Patents

Literature

160 results about "Quality enhancement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality enhancement is therefore seen as an aspect of institutional quality management that is designed to secure, in the context of the constraints within which individual institutions operate, steady, reliable and demonstrable improvements in the quality of learning opportunities” (QAA 2006).

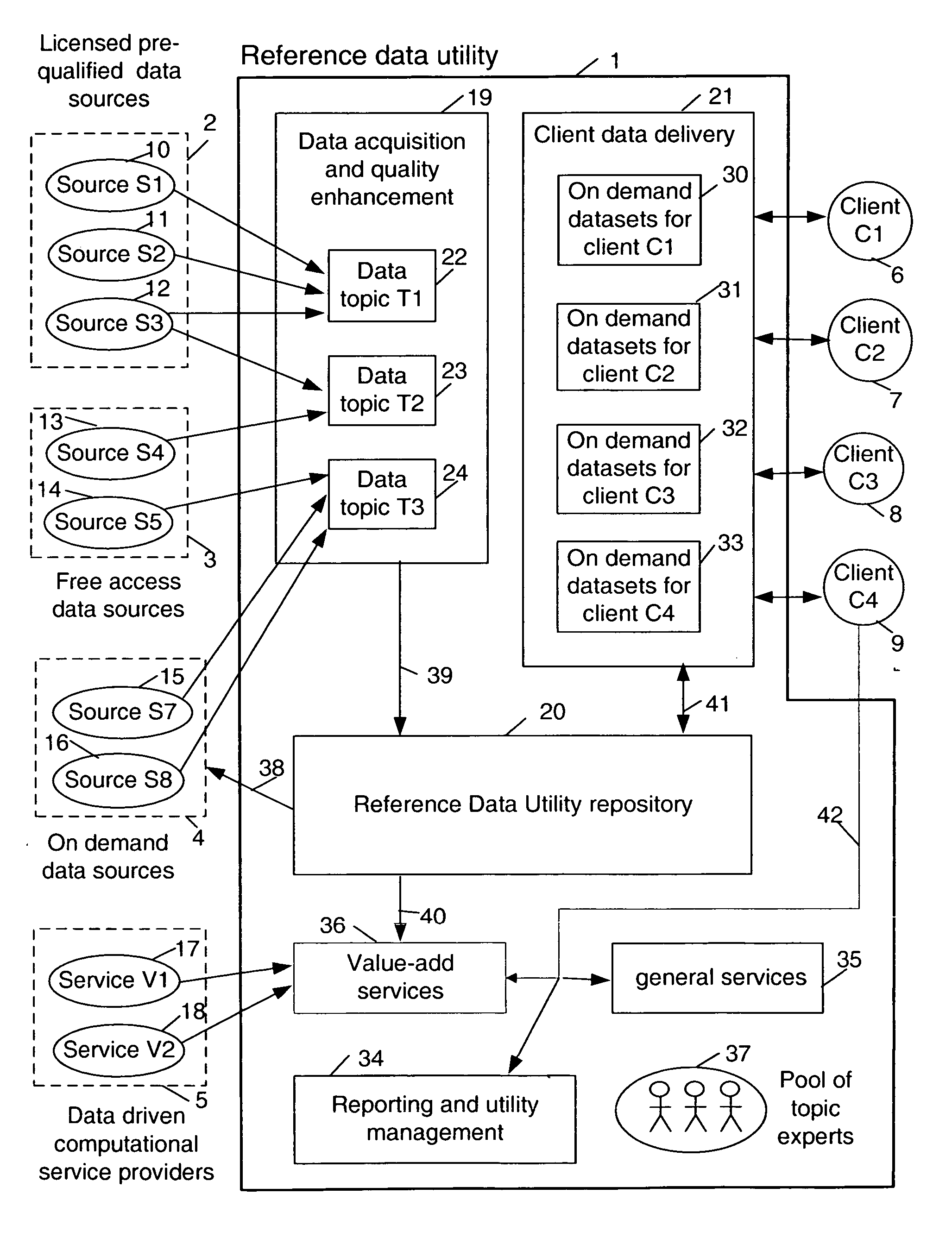

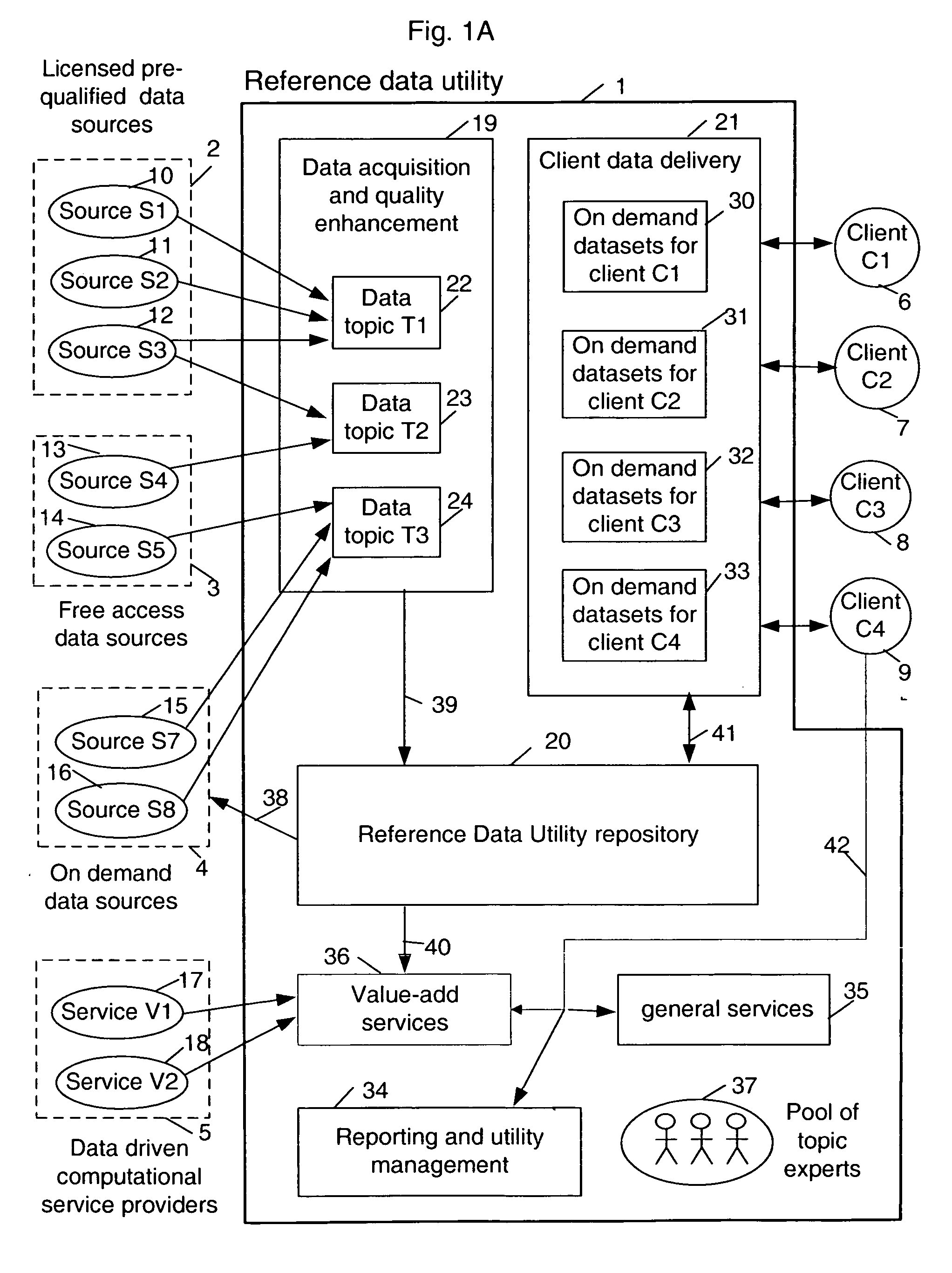

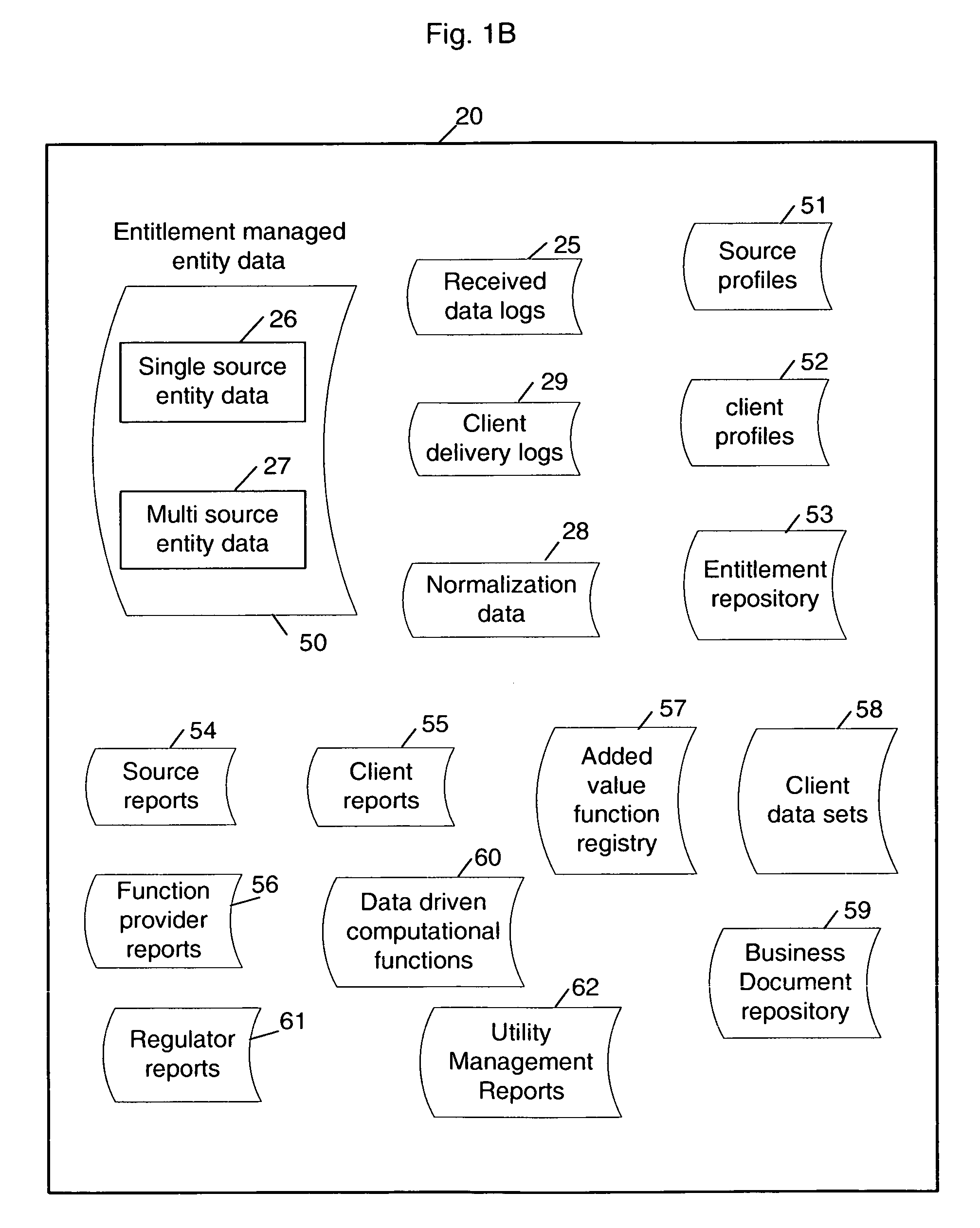

Multi-source multi-tenant entitlement enforcing data repository and method of operation

InactiveUS20060235831A1Easy to optimizeLow costFinanceSpecial data processing applicationsData qualityData store

Forming and maintaining a multi-source multi-tenant data repository on behalf of multiple tenants. Information in the multi-source multi-tenant data repository is received from multiple sources. Different sources and different data quality enhancement processes may yield different values for attributes of the same referred entity. Information in the multi-source multi-tenant data repository is tagged with annotations documenting the sources of the information, and any data quality processing actions applied to it. Tenants of the multi-source multi-tenant data repository have entitlement to values from some sources and to the results of some quality enhancement processes. Aspects of the method maintain this entitlement information; employ evolutionarily tracked source data tags; receive requests for information, locate the requested information, apply any sourcing preference, enforce entitlements and return entitled values to the requester. An outsourced reference data utility is one context where such a multi-source multi-tenant data repository is useful.

