Patents

Literature

113results about How to "Avoid affecting the drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

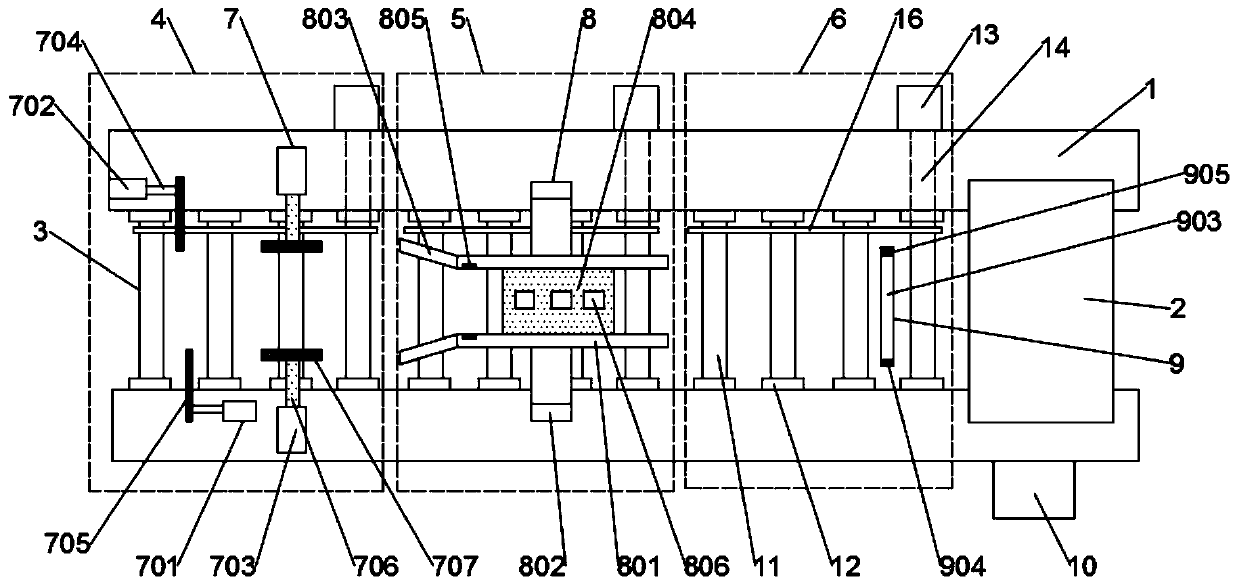

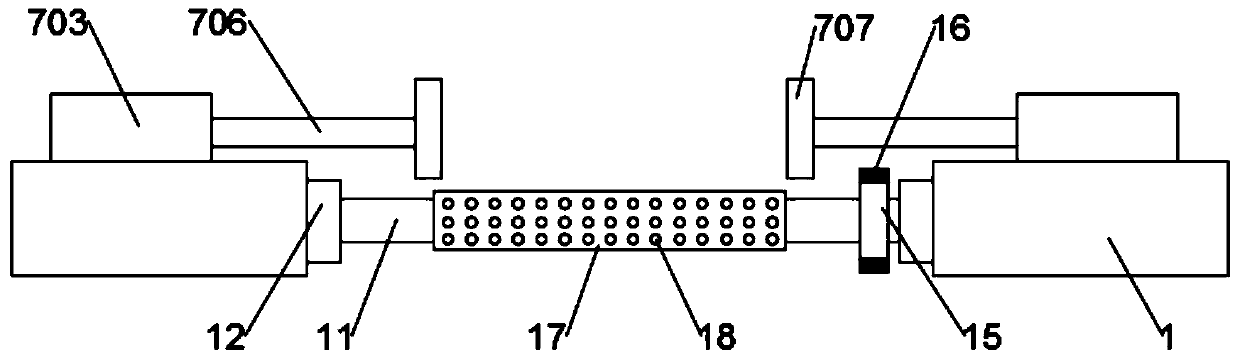

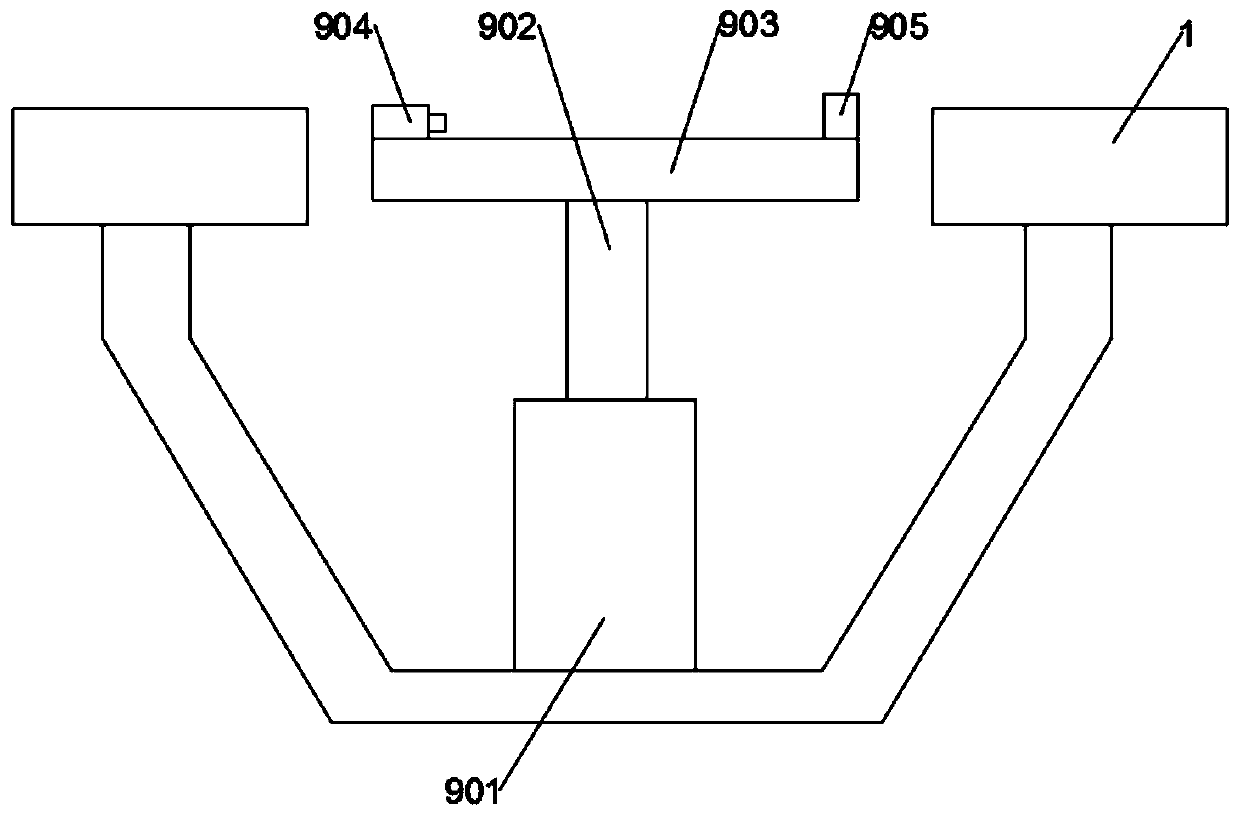

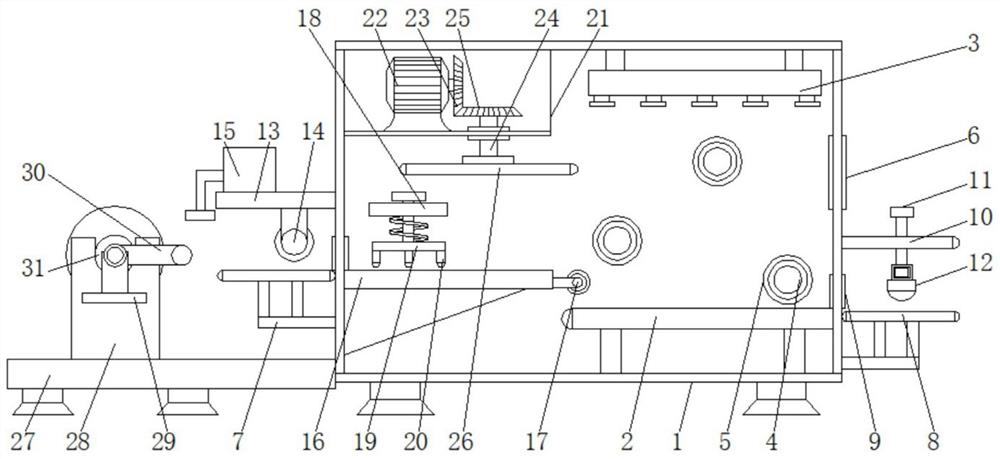

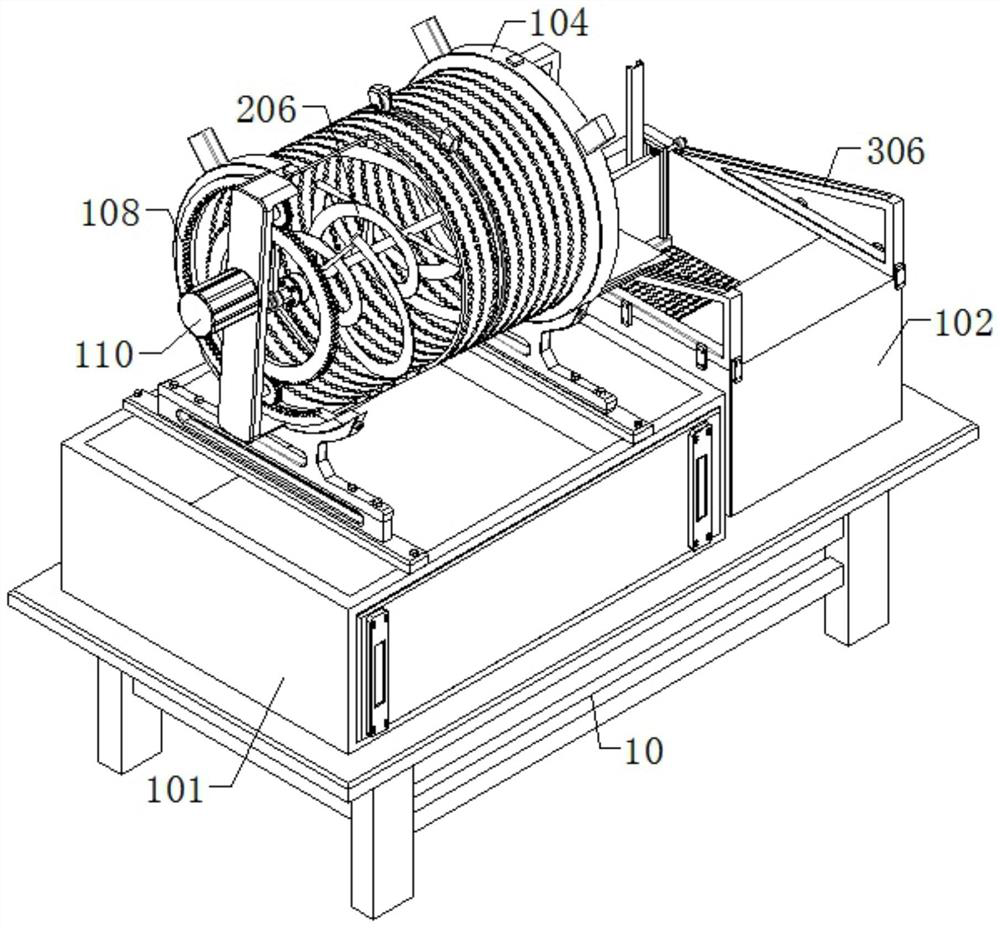

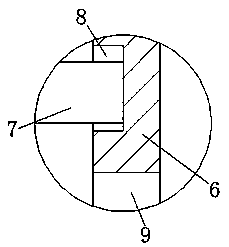

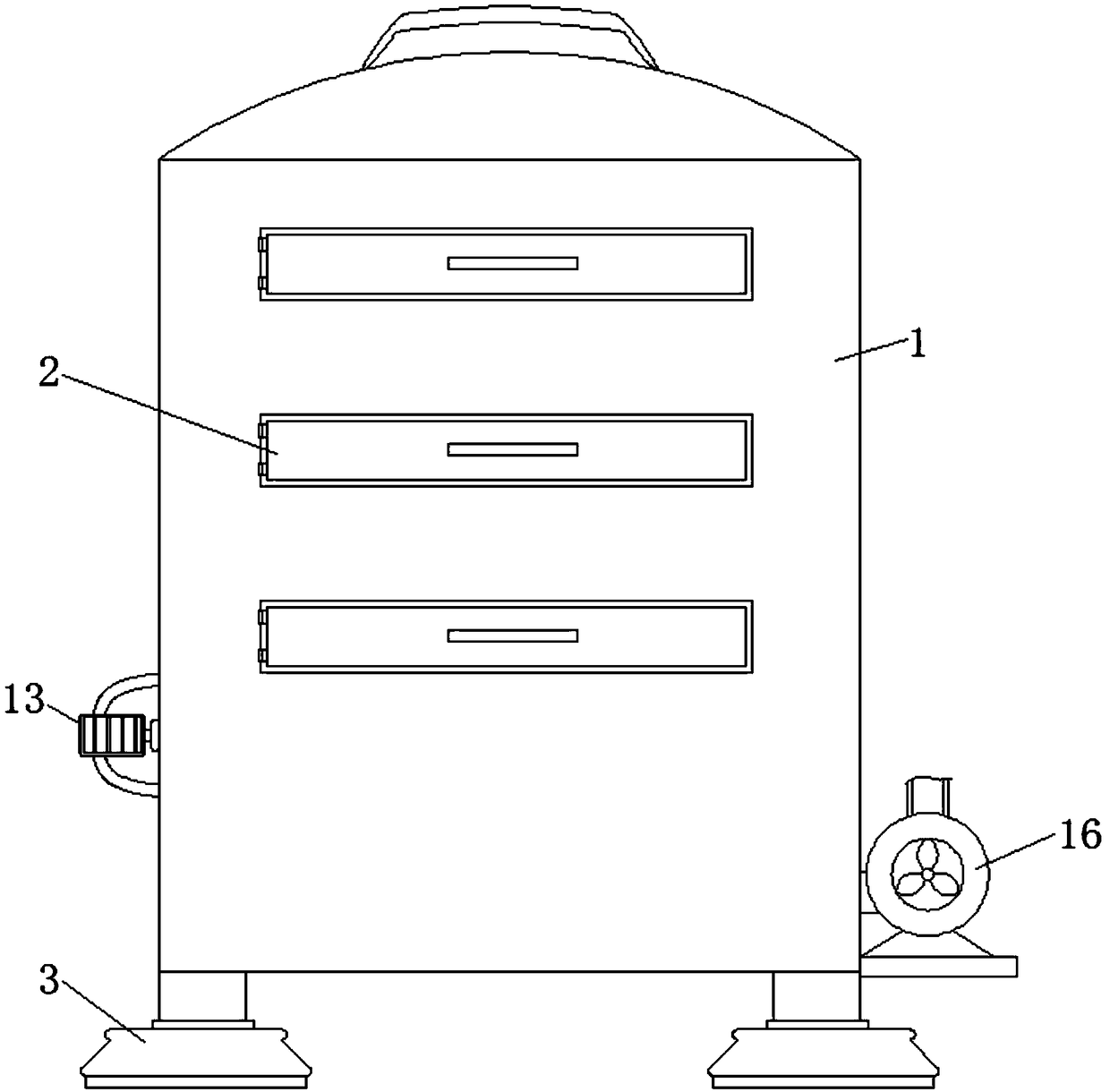

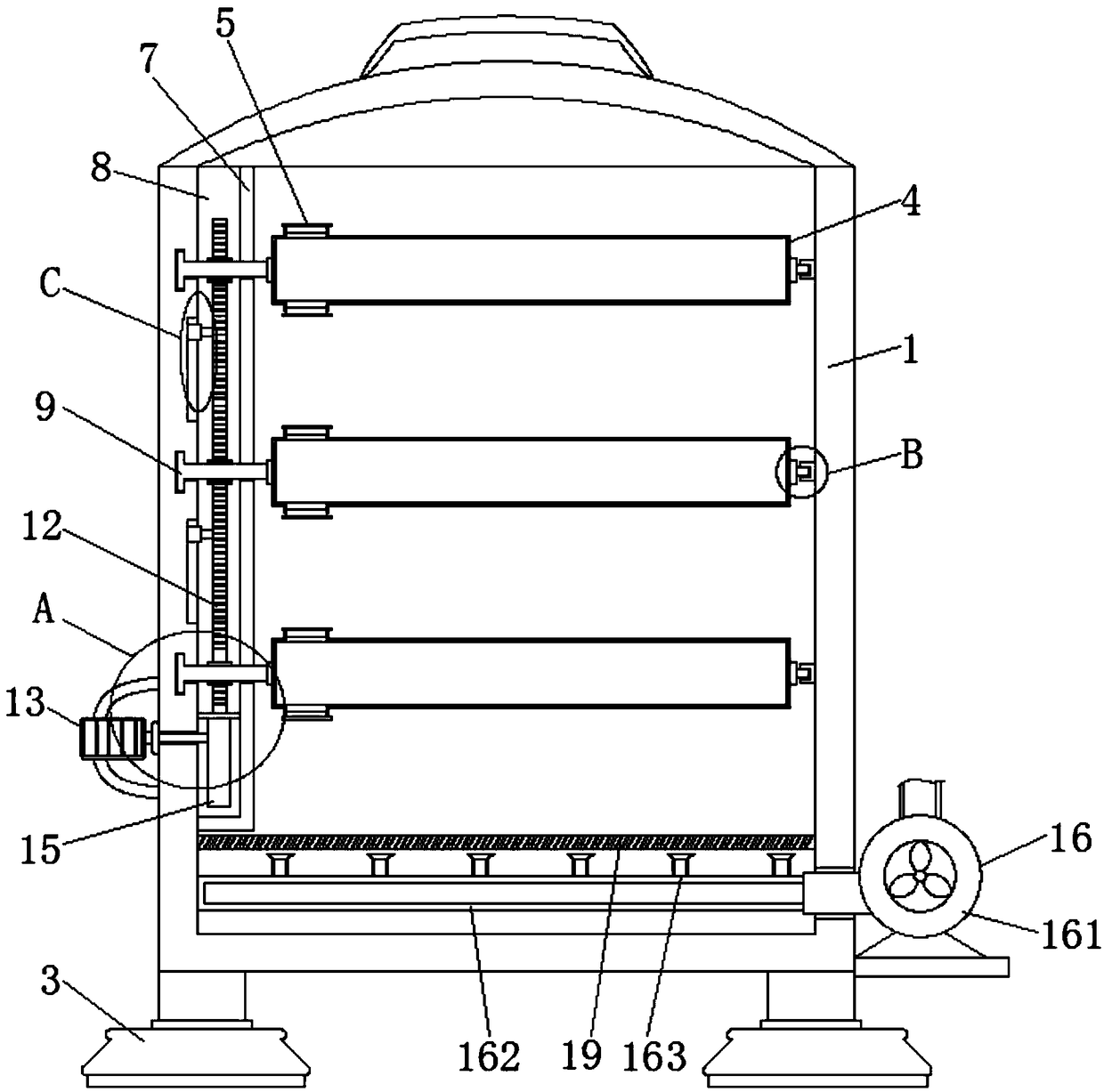

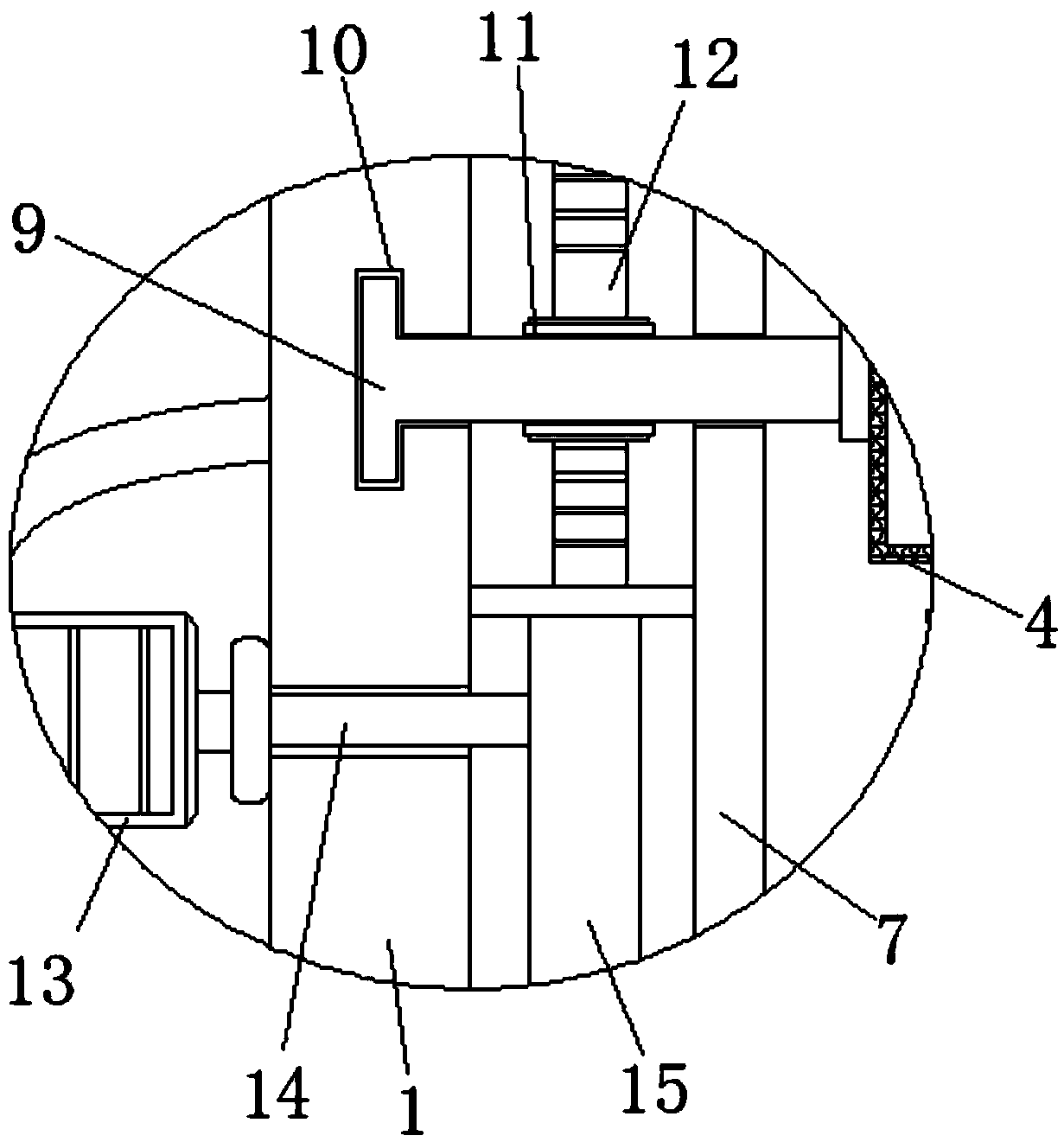

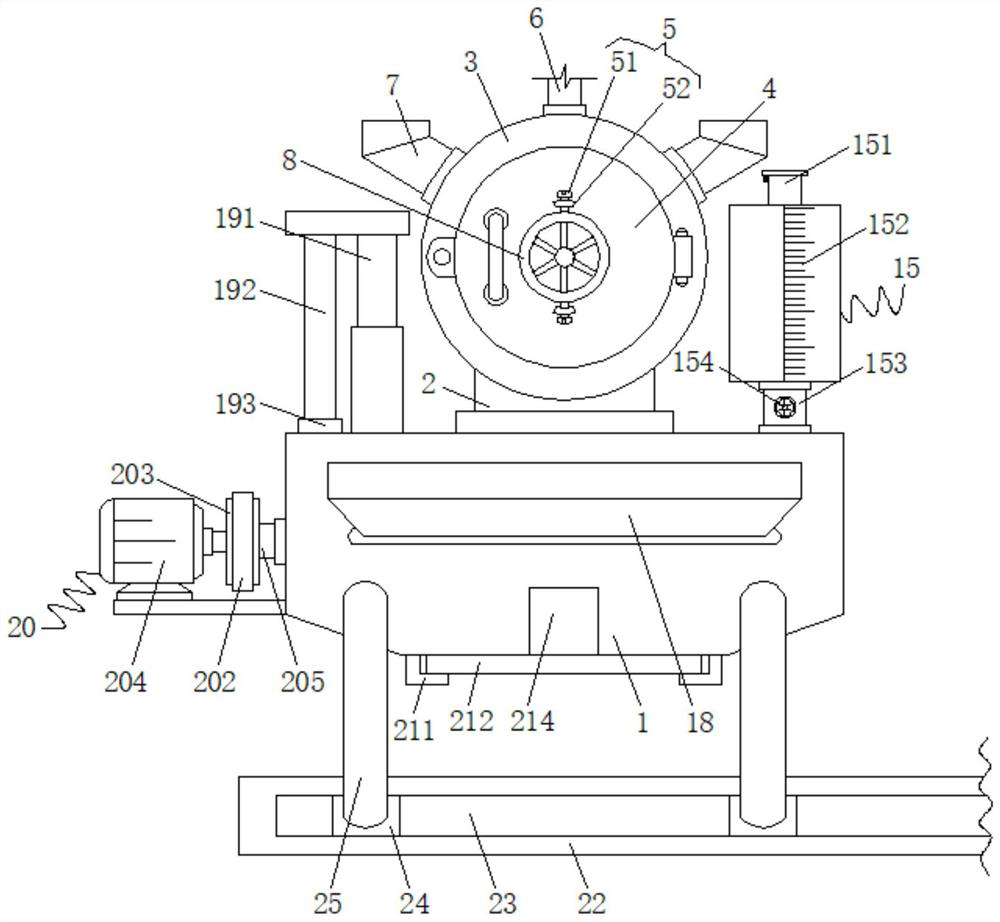

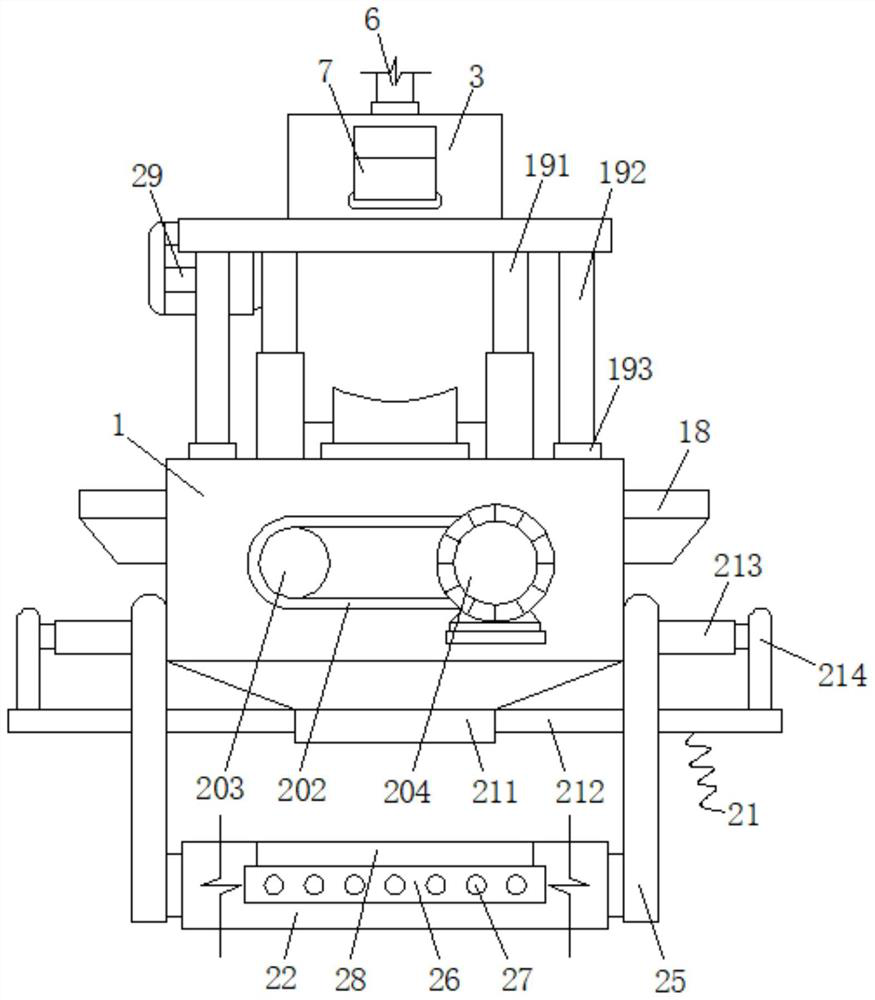

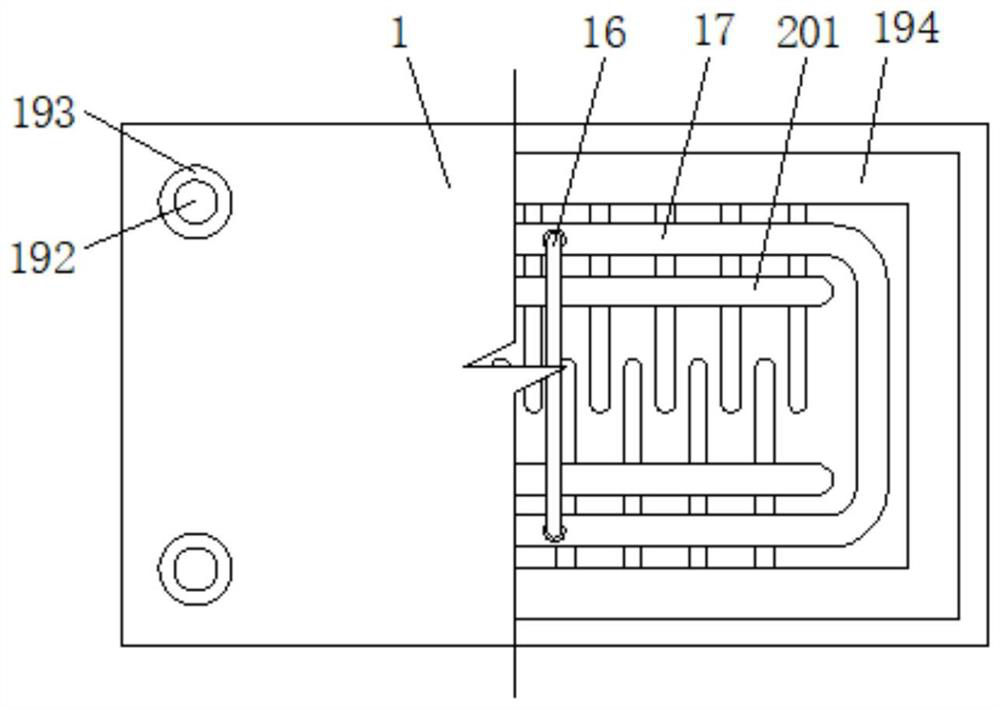

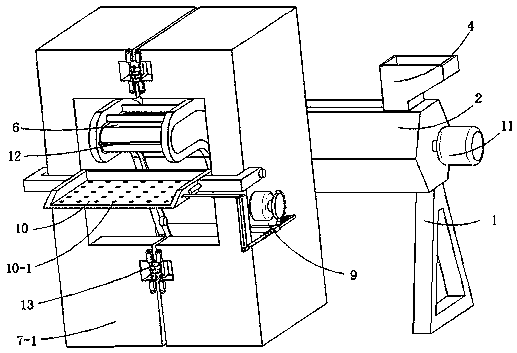

Melon seed drying and screening apparatus

InactiveCN107411140AImprove qualityAvoid affecting the drying effectGas current separationFood treatmentEngineeringAir blower

