Patents

Literature

437results about "Drying machine combinations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

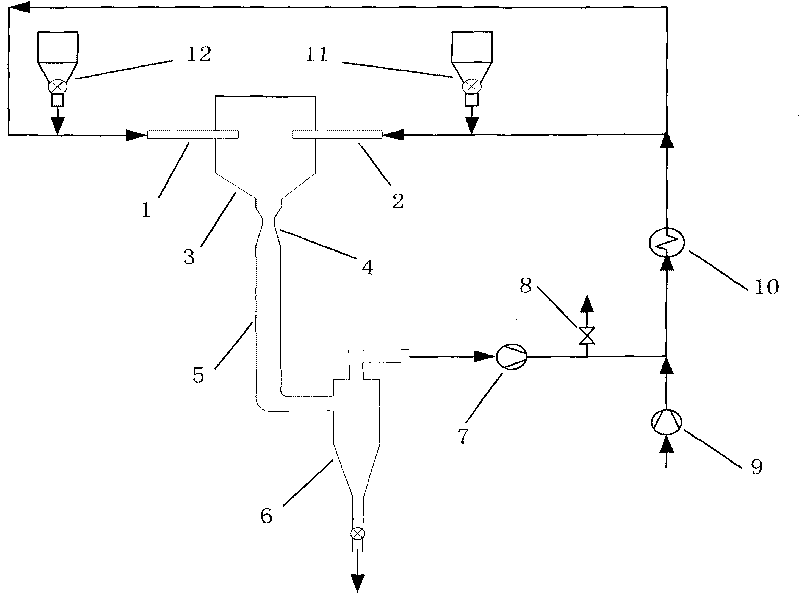

Drying method of high moisture material and dryer set thereof

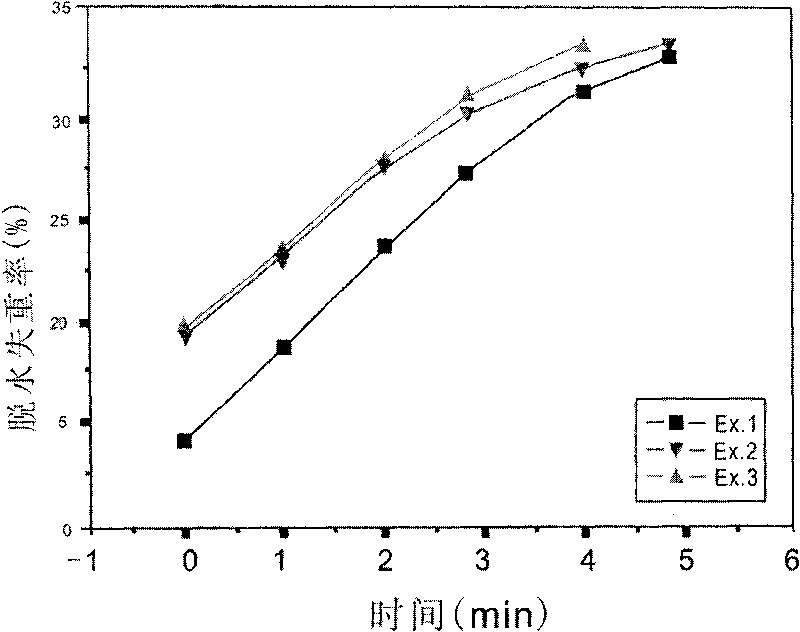

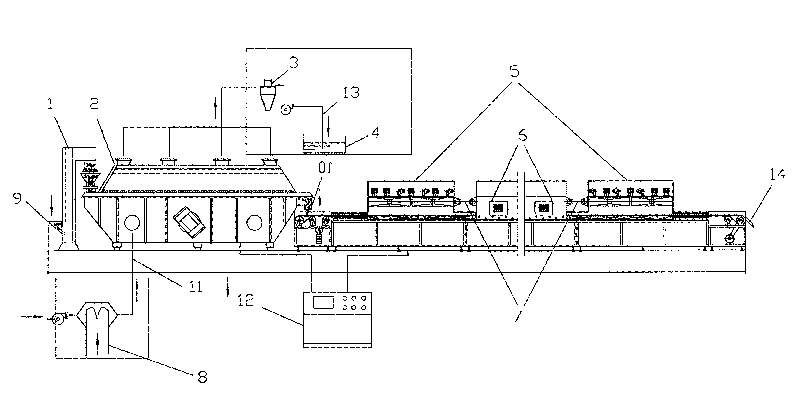

InactiveCN1834561AEven distribution of moisture contentReduce energy consumptionDrying solid materials with heatDrying machine combinationsThermal energyFluidized bed drying

The present invention discloses a method for drying high-wet material. Said method includes the following two steps: firstly, quickly drying high-wet material in rotary pneumatic dryer to make its water content be reduced to 25-35%, then feeding the material into fluidized bed drying machine to continuously dry said material and make its water content be less than 17%. Its drying machine unit includes rotary pneumatic dryer and fluidized bed drying machine.

Owner:王初阳

Brown coal drying and dehydrating device

InactiveCN101738077AAchieve dryingImprove coal qualityDrying solid materials with heatDrying machine combinationsComing outBrown coal

The invention relates to a brown coal drying and dehydrating device and an application method. The hot-air drying and dehydrating device dries and dehydrates brown coal at high speed and low energy consumption by main means of high-power microwaves and infrared. The application method for the device comprises the steps of: crushing raw coal; pretreating the coal through a hot-air drying system to remove external water; and then drying and dehydrating the coal further by microwaves, wherein an infrared scanning system is adopted in the drying and dehydrating process in order to prevent the brown coal from backwater. By applying the device, the water in the brown coal can be removed by over 98 percent in short time. The brown coal drying and dehydrating device has the advantages of simpleness and easy operation of process flow, quick dehydration and low energy consumption. The device and the method have no negative effect on the environment, the water coming out through drying can also be recycled, and the device and the method are economic and effective.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH +1

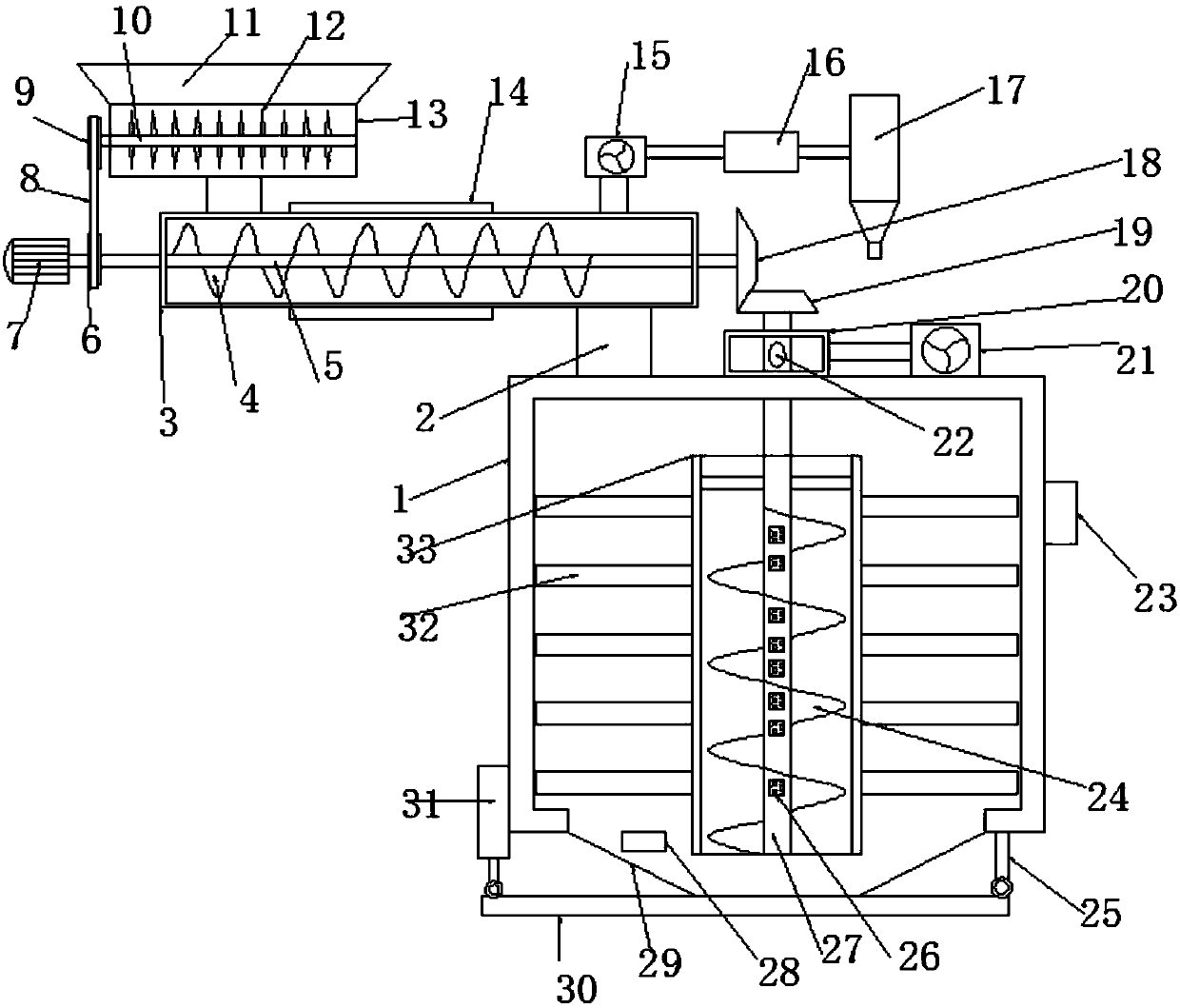

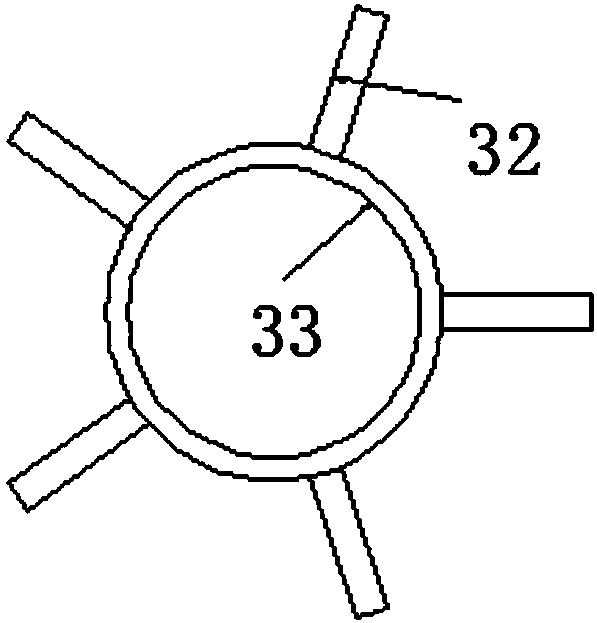

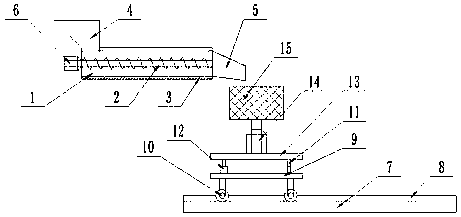

Internal circulation type traditional Chinese medicine drying equipment

InactiveCN107940974AReduce volumeFully dryDrying machine combinationsDrying gas arrangementsSpiral bladeBiochemical engineering

The invention discloses internal circulation type traditional Chinese medicine drying equipment. The equipment comprises a processing box, a connecting channel and a feeding cylinder; the connecting channel is formed in the left upper end of the processing box, and the upper end of the connecting channel is connected with and fixed to the feeding cylinder, a pushing shaft is arranged in the feeding cylinder in a penetrating mode, and a spiral blade is arranged on the pushing shaft; a heating block sleeves the outer side of the feeding cylinder and is used for heating materials in the feeding cylinder, the two ends of the pushing shaft penetrate through the feeding cylinder, the left end of the pushing shaft is fixedly connected with the output end of a driving motor, and a driving gear isarranged at the right end of the pushing shaft; and a driving belt wheel is arranged on the part, close to the driving motor, of the pushing shaft, a feeding pipe is arranged on the upper left side ofthe feeding cylinder, and a crushing box is arranged at the upper end of the feeding pipe. According to the equipment, the structure is simple and reasonable; the materials are crushed in advance sothat the size of the materials can be reduced, and later drying can be facilitated; and meanwhile, circulation drying of the materials in the processing box can be realized through the equipment so that the materials can be fully dried, and the equipment is high in practicability.

Owner:马良彬

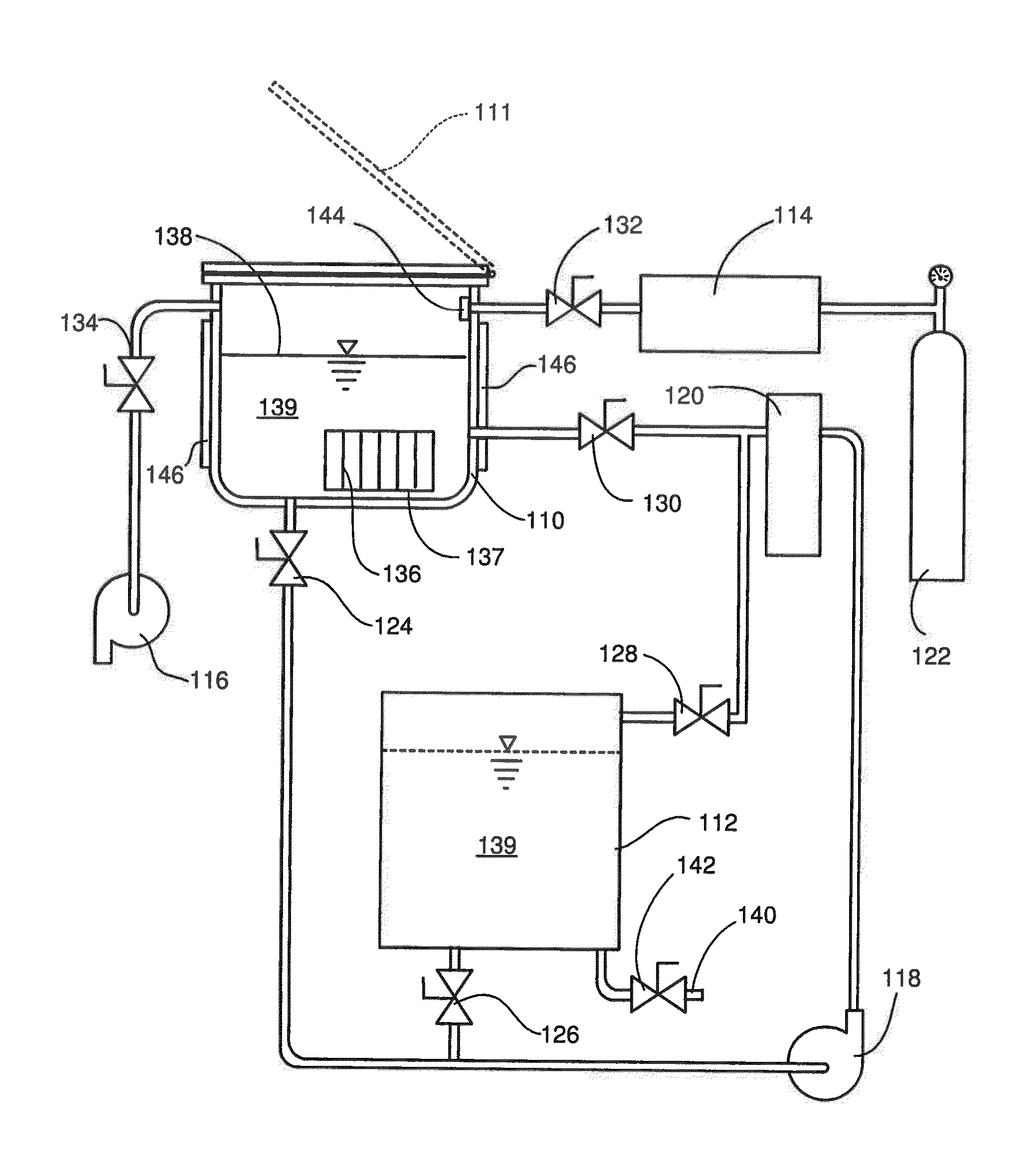

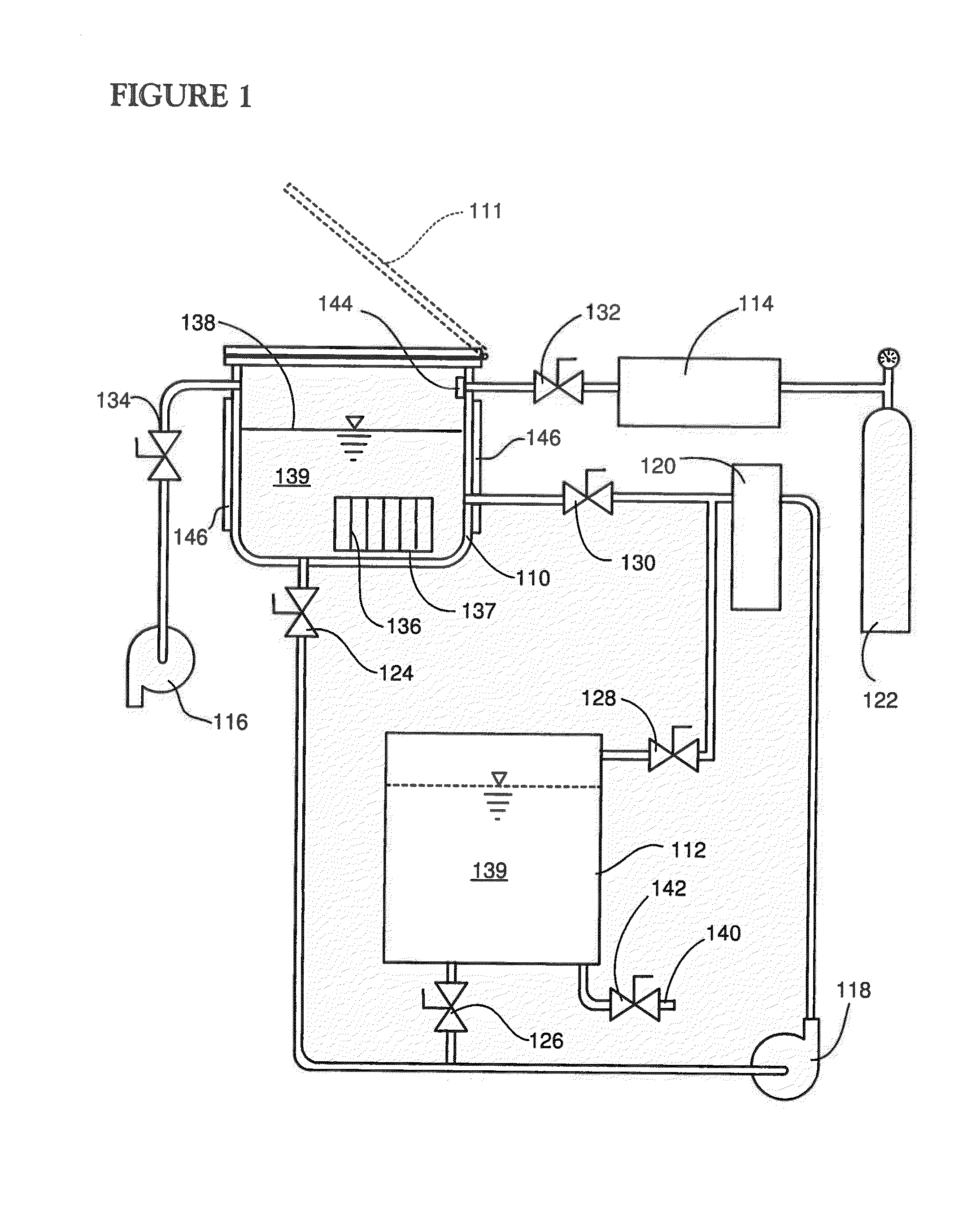

Optimization Of Vacuum Systems And Methods For Drying Drill Cuttings

InactiveUS20130074360A1Minimizing damageIncrease volumeSievingLiquid degasificationProcess engineeringDrill cuttings

Systems and methods for separating fluids from drill cuttings. Specifically, the invention relates to shakers that incorporate a vacuum system and methods of operating such systems to effect a high degree of fluid separation. The system and methods are effective across a variety of screen sizes, vacuum flows and vacuum designs.