Owner:ADINOLFI RONALD EMMETT +9

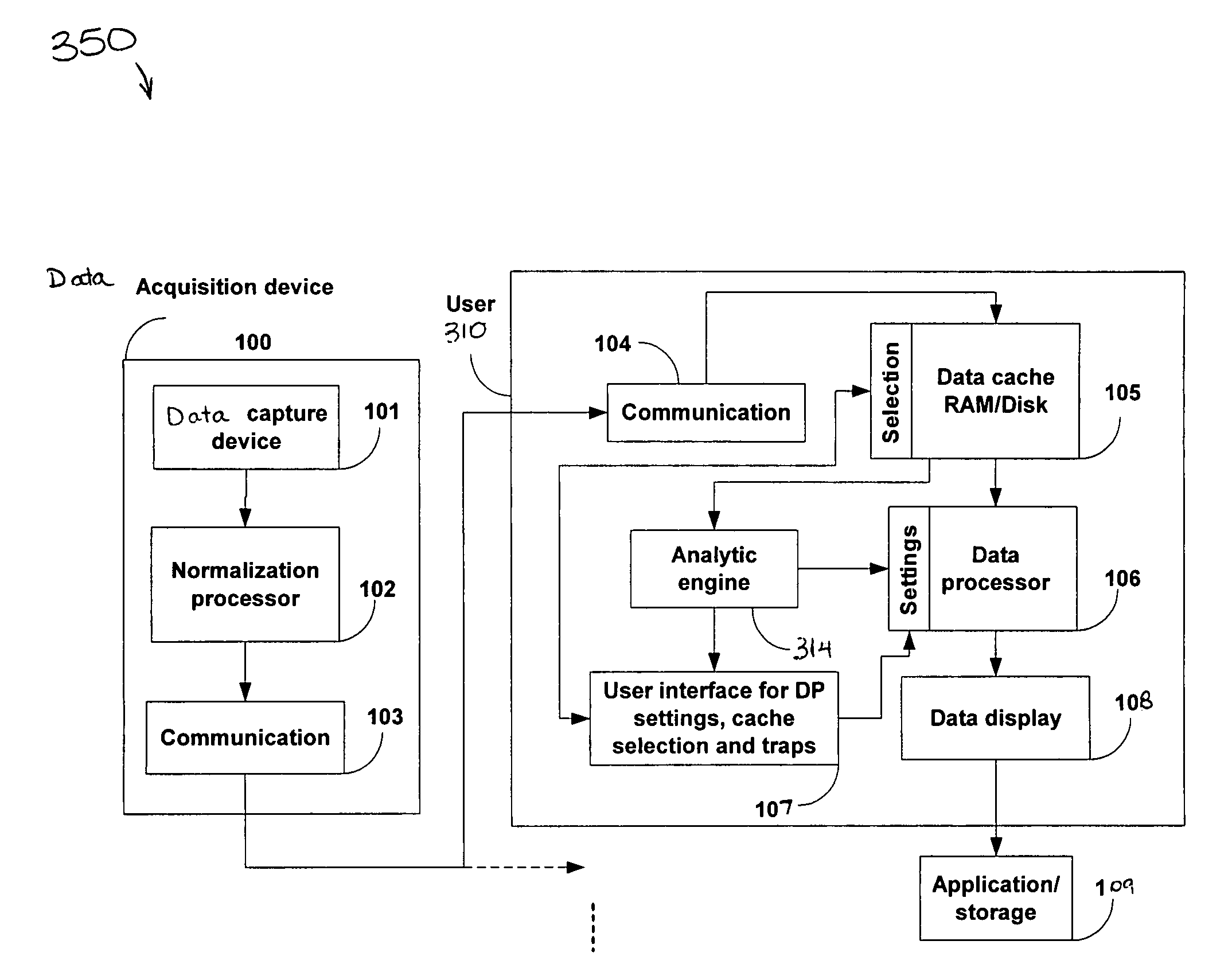

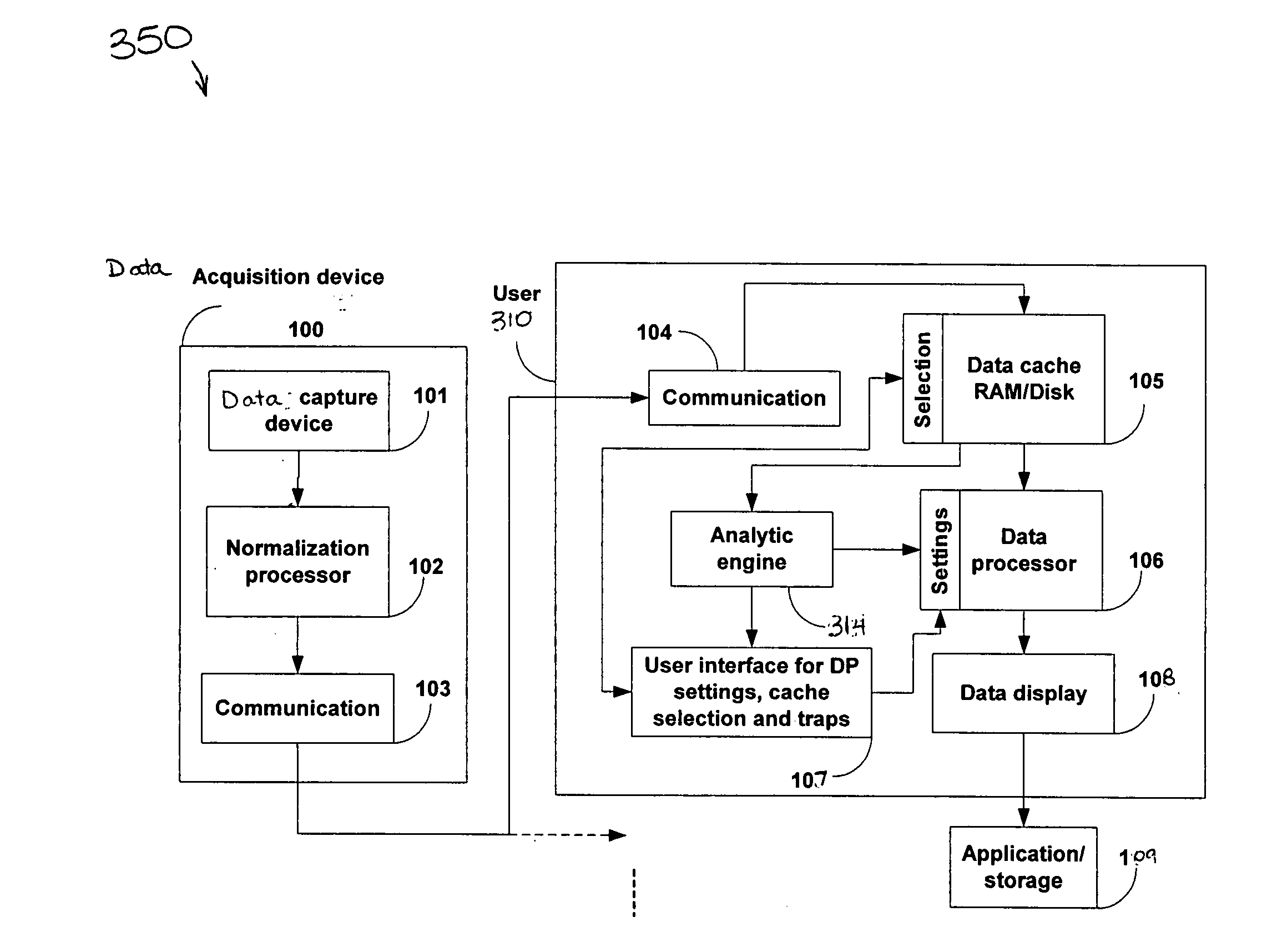

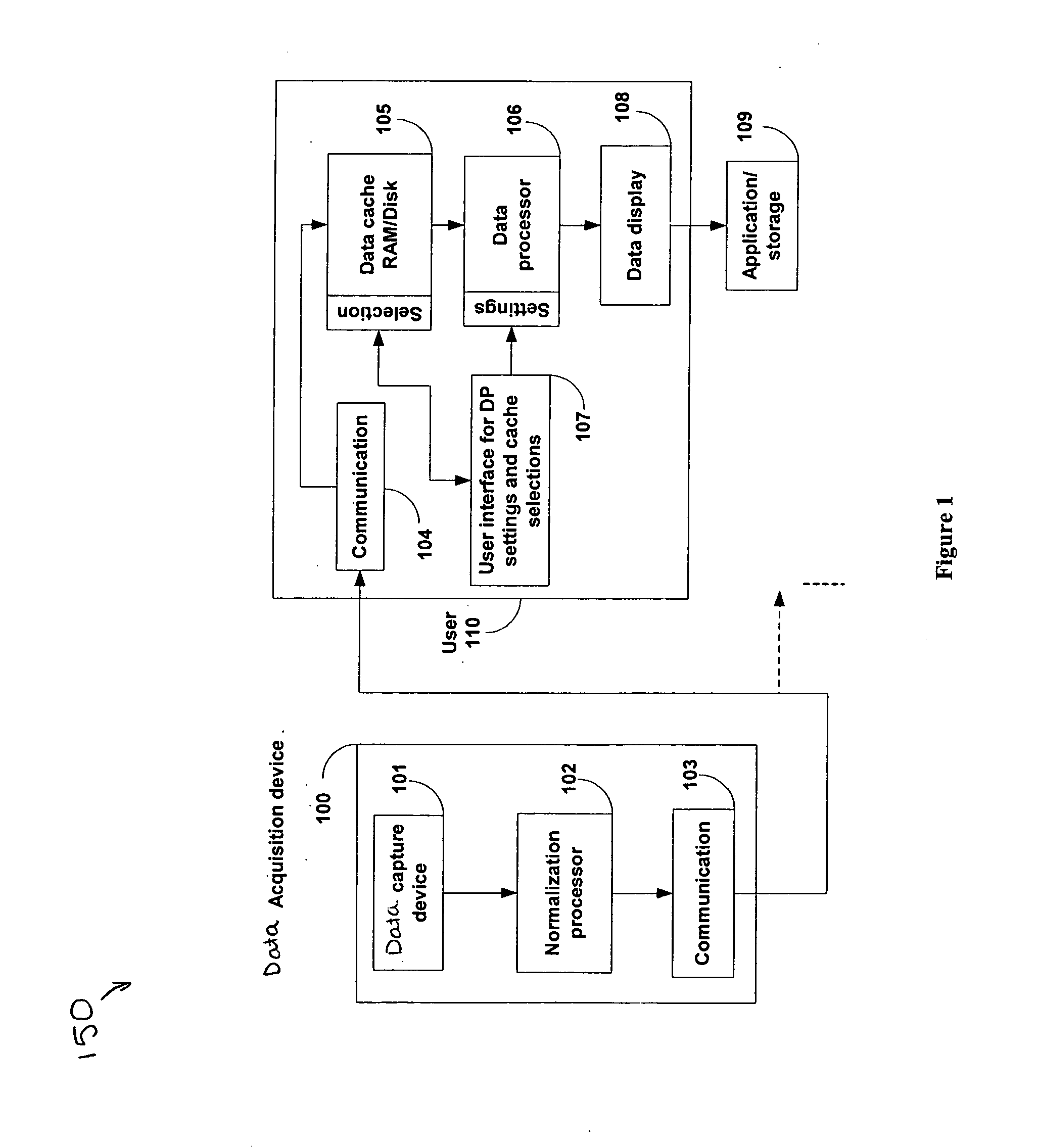

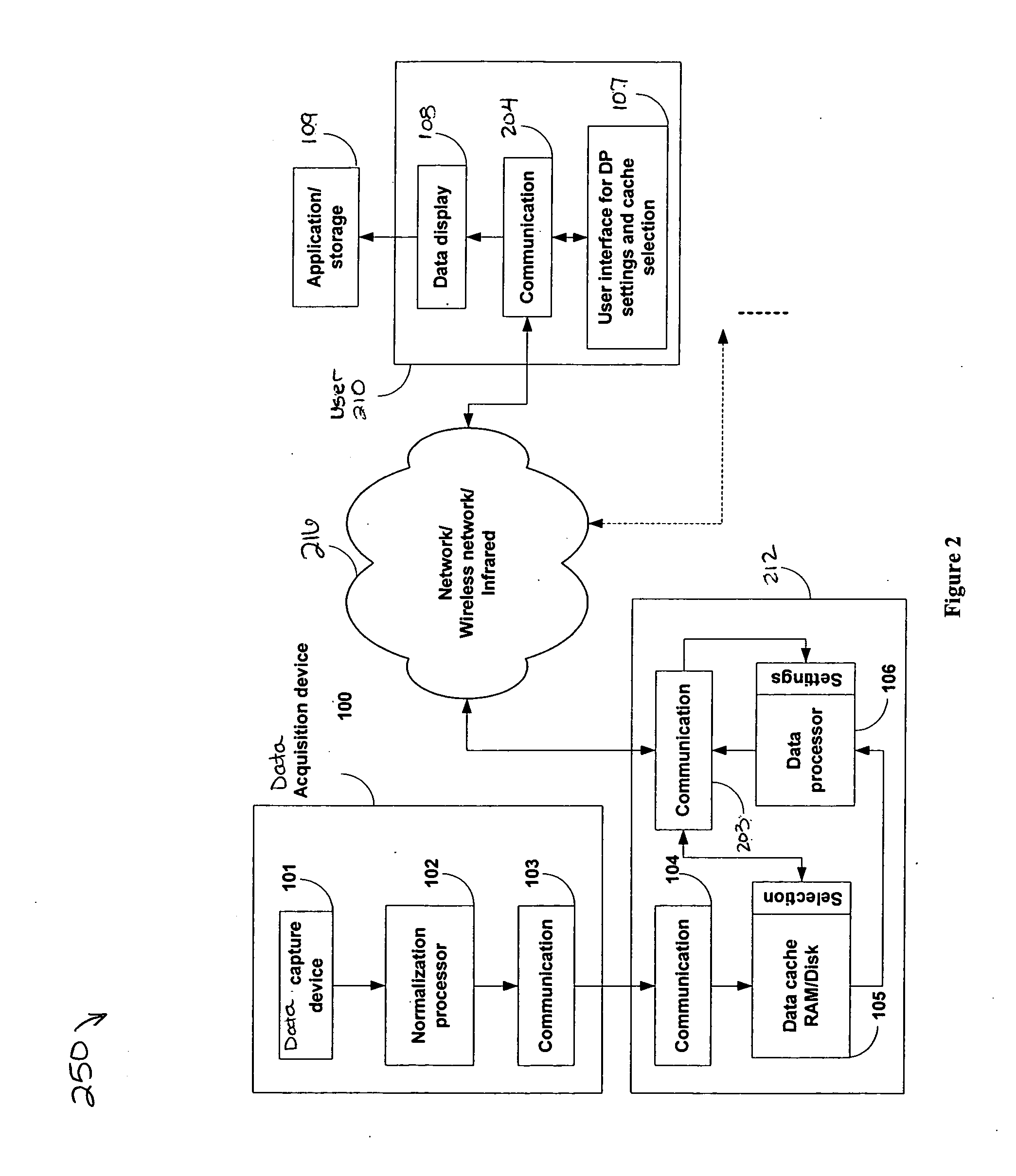

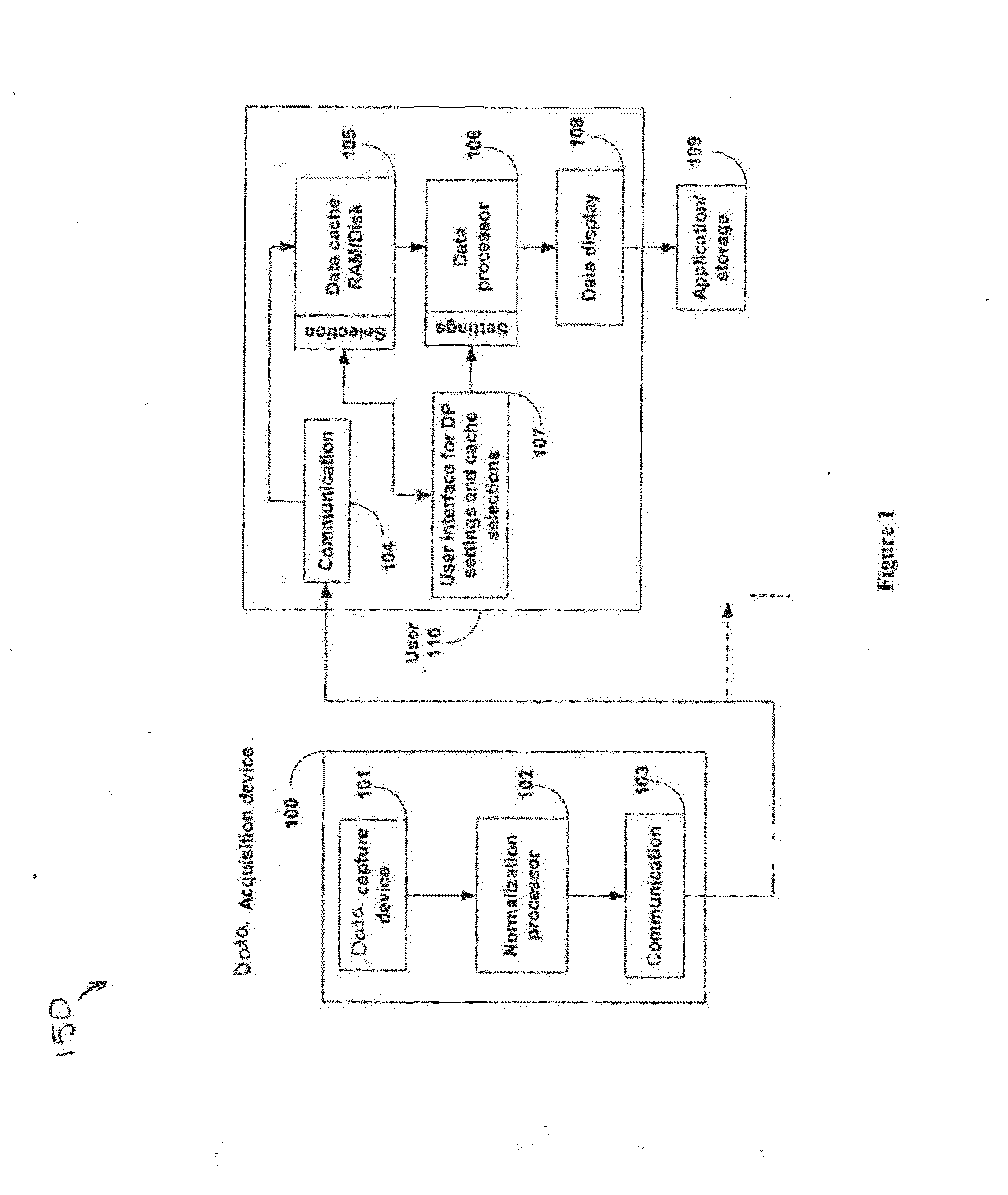

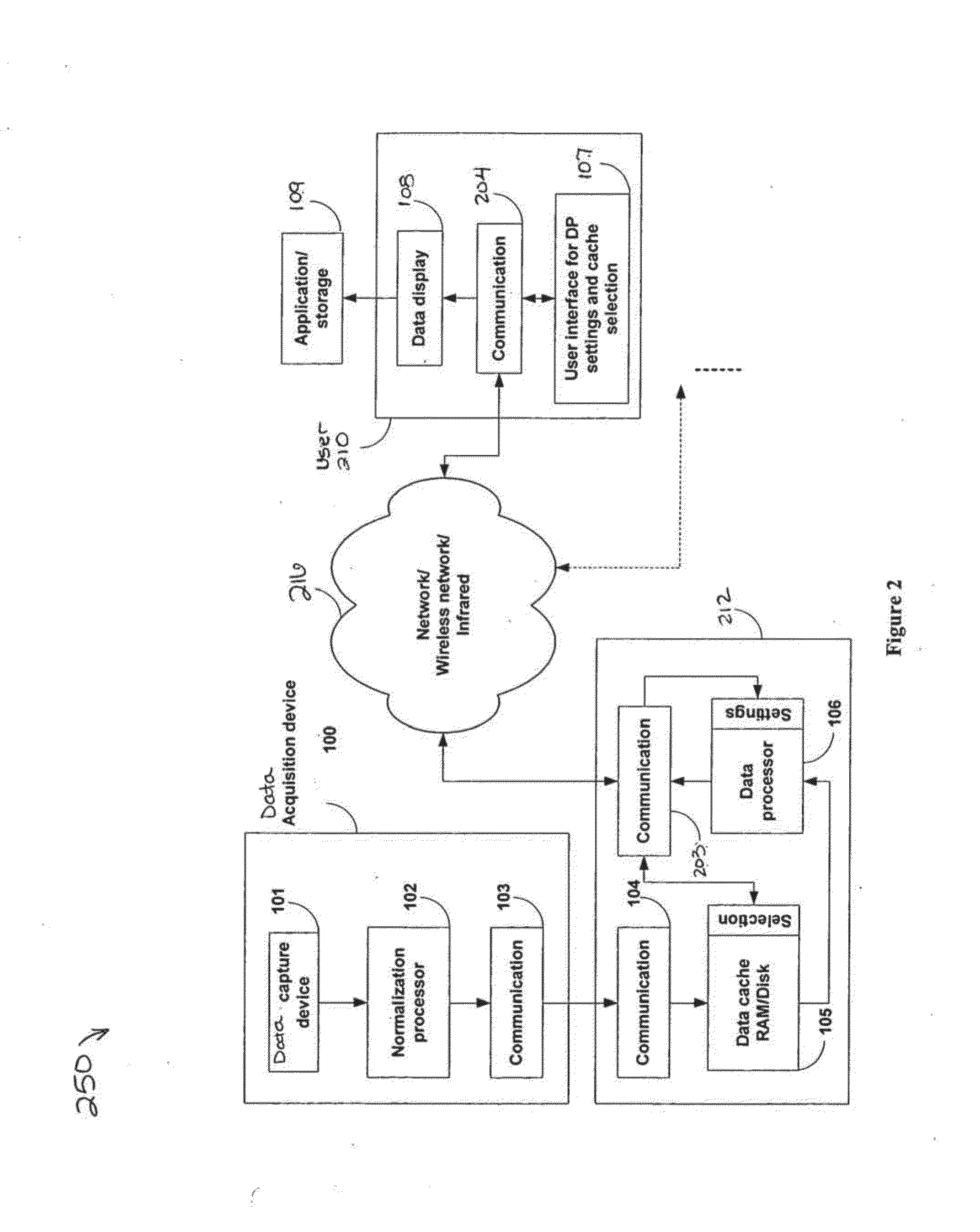

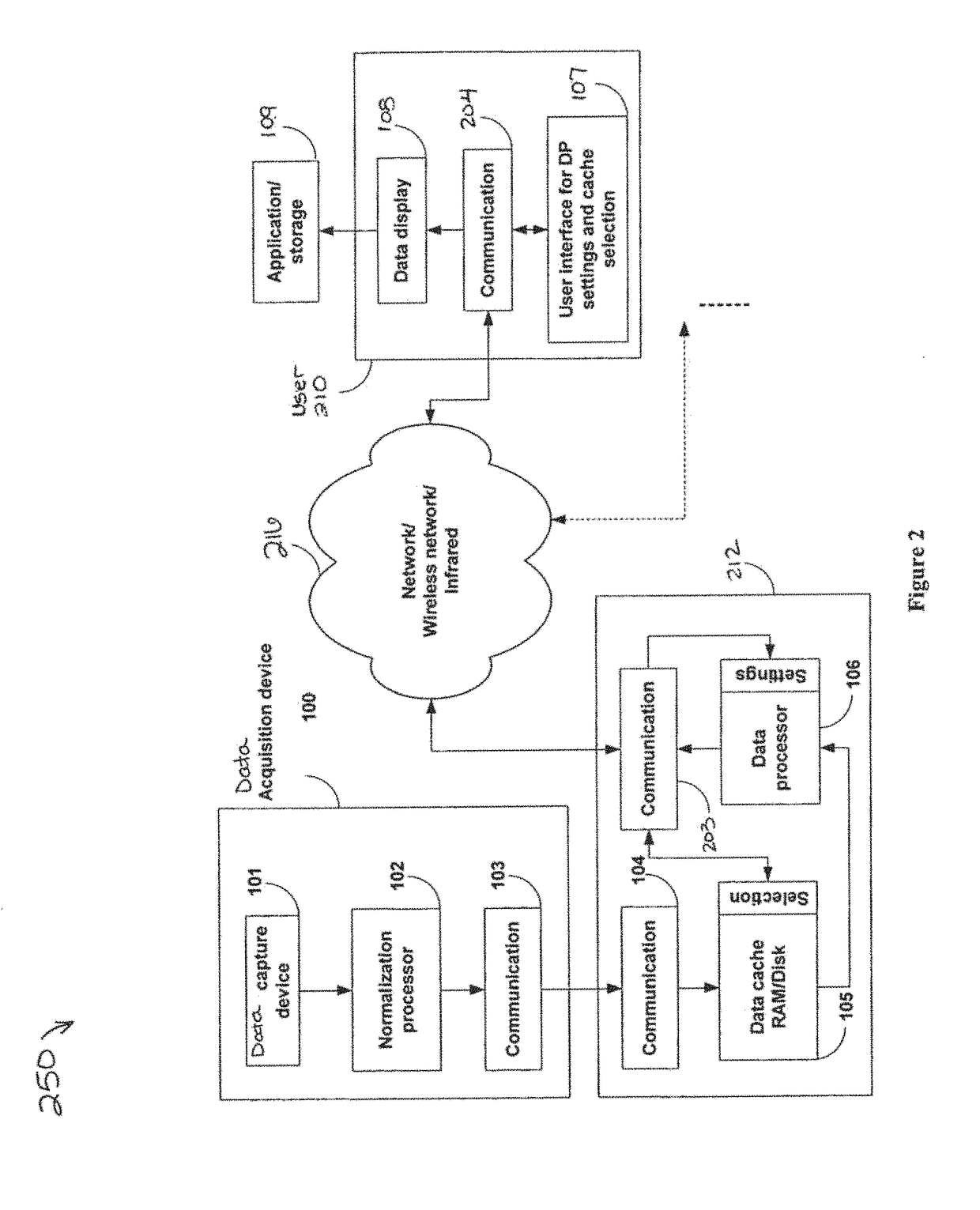

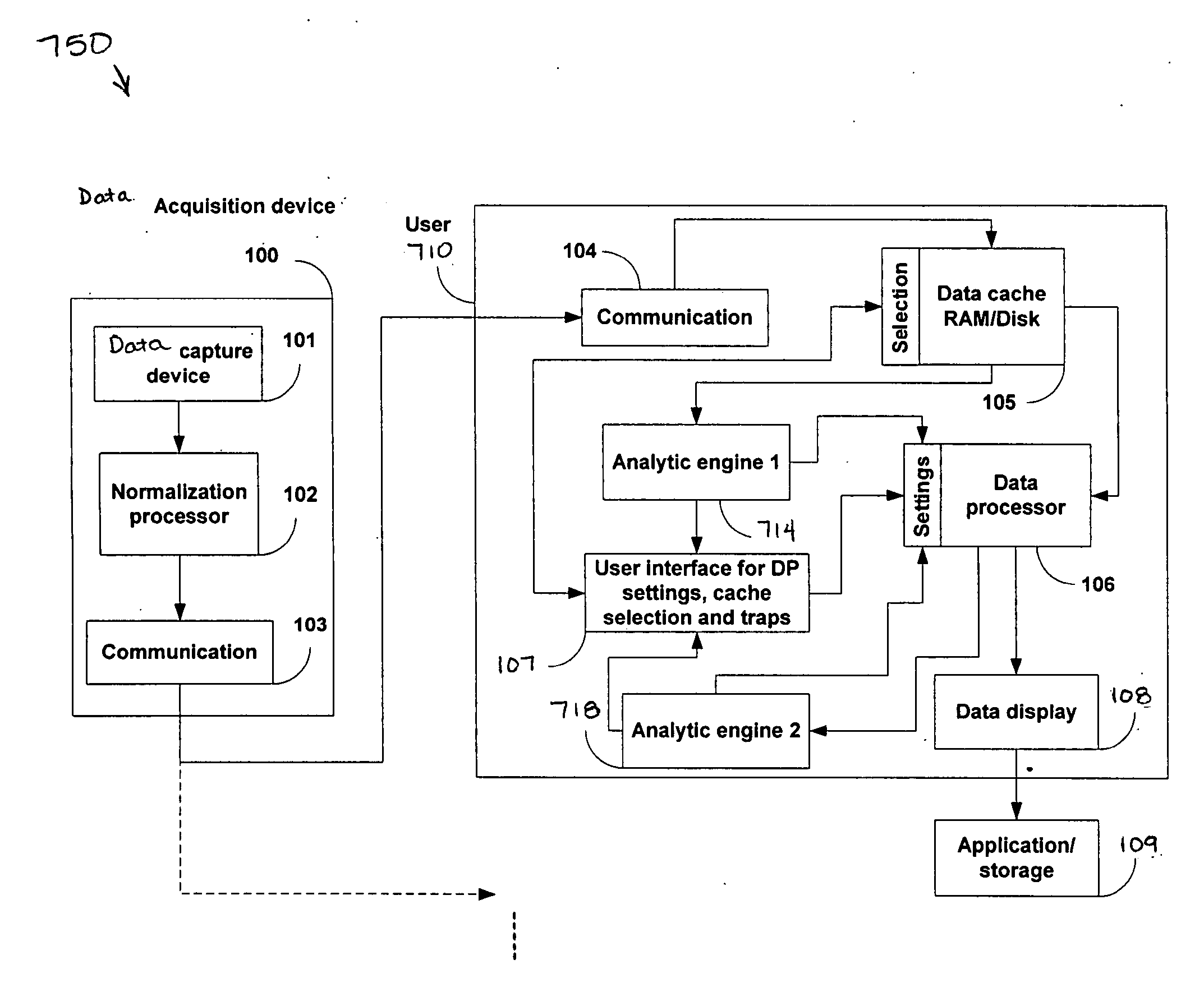

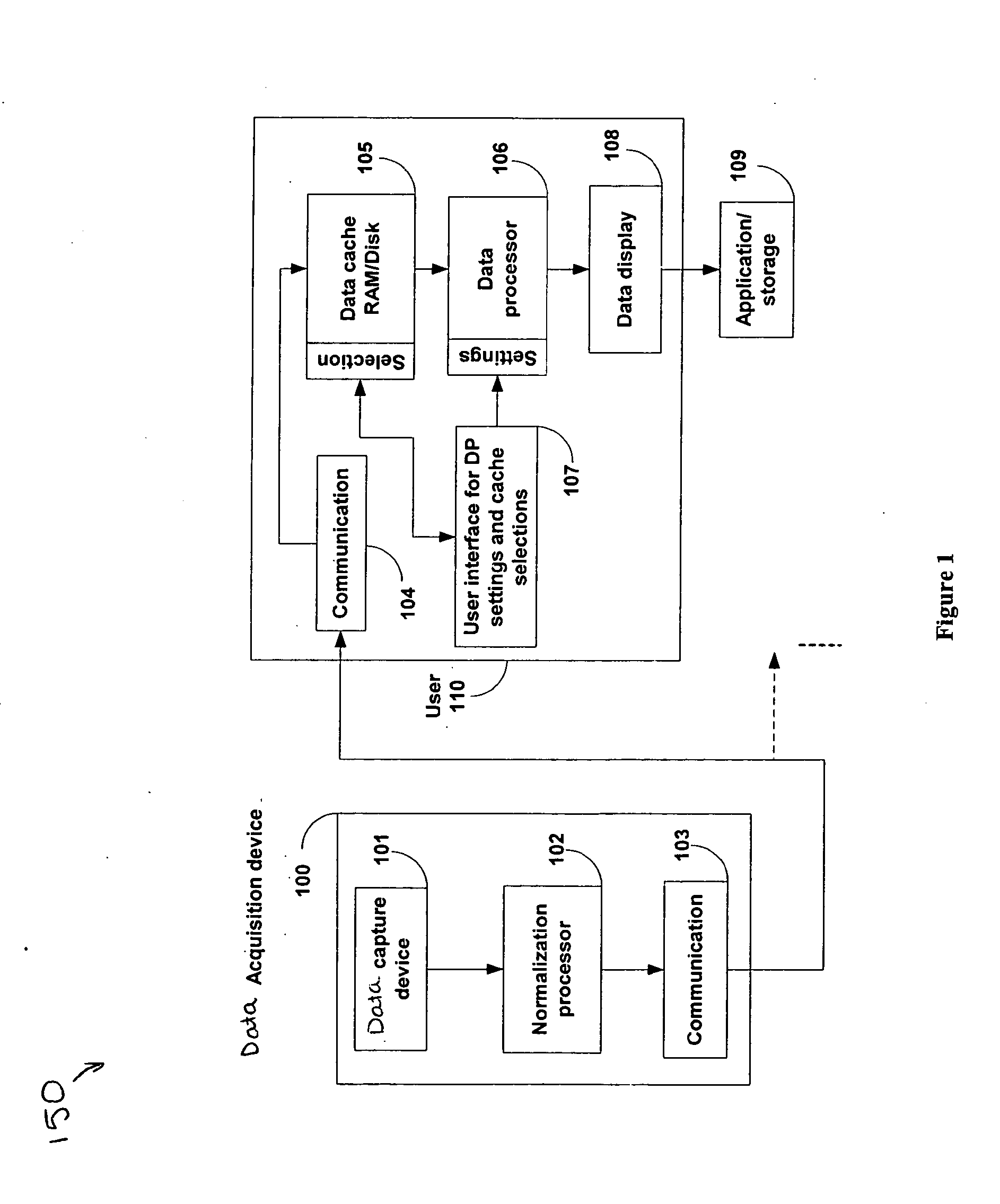

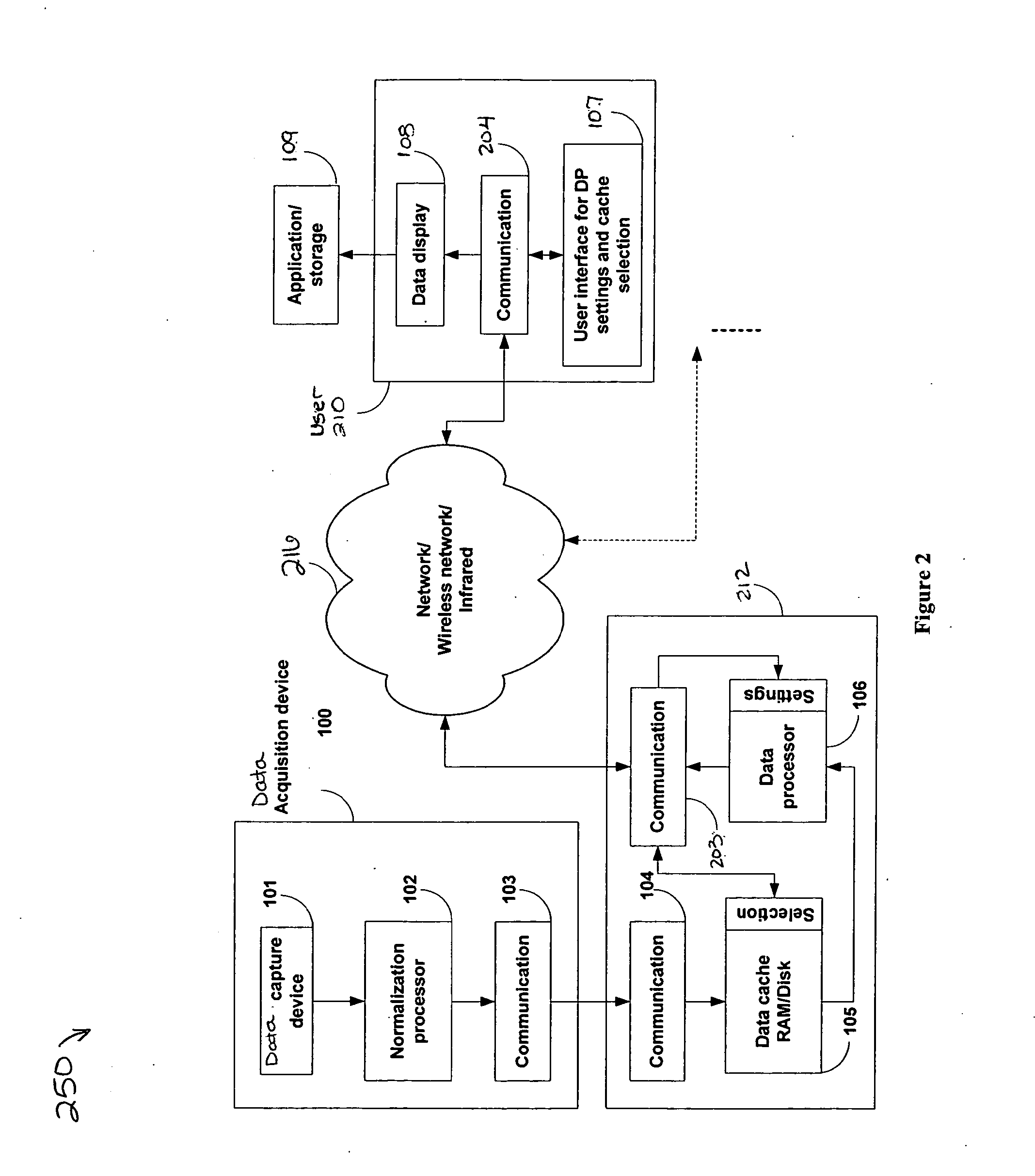

Systems and methods of accessing random access cache for rescanning

ActiveUS7545529B2Data augmentationAdvantages with regard to speedDigitally marking record carriersDigital computer detailsDigital dataNon real time

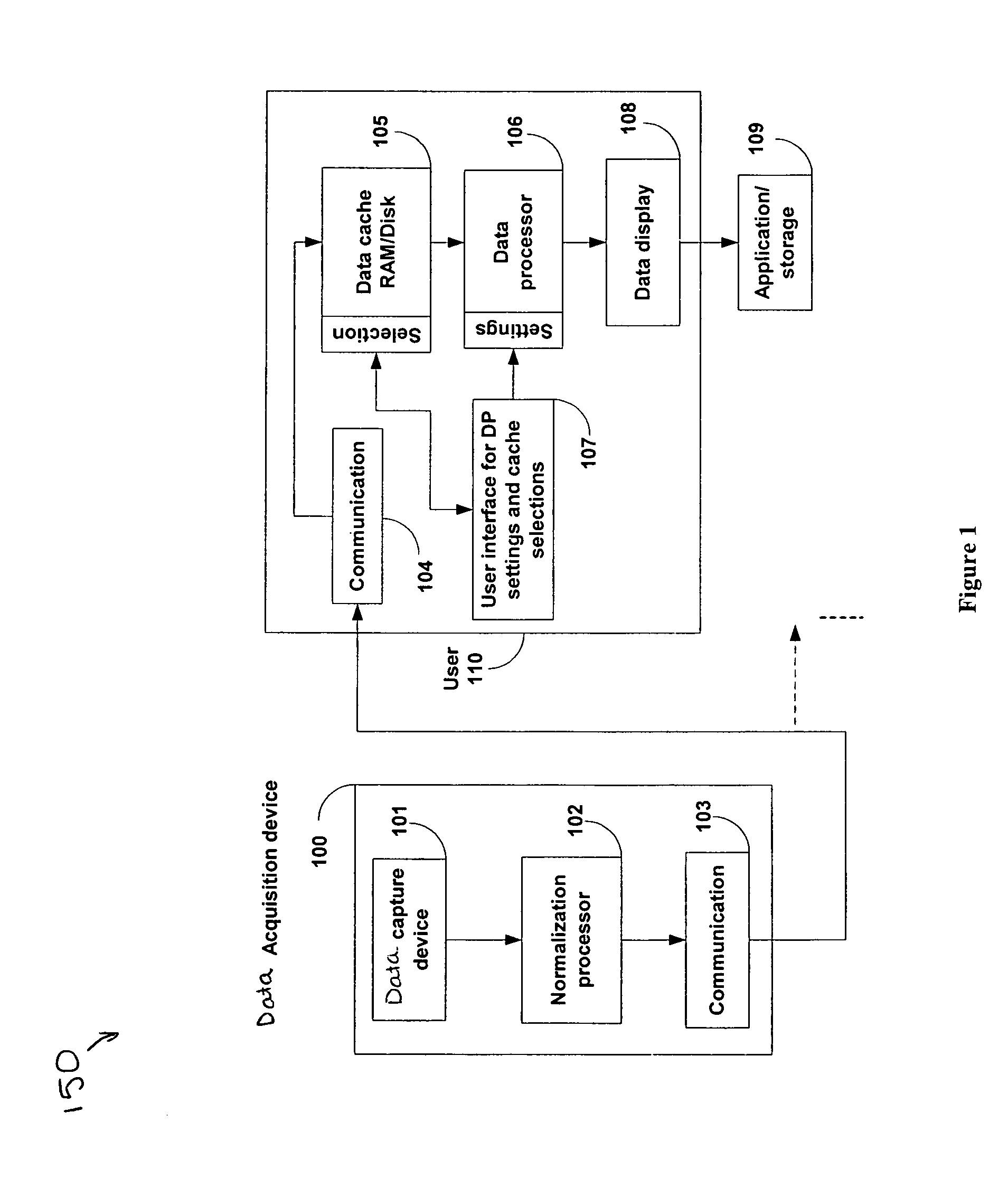

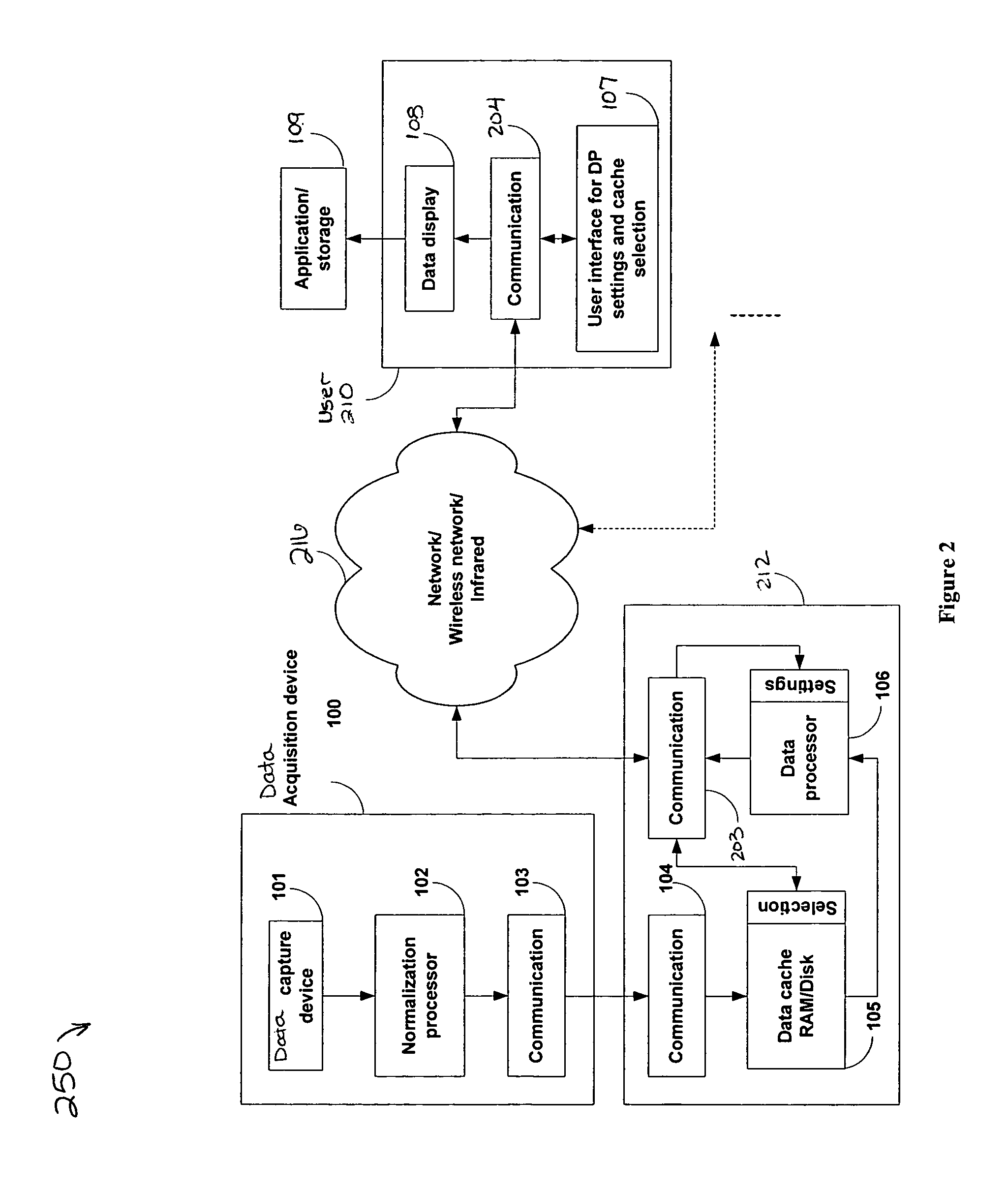

An efficient method and system to enhance digital acquisition devices for analog data is presented. The enhancements offered by the method and system are available to the user in local as well as in remote deployments yielding efficiency gains for a large variety of business processes. The quality enhancements of the acquired digital data are achieved efficiently by employing virtual reacquisition. The method of virtual reacquisition renders unnecessary the physical reacquisition of the analog data in case the digital data obtained by the acquisition device are of insufficient quality. The method and system allows multiple users to access the same acquisition device for analog data. In some embodiments, one or more users can virtually reacquire data provided by multiple analog or digital sources. The acquired raw data can be processed by each user according to his personal preferences and / or requirements. The preferred processing settings and attributes are determined interactively in real time as well as non real time, automatically and a combination thereof.

Owner:KOFAX

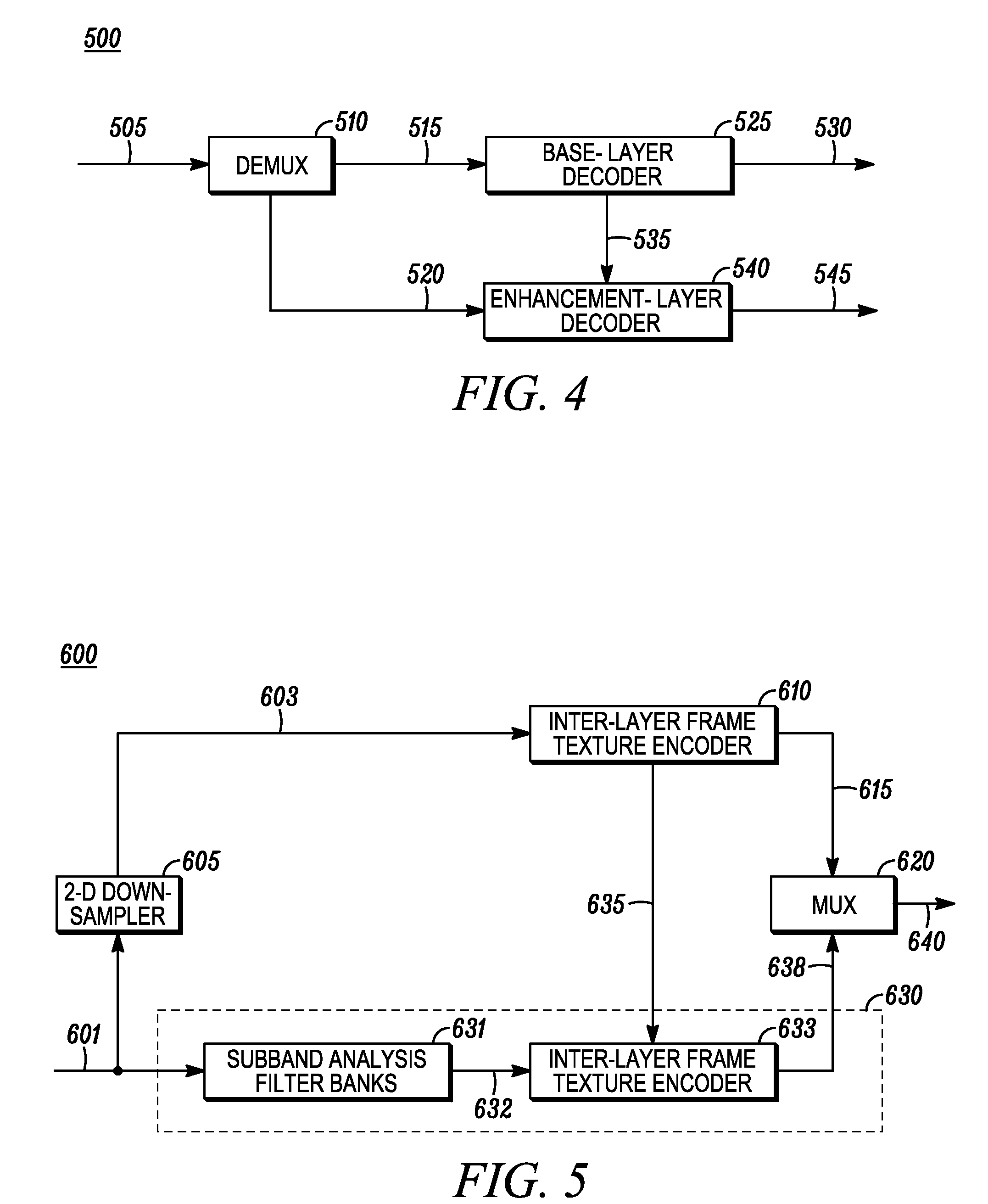

Method and apparatus for highly scalable intraframe video coding

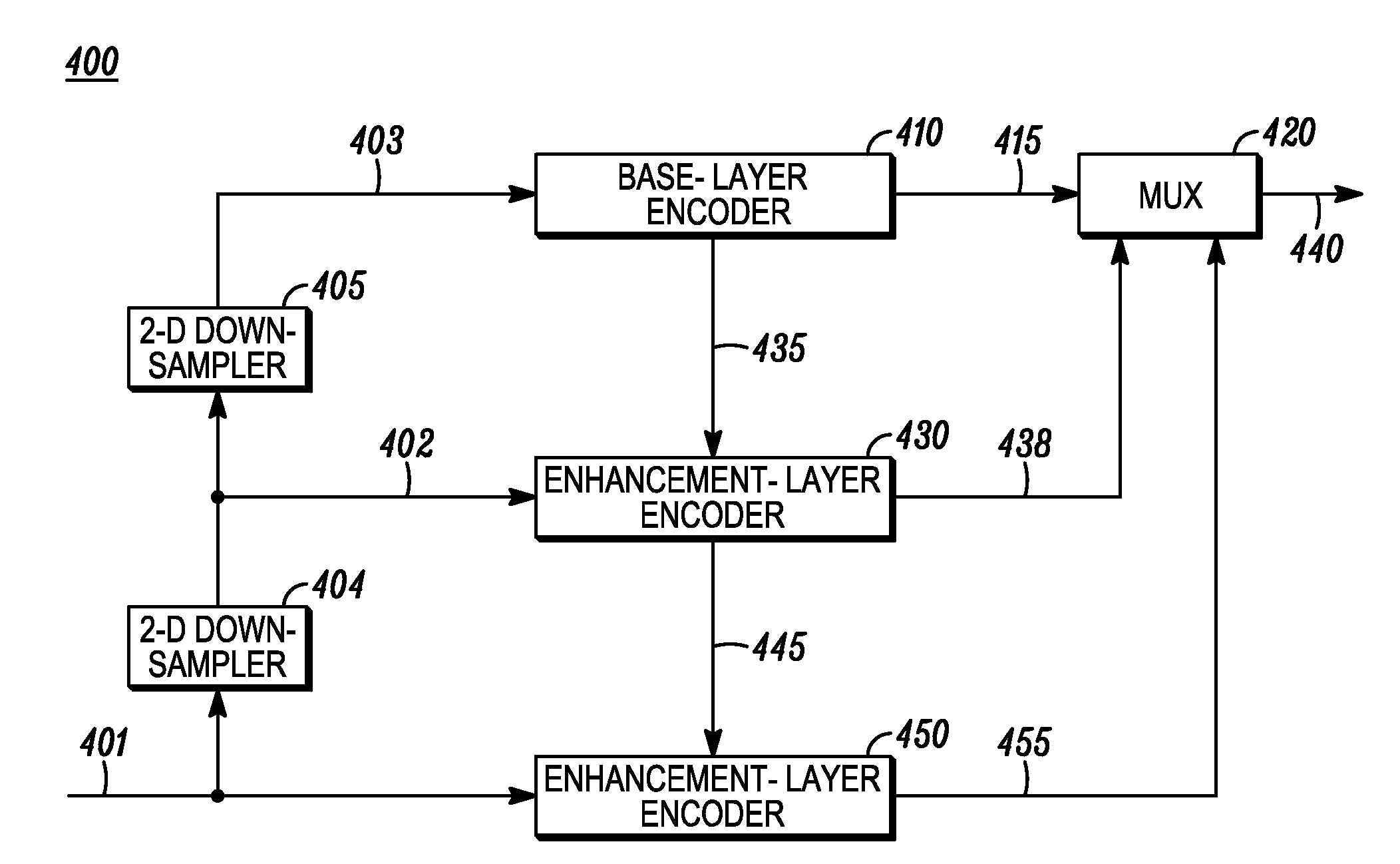

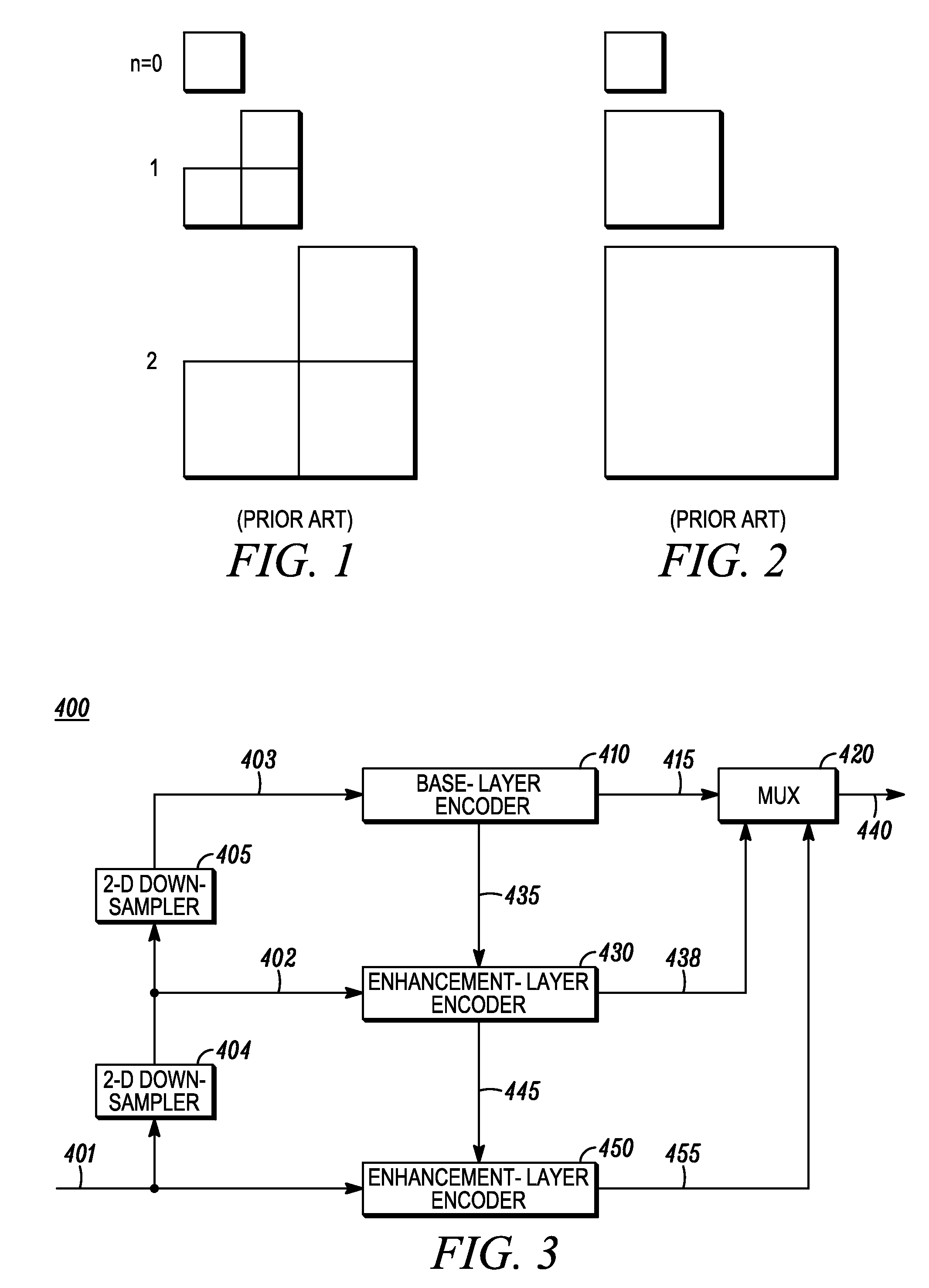

ActiveUS20090175333A1Color television with pulse code modulationColor television with bandwidth reductionComputer architectureInter layer

An apparatus and method is provided for highly scalable intraframe video coding. The conventional macroblock DCT tools are integrated with the subband filter banks for the improved efficiency of scalable compression. The enhancement layers are represented in a subband domain and coded by an inter-layer frame texture coder utilizing inter-layer prediction signal formed by the decoded previous layer. Each quality enhancement layer is additionally scalable in resolution.

