Cyclonic flash drying device

A technology of flash drying and cyclone drying, which is applied in the direction of drying machine combination, drying solid materials, drying gas arrangement, etc. It can solve the problems of easy softening or coking of products, low collection rate of finished products, and difficult drying of materials, so as to improve the collection of finished products The effect of increasing the drying rate, ensuring the temperature and increasing the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

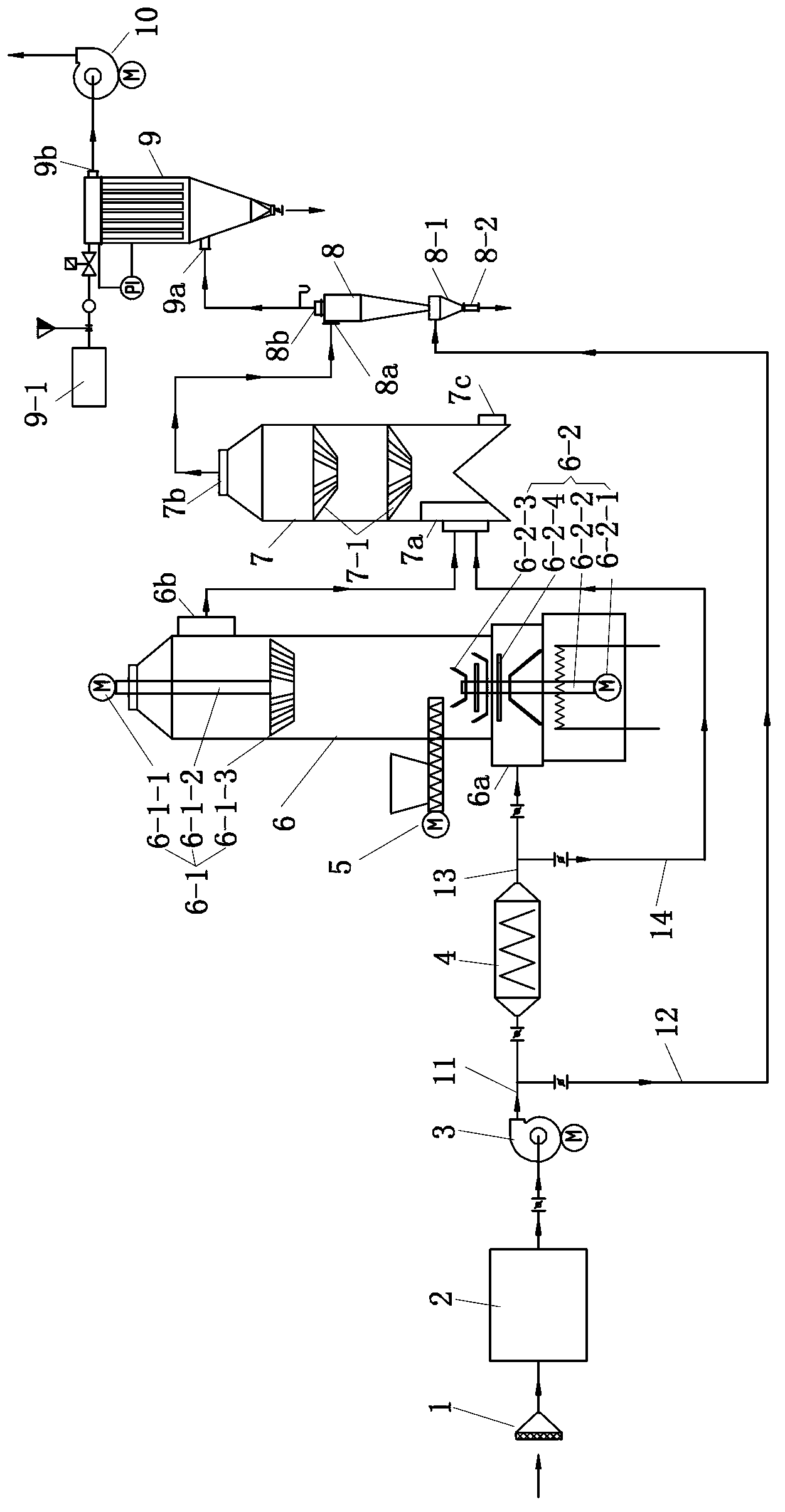