Owner:FP MARANGONI INC

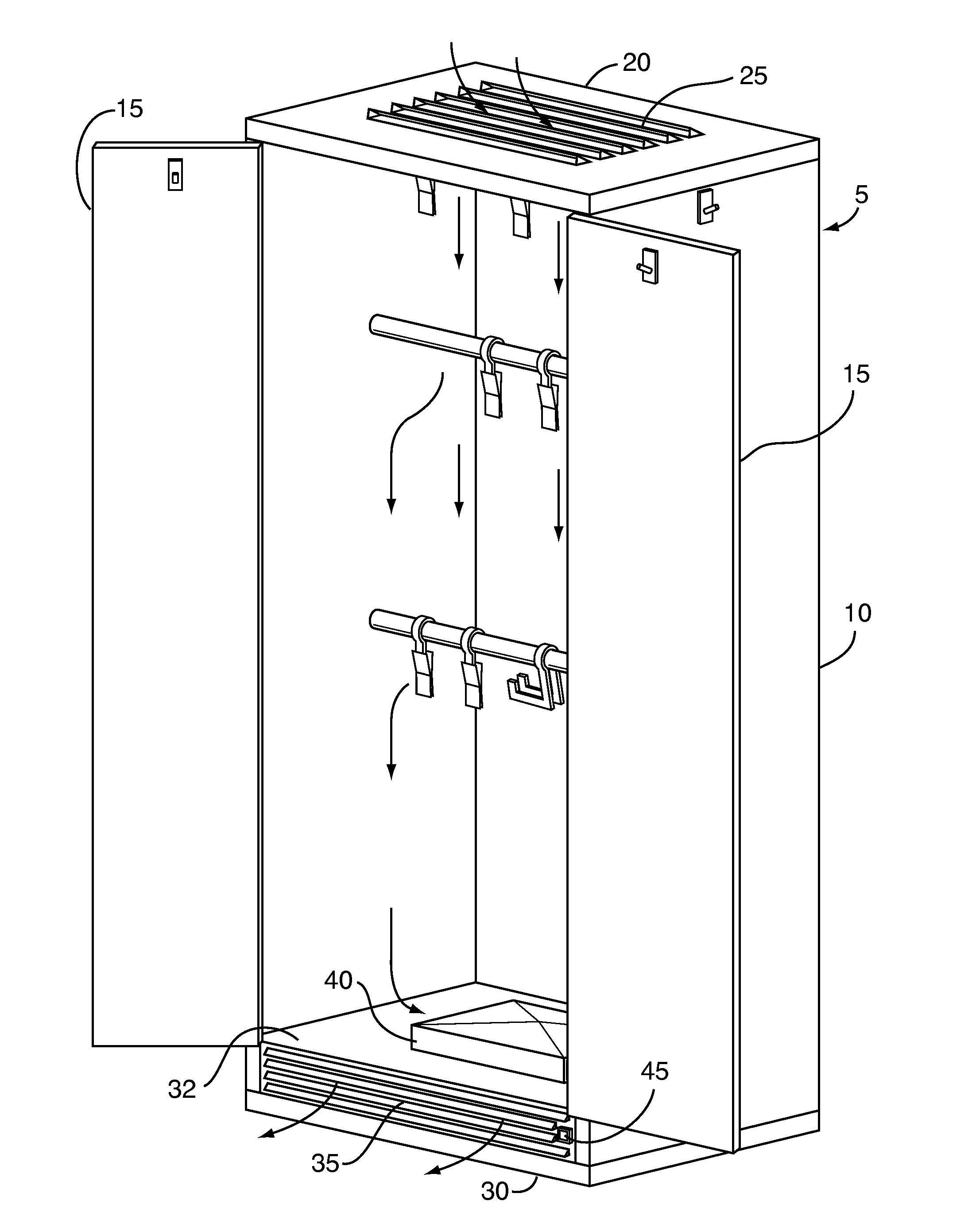

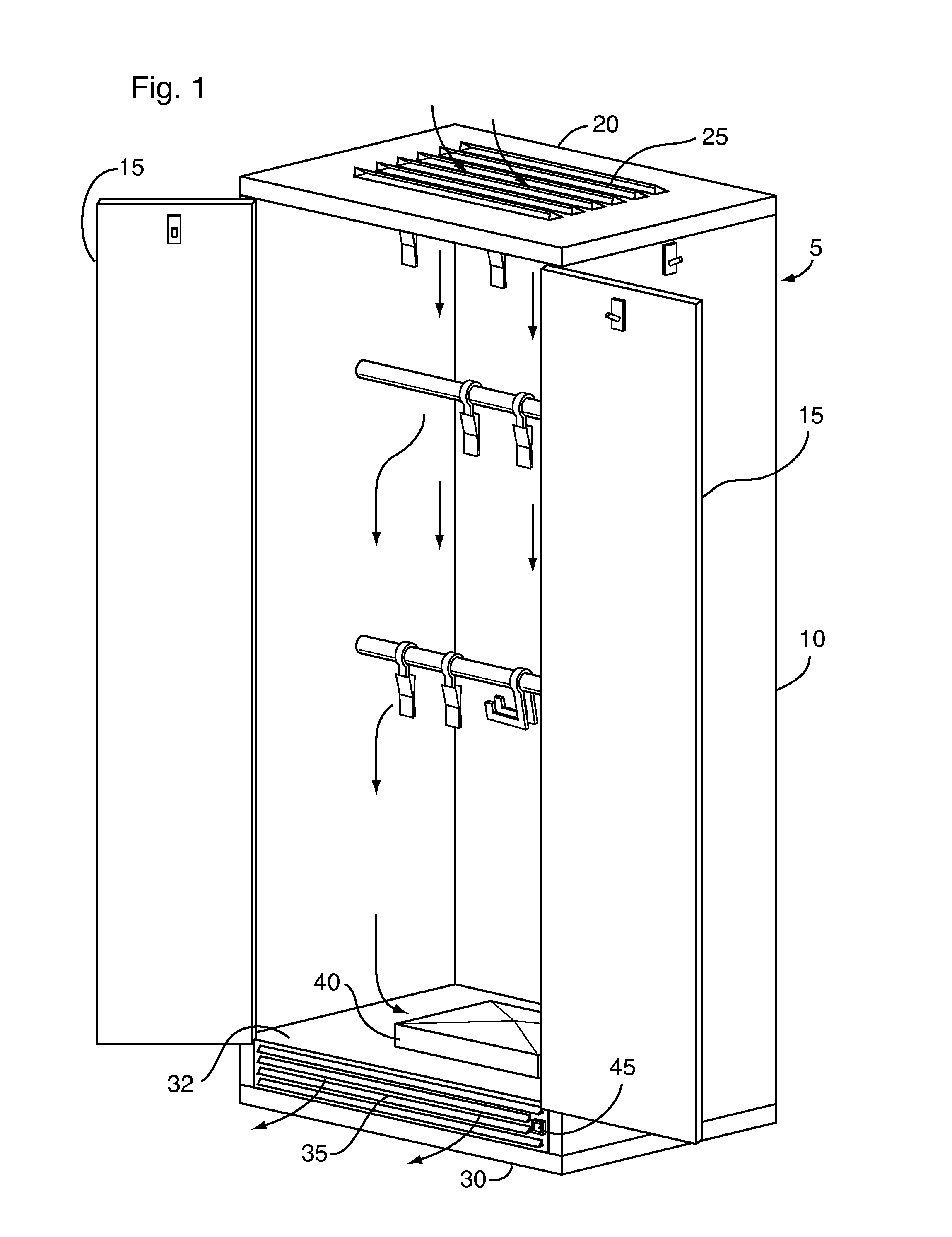

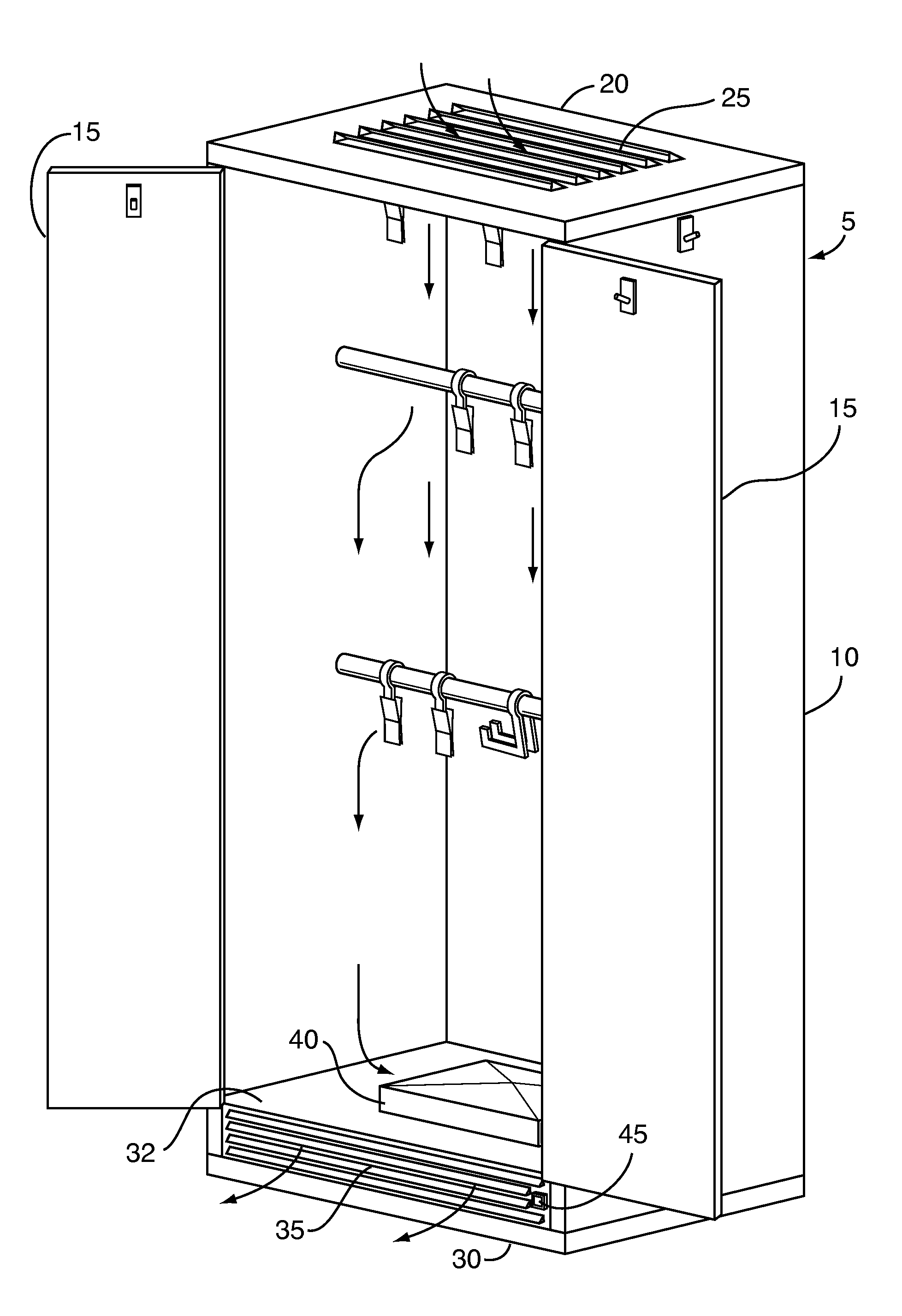

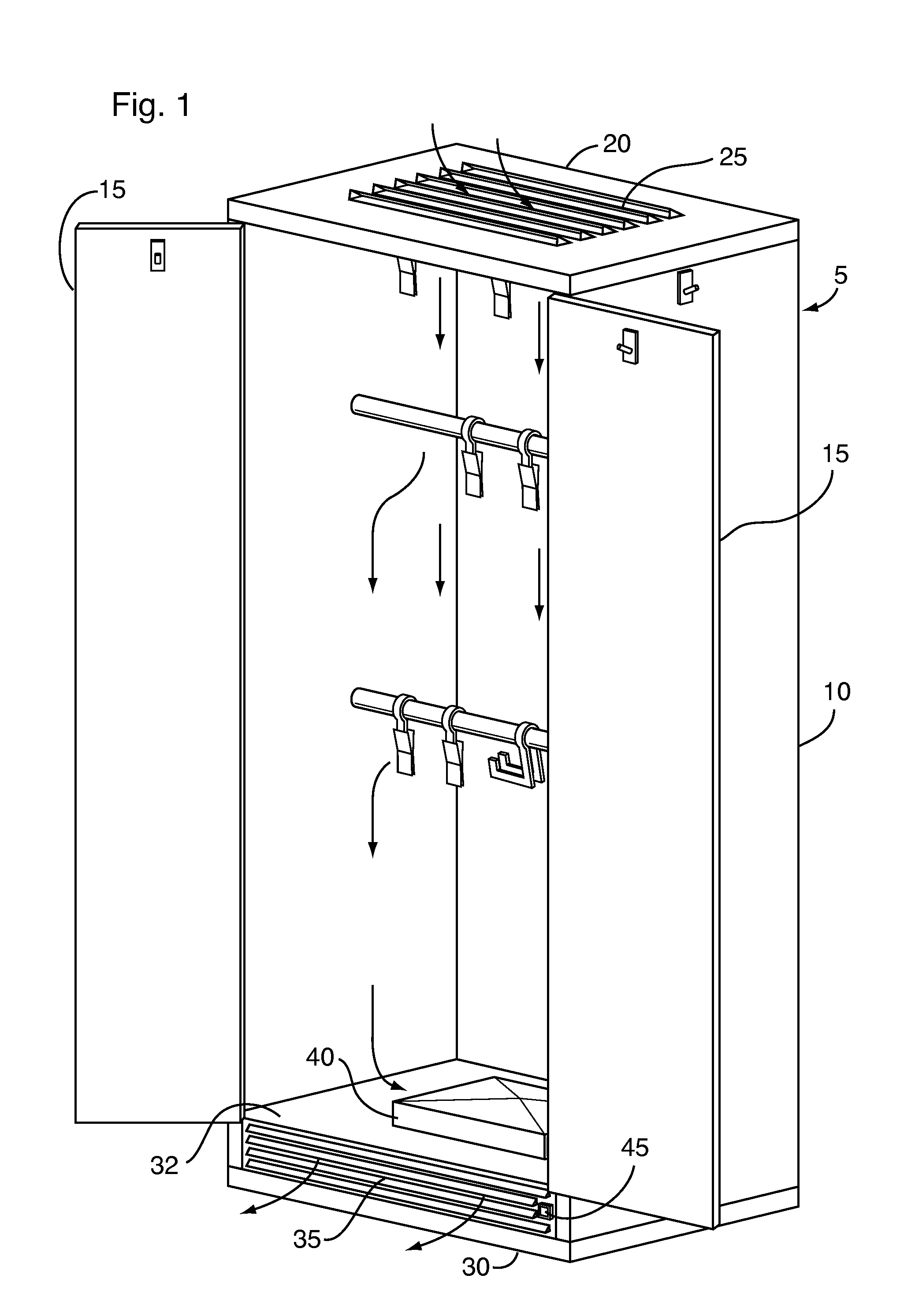

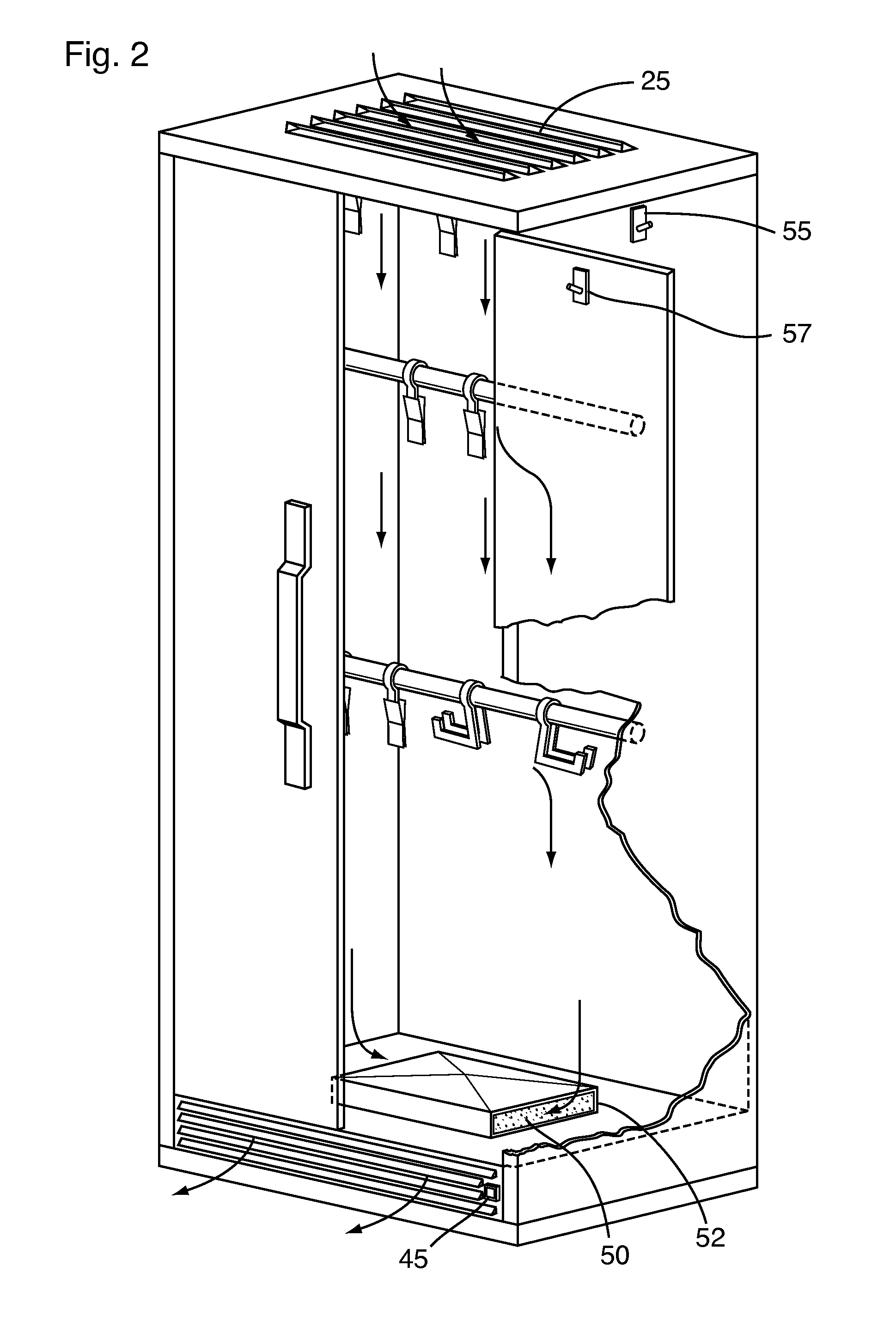

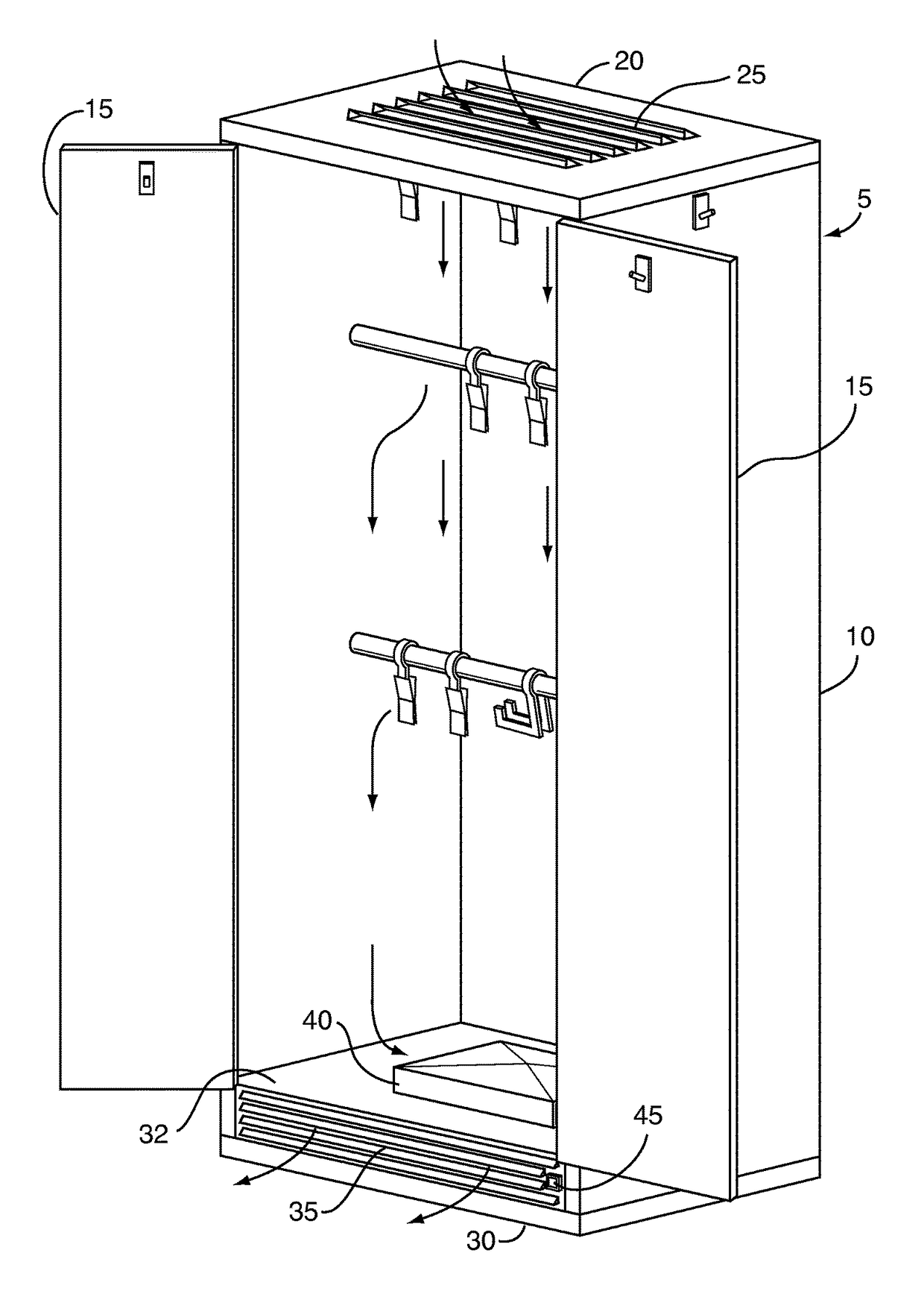

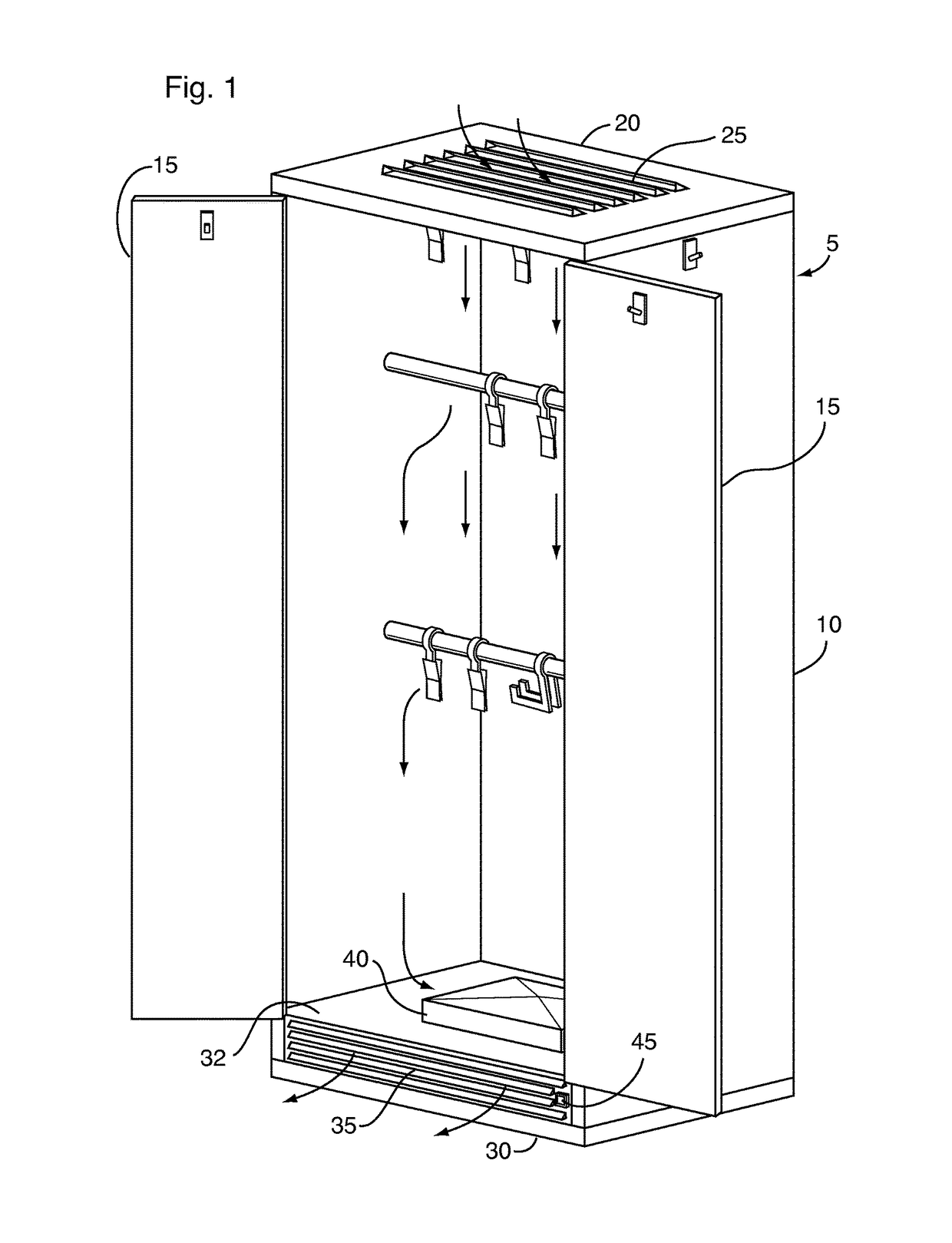

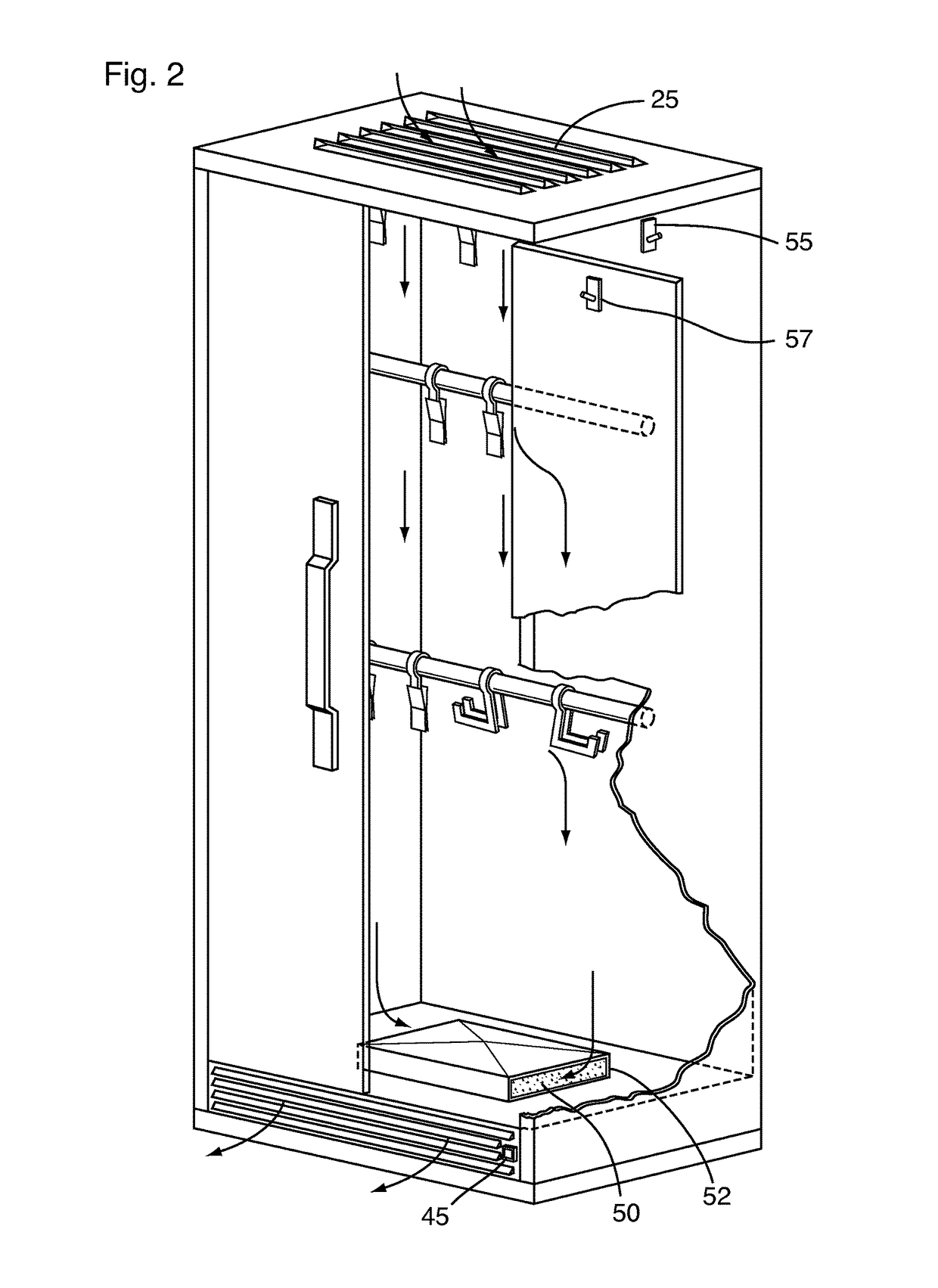

Wardrobe for drying clothing and sports equipment

The present invention relates to a wardrobe for storage and drying of sports equipment and / or clothes. This wardrobe has an opening, an air circulation fan and an exhaust vent at the bottom, an intake vent at the top, and suspending means for suspending articles such as sports equipment or clothes. Turning on the fan activates active drying of the articles. Additionally, the present invention relates to a method of storing and drying articles comprising suspending the articles in a wardrobe, the interior of said wardrobe comprising an air circulation fan and an exhaust vent at the bottom; an intake vent at the top; and suspending means for suspending the articles. The articles that are difficult or take more time to dry can be placed closest to the fan. The wardrobe can have a rigid or flexible interior cavity and the flexible wardrobe can be capable of hanging on a rod and additionally can be packed in a bag with or without a kit with support poles and feet.

Owner:ADAPTIVE STORAGE SOLUTIONS

Superheat steam drying device

InactiveCN102914134AEasy accessEnsure normal dischargeDrying using combination processesDrying machine combinationsEngineeringProcess engineering

The invention provides a superheat steam drying device which comprises a steam drying mechanism, a vacuum drying mechanism, a first discharging valve, a second discharging valve and a steam heating part. A superheat steam drying and vacuum drying combined structure is adopted by the superheat steam drying device, namely, a full-closed belt pressing drying system is adopted; the structure is simple; the steam heat energy for drying and evaporating materials is fully recycled; a waste heat recovery device is simple or the waste heat is directly sent to the other heating device; the energy consumption is greatly reduced; the whole set of device is full-automatically controlled; the device can continuously produce; the operating flexibility is high; and the handling capacity is high.

