end of the airpump is provided with a heating device, the inner wall of the machine body is vertically provided with a plurality of conveying rollers, the conveying rollers abut against a plate body, two ends of each conveying roller are coaxially provided with chain wheels, and the chain wheels are connected with the output end of a driving device through chains. The plate drying device is used for solving the problems of low drying efficiency and poorer drying effect on the clamped part of the plate, and can effectively reduce the area of the clamped part of the plate, improve the plate drying efficiency, the energy is saved, and the plate body is protected while the consistency of the plate drying effect is guaranteed.

Owner:长兴欧普利斯家具有限公司

Board drying treatment device

InactiveCN106766725ASimple structureEasy to useDrying gas arrangementsDrying machines with local agitationEngineeringPulley

A board drying treatment device comprises a cuboid horizontal box body. The front surface of the box body is at least provided with a box door which can be opened towards one side. An upper partition board is arranged at the top of an inner cavity of the box body. An upper cavity is formed between the upper partition board and the inner upper wall of the box body. Side partition boards are arranged on the two sides of the box body correspondingly, and side cavities are formed between the side partition boards and the side walls of the box body. A drying channel is formed among the upper partition board, the two side partition boards and the bottom wall of the box body. The two outer side walls of the box body are provided with heat transporting devices for transporting heat to the corresponding side cavities. The two side partition boards are provided with heat transporting through holes communicating with the side cavities and the drying channel. The upper partition board is provided with first heat regenerative through holes communicating with the upper cavity and the drying channel. The two side edges of the upper partition board are provided with second heat regenerative through holes communicating with the upper cavity and the side cavities. The drying channel is internally provided with a bracket platform which is provided with a pulley and can get in and out of the drying channel.

Owner:DEQING HUAMENG WOODWORK

Assembled plate airing frame

InactiveCN105972952AEasy to dryDrying machines with local agitationDrying machines with materials at restEngineering

The invention provides an assembled plate airing frame, and relates to the field of airing equipment. The assembled plate airing frame comprises a support frame provided with a moving device at the bottom, wherein the support frame is of a rectangular structure; a plurality of insertion rods are uniformly and oppositely arranged on one pair of sides of the support frame; and the distance between each two adjacent insertion rods is equal. The assembled plate airing frame further comprises a plurality of circular sleeves with hollow interiors, wherein the circular sleeves are detachably connected with the insertion rods. The assembled plate airing frame provided by the invention is simple in structure, reasonable in design, and capable of conveniently and efficiently clamping and airing plates.

Owner:ANHUI DONGPING WOOD GRP

Super-critical drying method for fiber needled felt/silicon-aluminum aerogel composite insulation board

PendingCN105605885AImprove yieldIncrease productivityDrying solid materials with heatHearth type furnacesSupercritical dryingFiber

The invention provides a super-critical drying method for a fiber needled felt / silicon-aluminum aerogel composite insulation board. The super-critical drying method comprises the following steps: performing solvent substitution and hydrophobic modification on fiber needled felt / silicon-aluminum wet gel; placing the wet gel subjected to the hydrophobic modification in a high pressure reactor; pouring a super-critical medium into the reactor; setting a heating temperature for heating; deflating or reflowing after the medium state of the reactor reaches a super-critical state to carry a solvent out of the wet gel till the solvent is recovered fully, wherein the super-critical medium is an acetonitrile, ethanol or carbon dioxide solvent. A product produced with the super-critical drying method provided by the invention has high product yield, high production efficiency and low powder falling rate, and can be amplified industrially; the super-critical drying method can be integrated into a production line; a whole preparation method is easy to operate, is free from strong acid and strong alkali corrosion, has low equipment requirement, and is suitable for industrial production after amplification.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Drying device for furniture production

InactiveCN110411168AAchieve dryingAffect qualityDrying gas arrangementsPretreated surfacesBraced frameFixed frame

The invention discloses a drying device for furniture production. The drying device for the furniture production comprises a base, a supporting frame and a fixed frame; a rotary motor is arranged in the center of an inner cavity of the base; the rotary motor is connected with an air supply cylinder through an auxiliary rotary shaft, and the air supply cylinder is inserted between an inner cavity of a first annular supporting frame and an inner cavity of a second annular supporting frame in the vertical direction in a sliding mode; a plurality of first U-shaped limiting plates are welded on theouter wall of a first annular fixed frame in the radial direction; a plurality of second U-shaped limiting plates are welded on the outer wall of a second annular fixed frame in the radial direction;a plurality of guide wheels are respectively and rotatably arranged on the left side and the right side of inner cavities of each first U-shaped limiting plate and the corresponding second U-shaped limiting plate through rotary shafts; and the fixed frame is connected to the outer walls of the first annular supporting frame and the second annular supporting frame of the supporting frame through the first annular fixed frame and the second annular fixed frame in a sliding mode. According to the drying device for furniture production, furniture production boards can be conveniently dried, the painted boards can also be subjected to alternate hot air drying treatment, and the oil paint bulging caused by overhigh temperature and the influence of the quality of the painted boards are prevented.

Owner:SHENZHEN POLYTECHNIC

Evenly heating wood board dryer device

InactiveCN109084545ATo achieve the purpose of rotating heatingIncrease the heating areaDrying gas arrangementsDrying machines with non-progressive movementsPulp and paper industryThermal treatment

The invention discloses an evenly heating wood board dryer device. The evenly heating wood board dryer device comprises a base, a first upright is fixedly connected onto the right side of the top partof the base, a first motor is fixedly connected with the top part of the first upright, a second upright is fixedly connected onto the left side of the top part of the base, a block body is fixedly connected with the top part of the second upright, a revolving drum is rotatably connected between the block body and the first motor, clamping devices are arranged at the two ends of the revolving drum, a drying device is arranged between the first upright and the second upright at the top part of the base, and rotating shafts are arranged at the middle part of the first upright and at the middlepart of the second upright. The invention relates to the technical field of thermal treatment equipment for wood boards. The evenly heating wood board dryer device fulfills the purpose of rotary heating, the heating area is increased, the drying efficiency is improved, the purpose of automatically dismounting the wood board is fulfilled through the rotating shafts and a tank door, and directly fetching the wood board by hands at the higher temperature is avoided.

Owner:连云港军振木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com