Centrifugal PCB plate automatic drying device

A technology of PCB board and drying device, which is applied in drying, drying machine, heating device and other directions, can solve the problem of high energy consumption of drying equipment, and achieve the effects of saving energy consumption, reducing production cost and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

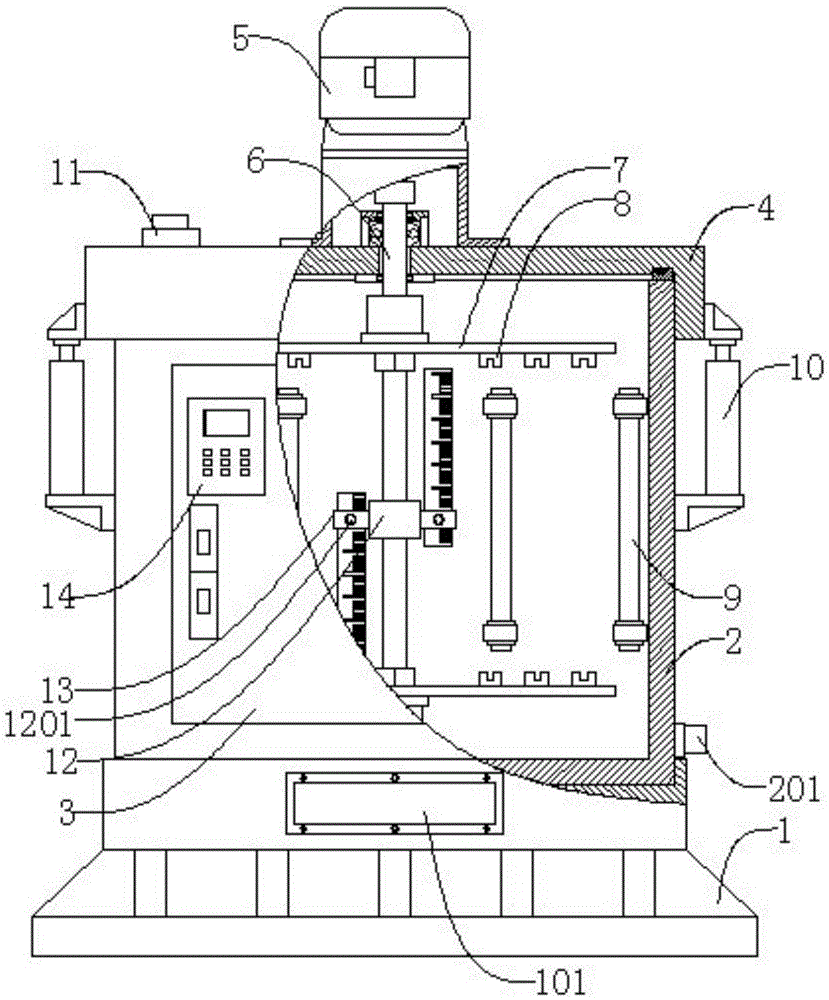

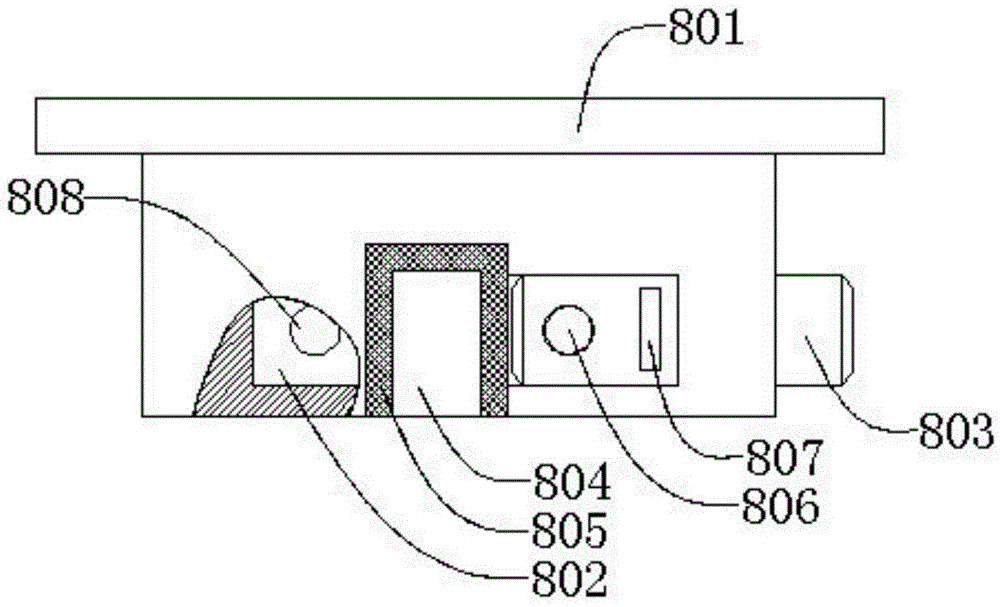

[0031] Such as figure 1 , figure 2 As shown, a centrifugal type PCB board automatic drying device includes a base 1, a drying barrel 2, a front door 3, a cover plate 4, a motor 5, a main shaft 6, a wheel 7 arranged symmetrically along the main shaft 6, and a limit Seat 8, heating pipe 9, cylinder 10, temperature sensor 11, sliding seat 12, scale 13, controller 14, the drying barrel 2 is located on the top of the base 1, and the drying barrel 2 is connected to the base 1 by threads , the front door 3 is located on the outer wall of the drying barrel 2, the front door 3 is hinged to the drying barrel 2, the cover plate 4 is located on the top of the drying barrel 2, and the cover plate 4 is connected to the drying barrel 2 Buckle connected, the motor 5 is located at the top of the cover plate 4, the motor 5 is threadedly connected with the cover plate 4, the main shaft 6 is located at the lower end of the motor 5 and runs through the cover plate 4, the said main shaft 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com