Owner:GOOGLE TECH HLDG LLC

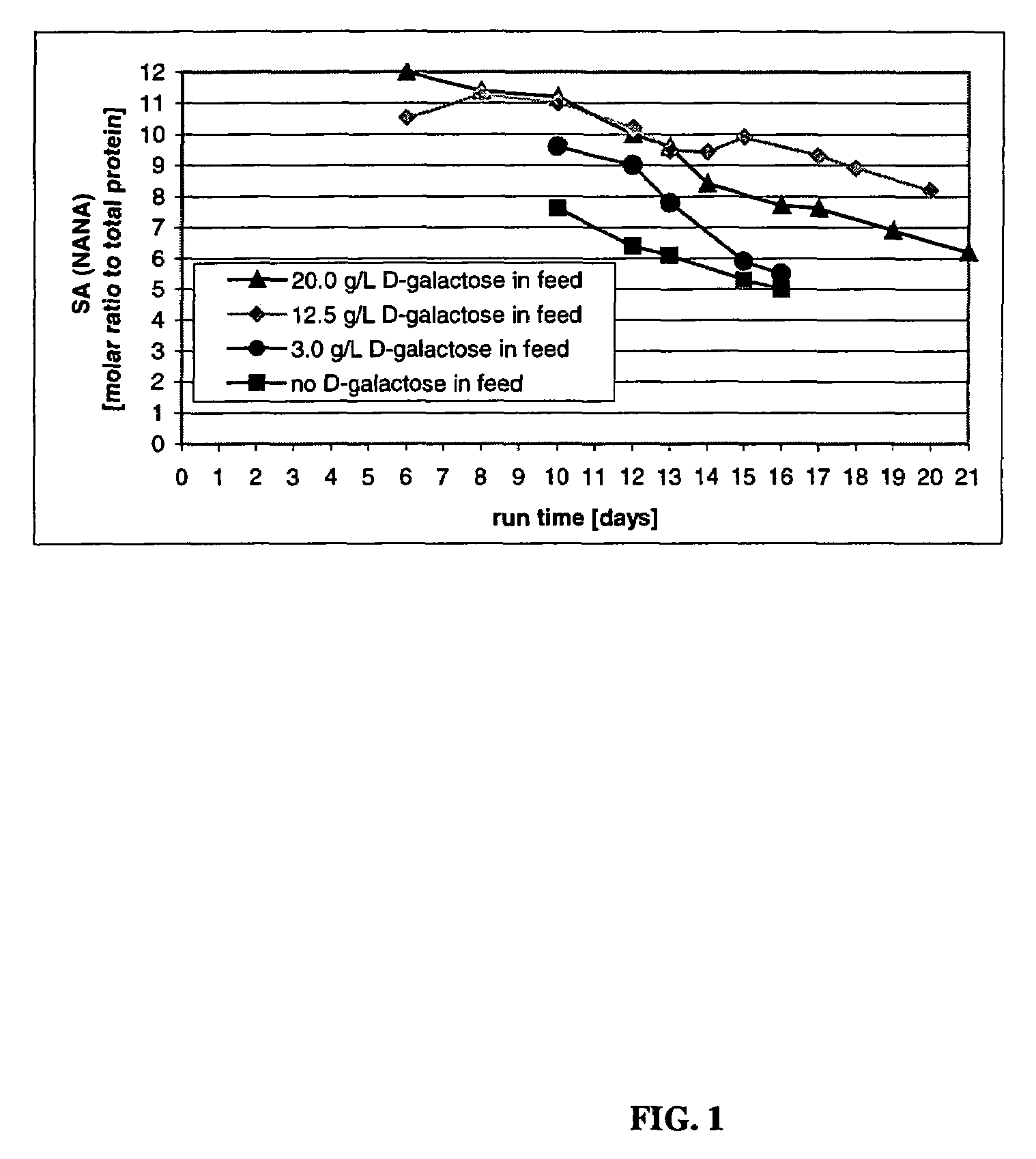

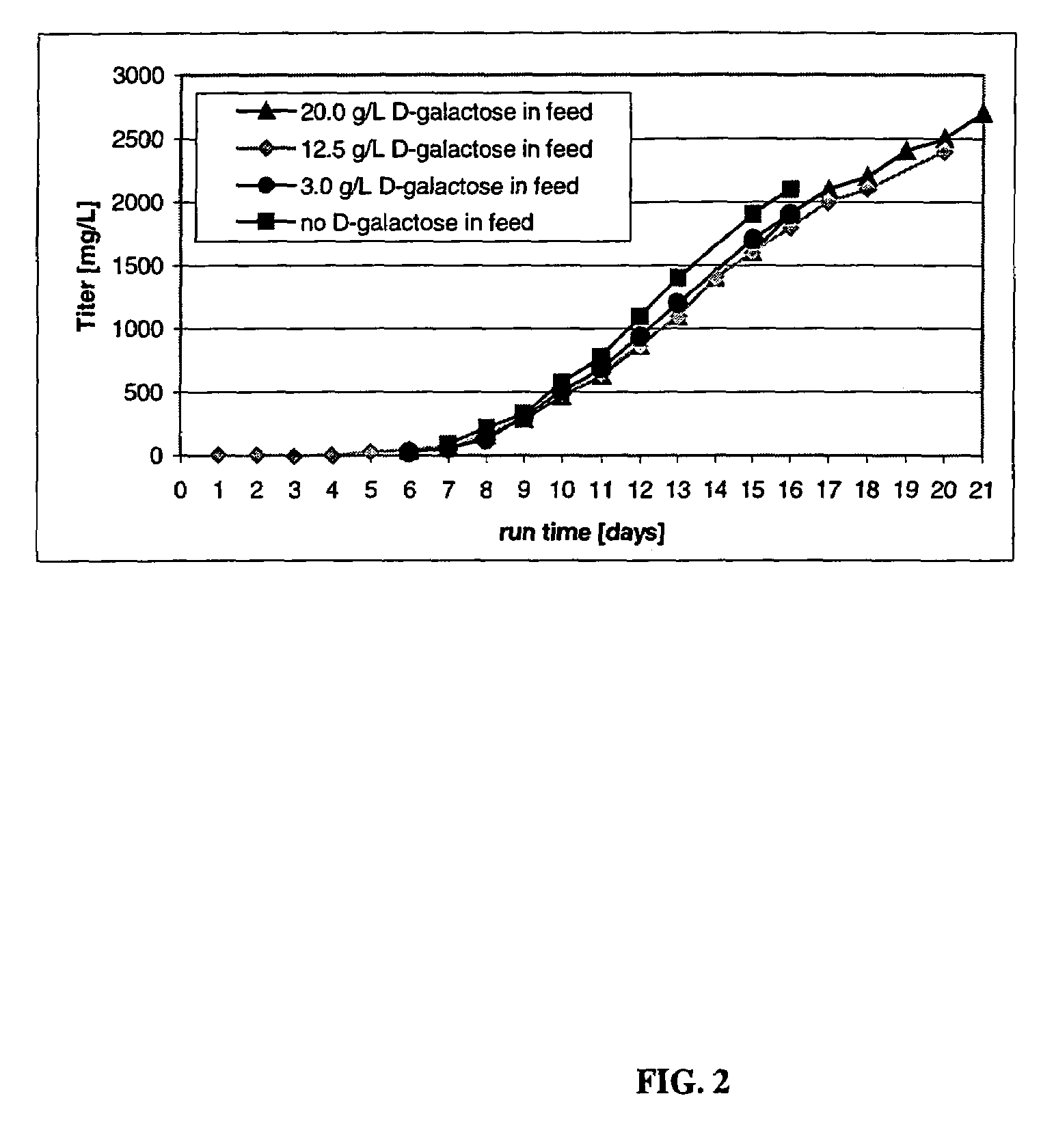

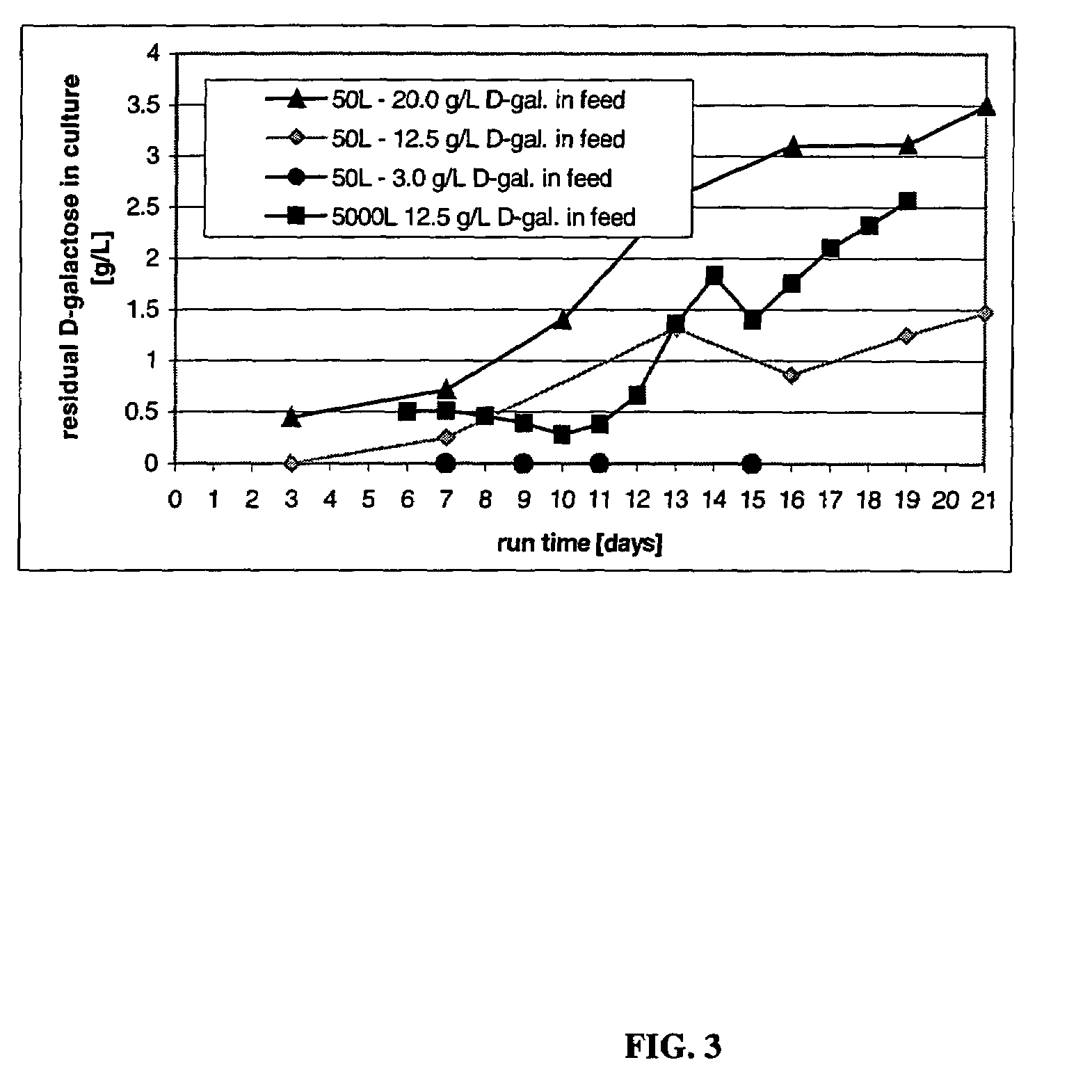

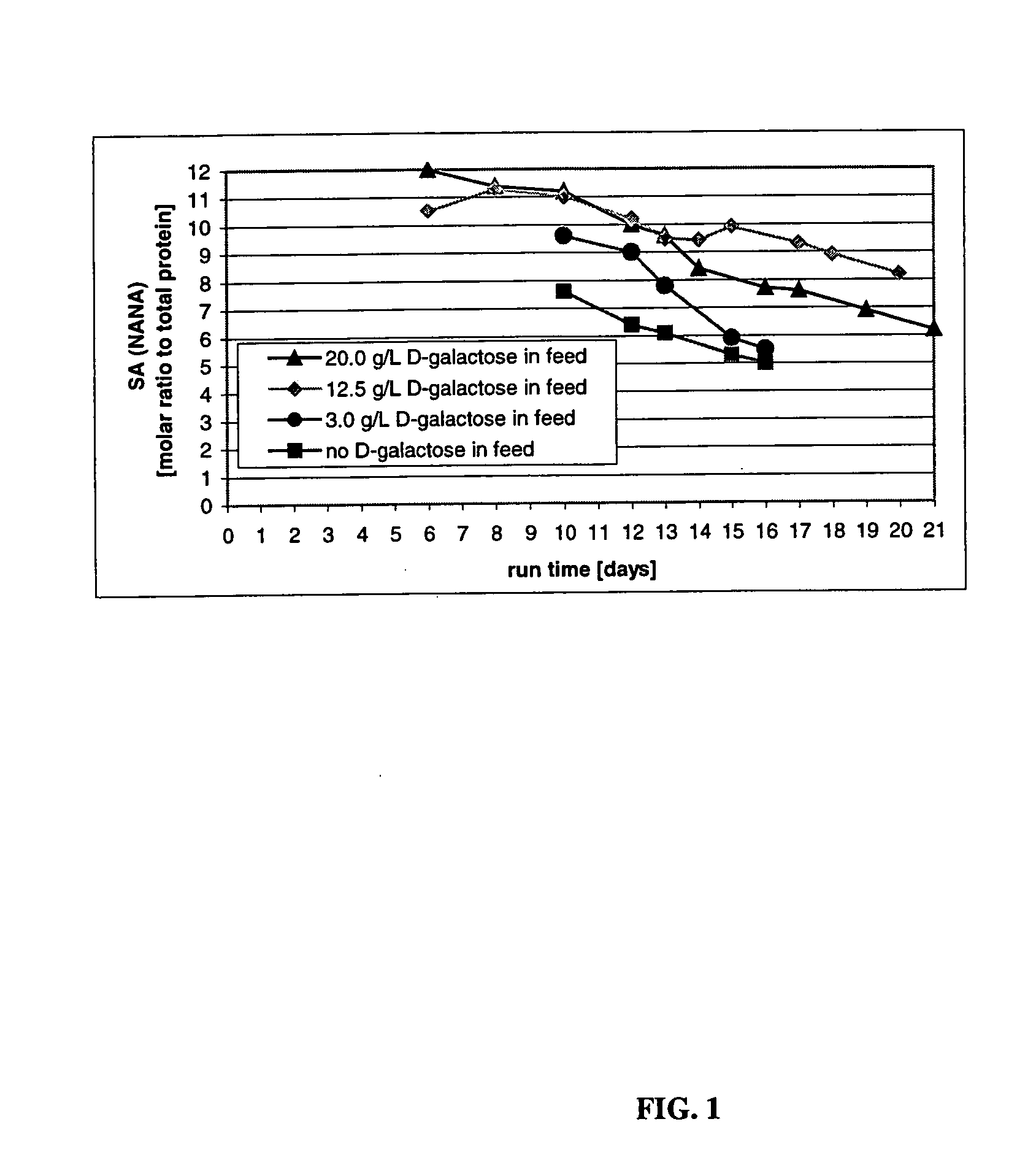

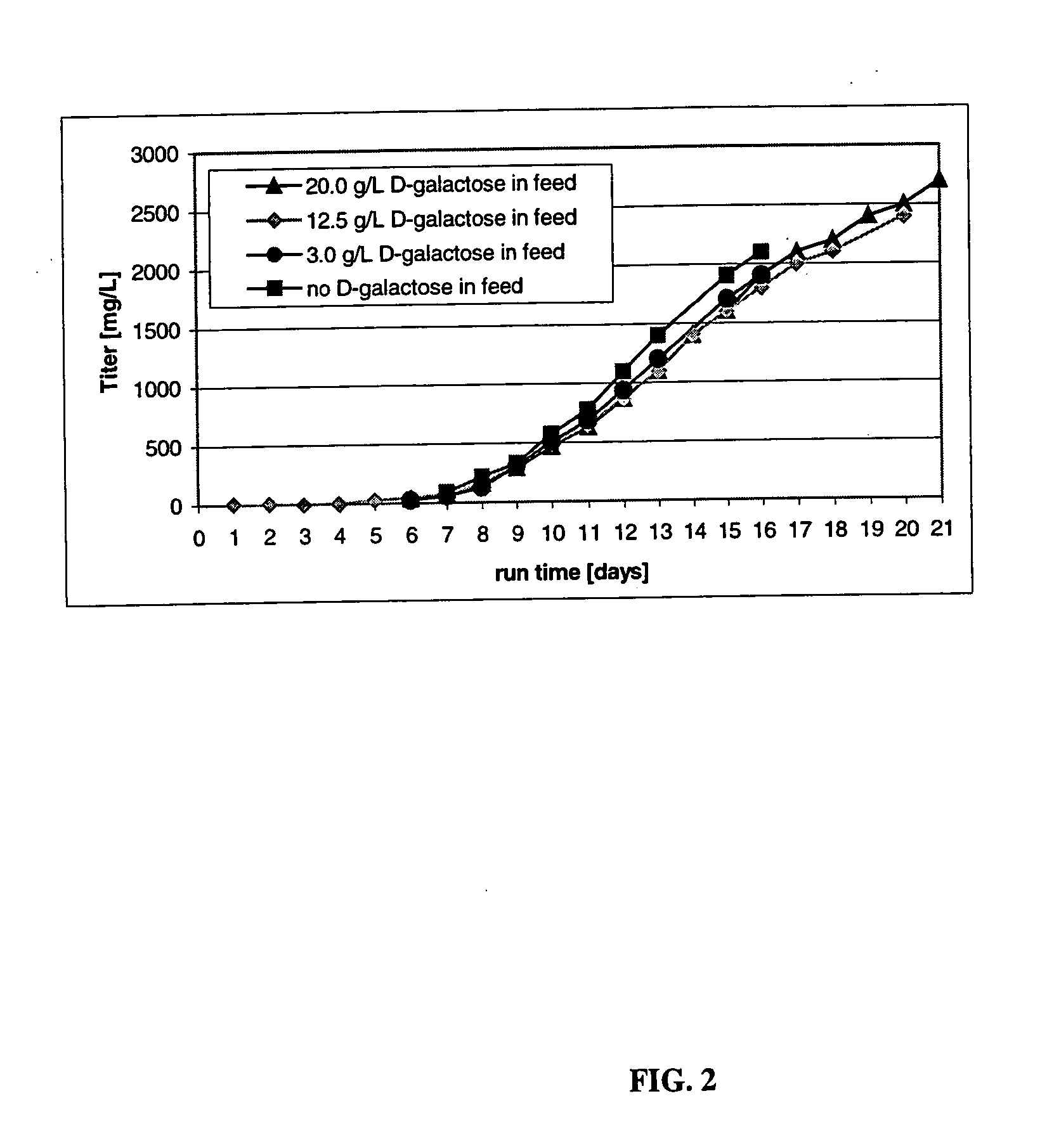

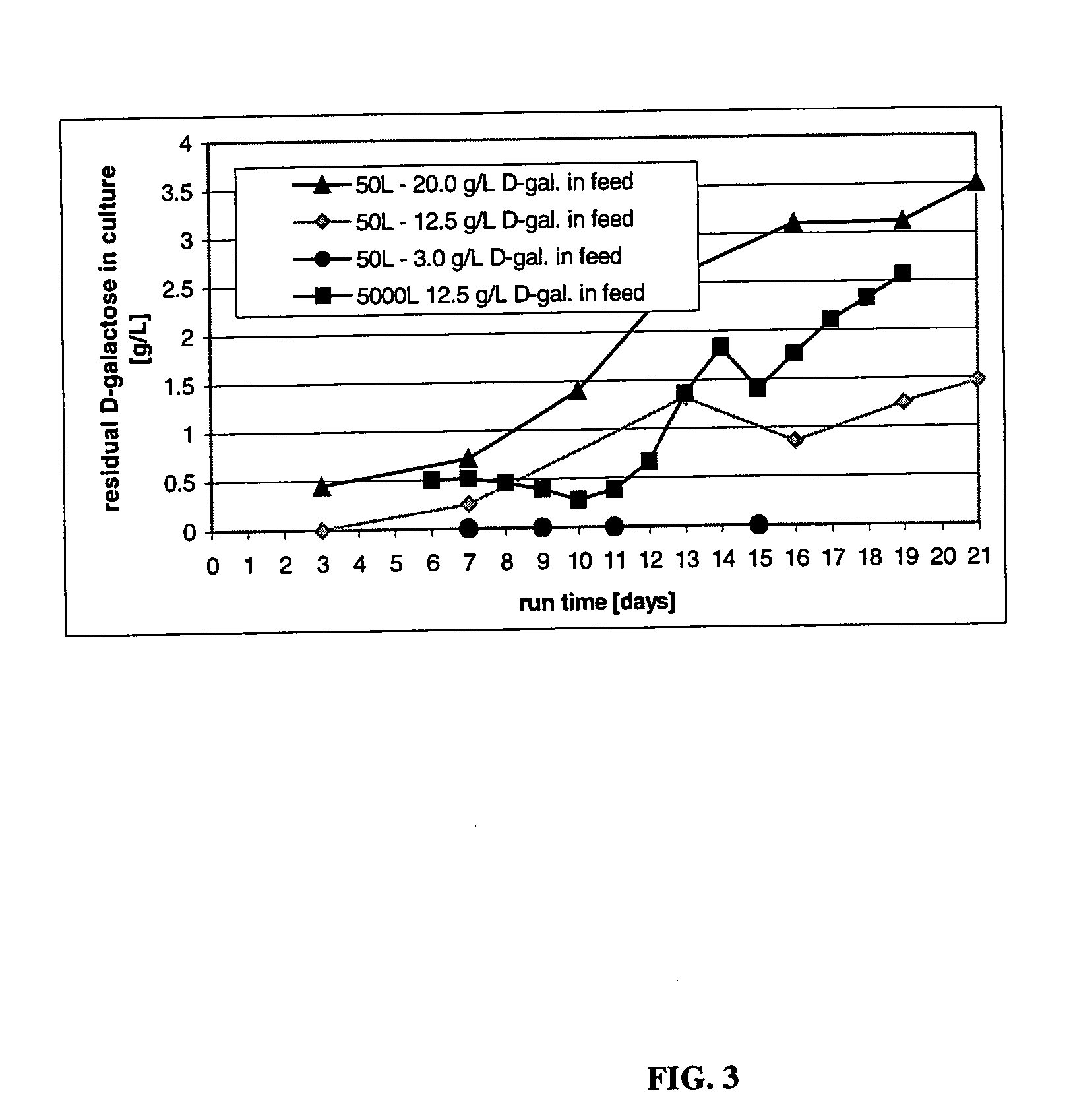

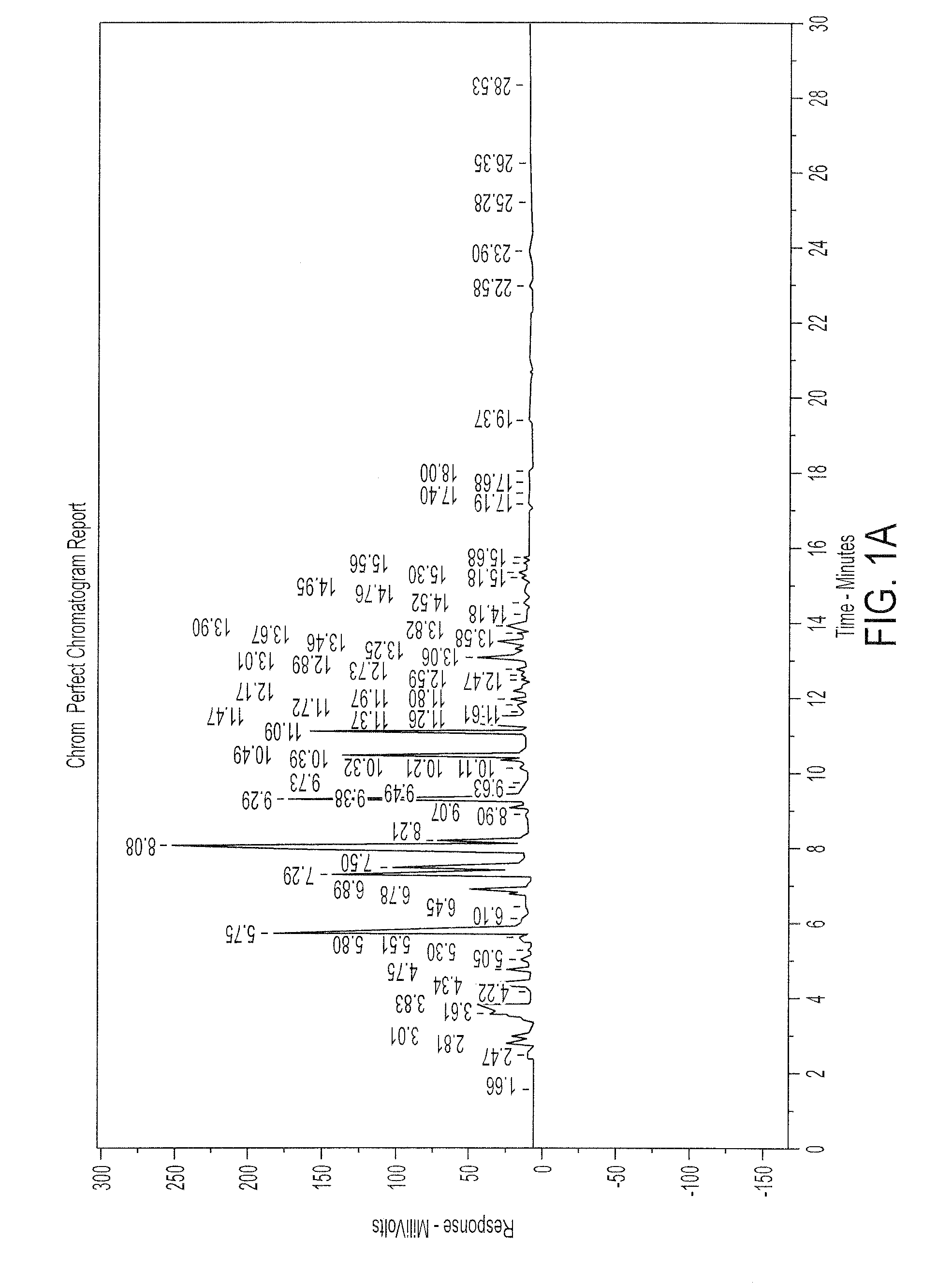

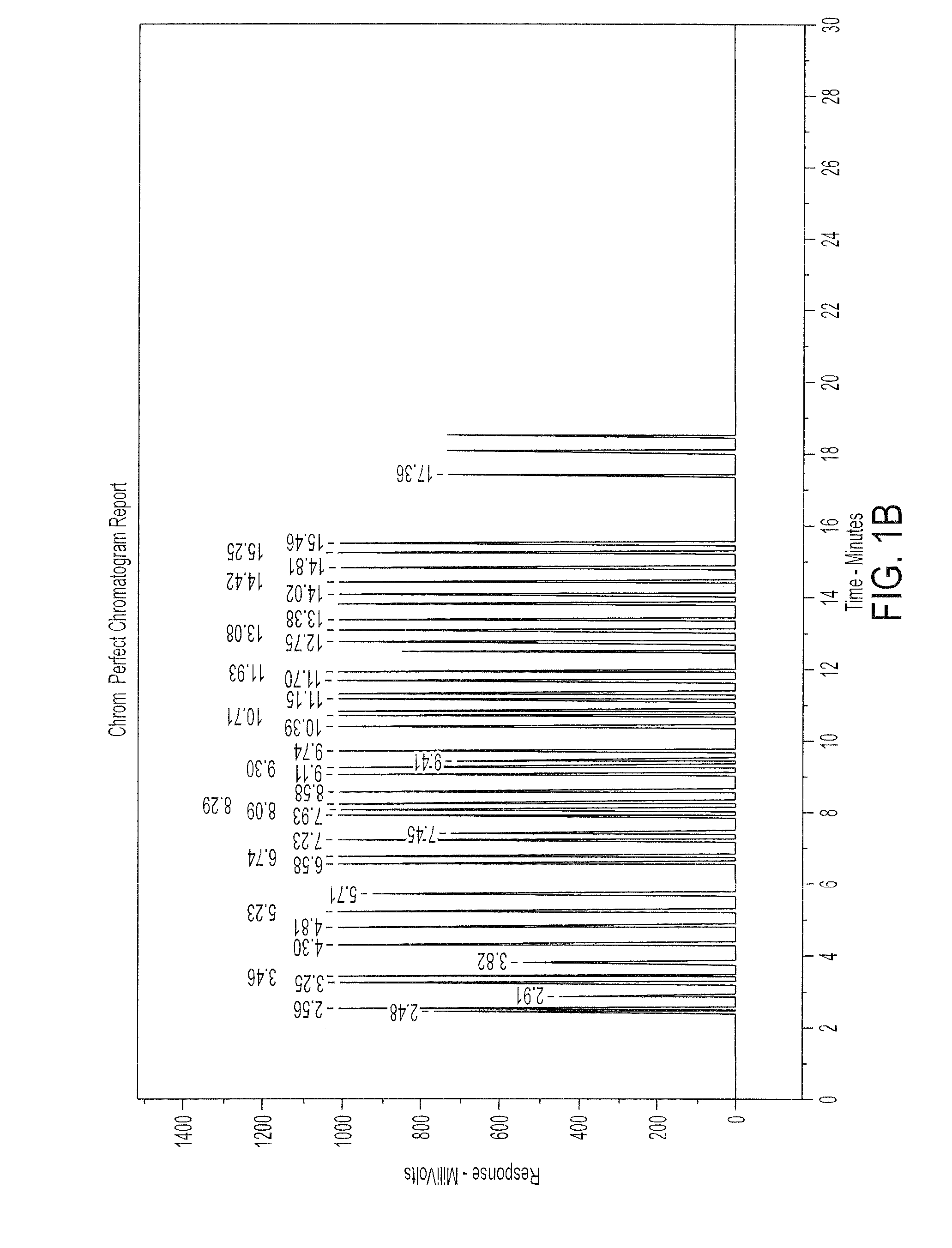

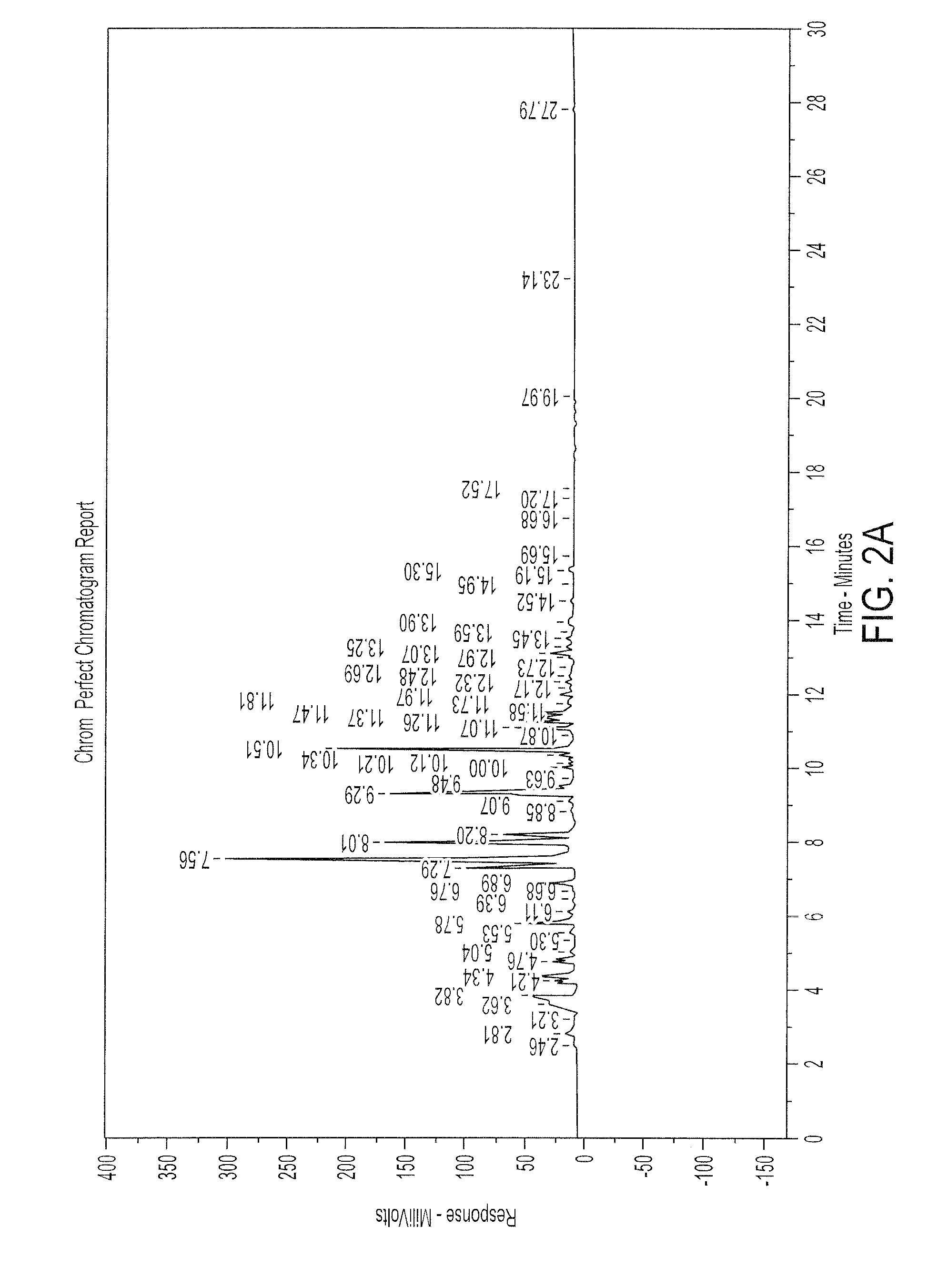

Product quality enhancement in mammalian cell culture processes for protein production

ActiveUS7332303B2Low production costQuality improvementAnimal cellsCell receptors/surface-antigens/surface-determinantsHigh cellBiotechnology

Owner:BRISTOL MYERS SQUIBB CO

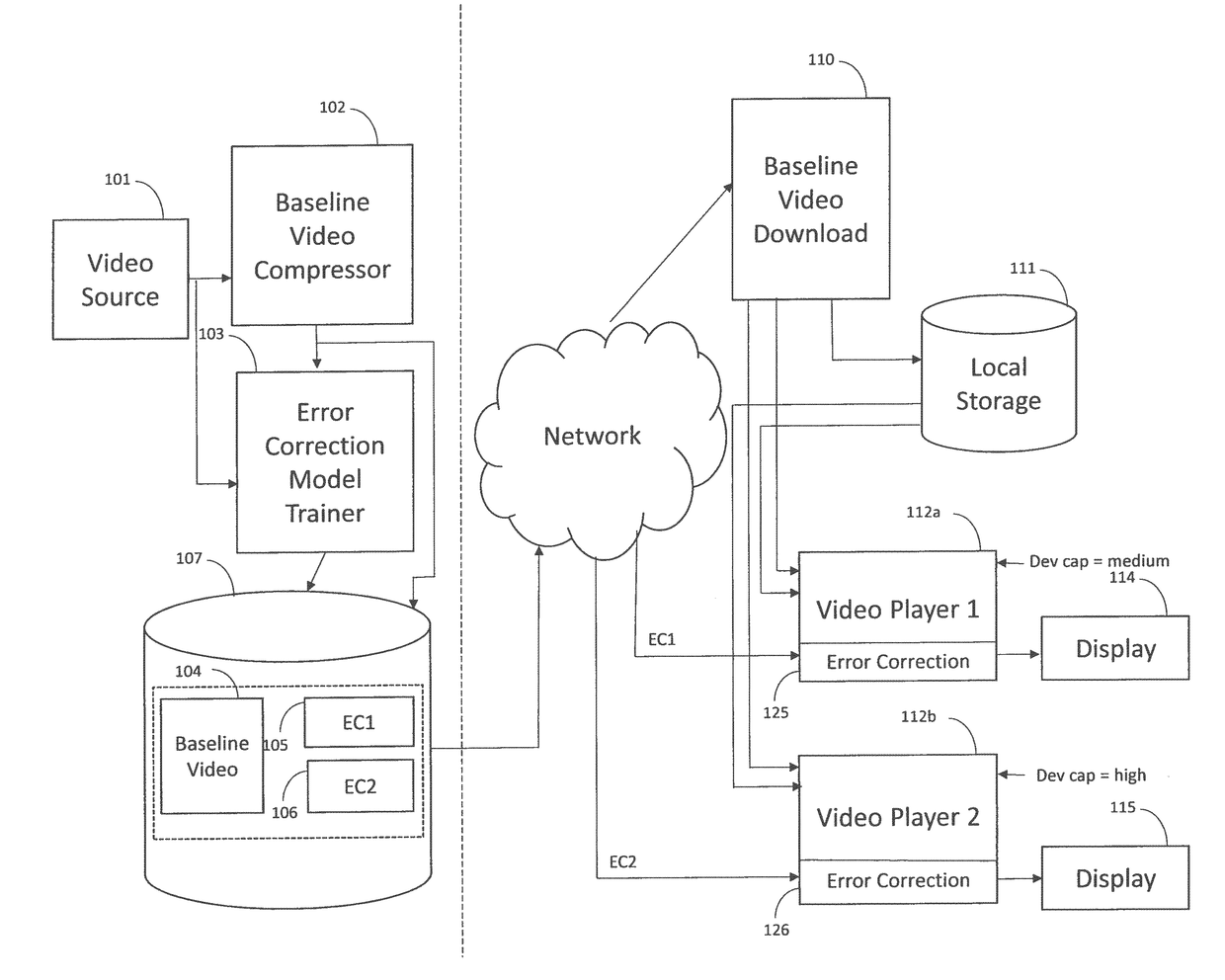

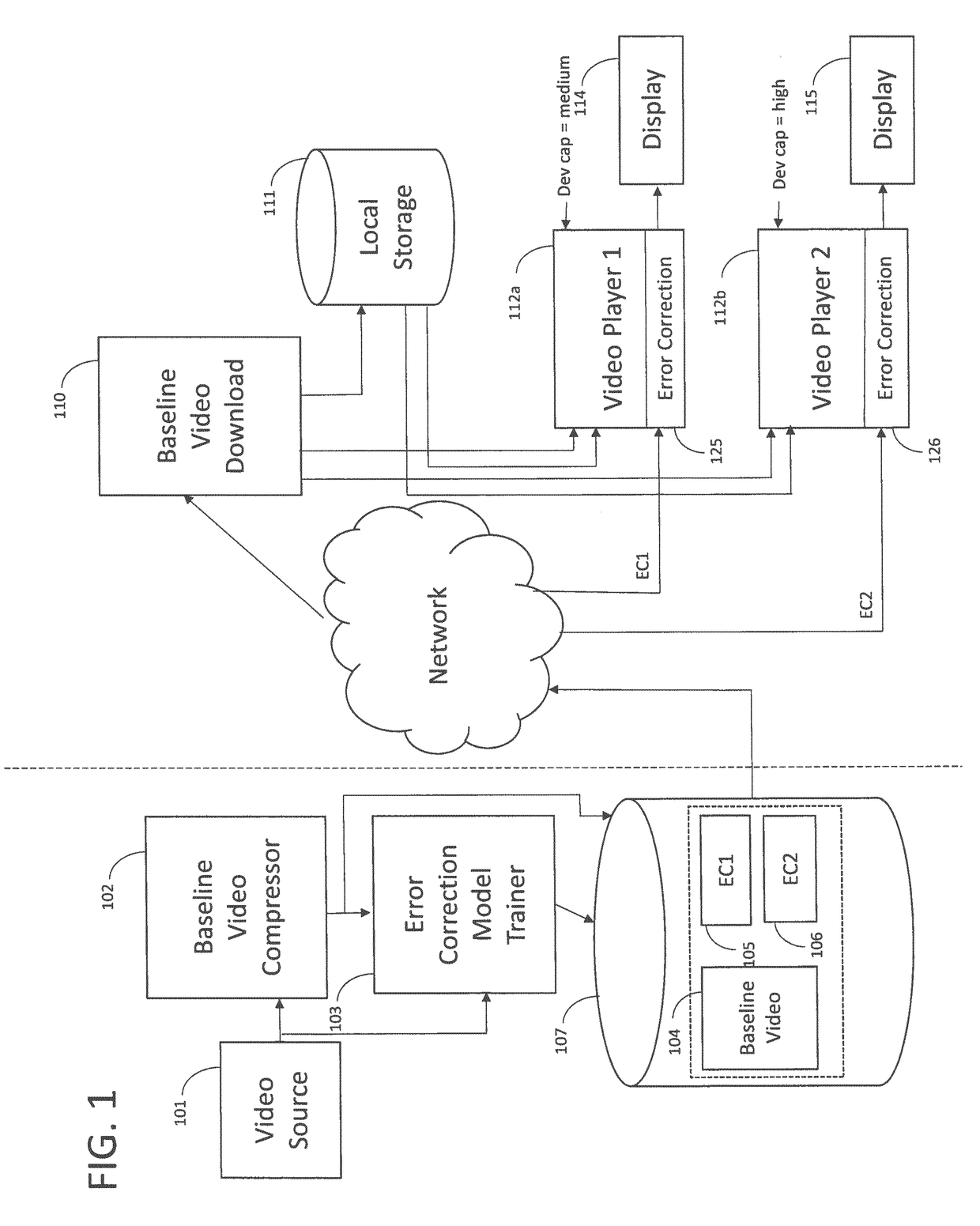

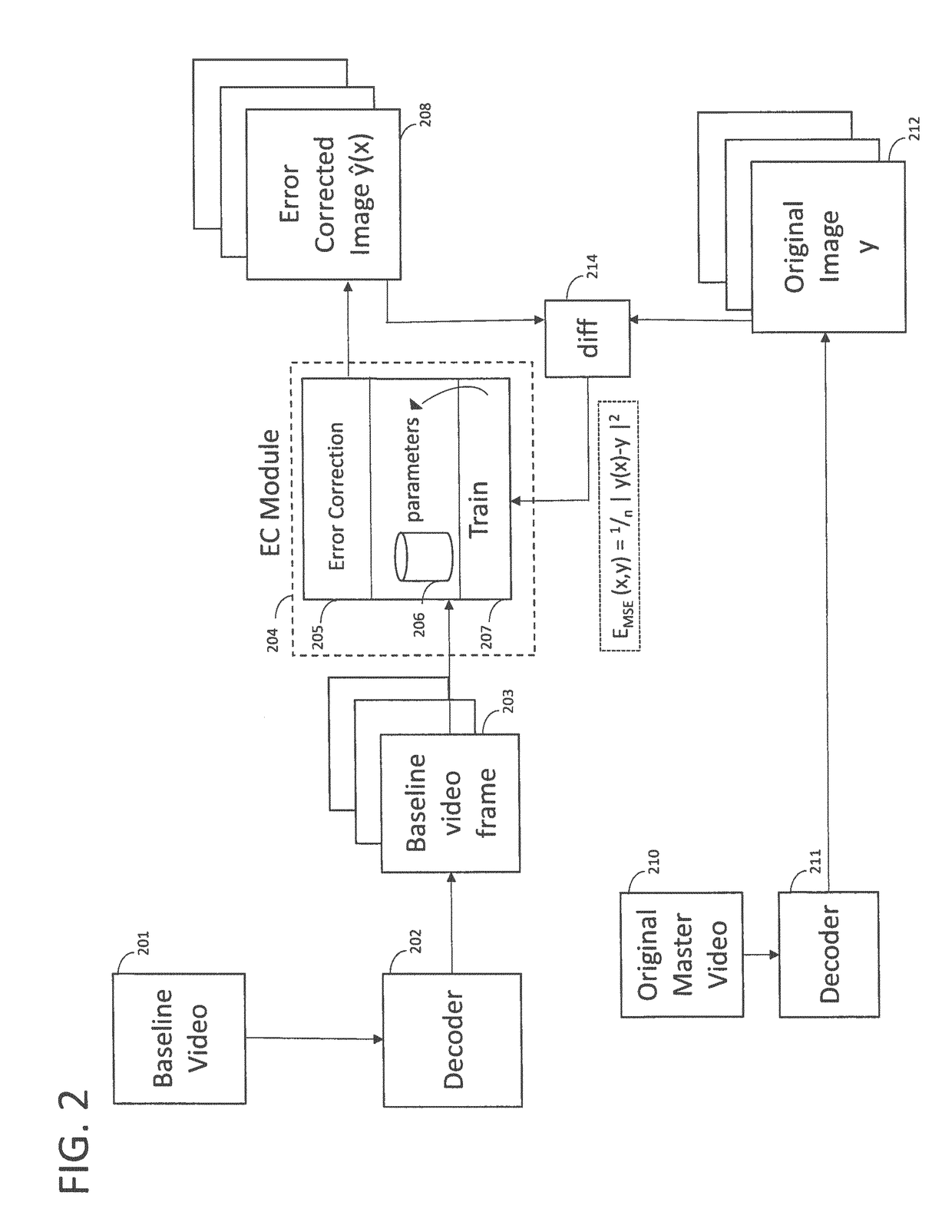

Improved video stream delivery via adaptive quality enhancement using error correction models

ActiveUS20180288440A1Attenuation bandwidthReduce duplicationCharacter and pattern recognitionImage codingComputer hardwareSelf adaptive

There is disclosed a technique for providing multimedia content comprising: compressing a multimedia stream; and generating an error correction model for providing an alternative version of the compressed multimedia stream by: decompressing the compressed multimedia stream; determining errors in the decompressed version by comparing to the input multimedia stream; and correcting the errors to minimise the difference between the decompressed version and the input multimedia stream.