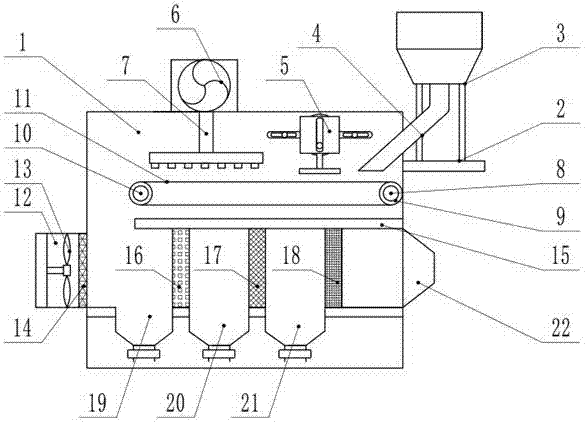

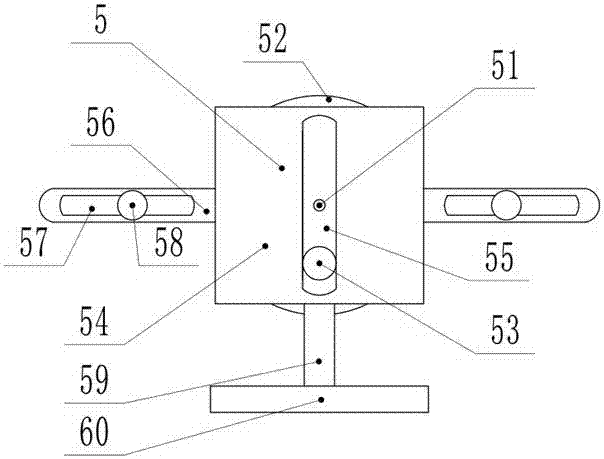

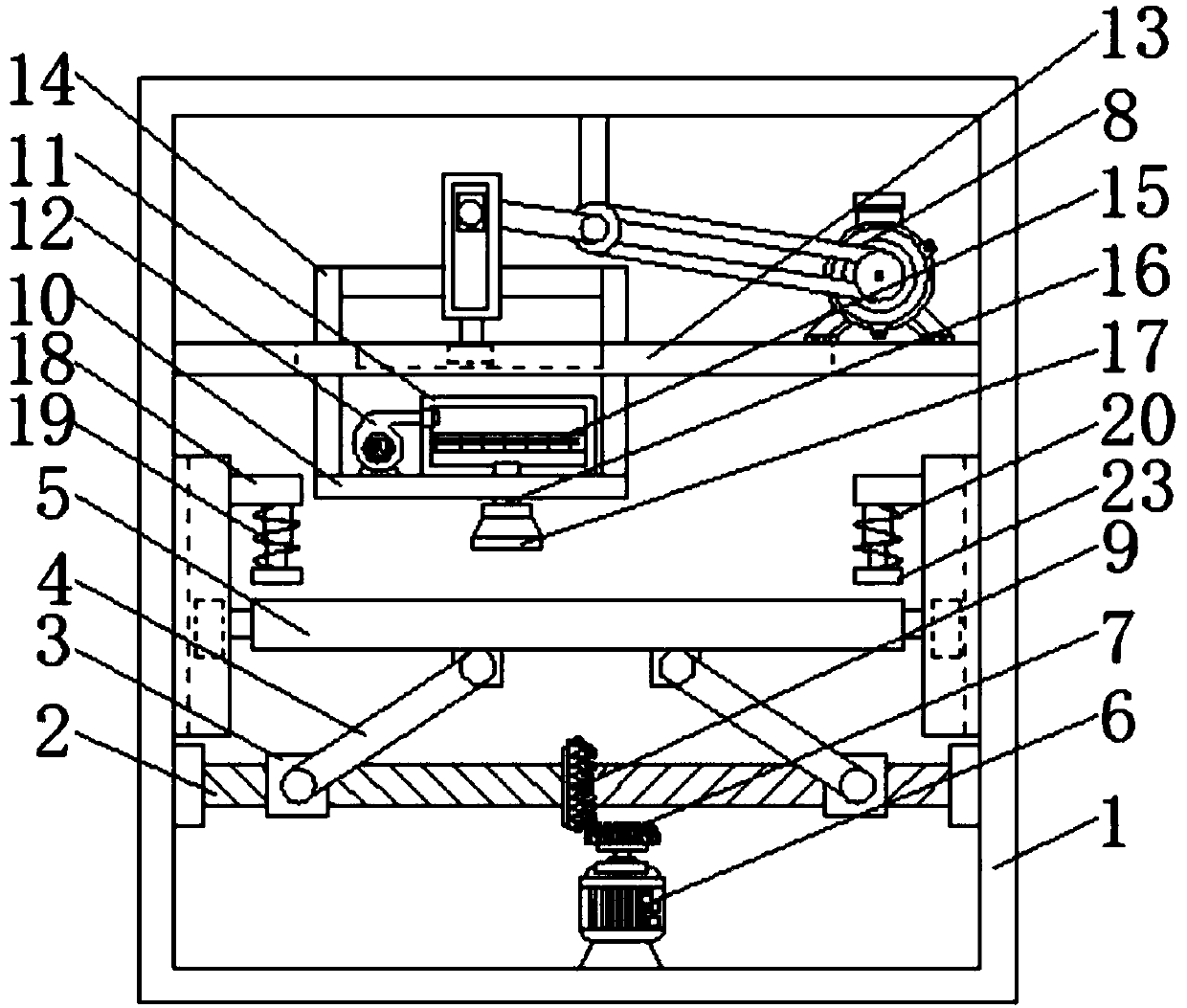

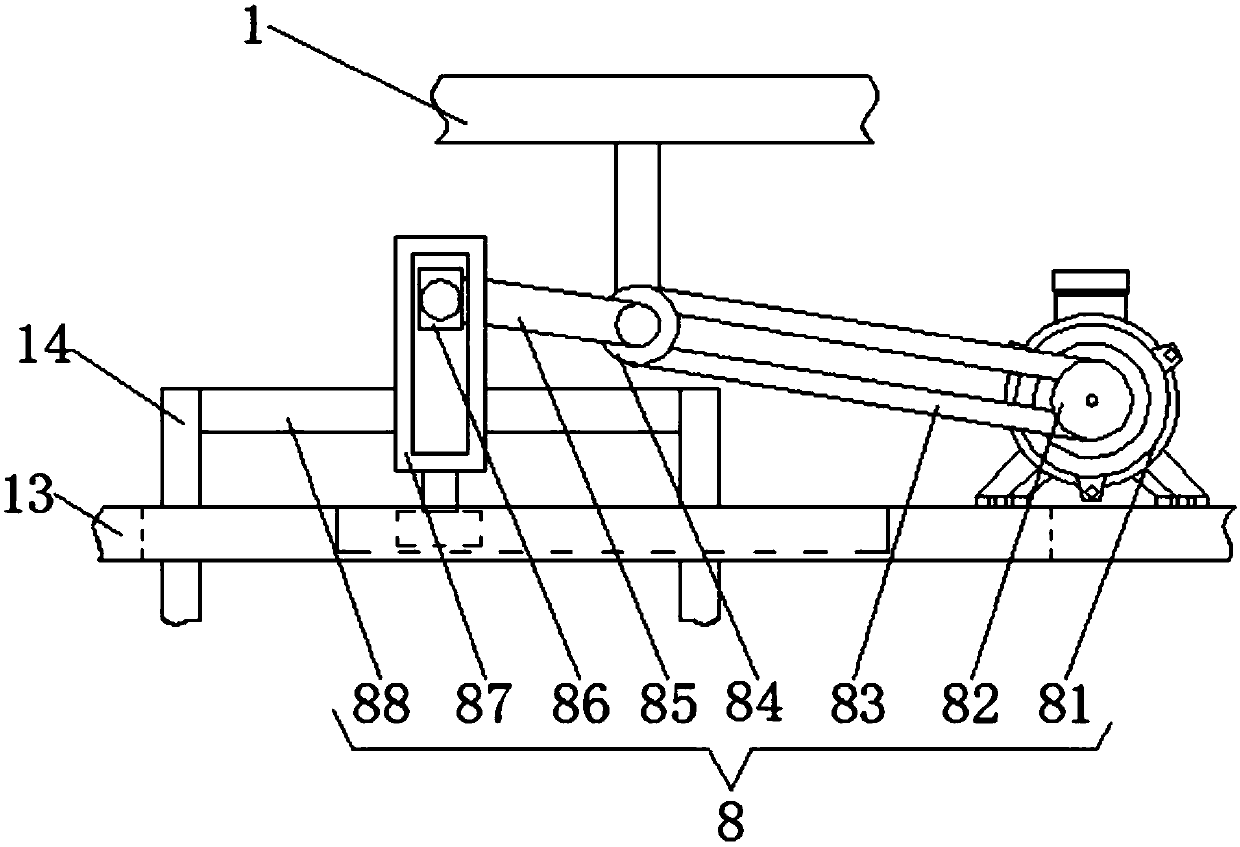

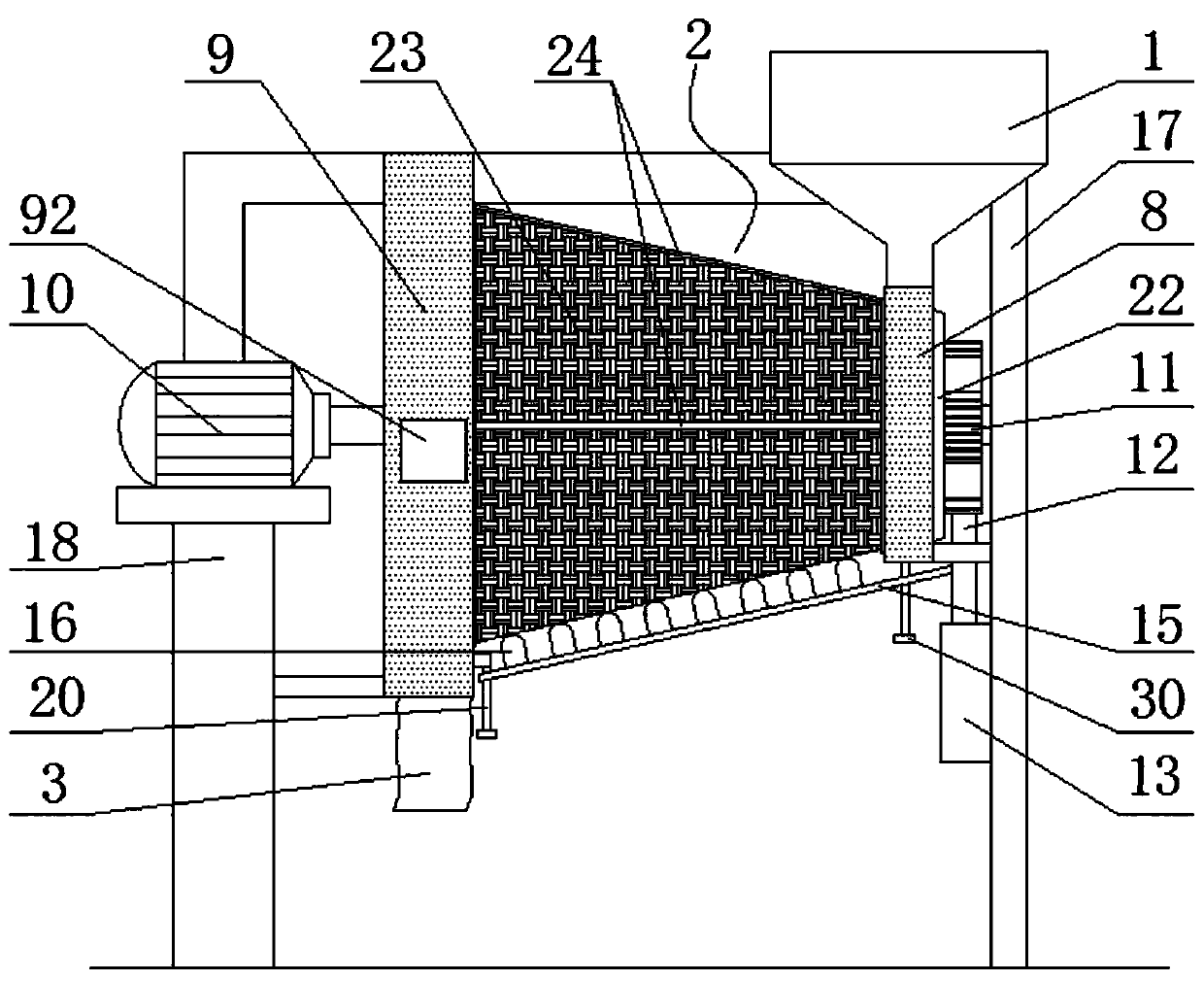

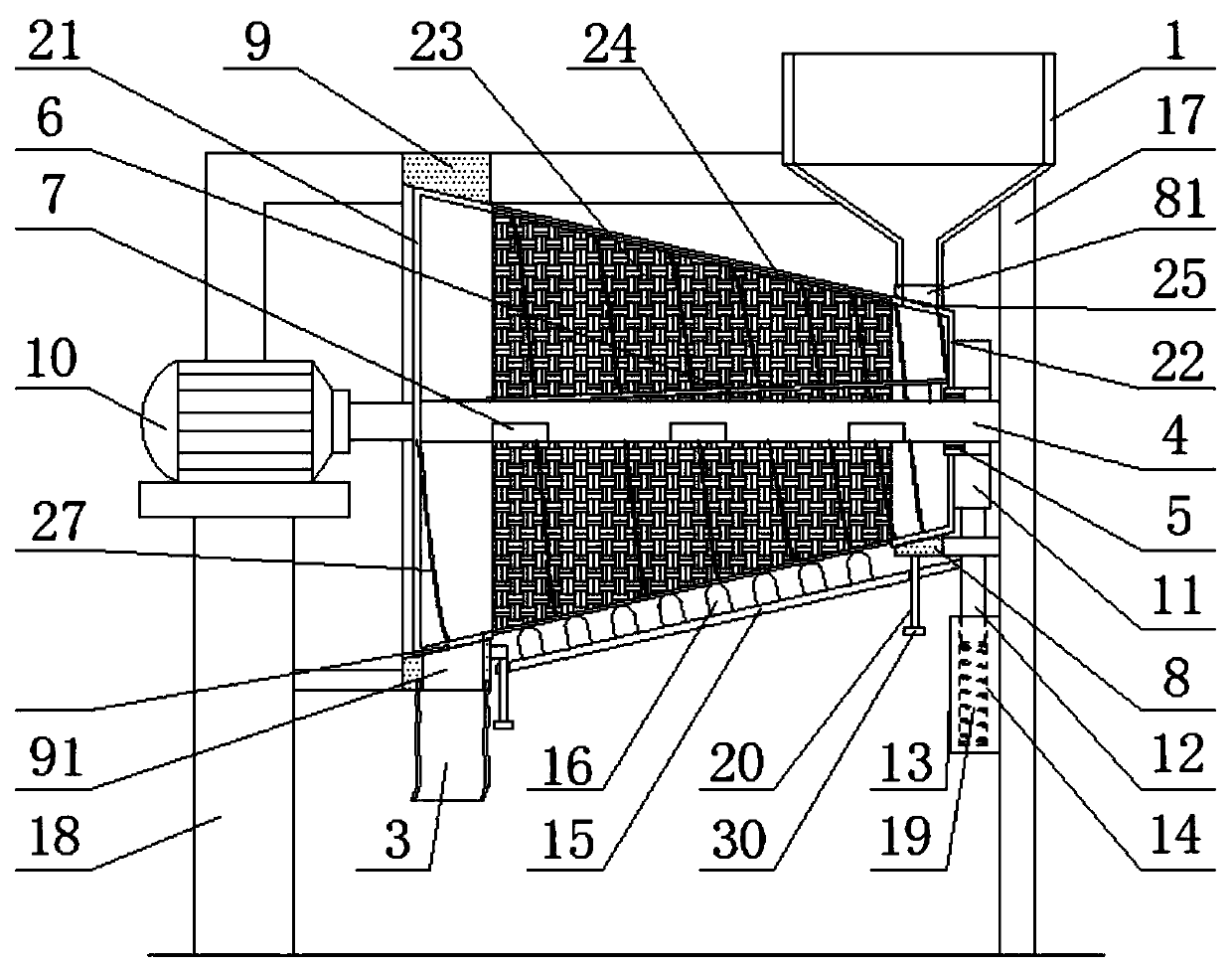

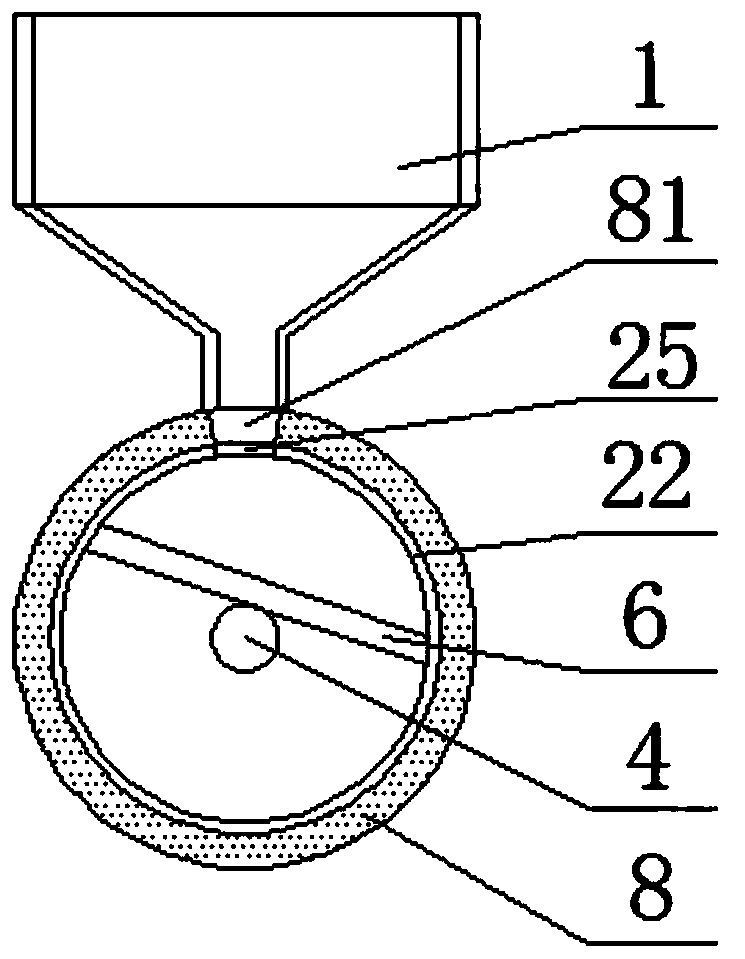

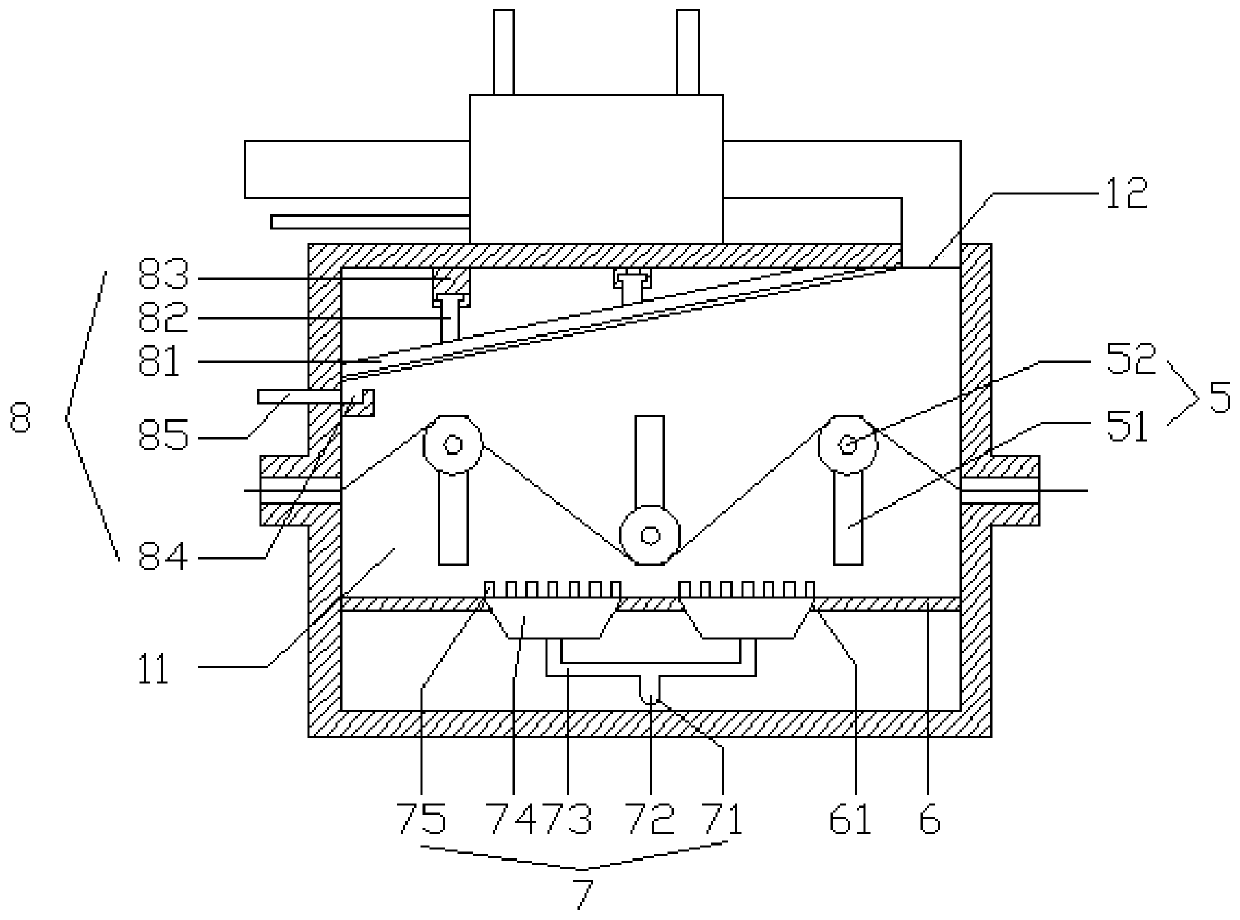

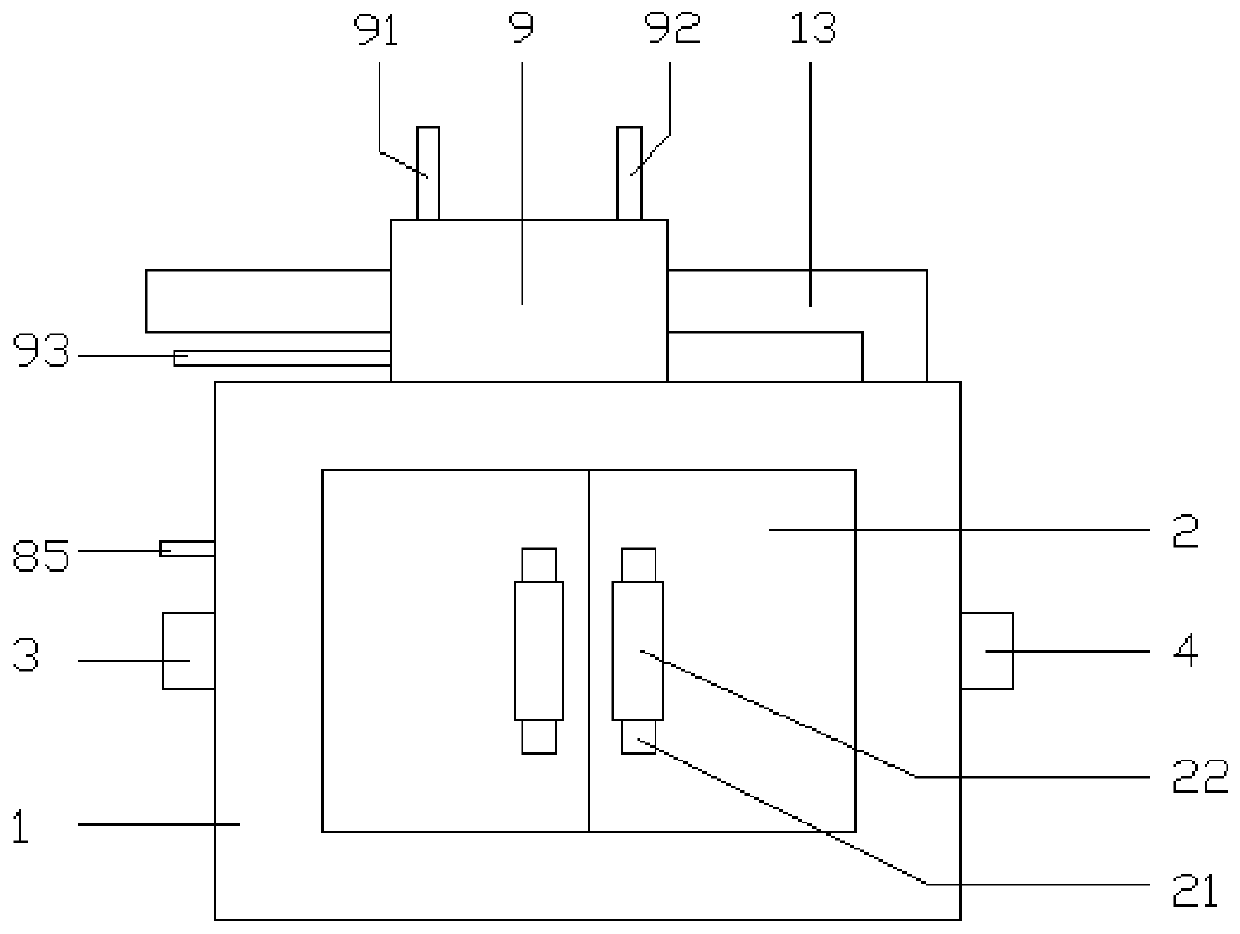

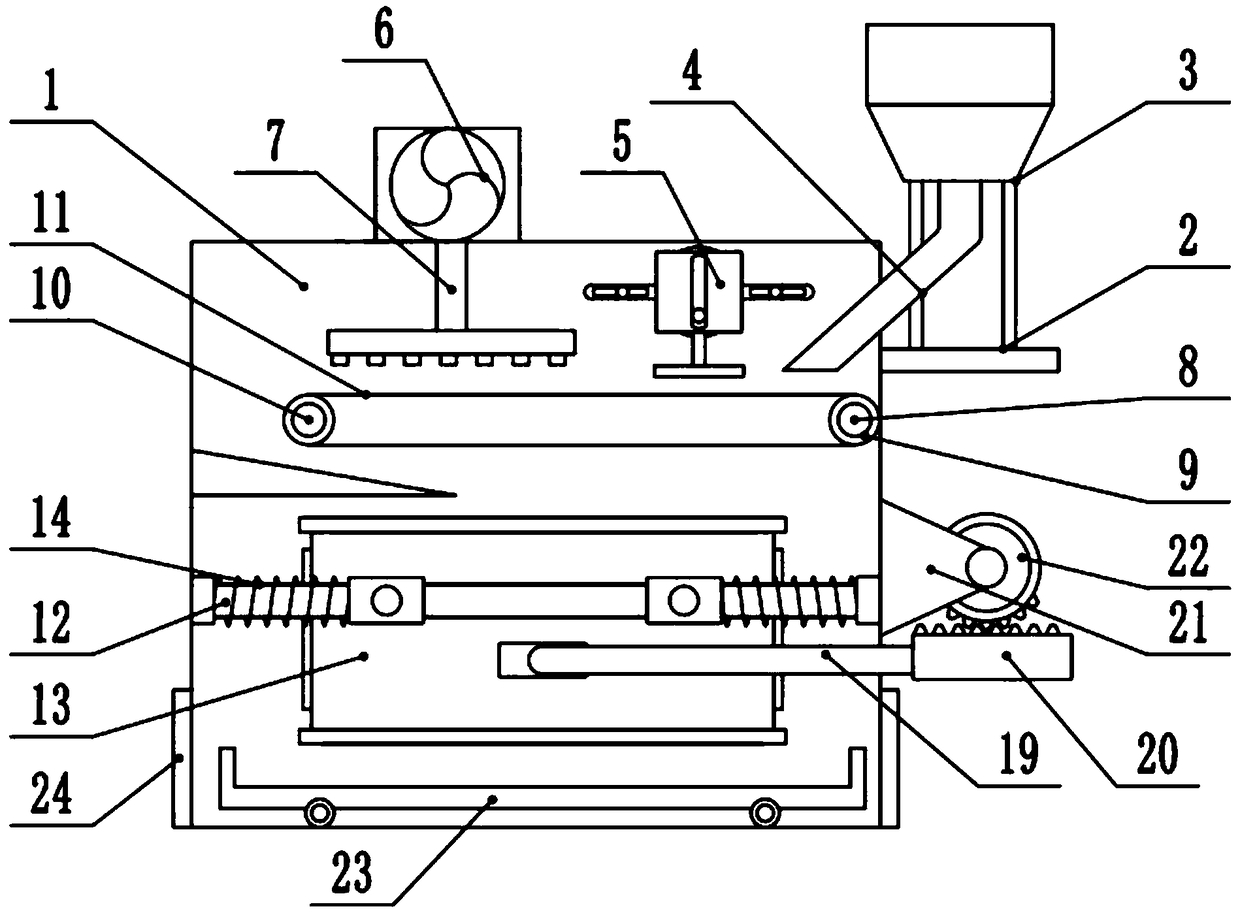

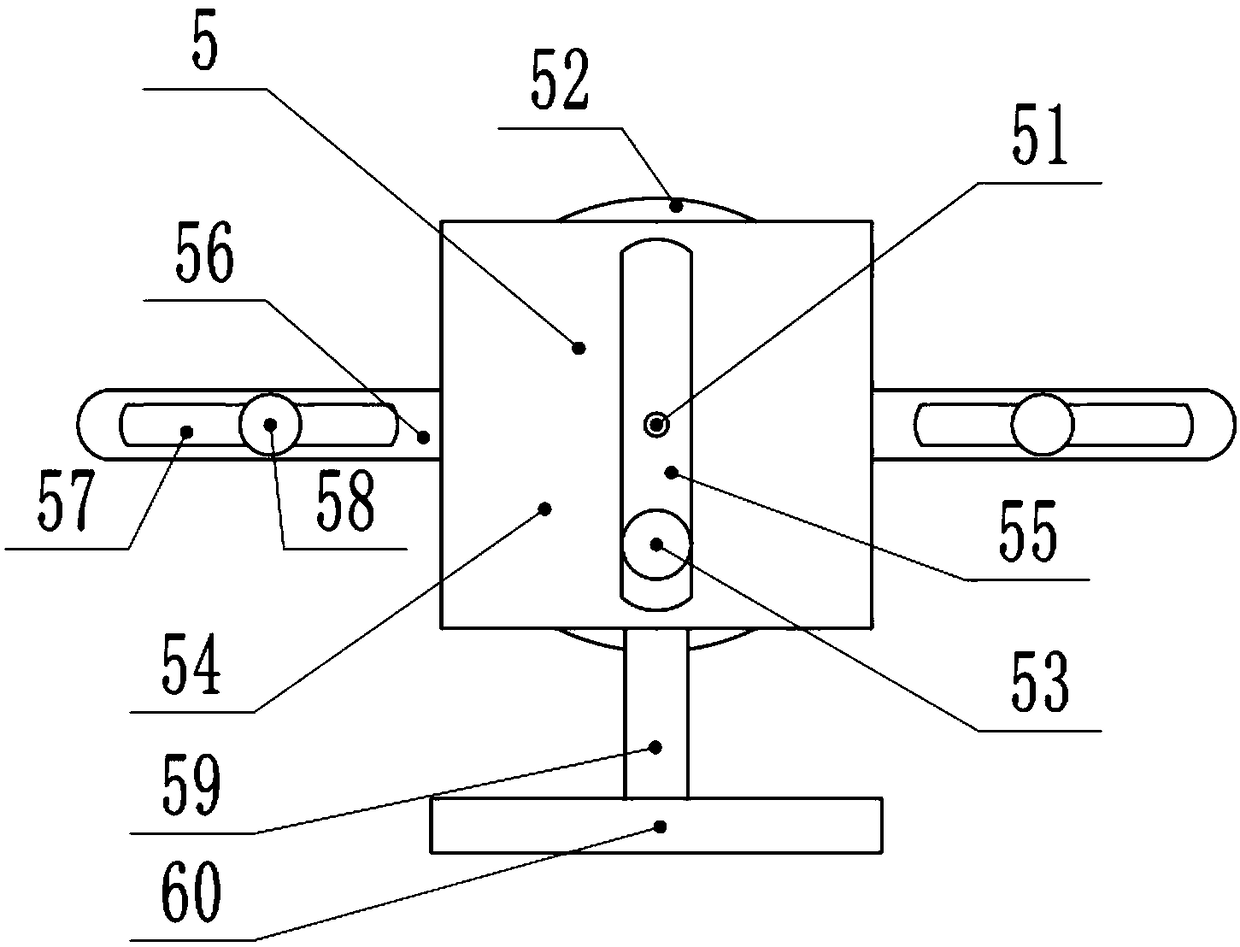

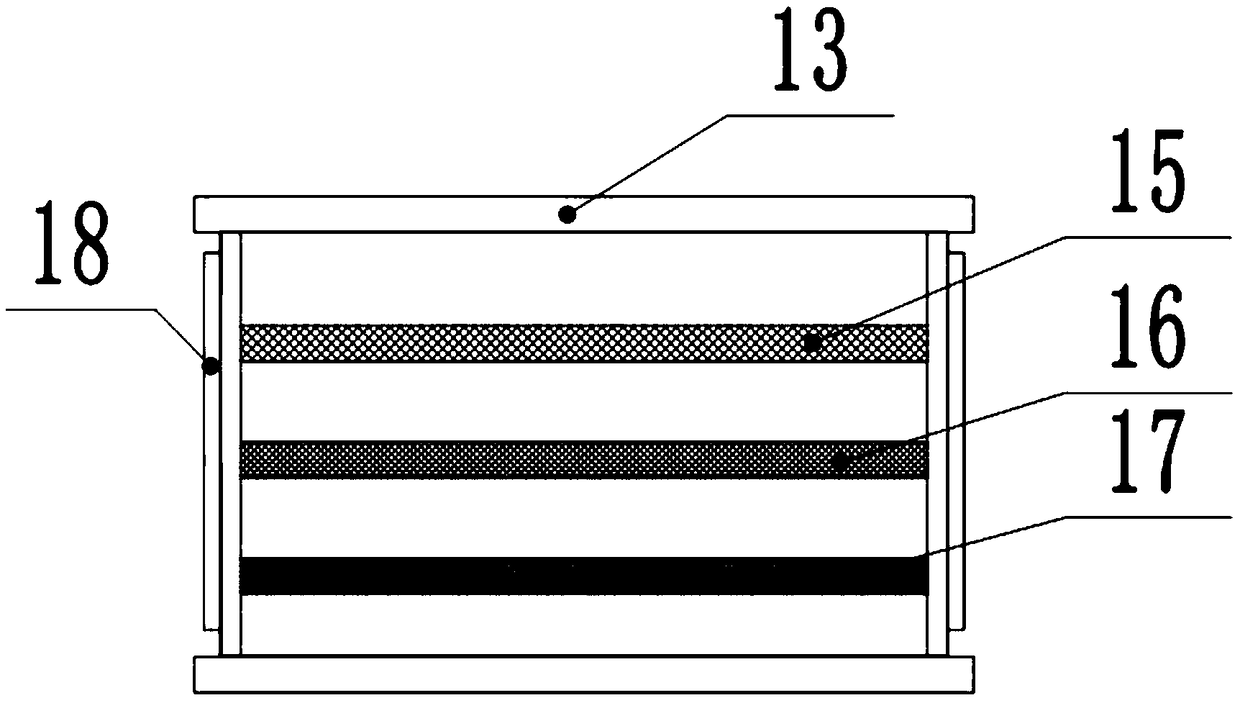

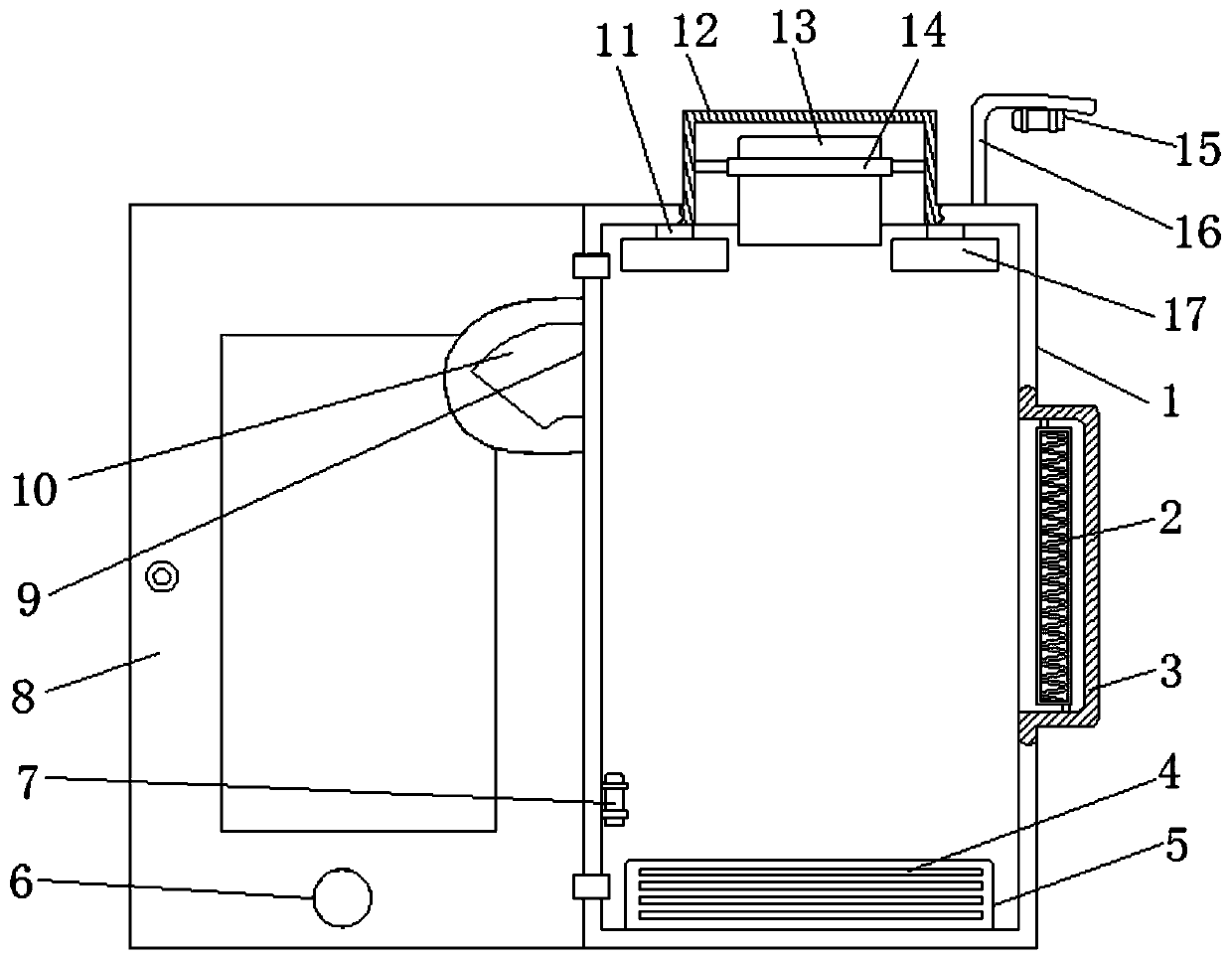

The invention discloses a drying and screening device for melon seeds, which comprises a machine casing, a paving device, a hot air blower, a casing wind separator, a first sieve plate, a second sieve plate and a third sieve plate. There is a paving device, a hot air blower is fixedly installed on the upper side of the casing, and a hot air pipe is connected to the air outlet of the hot air blower; a wind separation device chamber is installed on the left side of the casing, and a wind separation device cavity is installed inside the wind separation device cavity. A sorting machine, the first sieve plate, the second sieve plate and the third sieve plate are fixedly installed between the upper and lower sets of partitions. Compared with the ordinary paving device, the device indirectly drives the paving plate to move left and right through the drive motor, so that the melon seeds can be evenly spread on the conveyor belt, preventing the melon seeds from being fed and accumulated to affect the drying effect. The sieve plate with aperture can fall into the corresponding outlet according to the particle size of melon seeds, so as to realize the automatic grading and screening of the particle size of melon seeds, and at the same time, it is more efficient than manual selection.

Owner:盐城千之诺机械有限公司

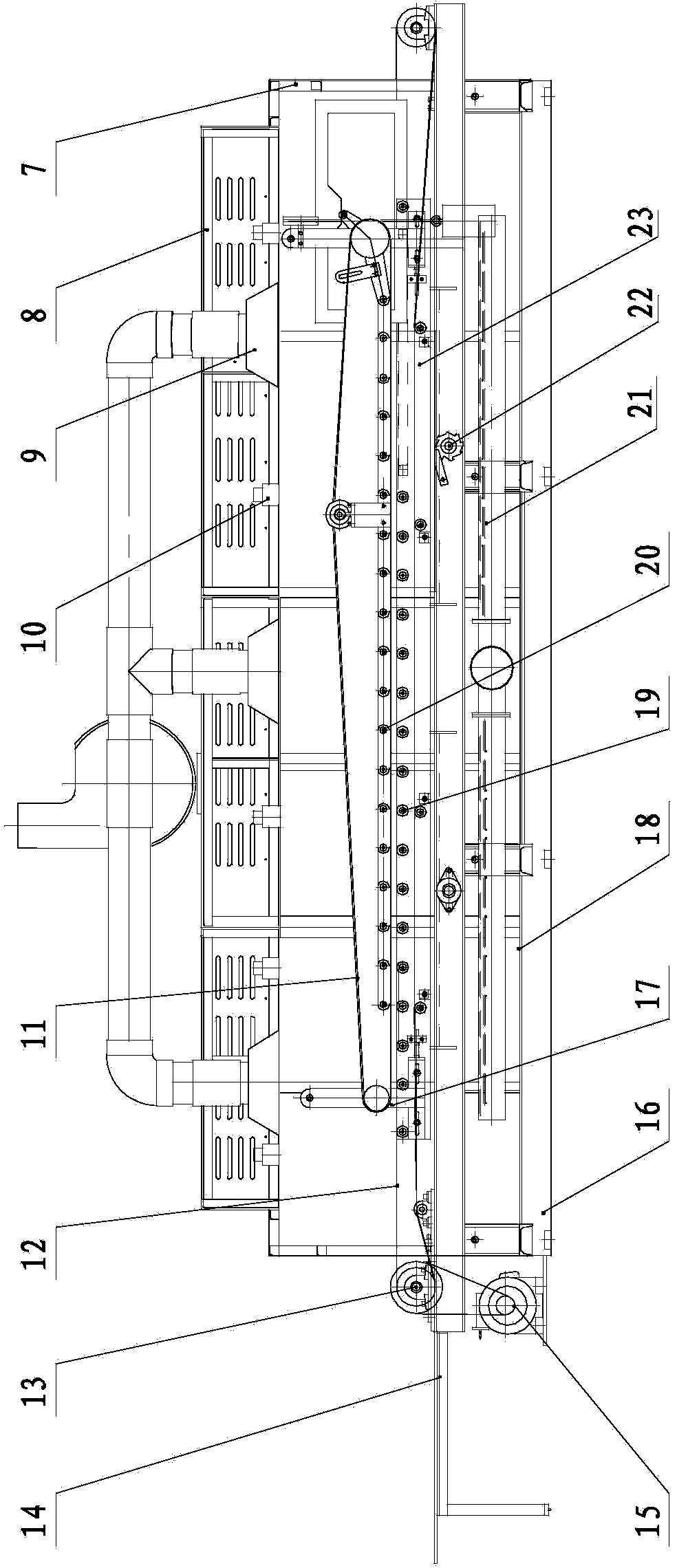

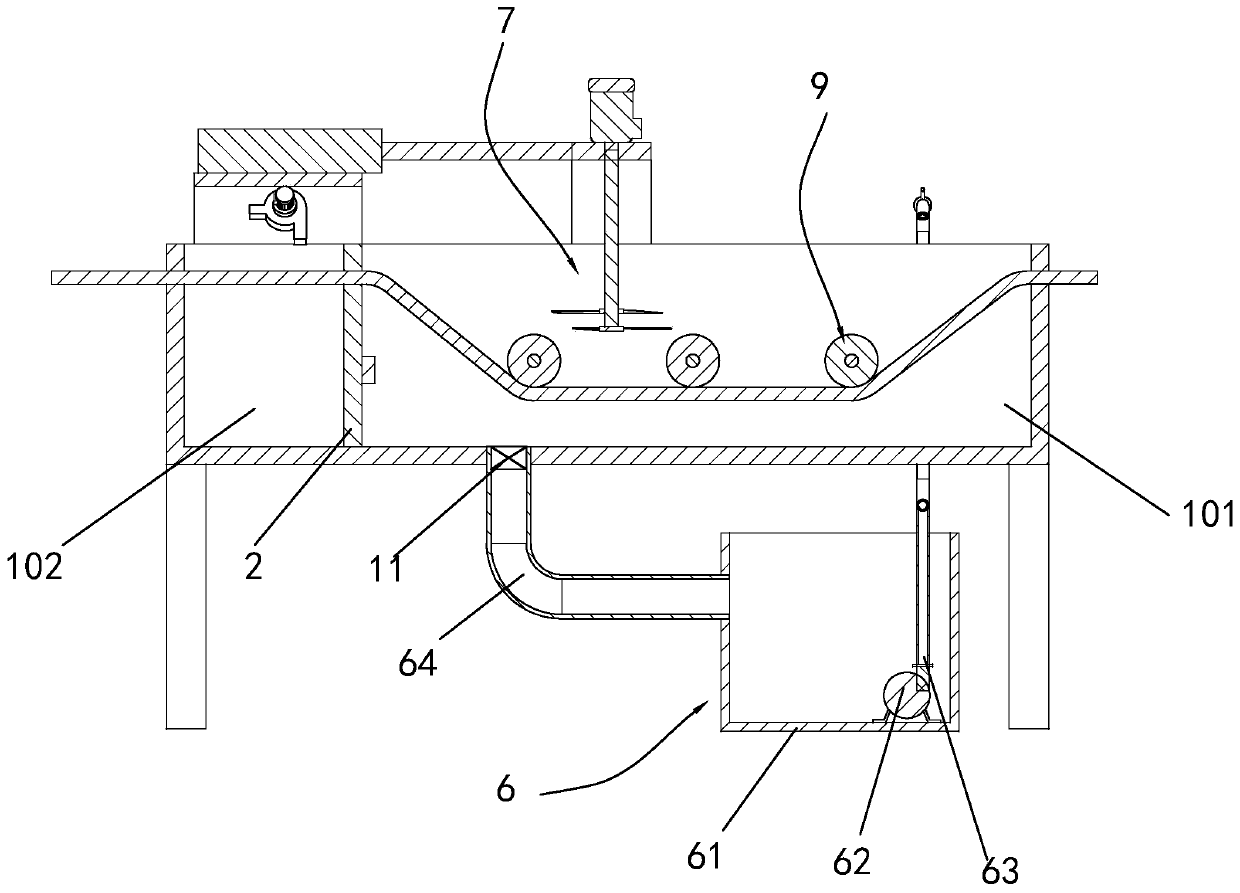

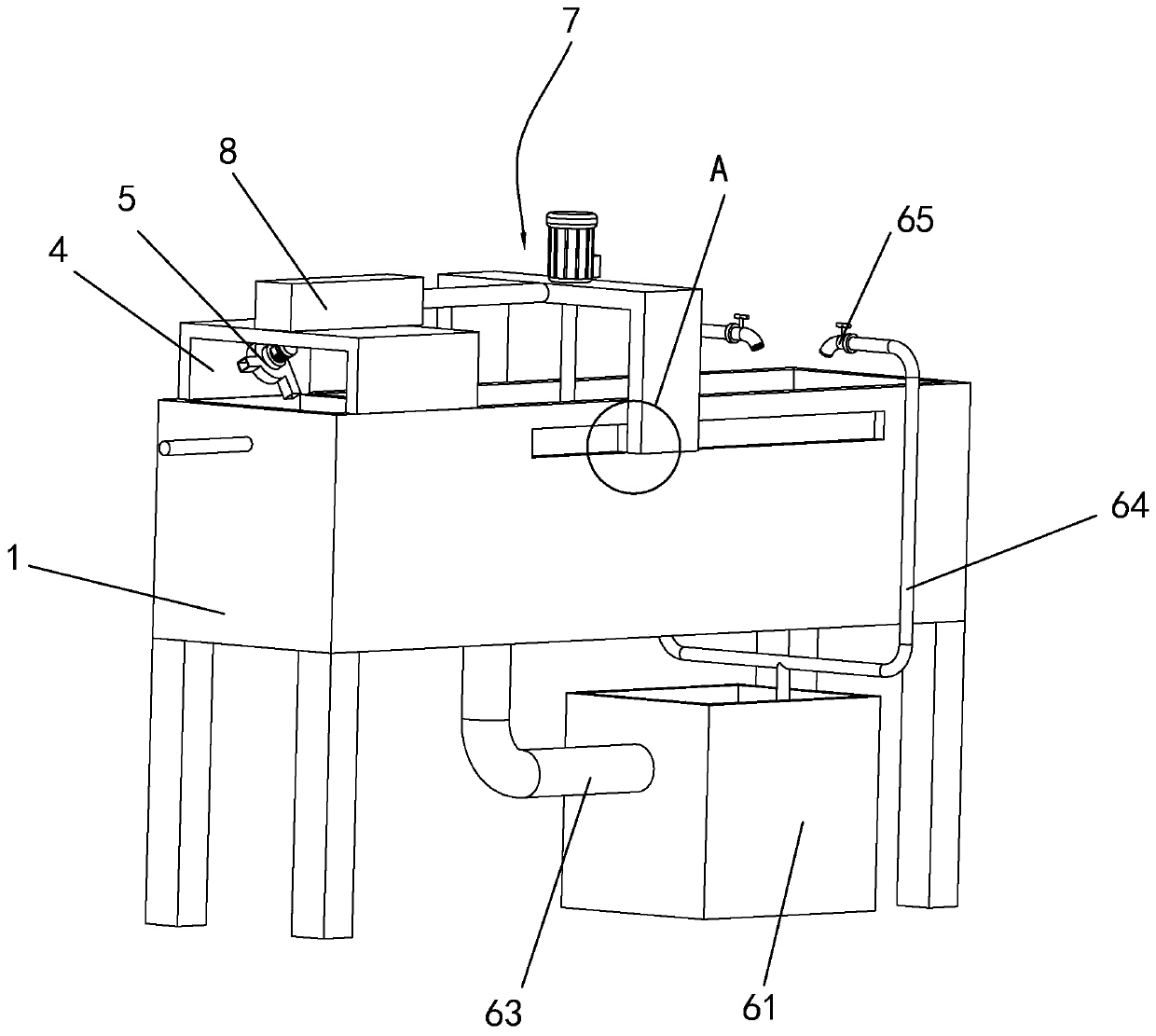

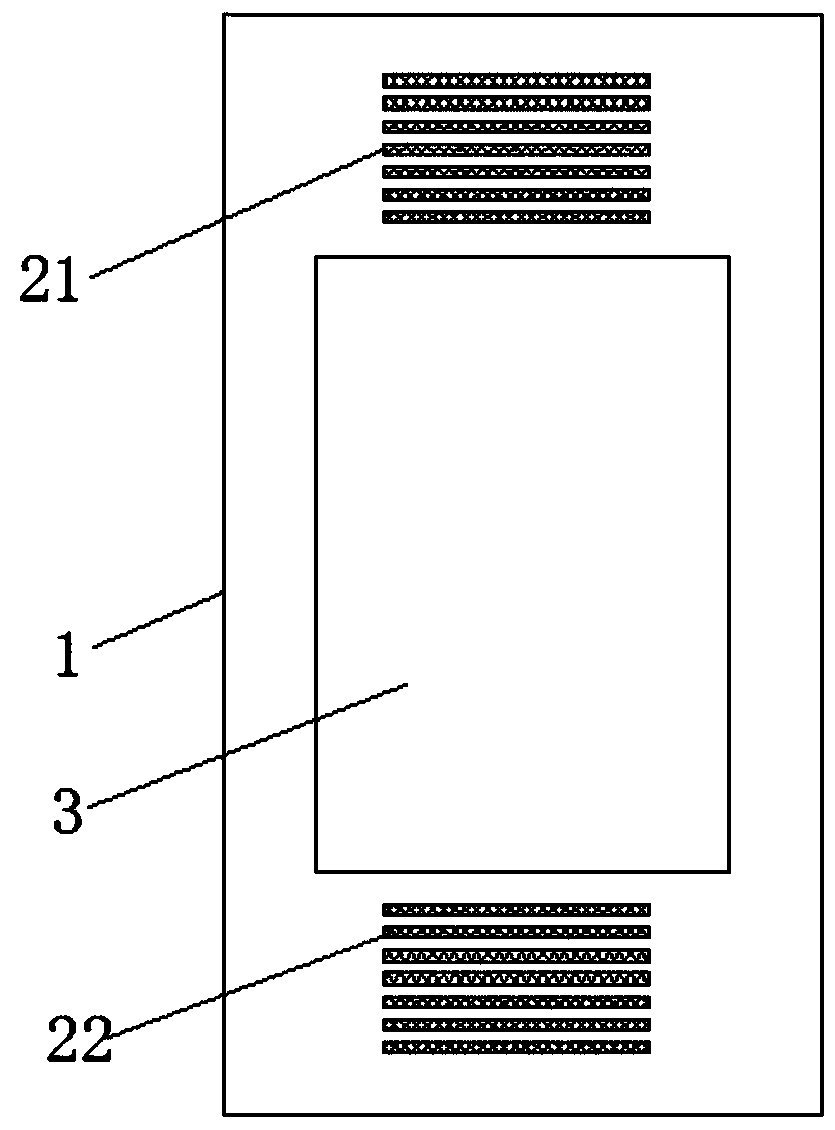

Paper mounting machine

ActiveCN103434329ADry evenlyImprove mildew resistanceMechanical working/deformationPaperhangingWater vaporPaperboard

The invention discloses a paper mounting machine, belonging to the technical field of packaging mechanical equipment. The paper mounting machine comprises a surface paper conveying device and a bottom paper conveying device, wherein the bottom paper conveying device is connected to a bottom paper gluing device, an output mechanism and a laminating device are sequentially arranged at the lower part of the bottom paper gluing device, the laminating device comprises a plurality of upper carrier rollers and lower carrier rollers which are arranged on a frame, laminating belts surround the upper carrier rollers, and conveying belts driven by a power device are arranged on the lower carrier rollers; a sealing cover is arranged on the periphery of the rack, and a heating element is arranged in the sealing cover; and a suction pipe communicated with the inner part of the sealing cover is arranged on the top of the sealing cover and is connected to a suction fan. The paper mounting machine has the advantages that water molecules inside paperboards are rapidly heated and discharged by using a heat source generated by the heating element in the processes of forwards pressing, flattening and transporting the paperboards by using the laminating belts and the conveying belts, water vapor is discharged through the suction fan and the suction pipe, the online rapid and uniform drying is realized, the curing time of glue is reduced, the anti-mildew capacity of the paper boards is improved, the defect of easiness in bending and deformation is overcome, and the strength and the manufacturing efficiency of the paper boards are improved.