Owner:曾应祥

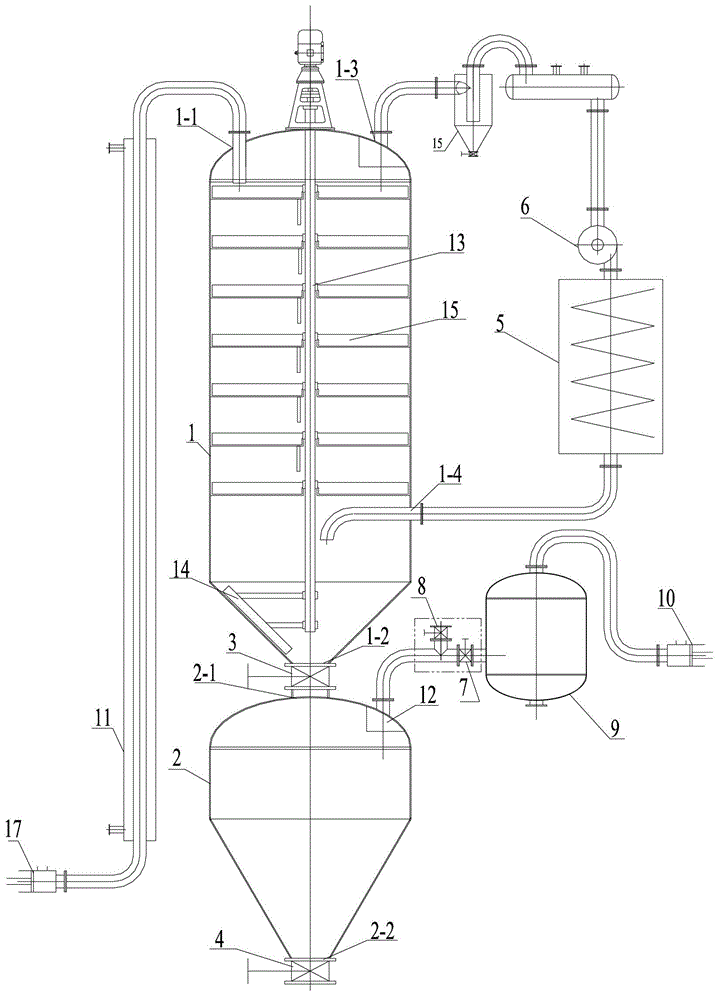

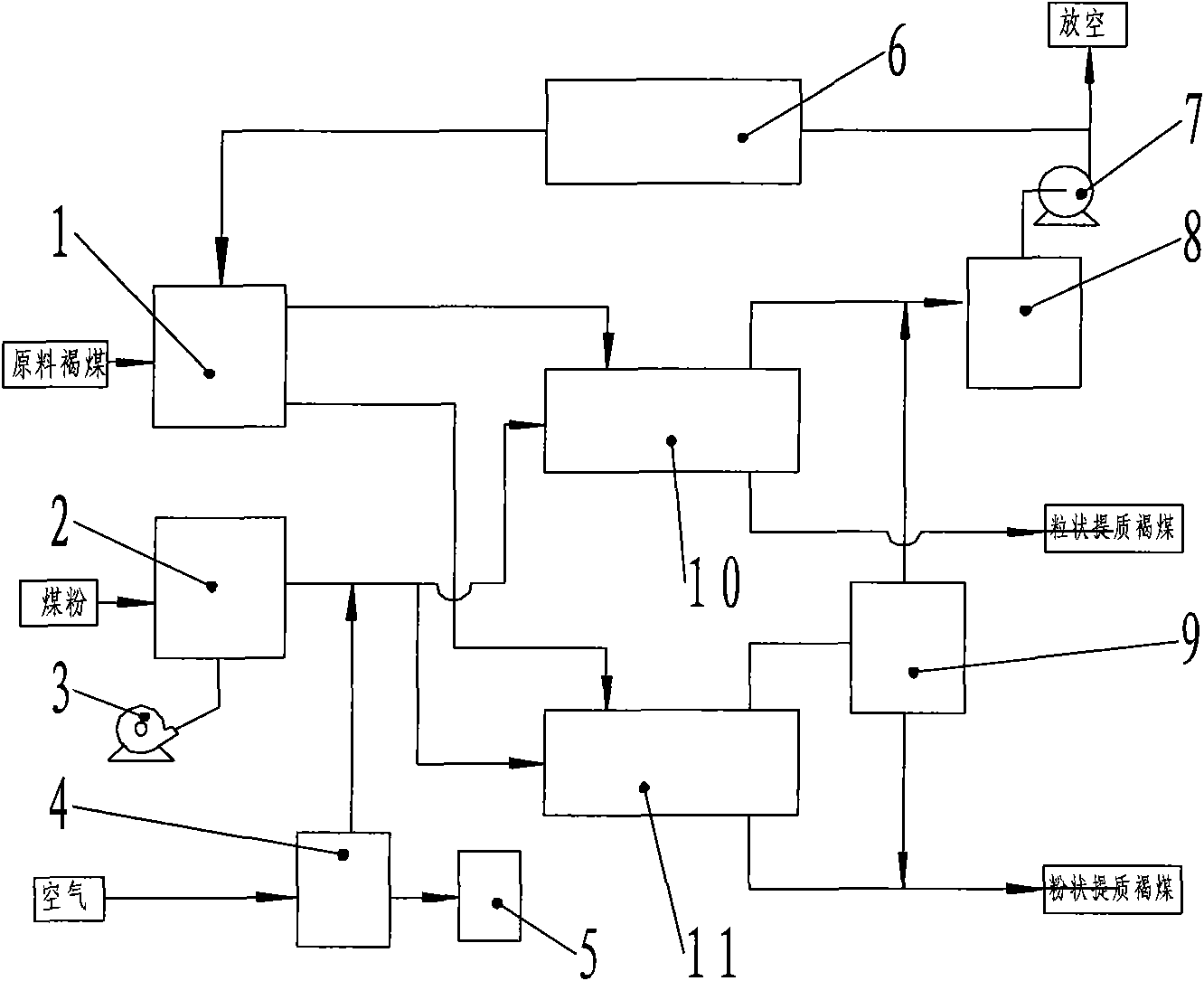

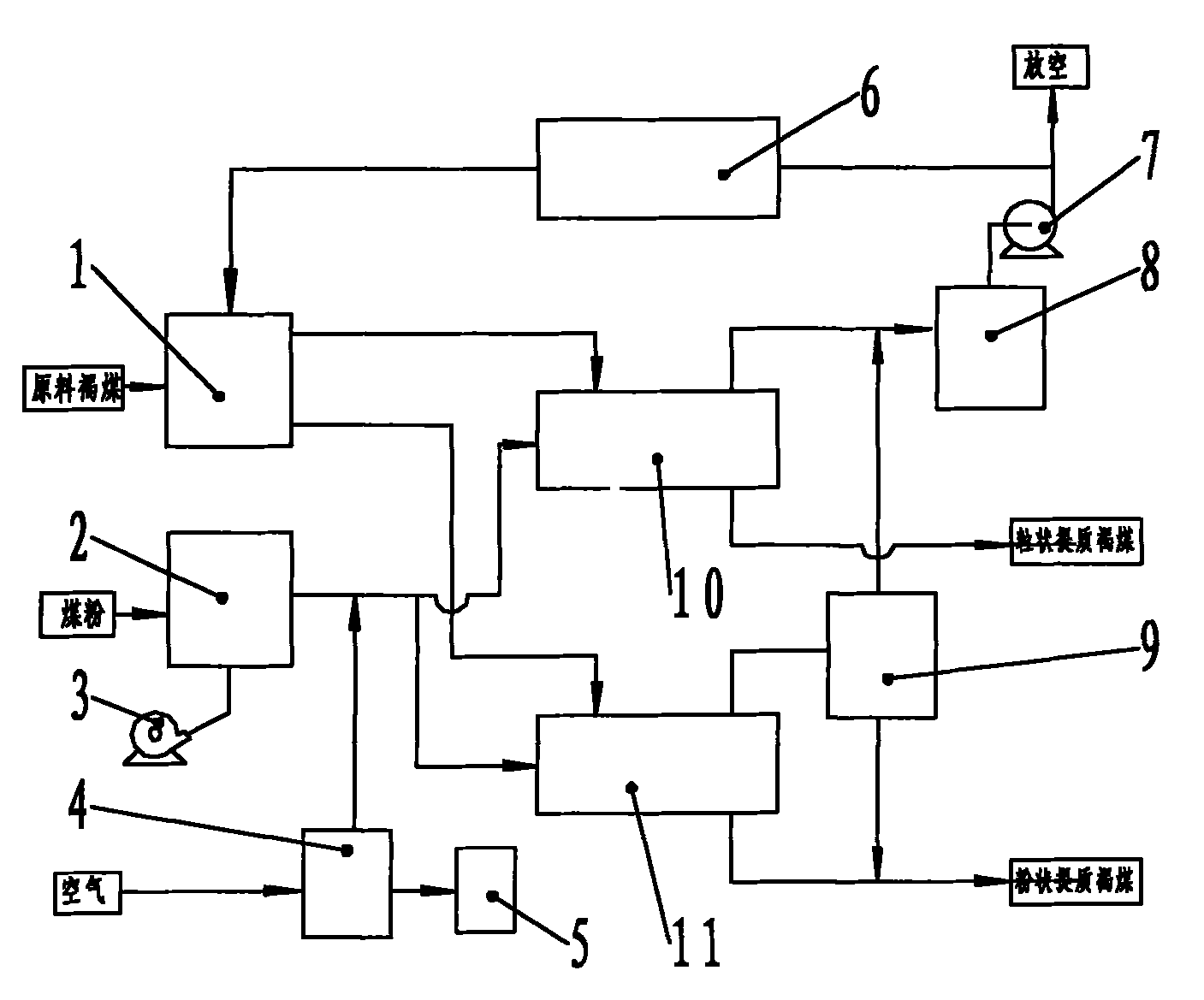

Method and device for drying and quality enhancement of lignite

InactiveCN101776370AImprove qualityIncrease useDrying solid materials with heatDrying machine combinationsLow oxygenCoal

The invention provides a method and a device for the drying and the quality enhancement of lignite. The device comprises a drying / sieving device, a preheating and drying / sieving device, a hot blast heater, a drying drum, a vibration fluidized bed, a cyclone separator, a defogger and a dust remover. The hot blast heater is respectively connected to the drying drum and the vibration fluidized bed, and an outlet of the preheating and drying / sieving device is respectively connected with the drying drum and the vibration fluidized bed. The preheating and drying / sieving device divides the lignite into two stages of big particle diameter and small particle diameter, high-temperature flue gas generated by the hot blast heater is used as a heating medium, the temperature of the flue gas is regulated by the residual low-oxygen gas after oxygen gas is separated by using an air separation system, the drying drum and the vibration fluidized bed are used for producing the quality-enhanced lignite with the big particle diameter and the small particle diameter, different production requirements are met, and part of exhausted tail gas is circularly used for preheating the raw materials of the lignite after being defogged. The invention respectively carries out drying and quality enhancement on the lignite according to the sizes of the particle diameters by grading equipment, eliminates the problem of uneven drying caused by different particle diameters, realizes the effective quality enhancement and the comprehensive utilization of coal resources, and is used for the large-scale process of drying and quality enhancement of the lignite.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Medical waste disposal device

InactiveCN107913896AMaximize recyclingHigh degree of killingDrying solid materials with heatSolid waste disposalMedical wasteMedical treatment

The invention relates to a medical waste disposal device. The medical waste disposal device comprises a crushing chamber, a soaking chamber, a water removal cavity, a first drying chamber, a first compression chamber, a first storage box, a second drying chamber, a second compression chamber, a second storage box and a disinfectant fluid collecting chamber. Due to the fact that medical waste contains a number of harmful microorganisms, the soaking chamber is arranged to conduct disinfection treatment on the medical waste. Meanwhile, the soaking chamber is arranged to enable the medical waste to be classified, two sets of drying components and two sets of compression components are arranged to dispose and store different kinds of medical waste, and therefore refined classification disposalof the medical waste is achieved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