Owner:PRJ HLDG CO LLC

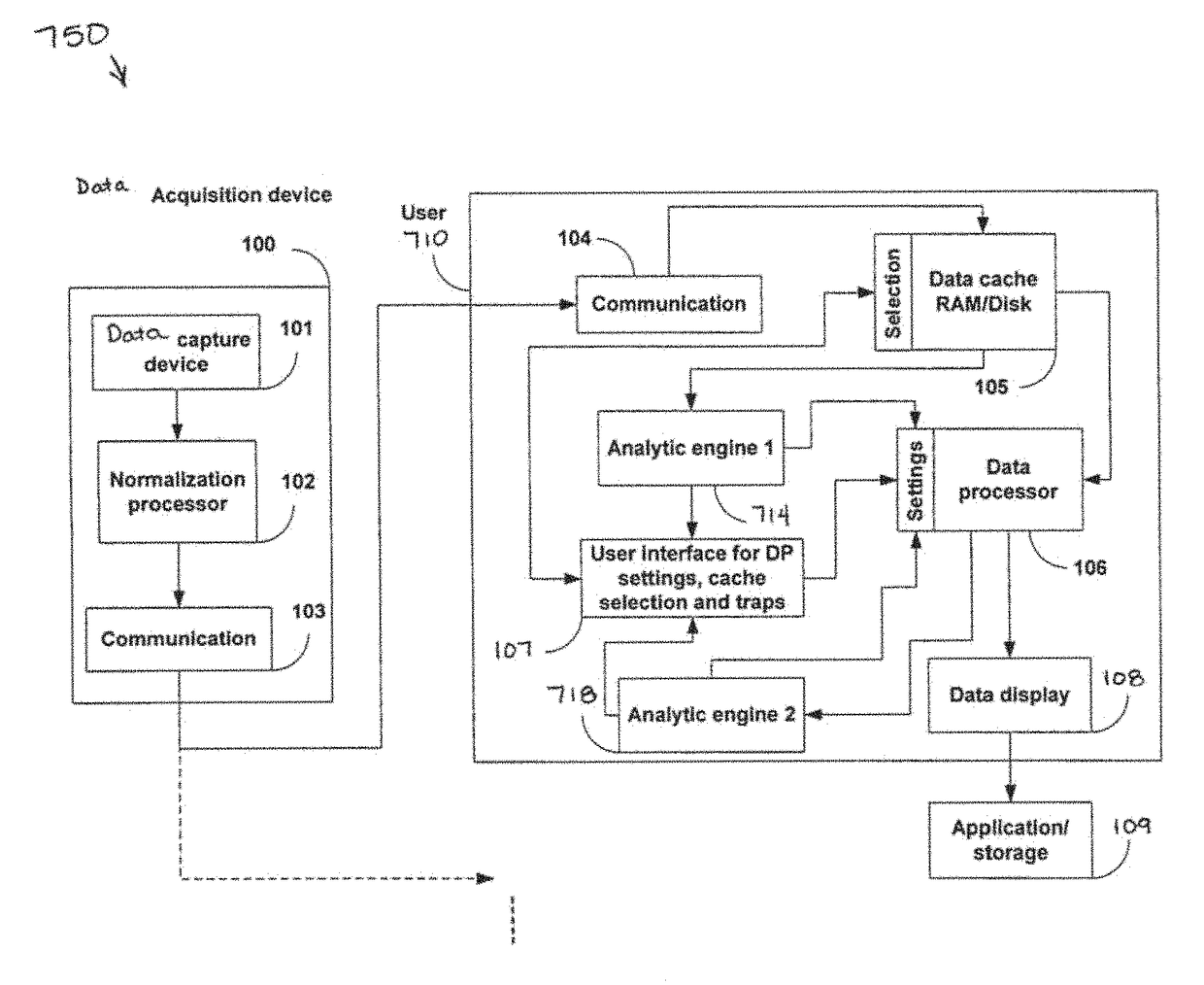

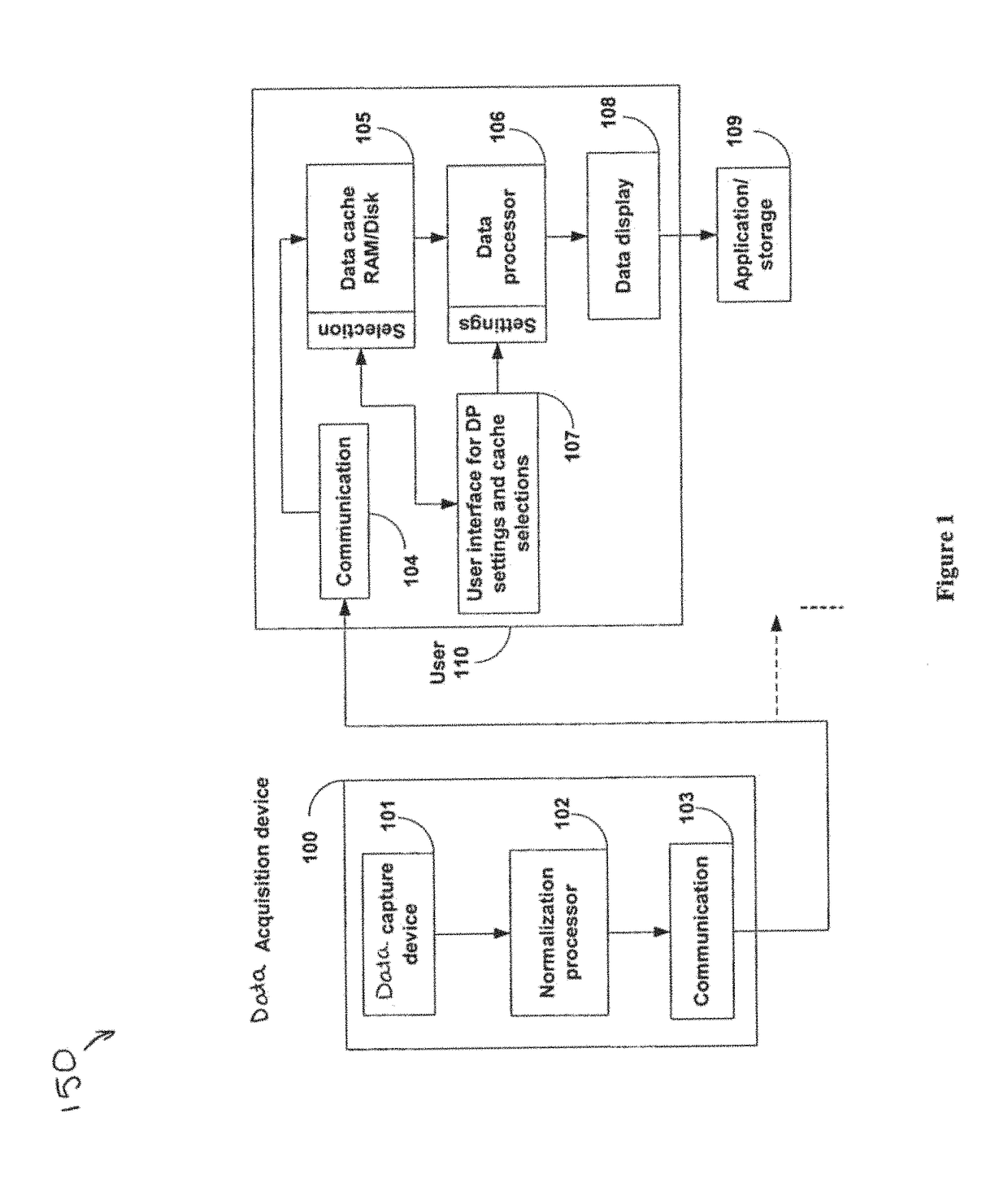

Systems and methods of processing scanned data

ActiveUS20060215231A1Data augmentationAdvantages with regard to speedImage enhancementCharacter and pattern recognitionDigital dataNon real time

An efficient method and system to enhance digital acquisition devices for analog data is presented. The enhancements offered by the method and system are available to the user in local as well as in remote deployments yielding efficiency gains for a large variety of business processes. The quality enhancements of the acquired digital data are achieved efficiently by employing virtual reacquisition. The method of virtual reacquisition renders unnecessary the physical reacquisition of the analog data in case the digital data obtained by the acquisition device are of insufficient quality. The method and system allows multiple users to access the same acquisition device for analog data. In some embodiments, one or more users can virtually reacquire data provided by multiple analog or digital sources. The acquired raw data can be processed by each user according to his personal preferences and / or requirements. The preferred processing settings and attributes are determined interactively in real time as well as non real time, automatically and a combination thereof.

Owner:KOFAX

Product quality enhancement in mammalian cell culture processes for protein production

ActiveUS20050084933A1Increased and enhanced sialic acid contentLow production costAnimal cellsCell receptors/surface-antigens/surface-determinantsBiotechnologyHigh cell

The present invention describes methods and processes for the production of proteins, particularly glycoproteins, by animal cell or mammalian cell culture, illustratively, but not limited to, fed-batch cell cultures. The methods comprise feeding the cells with D-galactose, preferably with feed medium containing D-galactose, preferably daily, to sustain a sialylation effective level of D-galactose in the culture for its duration, thus increasing sialylation of the produced proteins. The methods can also comprise at least two temperature shifts performed during the culturing period, in which the temperature is lower at the end of the culturing period than at the time of initial cell culture. The cell culture processes of the invention involving two or more temperature shifts sustain a high cell viability, and can allow for an extended protein production phase. The methods can also comprise the delayed addition of polyanionic compound at a time after innoculation. Supplementation of the cultures with D-galactose, preferably in a feed medium, to sustain galactose at sialylation effective levels in the cultures until the end of a culture run reverses a decline in sialylation that accompanies culture scale up, and is advantageous for large scale culturing processes.

Owner:BRISTOL MYERS SQUIBB CO

Quality Enhancement of Coffee Beans by Acid and Enzyme Treatment

The subject invention provides methods for treating unroasted or green coffee beans to improve their quality of flavor to the palate, including reduced bitterness, better tasting, and improved aroma. In one embodiment, the invention pertains to the treatment of either green and un-dried, or green and dried, coffee beans with enzymes in a pH adjusted environment. According to the subject invention, the enzymes to be used, the pH of the treatment medium, and the times of treatment are parameters that are optimized based on different desired flavor and / or aroma outcomes.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

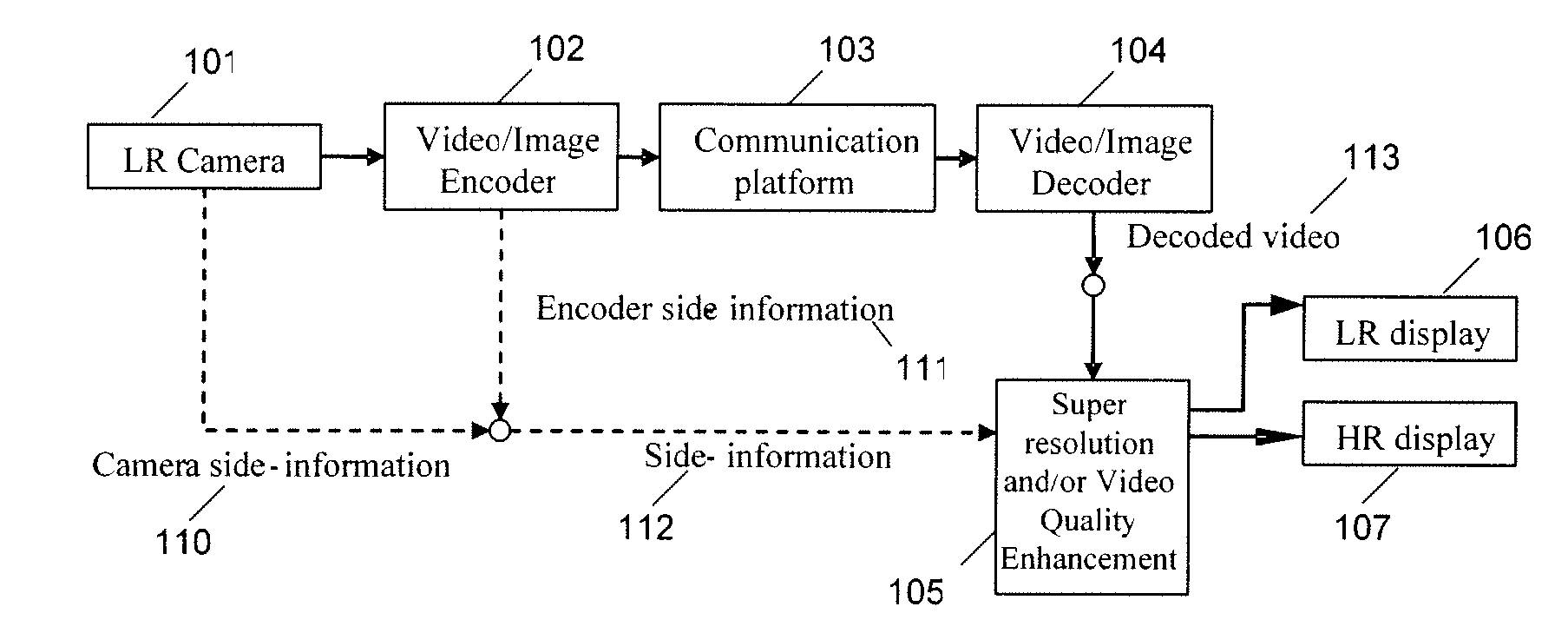

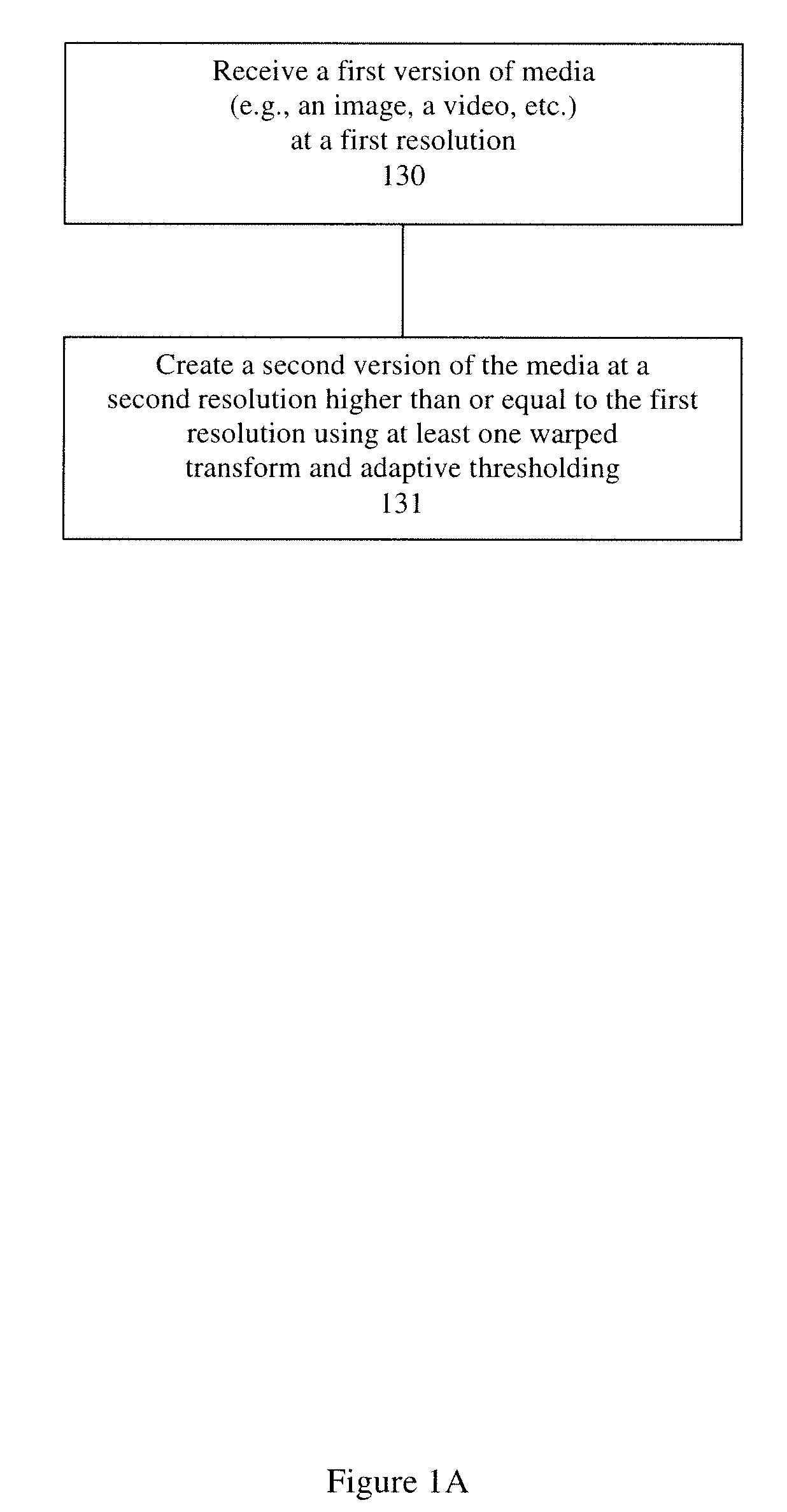

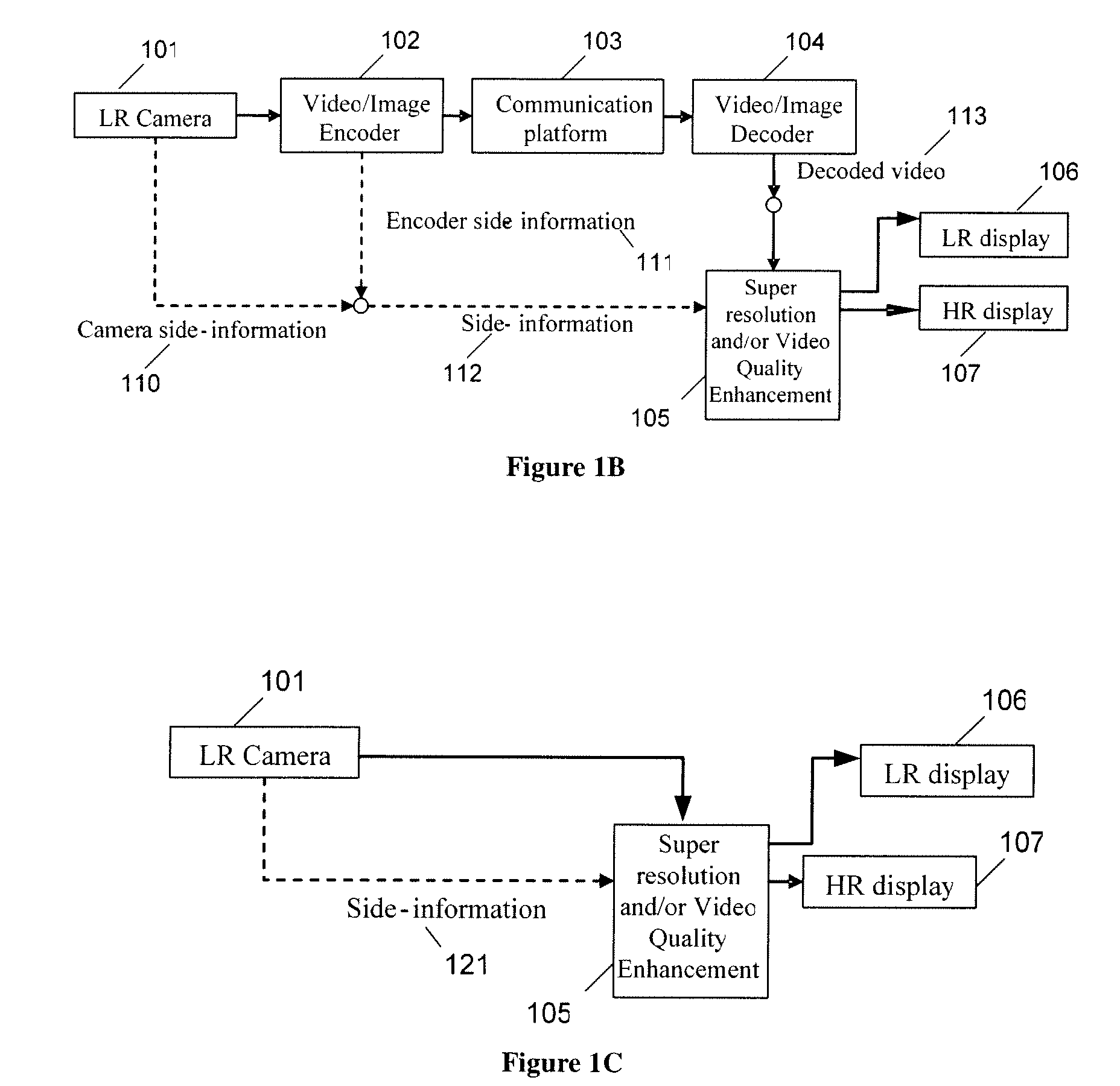

Image/video quality enhancement and super-resolution using sparse transformations

A method and apparatus is disclosed herein for a quality enhancement / super resolution technique. In one embodiment, the method comprises receiving a first version of media at a first resolution and creating a second version of the media at a second resolution higher or equal to the first resolution using at least one transform and adaptive thresholding.