Owner:SHANDONG CENTURY MACHINERY

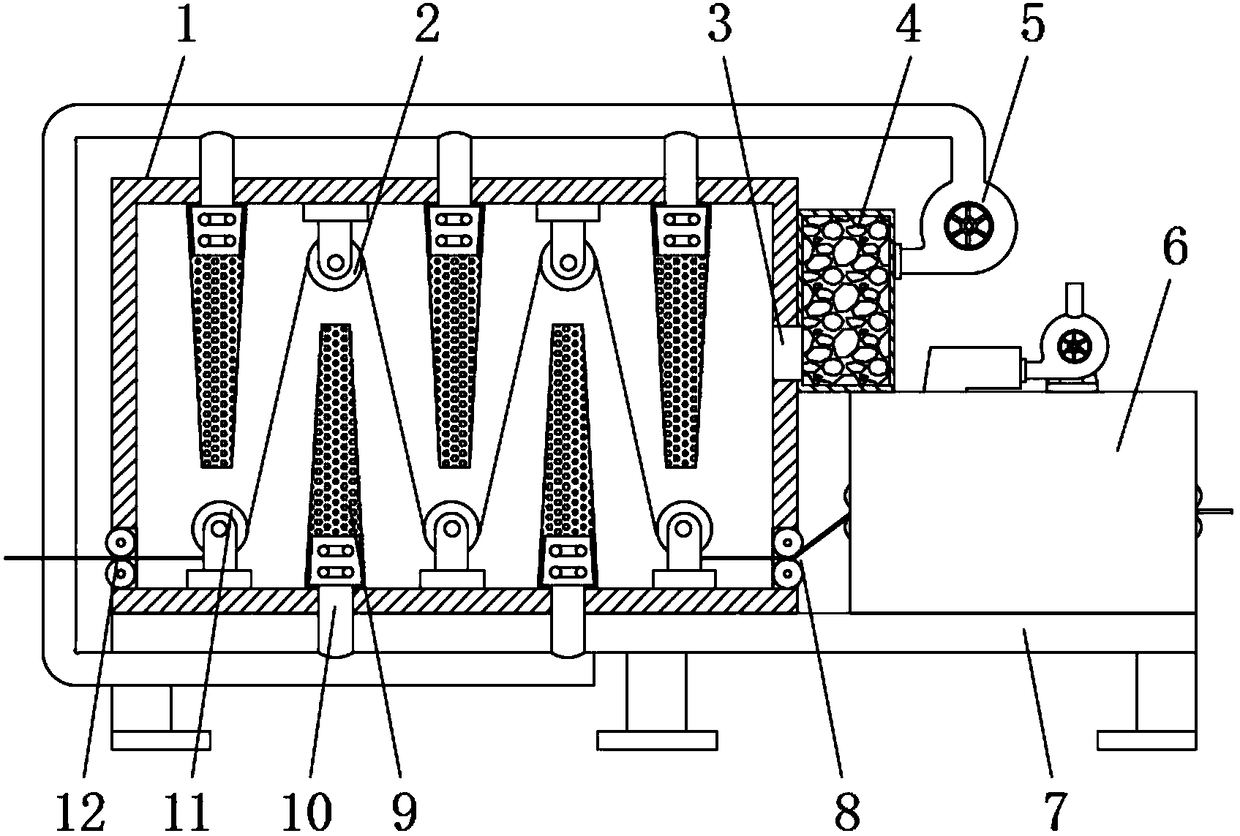

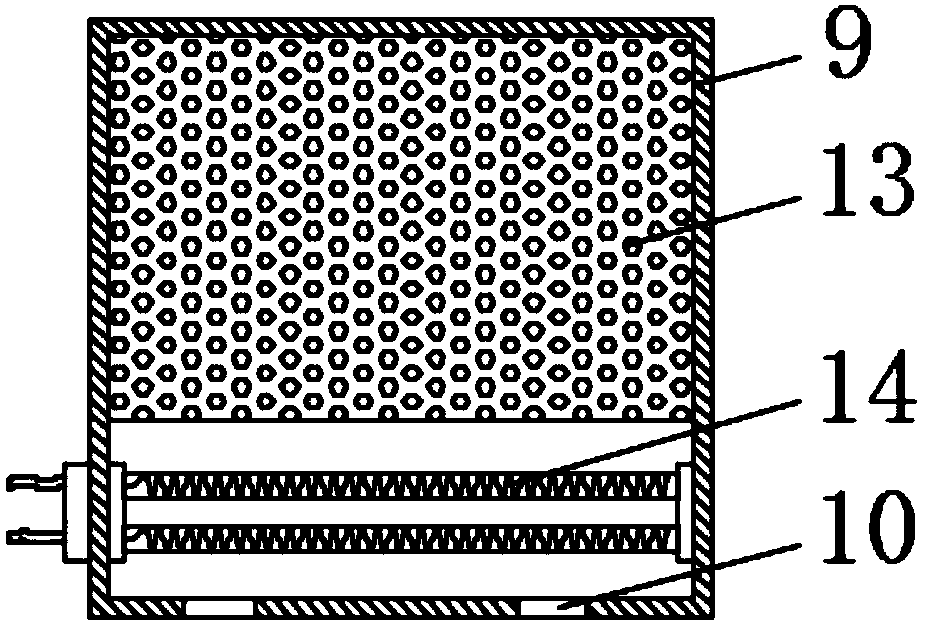

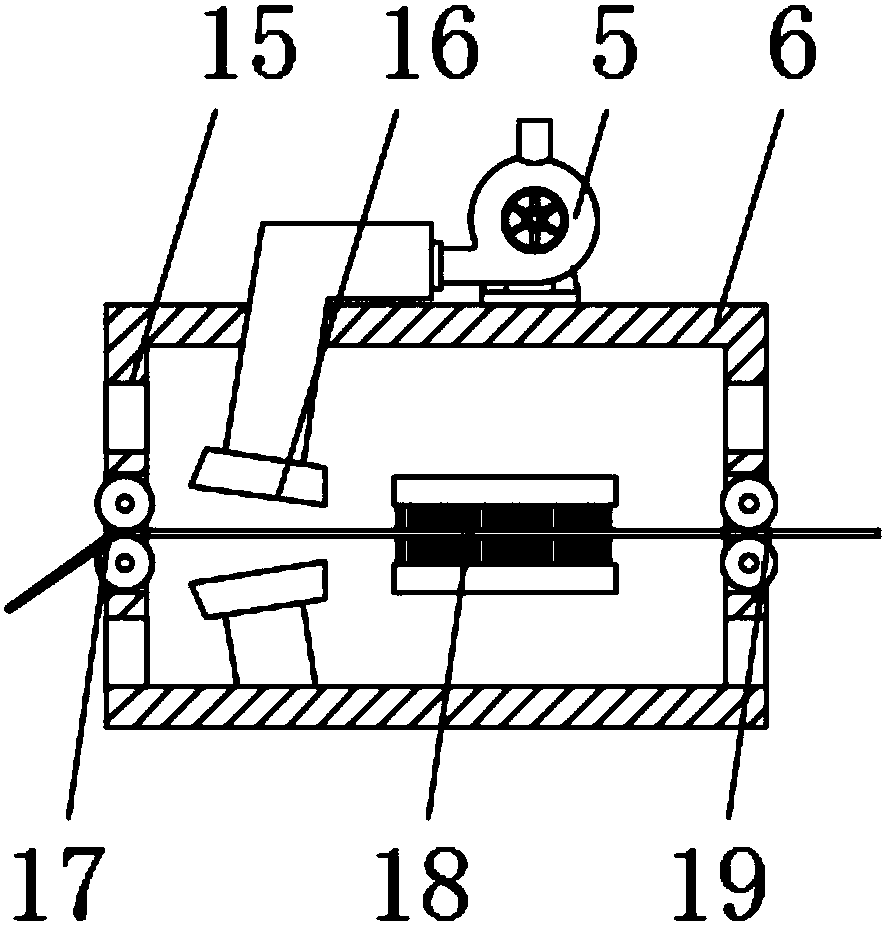

Novel hot air circulating and drying equipment for non-woven fabric production

PendingCN109140975AGuarantee product qualityImprove product qualityMechanical cleaningPressure cleaningPulp and paper industryDry box

The invention discloses novel hot air circulating and drying equipment for non-woven fabric production. The novel hot air circulating and drying equipment comprises a drying box and a heating box, wherein a lower guide roller is installed on one side of the lower part of the inner wall of the drying box, the heating box is fixedly arranged on one side of the lower guide roller, a ceramic heating pipe is arranged in the lower part of the heating box, a plurality of air holes are formed in the surface of the heating box, an air inlet is formed in the bottom of the heating box, an upper guide roller is fixed to the inner wall of the drying box above the heating box, and a plurality of air return ports are formed above the surface of one side of the drying box. According to the novel hot air circulating and drying equipment, the upper guide roller, the lower guide roller and the heating box are arranged on the equipment, and non-woven fabrics are distributed on both sides of the heating box in an S shape by virtue of the upper guide roller and the lower guide roller, so that the upper and lower surfaces of the non-woven fabrics can be heated for many times in the drying box, water in the non-woven fabrics is quickly removed, the drying effect is increased, and the production quality of the non-woven fabrics is guaranteed.

Owner:南通汇优洁医用材料有限公司

Drying device uniform in heating for garment processing

InactiveCN107747200AHeating evenlyDry evenlyTextiles and paperLaundry driersEngineeringControl effect

The invention discloses a drying device uniform in heating for garment processing, and relates to the technical field garment processing. The device comprises a shell, a lead screw is rotationally connected between the two sides of the inner wall of the shell, movable blocks are rotationally connected to the two sides of the surface of the lead screw, connecting rods are rotationally connected tothe tops of the movable blocks, a movable plate is rotationally connected to the tops of the connecting rods, a transverse plate is fixedly connected between the two sides of the inner wall of the shell, a motion device is fixedly connected to the top of the transverse plate, vertical rods are fixedly connected to the two sides of the motion device, and the bottoms of the vertical rods penetrate through the transverse plate and extend to the bottom of the transverse plate. According to the drying device uniform in heating for garment processing, clothes are dried uniformly, the phenomenon thatdue to the fact that the temperature is too high or too low, the drying effect is affected is avoided, the processing quality is improved, the height of the movable plate is adjusted conveniently, the clothes drying temperature is controlled conveniently, the control effect is good, and the quality of finished clothes products is improved.