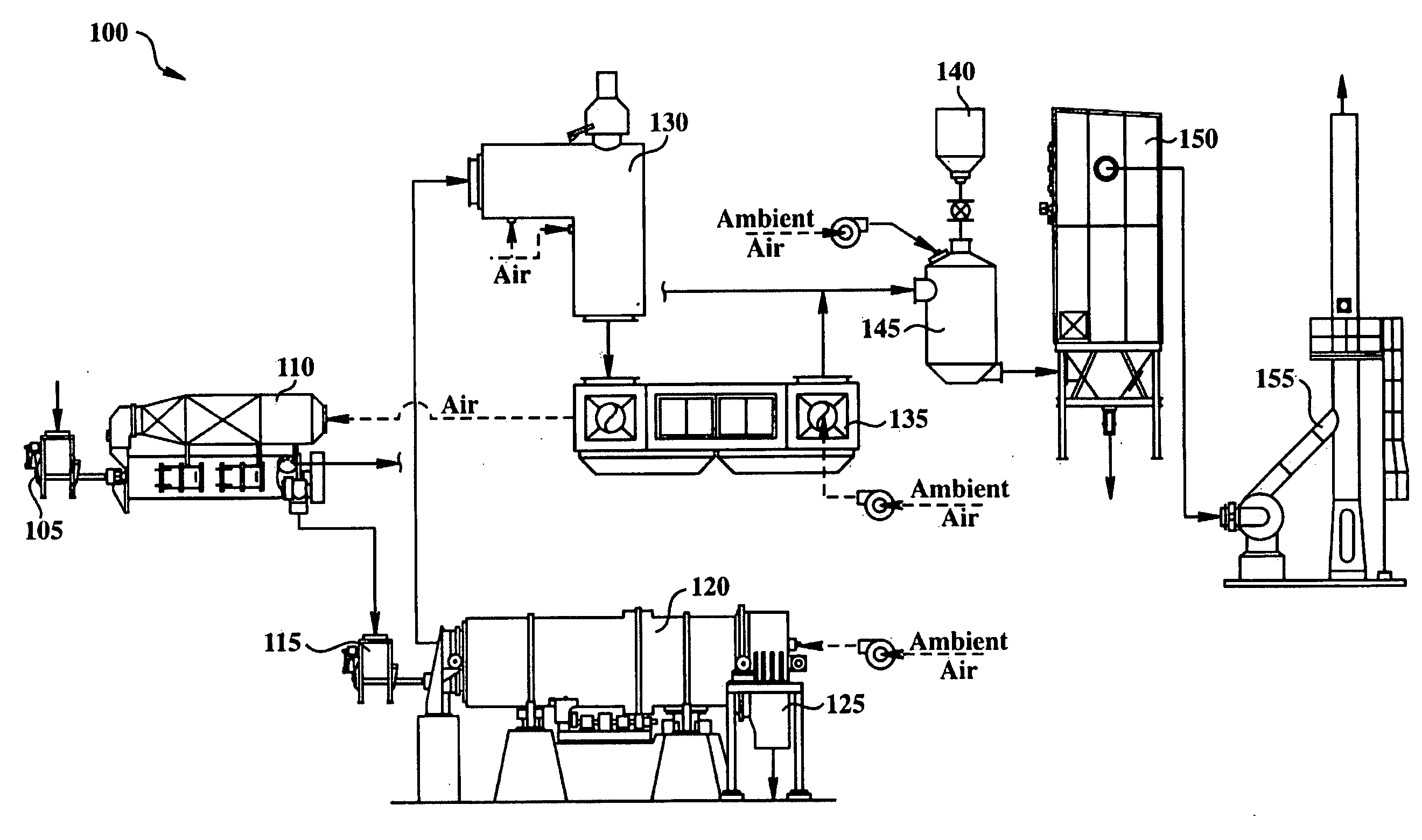

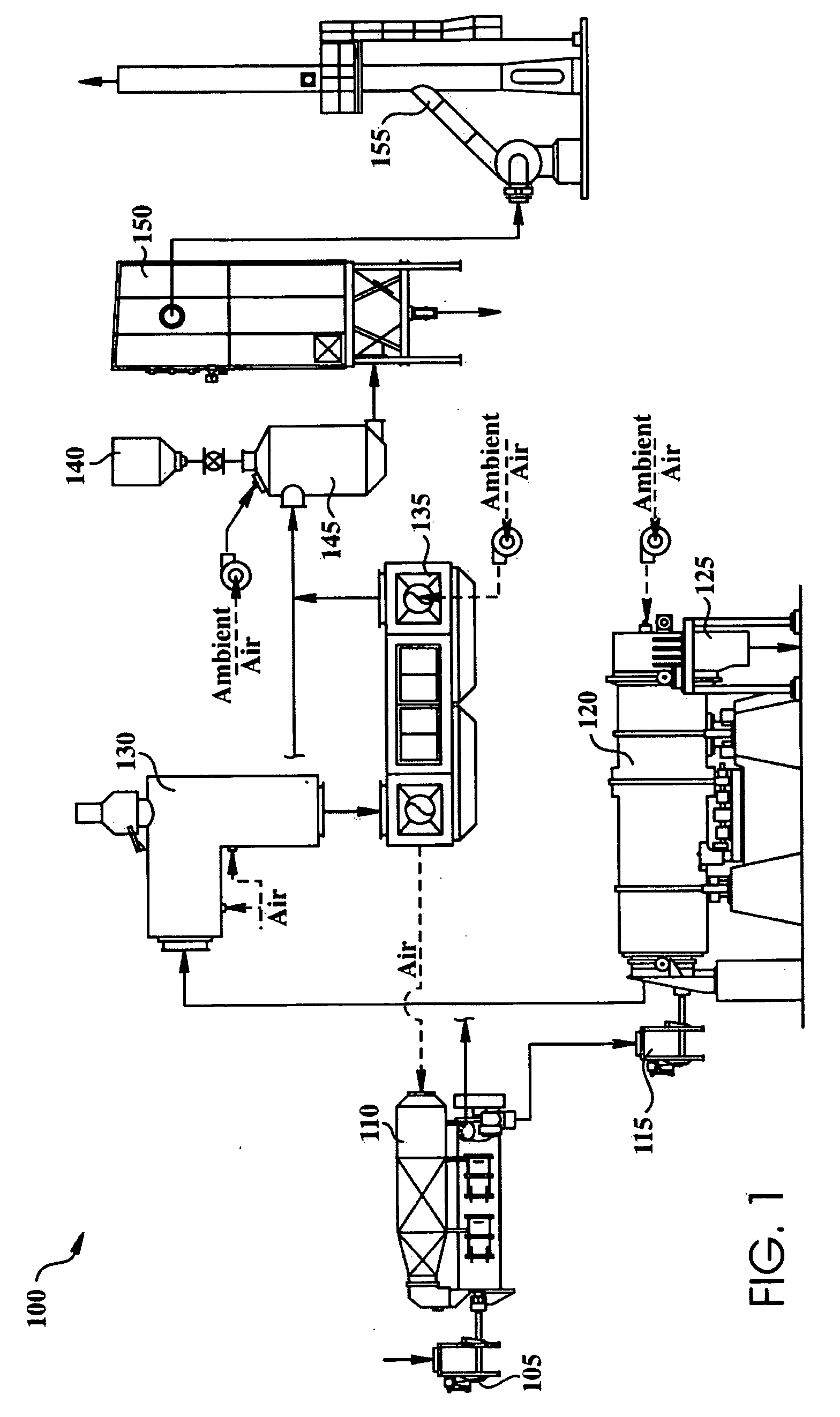

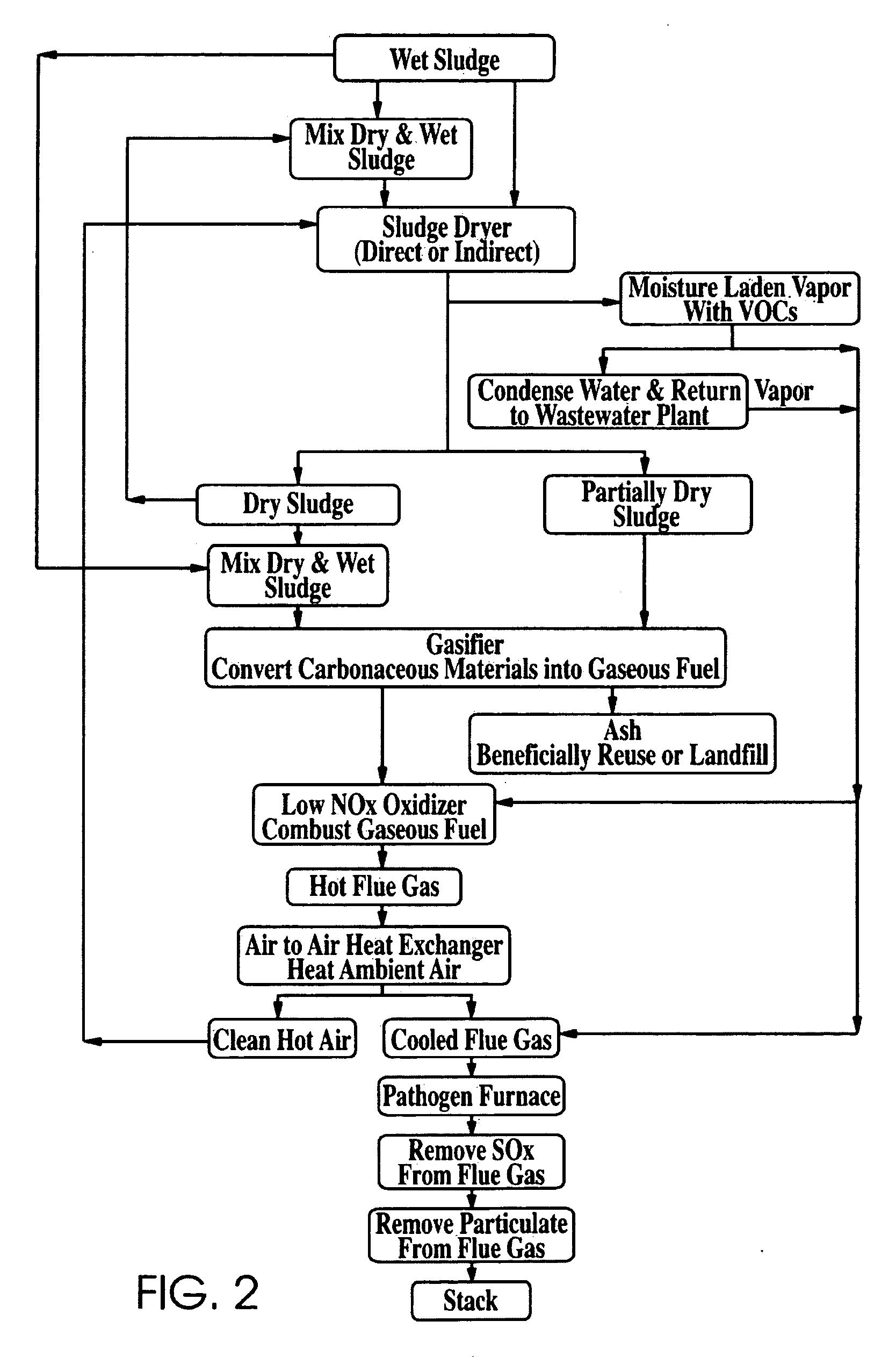

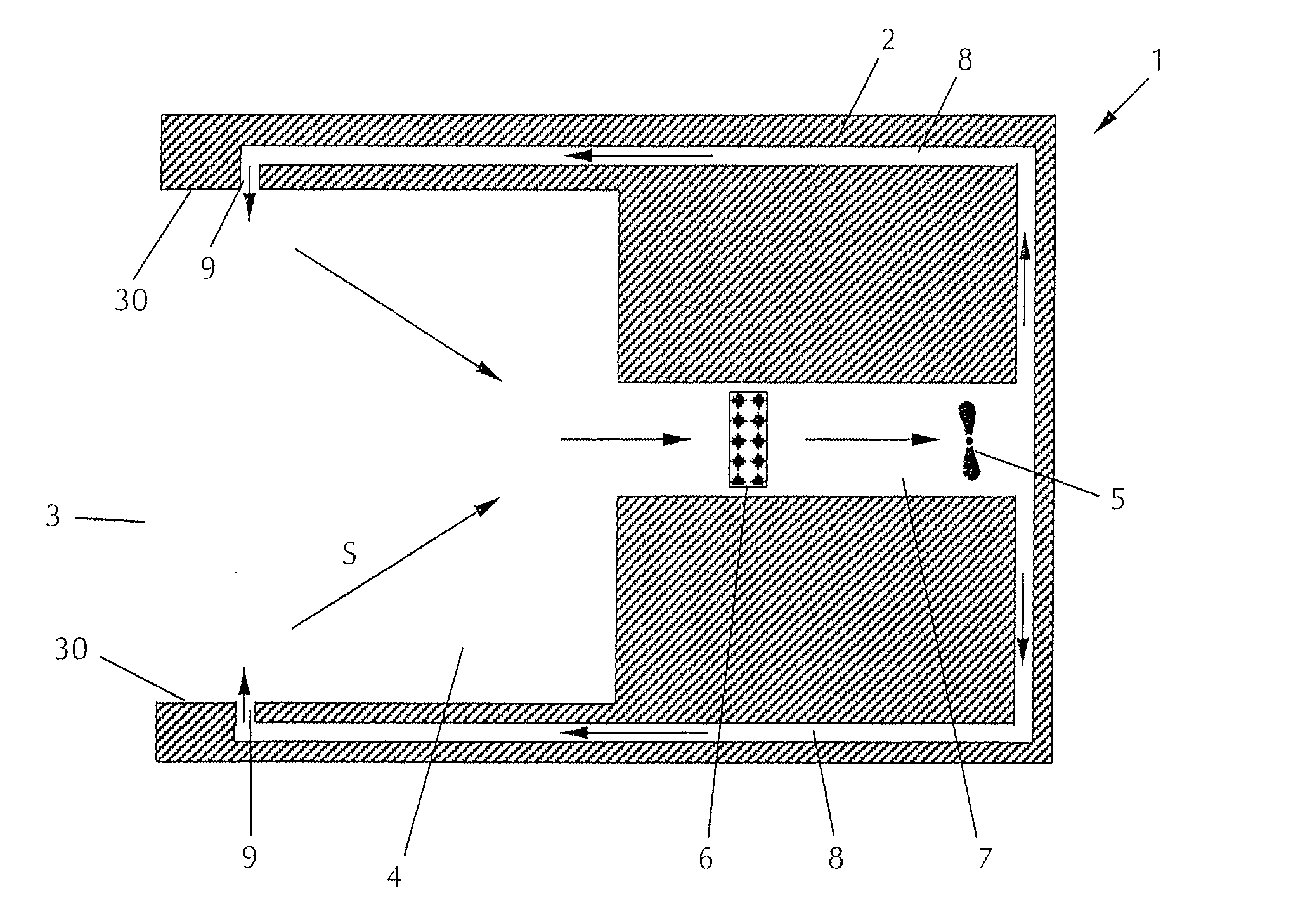

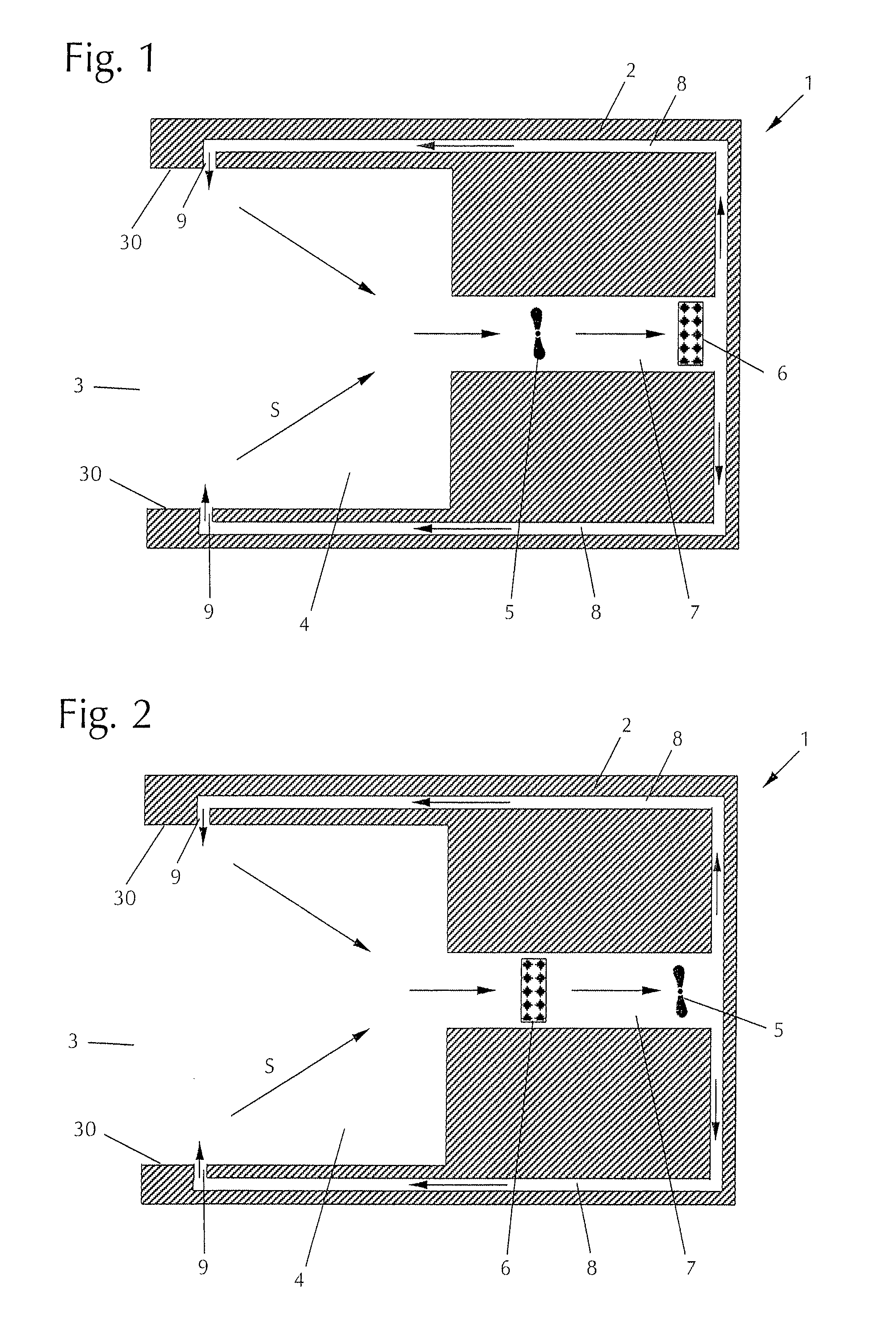

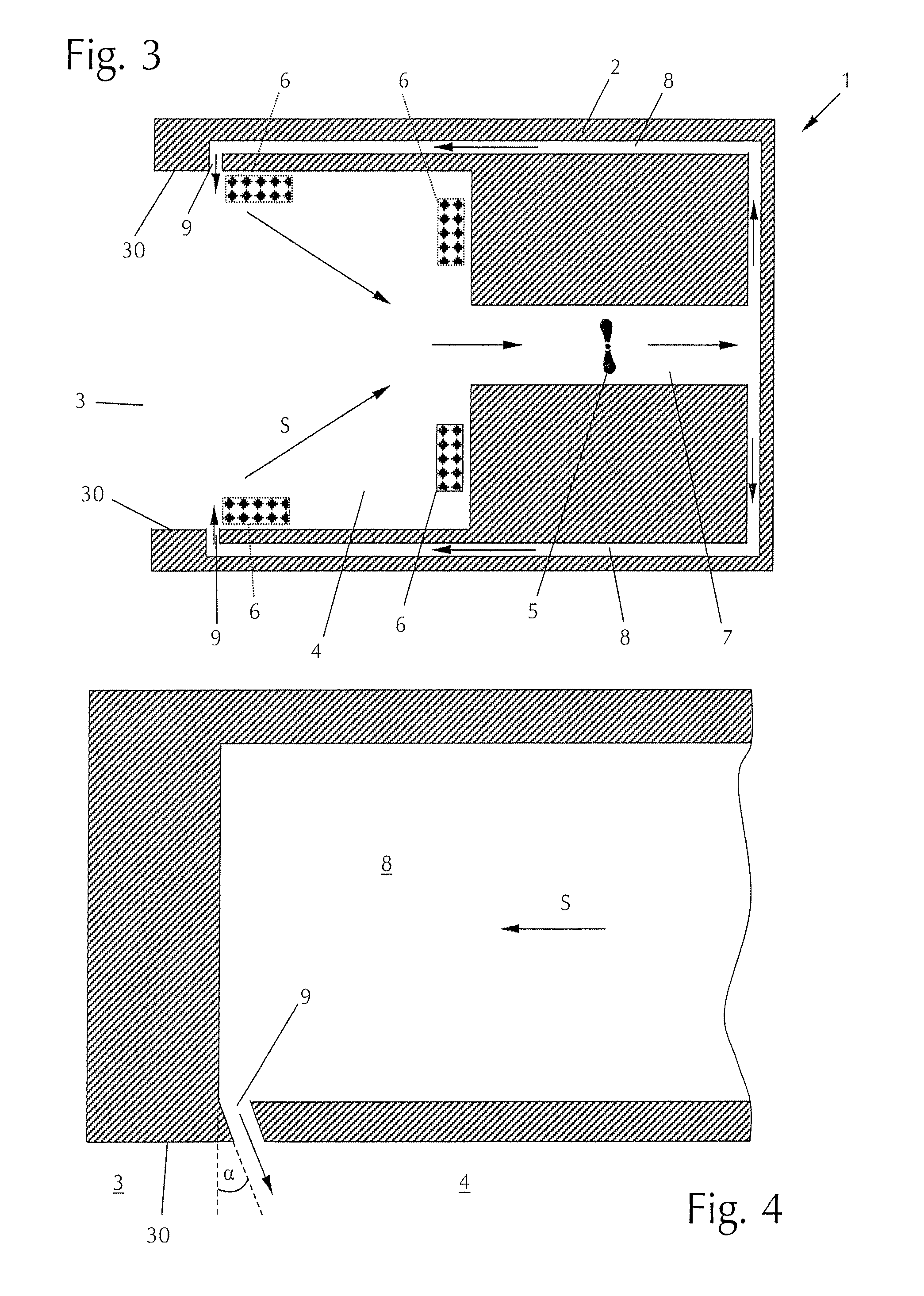

Systems and Methods for Processing Municipal Wastewater Treatment Sewage Sludge

InactiveUS20090249641A1Low cost of treatmentSimple methodDrying using combination processesDrying machine combinationsWastewaterMunicipal sewage

The present invention relates generally to systems and methods for drying and gasifying substances using the calorific value contained in the substances, and it more specifically relates to apparatus and methods for processing wet, pasty, sticky substances, such as municipal wastewater treatment sewage sludge, into a workable, powdered product.

Owner:JOHNSON BRUCE +1

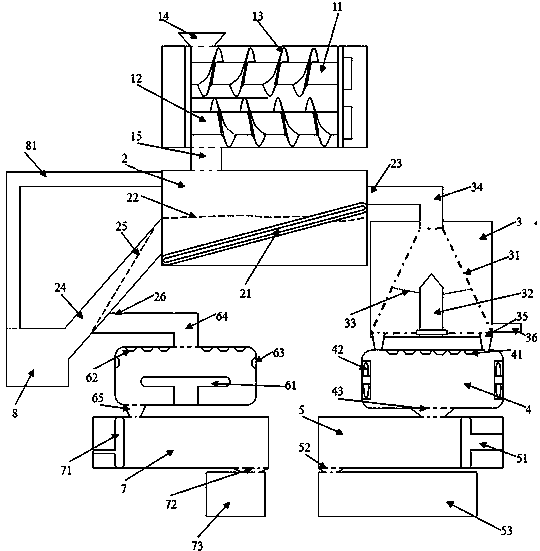

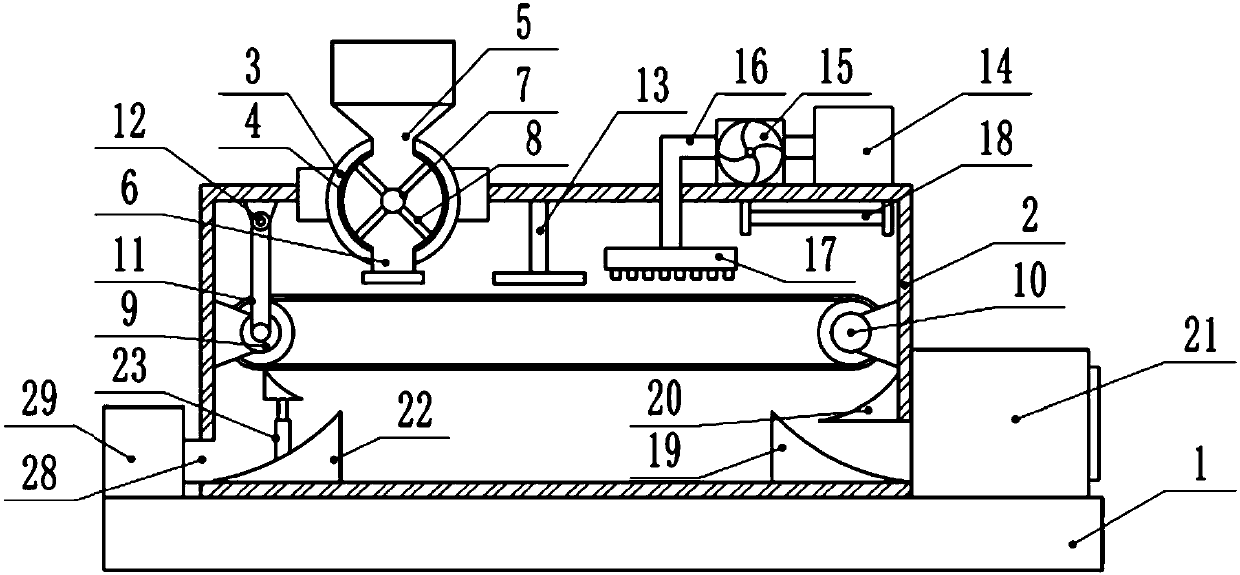

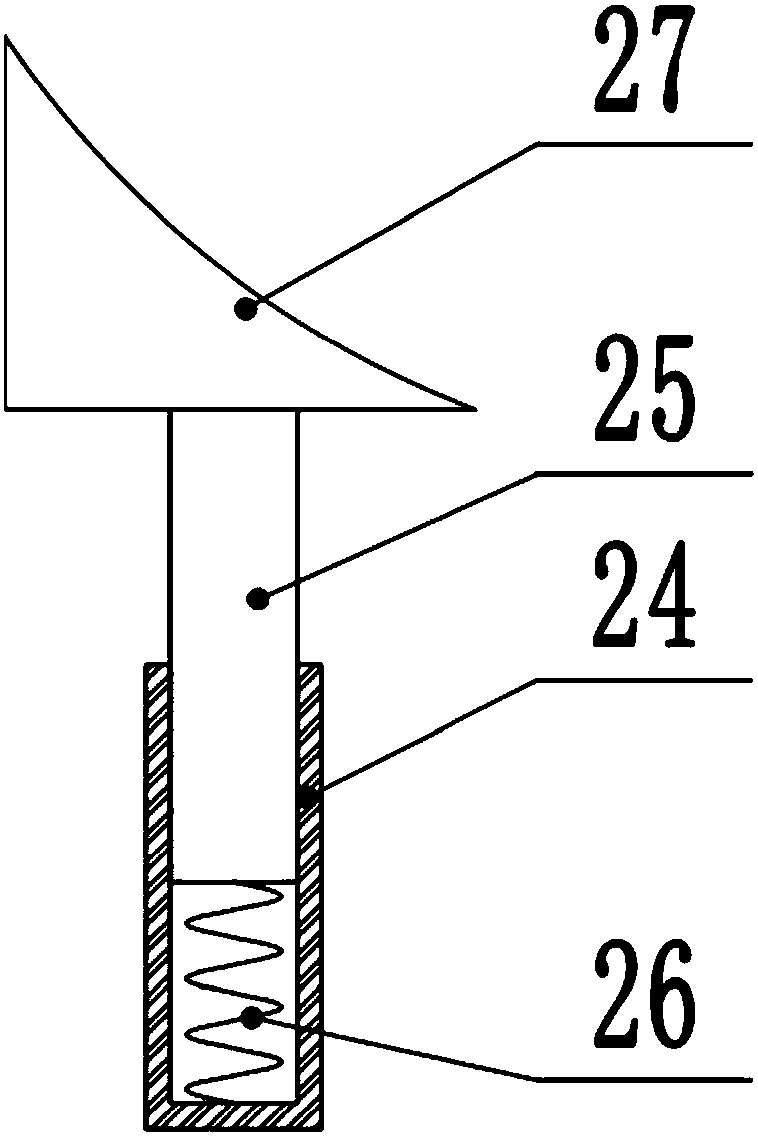

Mixing and drying all-in-one machine and mixing and drying process

ActiveCN104279839AMixed dryingQuick mixDrying machine combinationsMixersAutomatic controlHybrid system

The invention provides a mixing and drying all-in-one machine. The mixing and drying all-in-one machine comprises a burdening system, a mixing system, a drying system, a smashing and screening system and an automatic control system, wherein material transport pipelines are arranged among the burdening system, the mixing system, the drying system and the smashing and screening system; the burdening system can be used for burdening materials of a preset weight; the mixing system can be used for mixing the materials; the drying system can be used for drying the materials; the smashing and screening system can be used for smashing and screening the materials; screen underflow left after screening can be transported to a storage cabin or used later; the automatic control system is used for controlling the work of the burdening system, the mixing system, the drying system and the smashing and screening system. The invention further provides a mixing and drying process. By adopting the mixing and drying all-in-one machine provided by the invention, the materials can be mixed uniformly and dried effectively, hermetic production is performed, safety and reliability are realized, environmental pollution is prevented, the equipment integration level is high, the occupied floor area is small, the problems of long halt time and high cleaning workload caused by bonding of the materials are solved, and the production efficiency is increased.

Owner:ASIA CUANON TECH SHANGHAI

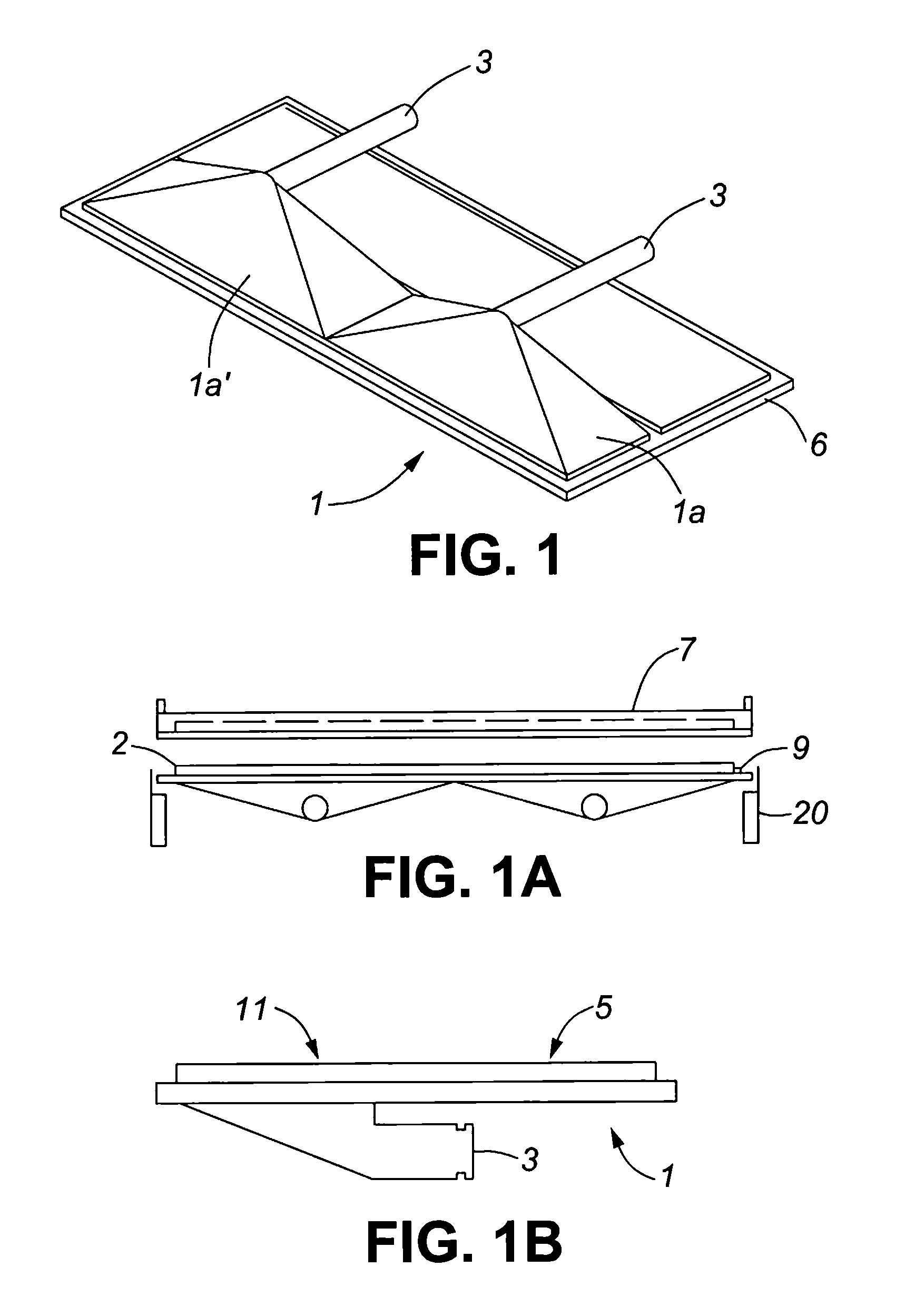

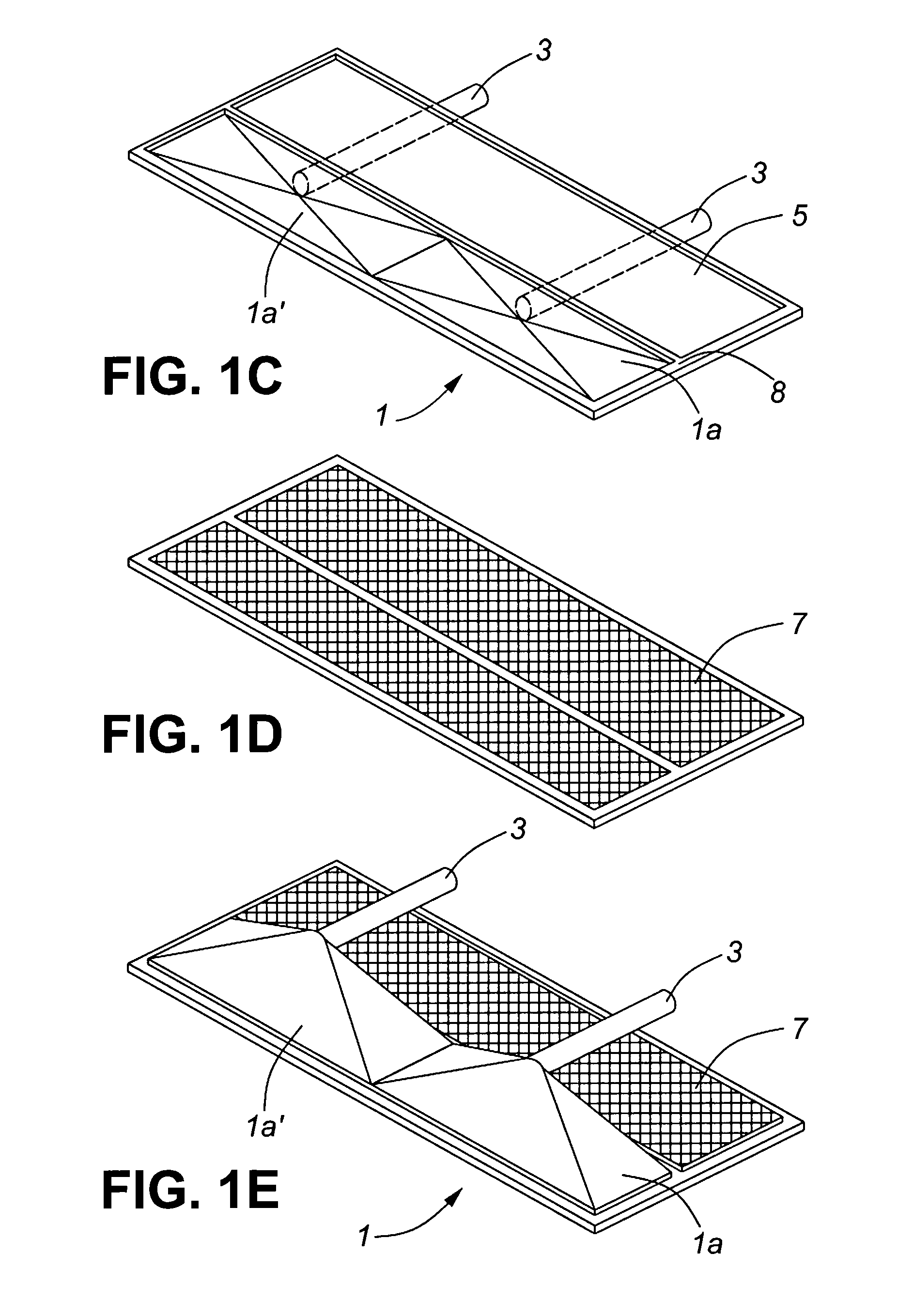

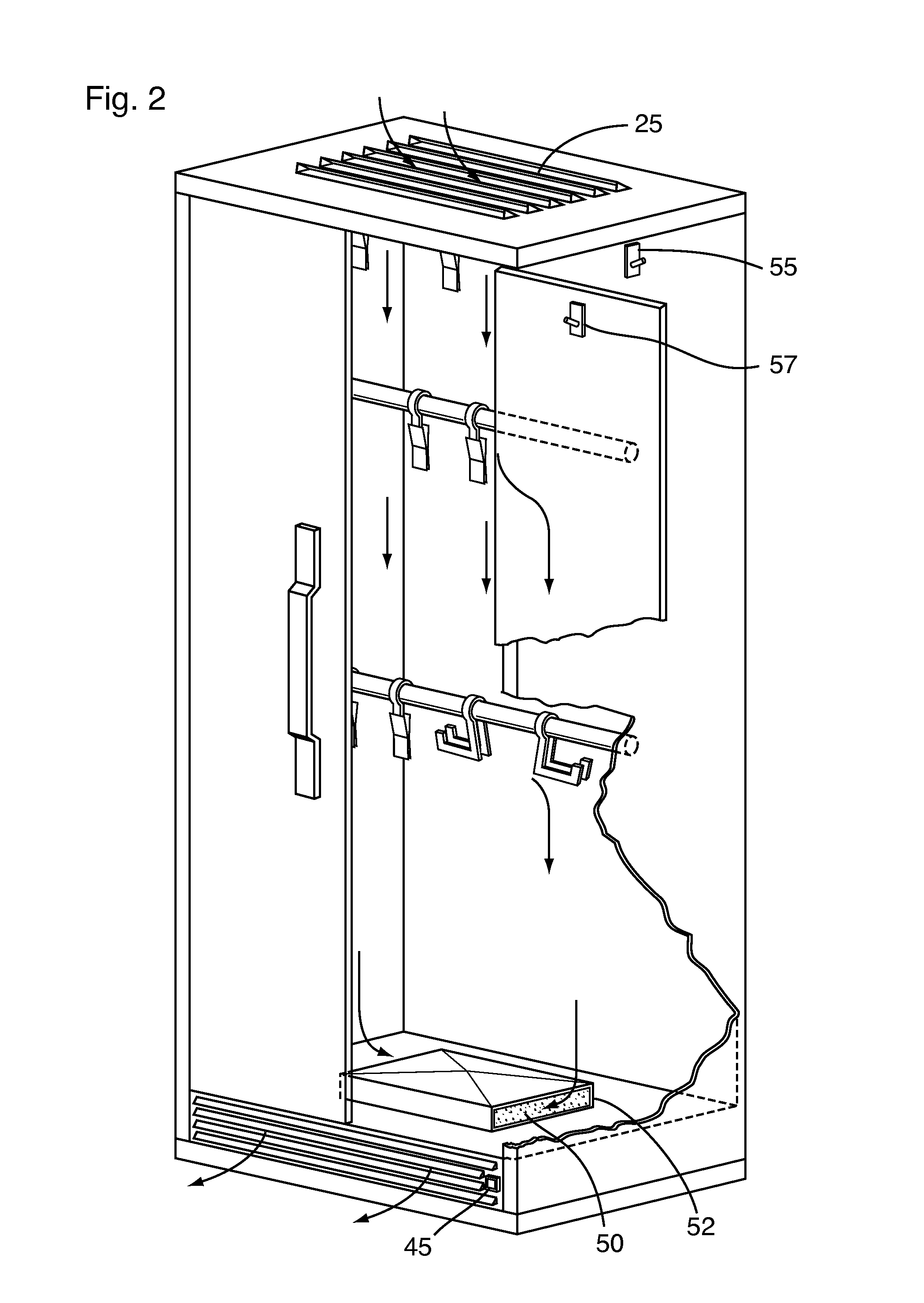

Drying cabinet for clothing and sports equipment

InactiveUS20150113825A1Drying solid materials with heatDrying solid materials without heatAir cycleSports equipment

The present invention relates to a cabinet for storage and drying of sports equipment and / or clothes. This cabinet has doors, an air circulation fan and an exhaust vent at the bottom, an intake vent at the top, and suspending means for suspending articles such as sports equipment or clothes. Turning on the fan activates active drying of the articles. Additionally, the present invention relates to a method of storing and drying articles comprising suspending the articles in a cabinet with doors, the interior of said cabinet comprising an air circulation fan and an exhaust vent at the bottom; an intake vent at the top; and suspending means for suspending the articles. The articles that are difficult or take more time to dry can be placed closest to the fan.