Owner:NTT DOCOMO INC

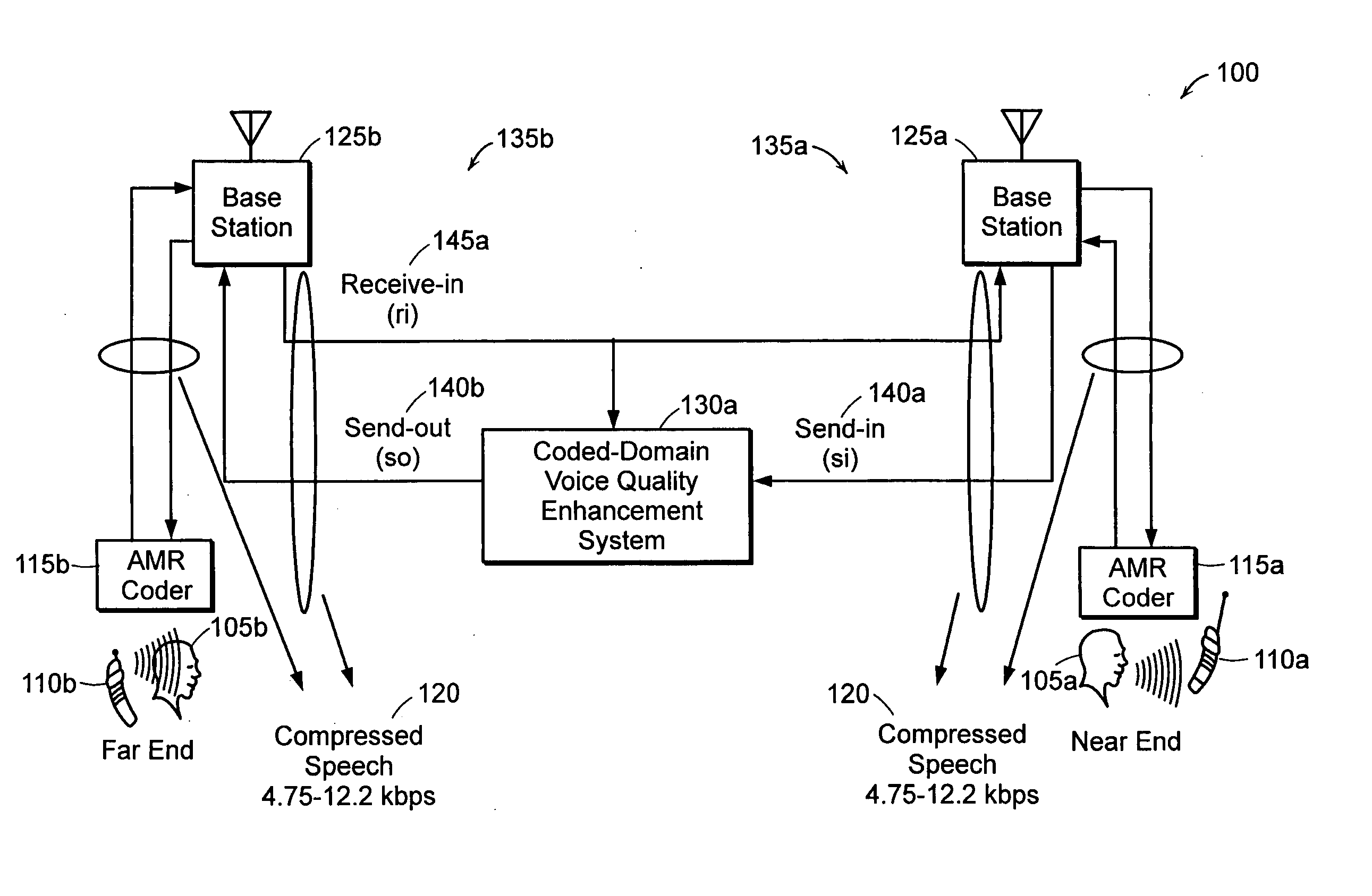

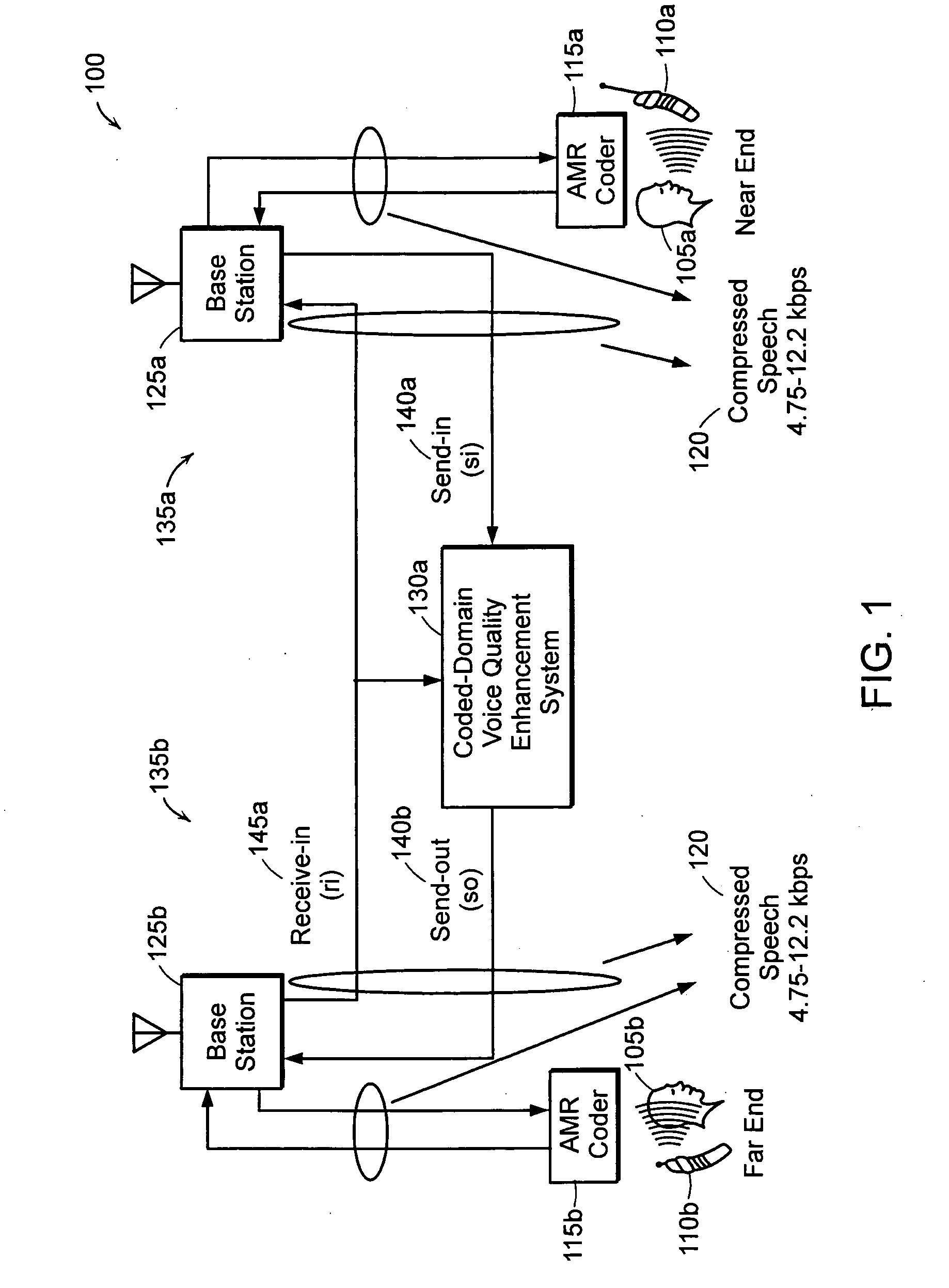

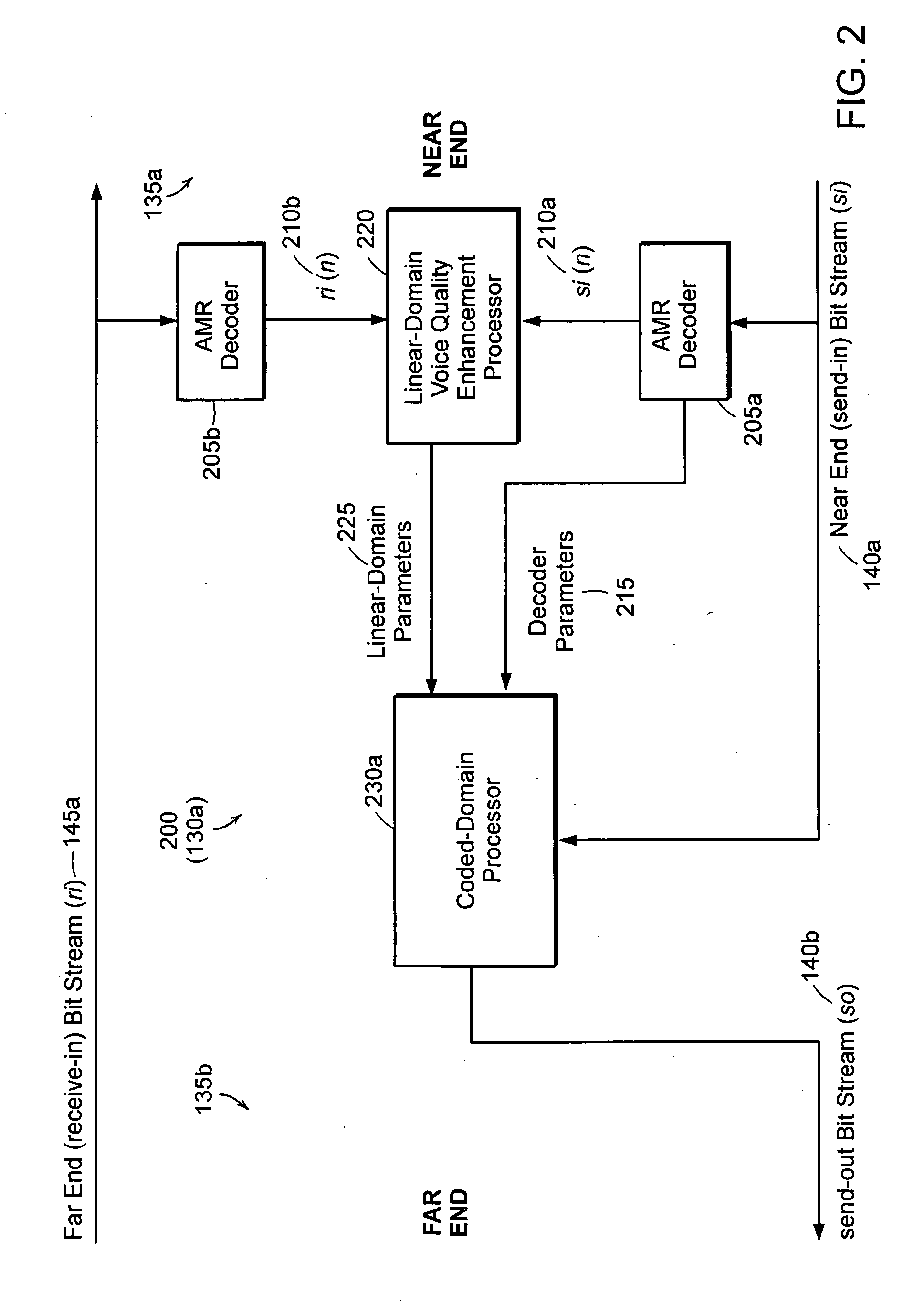

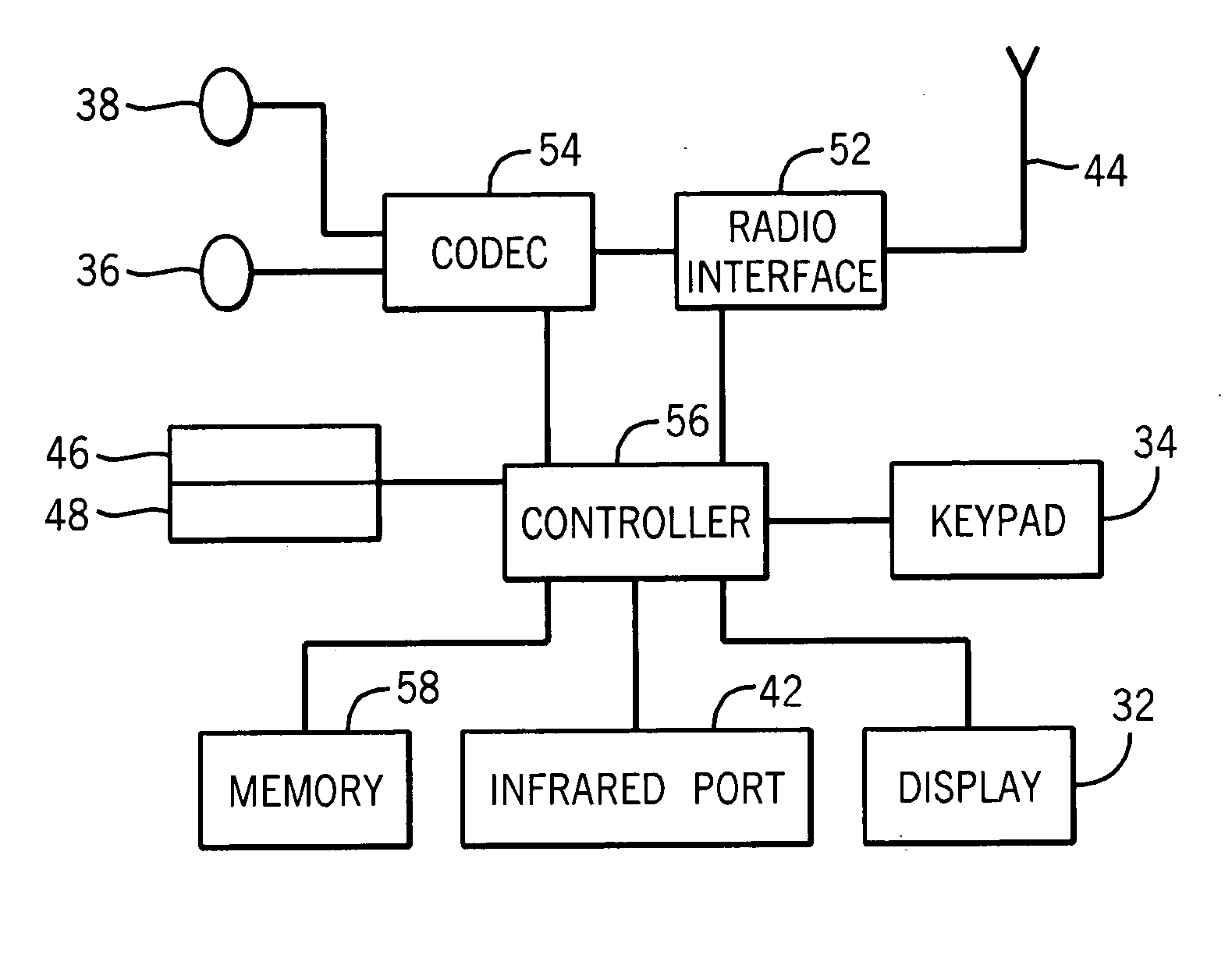

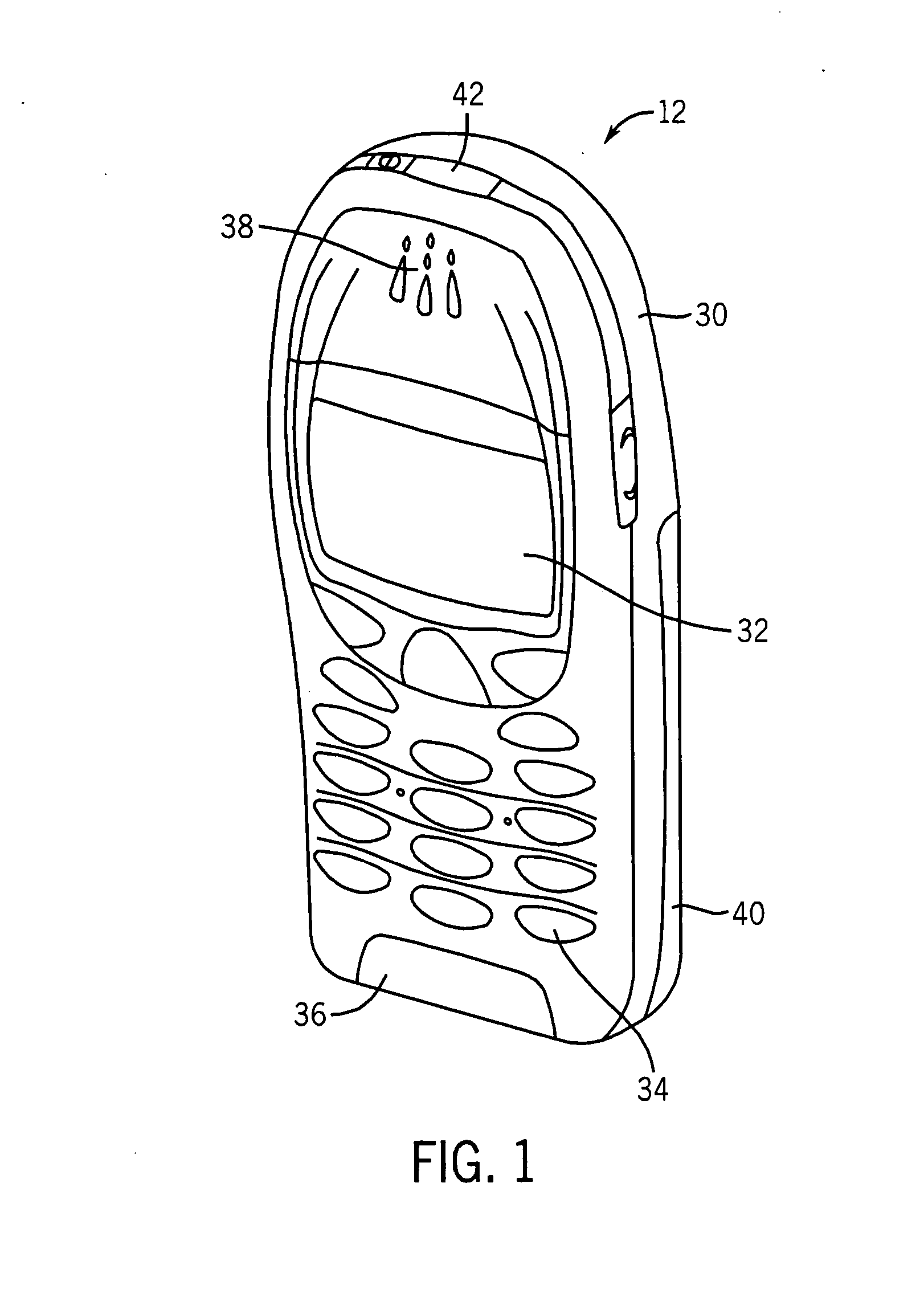

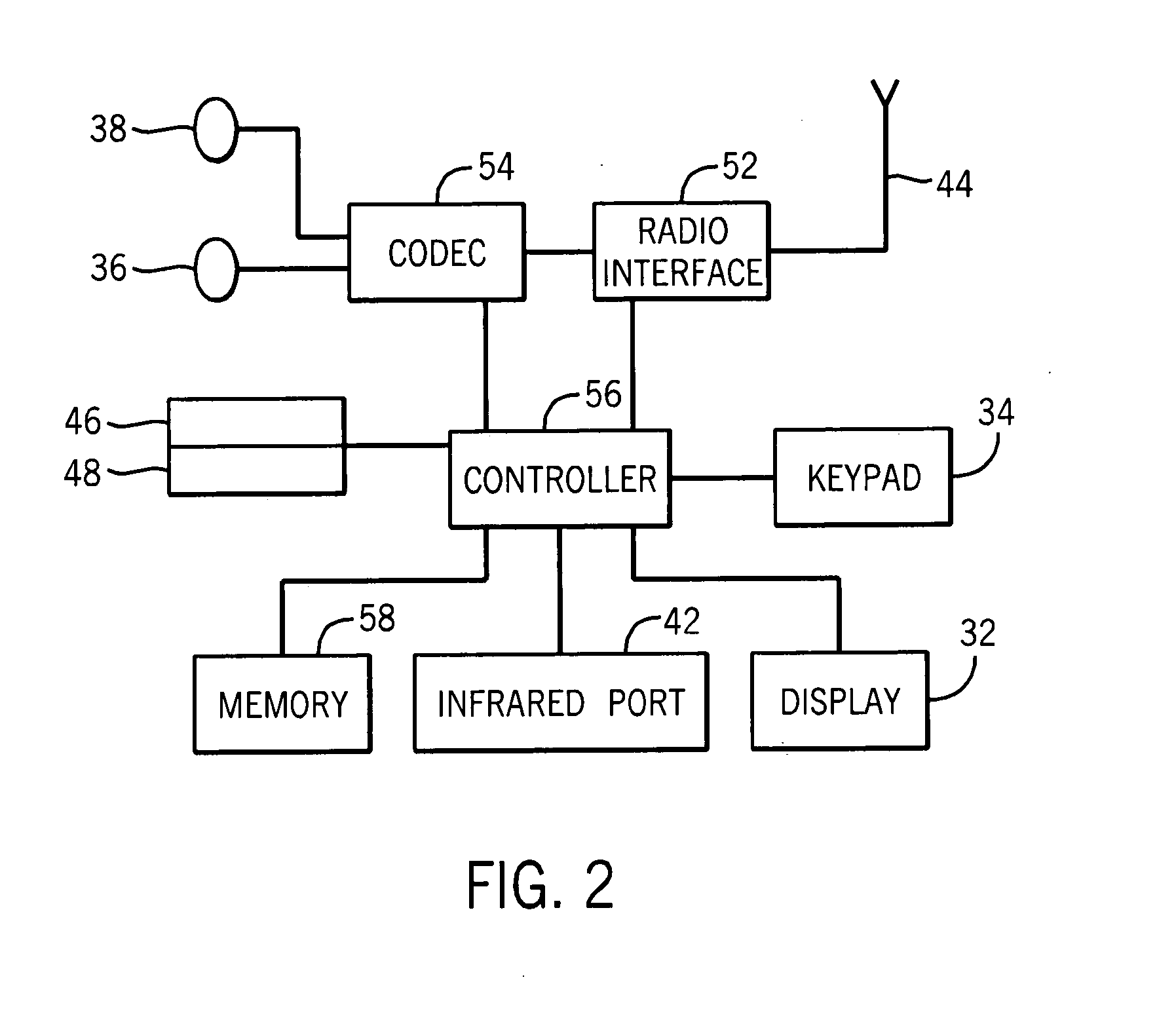

Method and apparatus for voice quality enhancement

InactiveUS20060215683A1Improve voice qualityError preventionFrequency-division multiplex detailsTarget signalThird generation

Voice Quality Enhancement (VQE) is performed directly in a coded domain. A Coded Domain Voice Quality Enhancement (CD-VQE) system modifies at least one parameter of a first encoded signal, resulting in corresponding modified parameter(s). The CD-VQE system replaces the parameter(s) of the first encoded signal with the modified parameter(s), resulting in a second encoded signal. In a decoded state, the second encoded signal approximates a target signal that is a function of at least the first encoded signal in at least a partially decoded state. Thus, the first encoded signal does not have to go through intermediate decode / re-encode processes, which can degrade overall speech quality. The CD-VQE system may cascade functions. Computational resources required for a complete re-encoding are not needed. Overall delay of the system is minimized. The CD-VQE system can be used in networks in which signals are communicated in a coded domain, such as a Third Generation (3G) wireless network.

Owner:TELLABS OPERATIONS

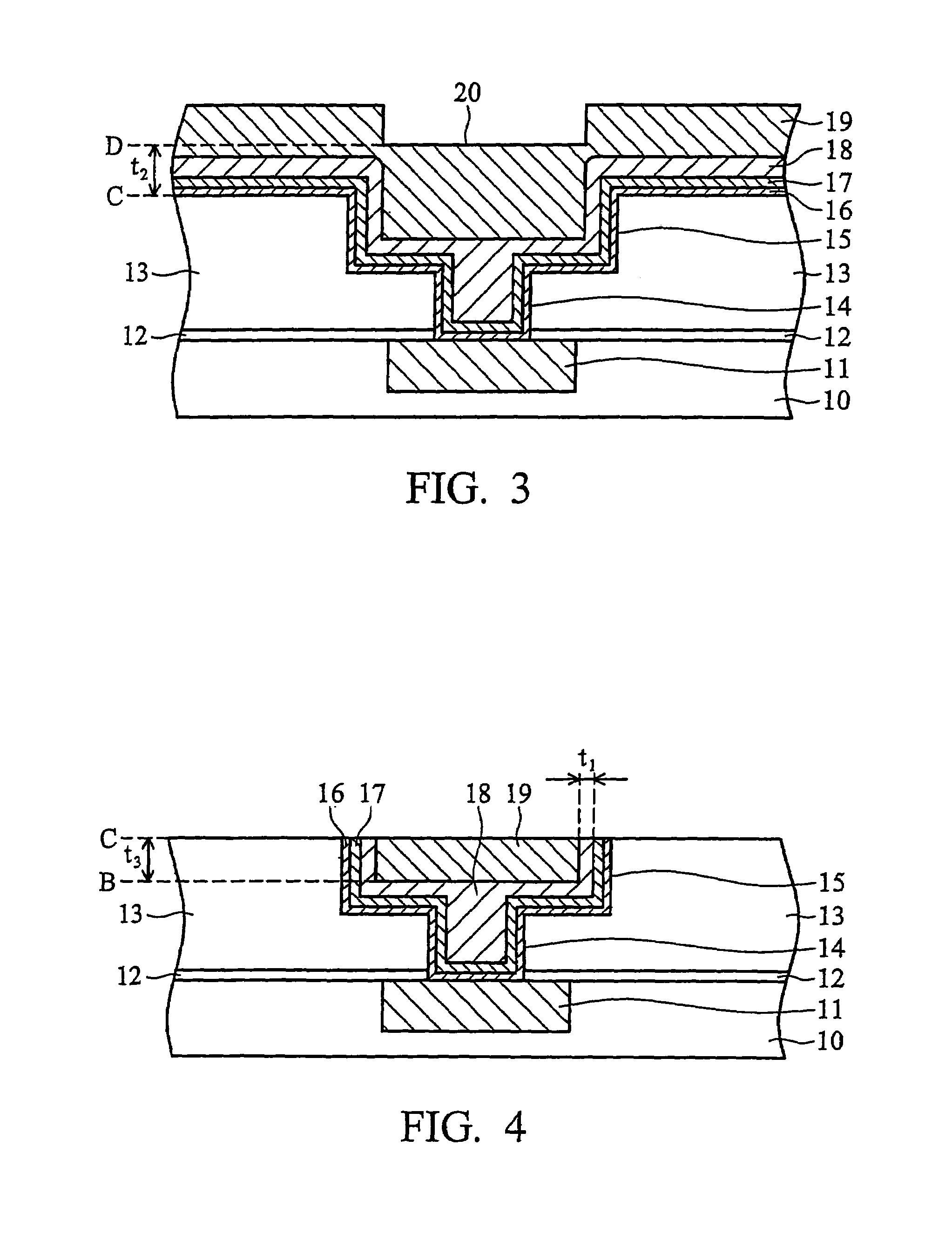

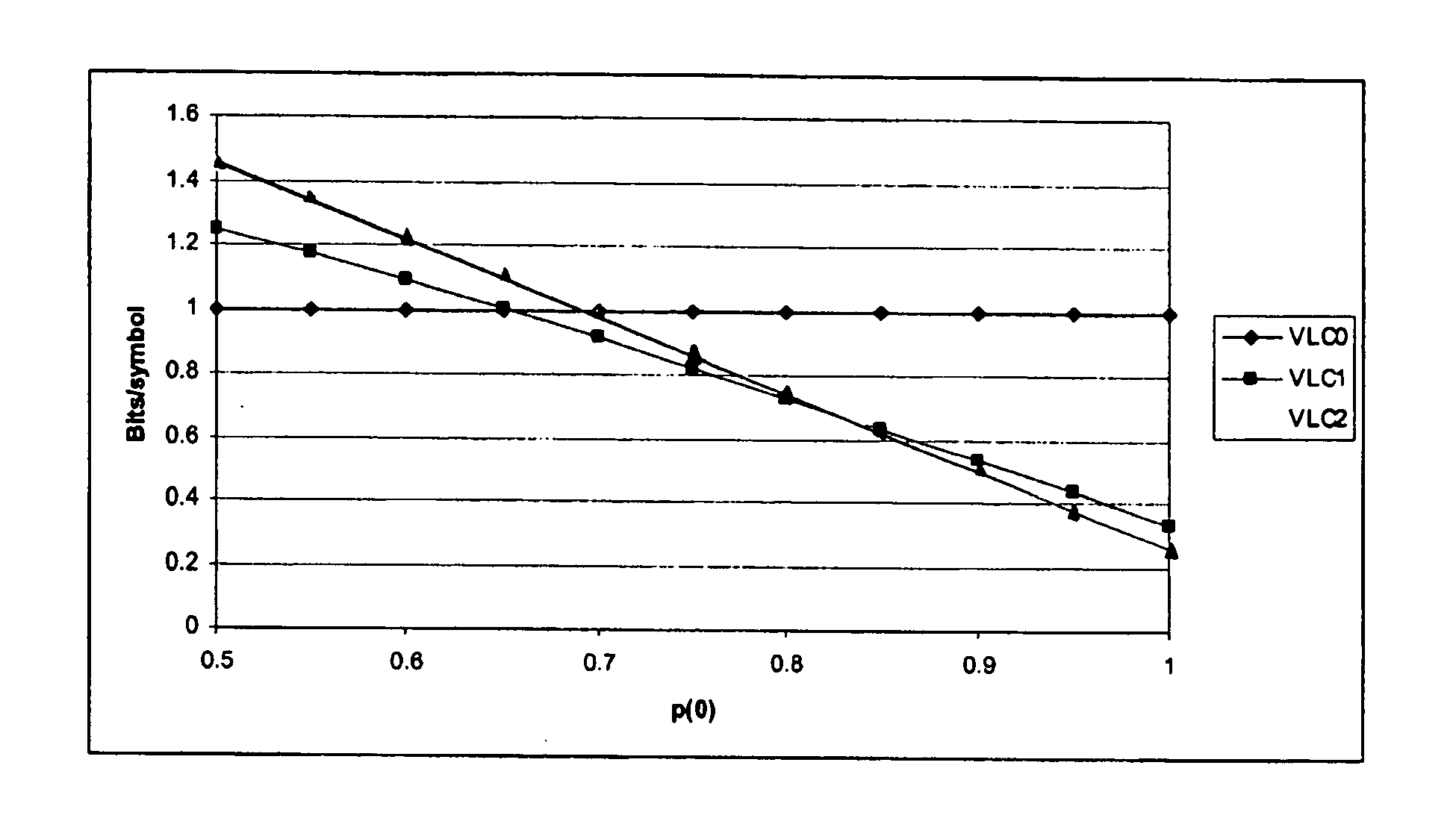

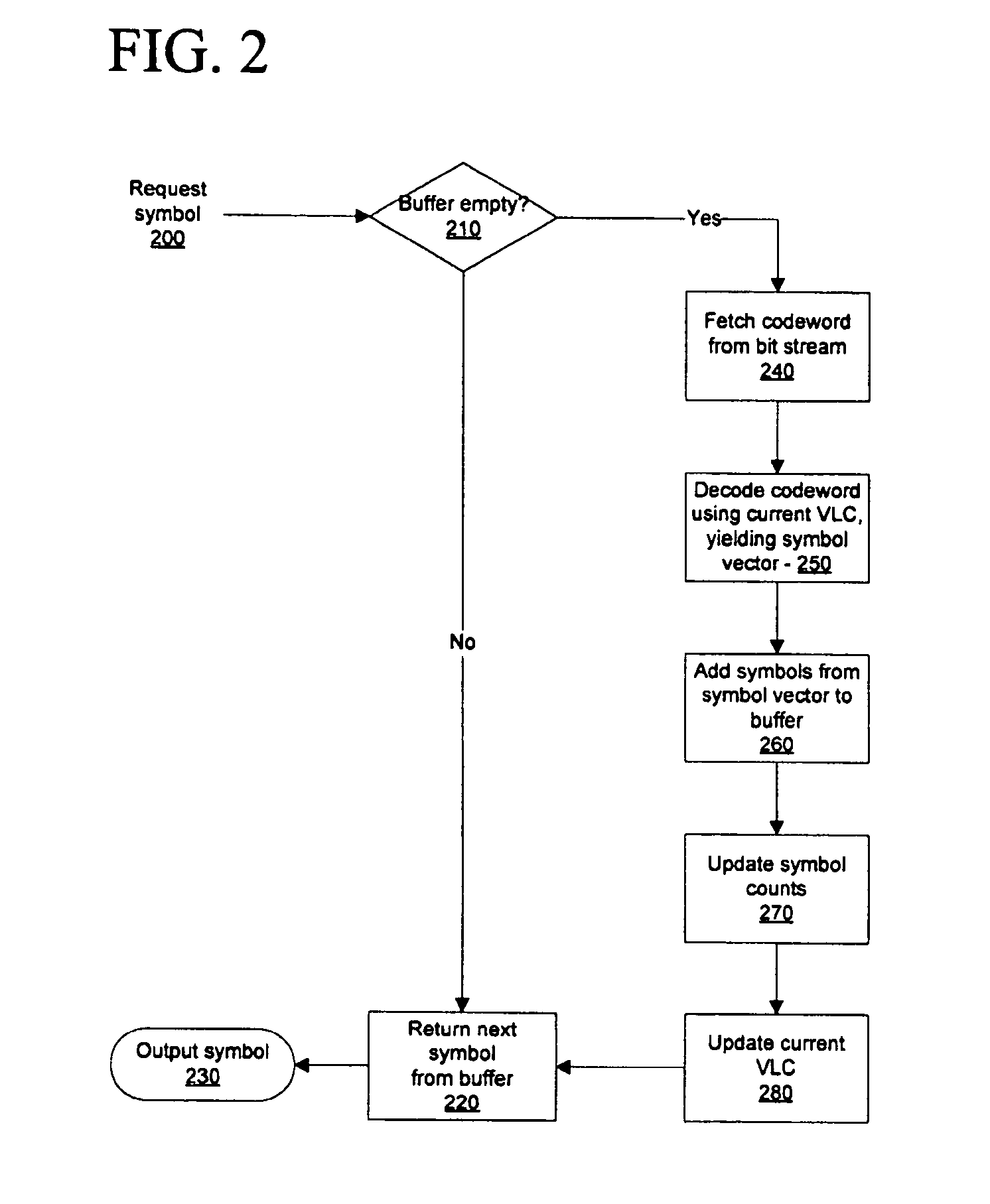

Variable length codes for scalable video coding

InactiveUS20070126853A1Improvement in coder complexityIncreased complexityTwo-way working systemsDigital video signal modificationVariable-length codeCoding block

A method for coding spatial and quality enhancement information in scalable video coding using variable length codes. Conventional systems have been capable of using variable length codes only with nonscalable video coding. In the present invention, the coded block pattern for each block of information, significance passes, and refinement passes can all be coded with different types of variable length codes.

Owner:NOKIA CORP

Systems and methods of processing scanned data

ActiveUS20160028921A1Data augmentationAdvantages with regard to speedCharacter and pattern recognitionVisual presentationDigital dataNon real time

An efficient method and system to enhance digital acquisition devices for analog data is presented. The enhancements offered by the method and system are available to the user in local as well as in remote deployments yielding efficiency gains for a large variety of business processes. The quality enhancements of the acquired digital data are achieved efficiently by employing virtual reacquisition. The method of virtual reacquisition renders unnecessary the physical reacquisition of the analog data in case the digital data obtained by the acquisition device are of insufficient quality. The method and system allows multiple users to access the same acquisition device for analog data. In some embodiments, one or more users can virtually reacquire data provided by multiple analog or digital sources. The acquired raw data can be processed by each user according to his personal preferences and / or requirements. The preferred processing settings and attributes are determined interactively in real time as well as non real time, automatically and a combination thereof.

Owner:KOFAX

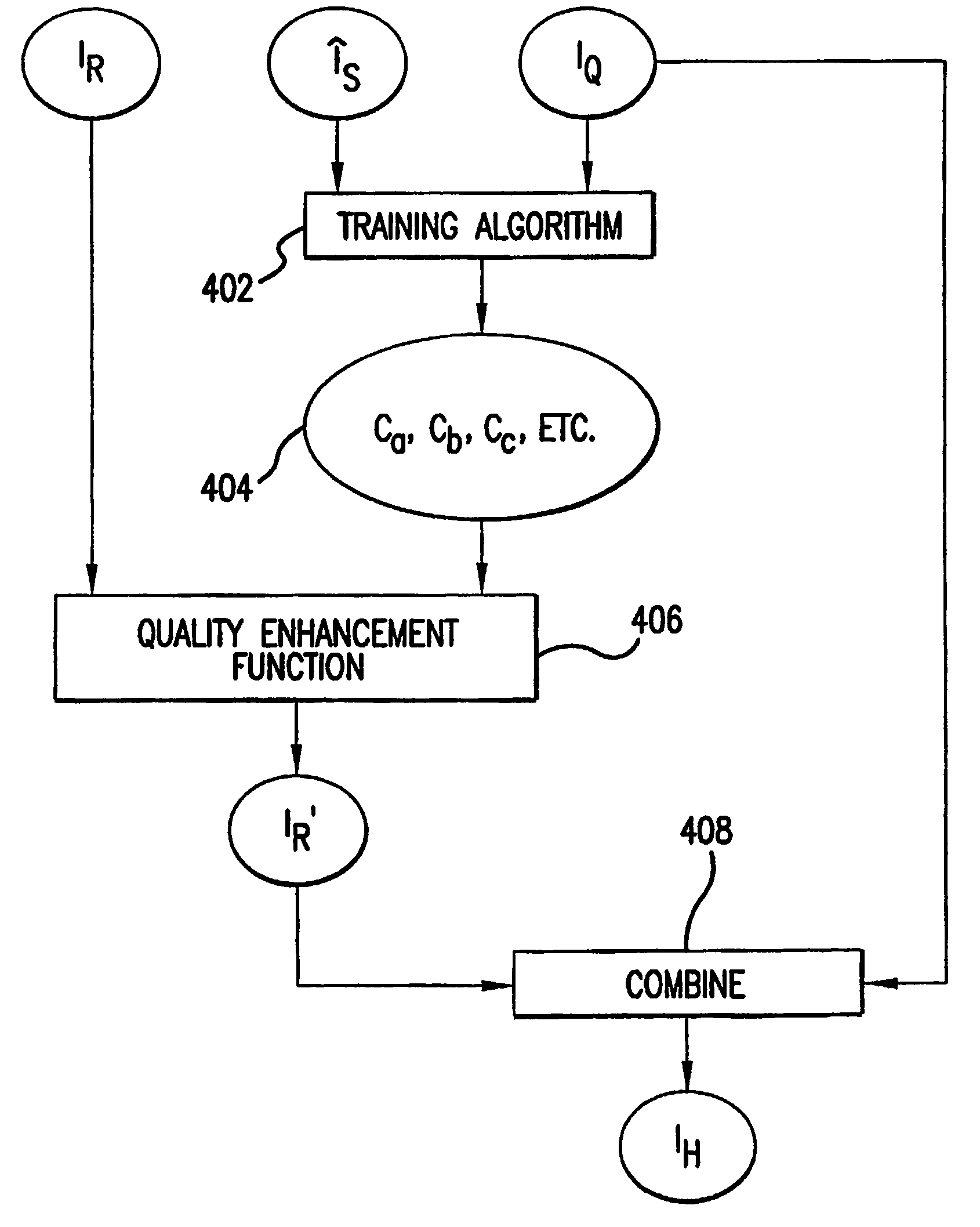

Method and system for enhancing data quality

InactiveUS20060003328A1Improve data qualityEasy to useBioreactor/fermenter combinationsImage enhancementImage resolutionData quality

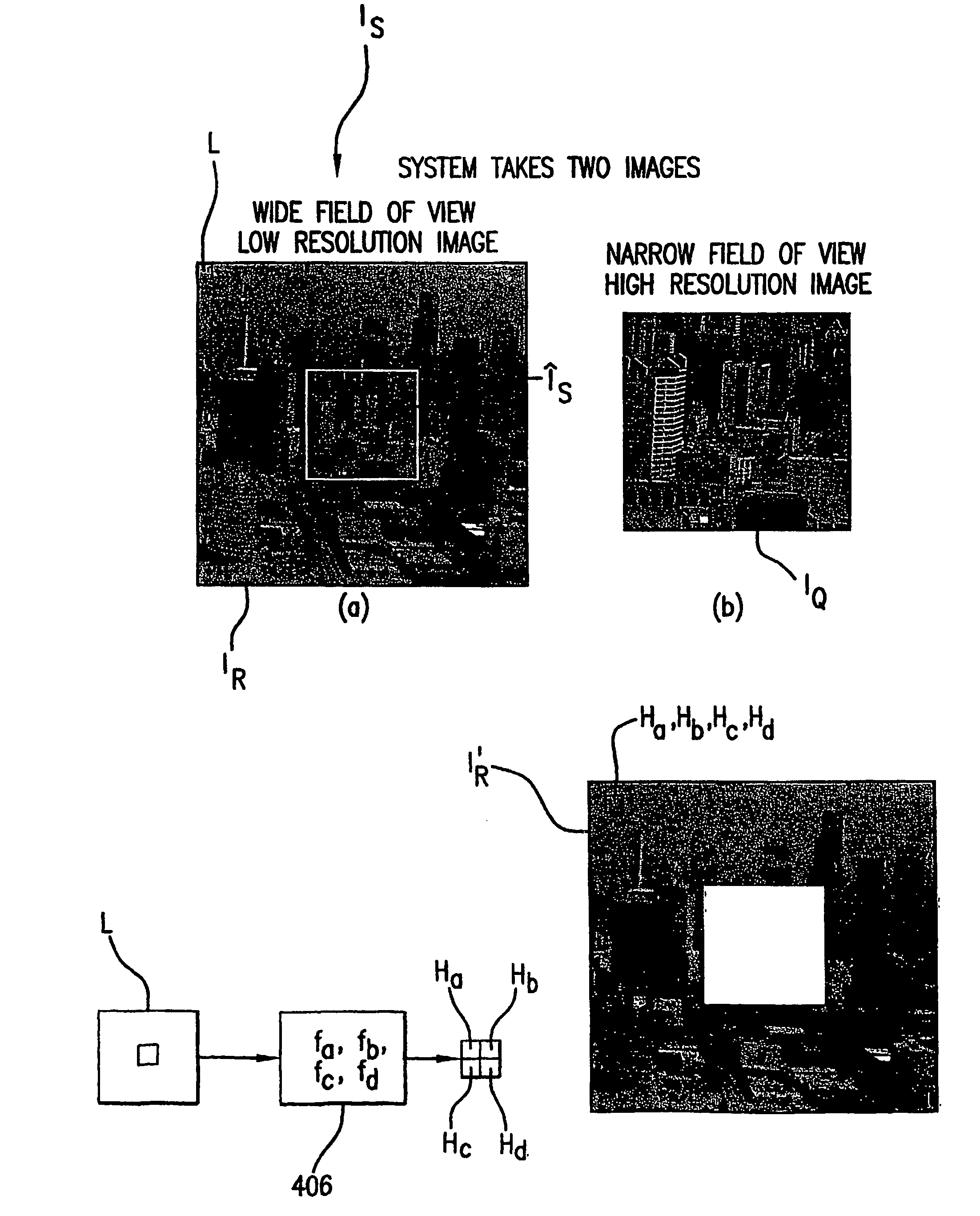

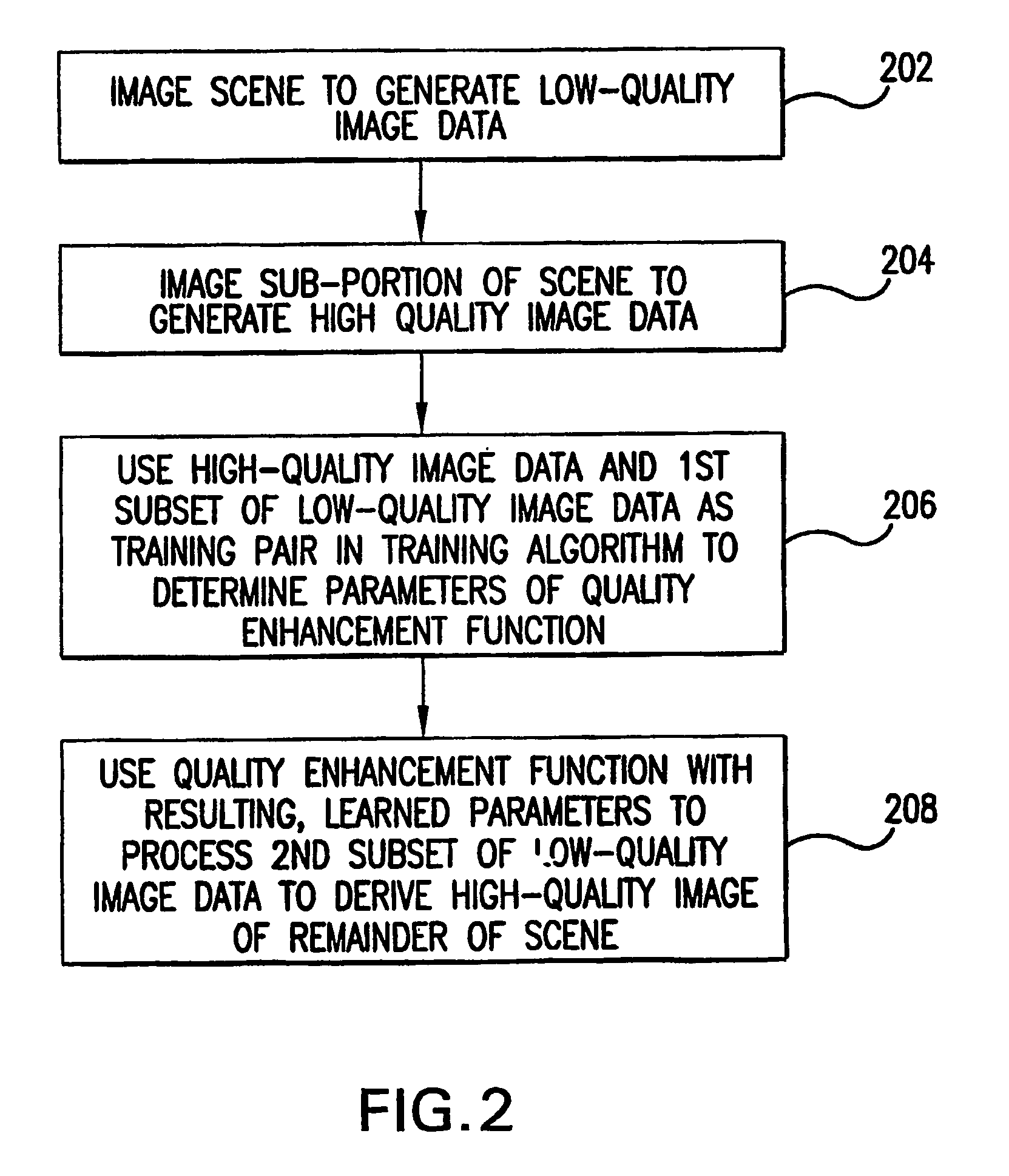

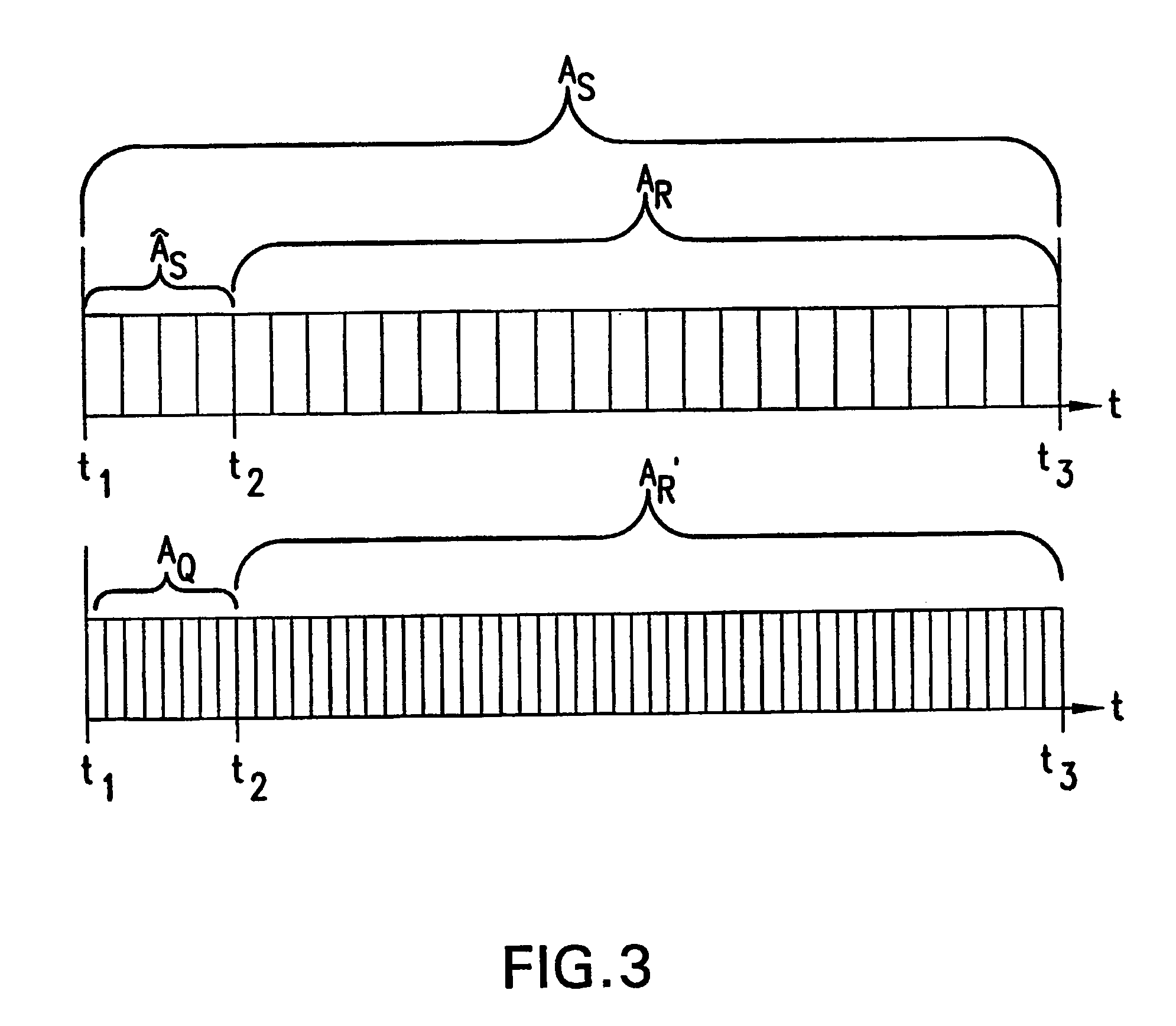

The quality (e.g., resolution) of image data, video data, and sound data representing a scene or signal is enhanced by a quality enhancement function trained on high quality and low quality representations of a portion of the same scene or signal. The enhancement function is thus optimized to the most relevant input. A training algorithm uses low quality image of a scene or scene portion, along with a high quality image of the same scene or scene portion, to optimize the parameters of a quality enhancement function. The optimized enhancement function is then used to enhance other low quality images of the scene or scene portion. Sound data is enhanced by using a low resolution sample of a portion of a signal, and a high resolution sample of the same signal portion, to train a quality enhancement function which is then used to enhance the remainder of the signal.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

