Wood dryer

A drying machine, wood technology, applied in the direction of drying machine, drying, non-progressive drying machine, etc., can solve the problems of low energy utilization rate, uneven air supply, high energy consumption, etc., and achieve the improvement of energy utilization rate , prevent cracking and curling, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

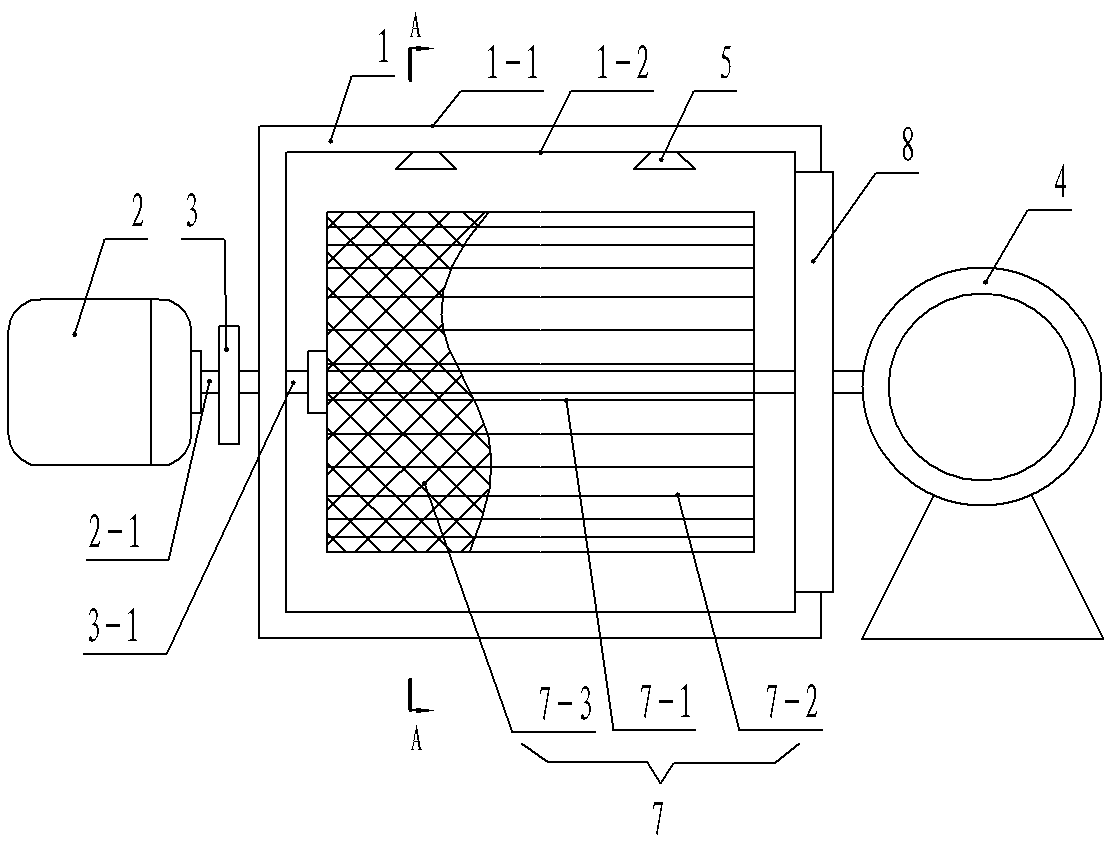

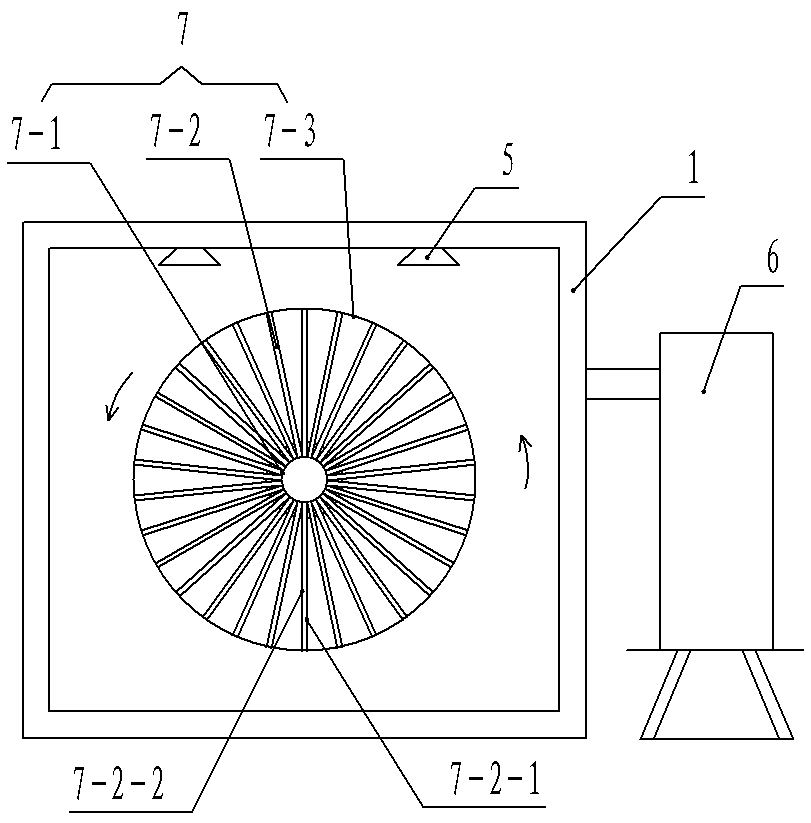

[0013] figure 1 , figure 2 The wood dryer shown includes a drying chamber surrounded by a shell 1, a door 8 for opening or closing the feed port is provided on one side of the shell 1, and an inner shell 1-2 and There is a steam channel between the outer shell 1-1, the inner shell 1-2 and the outer shell 1-1, and the inner shell is provided with a plurality of steam nozzles 5 facing the plate frame; the steam nozzles 5 pass through the steam channel and the outer shell 1-1. The steam outlet of the boiler 6 is connected; the casing 1 is provided with a plate frame driven by a power machine, and the power machine is a motor 2; the output shaft 2-1 of the motor 2 is connected with the input shaft of the reducer 3, and the reducer The output shaft 3-1 of 3 passes through the other side of the housing 1 and is fixedly connected to the side wall of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com