Patents

Literature

1427 results about "Grain drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grain drying is process of drying grain to prevent spoilage during storage. The grain drying described in this article is that which uses fuel- or electric-powered processes supplementary to natural ones, including swathing/windrowing for drying by ambient air and sunshine.

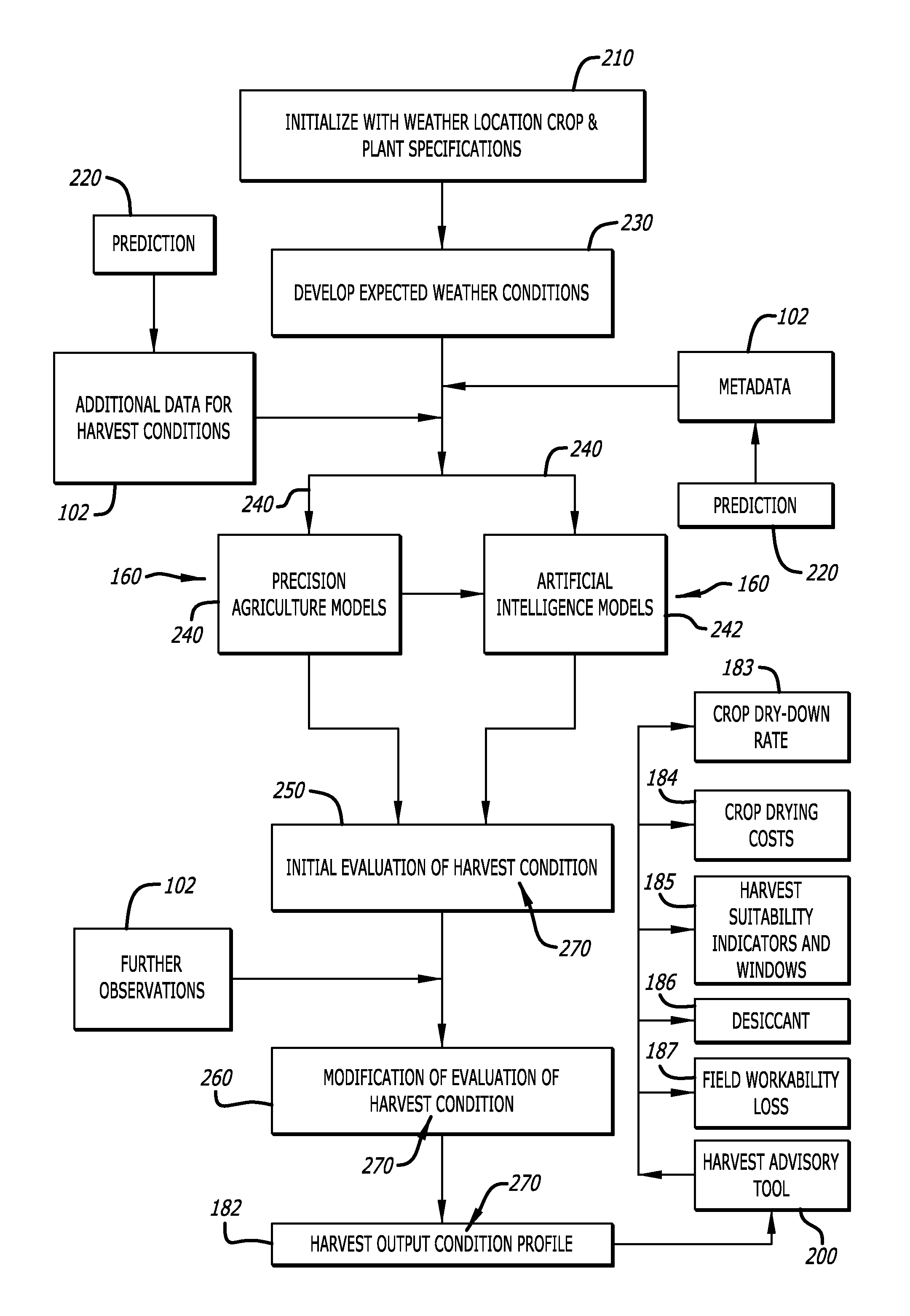

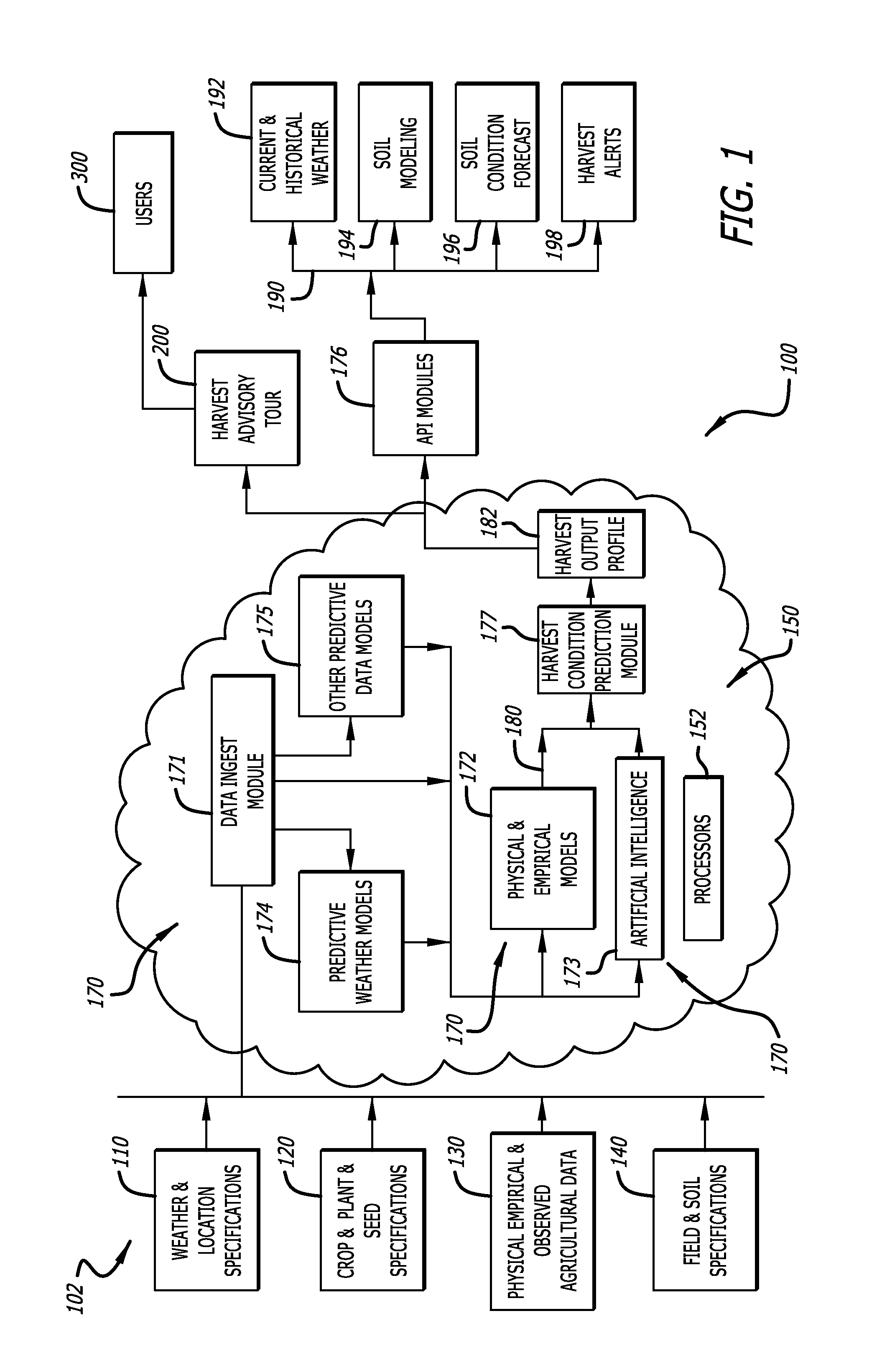