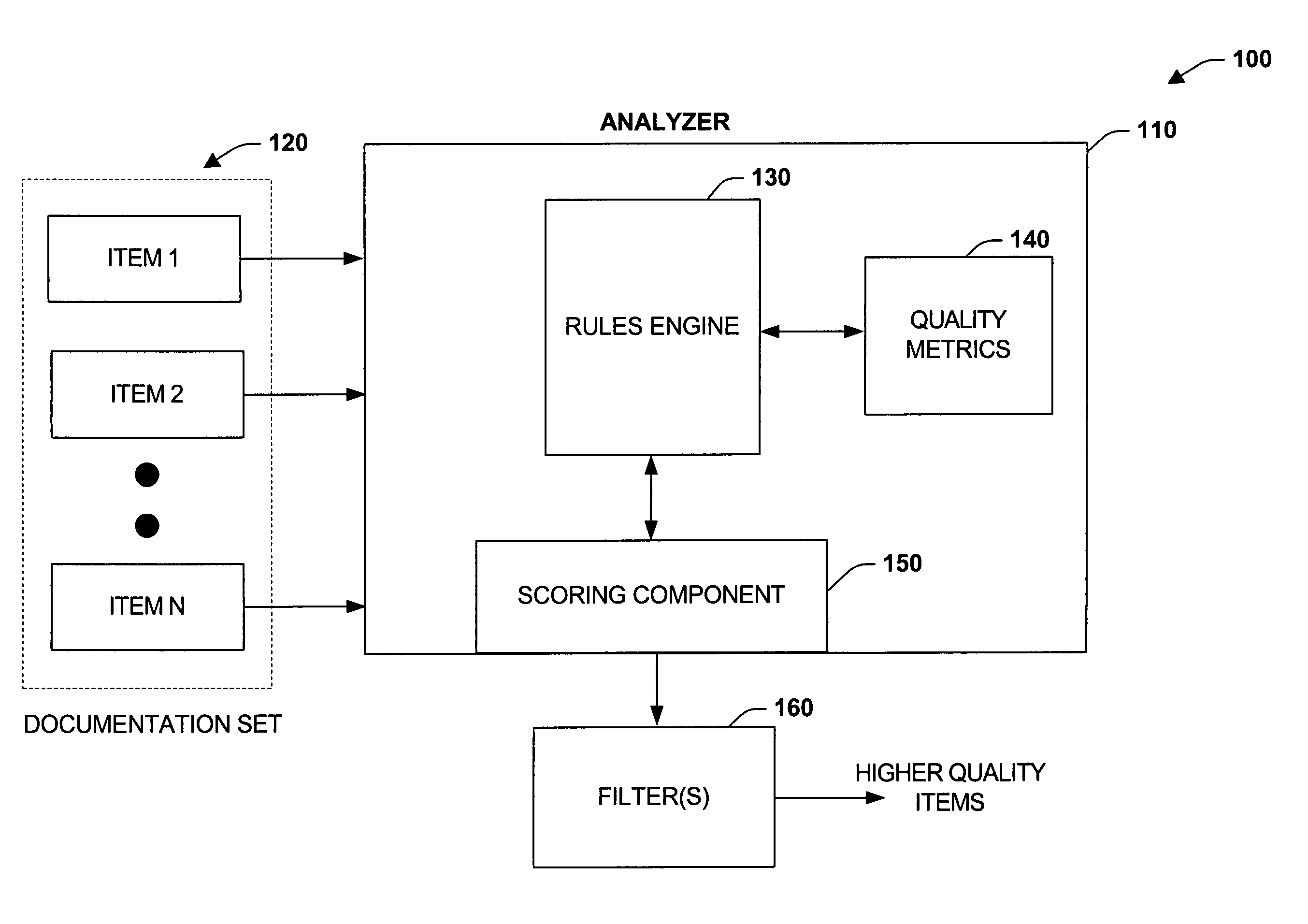

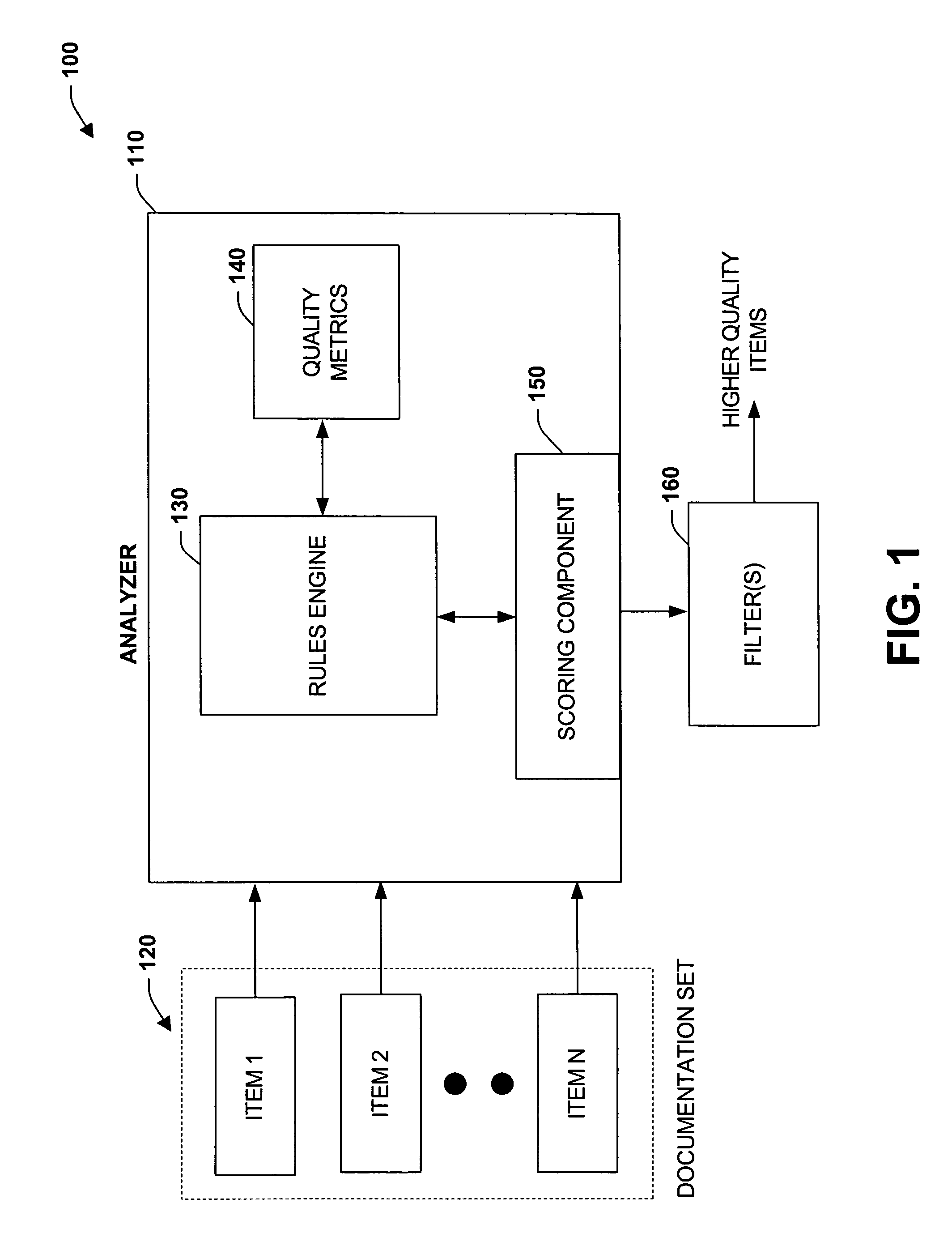

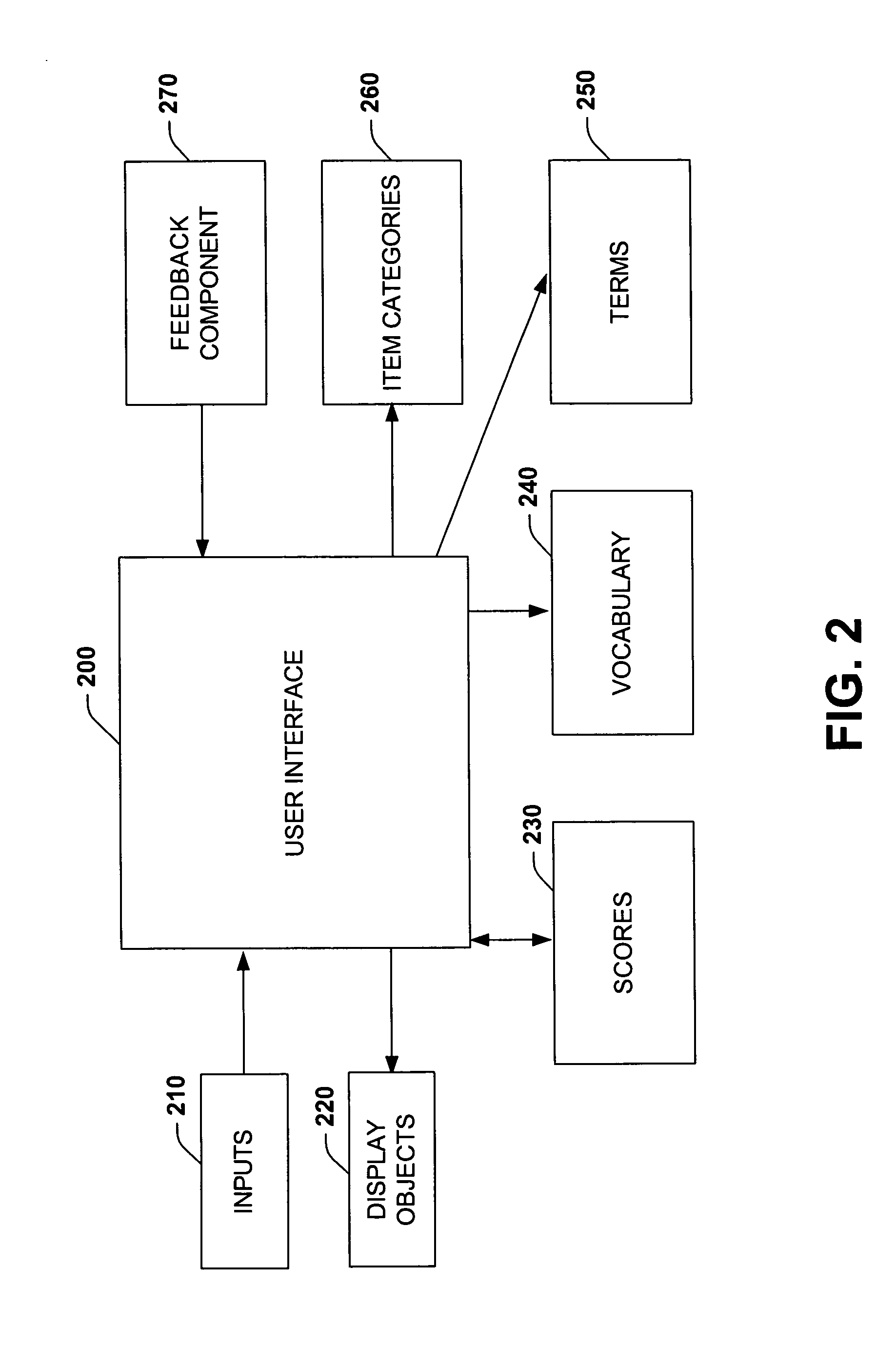

Quality enhancement systems and methods for technical documentation

InactiveUS20050125422A1Quality improvementFacilitate automated and interactive quality controlData processing applicationsNatural language data processingDocumentation procedureSubject matter

The present invention relates to a system and methodology to facilitate automated quality management and controls for one or more items appearing in a documentation set. Respective items are analyzed in accordance with a plurality of quality metrics that can be tracked according to an automated identification process. A system is provided that facilitates quality measurements of data and / or documents appearing in a documentation set, collection or database. A quality component tracks one or more quality metrics associated with the items, wherein the items can include topics, subtopics, or other categories. A rules engine automatically applies the quality metrics to the items to facilitate interactive quality assessments of the items, wherein a scoring component automatically ranks the items based at least in part on the interactive quality assessments of the items.

Owner:MICROSOFT TECH LICENSING LLC

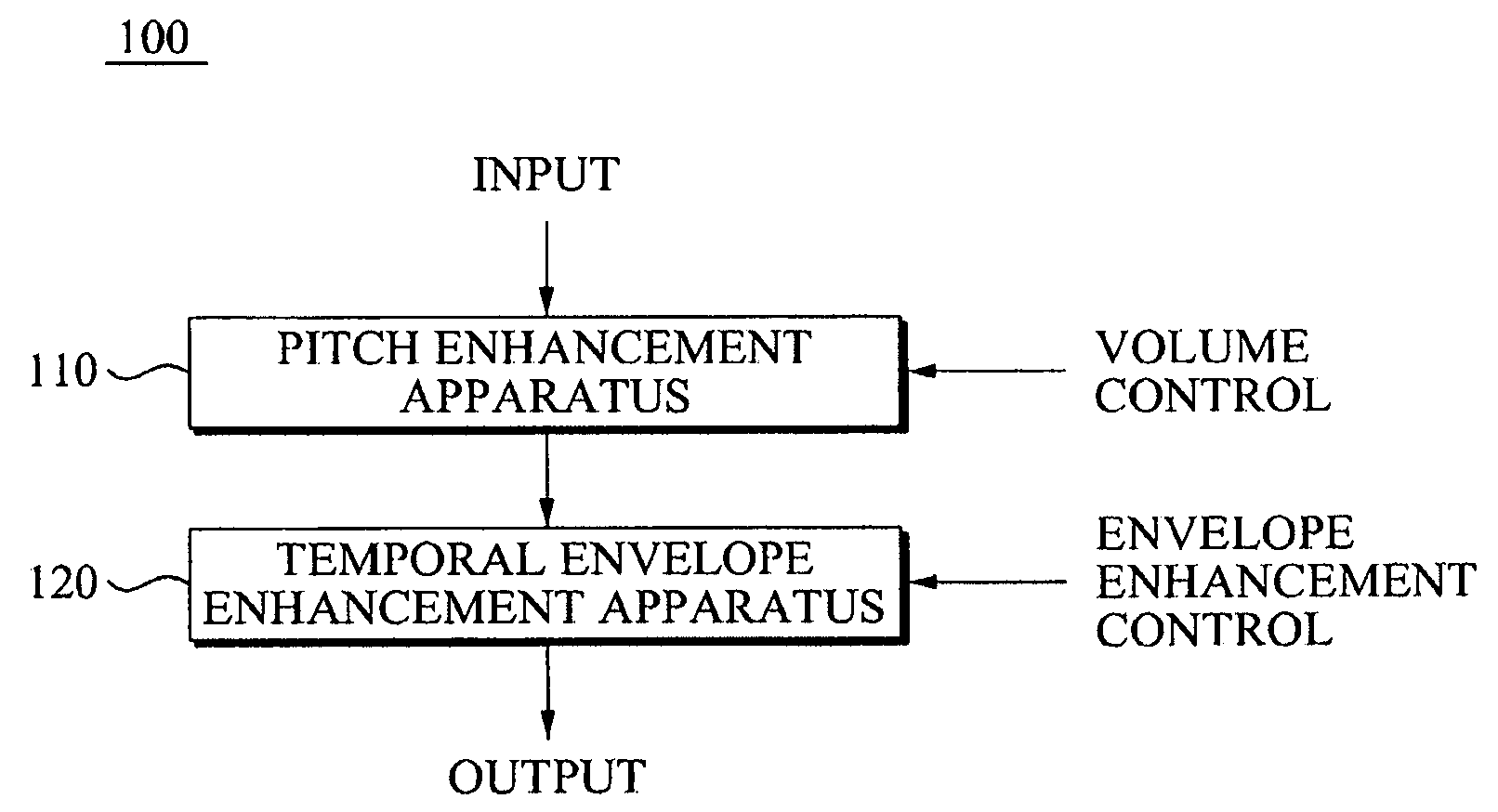

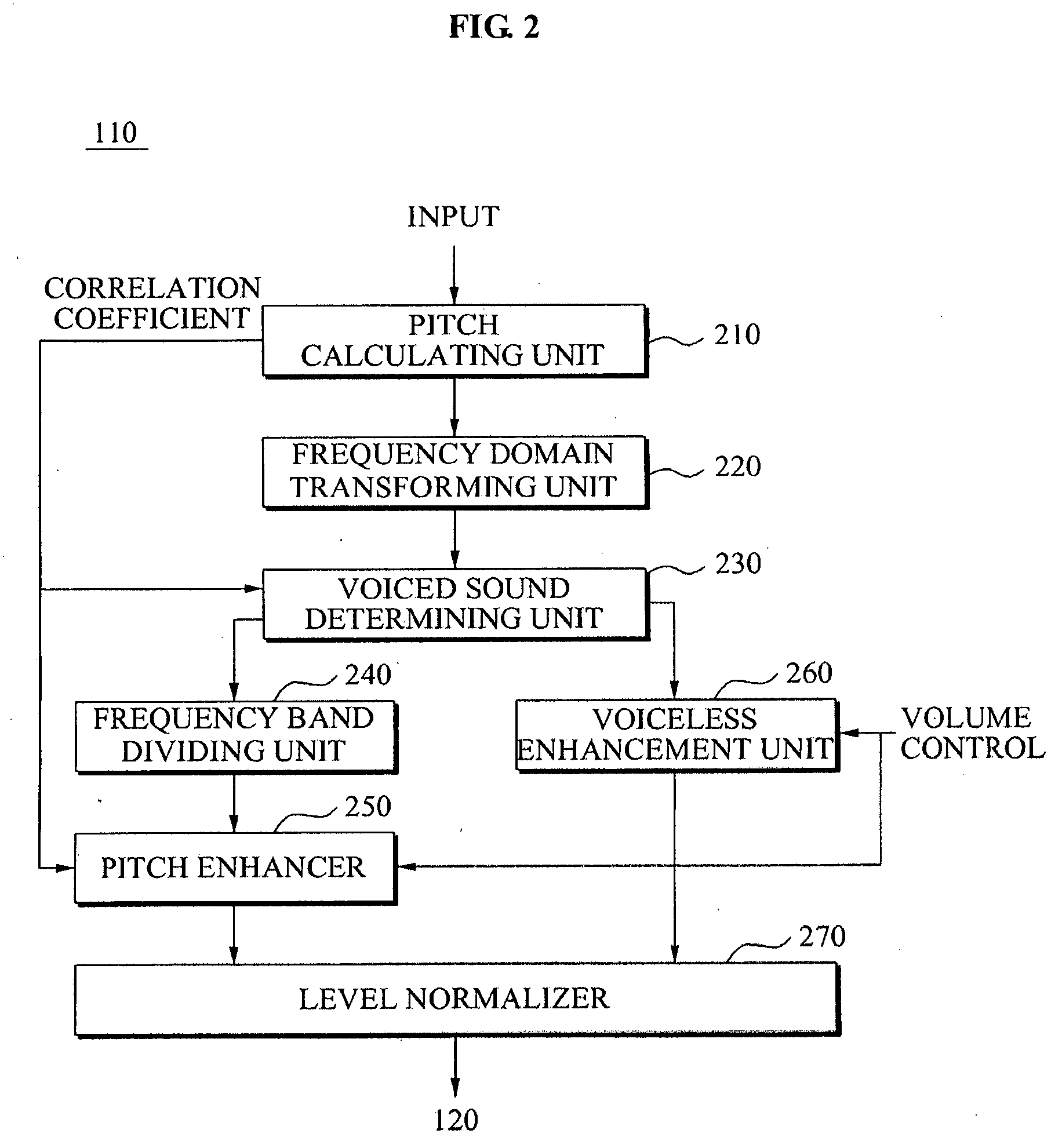

Audio signal quality enhancement apparatus and method

ActiveUS20090306971A1Improve signal qualitySpeech analysisDigital computer detailsSignal qualityAudio frequency

An audio signal quality enhancement apparatus and method. The apparatus includes a pitch calculating unit to extract a pitch period of an audio signal, a frequency domain transforming unit to transform the audio signal to a frequency domain, a frequency band dividing unit to classify the transformed audio signal into audio signals for each of the plurality of frequency bands based on the extracted pitch period, and a pitch enhancement unit to determine a gain based on a volume of the transformed audio signal, and to generate an output signal by multiplying each of the classified audio signals with respect to each of the plurality of frequency bands by the gain, thereby enhancing quality of the audio signal.

Owner:SAMSUNG ELECTRONICS CO LTD +1

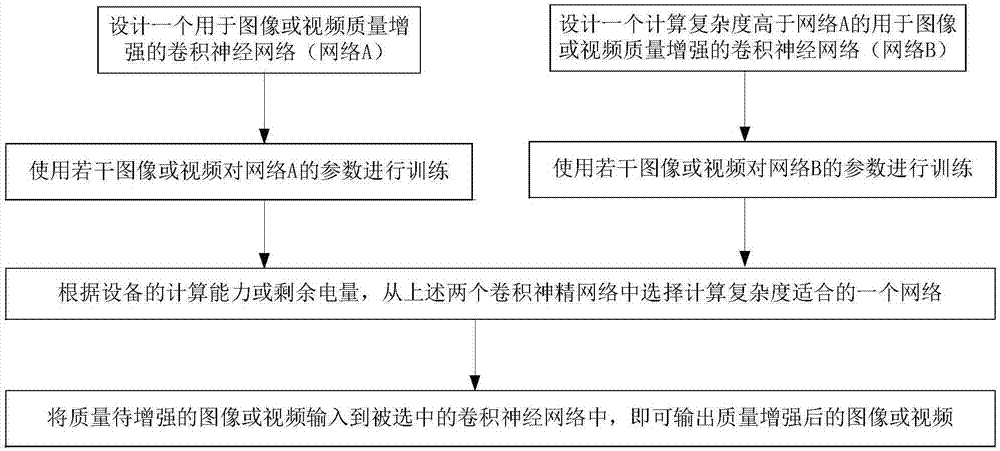

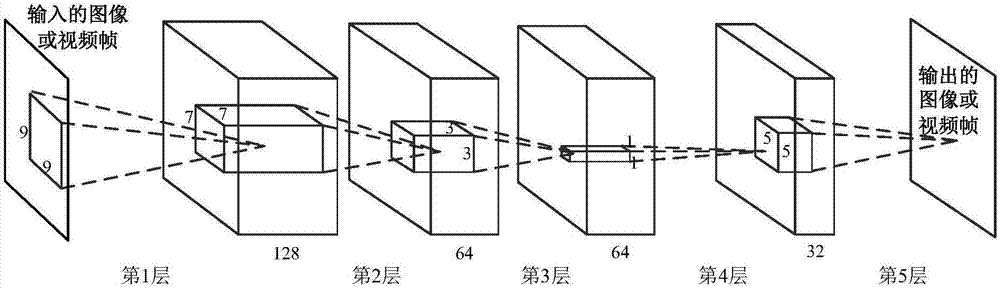

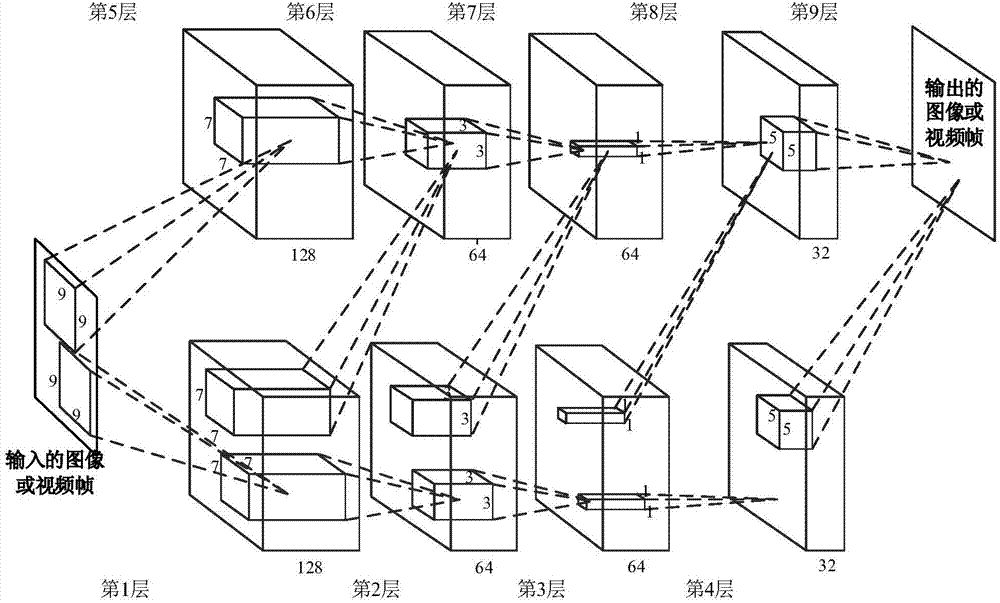

Image or video quality enhancement method based on convolution neural networks

ActiveCN107481209AQuality improvementEnhance videoImage enhancementImage analysisComputation complexityRound complexity

The invention discloses an image or video quality enhancement method based on convolution neural networks, and belongs to the field of computer vision. The method comprises the steps of firstly, designing the two convolution neural networks for video quality enhancement, wherein the two networks have different computational complexities; secondly, selecting a plurality of training images or videos to train parameters in the two convolution neural networks; thirdly, selecting the convolution neural network with the more suitable computational complexity according to actual needs to input the images or videos with the quality to be enhanced into the selected network; finally, outputting the images or videos after quality enhancement through the network. According to the image or video quality enhancement method based on the convolution neural networks, the quality of the videos can be effectively enhanced; a user can select the specified convolution neural network with the more suitable computational complexity to enhance the quality of the images or videos according to the computational capacity or remaining power capacity of equipment.

Owner:BEIHANG UNIV

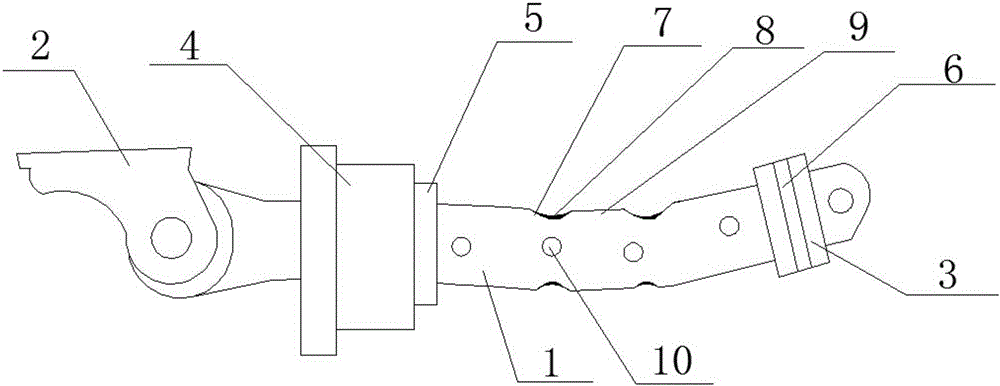

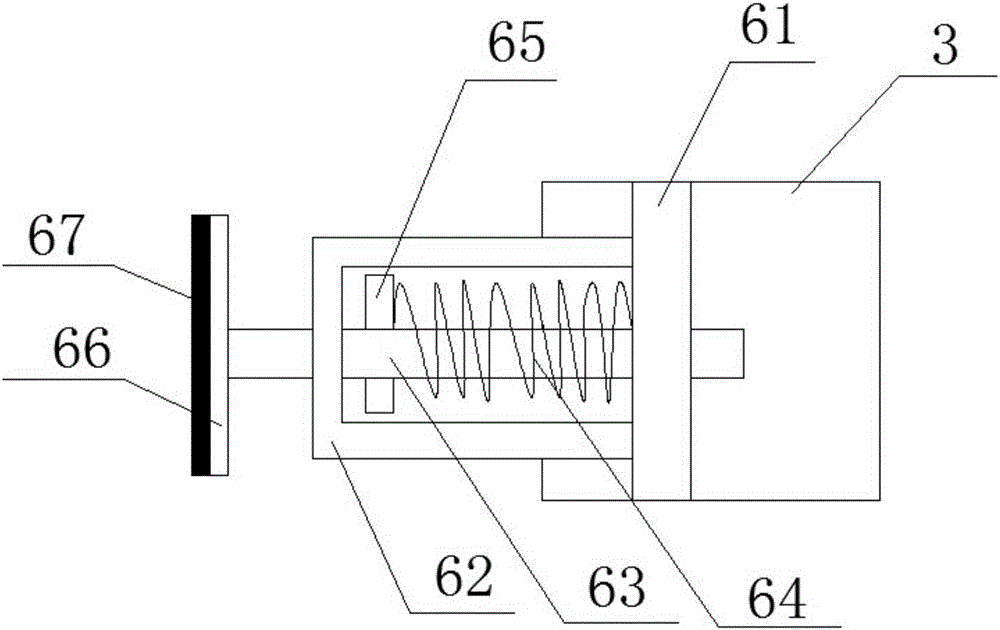

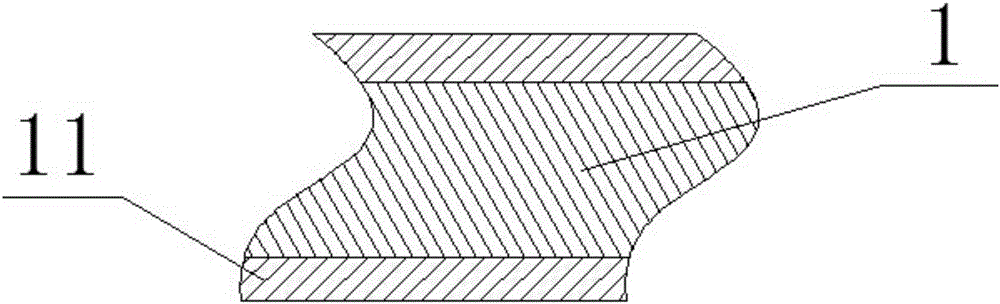

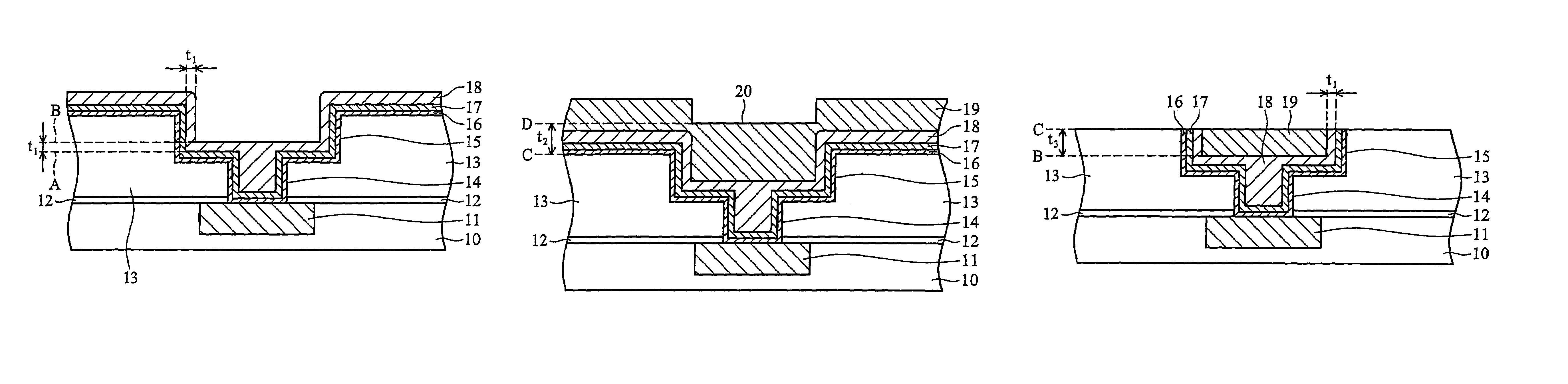

Vehicle door stop

The invention discloses a vehicle door stop and relates to the field of auto parts. The vehicle door stop comprises a limit arm, one end of which is provided with a mounting bracket and the other end of which is provided with a block. The limit arm is equipped with a limit box, which is in slip connection with the limit arm. The limit box is provided with a limit block. The block is provided with a buffer device. The buffer device comprises a fixed plate, a trough body and a connecting shaft. The fixed plate is arranged on the block. The trough body is disposed on the fixed plate. One end of the connecting shaft successively passes through the trough body and the fixed plate to be arranged on the outside, and the other end of the connecting shaft is provided with a movable plate. The connecting shaft is provided with a retaining lug which is arranged inside the trough body. A spring is arranged between the retaining lug and the fixed plate. The spring is mounted on the connecting shaft. By the above design, the vehicle door stop has a simple and reasonable structure, can effectively used for limitation and reduction of abnormal sound, can give users a pleasant opening experience and is beneficial to automobile quality enhancement.