Owner:ADAPTIVE STORAGE SOLUTIONS

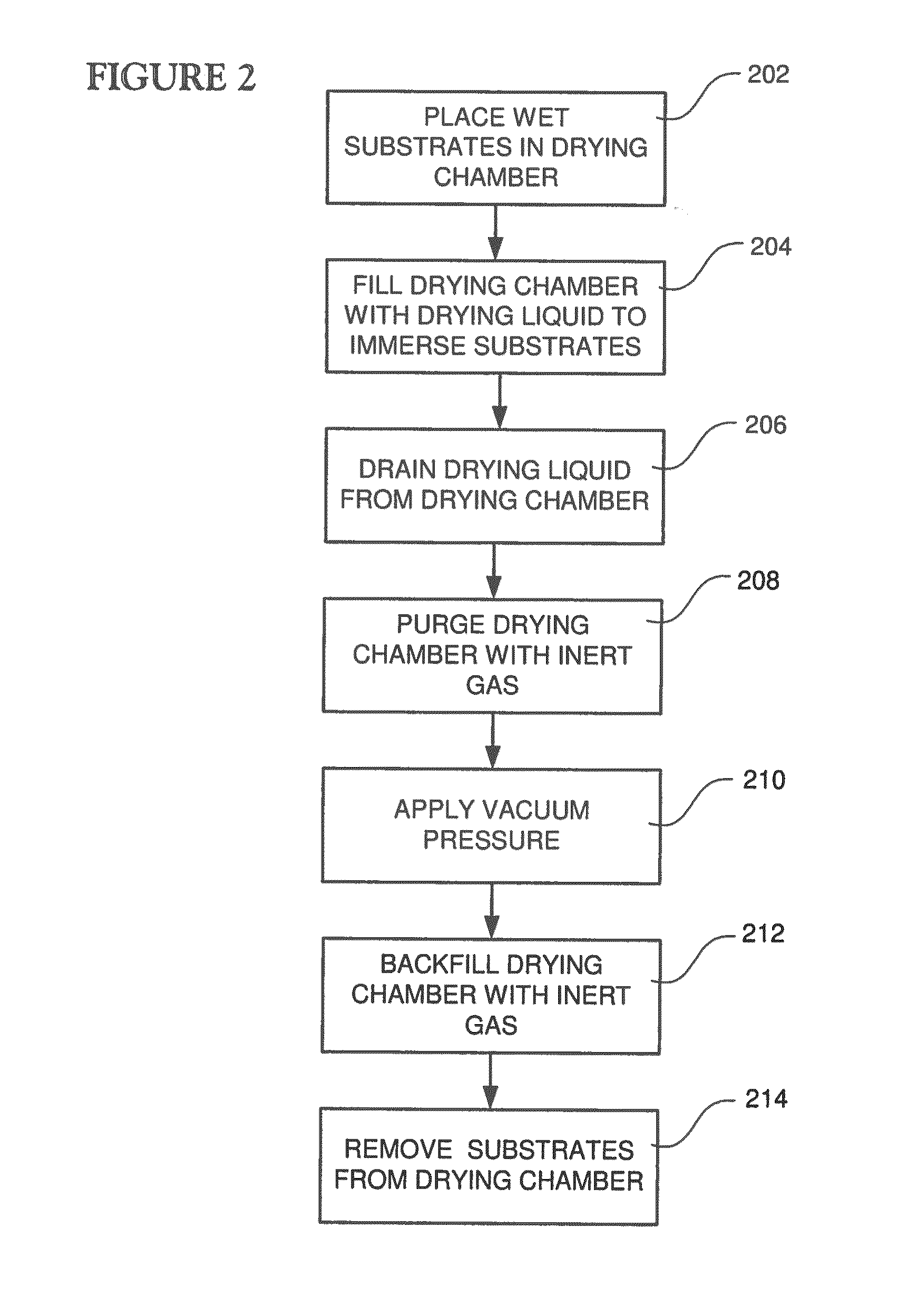

System and method for drying substrates

InactiveUS20140290090A1Drying using combination processesDrying machine combinationsVacuum pressureProcess engineering

A method for drying a wet semiconductor substrate includes immersing the wet substrate in a rinsing liquid in a sealed drying chamber, producing a volume of vaporized drying fluid in a vapor generator, establishing fluid communication between the vapor generator and the drying chamber, transferring the vaporized drying fluid to the drying chamber by removing the rinsing liquid from the drying chamber, and allowing the vaporized drying fluid to condense on the wet substrate. The method further includes providing vacuum pressure within the drying chamber and backfilling the drying chamber with an inert gas to substantially achieve atmospheric pressure.

Owner:JST MFG CO LTD

Tea drying device with deironing function

InactiveCN107660623ADry thoroughlyAvoid accumulationPre-extraction tea treatmentDrying machine combinationsPulp and paper industryAir blower

The invention discloses a tea drying device with a deironing function. The tea drying device comprises a base, a drying box, a primary drying roller, a flatly laying plate, a drying fan, an ultraviolet sterilization lamp and a scraping device, wherein the drying box is arranged on the base; the primary drying roller is fixedly arranged at the upper side of the drying box in an embedded way; a magnetic material is coated on the upper surface of the conveying belt; the flatly laying plate is also arranged inside the drying box; a heating box is fixedly arranged at the upper side of the drying box; the drying fan is also arranged at the left side of the heating box; the scraping device is arranged on a chip guide plate. The drying device can be used for performing primary drying and secondarydrying on the tea, so that the drying of the tea can be more thorough; the ultraviolet sterilization lamp performs sterilization on the tea; the residual germ growth on the surface of the tea can beprevented; the quality of the tea is improved; the shelf life of the tea is improved; meanwhile, iron chips in the tea can be removed through suction; the iron chips can be automatically scraped awaythrough the scraping device; simplicity and effectiveness are realized.

Owner:葛善文

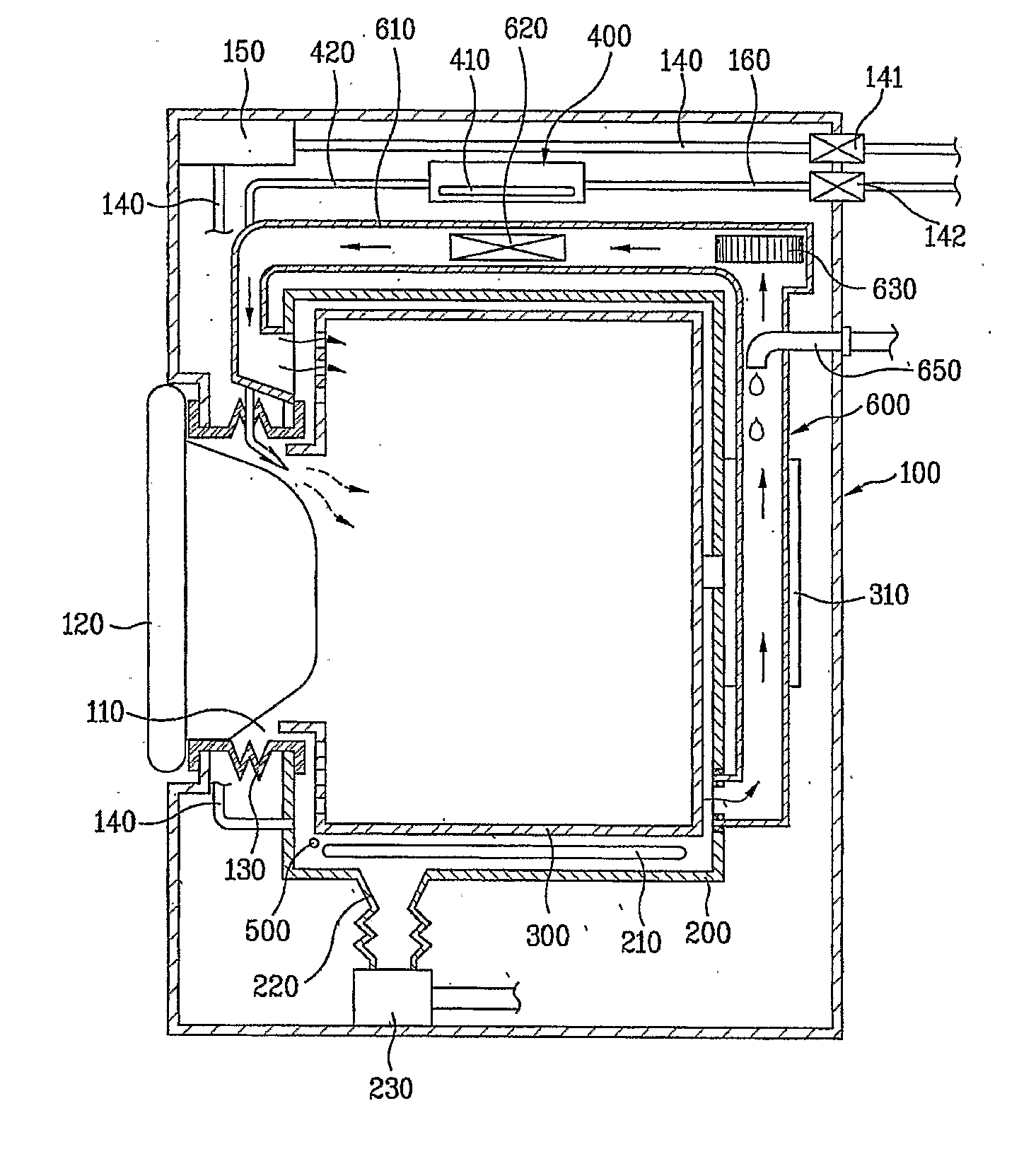

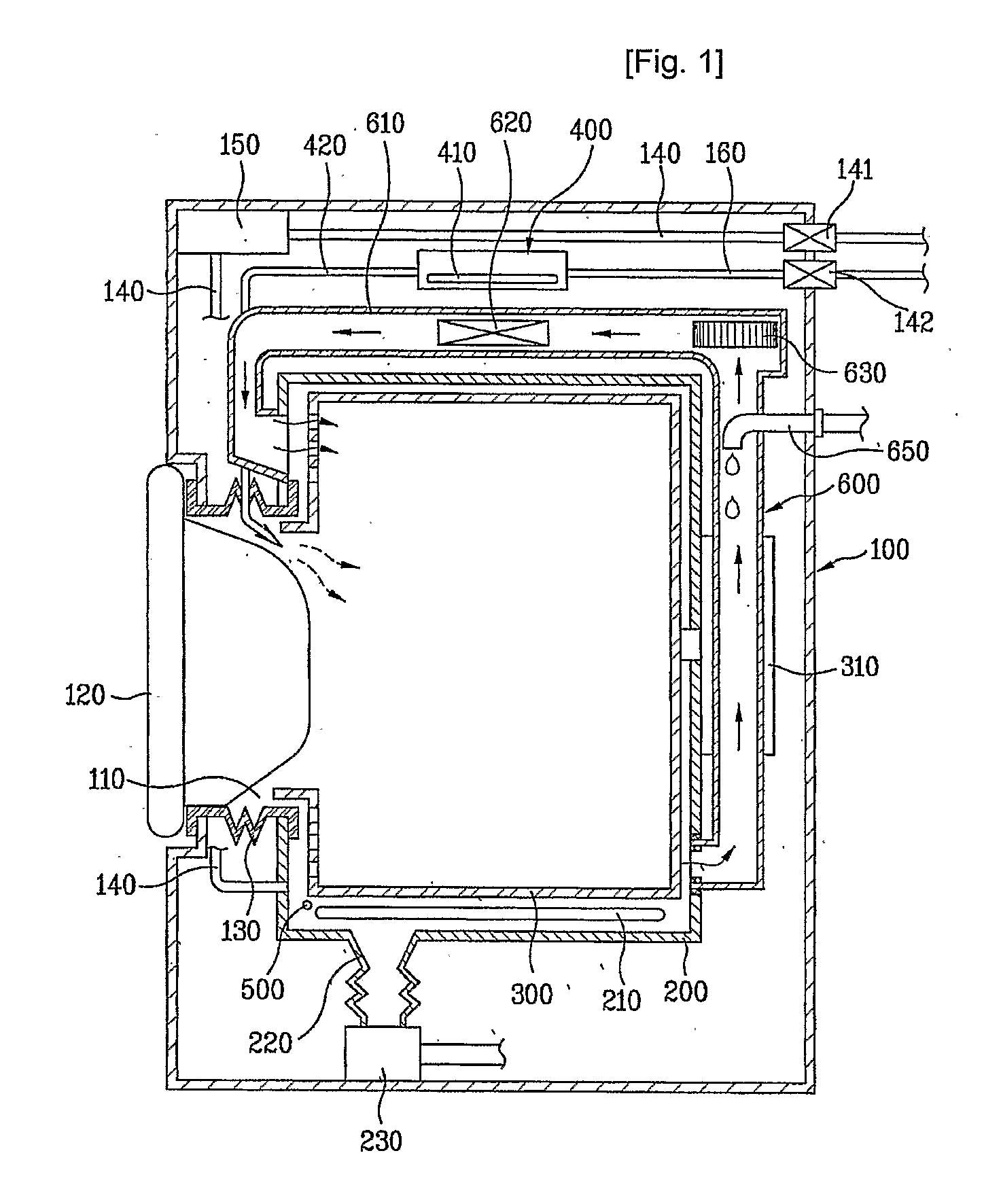

Laundry Machine and a Method for Operating the Same

ActiveUS20080209757A1Drying using combination processesDrying solid materials without heatHigh humidityProcess engineering

The present invention relates to a laundry machine and a method for operating the same for removing wrinkles or the like from laundry by using high temperature and high humidity air instead of steam. The method for operating a laundry machine includes the steps of a course selecting step for selecting an operating course, and a high temperature and high humidity air supply step for supplying high temperature high humidity air to a drum from an air supply unit.

Owner:LG ELECTRONICS INC

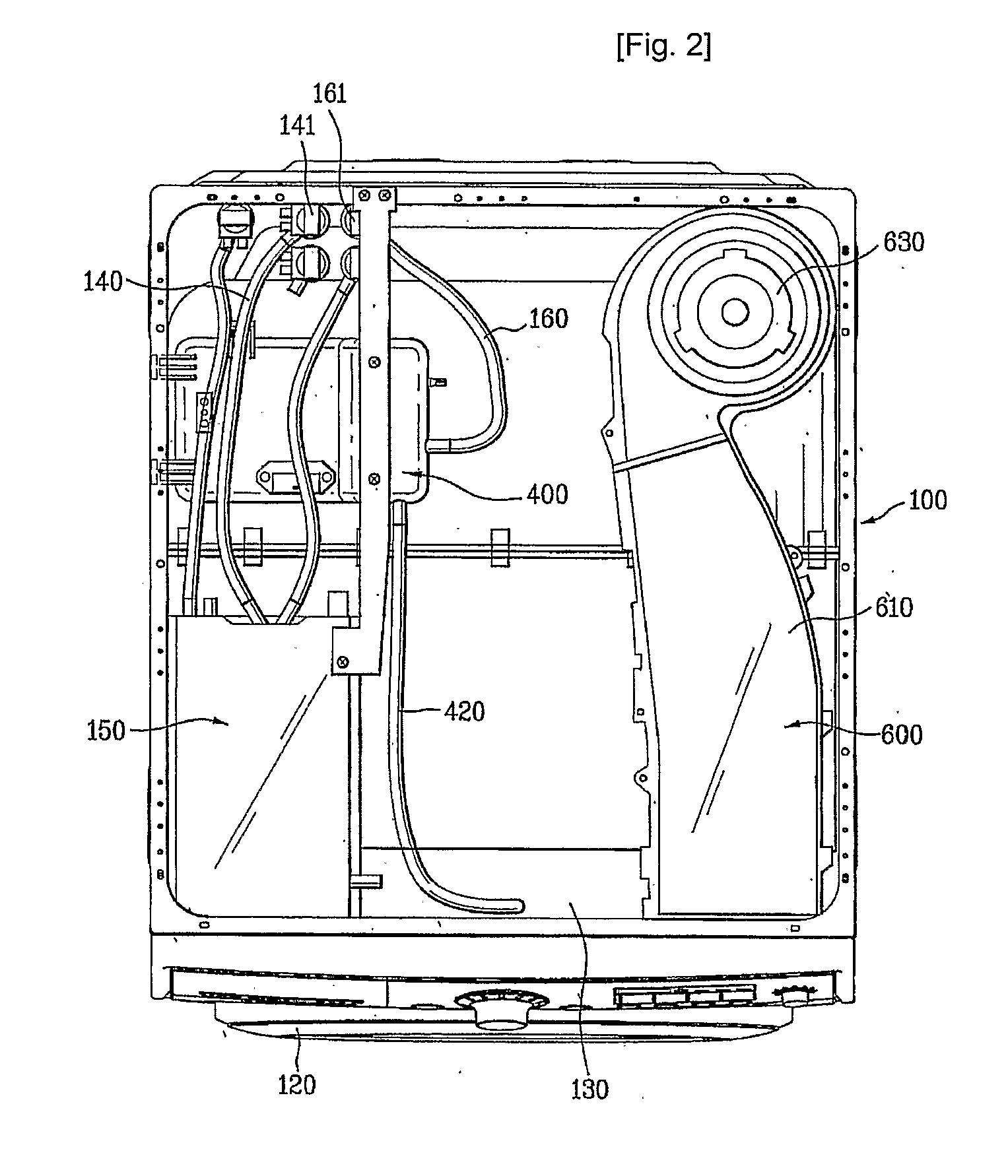

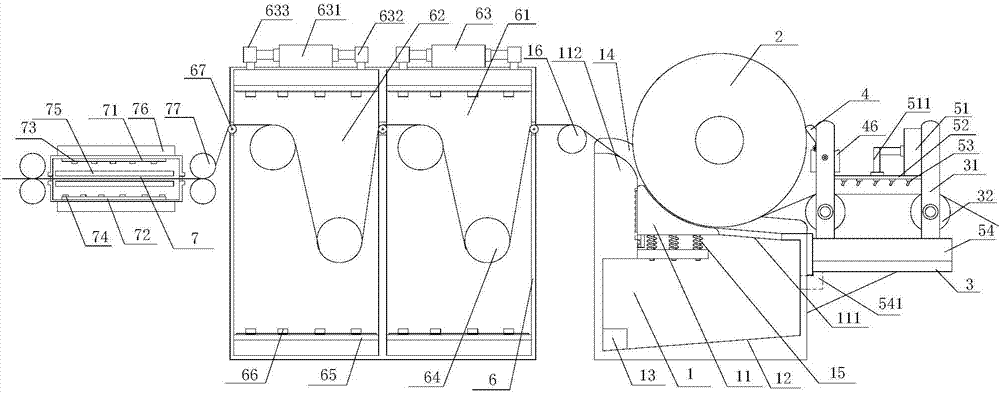

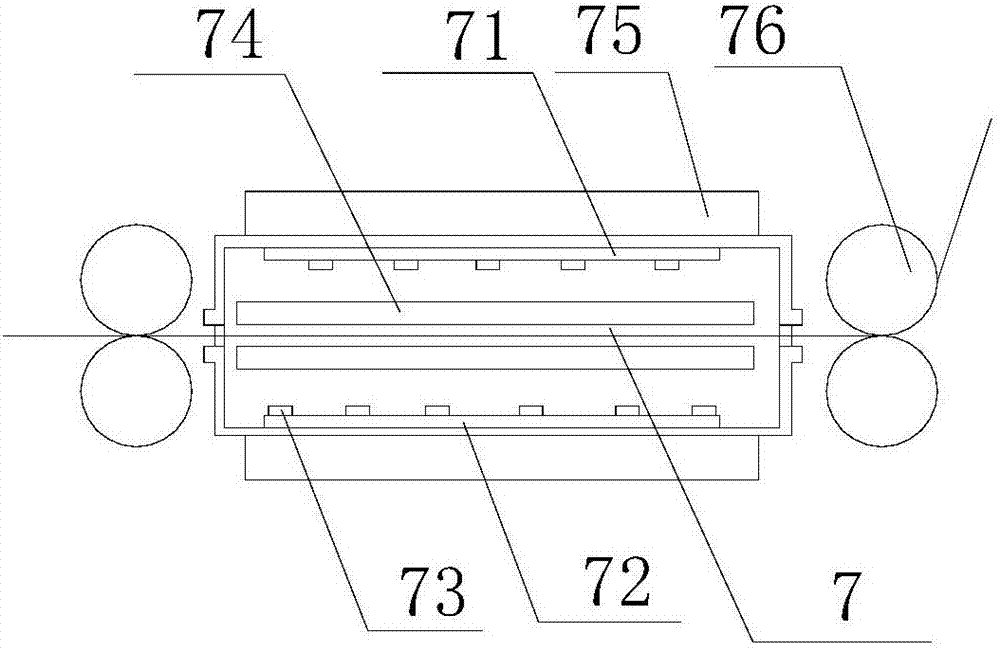

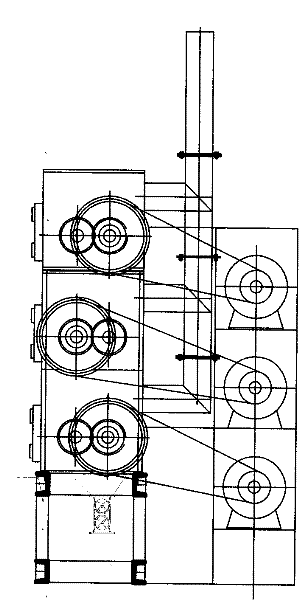

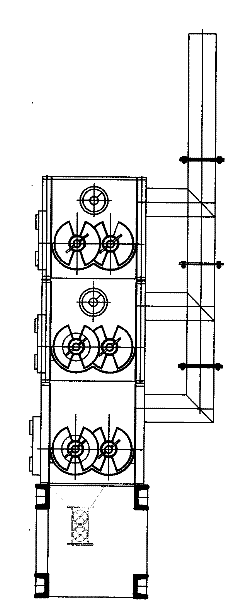

Water jet loom drying device

InactiveCN107356058ARealize extrusion dehydrationImprove drying effectDrying solid materials without heatDrying machine combinationsPulp and paper industryWater jet

The invention provides a water jet loom drying device. The water jet loom drying device comprises a water collecting tank, a dewatering compression roller mechanism, a mounting frame, an auxiliary dewatering mechanism, a blowing and dewatering mechanism, a drying device and an air cooling drying device, wherein the dewatering compression roller mechanism is arranged above the water collecting tank; the mounting frame is arranged on one side of the water collecting tank, supporting frames are symmetrically arranged on the mounting frame, the auxiliary dewatering mechanism is arranged on one of the supporting frames, the blowing and dewatering mechanism is arranged on the other supporting frame, the auxiliary dewatering mechanism is arranged at the upper part of the supporting frame, and the auxiliary dewatering mechanism is matched with the dewatering compression roller mechanism; and the other side of the water collecting tank is provided with an auxiliary guide roller assembly, the auxiliary guide roller assembly is located on one side of the input end of the drying device, and one side of the output end of the drying device is provided with the air cooling drying device. According to the water jet loom drying device, the blowing and dewatering mechanism and the dewatering compression roller mechanism are used for carrying out secondary dehydration on grey cloth, the drying device is used for drying the grey cloth, and finally the air cooling drying device is used for cooling and further drying the grey cloth, so that multi-stage drying is carried out, and the drying effect is good.

