Method and device for drying and quality enhancement of lignite

A lignite drying technology, which is applied in the direction of drying machine combination, drying solid materials, heating to dry solid materials, etc., can solve the problem of uneven drying effect of lignite, achieve high-efficiency quality improvement and comprehensive utilization, low energy consumption, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

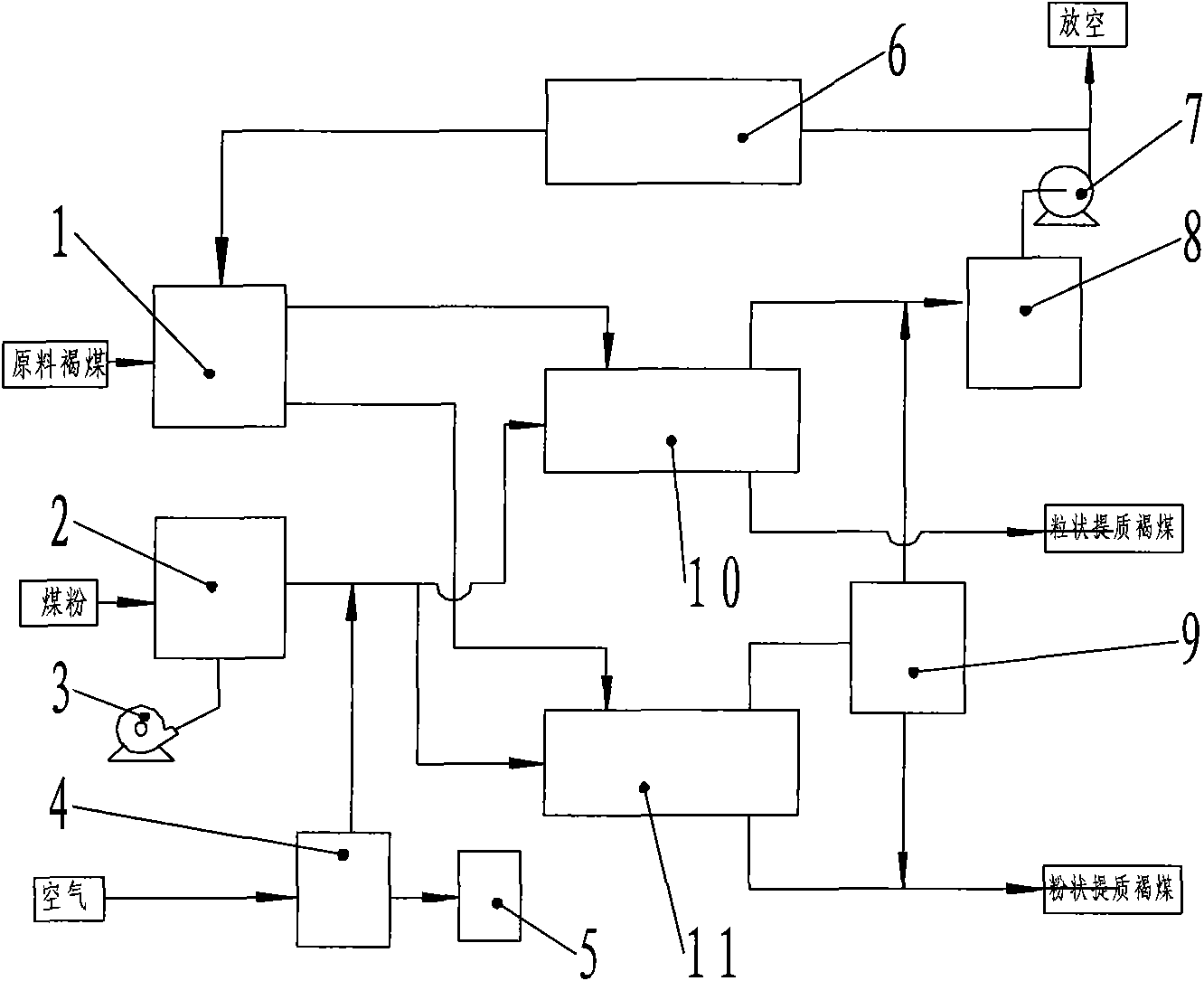

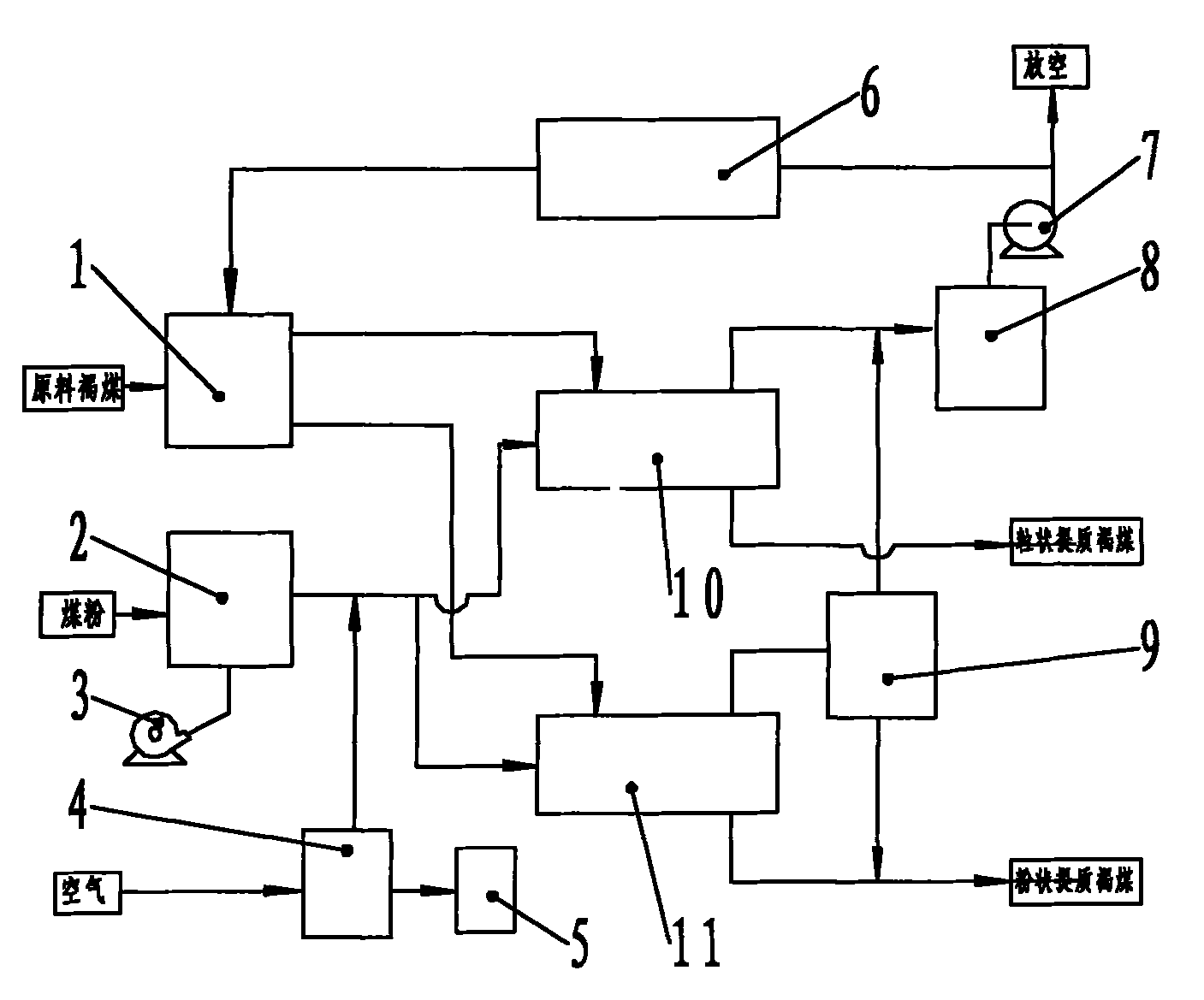

[0019] The lignite drying and upgrading device of the present invention is as figure 1 As shown, it is mainly composed of pre-drying / screening device 1, hot blast stove 2, drying drum 10, vibrating fluidized bed 11, cyclone separator 9, dust collector 8, and mist eliminator 6. The hot air stove is respectively connected to the drying drum and the vibrating fluidized bed to provide dry hot air for the drying drum and the vibrating fluidized bed. The inlet of the pre-drying / screening device is connected with the lignite raw material bin, and the outlet is respectively connected with the drying drum and the vibrating fluidized bed. The product outlet of the drying drum 10 is connected to the large-diameter lignite product storehouse outside the device, and the gas outlet is connected to the dust collector 8 . The product outlet of the vibrating fluidized bed 11 is connected to the small-diameter lignite product bin, and the gas outlet is connected to the dust collector through t...

Embodiment 2