Owner:ANHUI WANSHANHONG TECH

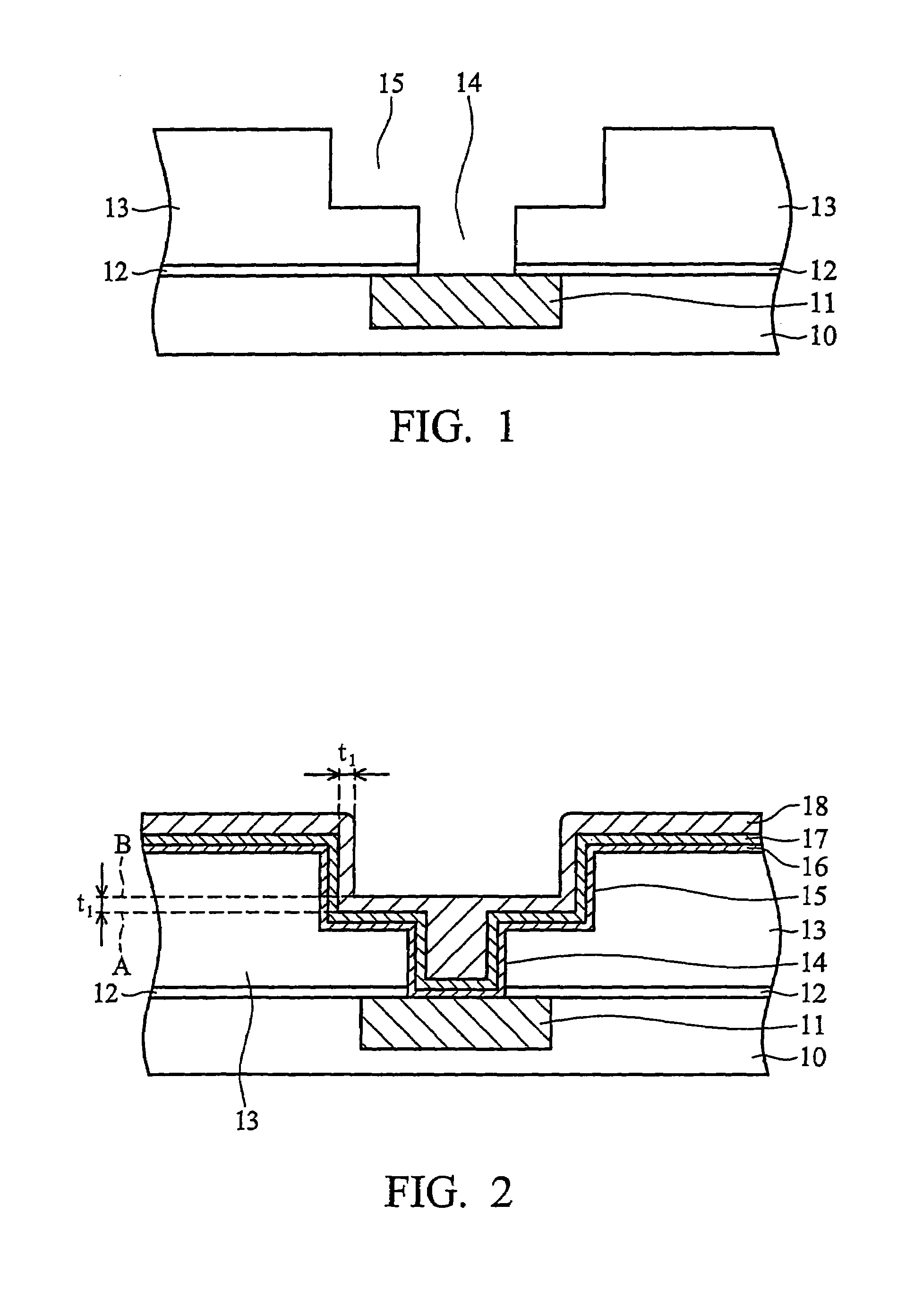

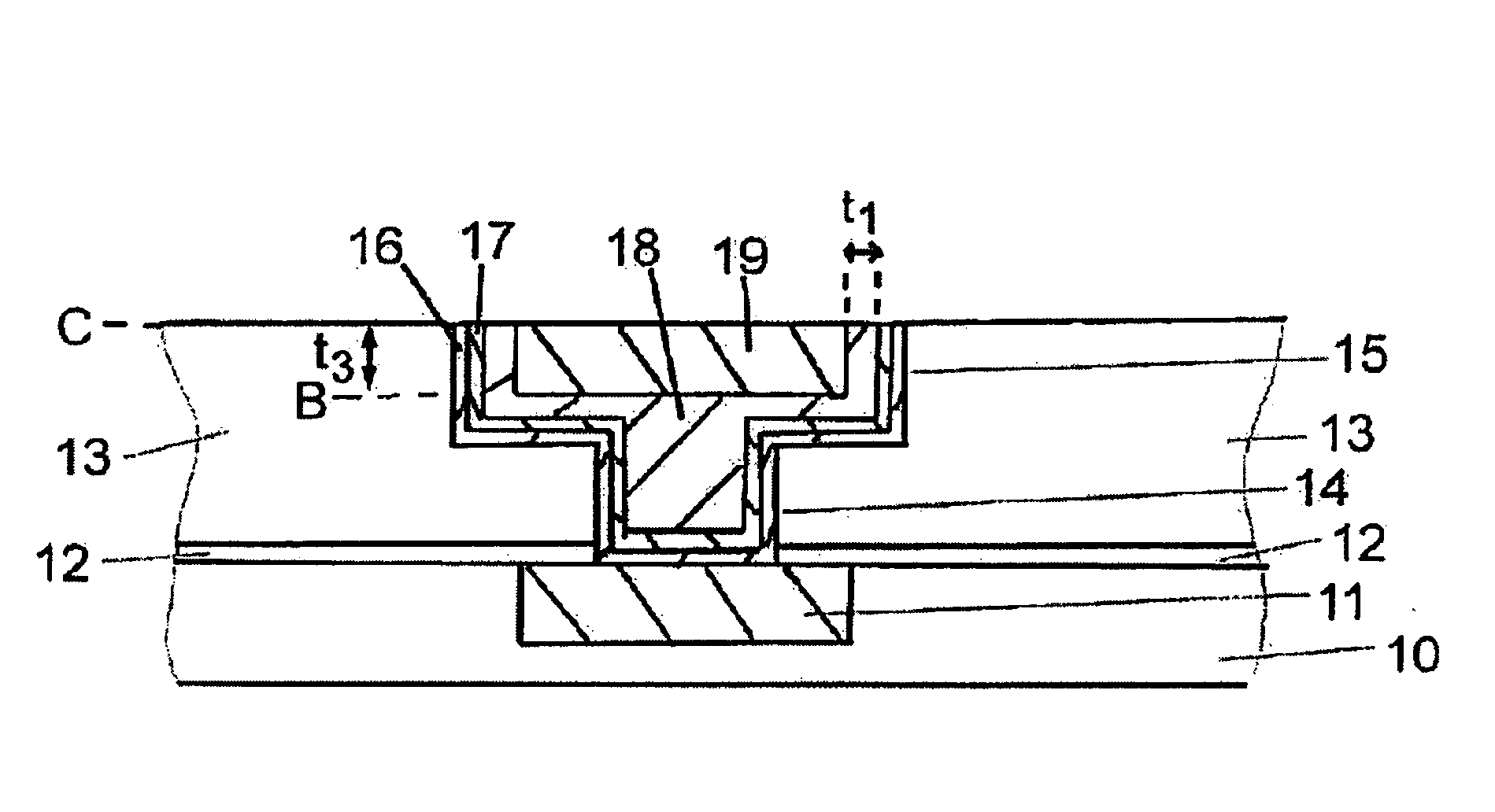

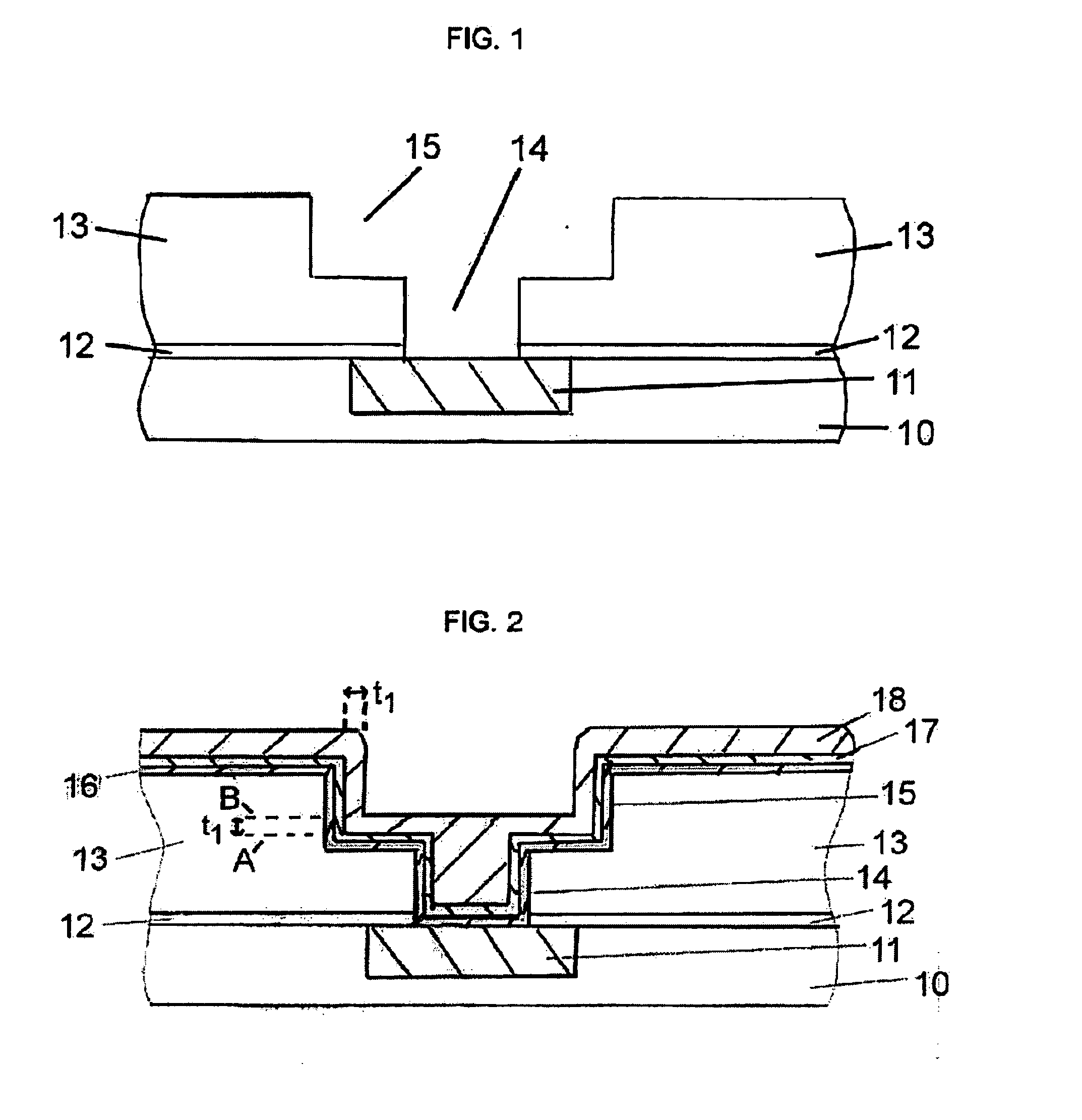

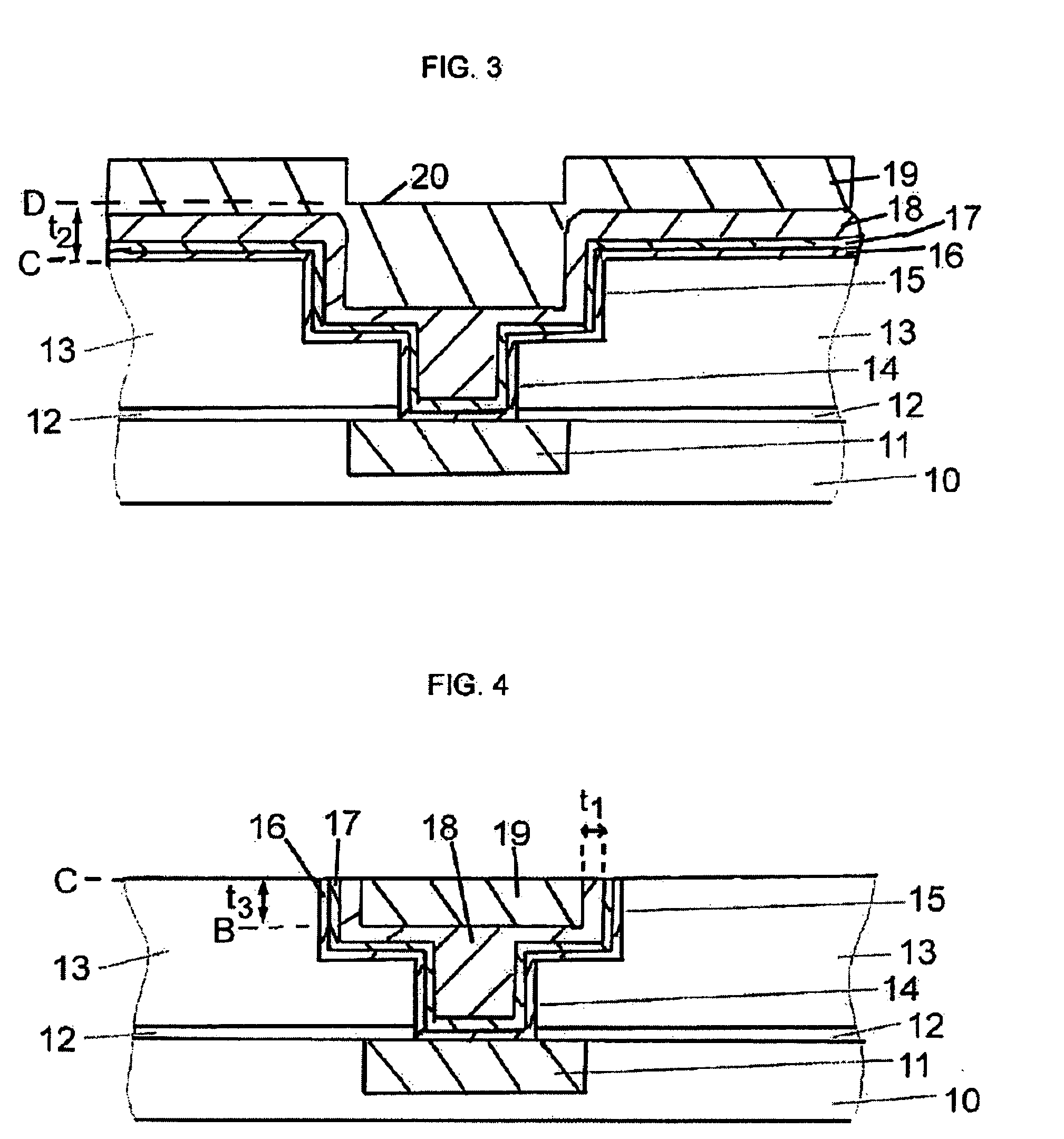

Method and apparatus for copper film quality enhancement with two-step deposition

InactiveUS7189650B2Improve performanceLower performance requirementsSemiconductor/solid-state device manufacturingSemiconductor devicesCopperSputter deposition

The disclosure relates to a method and apparatus for enhancing copper film quality with a two-step deposition. The two step deposition may include depositing a first copper film by electrochemical plating, annealing the first copper film at a desired temperature for a duration of time to remove any impurities, depositing a second copper film and annealing the second copper film for a duration of time to remove impurities. The second copper film can be deposited by electrochemical plating without HCl / C-based additive. The second copper film can also be deposited by sputtering to avoid impurities including C, Cl and S.

Owner:TAIWAN SEMICON MFG CO LTD

Adaptive variable length codes for independent variables

InactiveUS20070046504A1Improve coding efficiencyCode conversionDigital video signal modificationVariable-length codeCoding block

A method for coding spatial and quality enhancement information in scalable video coding using variable length codes. Conventional systems have been capable of using variable length codes only with nonscalable video coding. In the present invention, the coded block pattern for each block of information, significance passes, and refinement passes can all be coded with different types of variable length codes. The present invention also provides for a variable length encoder / decoder that dynamically adapts to the actual symbol probability. The encoder / decoder of the present invention counts the number of times each symbol is coded. Based upon these counts, the encoder / decoder selects how many symbols to group when forming a code word. The encoder also uses these counts to select the specific codeword that should be used.

Owner:NOKIA CORP

Systems and methods of processing scanned data

ActiveUS9769354B2Data augmentationAdvantages with regard to speedCharacter and pattern recognitionVisual presentationDigital dataNon real time

Owner:KOFAX

Method and apparatus for copper film quality enhancement with two-step deposition

InactiveUS20060105565A1Improve film qualityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesSputter depositionElectrochemistry

The disclosure relates to a method and apparatus for enhancing copper film quality with a two-step deposition. The two step deposition may include depositing a first copper film by electrochemical plating, annealing the first copper film at a desired temperature for a duration of time to remove any impurities, depositing a second copper film and annealing the second copper film for a duration of time to remove impurities. The second copper film can be deposited by electrochemical plating without HCl / C-based additive. The second copper film can also be deposited by sputtering to avoid impurities including C, Cl and S.

Owner:TAIWAN SEMICON MFG CO LTD

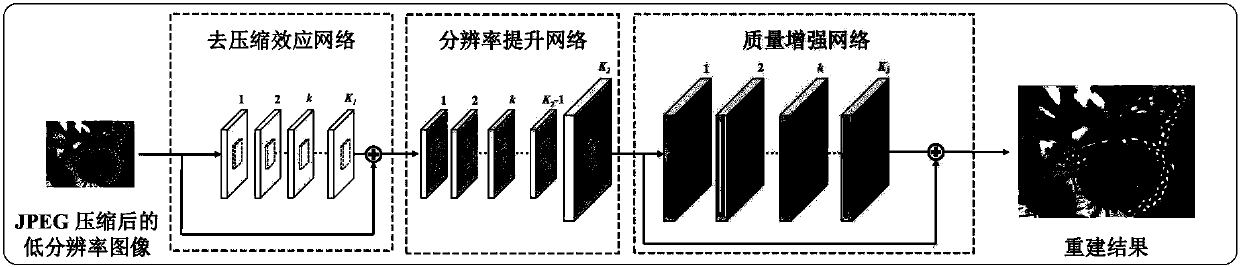

JPEG compressed image super-resolution reconstruction method based on convolutional neural network

InactiveCN107563965AEfficient super-resolution reconstruction methodGeometric image transformationNeural architecturesImage resolutionJPEG

The invention discloses a JPEG compressed image super-resolution reconstruction method based on a convolutional neural network (CNN). The method mainly includes the following steps of: constructing asuper-resolution reconstruction model based on the CNN for a JPEG compressed image; training the constructed CNN by using a training image; reconstructing a JPEG-compressed low-resolution image by using a trained CNN model. The constructed CNN framework comprises a decompression effect network, a resolution enhancement network and a quality enhancement network, and can be subjected to end-to-end optimization training. The method of the present invention can reduce the compression noise in the JPEG compressed image and improve the resolution of the JPEG compressed image, can be applied to the fields of image and video compression, digital multimedia communication and the like.

Owner:SICHUAN UNIV

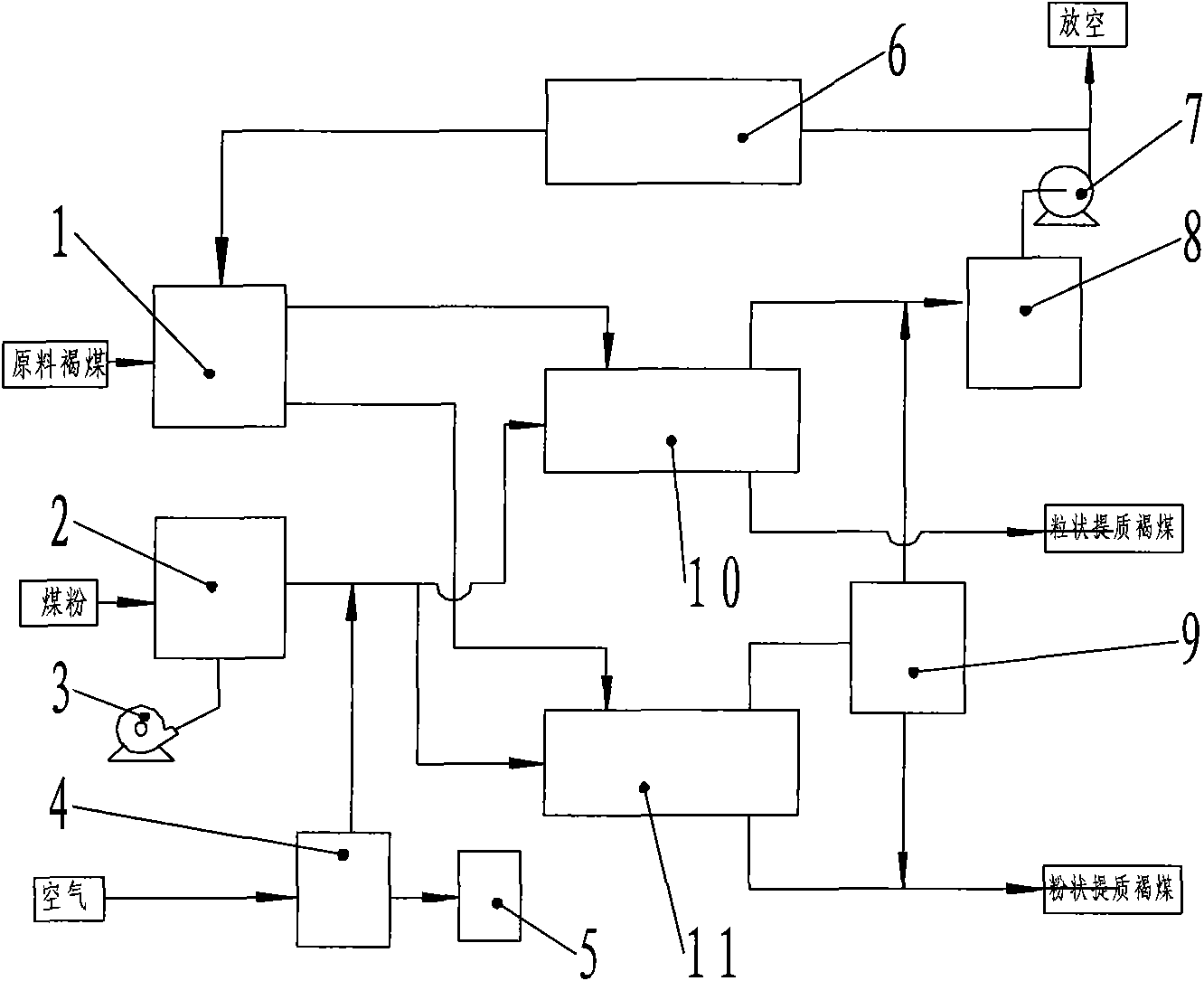

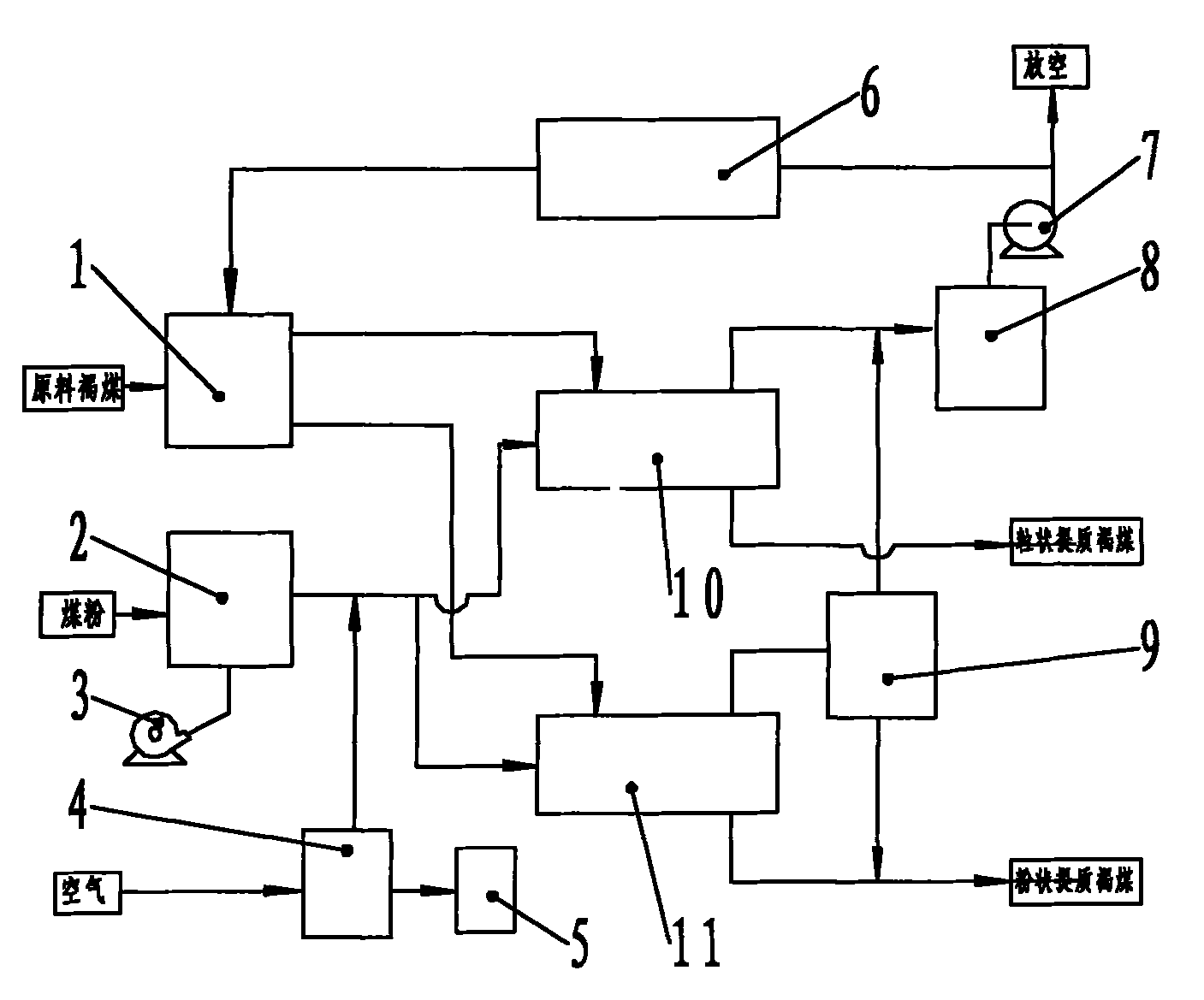

Method and device for drying and quality enhancement of lignite

InactiveCN101776370AImprove qualityIncrease useDrying solid materials with heatDrying machine combinationsLow oxygenCoal

The invention provides a method and a device for the drying and the quality enhancement of lignite. The device comprises a drying / sieving device, a preheating and drying / sieving device, a hot blast heater, a drying drum, a vibration fluidized bed, a cyclone separator, a defogger and a dust remover. The hot blast heater is respectively connected to the drying drum and the vibration fluidized bed, and an outlet of the preheating and drying / sieving device is respectively connected with the drying drum and the vibration fluidized bed. The preheating and drying / sieving device divides the lignite into two stages of big particle diameter and small particle diameter, high-temperature flue gas generated by the hot blast heater is used as a heating medium, the temperature of the flue gas is regulated by the residual low-oxygen gas after oxygen gas is separated by using an air separation system, the drying drum and the vibration fluidized bed are used for producing the quality-enhanced lignite with the big particle diameter and the small particle diameter, different production requirements are met, and part of exhausted tail gas is circularly used for preheating the raw materials of the lignite after being defogged. The invention respectively carries out drying and quality enhancement on the lignite according to the sizes of the particle diameters by grading equipment, eliminates the problem of uneven drying caused by different particle diameters, realizes the effective quality enhancement and the comprehensive utilization of coal resources, and is used for the large-scale process of drying and quality enhancement of the lignite.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

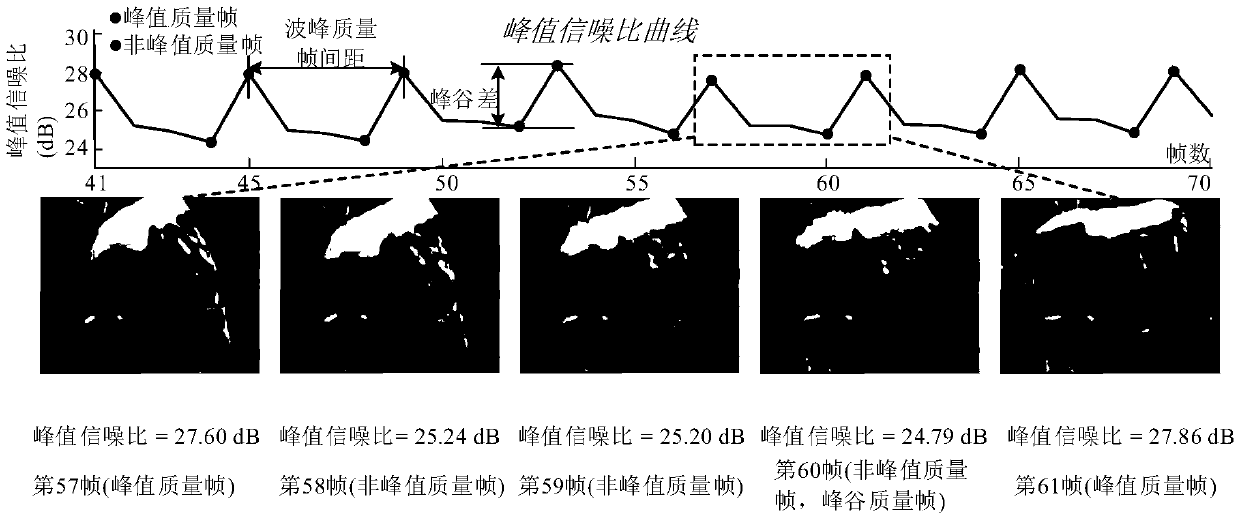

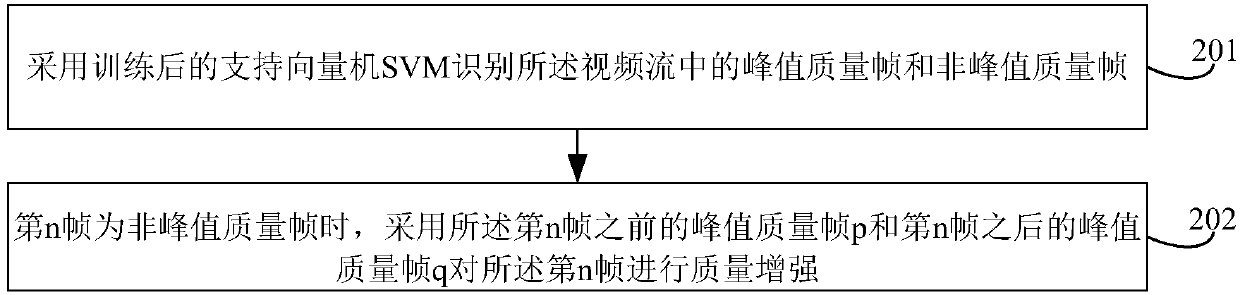

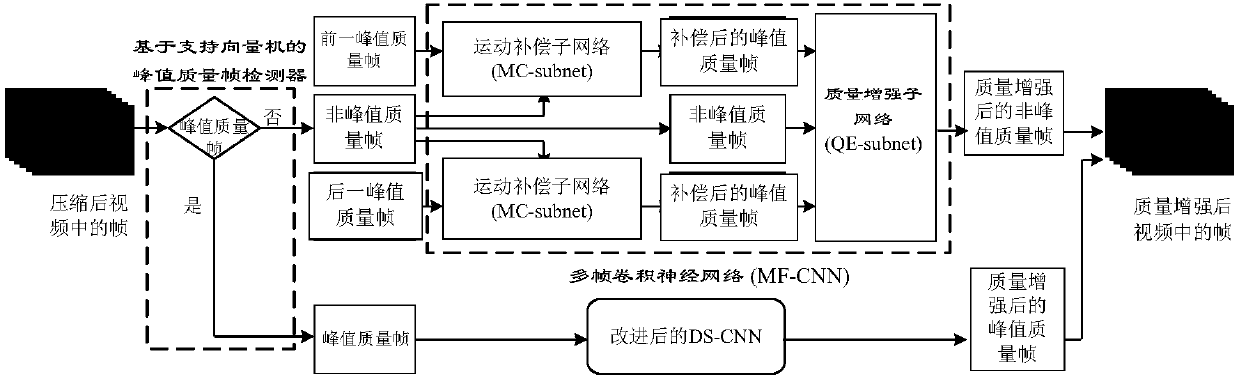

Multi-frame quality enhancement method and device for lossy compressed video

ActiveCN108307193ANo loss of qualityColor television signals processingKernel methodsPattern recognitionMultiple frame

The invention provides a multi-frame quality enhancement method and device for a lossy compressed video, and the method comprises the steps: employing m frames correlated with an i-th frame for the quality enhancement of the i-the frame of a decomposed video stream, so as to play the i-the frame after quality enhancement, wherein the m frames belong to the video stream, and each of the m frames and the i-th frame respectively have the same pixels, or the corresponding numbers of pixels are greater than a preset threshold value, and m is a natural number greater than one. In a specific application, the method can employ a peak quality frame for enhancing a non-peak quality frame between two peak quality frames. The above method alleviates the quality fluctuation between a plurality of frames in a play process of the video stream, and enables the quality of all frames in the video after the lossy compression to be improved.