Owner:CHANGXING SHENGFAN TEXTILE

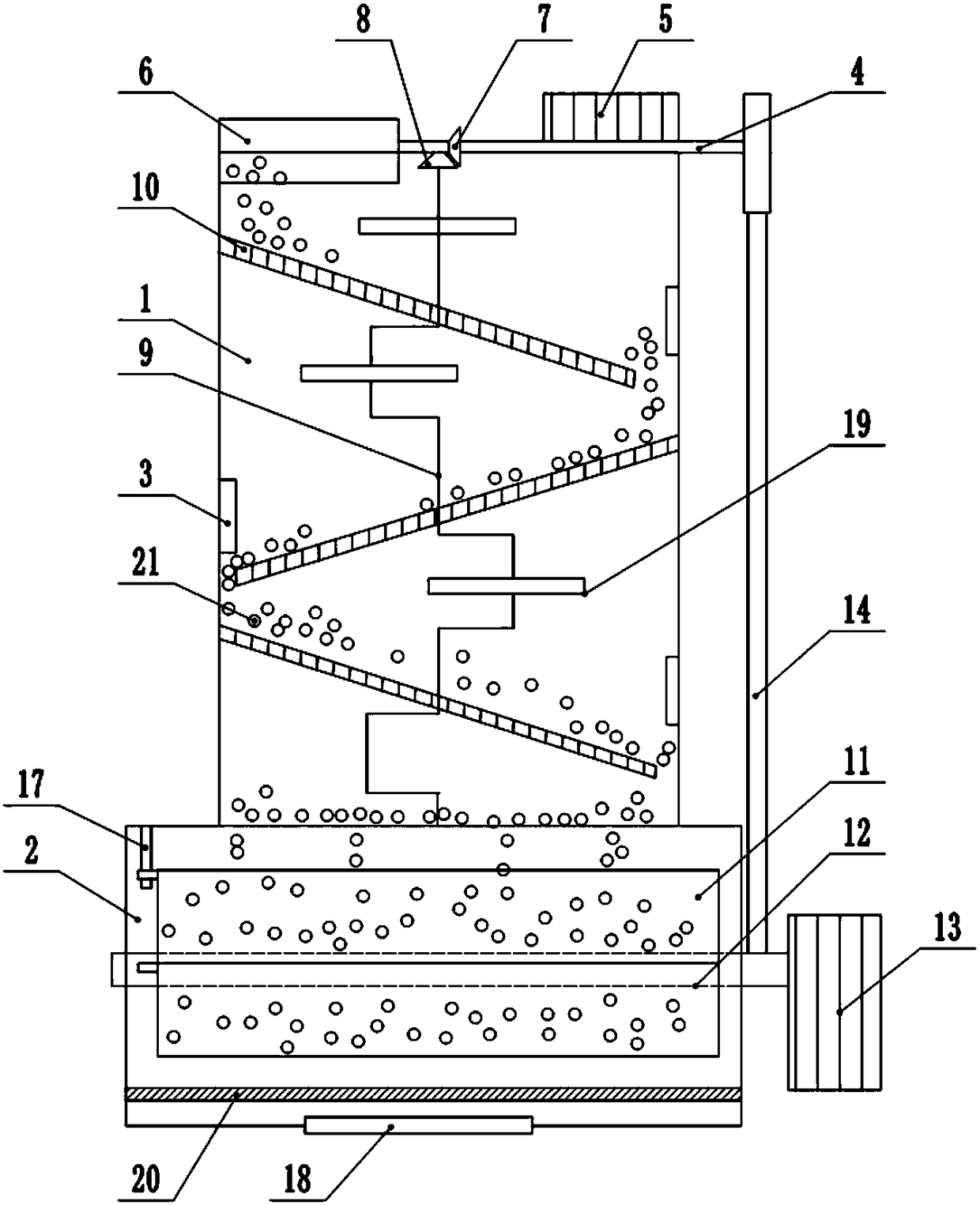

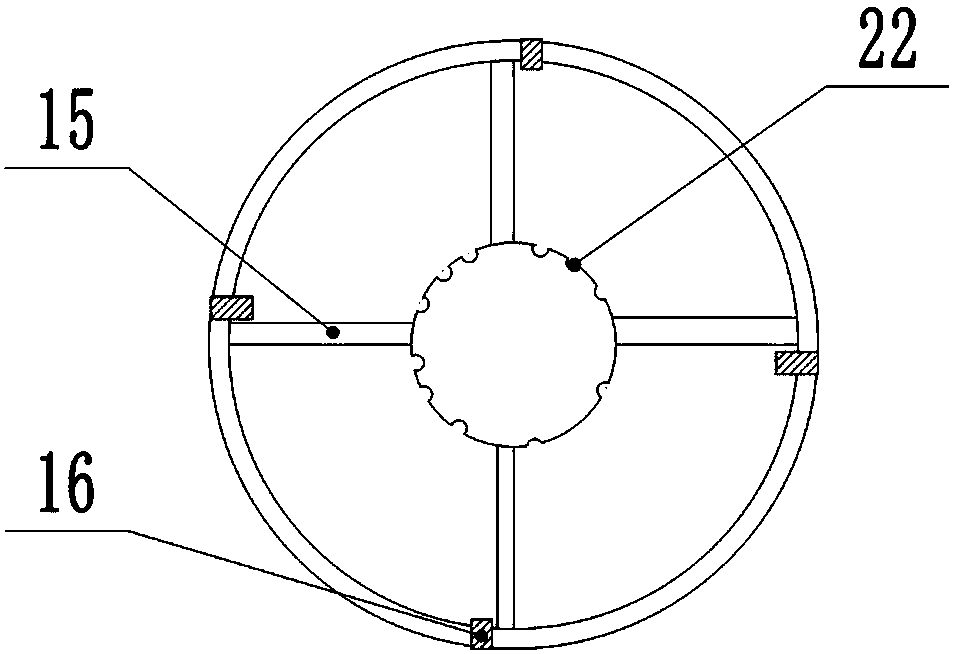

Rice drying device

InactiveCN108088225AExtended stayControl the speed of the slideSievingScreeningEngineeringDrying time

The invention relates to the technical field of rice drying, and specifically discloses a rice drying device. The rice drying device comprises a first drying box, a second drying box and hot air mechanisms, wherein the upper part of the first drying box is rotatably connected with a first rotary shaft; the first rotary shaft is connected with a motor; a charge hopper is fixedly mounted on the first rotary shaft; the first rotary shaft is connected with a crankshaft through a bevel gear; the other end of the crankshaft is rotatably connected on the lower wall of the first drying box; the side wall of the first drying box is hinged with a plurality of drying plates; the drying plates are equipped with material transfer ends; gaps are formed between the material transfer ends and side walls;the hot air mechanisms are arranged on the side walls which correspond to the material transfer ends; an unloading hole is formed in the bottom of the first drying box; an opening is formed in the upper part of the second drying box; a drying barrel is mounted in the second drying box; a second rotary shaft is arranged on the middle part of the drying barrel; the inner part of the second rotary shaft is hollow, and the second rotary shaft is equipped with an air outlet; the second rotary shaft is connected with a hot air blower; and a pulling rod is hinged between the second rotary shaft and the first rotary shaft. The rice drying device solves the problems such as long rice drying time, low efficiency and uneven drying.

