Novel wood floor drying plant

A technology for drying equipment and wood floors, applied in the field of wood floor manufacturing, can solve the problems of single function and poor drying effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

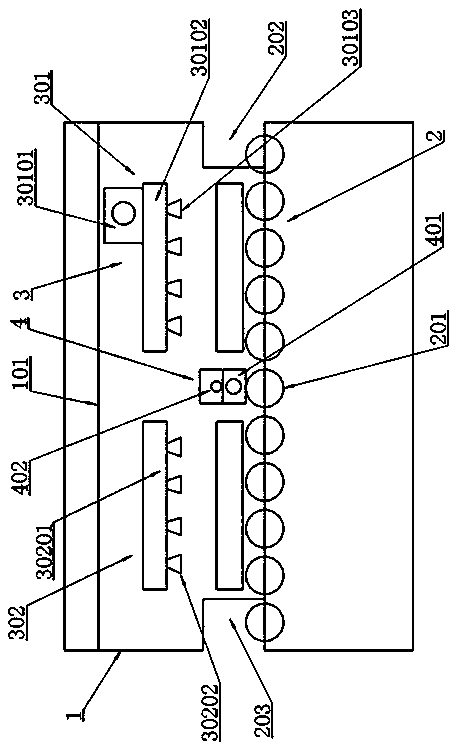

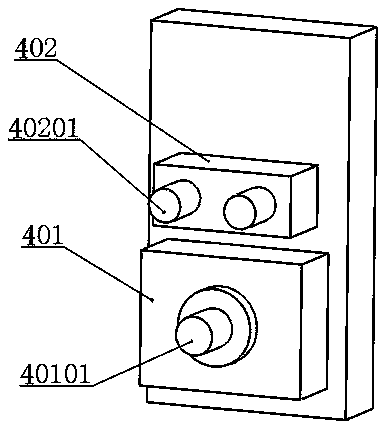

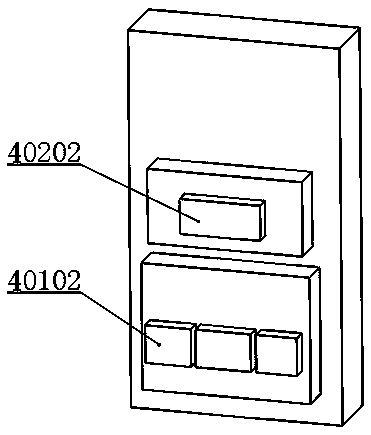

[0021] Example: as attached figure 1 , attached figure 2 and attached image 3 As shown, a new type of wood floor drying equipment includes a frame 1, a conveying unit 2 arranged in the frame 1 and a drying unit 3 above the conveying unit 2, and a drying unit 3 arranged in the conveying unit 2 and the photoelectric detection unit 4 between the drying unit 3, the photoelectric detection unit 4 includes a counting photoelectric part 401 and a flat detection photoelectric part 402, and the drying unit 3 includes a hot air quick drying unit 301 and a normal drying Dry unit 302 . This setting makes the drying equipment integrate the functions of drying, counting and flatness detection, and has the advantages of good drying effect, accurate counting of the floor, and high detection accuracy of floor surface lift.

[0022] The photoelectric detection unit 4 includes a photoelectric transmitting frame and a photoelectric receiving frame, and the photoelectric transmitting frame an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com