[0022] The process flow of the lignite drying and upgrading device in this example is the same as that in Example 1, the sieve opening of the pre-drying / sifter vibrating screen is 10mm, and the preheating temperature is 150-200°C. The lignite with large particle size larger than 10mm is dried in the drying drum 10. The flue gas temperature at the inlet of the drying drum is 350°C, and the outlet temperature is 280°C. After drying, the moisture content of the lignite drops below 10%. The lignite with a small particle size less than 10mm is dried in the vibrating fluidized bed 11. The flue gas temperature at the inlet of the vibrating fluidized bed is 350°C, and the outlet temperature is 260°C. After drying, the moisture content of the lignite drops below 8%. Others are the same as in Example 1.

Embodiment 3

[0024] The sieve hole of the pre-drying / sifter vibrating screen is 15mm, and the preheating temperature is 200-250°C. The lignite with a large particle size larger than 15mm is dried in the drying drum 10, and the flue gas temperature at the inlet of the pre-drying / sieving device is 400°C , the outlet temperature is 330°C, and the moisture content of the lignite after drying is reduced to below 10%; the lignite with a small particle size less than 15mm is dried in the vibrating fluidized bed 11, the flue gas temperature at the entrance of the vibrating fluidized bed is 400°C, and the outlet temperature is 310°C °C, the moisture content of the lignite drops below 10% after drying. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com