Owner:重庆市合川区云天食品科技有限公司

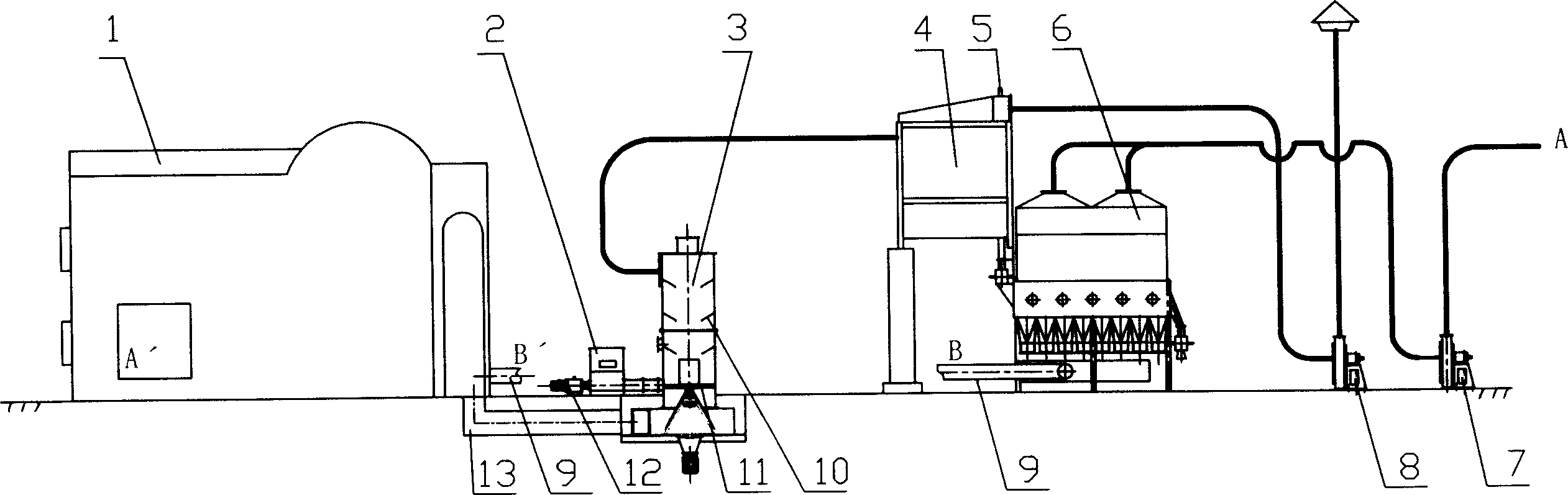

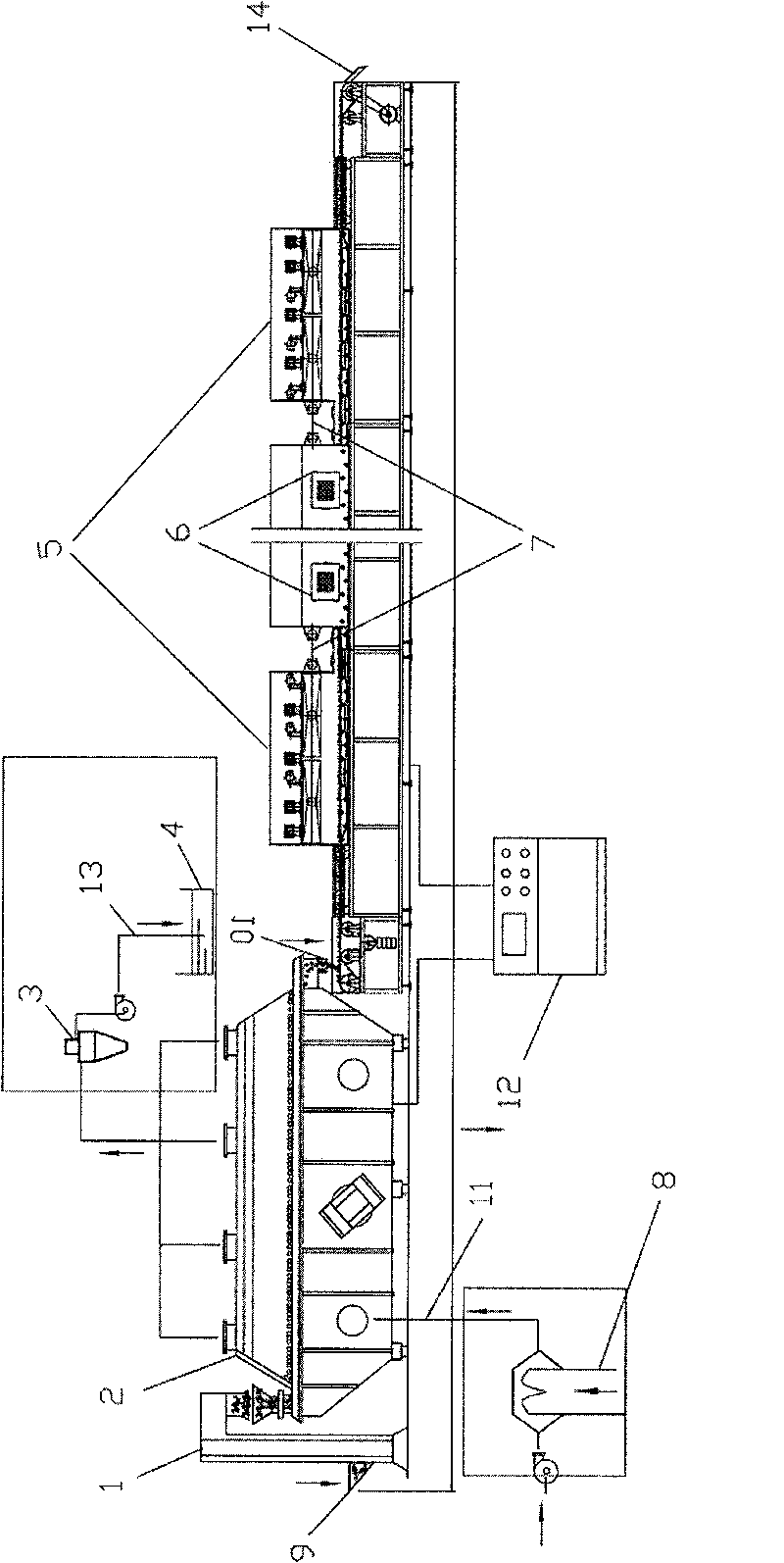

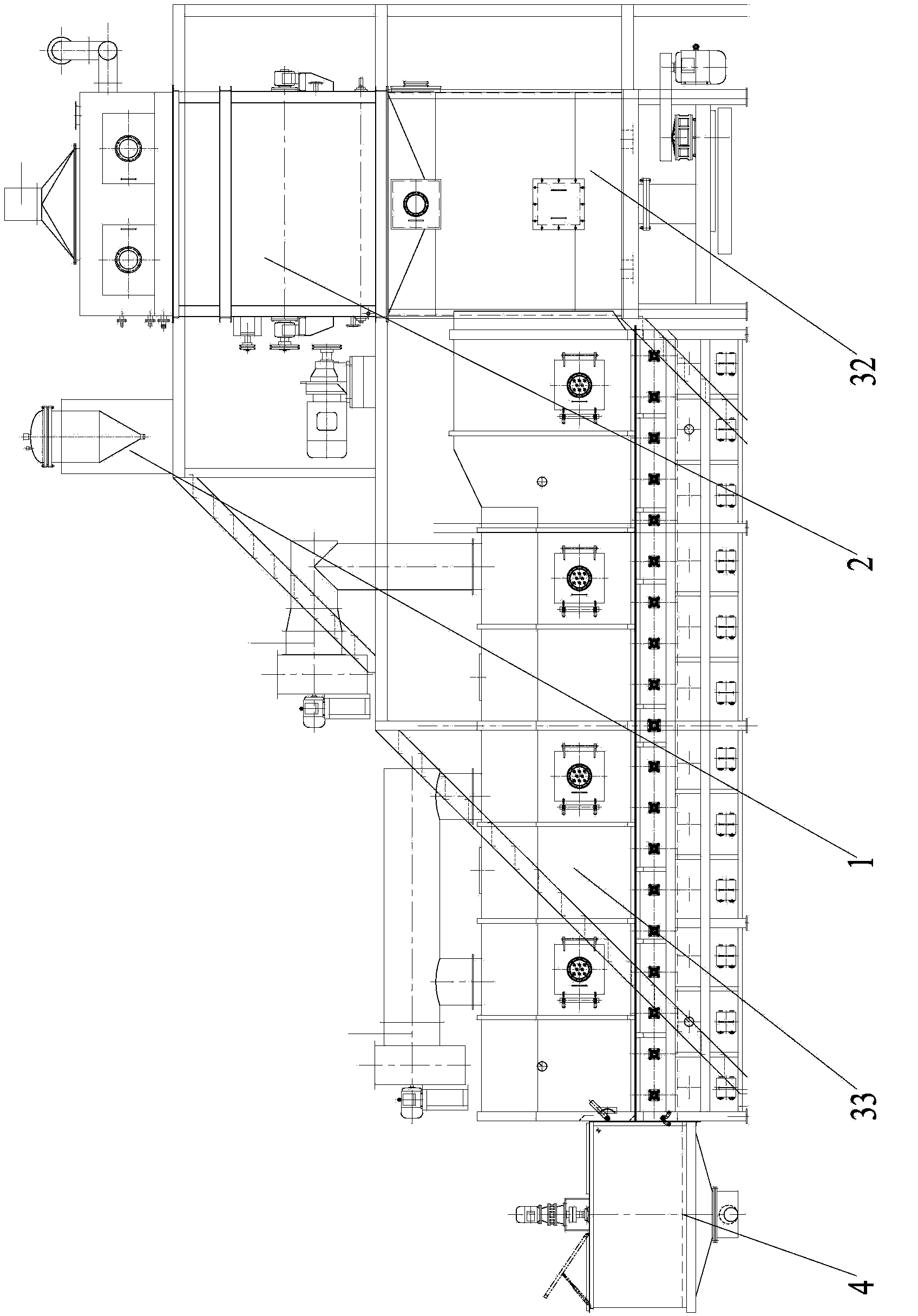

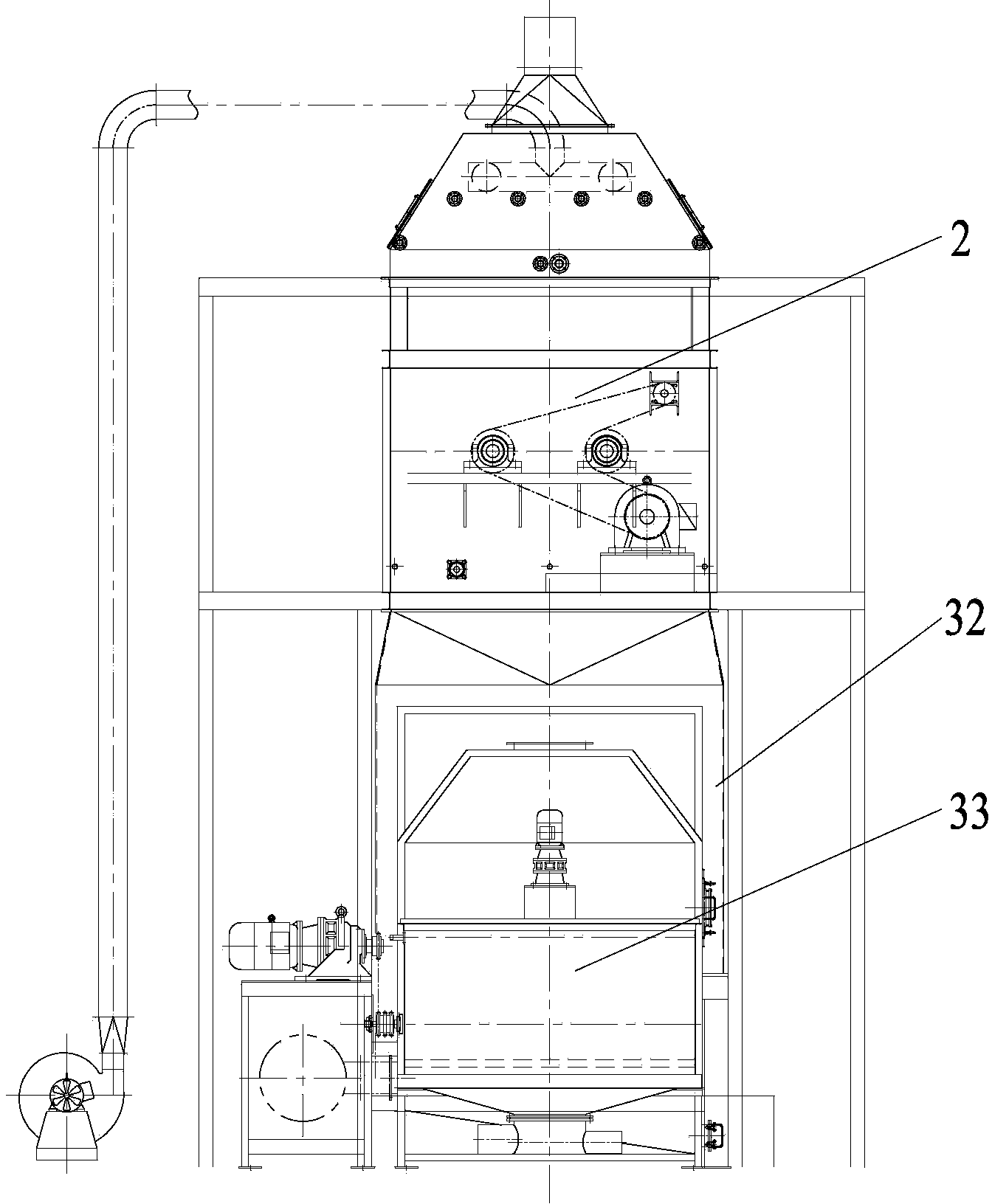

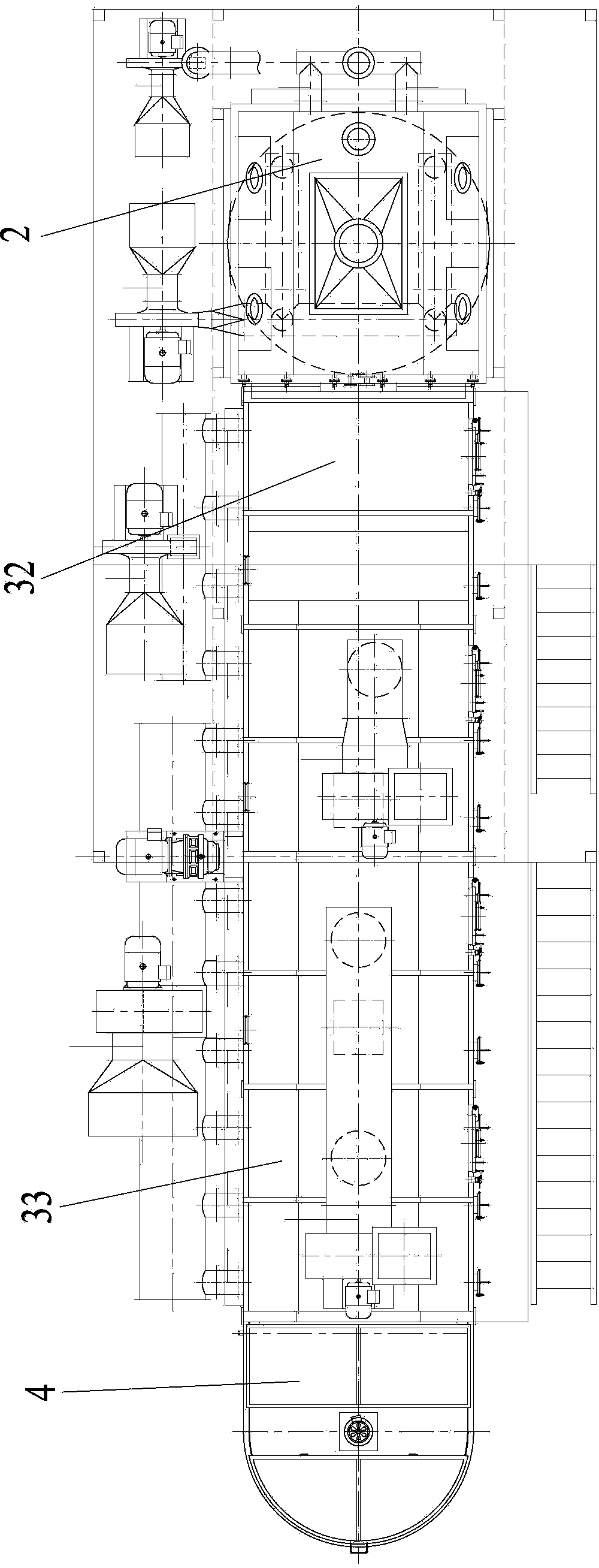

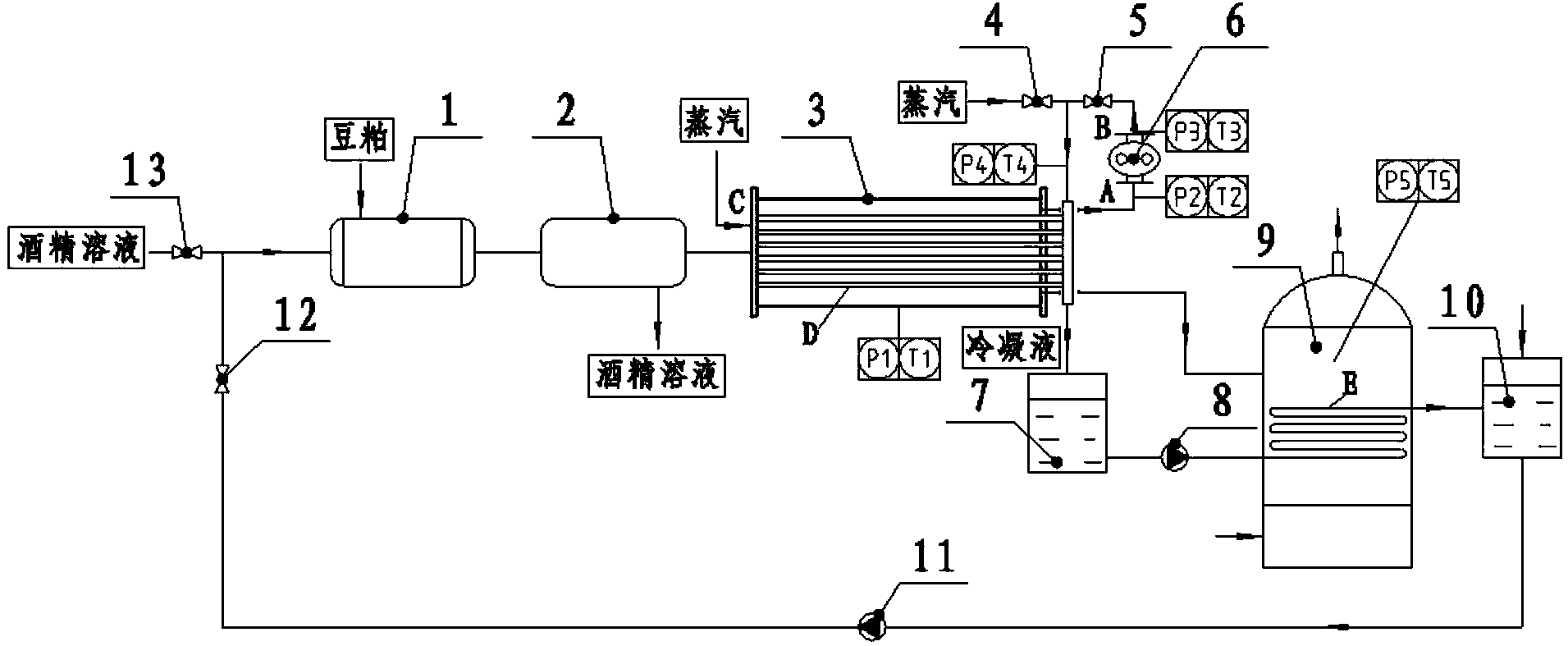

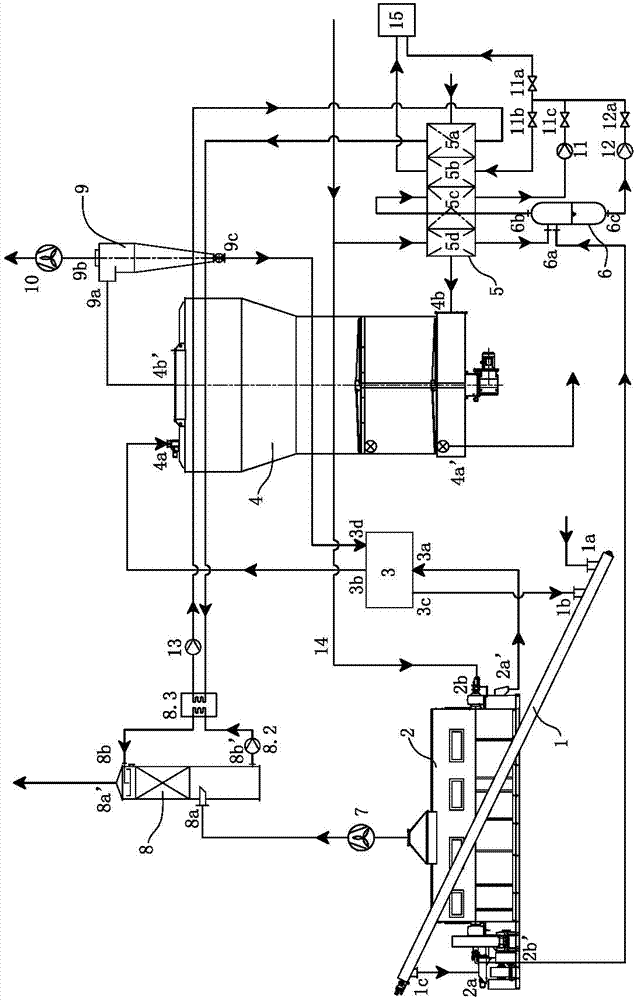

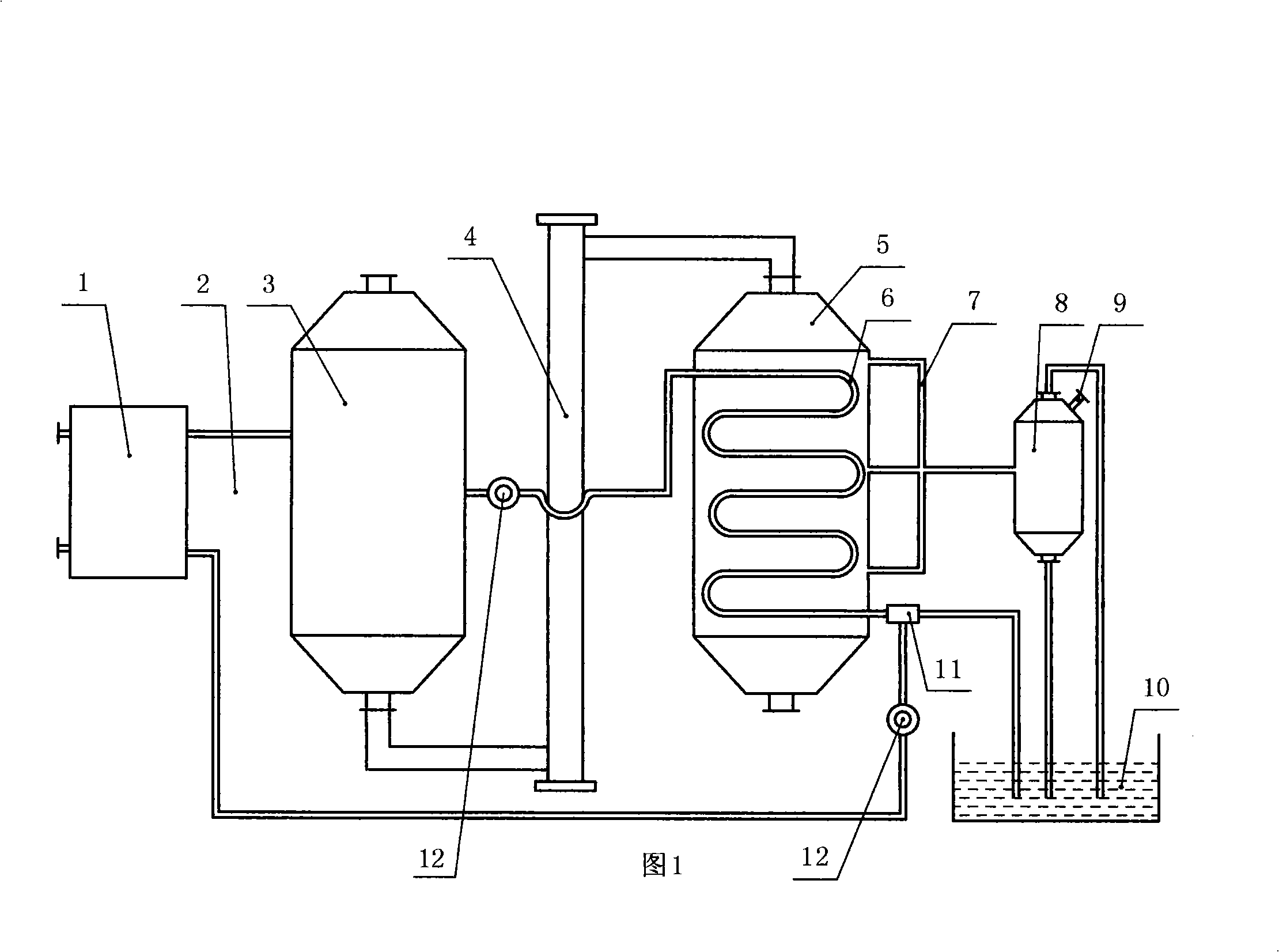

Wet meal drying system based on mechanical steam recompression and drying technique

ActiveCN103822454AReduce energy consumptionReduce power consumptionProtein composition from vegetable seedsDrying machine combinationsProcess engineeringFilter press

The invention discloses a wet meal drying system based on mechanical steam recompression which comprises a diffuser, wherein a discharging port of the diffuser is communicated with a feeding port of a press filter; the discharging port of the press filter is communicated with a superheated steam rotary drying machine; a secondary steam outlet of the superheated steam rotary drying machine is communicated with an air suction port of a mechanical steam compressor; an air outlet of the mechanical steam compressor is communicated with a heating tube beam in the superheated steam rotary drying machine; a steam inlet is arranged in the superheated steam rotary drying machine; a condensate water outlet which is communicated with a first storage jar is arranged in the superheated steam rotary drying machine; the discharging port of the superheated steam rotary drying machine is communicated with a hot air fluid bed dryer; the first storage jar is communicated with a heating tube in the hot air fluid bed dryer; a liquid outlet of the hot air fluid bed dryer is communicated with a second storage jar; the liquid outlet of the second storage jar is communicated with a liquid inlet of the diffuser. The invention also discloses a technique utilizing the system. The wet meal drying system based on the mechanical steam recompression has the advantages that the drying energy consumption is low, the equipment is free from dead angle and the recycling of alcoholic solution does not require a large amount of cooling water for cooling.

Owner:SHANDONG KEYUAN TIANLI ENERGY CONSERVATION ENG

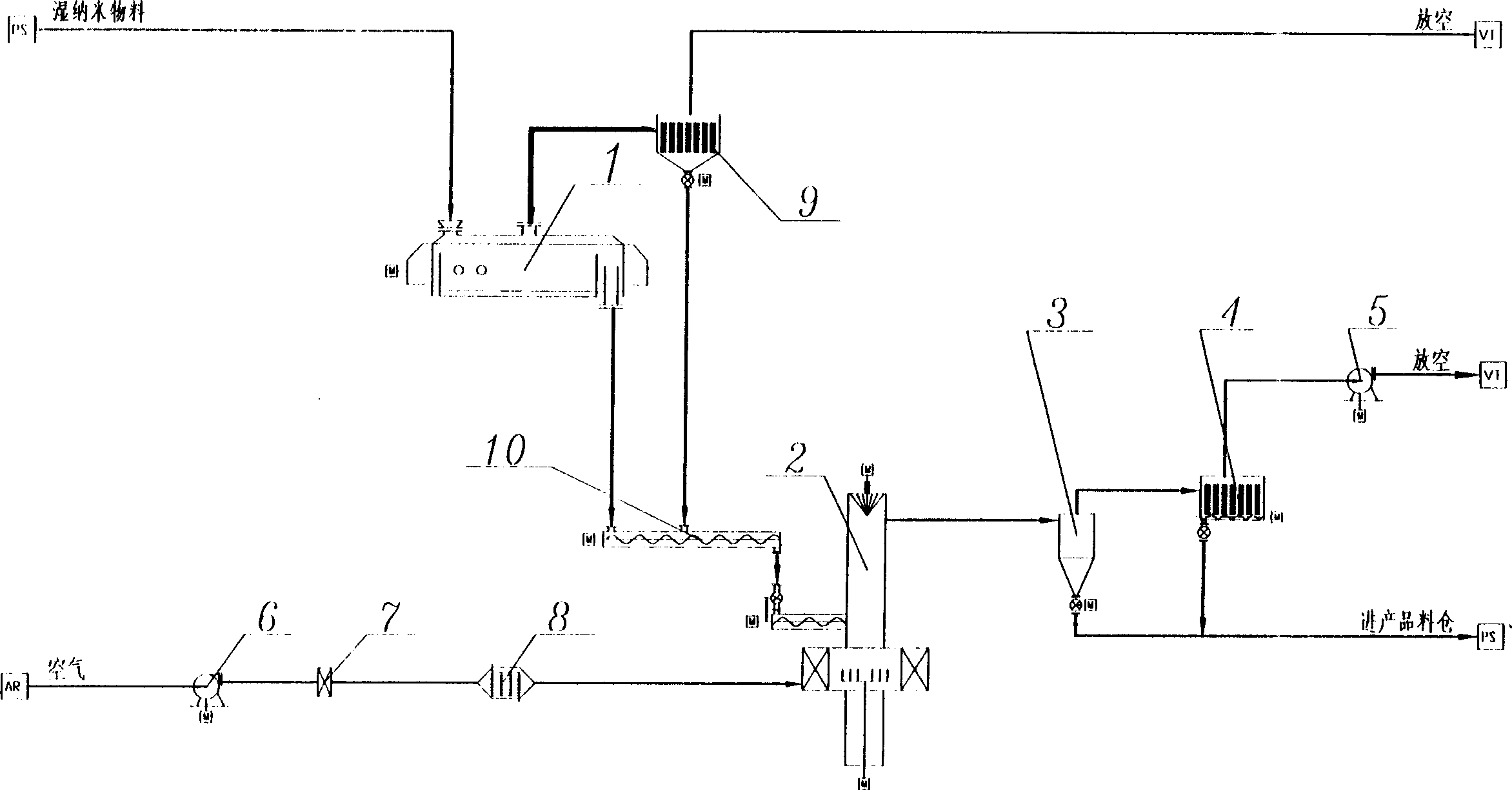

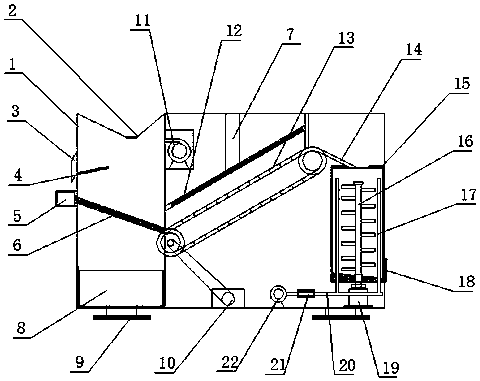

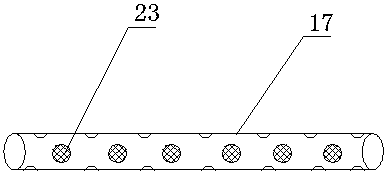

Propeller blade-micropowder composite drying method for nanometer grade material

InactiveCN1517657ASolve technical problems of reunionSolve the problem of high humidity and high viscosityDrying machine combinationsGranularityPropeller

A method for drying the nano-class material features the combination of paddle-type drier with microparticle drier. Said paddle-type drier is used for pre-drying at temp lower than 150 deg.C to remove the most of moisture. Said microparticle driver is used for drying, pulverizing, classifying and pneumatic delivering. Its advantages are high granularity uniformity and low energy consumption.

Owner:LANZHOU RUIDE DRYING TECH

Ginger rapid drying device

InactiveCN102721271AHeats up quickly and evenlyMaintain moisture contentDrying solid materials with heatDrying machine combinationsFluidized bedEngineering

The invention discloses a ginger rapid drying device, which comprises a machine body, a fluidized bed and a ginger conveying wire belt penetrating the machine body, wherein the machine body is sequentially divided into a shortwave infrared heating area, a medium-wave infrared heating area and a far-infrared heating area, a shortwave infrared heating pipe nest is arranged on the inner upper part of the shortwave infrared heating area, a medium-wave infrared heating pipe nest is arranged on the inner upper part of the medium-wave infrared heating area, a far-infrared heating pipe nest is arranged on the inner upper part of the far-infrared heating area, the top of the far-infrared heating area is provided with an air inlet, and the top of the shortwave infrared heating area and the top of the medium-wave infrared heating area are respectively provided with an air outlet; and the fluidized bed comprises a bed body and a blower, wherein the blower is communicated with the bed body, the bed body is provided with an air blowing hole, and the bed body of the fluidized bed is arranged inside the shortwave infrared heating area and the medium-wave infrared heating area and is closely abutted against the lower side of the ginger conveying wire belt. By adopting a way combining the infrared heating and the fluidized bed as well as the hot air circulation, a purpose for rapidly drying ginger is realized, and simultaneously the ginger can be prevented from being discolored.

Owner:CHONGQING TECH & BUSINESS UNIV

Fermented feed drying method

ActiveCN103575081AIncrease temperatureReduce consumptionDrying solid materials with heatFeeding-stuffEngineeringTubes types

The invention relates to a fermented feed drying method. The method comprises steps as follows in sequence: fresh fermented feed enters a feeding machine from a main feed opening, is lifted, then enters a feed opening of a tube-type drying machine, advances from front to back in the horizontal direction in the tube-type drying machine, and is subjected to indirect heat exchange with steam simultaneously; hot and humid air is exhausted by an exhaust fan from an exhaust outlet of the tube-type drying machine; the preliminarily dried fermented feed enters sieving and conveying equipment for sieving after discharged from the tube-type drying machine; after sieving, a screen underflow is sent into a feed opening in the top of a tower-type drying machine, and a screen overflow is sent into an auxiliary feed opening of the feeding machine and mixed with the fresh fermented feed; and the fermented feed moves from top to bottom in the tower-type drying machine, air enters an air inlet in the lower part of the tower-type drying machine after heated by an air heater, and hot air flows from bottom to top to perform secondary drying on the fermented feed and is exhausted from an air outlet in the upper part of the tower-type drying machine. The fermented feed drying method is low in energy consumption and high in drying efficiency, and can maintain the activity of the fermented feed.

Owner:MYANDE GRP CO LTD

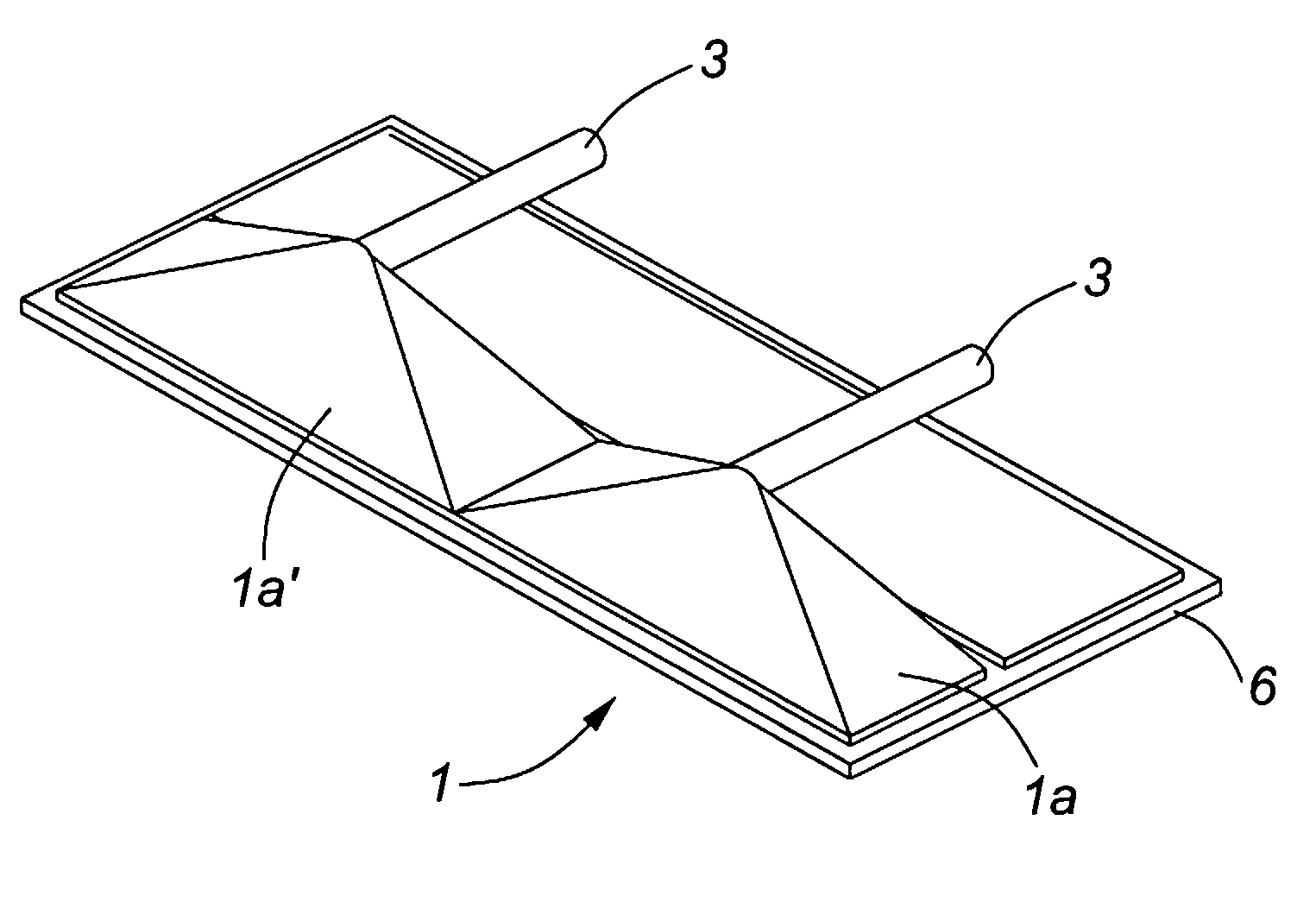

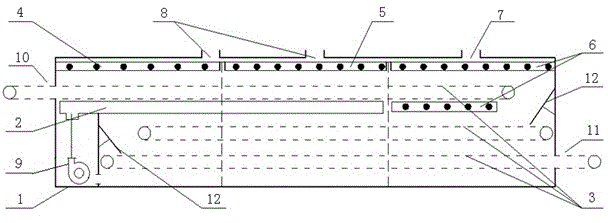

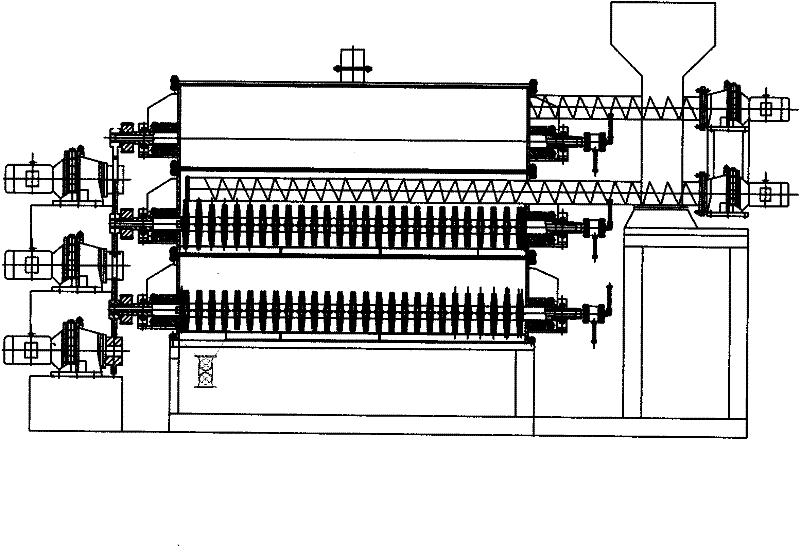

Multi-layer multi-stage large material mixing drying device and process

InactiveCN102235812AEnhance heat and mass transferFully dryDrying machine combinationsDrying machines with progressive movementsReciprocating motionSpray nozzle

The invention belongs to the technical field of material drying, and mainly provides a multi-layer multi-stage large material mixing drying device. The device is formed by superposing 2 to 6 drying unit layers, wherein a drying unit layer for drying a water-containing powdery material and a pasty material consists of a square shell part, two shaft parts which are arranged in the square shell and are provided with hollow blades, and a material distribution spiral part; a drying unit layer for drying a liquid material consists of a square shell (3), two shafts (1) which are arranged in the square shell and are provided with hollow blades, and a charging pipeline driven by a reciprocating charging running vehicle, or a charging pipeline (2) with a material distribution spray nozzle; and the side wall of each drying unit layer is provided with a discharging opening, and the discharging openings of the drying unit layers are connected through pipelines. By a multi-layer multi-stage drying method, a material to be dried is uniformly distributed through a spiral device or the charging pipeline driven by the reciprocating charging running vehicle, and is mixed with a dried material arranged at the bottom of a dryer, and the mixture is stirred by the blades, so that the drying rate is improved; and by a multi-stage drying method, the material is more fully dried.

Owner:洛阳瑞岛环保科技有限公司

Dryer, especially hand dryer

InactiveUS20130283629A1Reduce in quantityReduce germsDrying machine combinationsDrying gas arrangementsEngineeringIon source

A dryer comprising a housing in which there is a hollow space which is accessible from outside through a housing port and which serves to accommodate extremities, more particularly hands, to be dried by means of a current of air, and in which a device for generating the current of air is present. The dryer also includes a means for reducing germs in the current of air, such as a plasma or ion source, or a radiation source such as UV emitter or dielectric barrier discharge lamp.

Owner:USHIO EURO

Wardrobe for drying clothing and sports equipment

The present invention relates to a wardrobe for storage and drying of sports equipment and / or clothes. This wardrobe has an opening, an air circulation fan and an exhaust vent at the bottom, an intake vent at the top, and suspending means for suspending articles such as sports equipment or clothes. Turning on the fan activates active drying of the articles. Additionally, the present invention relates to a method of storing and drying articles comprising suspending the articles in a wardrobe, the interior of said wardrobe comprising an air circulation fan and an exhaust vent at the bottom; an intake vent at the top; and suspending means for suspending the articles. The articles that are difficult or take more time to dry can be placed closest to the fan. The wardrobe can have a rigid or flexible interior cavity and the flexible wardrobe can be capable of hanging on a rod and additionally can be packed in a bag with or without a kit with support poles and feet.

Owner:ADAPTIVE STORAGE SOLUTIONS

Seed screening and drying device

PendingCN108057623AKeep dryFast dryingGas current separationDrying machine combinationsEngineeringAir blower

The invention discloses a seed screening and drying device. The top of a box body is provided with a feed port. A vibrating screen is arranged under the feed port and is of an inclined structure in the box body, and one side of the part between the feed port and the vibrating screen is provided with a first air blower. A waste outlet is formed opposite to an air outlet of the first air blower, aninclined plate is arranged on the waste outlet, and the inclined plate is arranged in the box body and connected to the inner wall of the box body through welding. The drying cavity is internally provided with a stirring shaft, the stirring shaft is fixedly provided with a plurality of stirring blades, the drying cavity is internally and fixedly provided with two drying pipes, and the two drying pipes are symmetrically arranged on the two sides of the stirring shaft. The side face of the drying cavity is provided with a discharge port, the discharge port is fixedly provided with a connection block, the two sides of the connection block are symmetrically provided with sliding grooves, a baffle is connected into the sliding grooves in the two sides of the connection block in a sliding manner, and the end face of the baffle is further provided with a handle.