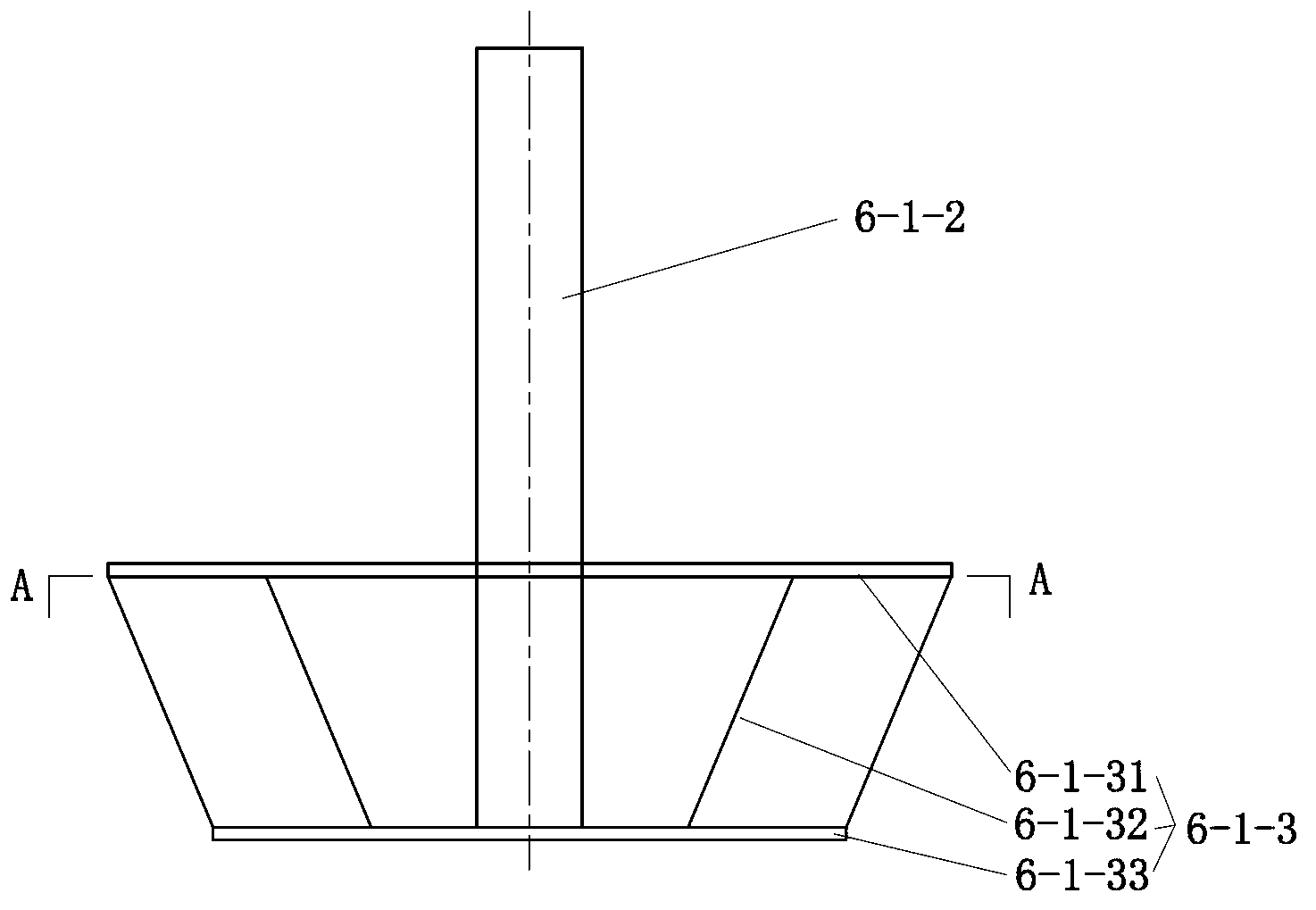

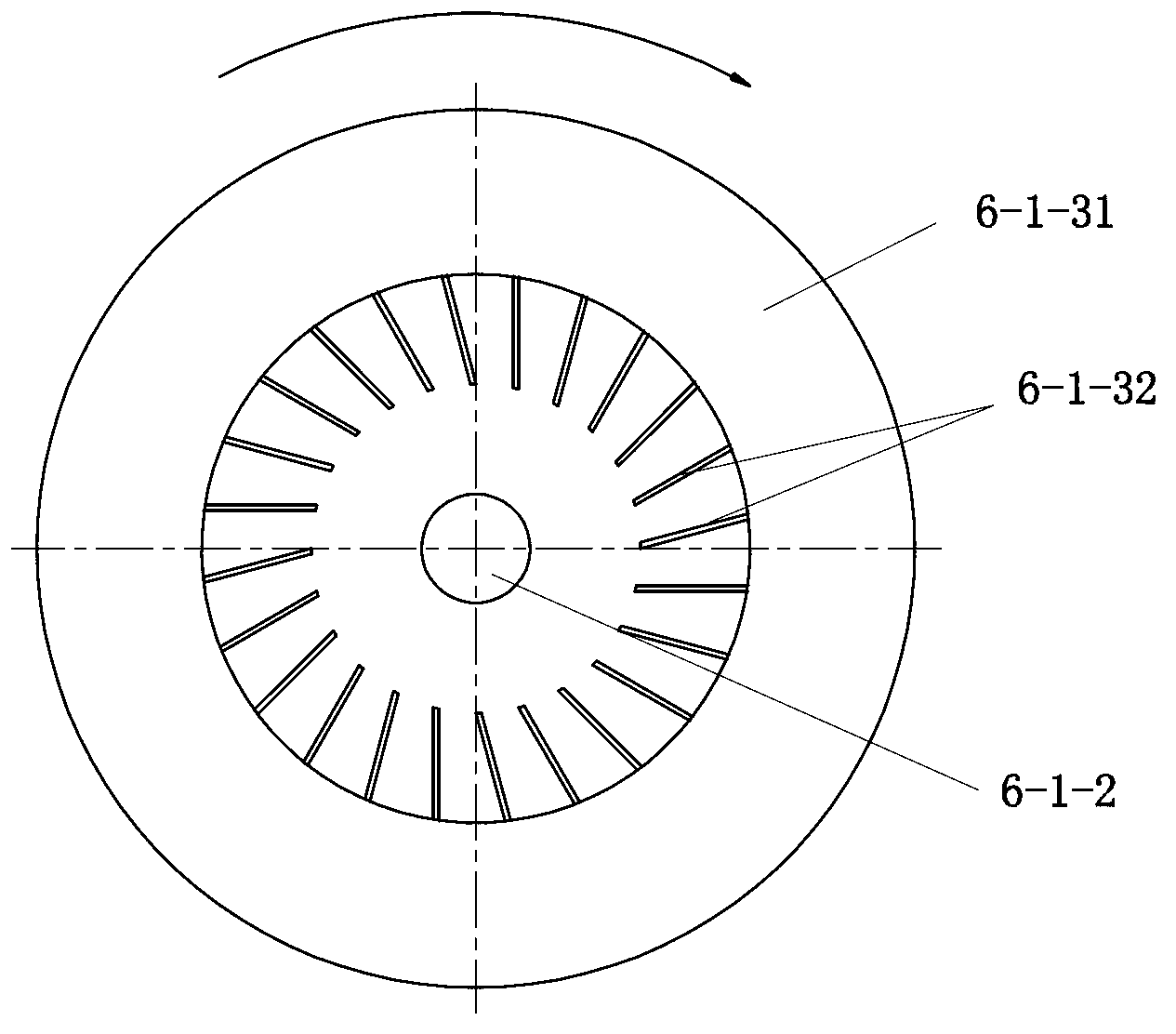

[0020] See Figure 1 to Figure 8 , the present embodiment has air filter 1, blower 3, air heater 4, screw feeder 5, drying host 6, cyclone separator 8, dust remover 9 and induced draft fan 10, between air filter 1 and blower 3 An air dehumidifier 2 is provided, and an impact cyclone drying tower 7 is provided between the drying host 6 and the cyclone separator 8 .

[0021] The air outlet 6b of the drying host 6 is connected with the air inlet 7a of the impact cyclone drying tower 7, the air outlet 7b of the impact cyclone drying tower 7 is connected with the air inlet 8a of the cyclone separator 8, and the air outlet 8b of the cyclone separator 8 and The air inlet 9a of the bag type dust collector 9 is connected, and the air outlet 9b of the bag type dust collector 9 is connected with the induced draft fan 10 . The high-temperature and low-humidity air output by the blower 3 is divided into two routes, one route leads to the air heater 4 for heating through the pipeline 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com