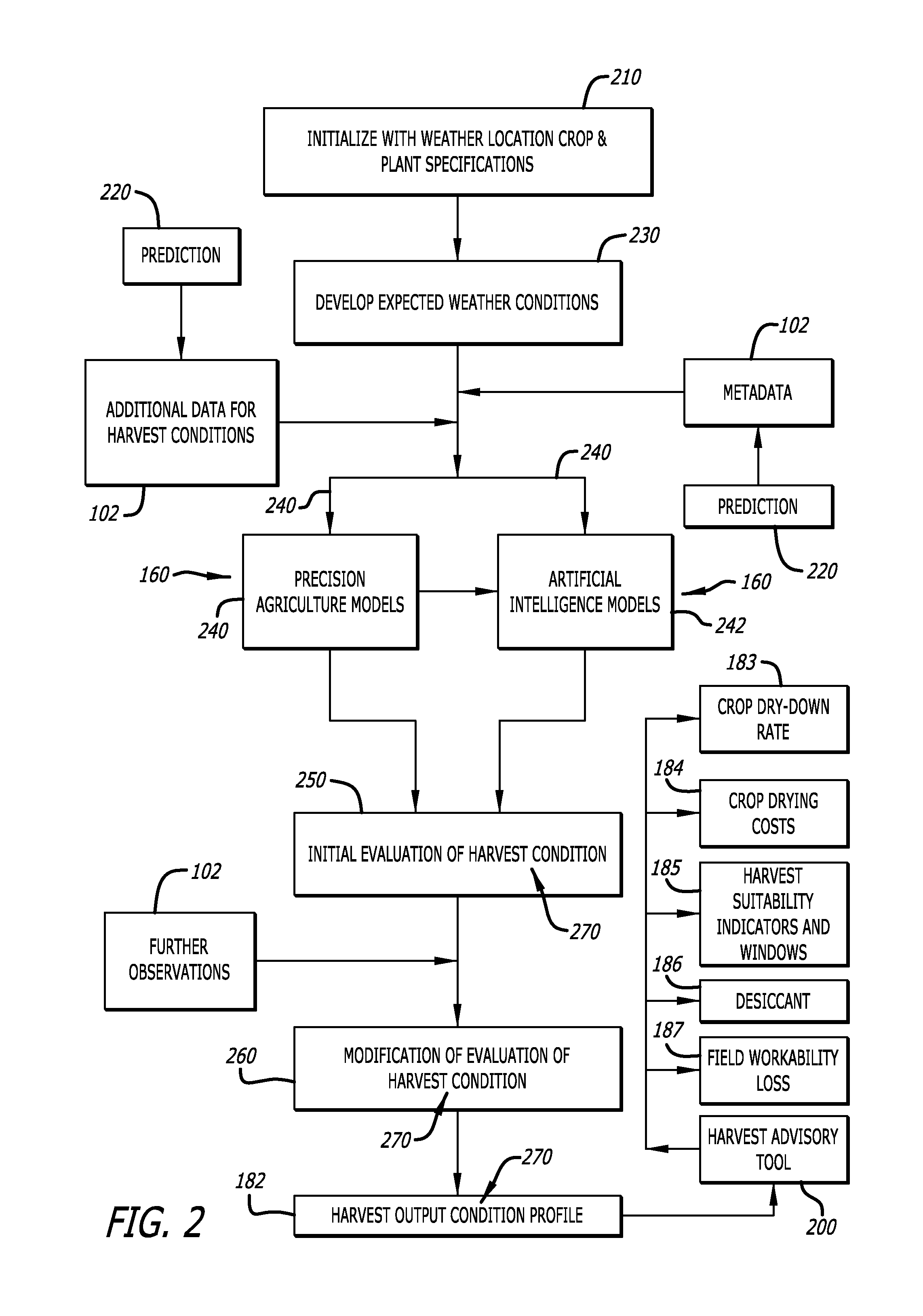

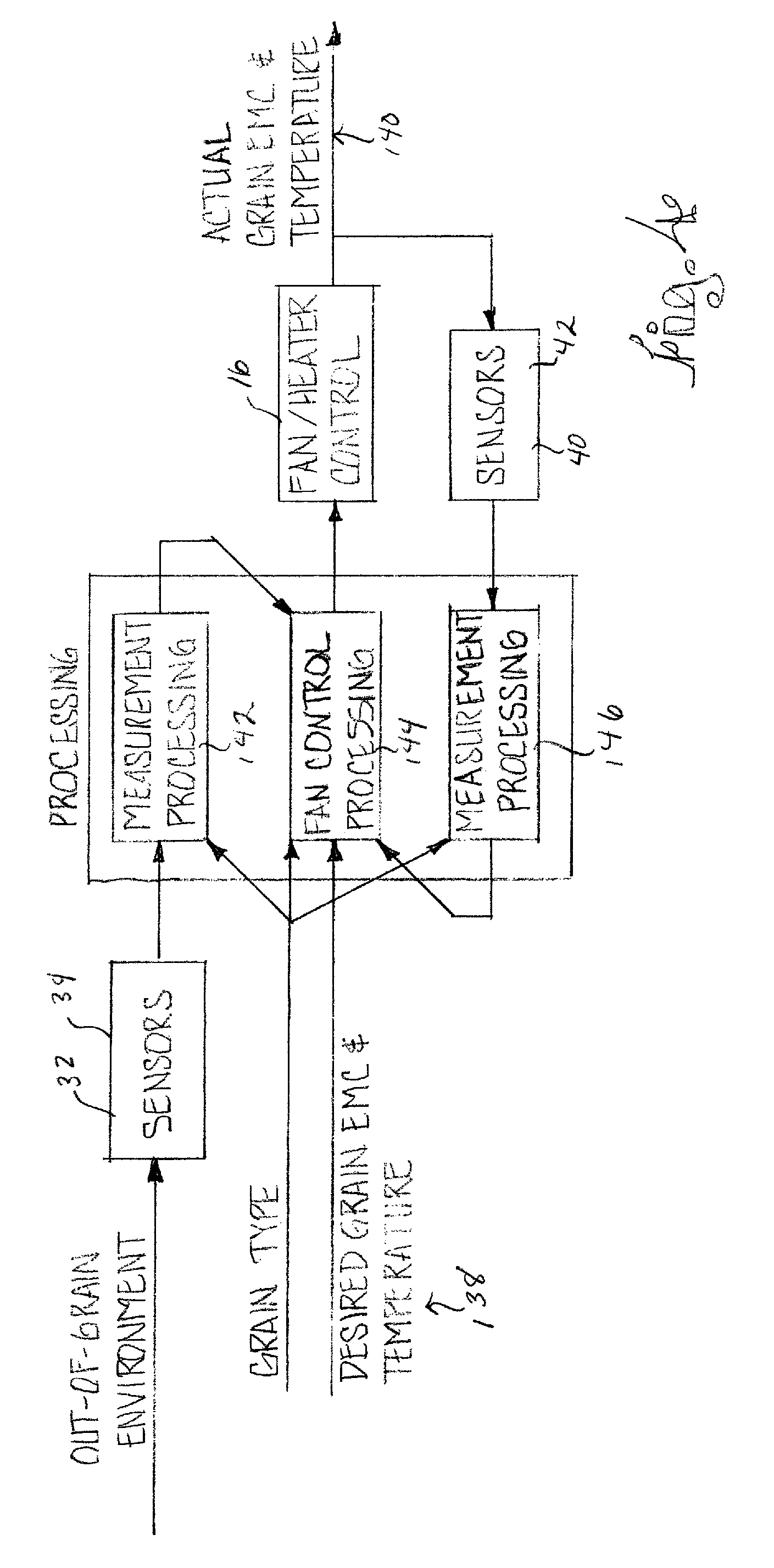

Modeling the impact of time-varying weather conditions on unit costs of post-harvest crop drying techniques using field-level analysis and forecasts of weather conditions, facility metadata, and observations and user input of grain drying data

ActiveUS9009087B1Convenient guidanceSignificant comprehensive benefitsClimate change adaptationDigital computer detailsAgricultural engineeringBiology

A modeling framework for evaluating the impact of weather conditions on farming and harvest operations applies real-time, field-level weather data and forecasts of meteorological and climatological conditions together with user-provided and / or observed feedback of a present state of a harvest-related condition to agronomic models and to generate a plurality of harvest advisory outputs for precision agriculture. A harvest advisory model simulates and predicts the impacts of this weather information and user-provided and / or observed feedback in one or more physical, empirical, or artificial intelligence models of precision agriculture to analyze crops, plants, soils, and resulting agricultural commodities, and provides harvest advisory outputs to a diagnostic support tool for users to enhance farming and harvest decision-making, whether by providing pre-, post-, or in situ-harvest operations and crop analyzes.