Owner:界首市永顺服饰有限公司

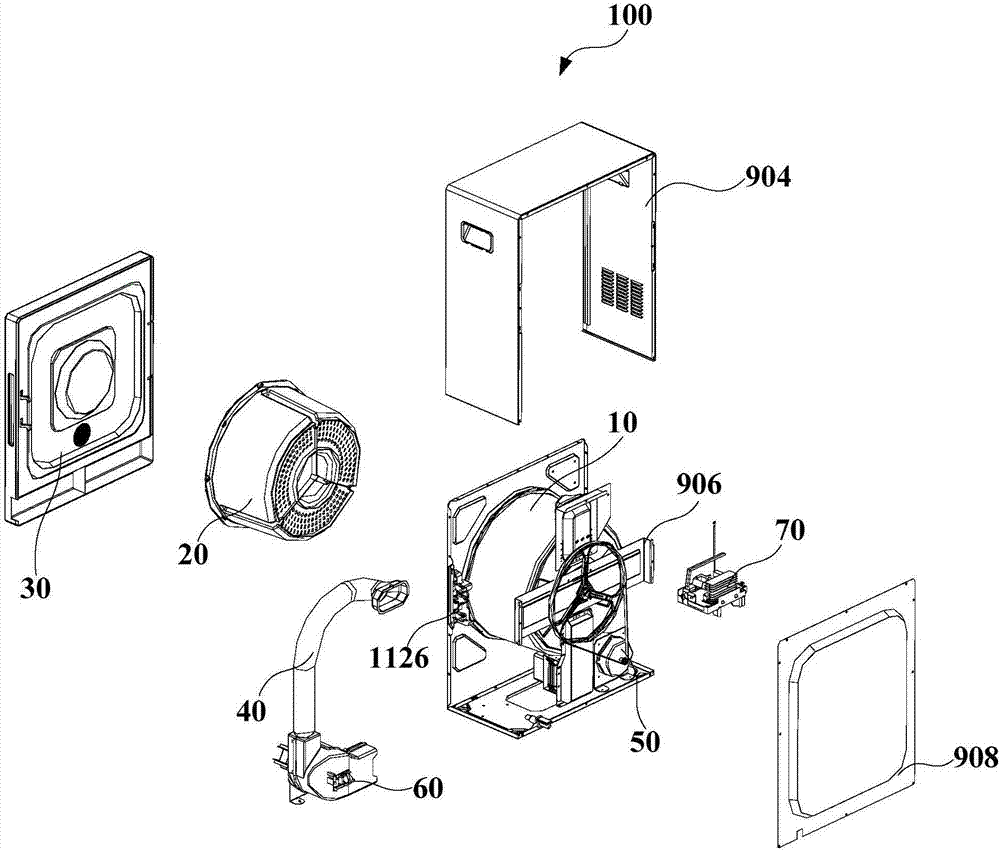

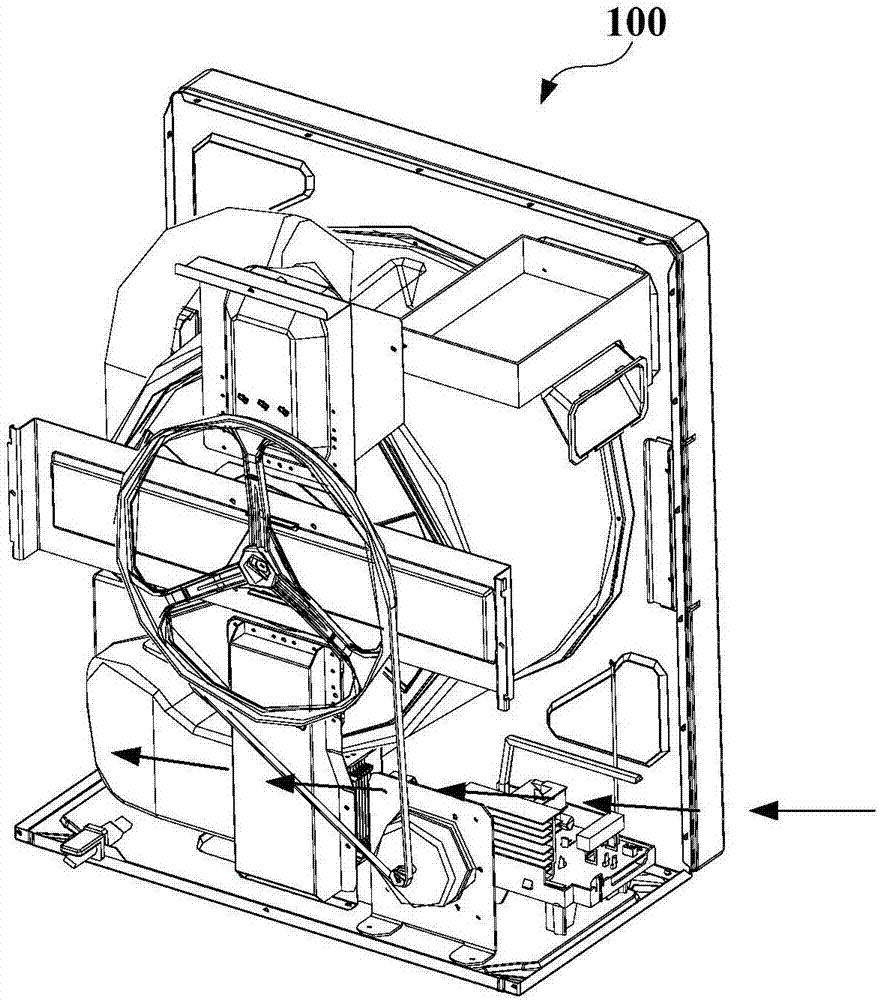

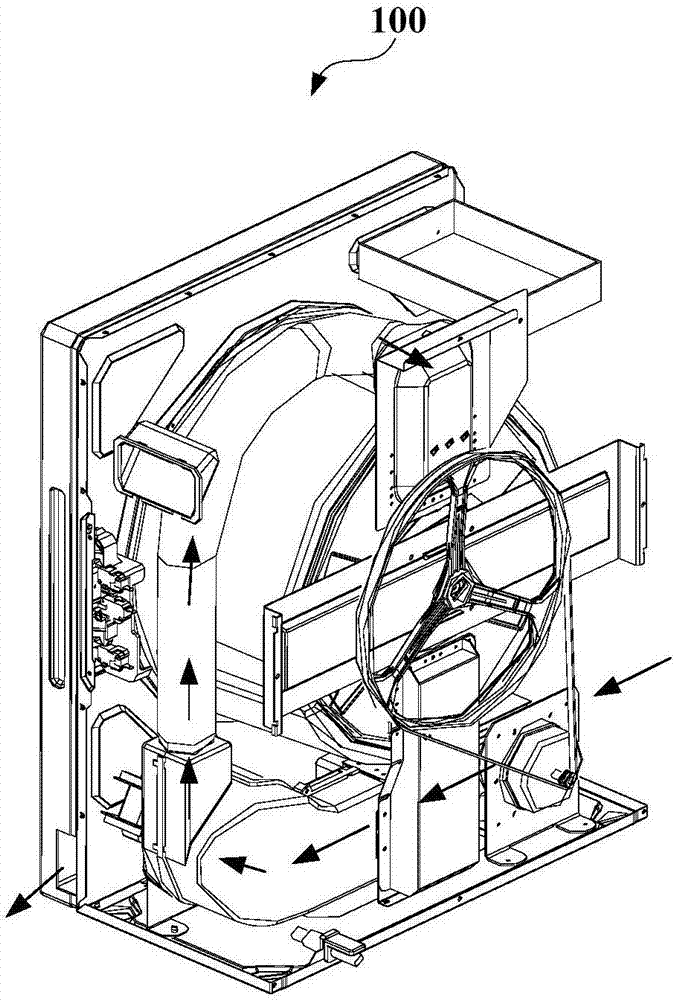

Microwave clothes dryer

ActiveCN106868827AGuaranteed aestheticsImprove satisfactionTextiles and paperHome appliance efficiency improvementMechanical engineeringEngineering

The invention provides a microwave clothes dryer which comprises a cavity assembly, an air suction assembly, a roller assembly and a machine door assembly. An air inlet hole is formed in one end of the bottom of the cavity assembly, and a first opening is formed in the other end of the cavity assembly. The air suction assembly is located outside the cavity assembly and communicated with the air inlet hole. The roller assembly is mounted in the cavity assembly, a first vent hole is formed in one end of the bottom of the roller assembly, and a second vent hole is formed in the other end of the roller assembly. The machine door assembly is mounted on the first opening and is in matching connection with the cavity assembly, and the machine door assembly is provided with a third vent hole and an air outlet hole. External air is guided in through the air suction assembly, flows into the cavity assembly through the air inlet hole, passes through the first vent hole, the second vent hole and the third vent hole and flows out through the air outlet hole. According to the microwave clothes dryer, soft flocks generated in the clothes washing process are discharged out of the roller assembly along with air flow, it is avoided that the soft flocks are scattered to the position between the roller assembly and the cavity assembly along with the air flow and cannot be cleared away, and consequently a pollution source is caused, and the use experience of a user is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Anti-caking sand dryer

InactiveCN108731419AAvoid accumulationAvoid damageDrying gas arrangementsDrying machines with non-progressive movementsEngineering

The invention relates to an anti-caking sand dryer, comprising a drying barrel, a controller, a sand incoming tube, a sand outgoing tube, a hot air tube and a plurality of support legs. A dischargingmechanism is arranged in the sand outgoing tube. A crushing mechanism and a filtering mechanism are arranged in the drying barrel; the crushing mechanism includes a first motor, a spindle, a rocking component and a plurality of crushing components; the filtering mechanism includes a strainer, a sealing component, support rods and a driving component. The anti-caking sand dryer has the advantages that blades are rotated and rocked through the crushing mechanism during drying, sandstone is cut and crushed at different parts, and drying effect being affected by moist sand caking is avoided; in addition, after drying, the strainer in the filtering mechanism is rotated down, a discharge plate in the sand outgoing tube is rotated down, sand in the drying barrel slips from the bottom, accumulation of fine sand, passing through the strainer, in the drying barrel is avoided, sand damage and dryer damage are avoided, and the dryer has improved practicality.

Owner:永春福源建材科技有限公司

Cable injection molding and cooling equipment

The invention discloses cable injection molding and cooling equipment. The equipment comprises a cooling groove. A partition plate is arranged in the cooling groove. Cable passing holes are formed inthe two sides of the cooling groove and in the partition plate correspondingly, and the three cable passing holes are located on the same straight line. The partition plate partitions the cooling groove into a cooling chamber and a blow-drying chamber. A waterproof hood is fixedly arranged on the blow-drying chamber. A hot air blower is arranged on the inner wall of the waterproof hood symmetrically and obliquely downwards. Cooling liquid is arranged in the cooling chamber. A water injection device is arranged under the cooling chamber. A stirring device is arranged on the cooling chamber. Thecable injection molding and cooling equipment is reasonable in structure, when injection molding is completed, a cable sequentially penetrates through the cooling chamber and the blow-drying chamber,the cable can be cooled and blow-dried, an injection molded rubber layer is shaped, and the cooling effect is good.

Owner:嘉兴振华电线电缆有限公司

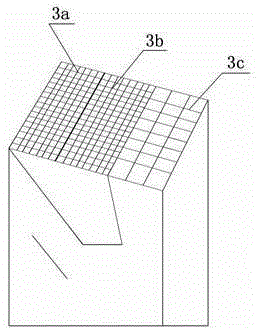

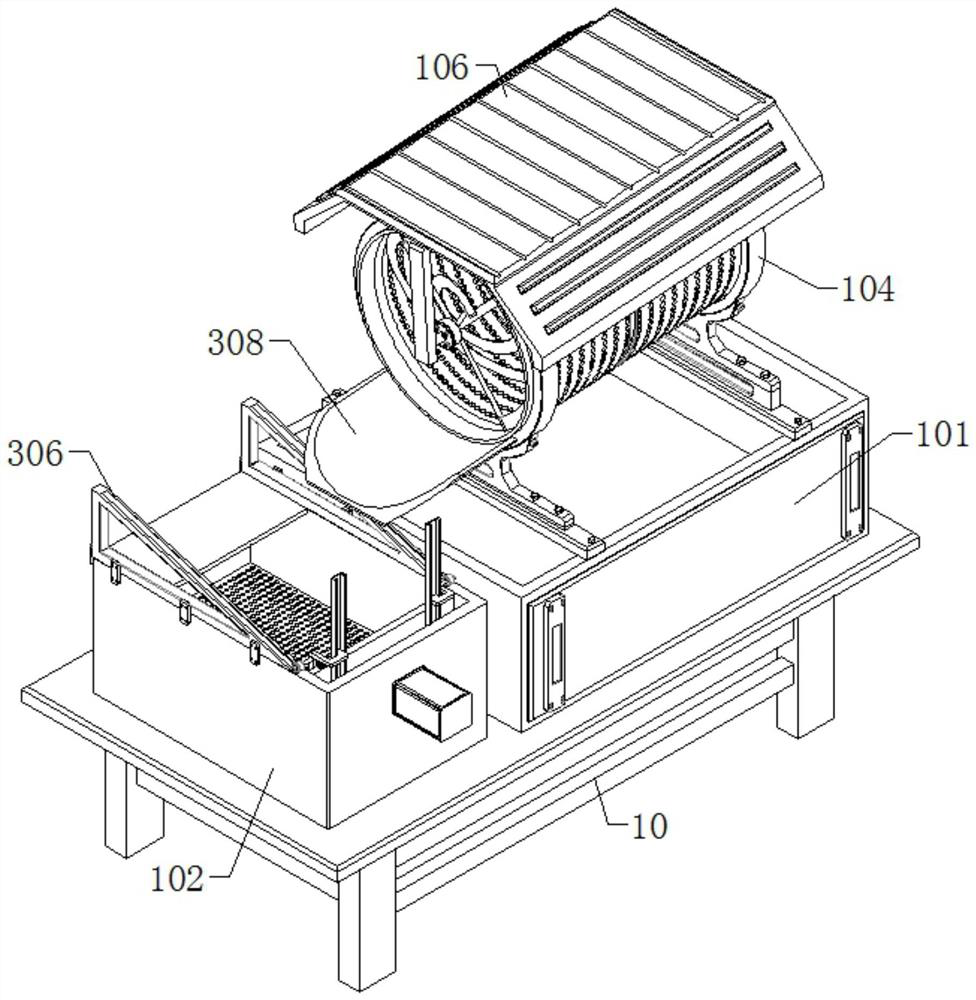

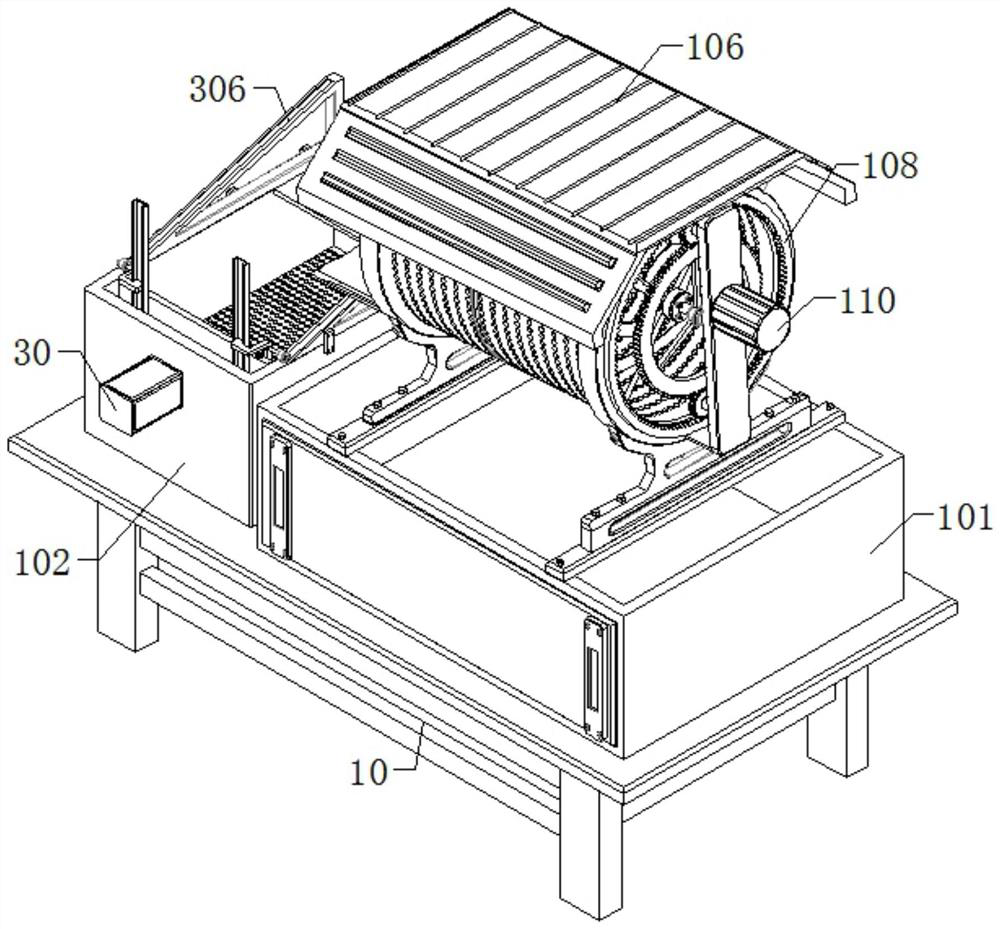

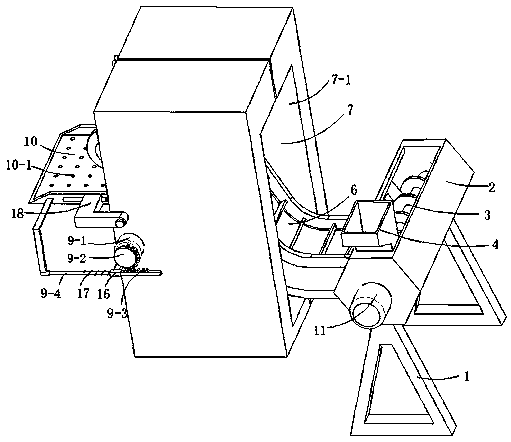

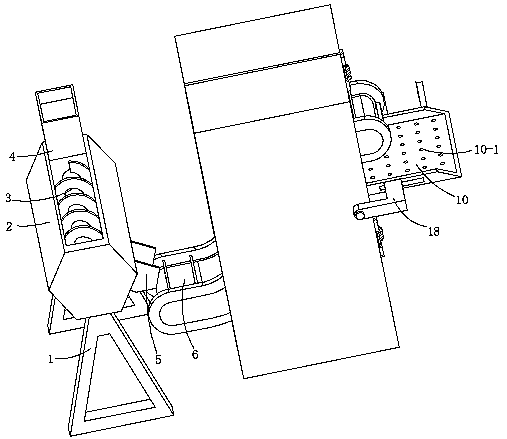

Vibrated food microwave drying device

ActiveCN110617684AAvoid cloggingAvoid affecting the drying effectSievingDrying solid materials with heatMicrowaveStone particle

The invention discloses a vibrated food microwave drying device, and belongs to the technical field of food drying. The vibrated food microwave drying device comprises a feeding hopper, a drying box and a discharging pipe; the drying box takes the shape of a horizontal circular truncated cone, and comprises a left bracket, a right bracket and a cylindrical filter screen connected between the leftbracket and the right bracket; a first feeding opening is formed in the top of the right bracket; a small plugging ring body connected to the bottom of the feeding hopper is arranged outside the rightbracket in an attaching manner; a second feeding opening is formed in the top of the small plugging ring body; an upper filter plate arranged in an inclining manner is arranged in the cylindrical filter screen; a first discharging opening is formed in the bottom of the left bracket; a large plugging ring body is arranged outside the right bracket in an attaching manner; a second discharging opening is formed in the bottom of the large plugging ring body; a small stone outlet is formed in the front side of the large plugging ring body; and a lifting plate parallel to the bottom of the drying box is arranged at the bottom of the drying box. The vibrated food microwave drying device can realize periodic and intermittent feeding synchronously, performs fractional separation and separate discharging on stone particles, generates an overturning effect on food, and can generate impact and vibration effects on the drying box.

Owner:哈尔滨土丰农业机械设备有限公司

Drying device used for textile printing and dyeing

PendingCN110455061AReduce foldingImprove drying uniformityDrying gas arrangementsDrying machines with progressive movementsTextile printerTextile printing

The invention discloses a drying device used for textile printing and dyeing. The drying device comprises a device body, a movable bin door, a feed port, a discharge port, a material guide mechanism,a partition plate, a drying mechanism, a flow guide mechanism and a waste heat collection device. Compared with the prior art, the drying device is simple in structure and reasonable in design; textiles are tensioned through the arranged material guide mechanism; hot gas flow is guided into the waste heat collection device through the arranged flow guide mechanism and the arranged waste heat collection device; and waste heat in the hot gas flow is effectively utilized. Furthermore, condensed liquid drops can also be guided out through the flow guide mechanism, it is avoided that because the liquid drops drop to the textiles, the drying effect is influenced, and the drying device is worthy of popularization.