Owner:BEIHANG UNIV

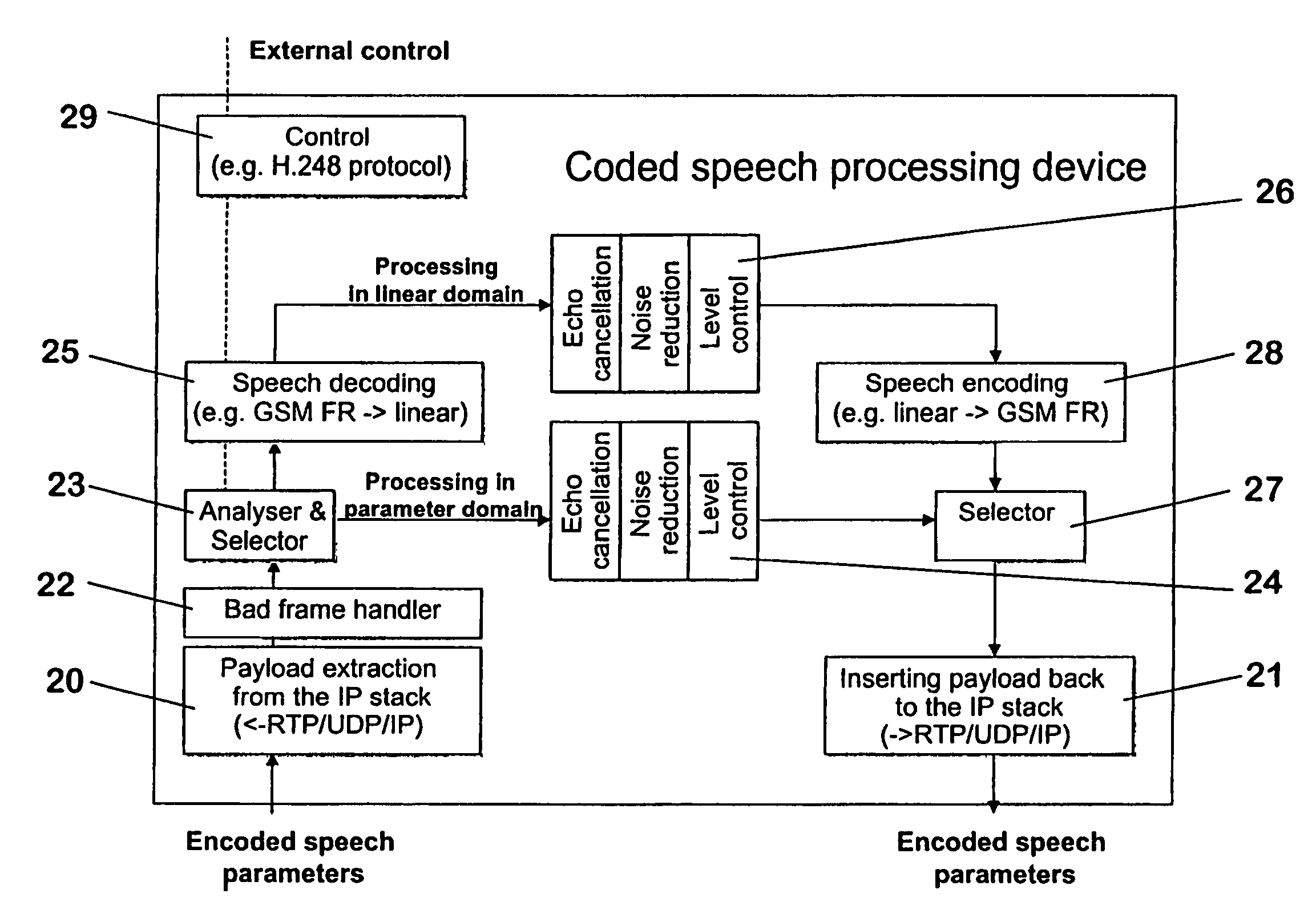

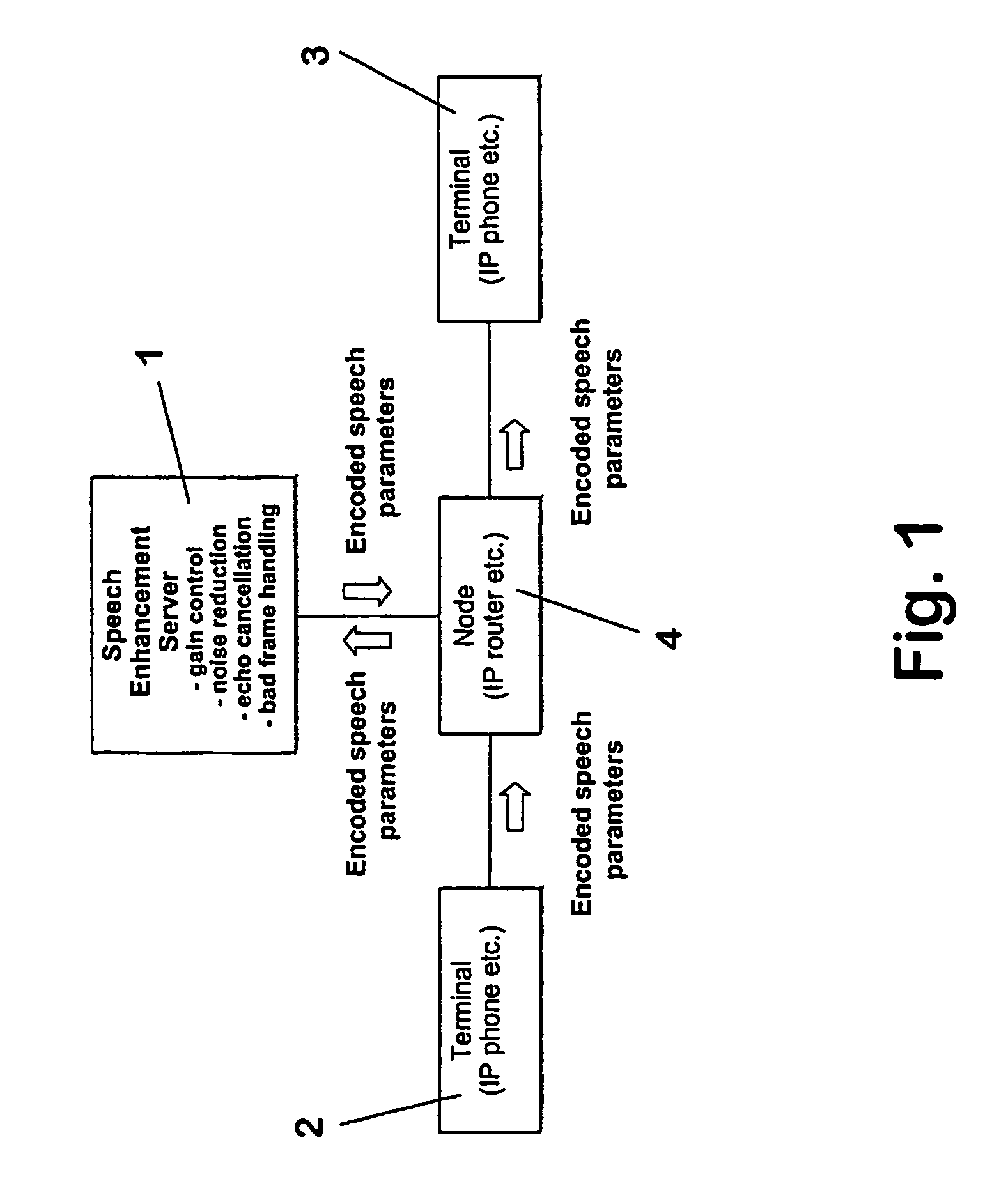

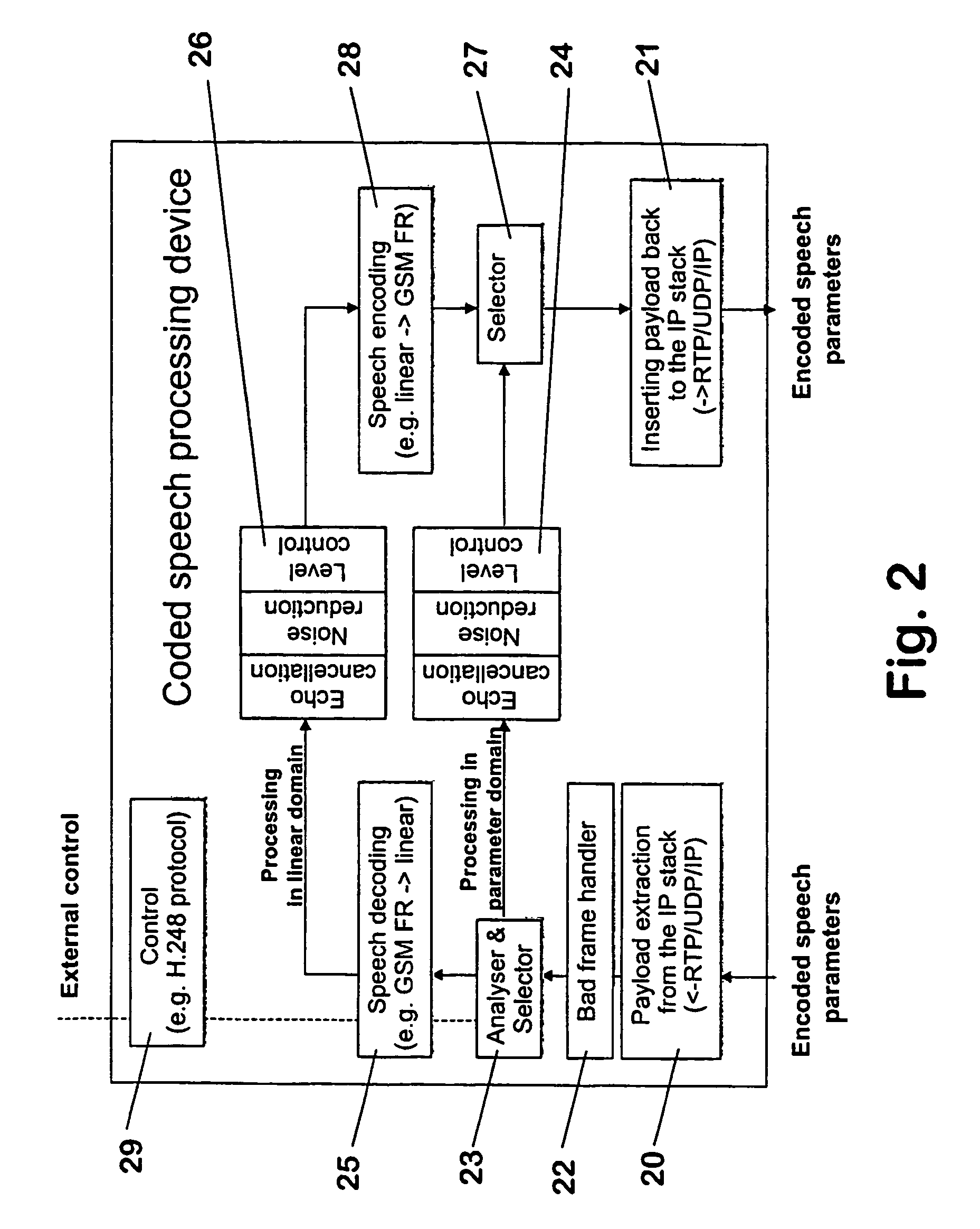

Audio signal quality enhancement in a digital network

InactiveUS7539615B2Satisfactory enhancement of qualityQuality improvementAutomatic call-answering/message-recording/conversation-recordingSpeech analysisSignal qualitySignal on

The invention relates to a network element (1) and a method for enhancing the quality of digitised analogue signals transmitted in parameterised coded form via a digital network. In order to enable an enhancement of the quality of the digitised analogue signals on network side, the network element comprises means (20, 21) for extracting signals from and insert signals into the network, first processing means (24) for processing the extracted parameters in the parameter domain with functions suitable to enhance the quality of the digitised analogue signals and second processing means (26) for processing the extracted parameters in the linear domain with functions suitable to enhance the quality of the digitised analogue signals. Moreover included analysing and selecting means (23, 27) determine the expected enhancement of quality in the different processing domains and cause a corresponding insertion of processed signals back into the network. The proposed method comprises corresponding steps.

Owner:NOKIA SOLUTIONS & NETWORKS OY

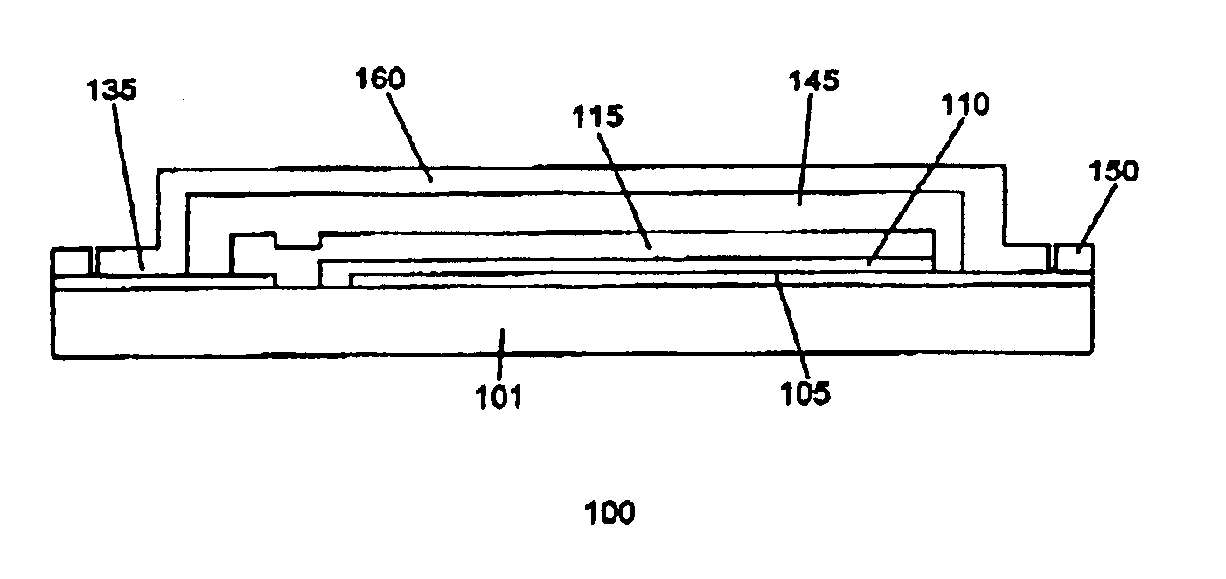

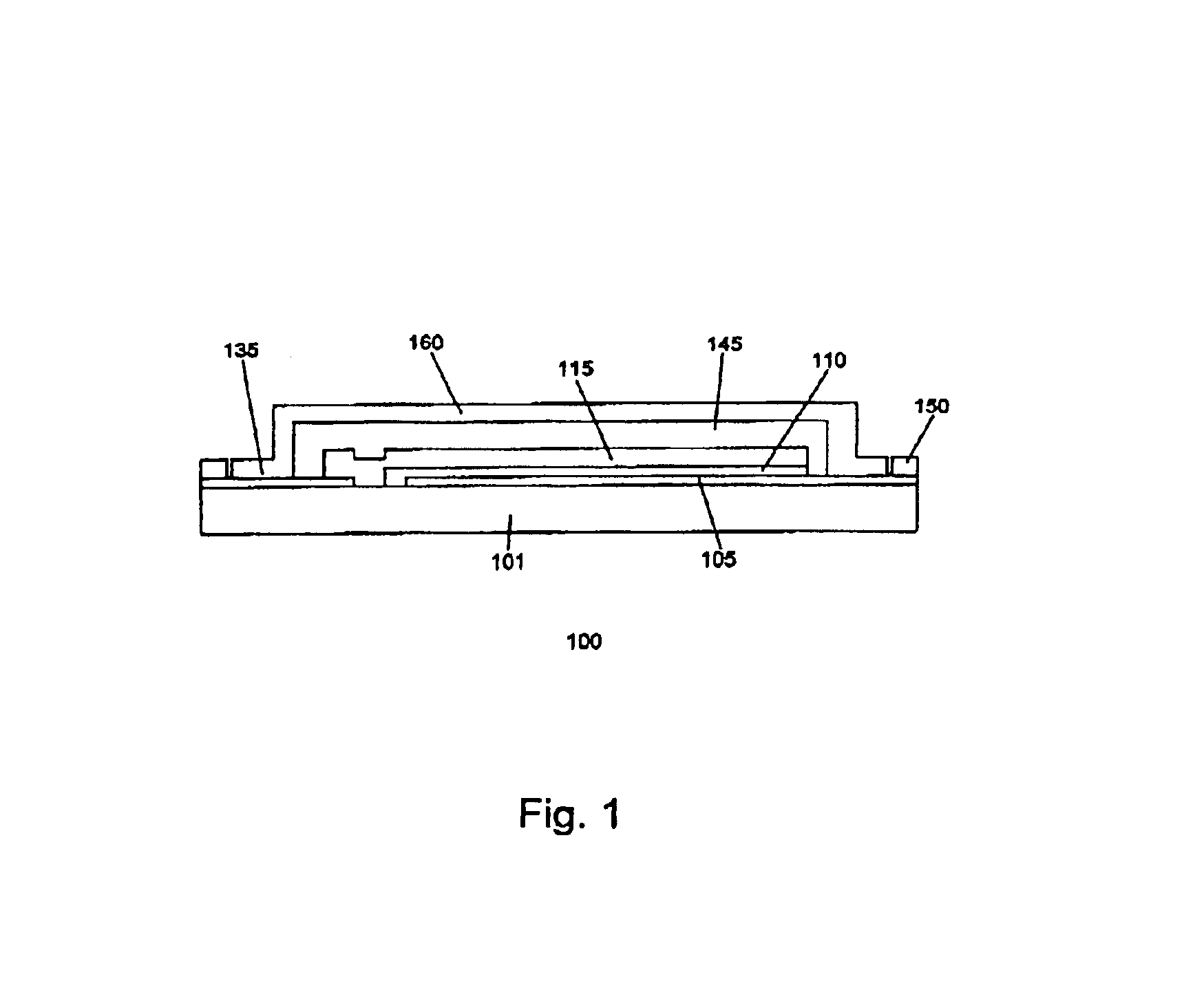

Transparent electrode material for quality enhancement of OLED devices

InactiveUS7098591B1Improve device performanceDischarge tube luminescnet screensElectroluminescent light sourcesCharge carrierIndium tin oxide

A transparent conductive material in which the desired resistivity is achieved with a high carrier concentration is provided for use in an OLED. In one embodiment, the transparent conductive material comprises indium-tin-oxide. (ITO) with a high carrier concentration of at least at least 7×1020 cm−3. The high carrier concentration improved the performance of the OLED device.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH +1

Systems and methods of processing scanned data

ActiveUS20130251280A1Data augmentationAdvantages with regard to speedImage enhancementCharacter and pattern recognitionNon real timeDigital data

An efficient method and system to enhance digital acquisition devices for analog data is presented. The enhancements offered by the method and system are available to the user in local as well as in remote deployments yielding efficiency gains for a large variety of business processes. The quality enhancements of the acquired digital data are achieved efficiently by employing virtual reacquisition. The method of virtual reacquisition renders unnecessary the physical reacquisition of the analog data in case the digital data obtained by the acquisition device are of insufficient quality. The method and system allows multiple users to access the same acquisition device for analog data. In some embodiments, one or more users can virtually reacquire data provided by multiple analog or digital sources. The acquired raw data can be processed by each user according to his personal preferences and / or requirements. The preferred processing settings and attributes are determined interactively in real time as well as non real time, automatically and a combination thereof.

Owner:KOFAX

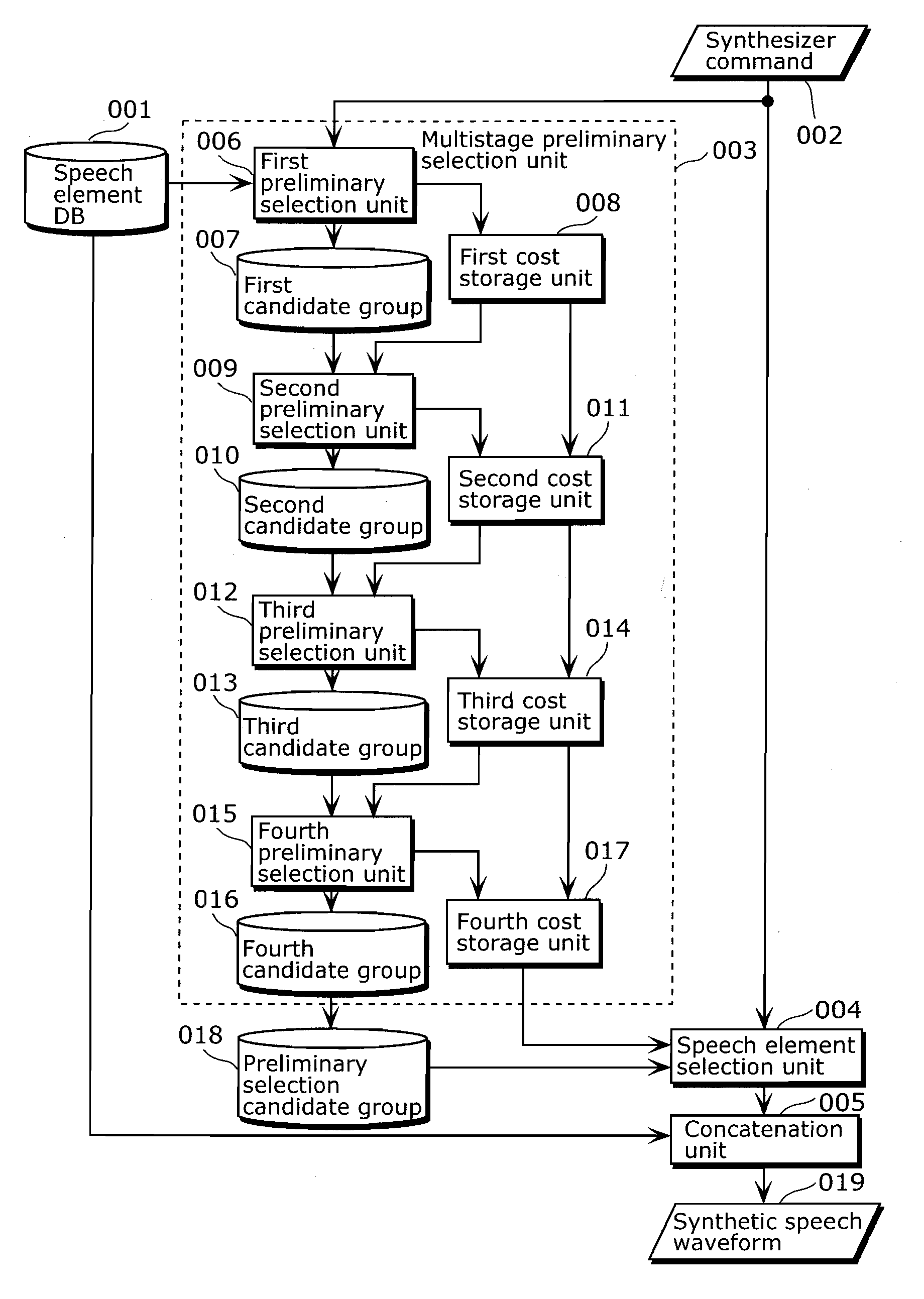

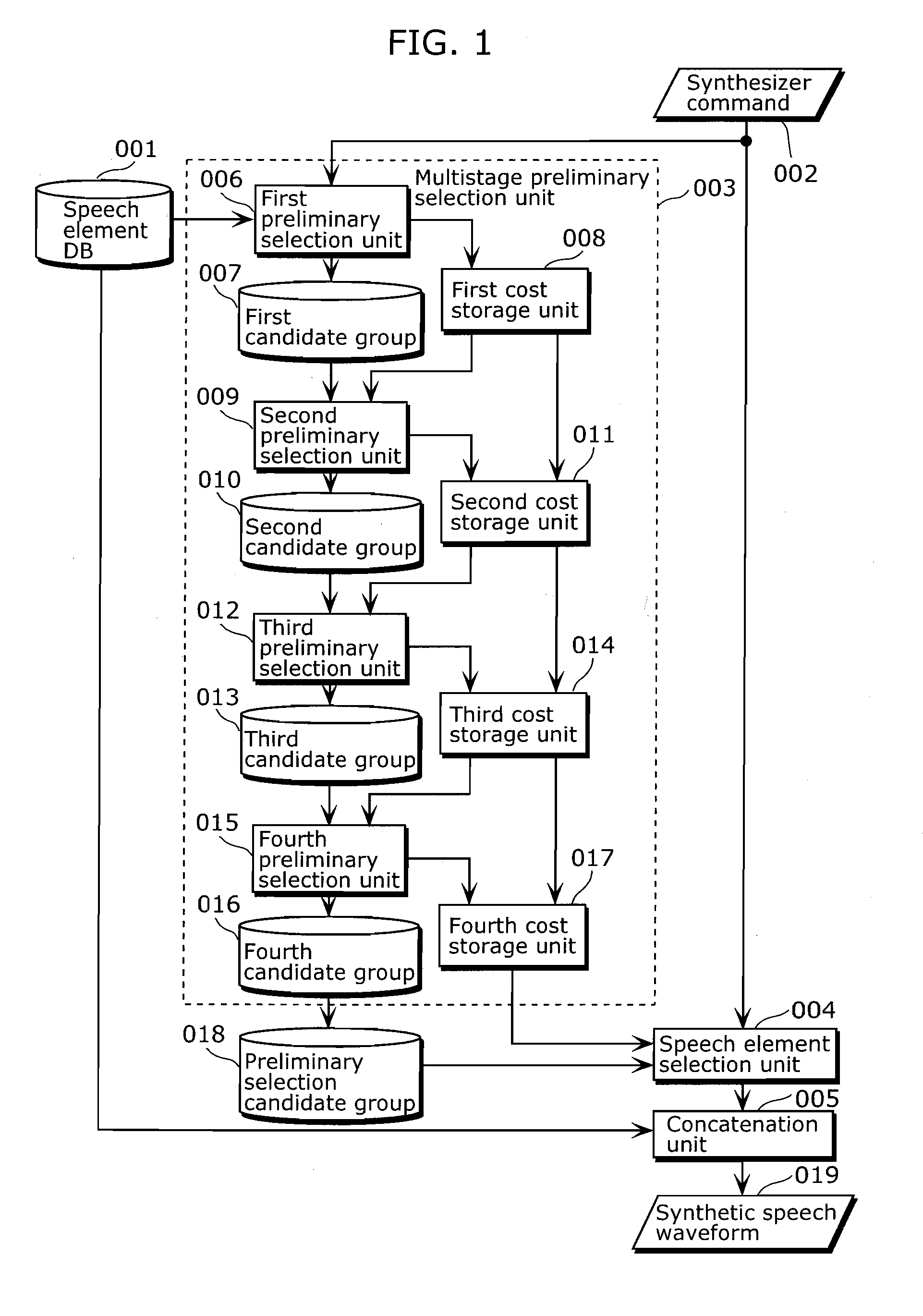

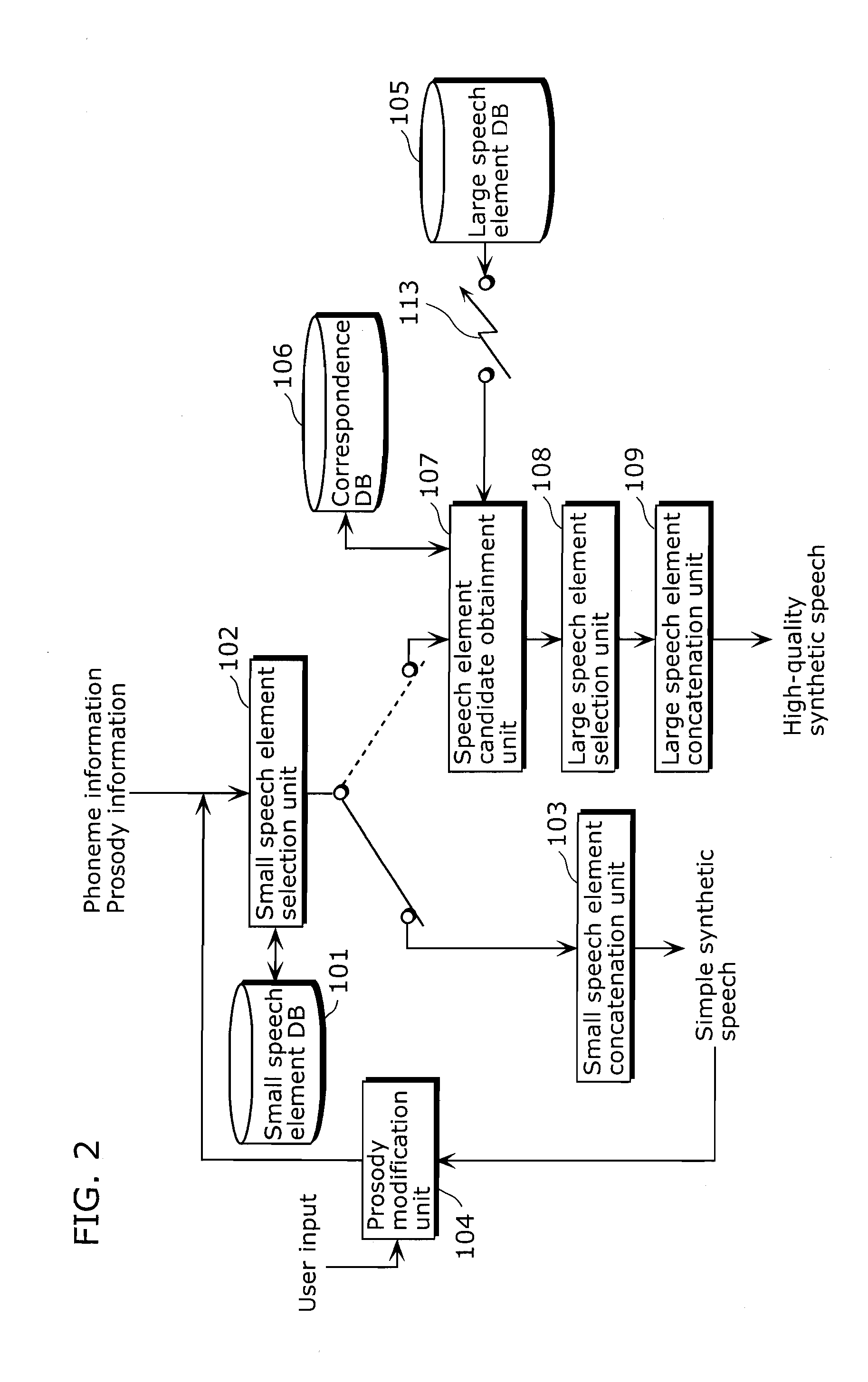

Speech synthesizer

InactiveUS20090254349A1Increase speedSimple contentSpecial data processing applicationsSpeech synthesisSpeech synthesisSpeech sound

A speech synthesizer can execute speech content editing at high speed and generate speech content easily. The speech synthesizer includes a small speech element DB (101), a small speech element selection unit (102), a small speech element concatenation unit (103), a prosody modification unit (104), a large speech element DB (105), a correspondence DB (106) that associates the small speech element DB (101) with the large speech element DB (105), a speech element candidate obtainment unit (107), a large speech element selection unit (108), and a large speech element concatenation unit (109). By editing synthetic speech using the small speech element DB (101) and performing quality enhancement on an editing result using the large speech element DB (105), speech content can be generated easily on a mobile terminal.

Owner:PANASONIC CORP

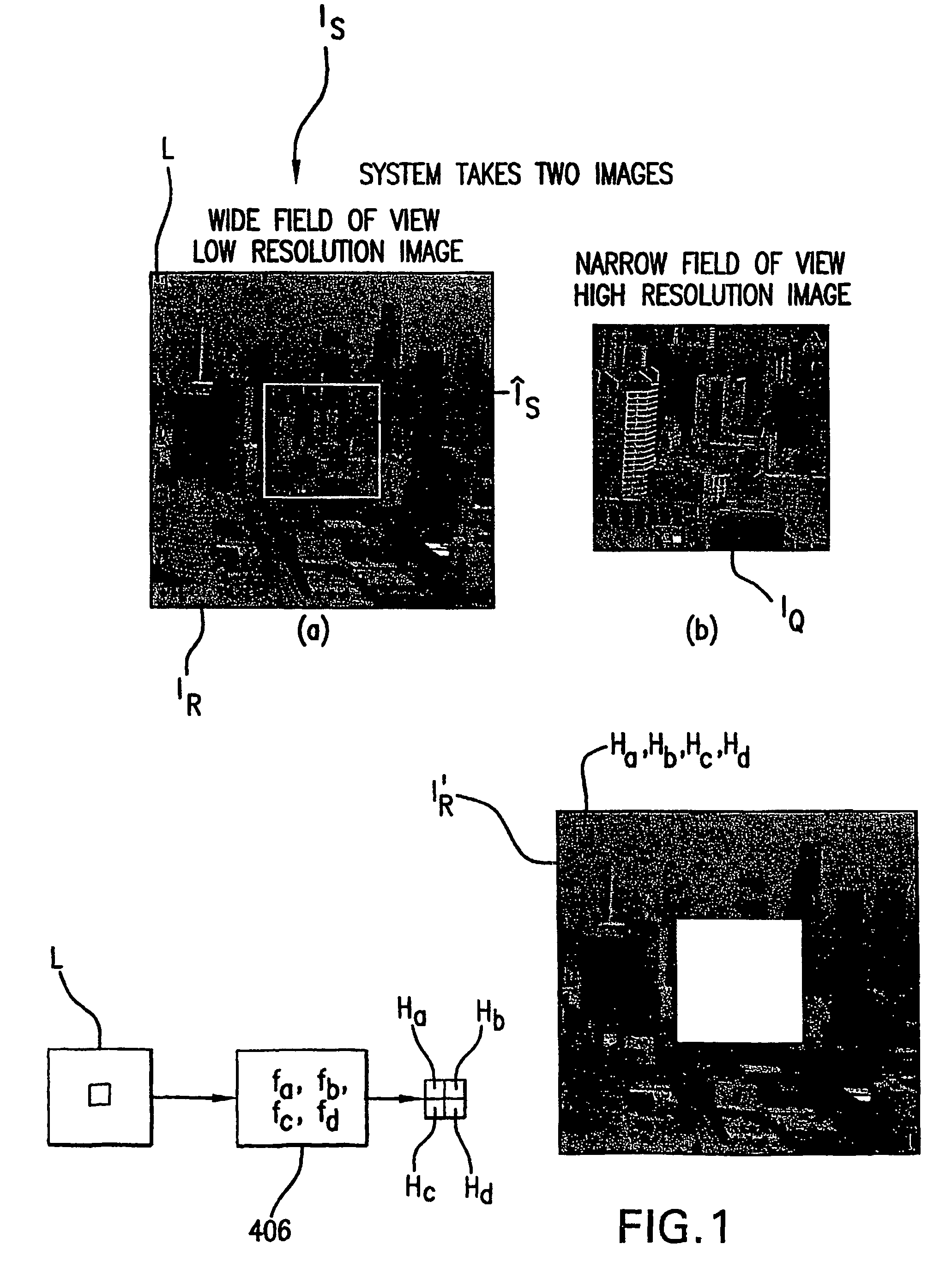

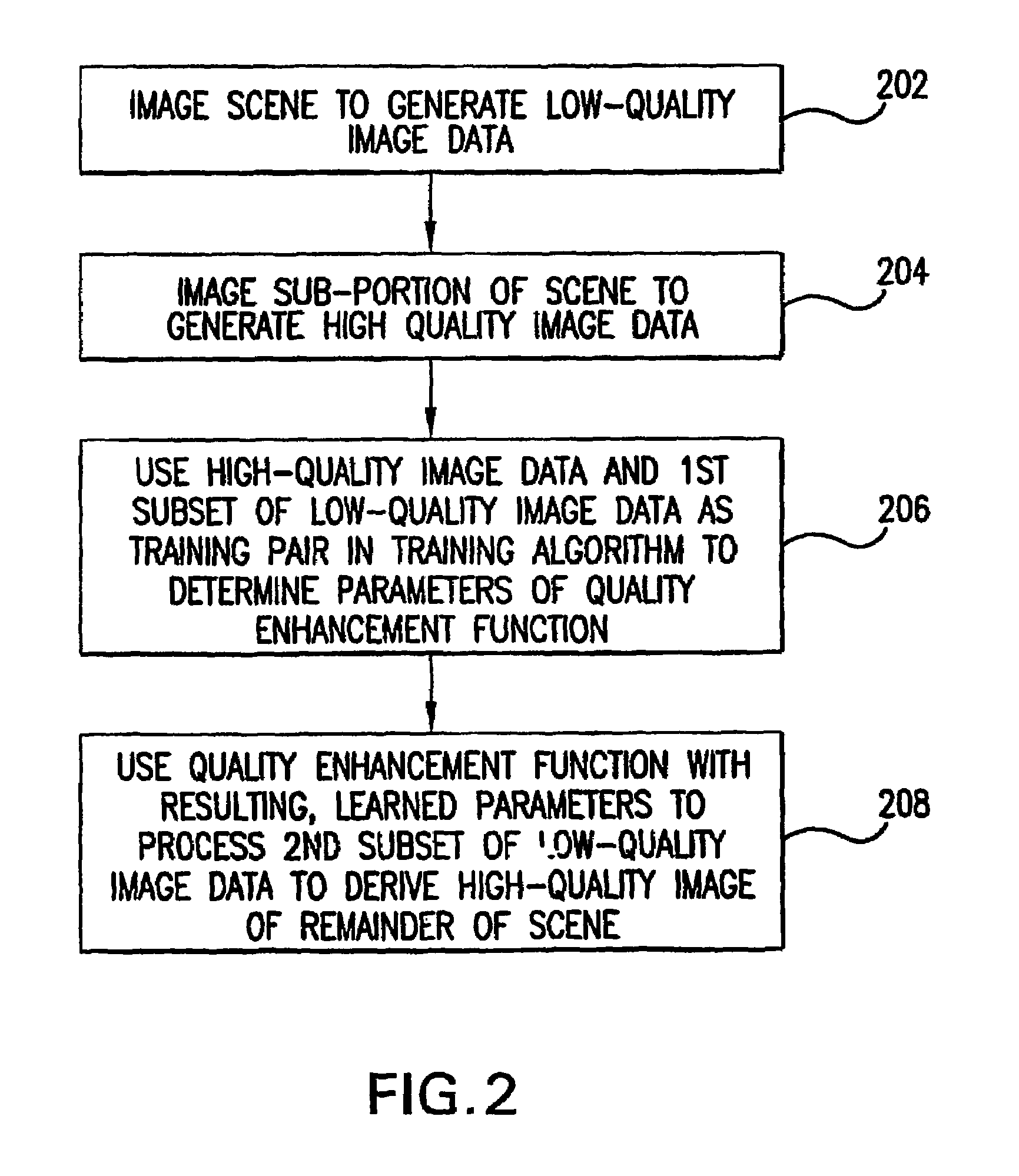

Method and system for enhancing data quality

InactiveUS7151801B2Improve data qualityEasy to useBioreactor/fermenter combinationsImage enhancementImage resolutionData quality

The quality (e.g., resolution) of image data, video data, and sound data representing a scene or signal is enhanced by a quality enhancement function trained on high quality and low quality representations of a portion of the same scene or signal. The enhancement function is thus optimized to the most relevant input. A training algorithm uses low quality image of a scene or scene portion, along with a high quality image of the same scene or scene portion, to optimize the parameters of a quality enhancement function. The optimized enhancement function is then used to enhance other low quality images of the scene or scene portion. Sound data is enhanced by using a low resolution sample of a portion of a signal, and a high resolution sample of the same signal portion, to train a quality enhancement function which is then used to enhance the remainder of the signal.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

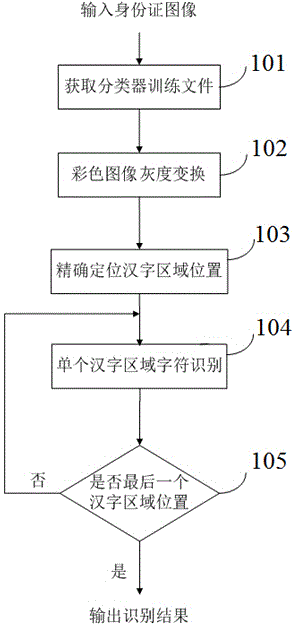

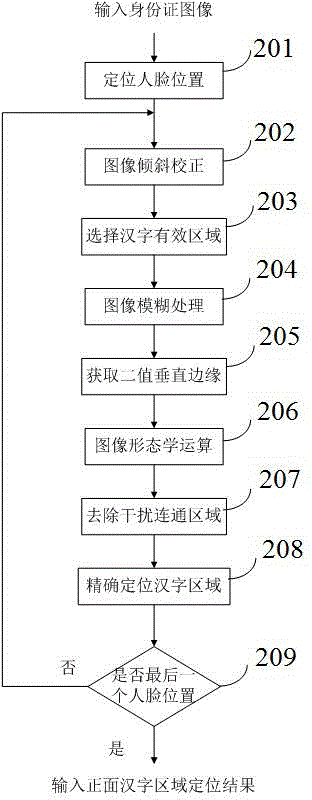

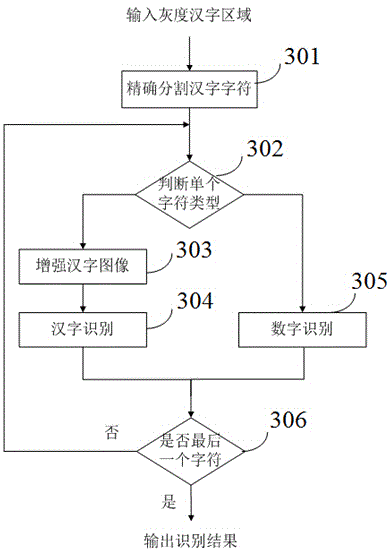

Chinese character recognition method for identification cards

InactiveCN104680130AImprove recognition accuracyLow costCharacter and pattern recognitionColor imageChinese characters

The invention provides a Chinese character recognition method for identification cards. The Chinese character recognition method comprises the following steps: acquiring a classifier training file; transforming a color image to be recognized into a gray scale image; accurately positioning a Chinese character region of each identification card; carrying out character recognition on each Chinese character region; judging whether the current Chinese character region is the last Chinese character region. According to the Chinese character recognition method provided by the invention, positioning and segmentation of Chinese characters of the identification cards can be carried out by adopting an image processing technology; character recognition is carried out on a Chinese character image on the basis of a tessract library and font structure quality enhancement; the recognition accuracy is higher, no specific equipment is needed, the cost is low and information of multiple identification cards can be simultaneously read.

Owner:ANHUI TSINGLINK INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com