Owner:DTN LLC

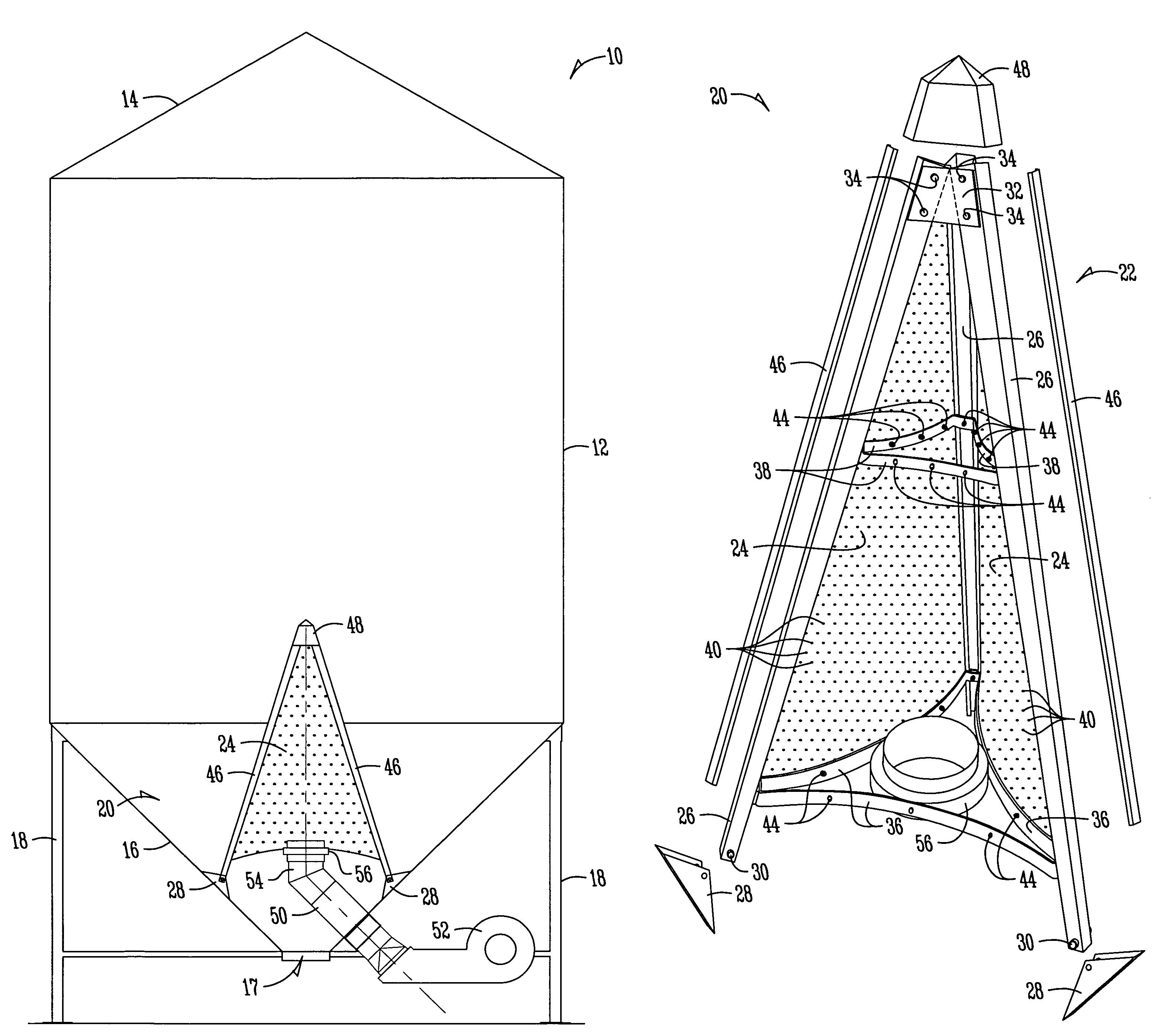