Owner:海盐鸳鸯丝绸印染股份有限公司

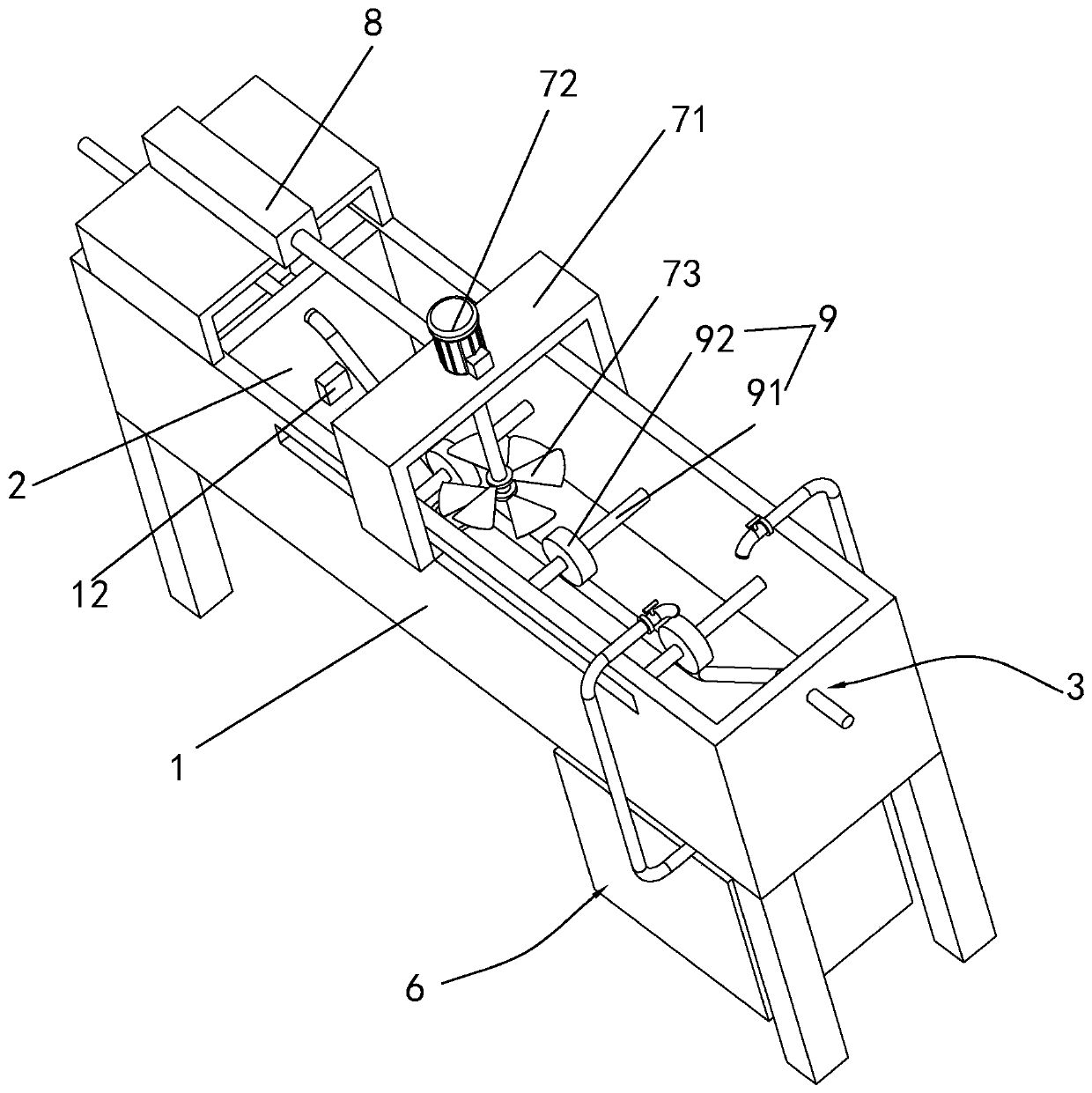

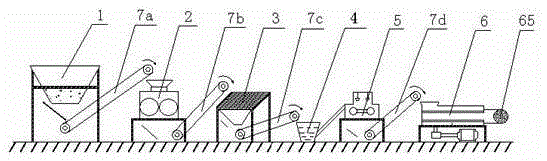

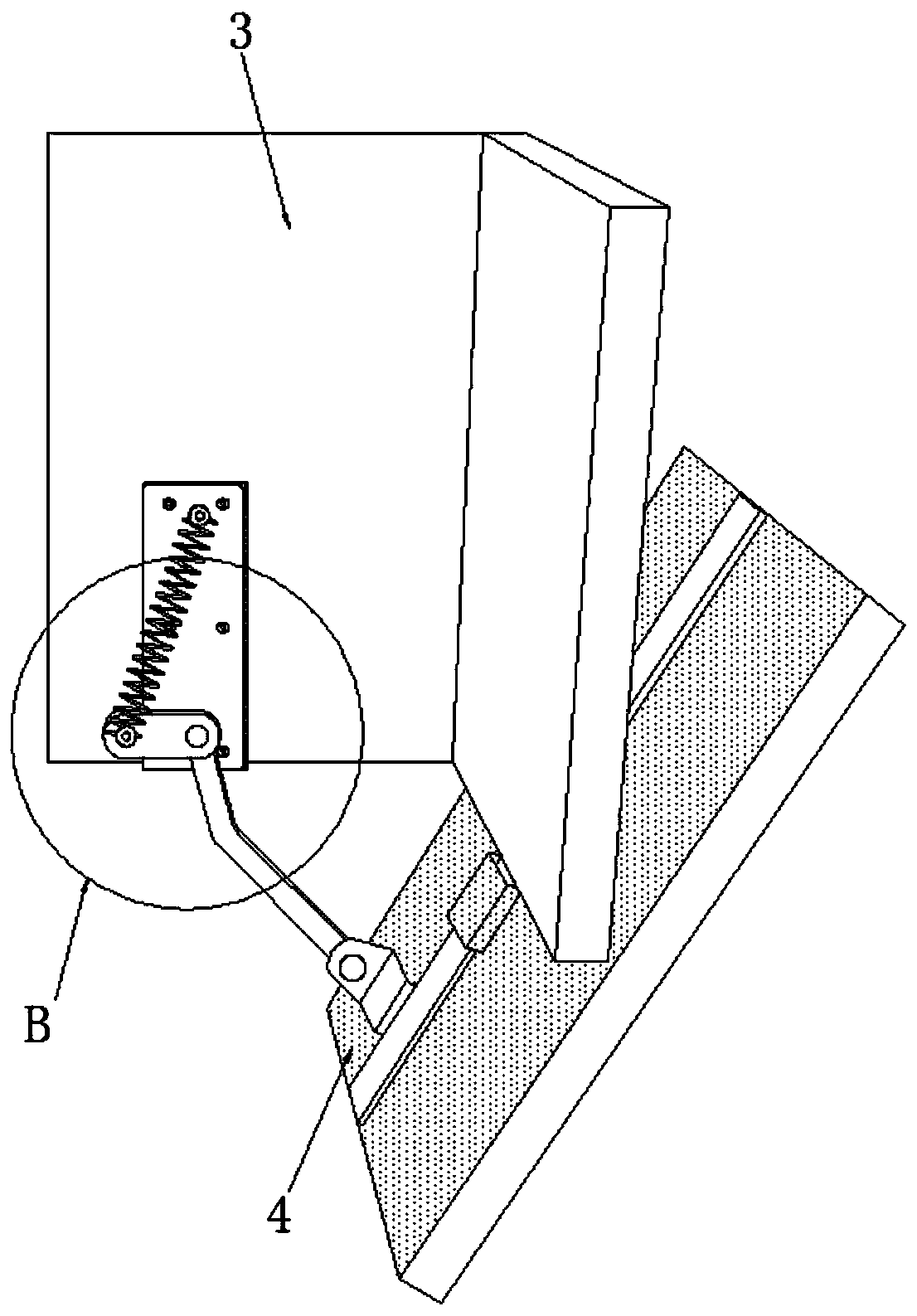

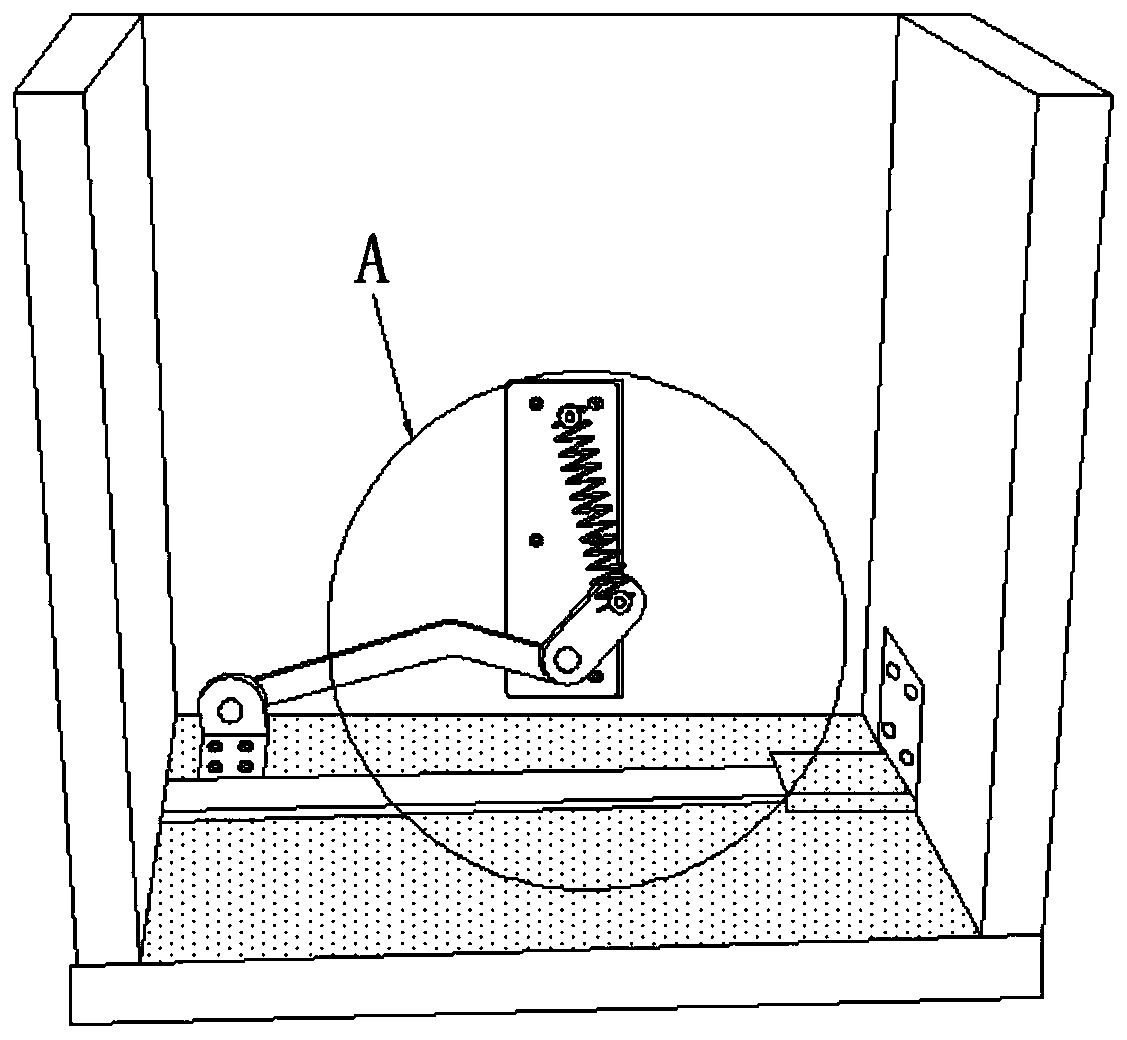

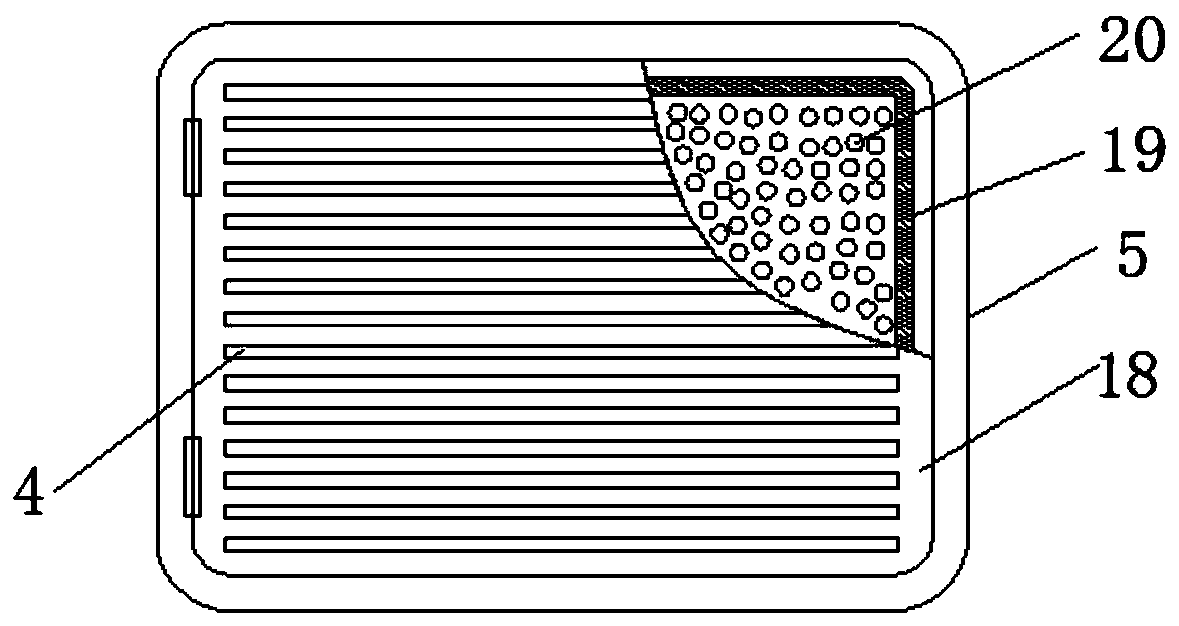

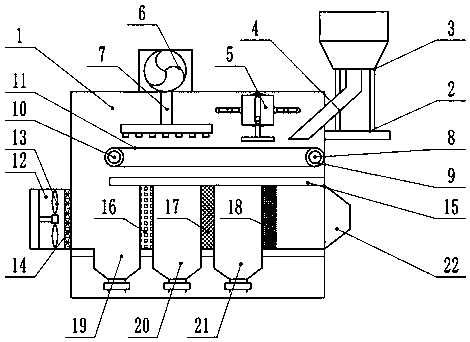

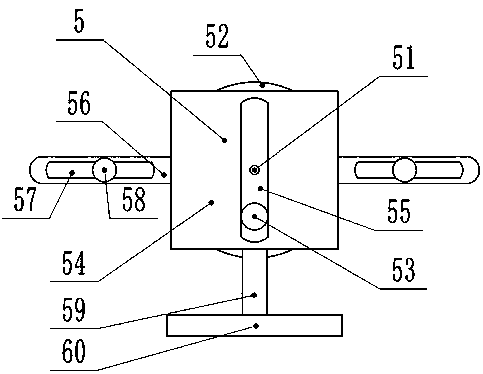

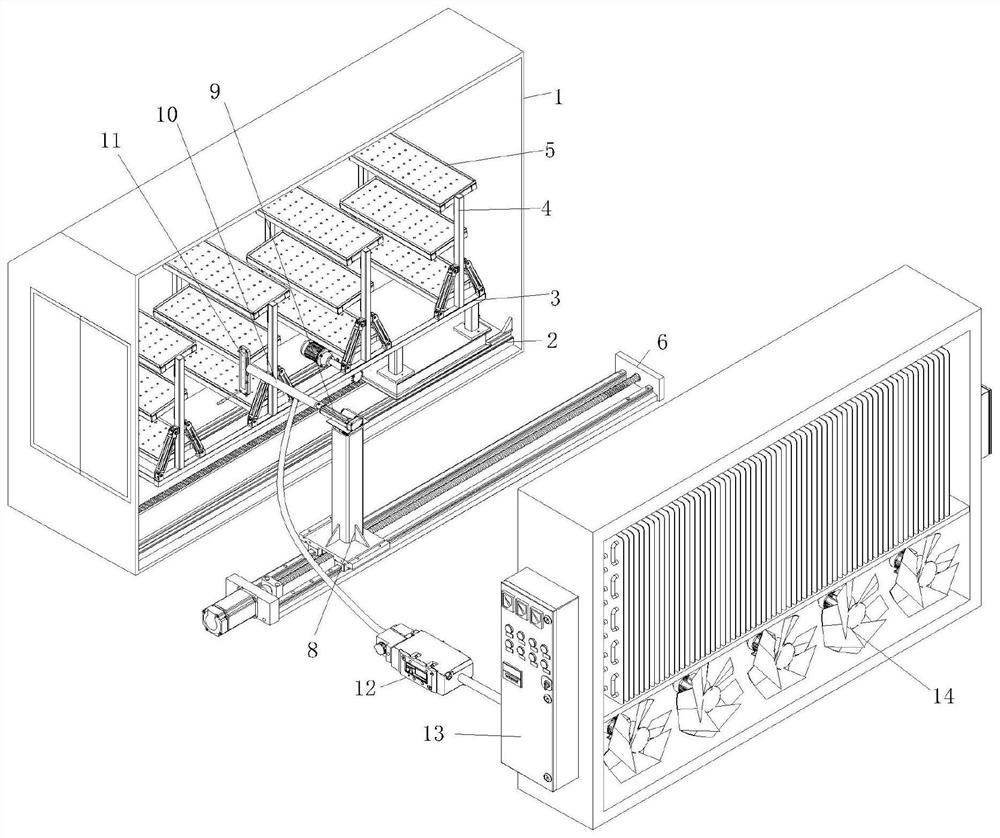

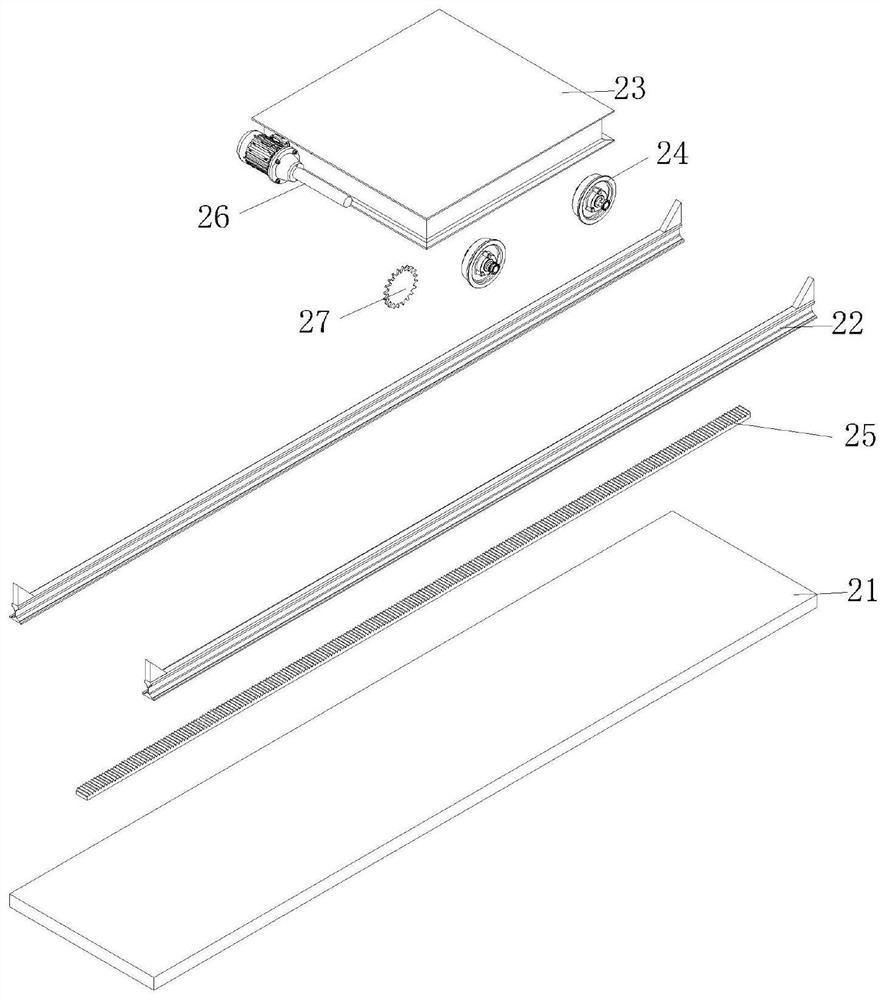

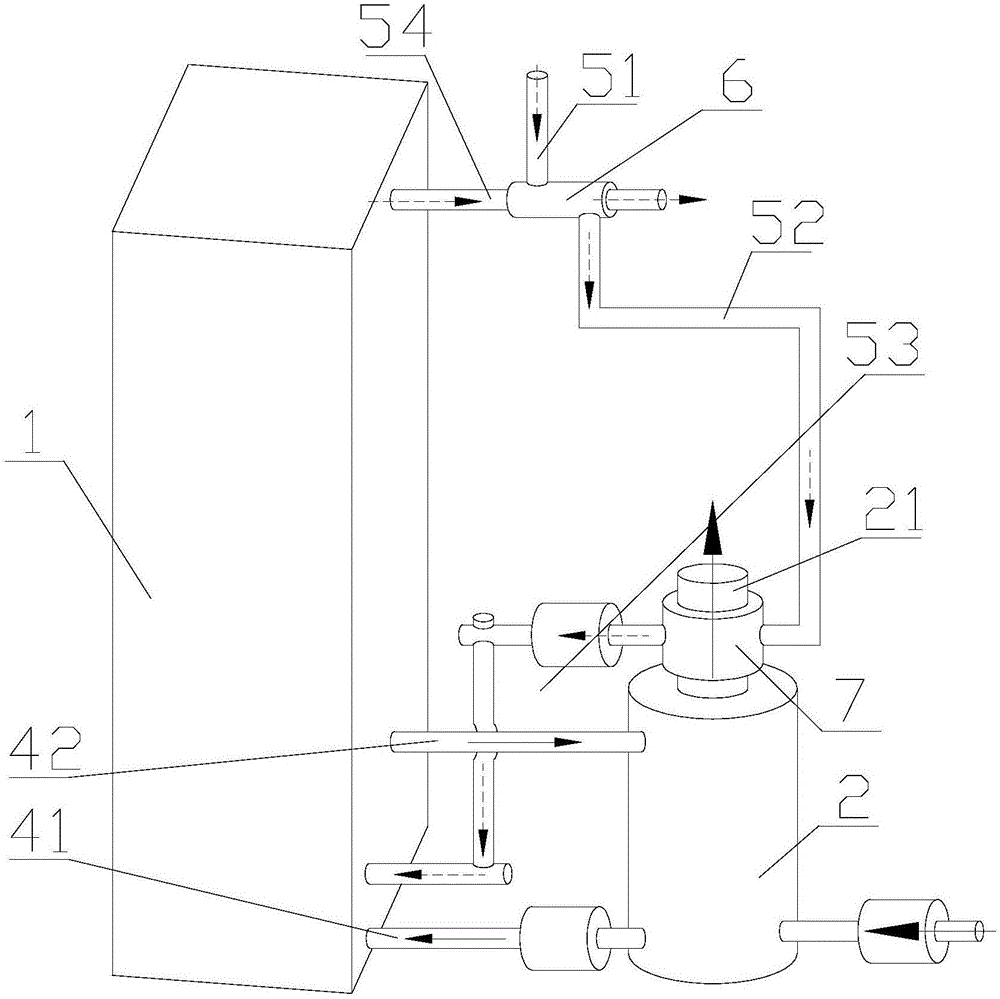

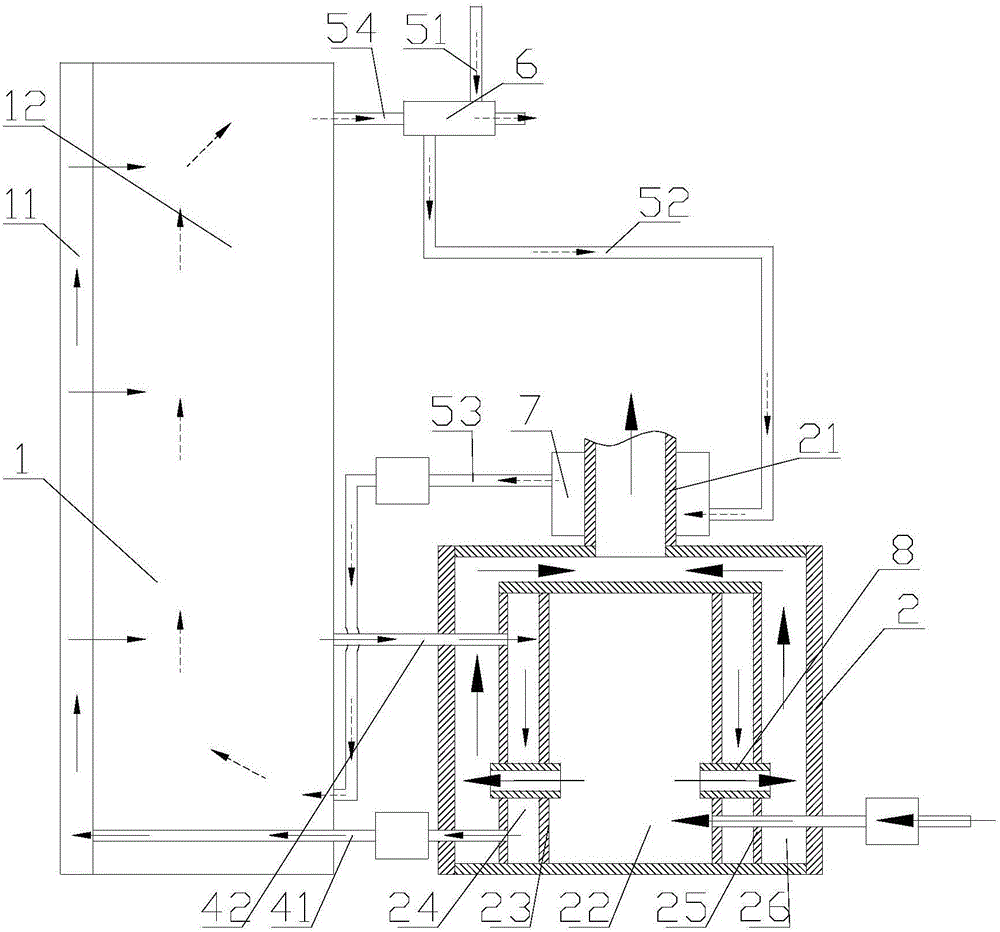

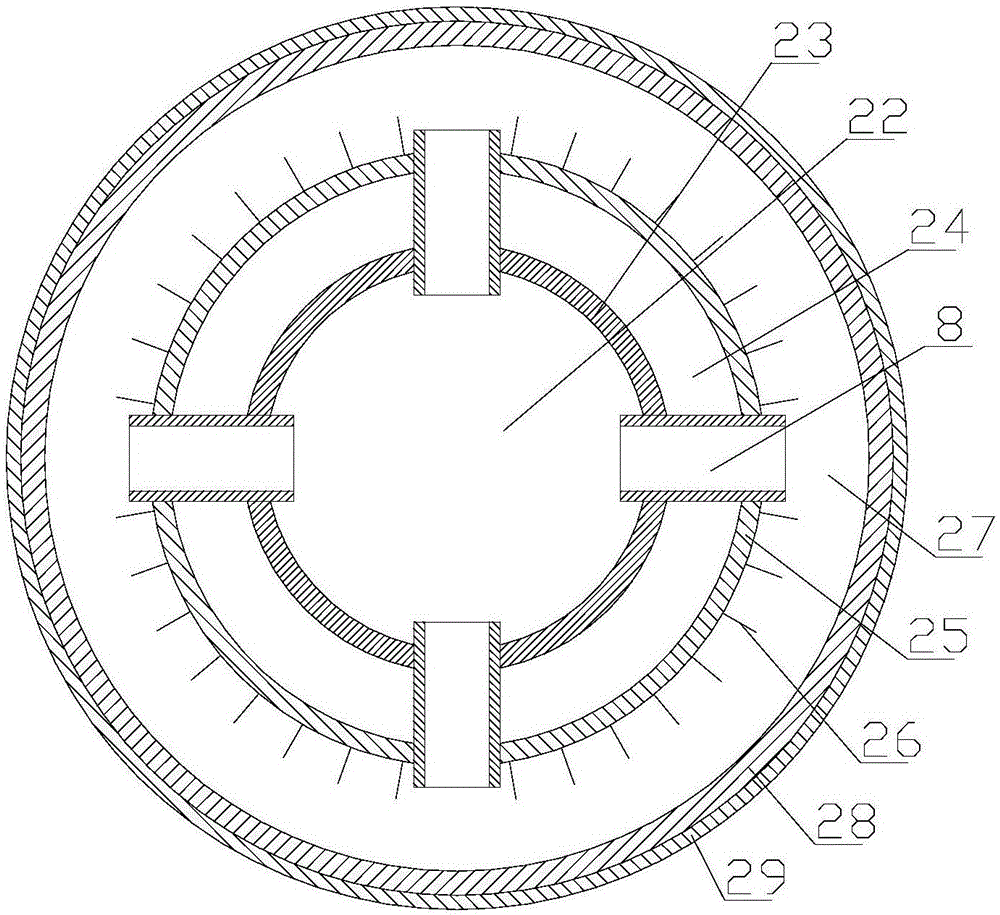

Grain drying and screening integrated device

The invention discloses a grain drying and screening integrated device. The grain drying and screening integrated device comprises a case, a spreading device, an air heater, a screening box and an impurity box. The spreading device is arranged in the case. Two horizontal sliding rods are arranged in the case. The two ends of each sliding rod are welded to the inner wall of the case. The screeningbox is slidably mounted between the two sliding rods. A first screen, a second screen and a third screen are sequentially arranged in the screening box from top to bottom. Compared with an ordinary spreading device, a flat spreading plate is indirectly driven by a driving motor to move left and right so that grain can be evenly spread on a conveying belt, the situation that the grain is accumulated in the feeding process, and consequentially, the drying effect is affected is prevented; the screening box moves left and right in the screening process, so that the flow rate of the grain in the screening box is improved, and the screening speed is improved; and meanwhile, a first screen, a second screen and a third screen are arranged in the screening box, so that grain with various sizes is separated, secondary operation is not needed, and the screening time is shortened.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Waste classification and environment-friendly treatment system

InactiveCN111495933AScientific and reasonable structureEasy to useSievingGas current separationElectric machineryStructural engineering

The invention discloses a waste classification and environment-friendly treatment system. The waste classification and environment-friendly treatment system comprises a smashing machine, a sorting machine, a filtering screen, a dryer and a conveying belt, wherein the smashing machine, the sorting machine, the filtering screen and the dryer are all connected through conveying belts. The smashing machine comprises a smashing box, a feeding channel, a baffle, rotary knobs, sliding grooves, sliding blocks, a first smashing roller, limiting plates, bolts, a second smashing roller, a cover plate anddriving motors. The feeding channel is fixedly connected to the top end of the smashing box, and the baffle is connected to the edge side position of the inner wall of the feeding channel in a rotating mode. The waste classification and environment-friendly treatment system is scientific and reasonable in structure and safe and convenient to use; the first smashing roller and the second smashingroller are driven to rotate through driving motors in the smashing box to smash waste; and meanwhile, the cover plate is opened, the sliding blocks slide to pull the limiting plates to move, and thusthe first smashing roller is driven to slide out of the smashing box, so that the waste between the first smashing roller and the second smashing roller can be conveniently cleaned, and accumulation of the waste can be avoided.

Owner:张官亮

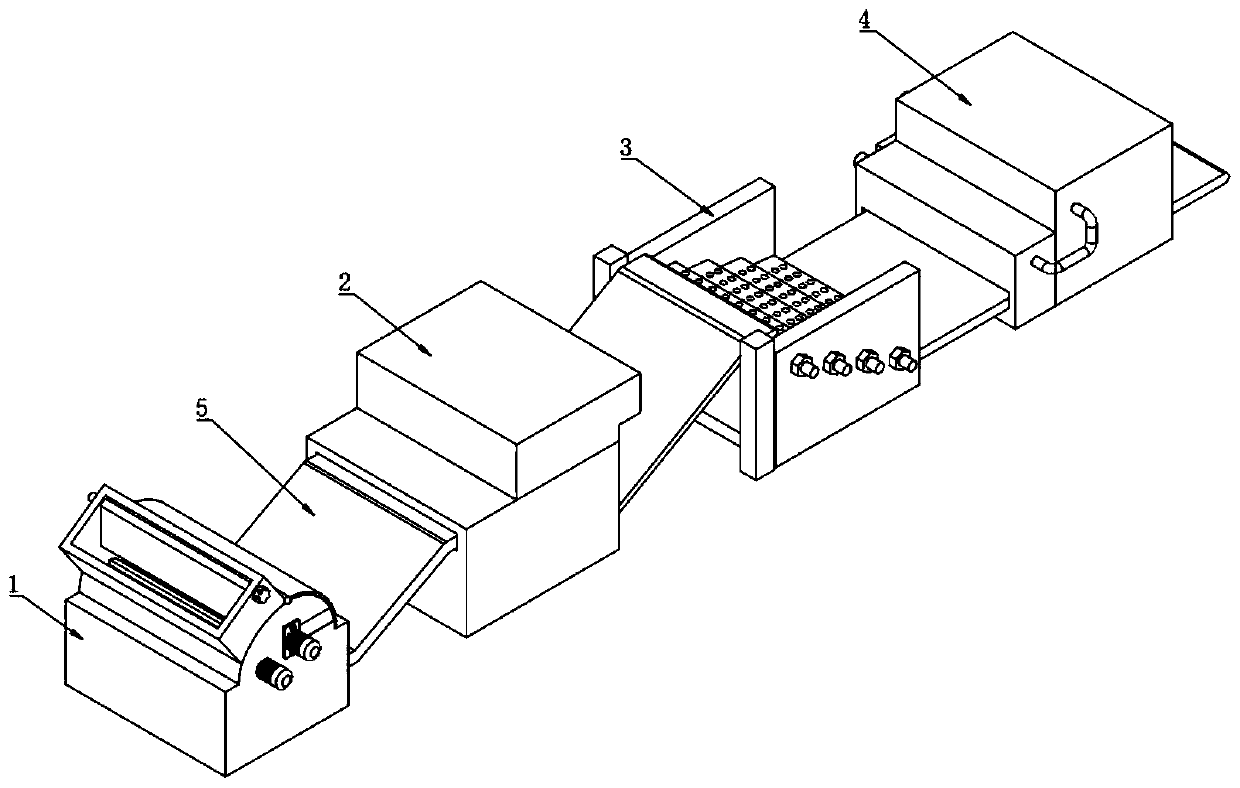

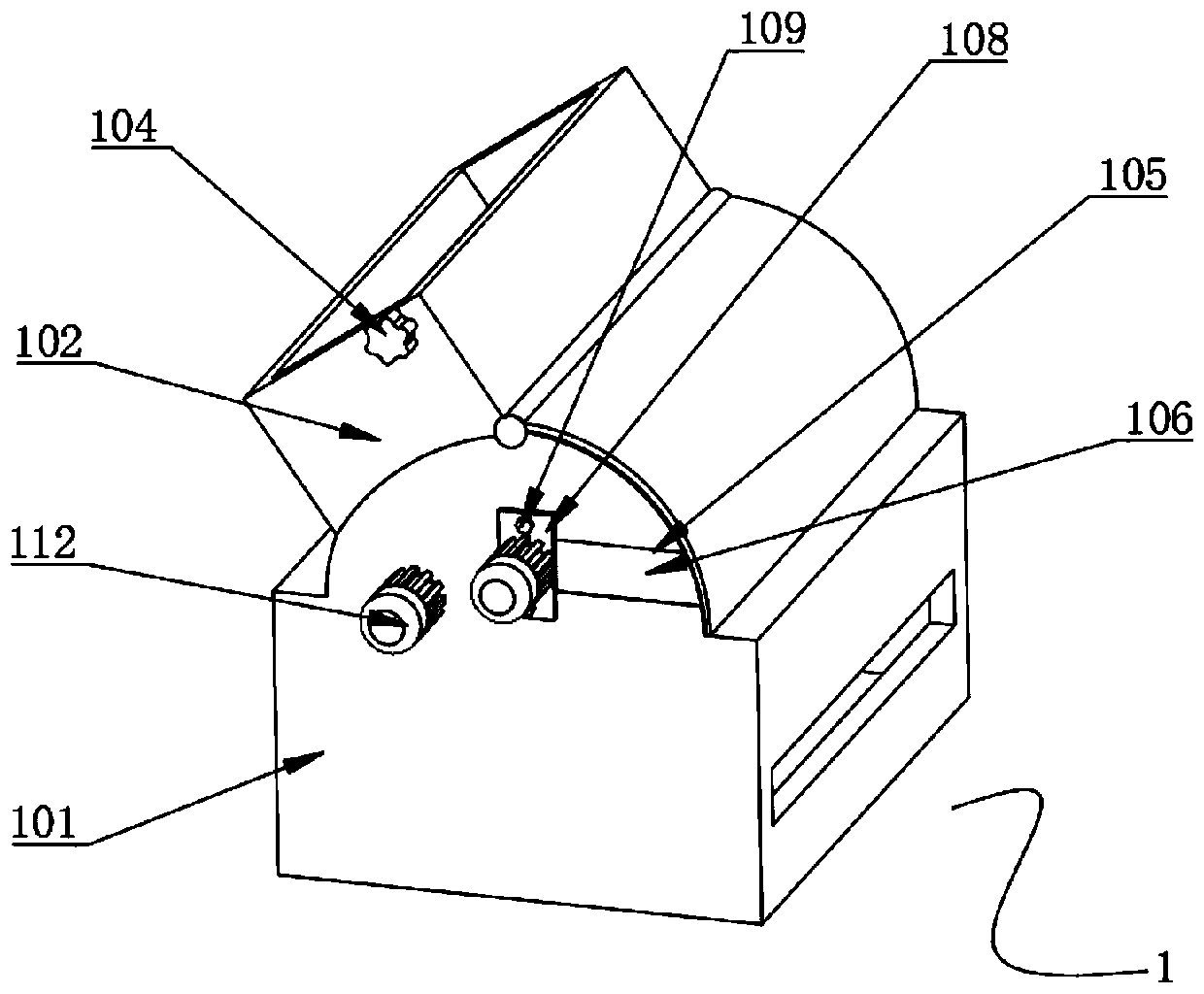

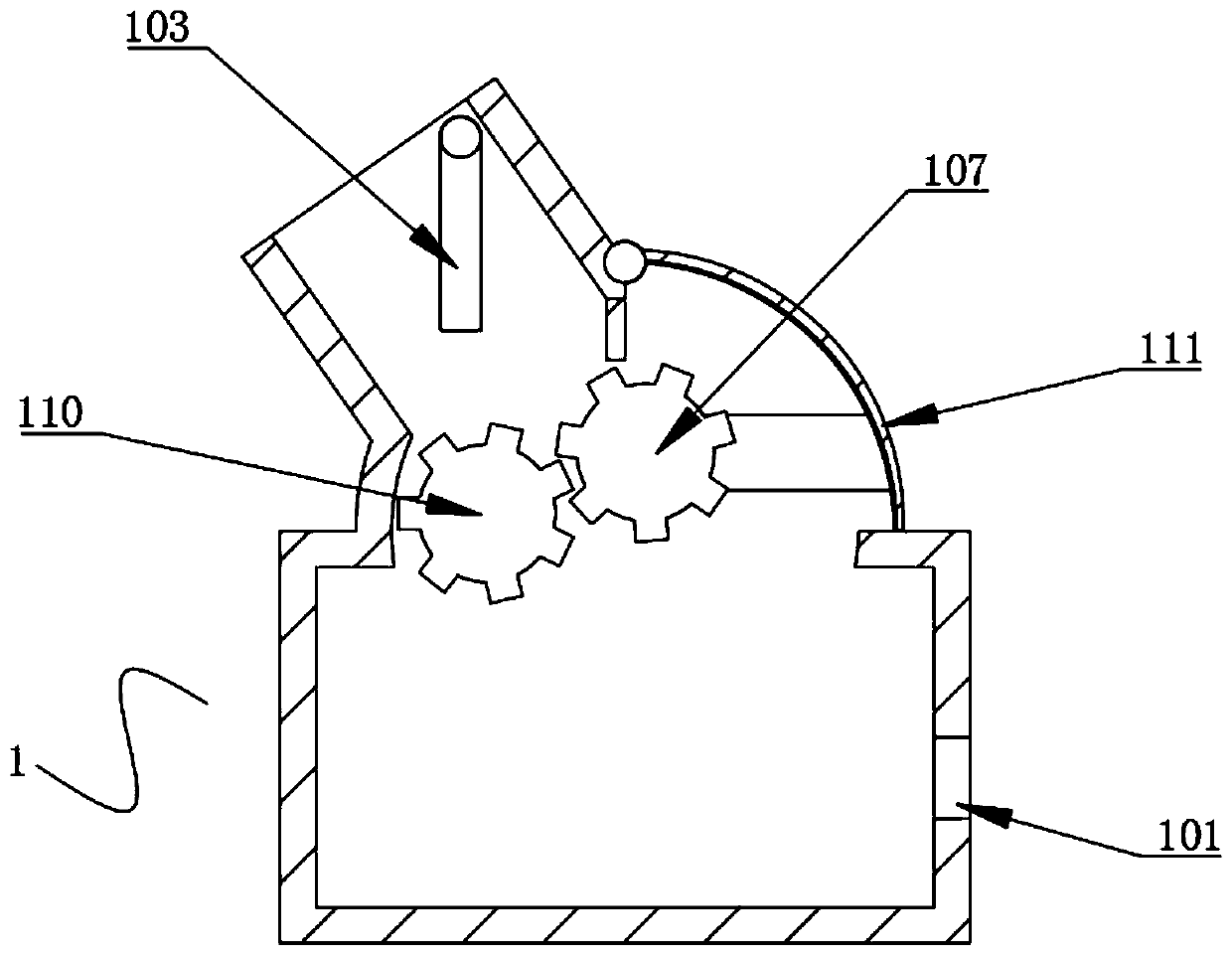

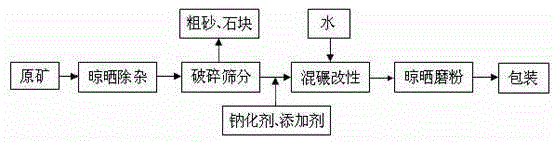

Preparation method of bentonite for drilling mud and device thereof

ActiveCN105366686AReduce usageGood modification effectDrilling compositionSilicon compoundsWell drillingVariable pitch propeller

The invention discloses a preparation method of bentonite for drilling mud and a device thereof. The preparation method comprises the following steps: crushing calcium bentonite raw ore and screening, conveying the crushed and screened calcium bentonite raw ore into a kolleroang to be fully mixed and ground together with a sodium modification agent, an auxiliary additive and water, carrying out extrusion modification by conveying the above mixture into a trans-variable-pitch screw extruder, extruding by masking to obtain a semi-finished product, airing, milling and packaging to obtain a bentonite finished product for drilling mud. According to the invention, trona is used as the sodium modifier, and the trans-variable-pitch screw extruder is adopted for modification. The materials are spirally pushed forward by two variable-pitch propellers, and extrusion force is gradually enhanced. Production problems such as material stacking and insufficient extrusion force are effectively solved. The modification effect is good, and product quality is stable. In addition, preparation cost is greatly reduced, and production cost can be saved by 60,000-70,000 yuan for each ton of the product.

