Water removing and drying device for food processing

A technology for dehydration drying and food processing, applied in drying, drying machines, food preservation, etc., can solve the problems of slow production line efficiency, no dehydration equipment, increased production costs, etc., to improve production efficiency, reduce The effect of baking time and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

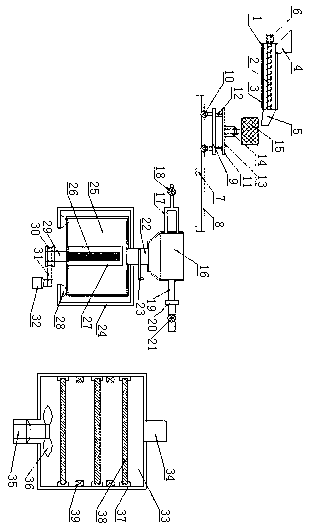

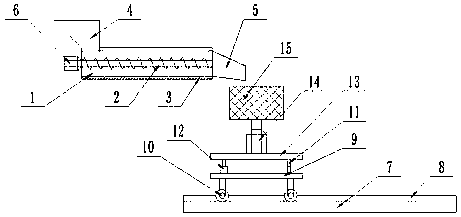

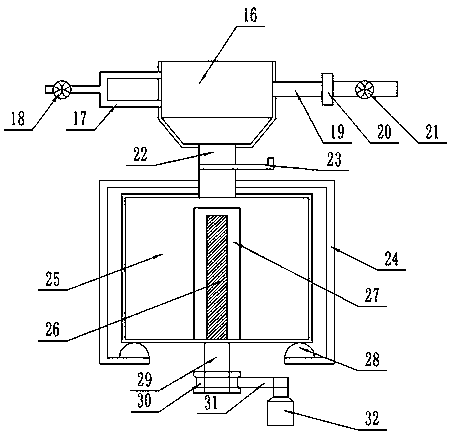

[0019] Such as figure 2 As shown, this specific embodiment adopts the following technical solutions: a dehydration and drying device for food processing, including a conveying cylinder 1, a screw shaft 2, a screen 3, a feed port 4, a discharge port 5, and a transport motor 6 , base 7, slide rail 8, lower fixed plate 9, pulley 10, follower rod 11, air pressure rod 12, upper fixed plate 13, rotating motor 14 and drying cylinder 15; There is a screw shaft 2; the inner lower end of the chamber of the delivery cylinder 1 is provided with a screen 3; the left side of the upper end of the delivery cylinder 1 is fixedly communicated with a feed port 4; the right side of the delivery cylinder 1 is fixedly communicated with There is a discharge port 5; the left side of the conveying cylinder 1 is fixedly connected with a transport motor 6; the output shaft of the transport motor 6 is connected with the screw shaft 2; the upper surface of the base 7 is fixedly connected with a Slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com