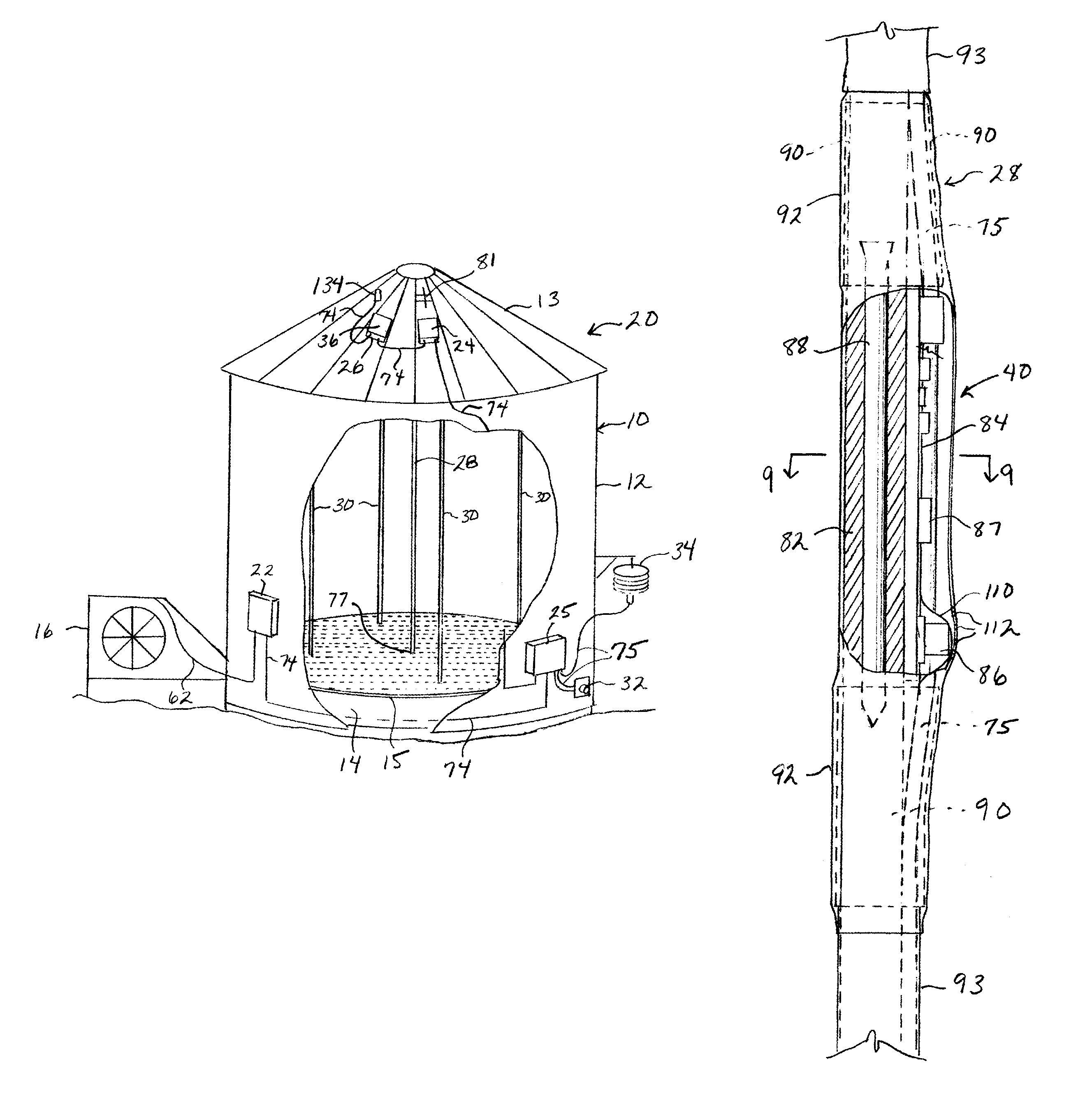