Owner:中国非金属矿工业有限公司

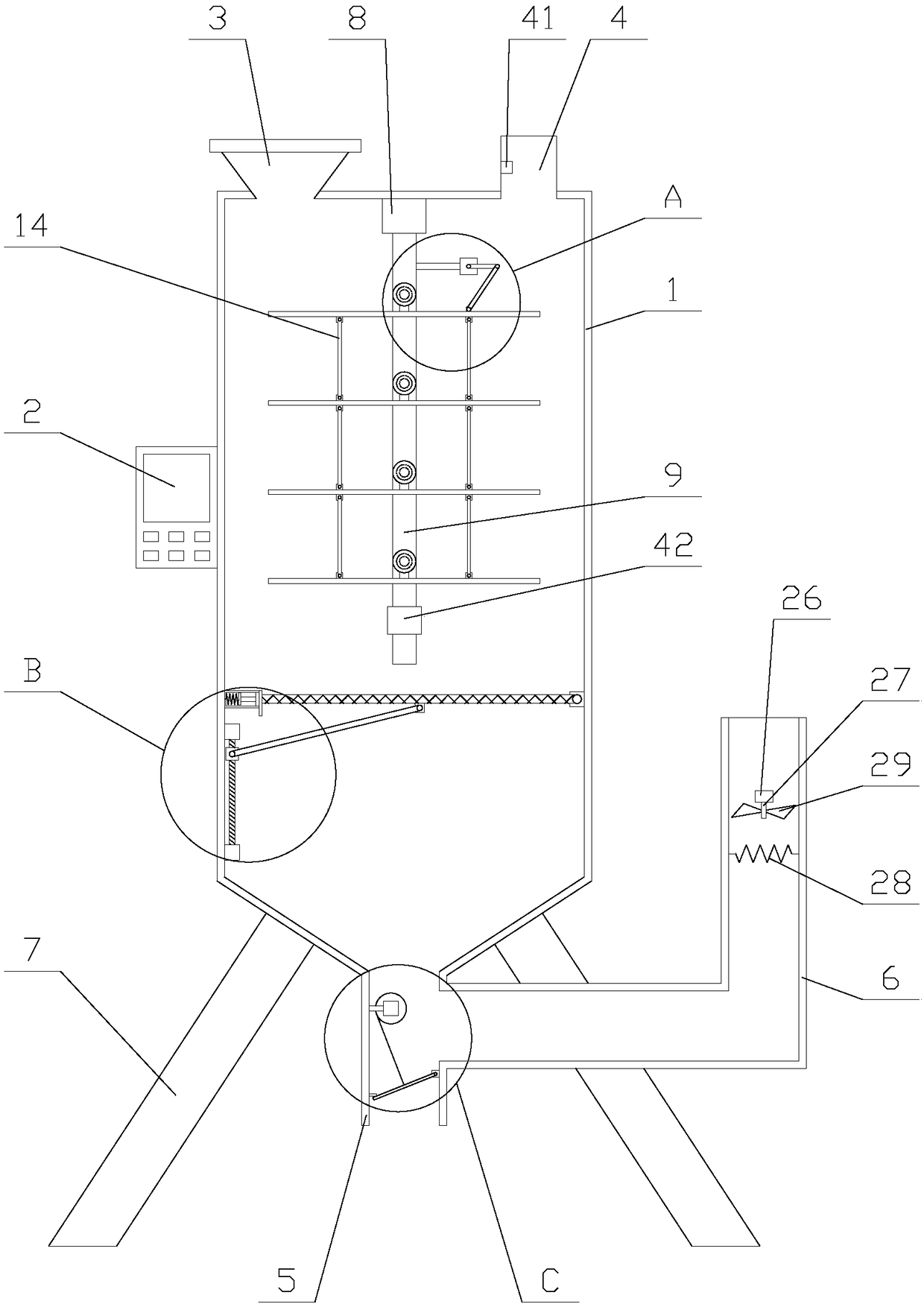

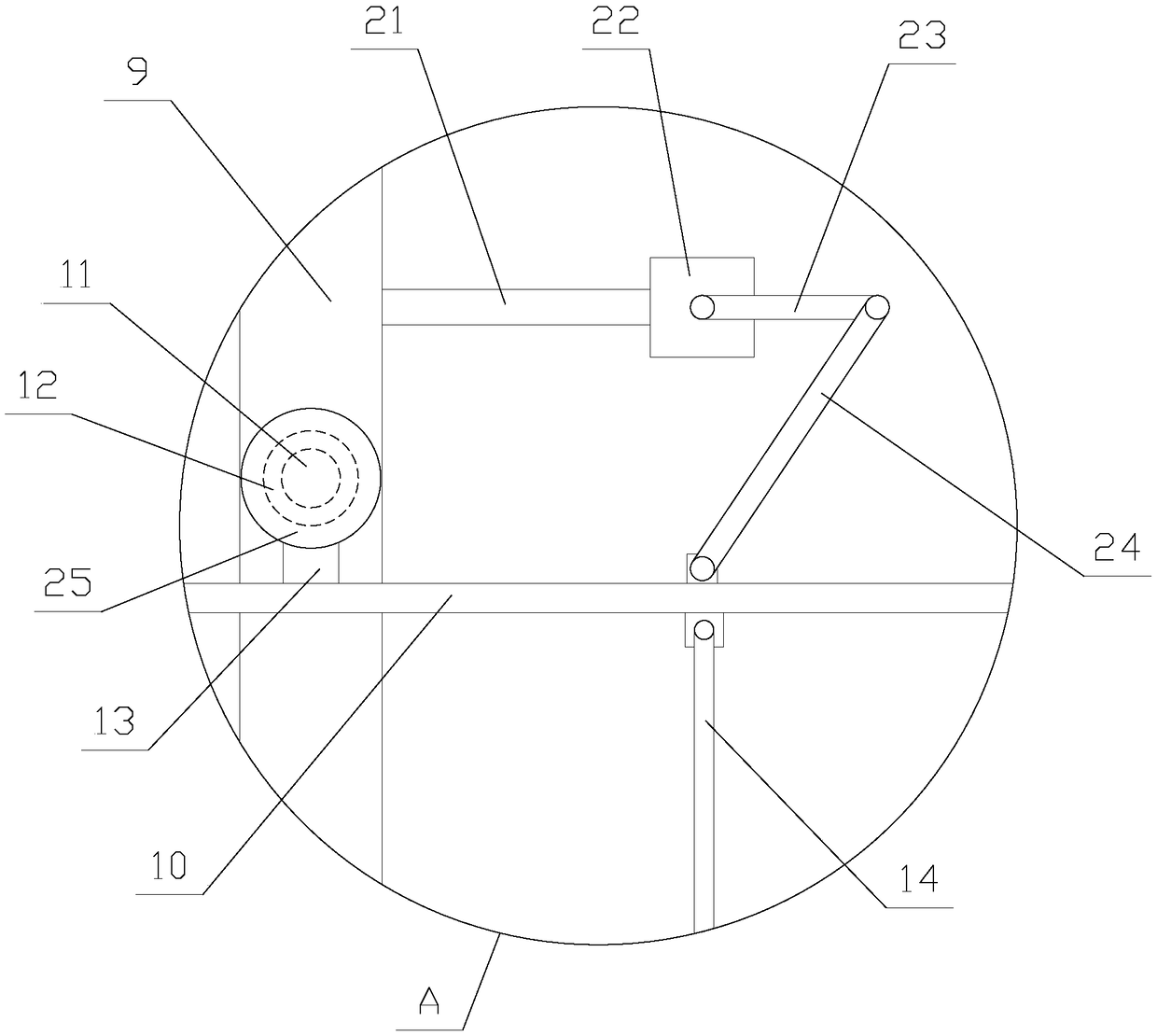

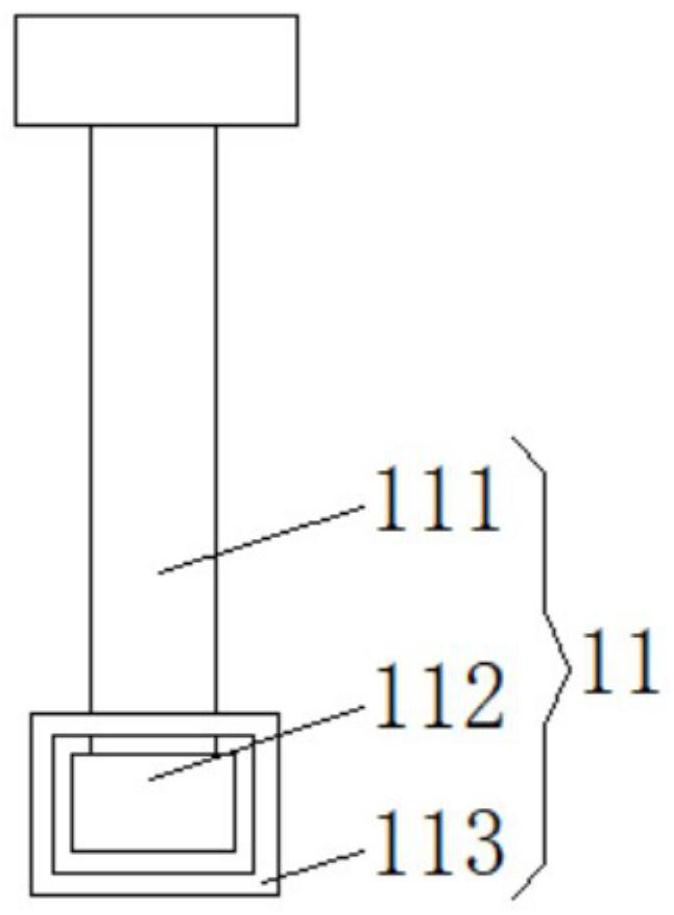

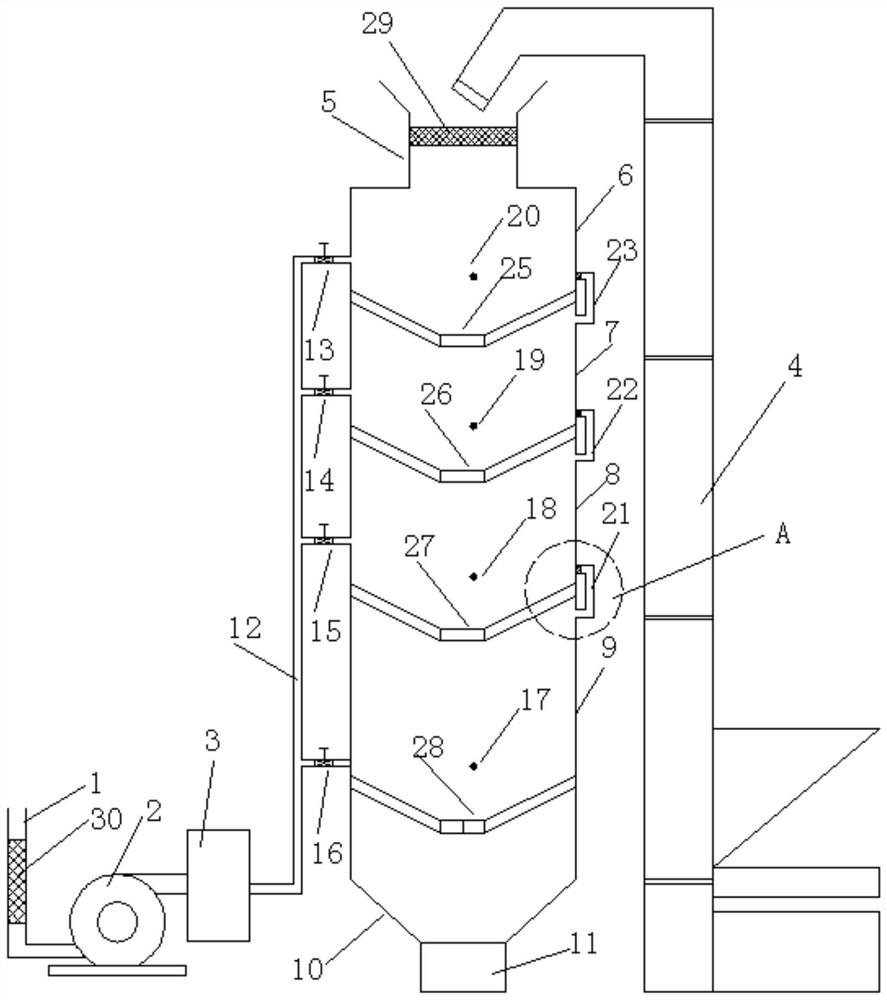

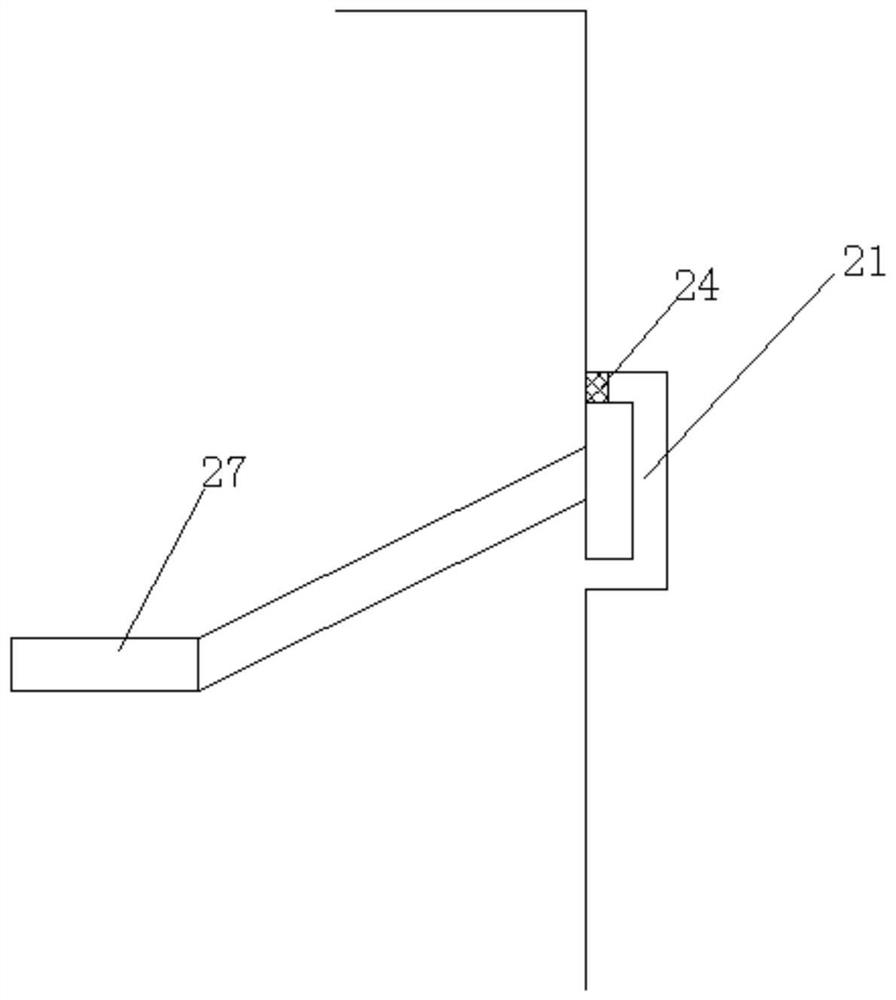

Intelligent labor-saving grain dryer for quantitatively drying based on gravity change

ActiveCN110986550AImpact wasteAvoid affecting the drying effectSeed preservation by dryingDrying solid materialsExternal energyControl theory

The invention relates to the technical field of agriculture and discloses an intelligent labor-saving grain dryer for quantitatively drying based on gravity change. The dryer comprises a shell, wherein a partition plate is movably connected into the shell. A feeding hole can be automatically closed by controlling a first baffle plate, so a purpose of quantitatively drying is achieved, problems ofexcessive or insufficient feeding, influence on the drying effect and waste of energy sources are avoided; through use of a second baffle, the discharging opening is automatically opened after being dried, so the drying degree is controlled, and excessive drying or insufficient drying is avoided; through use of a vertical rod, subsequent movement is linked, so linkage of the whole device is improved, operation is simpler, through use of the partition plate, movement of the partition plate is driven by utilizing gravity change, so other movement is triggered, operation does not need to be carried out by virtue of external energy, and the intelligence level and environmental protection of the whole device are improved.

Owner:江西东坚米业有限公司

Three-control timing board discharging control system

ActiveCN110332795AAvoid damageProcess stabilityDischarging arrangementControl devices for conveyorsControl systemMechanical engineering

The embodiment of the invention discloses a three-control timing board discharging control system. The system comprises a working frame body, wherein a drying machine is arranged on the right side ofthe top of the working frame body, and a three-control accelerating roller way is arranged on the left side of the top of the working frame body; the three-control accelerating roller way comprises afirst roller way section, a second roller way section and a third roller way section, and the first roller way section, the second roller way section and the third roller way section are respectivelyprovided with a board adjusting structure, a speed adjusting structure and an equidistant constant speed control structure; and a control box is arranged on the side of the working frame body. According to the system, the time interval and the distance between a front board and a rear board can be kept consistent when the boards are discharged, the phenomenon that the gypsum boards are frequentlydisordered in the three-control process is avoided, and meanwhile, the direction of the conveyed gypsum boards can be adjusted to be kept parallel to the conveying direction of a conveying roller way,and the drying effect of the gypsum boards is prevented from being influenced. In addition, the system can make the gypsum boards be selectively decelerated in the second conveying half section, so that the gypsum boards are prevented from colliding with the gypsum board waiting to be dried in front.

Owner:BEIJING NEW BUILDING MATERIALS PLC

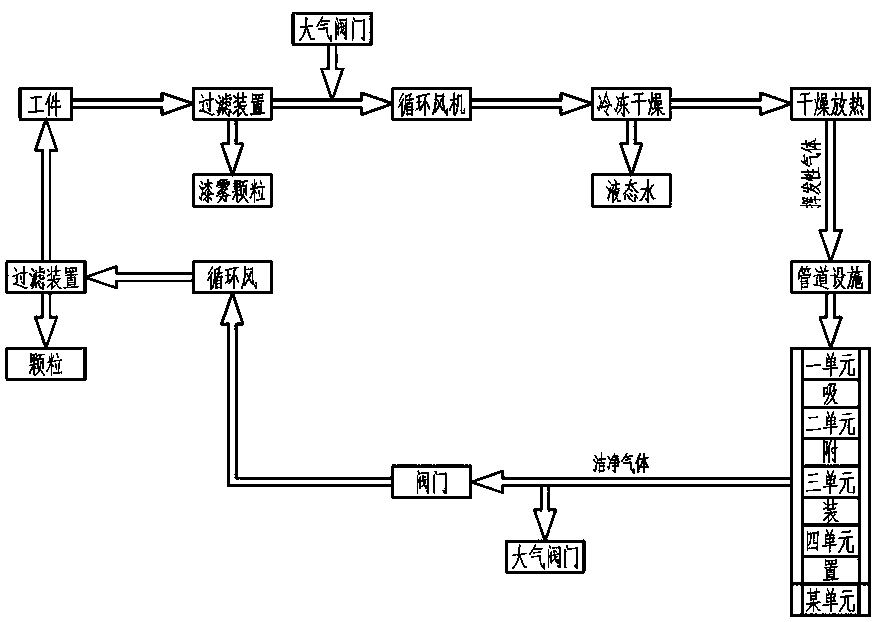

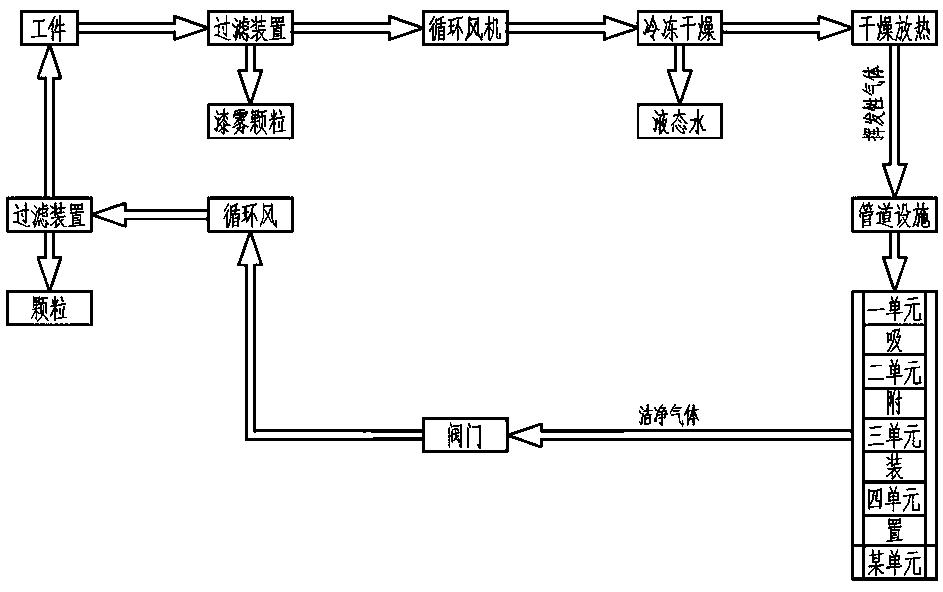

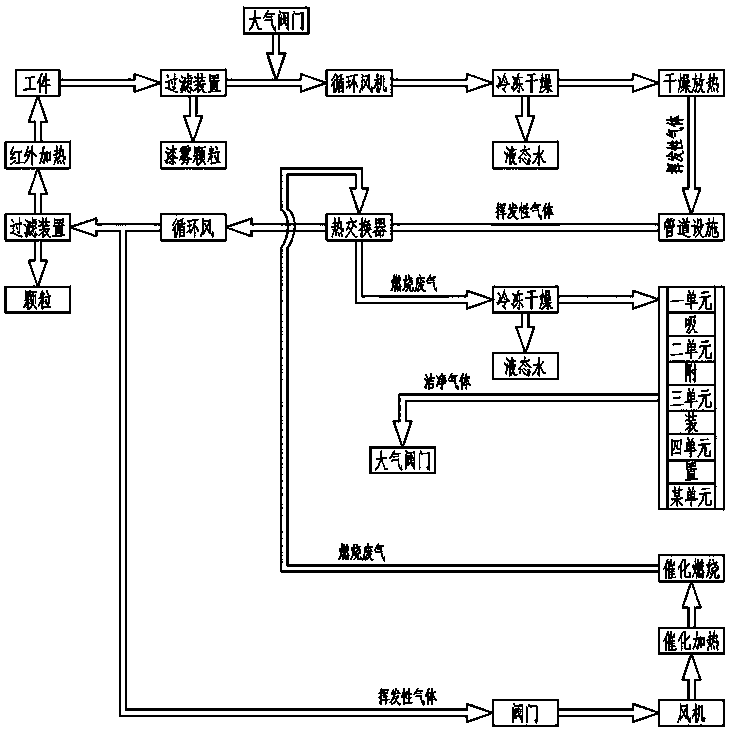

Energy-saving environment-friendly circulation type waste gas treatment method applied to paint spraying and paint baking process

ActiveCN108079738AAchieve recyclingAvoid affecting the painting and baking operation, or even polluting the workpieceGas treatmentDispersed particle filtrationHigh concentrationEnvironmental resistance

The invention discloses an energy-saving environment-friendly circulation type waste gas treatment method applied to a paint spraying and paint baking process. The method comprises the steps of paintspraying stage waste gas treatment, levelling stage waste gas treatment and drying stage waste gas treatment; during the drying stage waste gas treatment, after the levelling is completed, the operation enters the drying stage; waste gas in a drying chamber is taken away by gas exchange equipment; the taken waste gas is filtered and dried; the treated waste gas flows back into the drying chamber to form circulation airflow; when the concentration of organic volatile gas is high, and is lower than the lower explosive limit by 25 percent, a small part of high-concentration waste gas is extractedfrom the circulation airflow; heating and low-temperature catalytic oxidation are performed to form high-temperature combustion waste gas; after the high-temperature combustion waste gas and most circulation airflow are subjected to heat exchange, freeze drying and adsorption are performed; the waste gas is exhausted into atmosphere after reaching the standard. After the method is used, the wastegas can be thoroughly treated as much as possible; the discharging total quantity is reduced to the greatest degree; the resource utilization rate is improved; the effects of energy saving and environment protection are really achieved.

Owner:王理

Dryer for textile processing and production

InactiveCN111928618AEasy to spread outAvoid affecting the drying effectDrying gas arrangementsDrying machines with progressive movementsMechanical engineeringIndustrial engineering

The invention relates to the technical field of textile auxiliary equipment, and discloses a dryer for textile processing and production. The dryer comprises a drying box body, wherein a placement frame plate is fixedly arranged on one side of the bottom of an inner cavity of the drying box body, and the inner cavity of the drying box body is fixedly provided with a dryer body located above the placement frame plate in a sleeving mode; movable rods located between the placement frame plate and the dryer body are arranged inside the drying box body, and the outer portions of the movable rods are fixedly provided with rotating rollers in a sleeved mode; and one side of the drying box body is fixedly provided with a ventilation exhaust window located between the placement frame plate and thedryer body in a sleeved mode, and the bottoms of the two sides of the drying box body are fixedly connected with fixing frames. According to the dryer for textile processing and production, through aplacement sleeve plate, a positioning plate, an adjusting device and a flattening plate, to-be-dried textile fabric is conveniently spread, so that the situation that the drying effect is affected dueto the fact that the textile fabric is wrinkled together before entering the drying box body is avoided, normal drying is guaranteed, and the practicability of the device is improved.

Owner:东阳市川泽户外用品有限公司

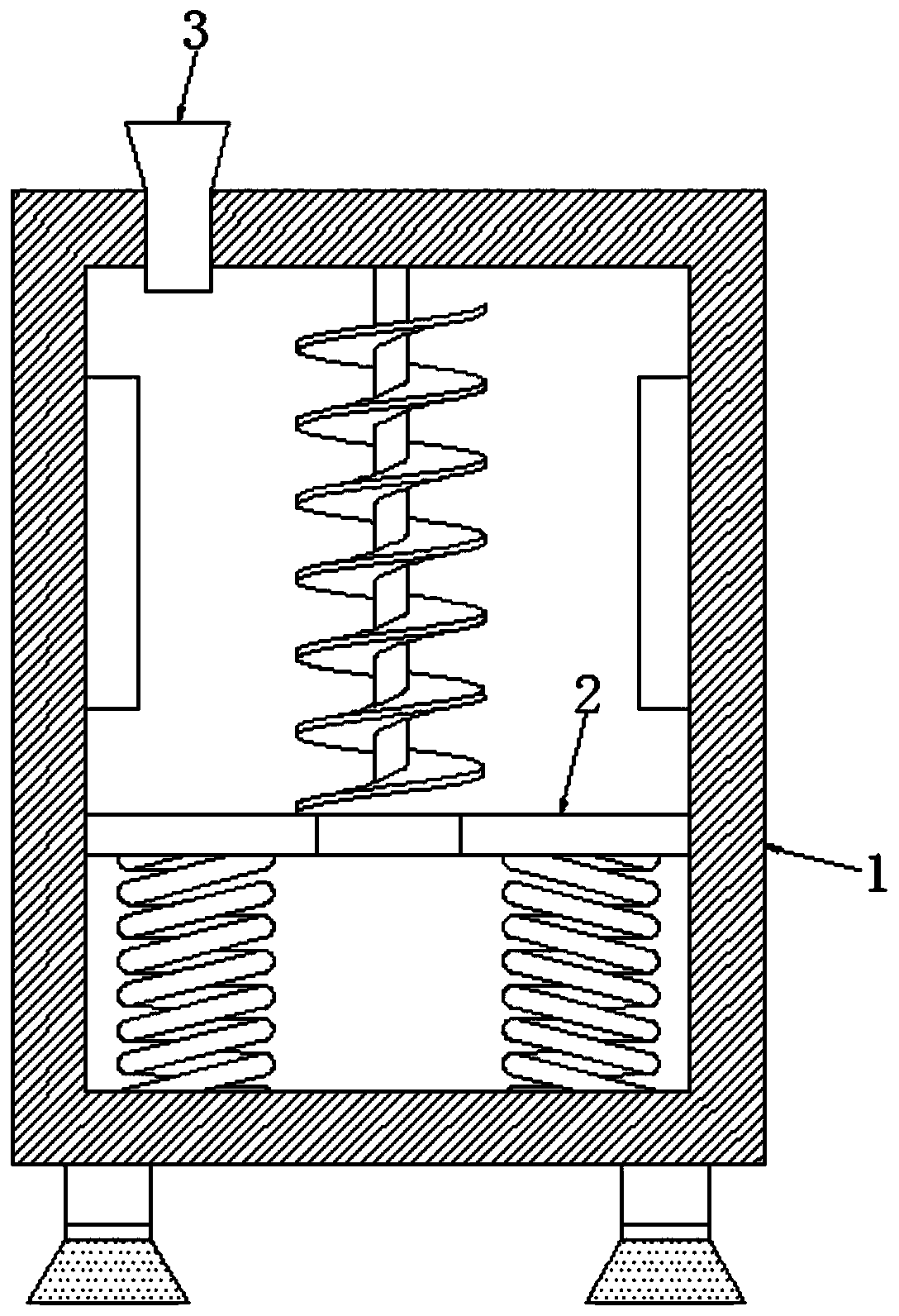

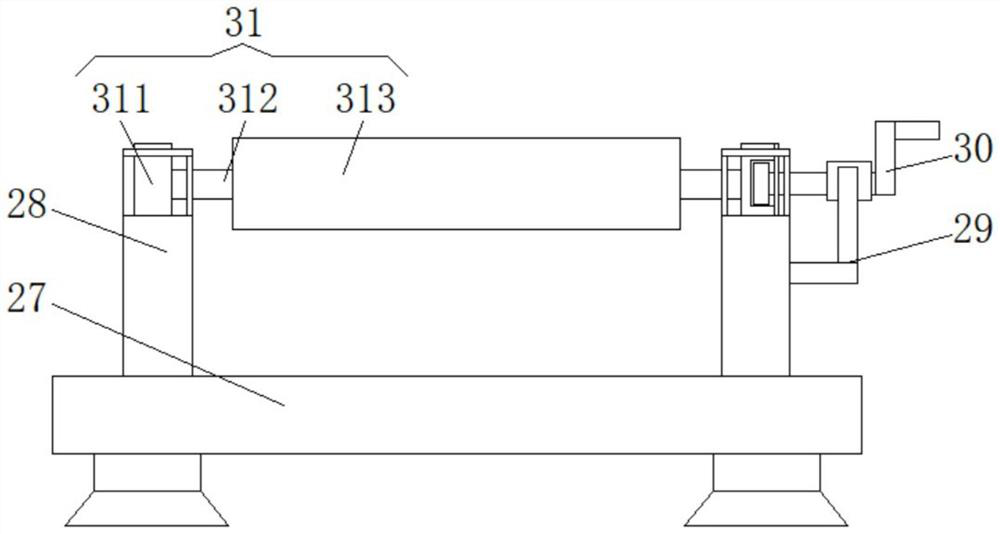

Spiral sludge dewatering machine with good drying effect and use method of spiral sludge dewatering machine

PendingCN114149163ASimple structureEasy to operateSludge treatment by de-watering/drying/thickeningProcess engineeringEnvironmental geology

The invention provides a spiral sludge dewatering machine with a good drying effect and a use method thereof.The spiral sludge dewatering machine with the good drying effect comprises a workbench and a dewatering box arranged at the top of the workbench and further comprises a collecting box fixedly connected to the top of the workbench, and a first fixing device and a second fixing device are connected to the top wall of the collecting box; the air cylinder is fixedly connected to the outer wall of the dewatering box, the output end of the air cylinder penetrates through the dewatering box to be connected with an extrusion cleaning device, and the end, away from the air cylinder, of the extrusion cleaning device is connected to the top of the dewatering box; a filter plate matched with the cleaning end of the extrusion cleaning device is arranged in the dewatering box and is used for carrying out secondary dewatering on the sludge; the sludge dewatering device is simple in structure and convenient to operate, the dewatering and drying effect of the device is greatly improved, the water content of sludge is effectively reduced, the phenomenon that sludge is blocked in the dewatering device is avoided, and silt is conveniently discharged.

