Vibrated food microwave drying device

A microwave drying and vibrating technology, used in non-progressive dryers, grain drying, drying of solid materials, etc., can solve the problems of clogging, mixing and influence of grain passages, and achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

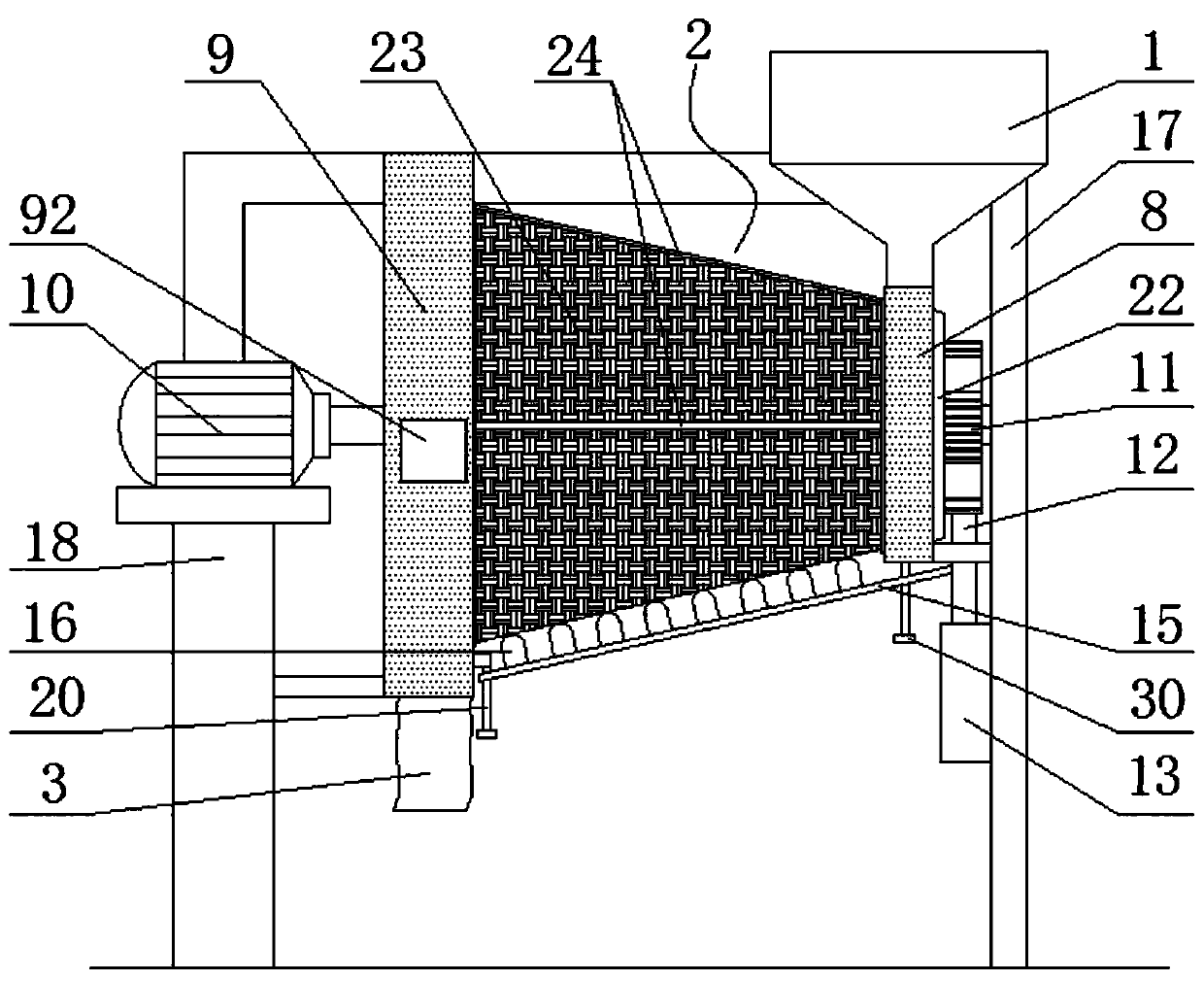

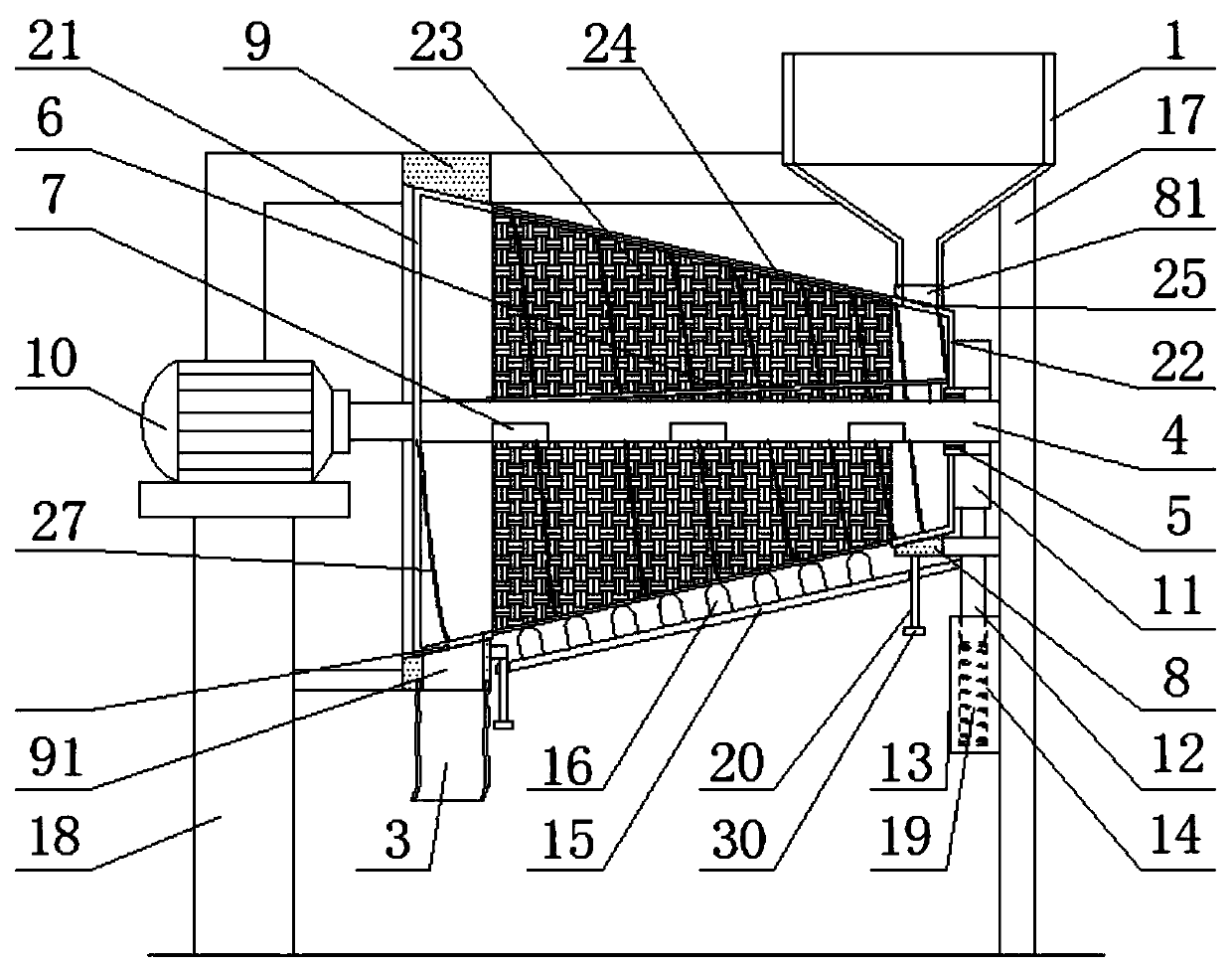

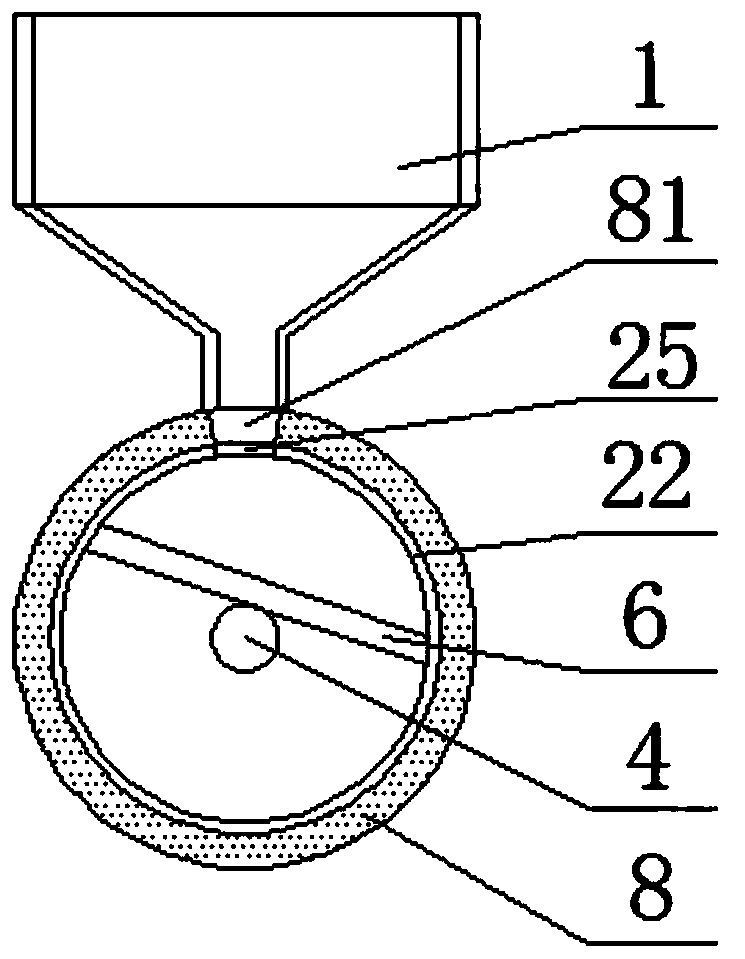

[0028] Such asfigure 1 and figure 2 The shown a kind of vibrating grain microwave drying device comprises a feed hopper 1, a drying box 2 and a discharge pipe 3 arranged sequentially from top to bottom; 2 includes a left bracket 21 and a right bracket 22 that are arranged oppositely, and a cylindrical filter screen 23 connected between the left bracket 21 and the right bracket 22, and the shapes of the left bracket 21 and the right bracket 22 are both It is a circular truncated structure that is hollow inside and open to each other, and the diameter of the end surface of the left bracket 21 is larger than that of the right bracket 22. The cylindrical filter screen 23 is connected to the left bracket 21 and the right bracket 22. Between the facing faces, and between the left bracket 21 and the right bracket 22, there are connecting rods 24 that are positioned at the top of the cylindrical filter screen 23 and the front and rear sides and are attached to the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com