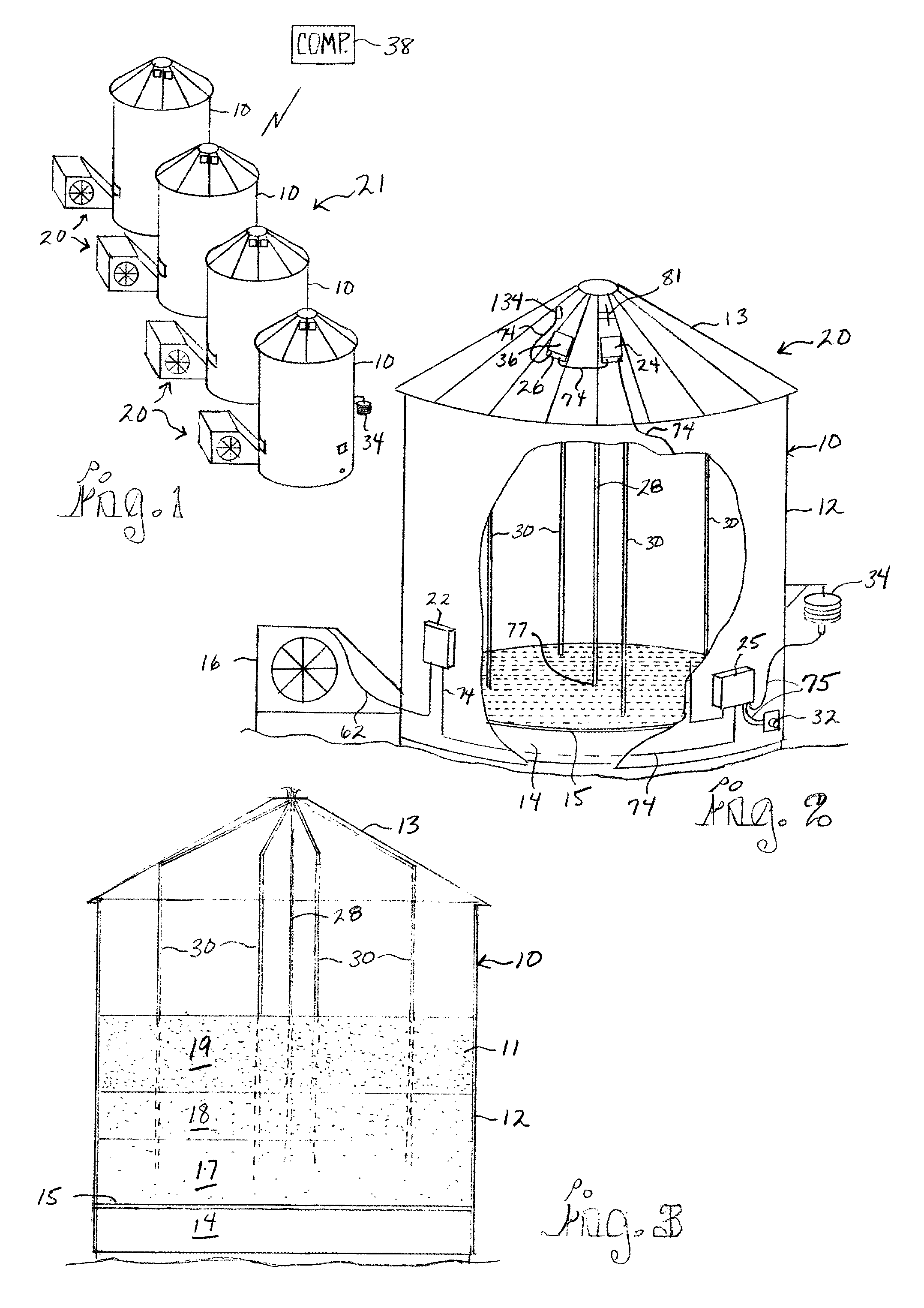

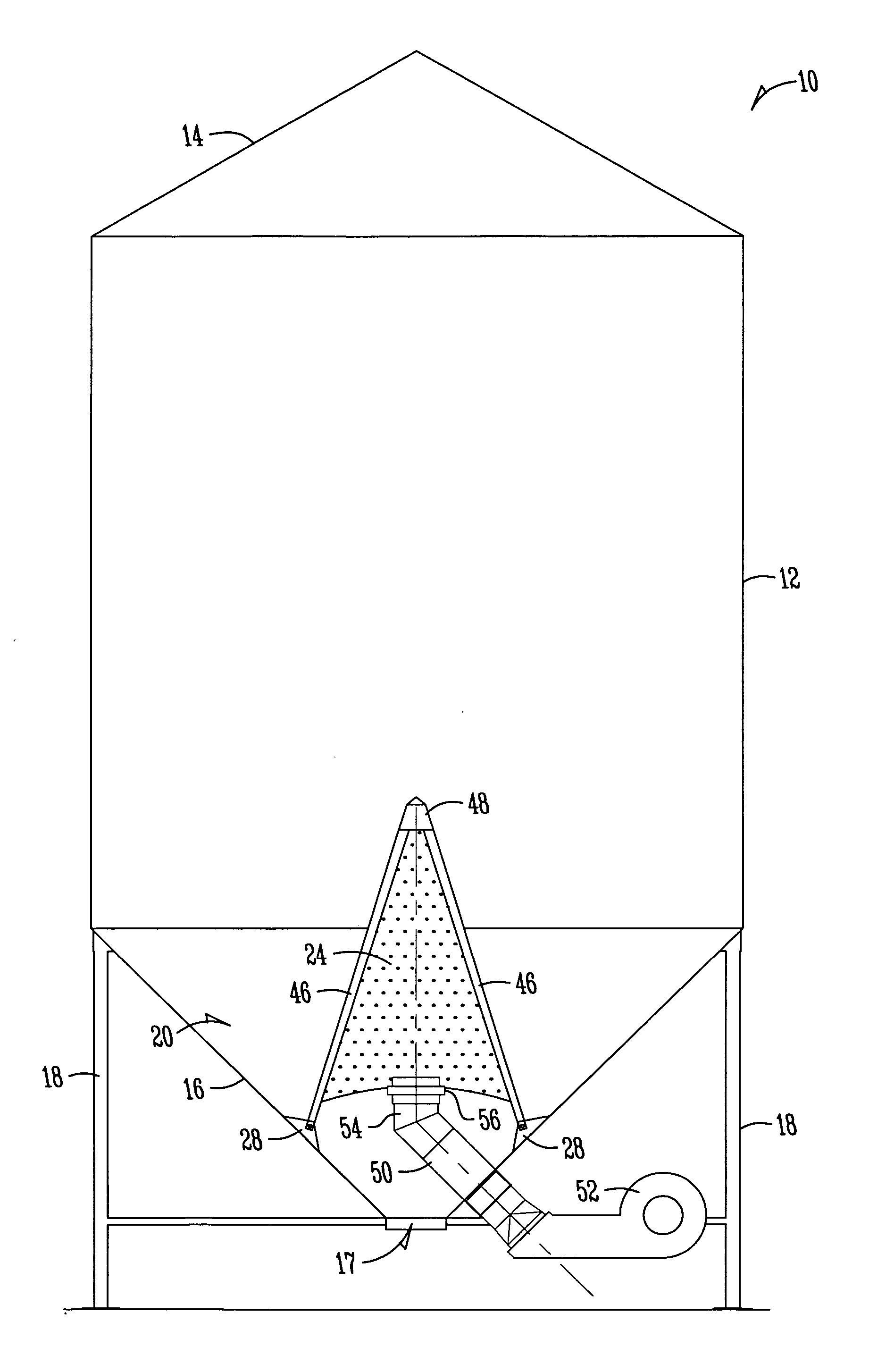