Owner:JIANGSU NEW YUTAIHUA ENVIRON PROTECTION

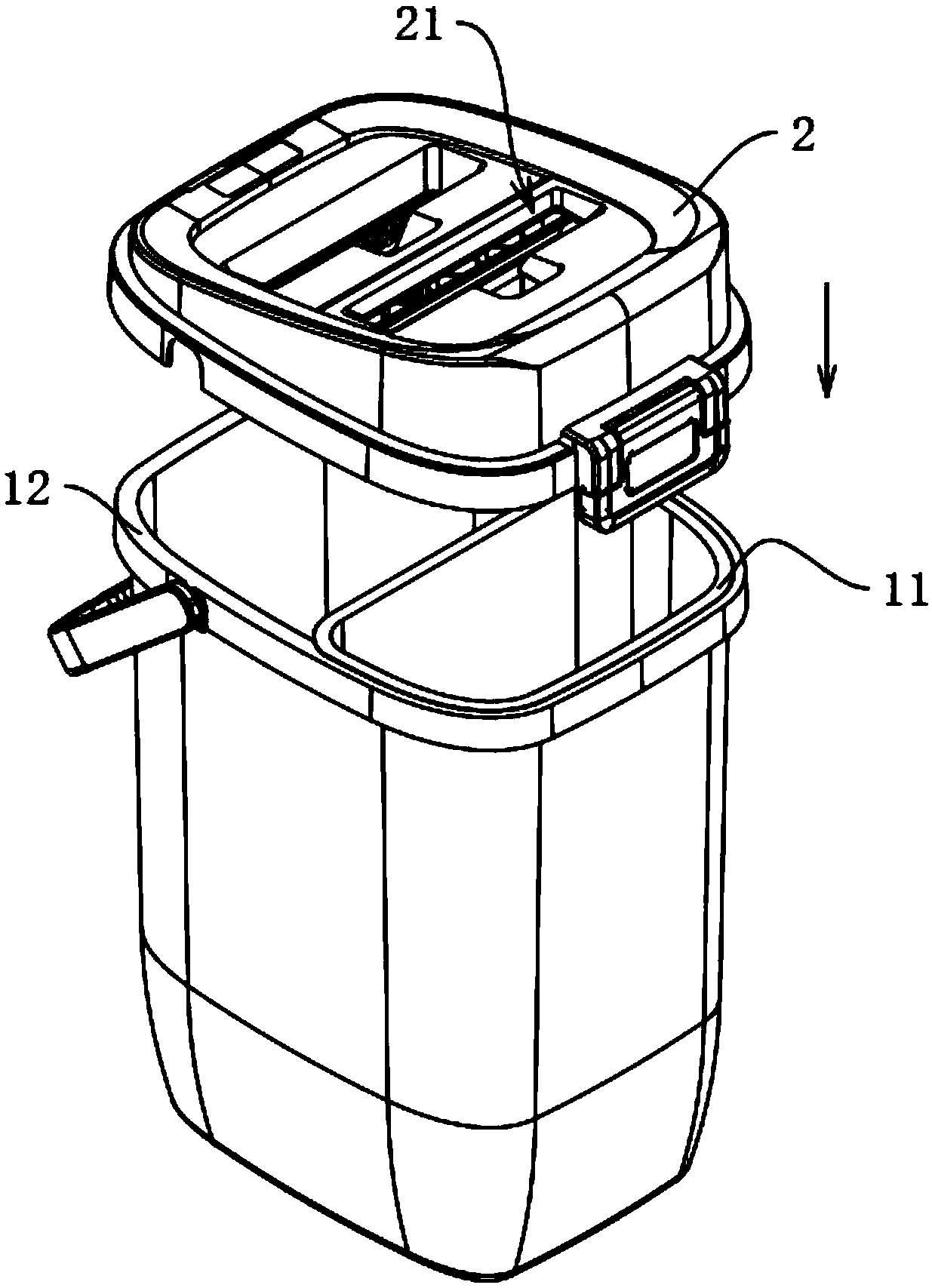

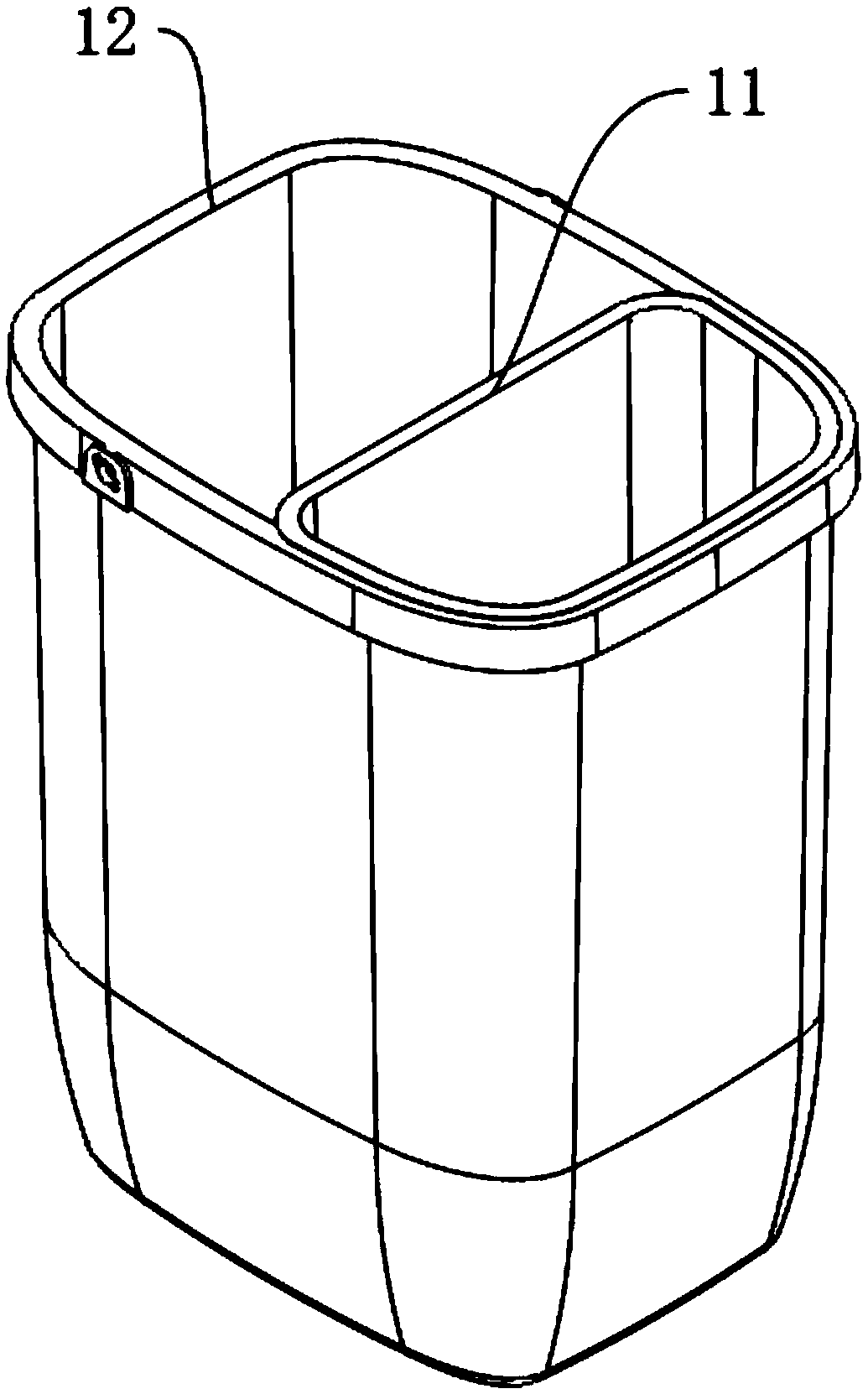

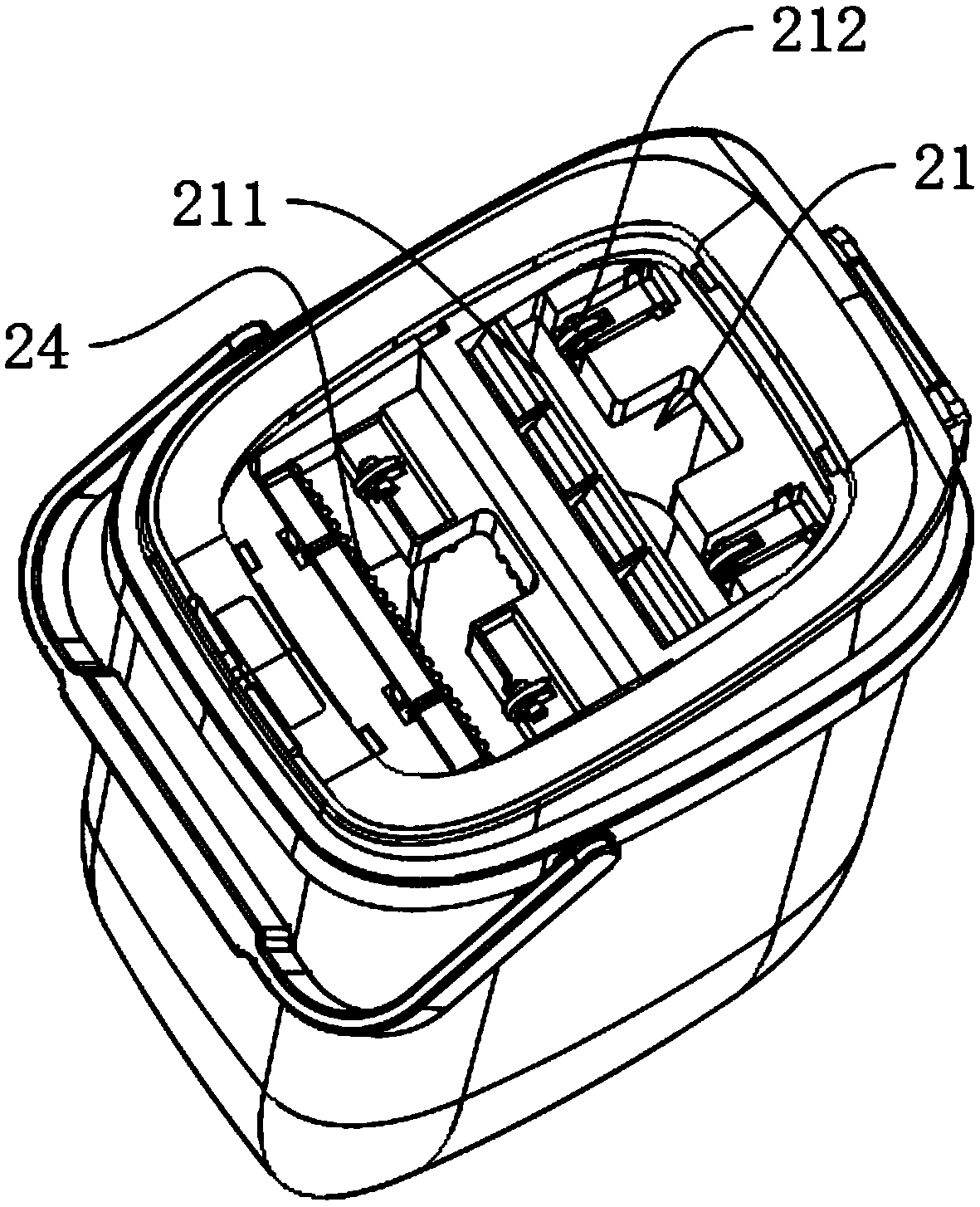

Mop bucket for flat-plate mop

PendingCN108714011AEasy to excavateAvoid affecting the drying effectCarpet cleanersFloor cleanersEngineeringWater diversion

The invention discloses a mop bucket for a flat-plate mop, belonging to the technical field of cleaning supplies. The mop bucket comprises a water squeezing bucket and a cleaning bucket, wherein the water squeezing bucket can be contained in the cleaning bucket and taken out; a water retaining cover is arranged on a wiper bucket; a wiper port is formed in the water retaining cover; a wiper strip and a popping-up piece opposite to the wiper strip are arranged at the wiper port; the wiper strip is fixed; an inclined water diversion slope is formed on the upper surface of the wiper strip; an upper drain outlet is formed in the bottom end of the water diversion slope; and the popping-up piece comprises a swing arm. The mop bucket disclosed by the invention comprises two separable buckets, theconvenience is improved, the wiper strip is integrally molded, the stability during water squeezing is ensured, the wiped water can be drained by the inclined wiper strip, the water is squeezed by enabling the swing arm to pop up the panel of the flat-plate mop, the fluctuation of the wiper strip can be alleviated, and the water squeezing effect is improved.

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

Anti-condensation electrical cabinet

ActiveCN109819630ASolve condensationNot prone to condensation problemsTemperatue controlCooling/ventilation/heating modificationsElectricityTemperature control

The invention discloses an anti-condensation electrical cabinet. The cabinet comprises a cabinet body; the top end of the cabinet body is provided with a cooling fan; an electric heating assembly is fixedly installed in the middle of the side wall of the cabinet body; the electrode end of the electric heating assembly is electrically connected with an external power supply; an inner temperature sensor is also fixedly mounted in the cabinet body; an outer temperature sensor is arranged on the outer side of the cabinet body; a first temperature controller is further installed in the cabinet body; the inner temperature sensor and the outer temperature sensor are both in signal connection with the input end of the first temperature controller; and the output end of the first temperature controller is in signal connection with the cooling fan and the electric heating assembly. An air conditioner adjusting device is further installed at the top end of the cabinet body, a second temperature controller is further installed in the cabinet body, the input end of the second temperature controller is in signal connection with the inner temperature sensor, and the output end of the second temperature controller is in signal connection with the air conditioner adjusting device, the electric heating assembly and the cooling fan. The anti-condensation electrical cabinet solves the problem thatmoisture condensation of the electrical cabinet cannot be fundamentally eradicated through a traditional dehumidification mode.

Owner:安徽辉宝智能装备有限责任公司

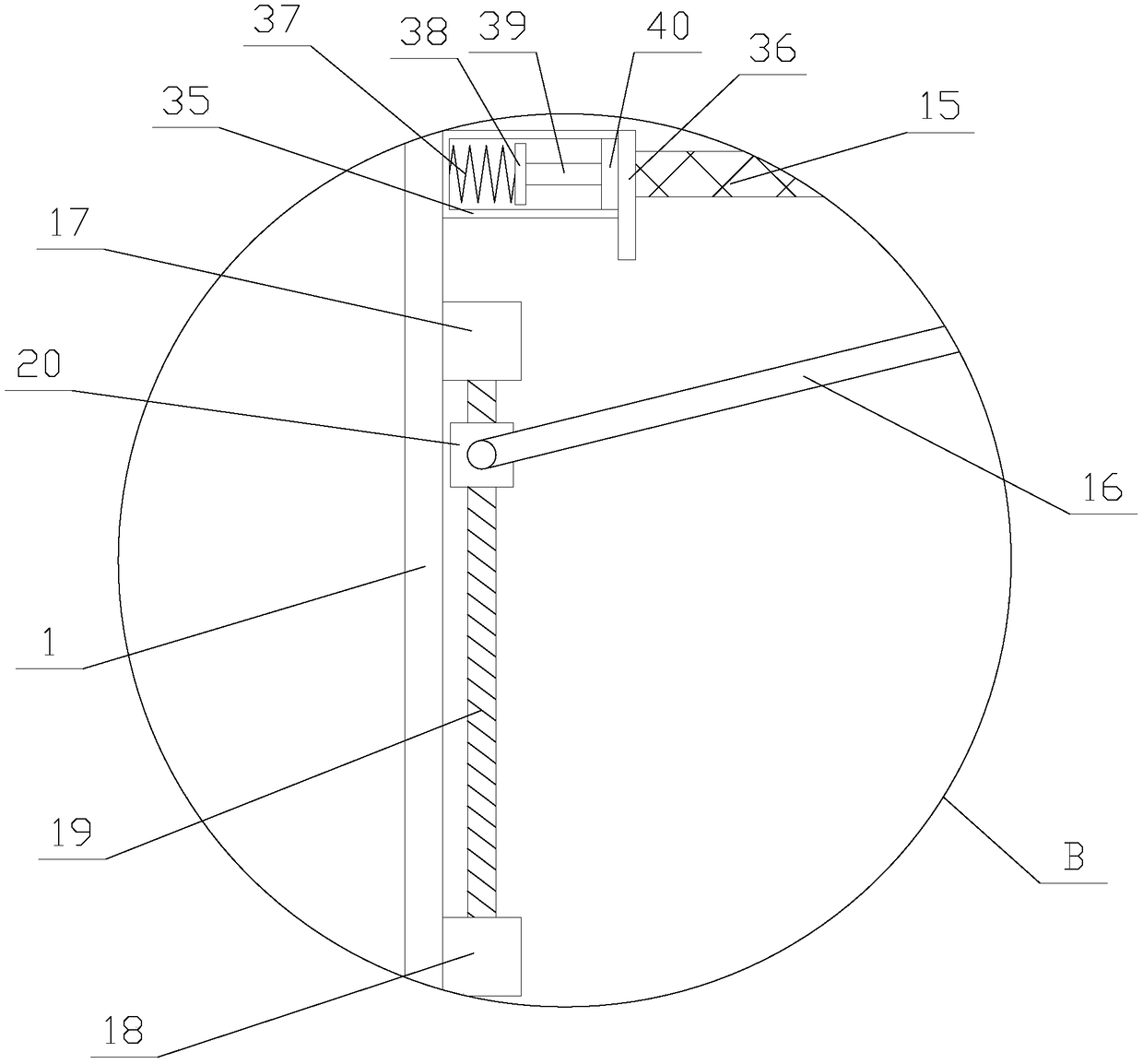

Shelled melon seed drying and screening device

InactiveCN107838030AImprove qualityAvoid affecting the drying effectGas current separationFood treatmentEngineeringDrive motor

The invention discloses a drying and screening device for melon seeds, which comprises a machine casing, a paving device, a hot air blower, a casing wind separator, a first sieve plate, a second sieve plate and a third sieve plate. There is a paving device, a hot air blower is fixedly installed on the upper side of the casing, and a hot air pipe is connected to the air outlet of the hot air blower; a wind separation device chamber is installed on the left side of the casing, and a wind separation device cavity is installed inside the wind separation device cavity. A sorting machine, the first sieve plate, the second sieve plate and the third sieve plate are fixedly installed between the upper and lower sets of partitions. Compared with the ordinary paving device, the device indirectly drives the paving plate to move left and right through the drive motor, so that the melon seeds can be evenly spread on the conveyor belt, preventing the melon seeds from being fed and accumulated to affect the drying effect. The sieve plate with aperture can fall into the corresponding outlet according to the particle size of melon seeds, so as to realize the automatic grading and screening of the particle size of melon seeds, and at the same time, it is more efficient than manual selection.

Owner:王明法

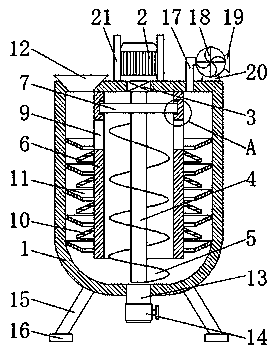

Agricultural fertilizer drying device capable of achieving rapid drying

InactiveCN109520268AImprove drying efficiencyDry fastManure dryingDrying solid materialsSpiral bladeAgricultural engineering

The invention discloses an agricultural fertilizer drying device capable of achieving rapid drying. The agricultural fertilizer drying device comprises a tank. A motor is fixedly connected to the center of the top of the tank. A bearing is arranged in the center of the top of the tank in a penetrating manner. The output end of the motor penetrates through the bearing and is fixedly connected witha rotating shaft. According to the agricultural fertilizer drying device, by means of cooperative use of the motor, the bearing, the rotating shaft, spiral blades, a pipe body, an isolating plate, a sliding groove and a material falling opening, the problem that an existing agricultural fertilizer drying device is low in drying efficiency is solved, the agricultural fertilizer drying device capable of achieving rapid drying has the advantage of rapid drying, in the using process, the situations that fertilizer accumulates on the bottom of a drying machine, and the fertilizer piled up is not dried thoroughly can be avoided, moreover, time for drying the fertilizer is shortened, and the working efficiency of drying is improved. In addition, water in drying equipment is further prevented fromevaporating in a centralized manner, the situation that due to the fact that moisture of the drying equipment is too large, the drying effect is influenced is prevented, and the agricultural fertilizer drying device is worth being used and popularized.

Owner:陈启亮

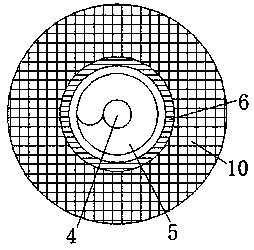

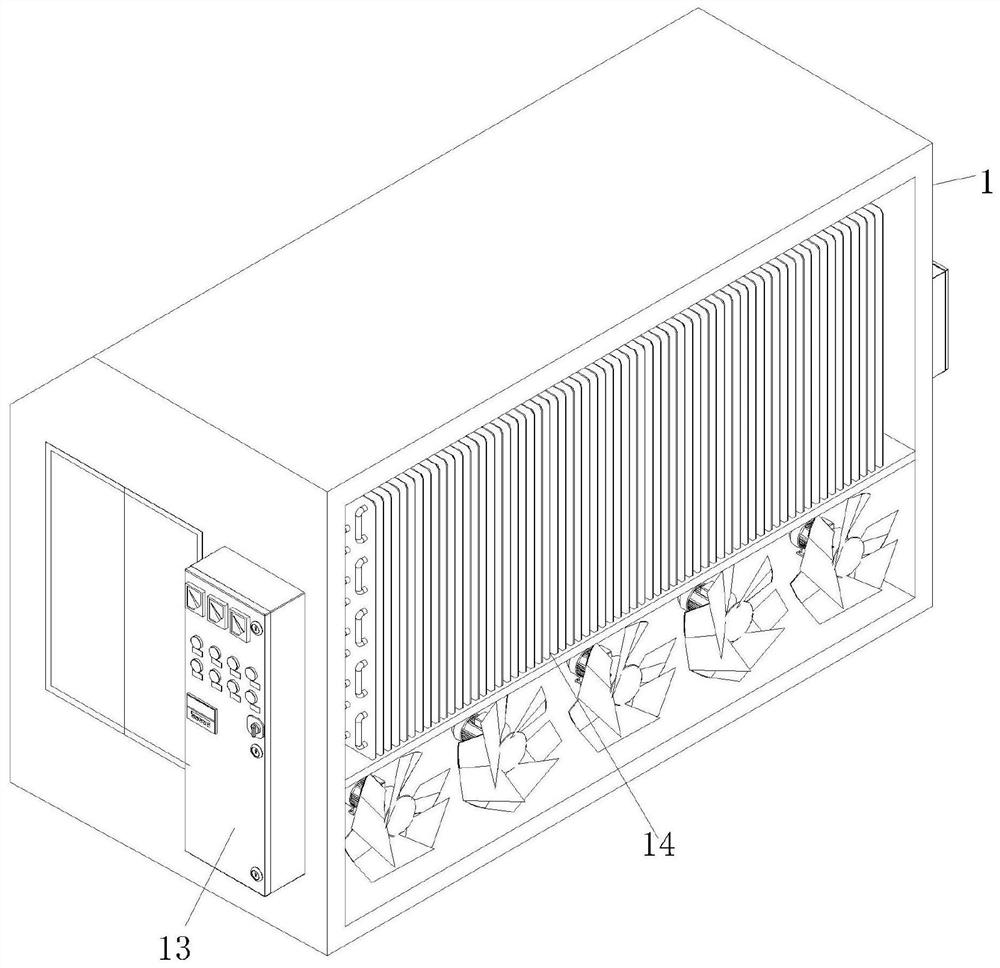

High-efficiency tea drying device

InactiveCN109452383AEfficient dryingDry evenlyPre-extraction tea treatmentPulp and paper industryDrive motor

The invention discloses a high-efficiency tea drying device, and belongs to the field of tea. The high-efficiency tea drying device comprises a drying box, the front surface of the drying box is provided with three feeding doors which are arranged at equal distances, four corners of the bottom of the drying box are fixedly connected to supporting legs, drying net cylinders corresponding to the three feeding doors are respectively arranged in the drying box, the top and the bottom of the left side of each drying net cylinder are respectively provided with material inlets, each material inlet isprovided with a cylinder plug, the right side of each drying net cylinder is provided with a transmission device, and the inside of the drying box is provided with an L-shaped clapboard. A driving motor, a T-shaped rack, gears, a T-shaped rotating groove, a T-shaped rotating shaft, transmission devices and a hot air device are used together with the drying net cylinders, the tea leaves can be dried at a high speed by 360 degrees without dead angles, the tea leaves are dried more uniformly, and meanwhile, the working efficiency and the working quality are improved.

Owner:安徽五亩生态农业发展有限公司

Efficient drying device for processing of traditional Chinese medicines

InactiveCN112082352ADry evenlyRealize automatic turning and dryingDrying gas arrangementsDrying chambers/containersMedicinal herbsStructural engineering

The invention discloses an efficient drying device for processing of traditional Chinese medicines. The efficient drying device comprises a box body, a loading and unloading mechanism, a base, fixingframes, medicinal material fixing mechanisms, a moving mechanism, a lifting mechanism, an electric push rod, a spray head pipe, a humidity sensor, an electromagnetic valve, a control box and a dryingdevice, wherein the loading and unloading mechanism is mounted on the rear side of the bottom end of the inner cavity of the box body in the left-right direction; a plurality of fixing frames are arranged at the top end of the base at intervals from left to right; a plurality of medicinal material fixing mechanisms are arranged on the inner sides of the fixing frames at intervals from top to bottom; the moving mechanism is arranged in the inner cavity of the box body in the left-right direction and is located on the front side of the loading and unloading mechanism; and the lifting mechanism is arranged at the top end of the moving mechanism in the vertical direction. The efficient drying device for processing of traditional Chinese medicines can achieve automatic turning over and drying of medicinal materials, improves the drying efficiency, guarantees uniform heating of the medicinal materials in the device, avoids influences on the drying effect, can also achieve large-batch loading, unloading and drying of the medicinal materials, and is easy to operate and high in practicability.

Owner:李海燕

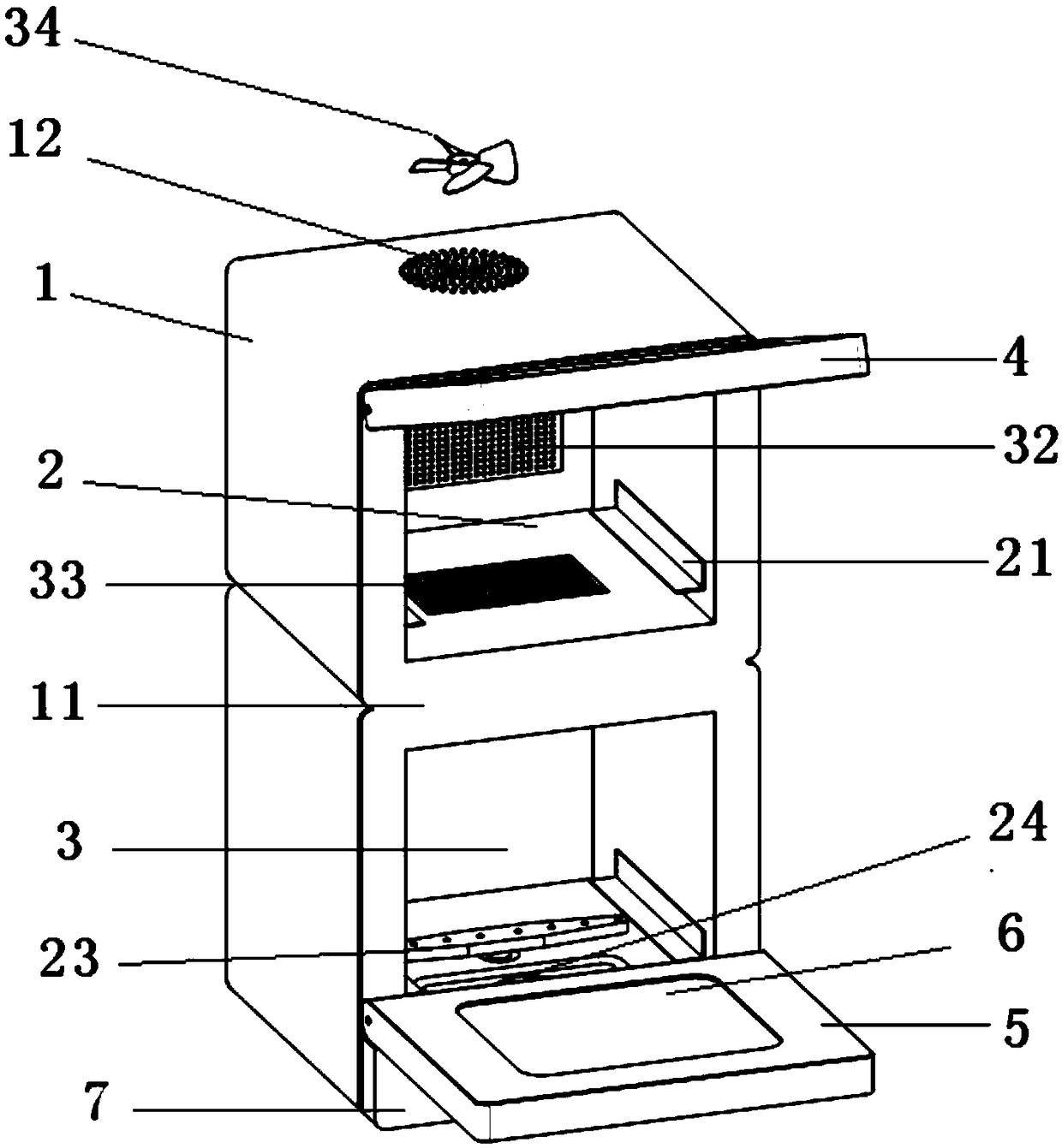

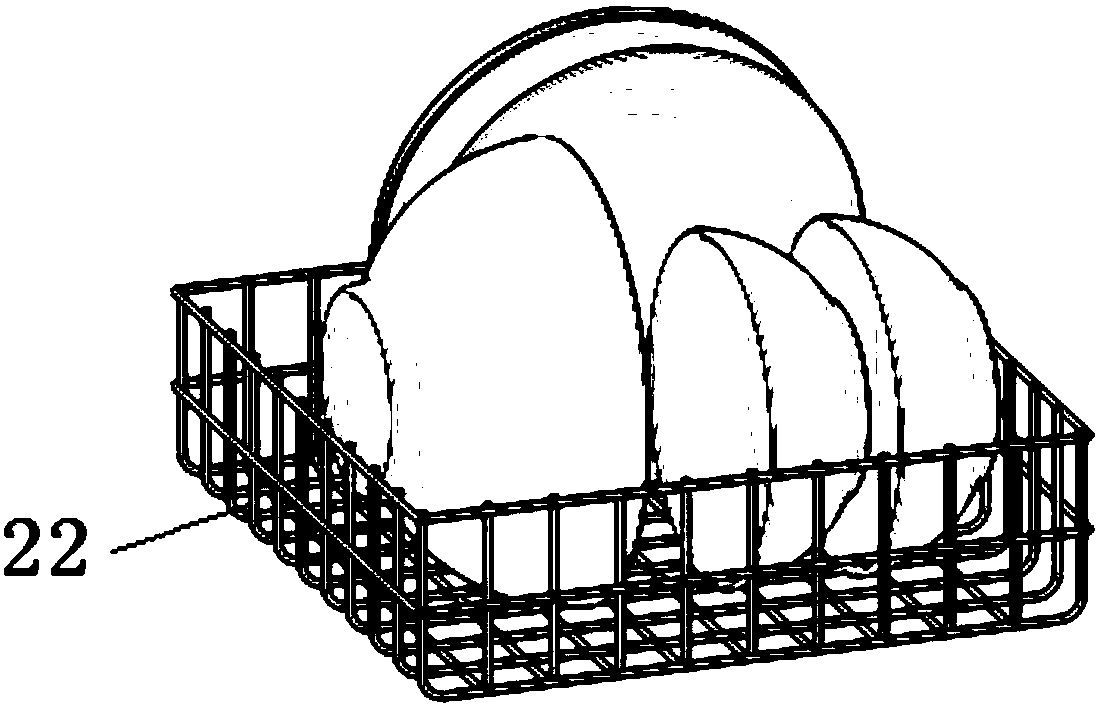

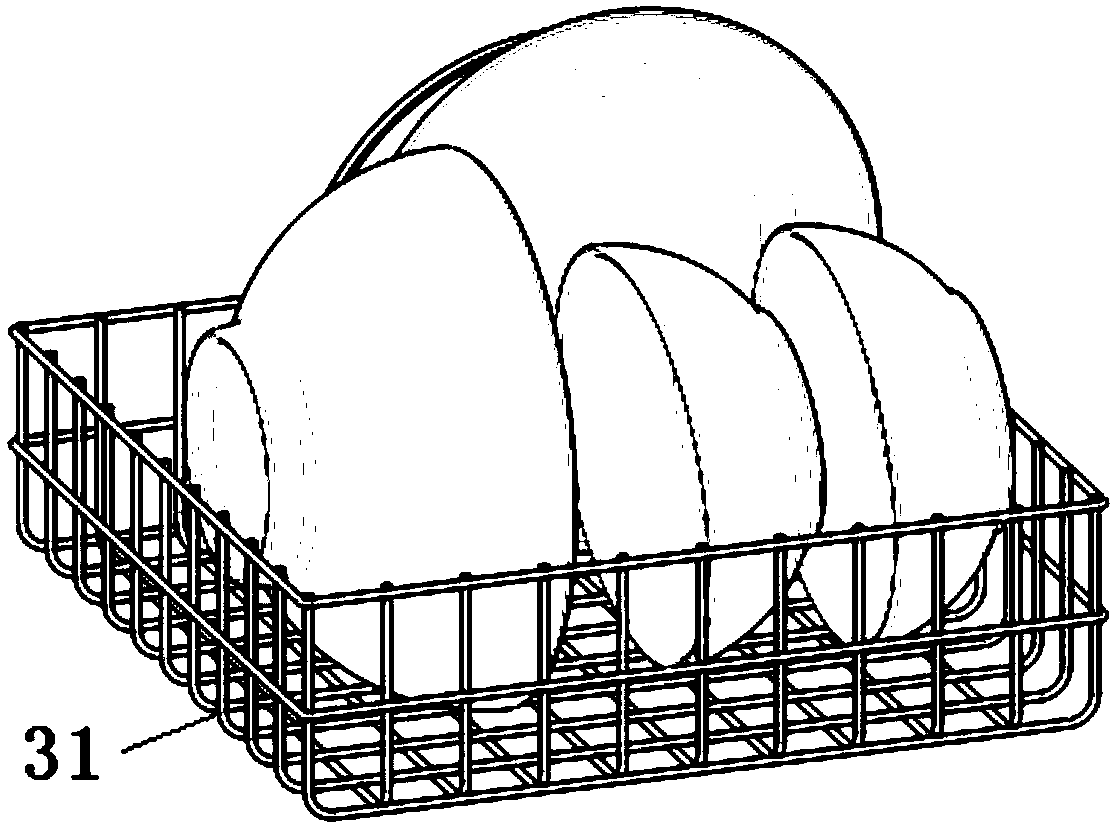

Dish washing machine with disinfection and drying functions

InactiveCN108720773AReduce occupancySimple structureTableware washing/rinsing machine detailsProcess engineering

The invention provides a dish washing machine with disinfection and drying functions. The dish washing machine comprises a shell and a controller, the shell is internally provided with a washing cavity and a disinfection and drying cavity which are adjacent to each other, the washing cavity and the disinfection and drying cavity are arranged separately, and the controller is arranged in the shelland used for controlling the washing cavity and the disinfection and drying cavity to work separately or synchronously. Accordingly, the washing cavity and the disinfection and drying cavity are integrated in the shell, and thereof the kitchen space occupied by the dish washing machine is effectively reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Dry type planting soil stirring and preparing device with multi-raw-material adding function

InactiveCN111617688AHigh nutritional valueImprove breathabilityTransportation and packagingMixer accessoriesSoil treatmentAgricultural engineering

The invention discloses a dry type planting soil stirring and preparing device with a multi-raw-material adding function, and belongs to the technical field of soil treatment devices. The dry type planting soil stirring and preparing device comprises a stirring box, a treatment shell and a bottom plate, and the lower surface of the treatment shell is communicated with the upper surface of the stirring box through a feeding pipe; a box door is arranged on the front surface of the treatment shell; a third bearing is clamped on the front surface of the box door; a third rotating shaft is sleevedin the third bearing; the stirring box, the stirring mechanism, the treatment shell and a fertilizer adding mechanism are arranged; construction waste can be placed in the stirring box to be stirred and crushed; the treatment shell can be used for crushing perishable garbage such as fish and shrimp gill shells, animal internal organs and waste fruits and vegetables; the soil can be effectively repaired, the nutritional value is increased, under the work of the stirring mechanism, the air permeability, the water permeability, the nutritional ingredients and the biological activity of soil are improved, the construction waste is turned into wealth, the soil can be used as greening soil and a planting organic fertilizer, and the resource utilization of the waste is truly achieved.