Owner:湖州鲜绿多健康农产品产业发展有限公司

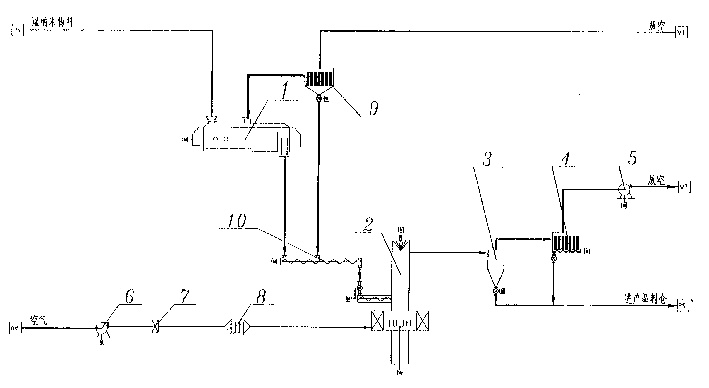

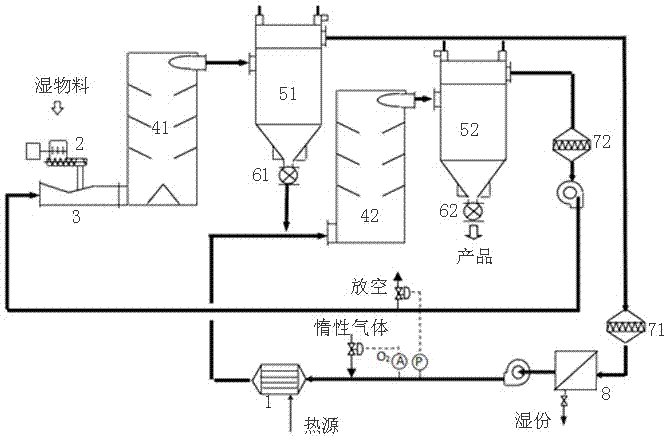

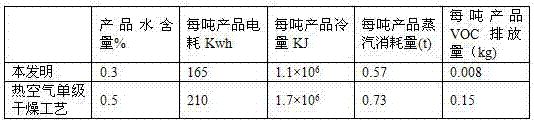

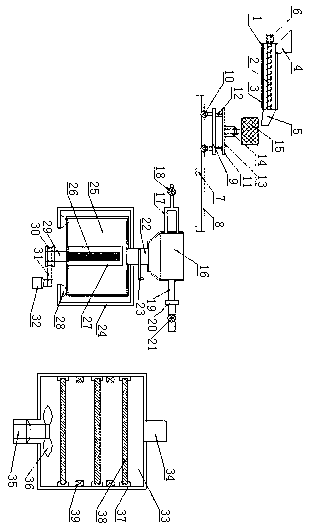

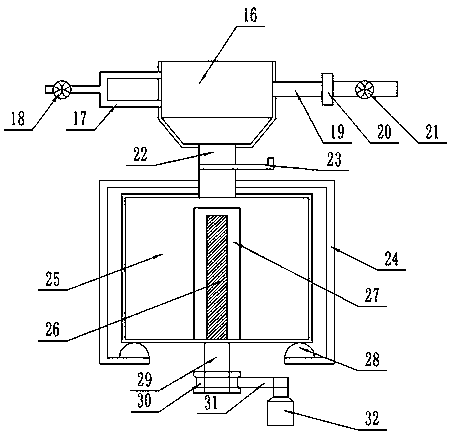

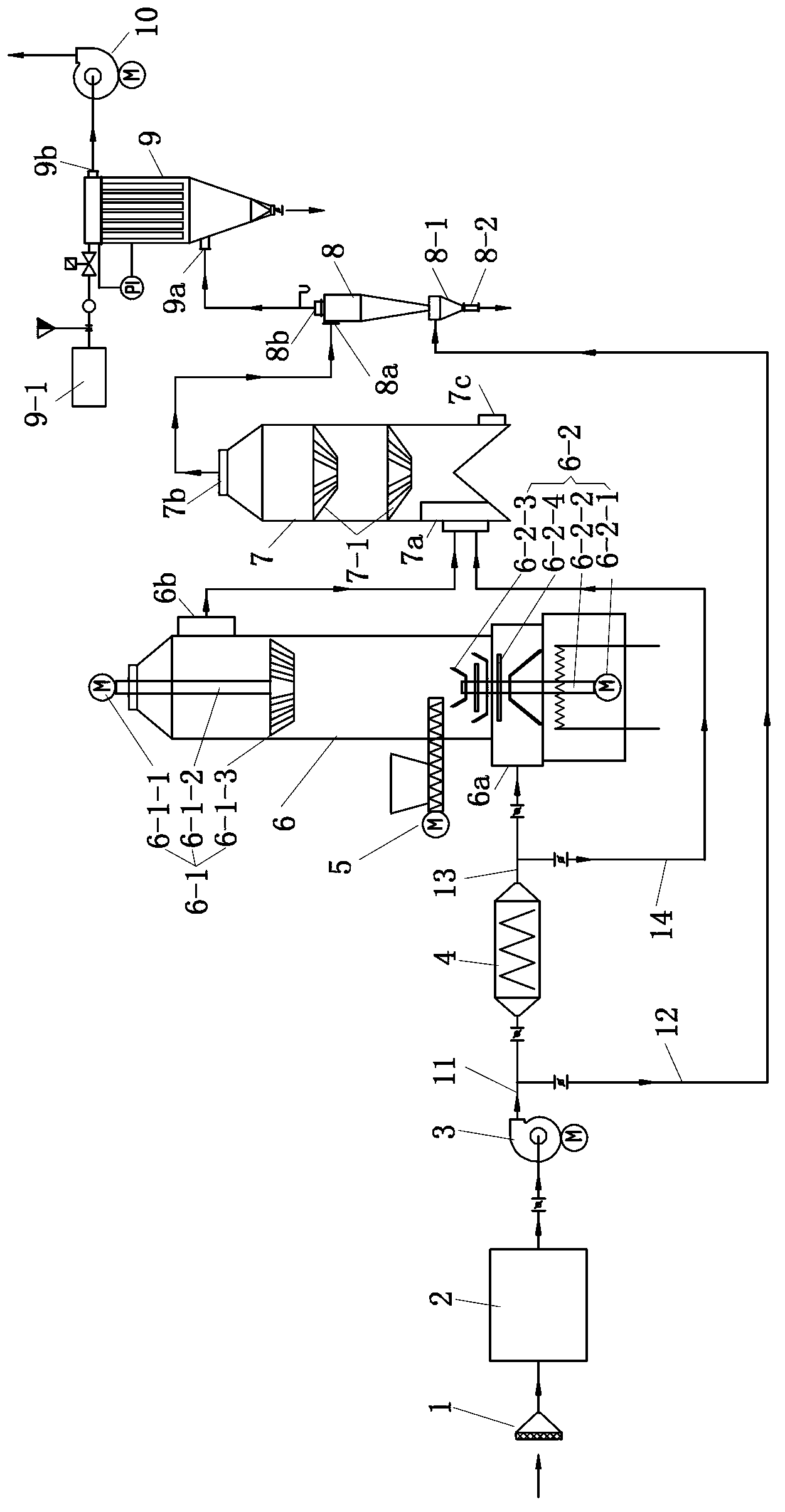

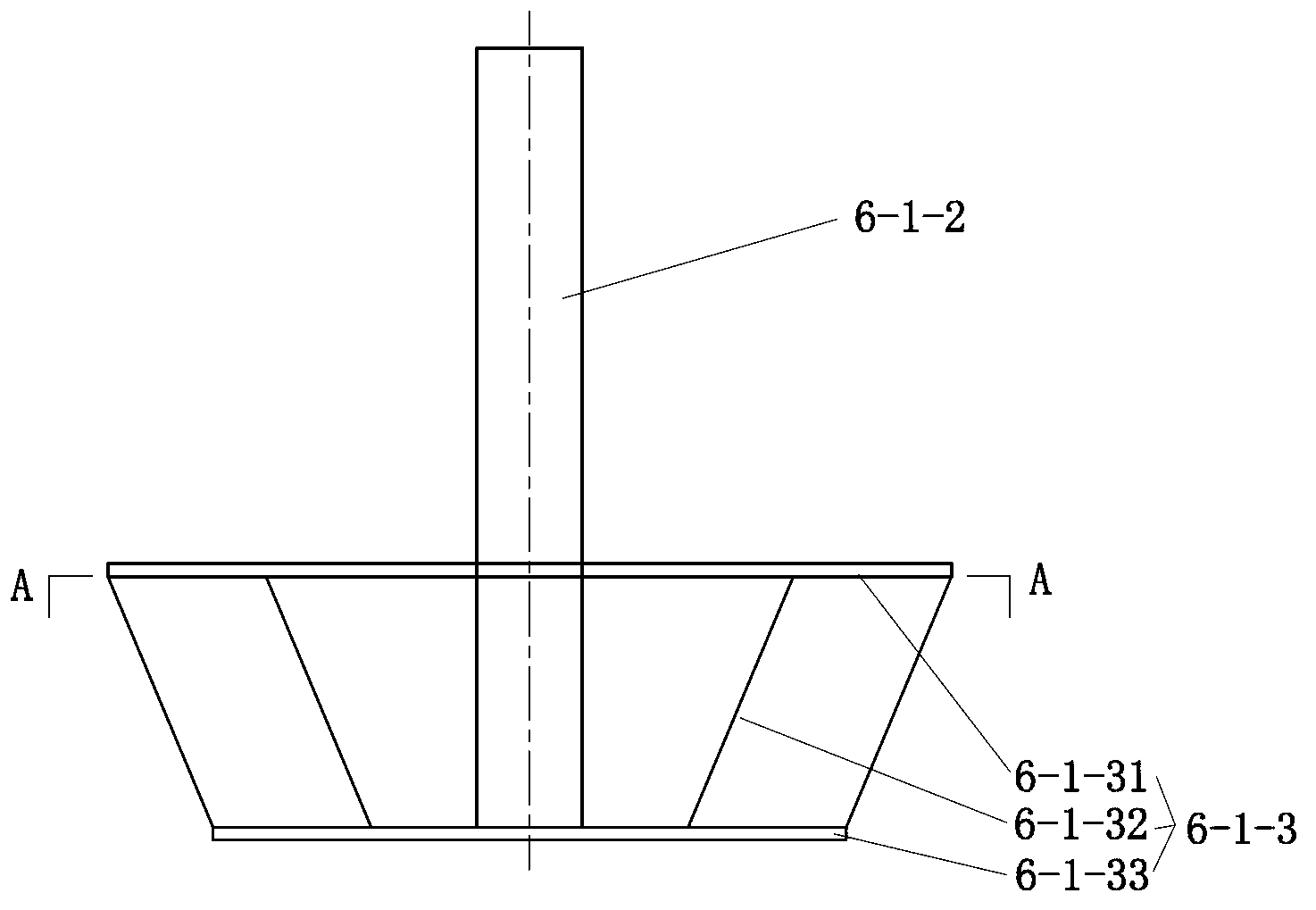

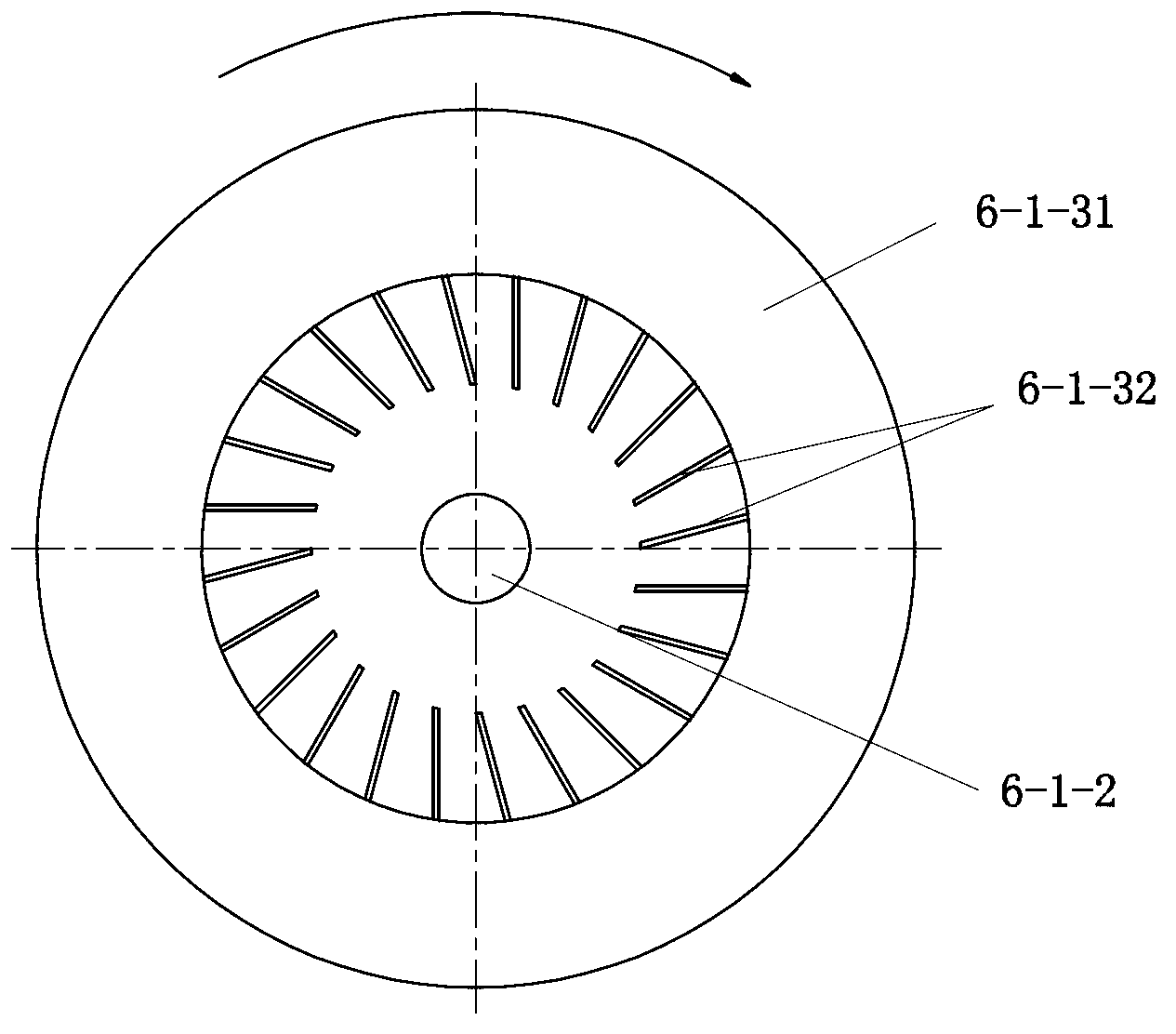

Closed cycle two-stage drying method and drying device of 1,3-cyclohexanedione

ActiveCN107976054AAir sealUniform feedingDrying machine combinationsDrying gas arrangementsGas solidDust explosion

The invention provides a closed cycle two-stage drying method and drying device of 1,3-cyclohexanedione. The closed cycle two-stage drying device of the 1,3-cyclohexanedione comprises a dryer, a gas-solid separator, a circulating fan, a heater, a feeding device, and a dehydrating device. Inert gases is adopted as drying carrier gas, the oxygen content of a system is strictly controlled, the dryingdevice has destaticization, the possibility of dust explosion during drying is reduced, and the security of a drying process of the 1,3-cyclohexanedione is enhanced; and a two-stage drying closed cycle technology is adopted, the energy consumption is effectively reduced, drying is more through, the water content of products is no more than 0.3%, the yield of the products is no less than 99.5%, the products are powdery particle from yellowish to white, block mass and impurities are inexistent, and the drying carrier gas closed cycle reduces the emission of harmful gases. The closed cycle two-stage drying method and drying device of the 1,3-cyclohexanedione has the advantages of low in energy consumption, good in production quality and high in process safety, and applies to the drying of flammable and combustible thermosensitive substance.

Owner:台州新农科技有限公司

Water removing and drying device for food processing

ActiveCN107843106ATake off quicklyEvenly heatedDrying machine combinationsFood preservationCooking & bakingSurface layer

The invention discloses a water removing and drying device for food processing. The water removing and drying device is reasonable and simple in structure, low in production cost, convenient to install and capable of rapidly removing water of food and shortening the baking time. A motor is used for driving rotation, agricultural products are heated evenly, the phenomena of surface layer dryness and inner layer damp are avoided, and the drying quality is guaranteed. Meanwhile, the whole agricultural and sideline product drying speed is increased, the service life of the machine is prolonged, the production cost is reduced, and the production efficiency is improved. The food enters from a feeding port, and when the food is conveyed in a conveying barrel, the water is filtered out from a screen, and after the food enters a spin-dry barrel, a rotation motor drives the spin-dry barrel to rotate, the water is thrown away, sliding wheels are moved, the spin-dry barrel is close to a drying barrel, an air pressure rod ascends, the spin-dry barrel pours out the food into the drying barrel, and steam in a steam engine conducts drying; after the food enters a sterilization barrel, an ultraviolet lamp is used for conducting sterilization and disinfection; and finally, the food is placed on a containing net on an air drying chamber to be subjected to air drying.

Owner:YANTAI SANXIN NEW ENERGY TECH CO LTD

High-efficiency energy-saving drying apparatus

InactiveCN101349497AIncrease profitWon't hurtDrying using combination processesDrying machine combinationsSocial benefitsThermal energy

The invention discloses a highly-effective energy-saving drying device, wherein an upper air inlet of an air flowing pipe which is arranged in a square vacuum drying cylinder of a vacuum dryer is communicated with the convection type hot-air drier through a draught fan, and a lower air outlet thereof is communicated with an air inlet of a vapor separator, the air inlet of the convection type hot-air drier is communicated with the air outlet of a heat exchanger, the air outlet of the vapor separator is communicated with the air inlet of the heat exchanger, the water outlet of the vapor separator is communicated with a water tank, the vacuum-pumping pipe of the square vacuum drying cylinder is communicated with a vacuum-pumping device after passing through a condenser, the water inlet and the water outlet of the condenser are both communicated with the water tank, the discharge port of the convection type hot-air direr is communicated with the feeding inlet of the square vacuum drying cylinder, and the heat source inlet and outlet of the heat exchanger are communicated with a heat source. The invention has the advantages of reasonable design, low energy consumption, excellent drying effect and high heat energy utilization, and favorable economic and social benefits.

Owner:COFCO ENG & TECH ZHENGZHOU +1

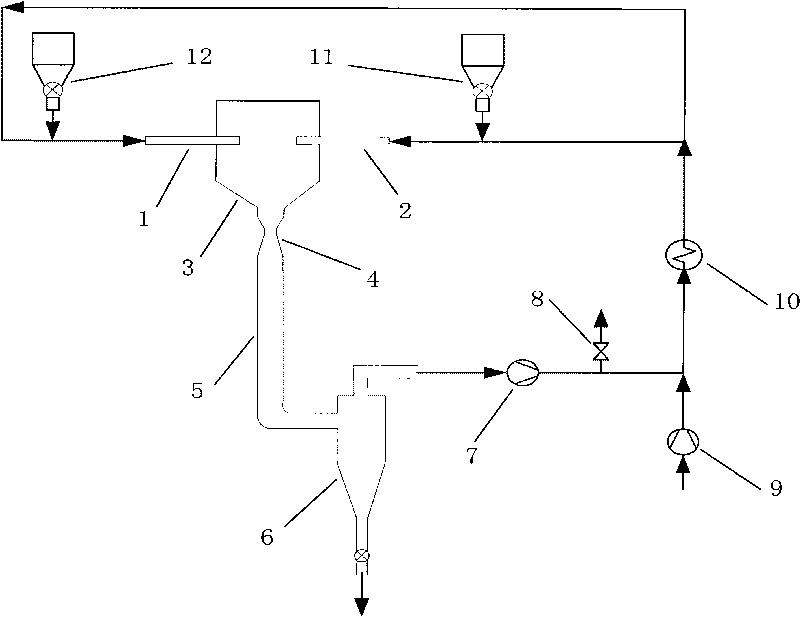

Airflow drying method and device for dispersed material

ActiveCN101726160AExtended intensive drying timeImprove utilization efficiencyDrying solid materials with heatDrying machine combinationsCycloneGas solid

The invention relates to airflow drying method and device for a dispersed material. The method is characterized in that the material is dried in a way of combining an impinging stream and a gas-solid cocurrent downlink bed, and the material is firstly subjected to an initial drying in an impinging stream contactor and then enters the gas-solid cocurrent downlink bed to exchange heat and mass witha drying medium to finish the drying process. The device comprises an impinging stream contactor cylinder body, wherein two airflow accelerating pipes are correspondingly arranged on the cylinder body; the lower end of the cylinder body is connected with the vertical gas-solid cocurrent downlink bed by a Venn distributor, and the lower end of the gas-solid cocurrent downlink bed is connected witha cyclone separator. Compared with a simple impinging stream drying method, the invention can prolong the strengthened drying time of the material and improve the utilization efficiency of a heat medium; and compared with a raising pipe airflow drying way, the gas-solid cocurrent downlink bed has evener gas-solid radial distribution and low agglomeration degree of particles and can effectively overcome the axial back mixture of the particles. The invention also has the characteristics of simple and compact device and simple and convenient operation.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Cyclonic flash drying device

InactiveCN103322784AIncrease collection rateDisperse fastDrying machine combinationsDrying gas arrangementsCycloneAir filter

A cyclonic flash drying device comprises an air filter, an air dehumidifier, an air blower, an air heater, a screw feeder, a drying main machine, an impact type cyclone drying tower, a cyclone separator, a dust catcher and an induced draft fan. High temperature low-humidity air output by the air blower is divided into two ways, one way leads to the air heater, the other way leads to a Dukang cone arranged on the upper portion of a discharge outlet of the cyclone separator, hot air output by the air heater is divided into two ways, one way leads to an air inlet of the drying main machine, the other way leads to an air inlet of the impact type cyclone drying tower, a dynamic flow stabilizing ring is arranged on the portion of the inside of a cylindrical body of the drying main machine, a lifting type stirrer is disposed on the lower portion of the inside of the cylindrical body of the drying main machine, upper and lower layers of impact type cyclone rings are fixed on the inner wall of the impact type cyclone drying tower, the screw feeder extends into the drying main machine, and a discharge outlet is located above the lifting type stirrer. The collection efficiency of finished products can be improved through the drying device, and the drying device is suitable for production drying technologies for products containing high sugar and grease.

Owner:CHANGZHOU LEMAR DRYING ENG

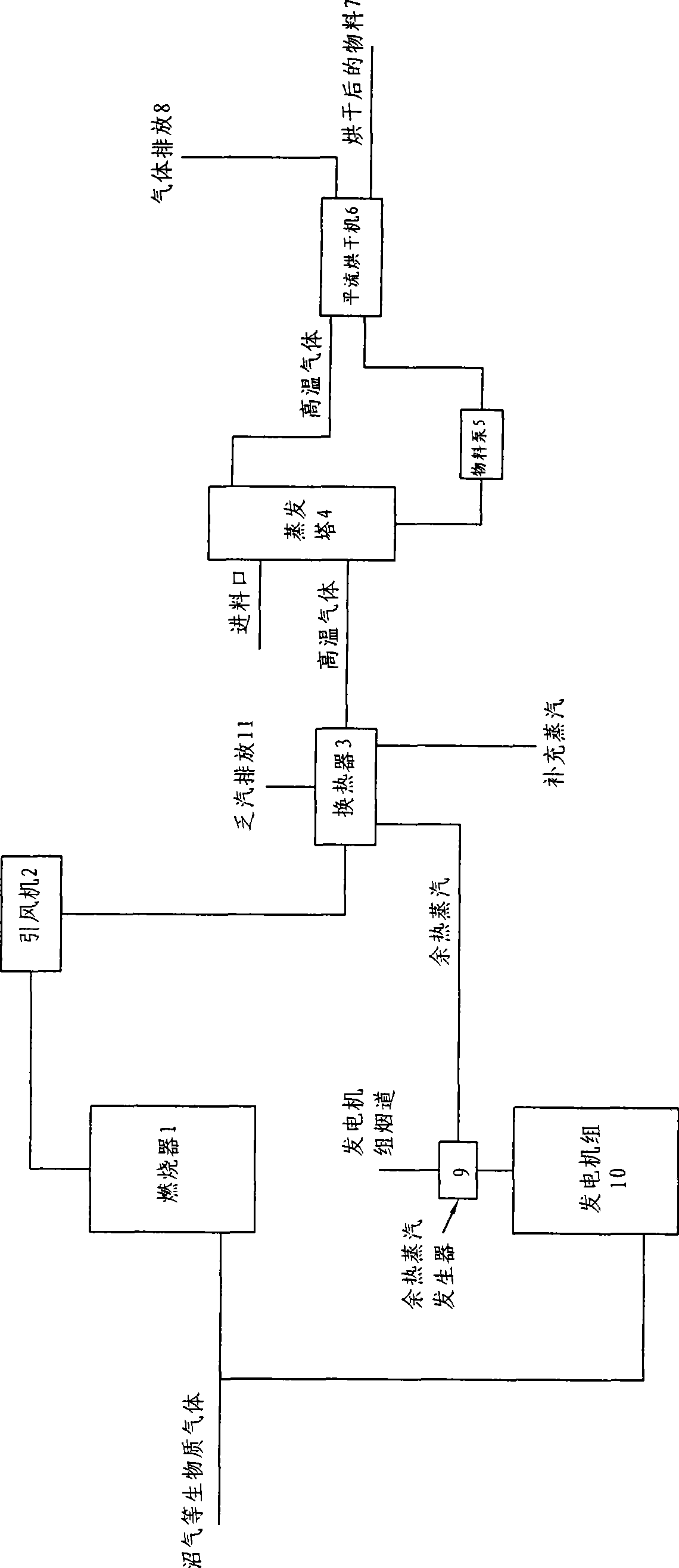

Biomass gas and exhaust heat combination type materiel drying system

InactiveCN101482363AReduce usageConducive to energy saving and emission reductionDrying machine combinationsDrying gas arrangementsCombustorProduct gas

The present invention provides a biomass gas and a residual-heat composite material drying mechanism. The invention is characterized in that the gas inlet end of combustor is connected with the gas source of biomass gas through a pipeline. The output of the combustor is connected with the gas suction opening of a draft fan through the pipeline. The output of the draft fan is connected with one gas inlet of a heat exchanger. The heat exchanger is also connected with a steam gas source for supplying steam and / or residual heat steam gas source through the pipeline. The output of the heat exchanger is connected with the gas inlet at the lower part of a vertical evaporator tower. The upper part of the vertical evaporator tower is installed with a dried material inlet. The lower part of the evaporator tower is provided with a material discharge opening and is connected with the material inlet end of a material pump through a conveying tube. The material discharge end of the material pump is connected with the material inlet end of a horizontal flow dryer. The upper part of evaporator tower is installed with a high temperature gas outlet opening which is led to the material inlet opening of the horizontal flow dryer or the lower part of the conveyor belt through the pipeline for further heating and drying the material in the horizontal flow dryer. The outlet end of horizontal flow dryer is connected with the subsequent material conveying device and is connected with a gas discharge tube. The biomass gas and a residual-heat composite material drying mechanism of the invention has the advantages of simple structure, easy realization, contribution to energy conservation and emission reduction and reduction of production cost.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com