Owner:浙江远新环保科技有限公司

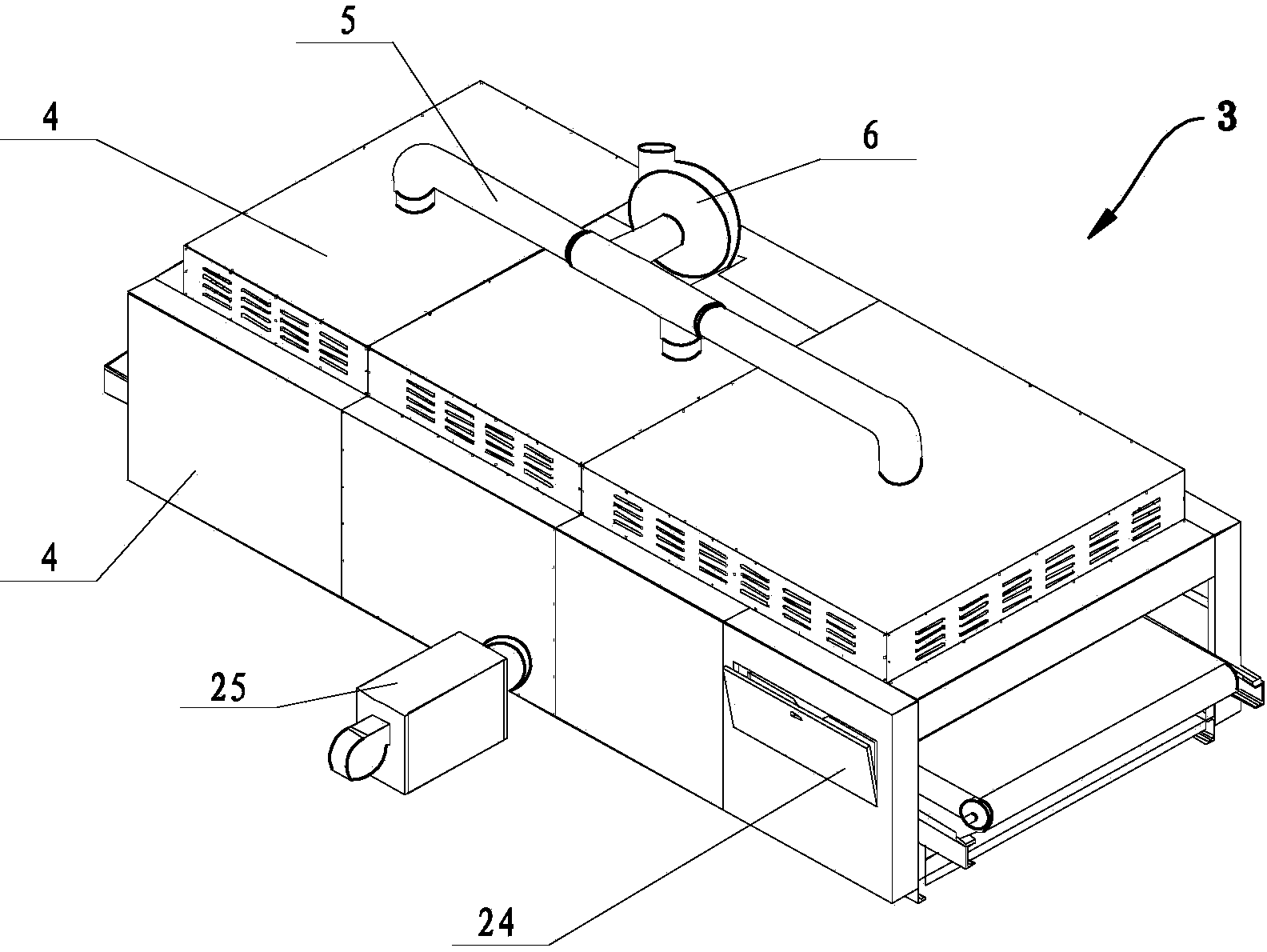

Double circulation energy saving drying equipment with humidity discharging function

PendingCN106766730AIncrease temperaturePurpose of dehumidificationDrying gas arrangementsDrying machines with local agitationProcess engineeringTraditional Chinese medicine

The invention discloses double circulation energy saving drying equipment with a humidity discharging function. According to the double circulation energy saving drying equipment, while a product to be dried is dried, the purpose of dehumidifying is achieved, so that discharging of heat is reduced, and the effect of energy saving is good. The double circulation energy saving drying equipment comprises a drying device and a heat source supplying device. A main circulation pipeline used for improving temperature in the drying device is arranged between the drying device and the heat source supplying device. A humidity discharging pipe used for discharging humidity is arranged on the drying device. A dehumidifying pipeline is further arranged. After exchanging heat with the heat source supplying device or the humidity discharging pipe, the dehumidifying pipeline communicates with the drying device. Because the temperature of air discharged from the humidity discharging pipe is slightly lower than the temperature of air in a dehumidifying air inlet pipe, under the condition that dehumidifying is achieved, the dissipation of heat energy can be reduced, the effect of energy saving is obvious, and the purposes of energy saving and consumption reducing are achieved. The double circulation energy saving drying equipment is applicable to drying and baking treatment of agricultural and sideline products such as grain, traditional Chinese medicine and timber and chemical products.

Owner:王峰云

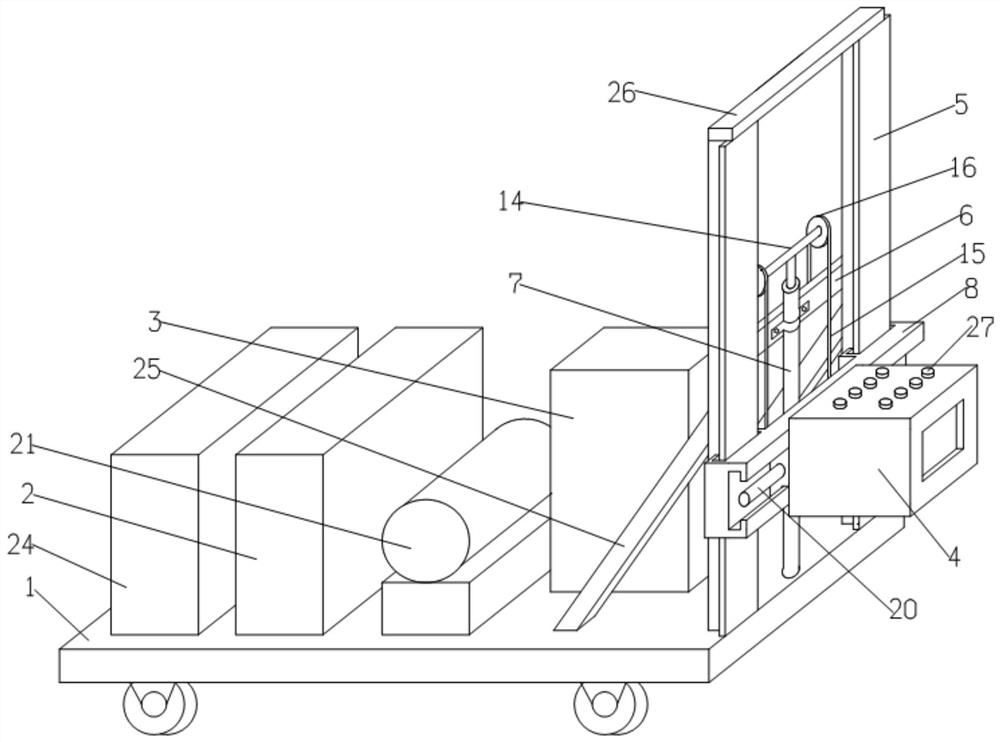

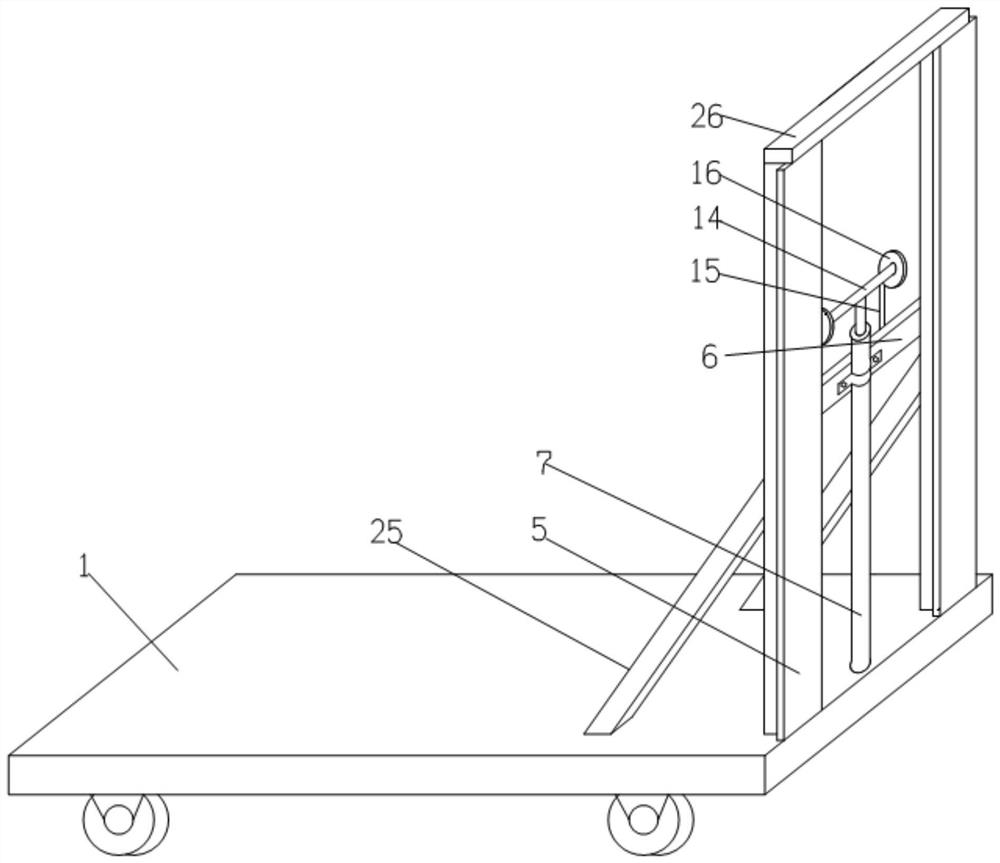

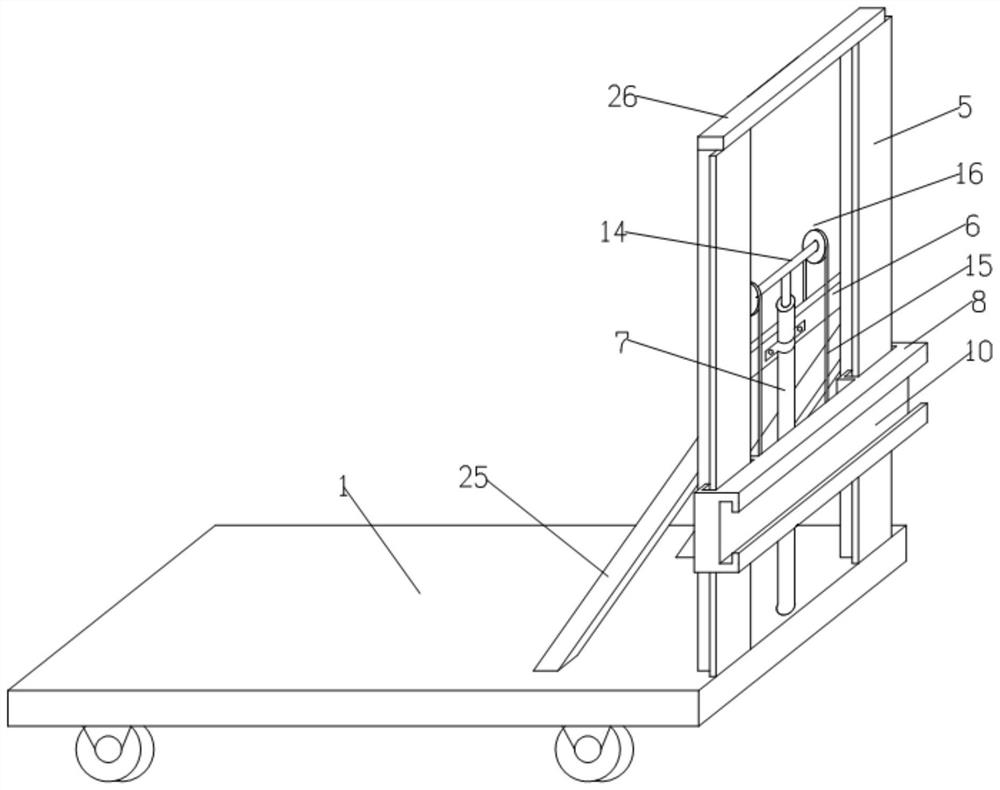

Dust removal purging equipment for drawer type cabinet body

PendingCN112024508AAchieve cleanupQuick washDrying gas arrangementsCleaning using gasesDust controlEngineering

The invention relates to the technical field of power supply and transformation maintenance, in particular to dust removal purging equipment for a drawer type cabinet. The equipment comprises a walking trolley, a purging case and a purging system. The purging case is of a box-shaped structure with an opening in one side and is arranged on the front side of the walking trolley through a movable bracket capable of realizing up-down and left-right movement of the purging case. The purging system comprises an air feeder, an insulating cleaning agent barrel and movable purging devices, the movablepurging devices comprise a plurality of upper movable purging devices and a plurality of lower movable purging devices, and the upper movable purging devices and the lower movable purging devices arecorrespondingly arranged on the inner upper side and the inner lower side of the purging case. The air feeder and the insulating cleaning agent barrel are connected with the movable purging devices through insulating conveying pipelines, negative pressure generated by the air feeder in the movable purging devices sprays out insulating cleaning agents to conduct dust removal purging on a drawer stretching into the purging case, and an air suction opening is formed in the bottom of the purging case and communicates with an air suction dust remover through an insulating pipeline. The drawer typecabinet body can be conveniently and rapidly cleaned.

Owner:国网河南省电力公司巩义市供电公司 +3

Agricultural grain drying device

InactiveCN110715533ARealize screeningAvoid affecting the drying effectSievingScreeningAgricultural scienceAgricultural engineering

The invention discloses an agricultural grain drying device, and belongs to the technical field of agricultural production equipment. The agricultural grain drying device comprises a conveying support, wherein a conveying box is fixedly arranged on the top part of the conveying support; a screw conveyor auger is rotatably connected into the conveying box; a feed hopper is fixedly arranged on the top part of the conveying box; a discharge hopper is arranged on the side wall of one end, far away from the feed hopper, of the conveying box; a stair-stepping grain conveying mechanism is arranged under the discharge hopper; a drying box is arranged on the outer side of the grain conveying mechanism and concretely comprises two shells connected rotatably; and heating pipes distributed in an S shape are arranged on the inner walls of the shells. According to the agricultural grain drying device provided by the invention, the drying box for drying is arranged on the outer side of the conveyingmechanism for conveying grain, and the drying box is used for drying the grain in conveying, so that the problem that a traditional natural drying manner is limited by the external environment is solved; and in addition, the grain can be screened after drying.

Owner:南京福力振农业科技有限公司

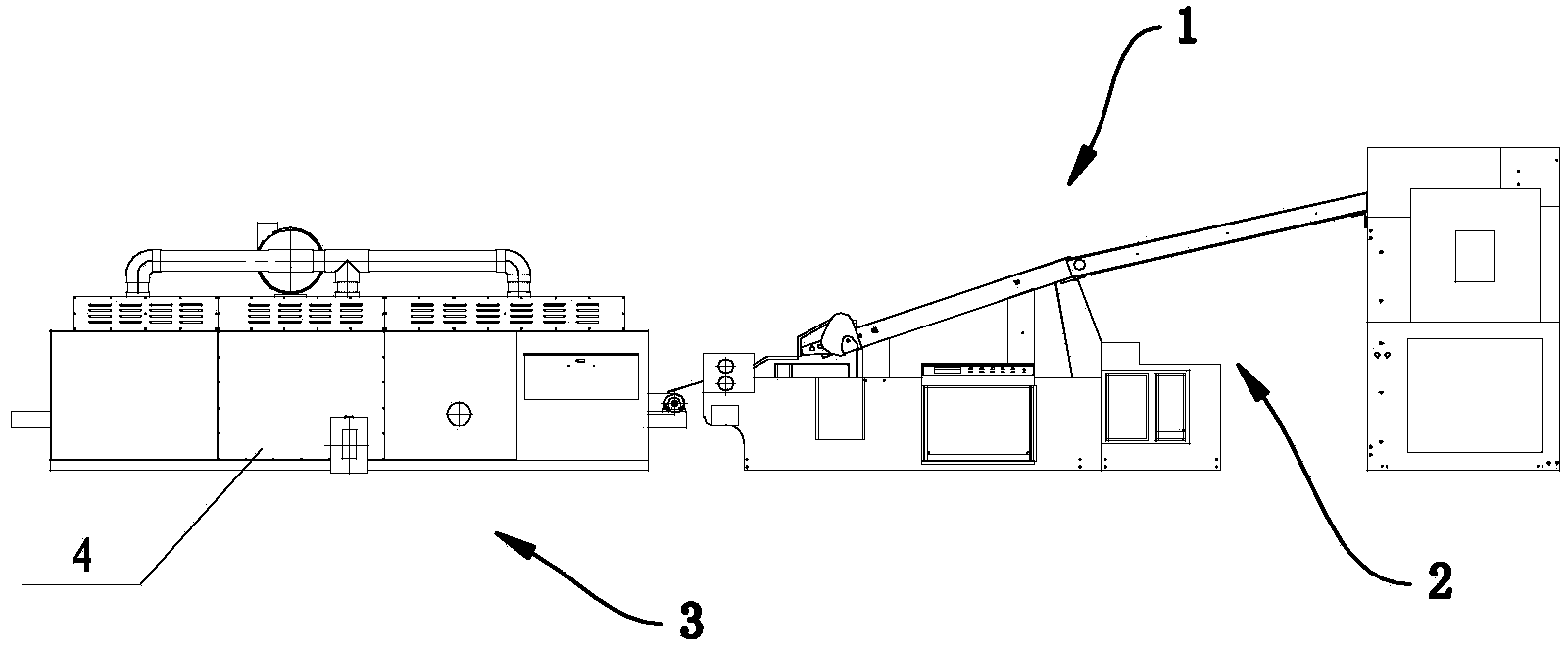

A grain dryer with automatic moisture monitoring

ActiveCN109028893BImprove utilization efficiencyKeep dryDrying gas arrangementsSeed preservation by dryingExhaust valveAgricultural engineering

The invention belongs to the technical field of grain dryers, and discloses a grain dryer with an automatic moisture monitoring function. The grain dryer includes a dryer body, an air inlet, a draughtfan, a burner and a grain feeding elevator, and the dryer body comprises a feeding port, a first drying box, a second drying box, a third drying box, a fourth drying box, a buffer box and a dischargeport; and the exhaust end of the grain feeding elevator is arranged above the feeding port, the lower end of the first drying box is provided with a first exhaust valve, the lower end of the second drying box is provided with a second exhaust valve, the lower end of the third drying box is provided with a third exhaust valve, and the lower end of the fourth drying box is provided with a fourth exhaust valve. The grain dryer with the automatic moisture monitoring function has simple structure, high energy utilization efficiency, automatic moisture monitoring function, sufficient grain drying,and wide application prospects.

Owner:ANHUI CHENYU MECHANICAL

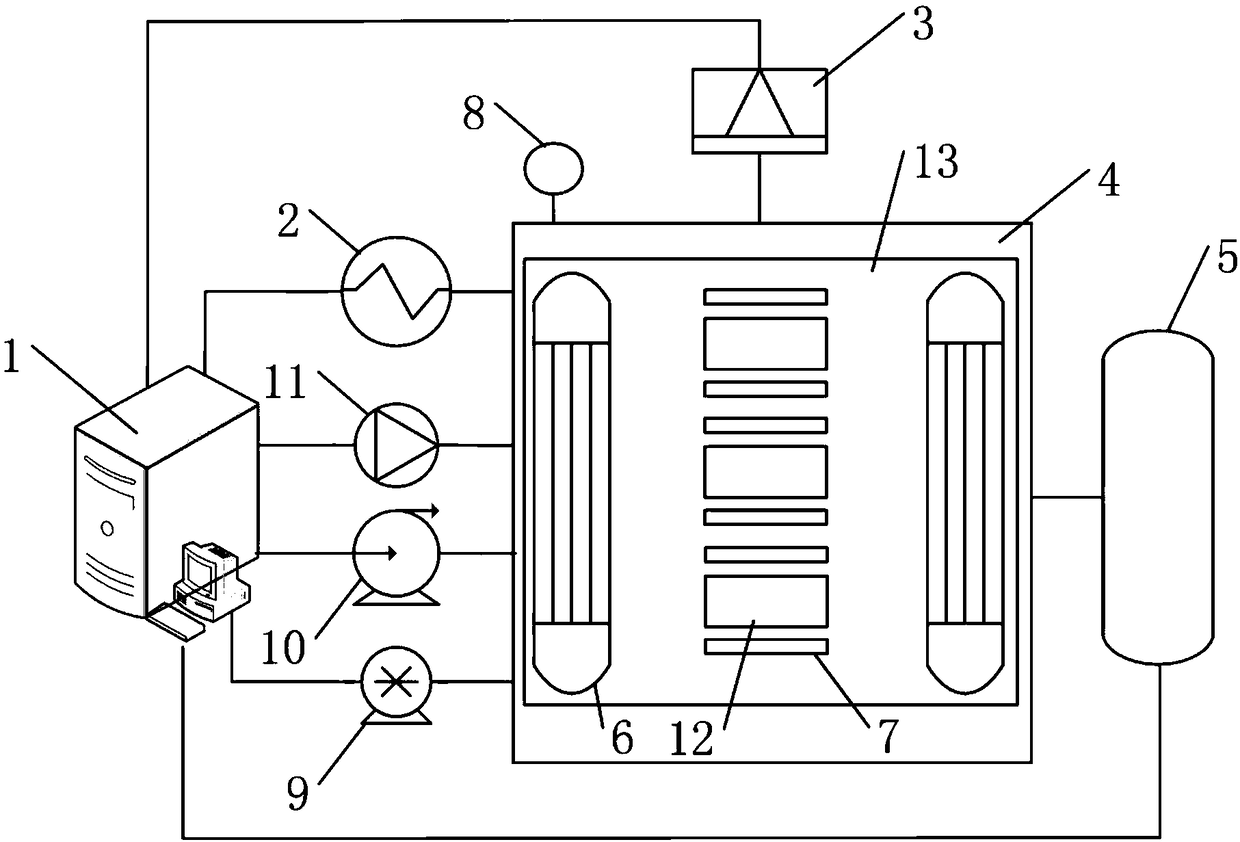

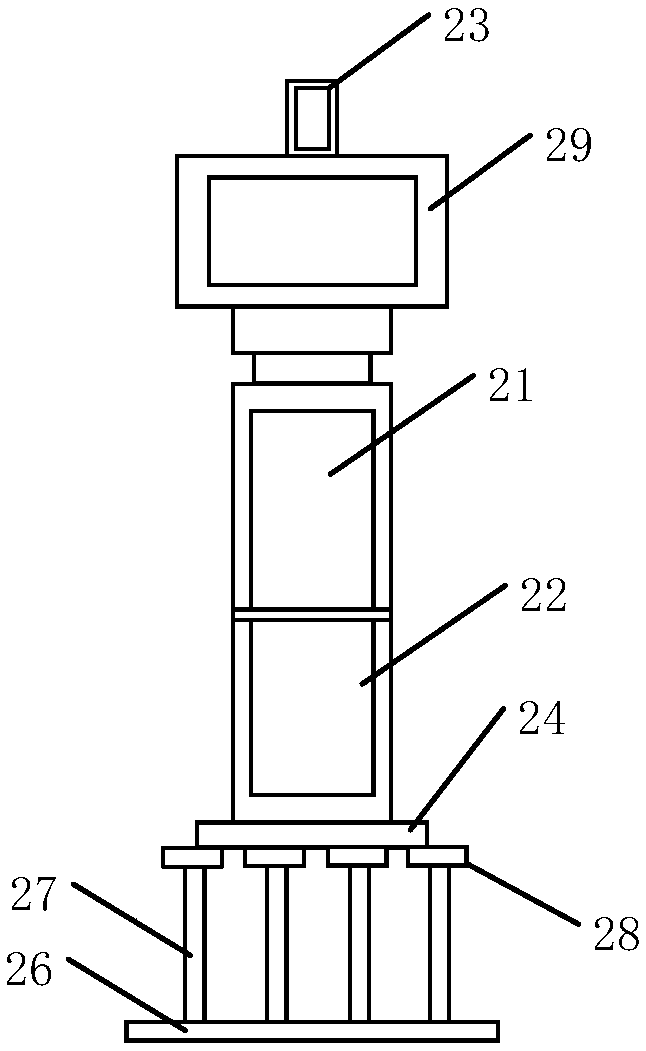

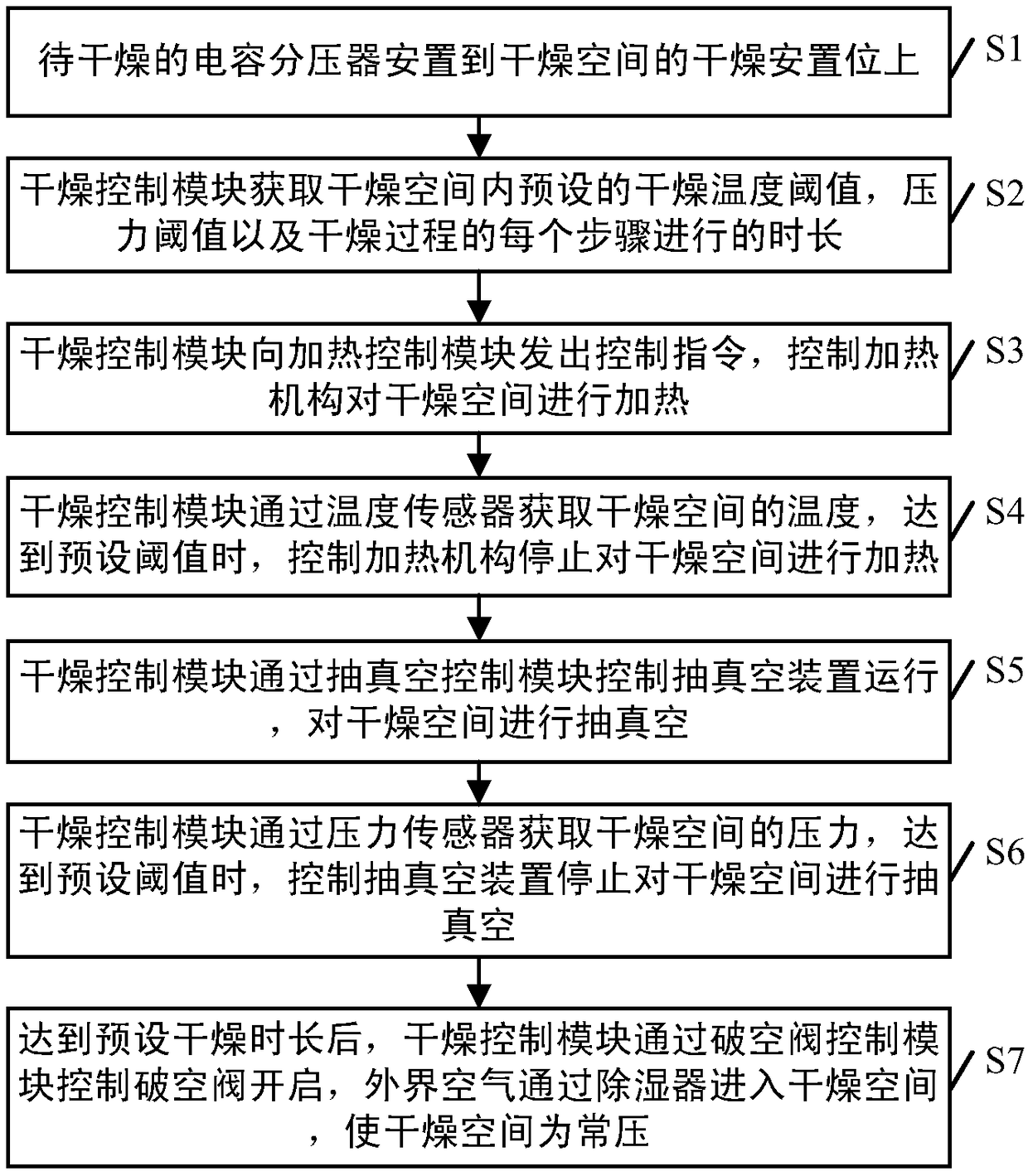

Capacitive voltage divider vacuum drying system and method for mutual inductor

ActiveCN109140907ASatisfy dry processingAvoid affecting the drying effectDrying solid materials without heatHeating arrangementVacuum pumpingCapacitive voltage divider

The invention provides a capacitive voltage divider vacuum drying system and method for a mutual inductor. A capacitive voltage divider to be dried is placed at a dry placement position of a drying space; a drying control module obtains a preset drying temperature threshold value, a pressure threshold value and duration of each step in the drying process in the drying space; a heating mechanism heats the drying space; a vacuum pumping device performs vacuum pumping on the drying space; after the preset drying duration is reached, the drying control module controls the opening of a vacuum breaker valve through a vacuum breaker valve control module, and the outside air enters the drying space through a dehumidifier, so that the drying space is atmospheric pressure. The presence or absence ofdew drops is observed by an observation mirror to determine the drying condition of the capacitive voltage divider. The entire drying process is free of insulating oil, and people and the environmentare not affected; and the drying rate is high, the product treatment effect is good, the temperature of the product drying process is easy to control, and the internal insulation damage of products is not caused.

Owner:山东泰开互感器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com