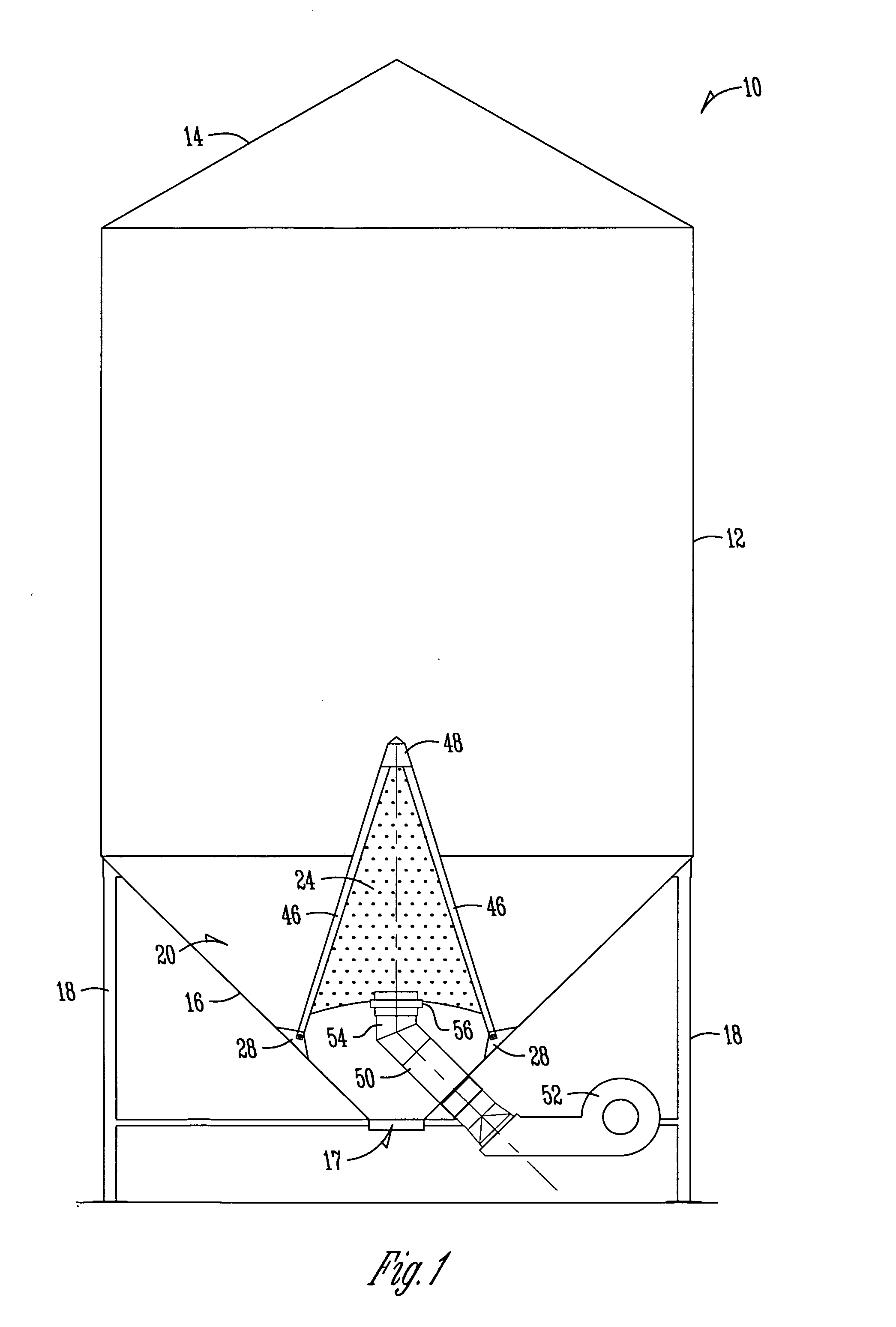

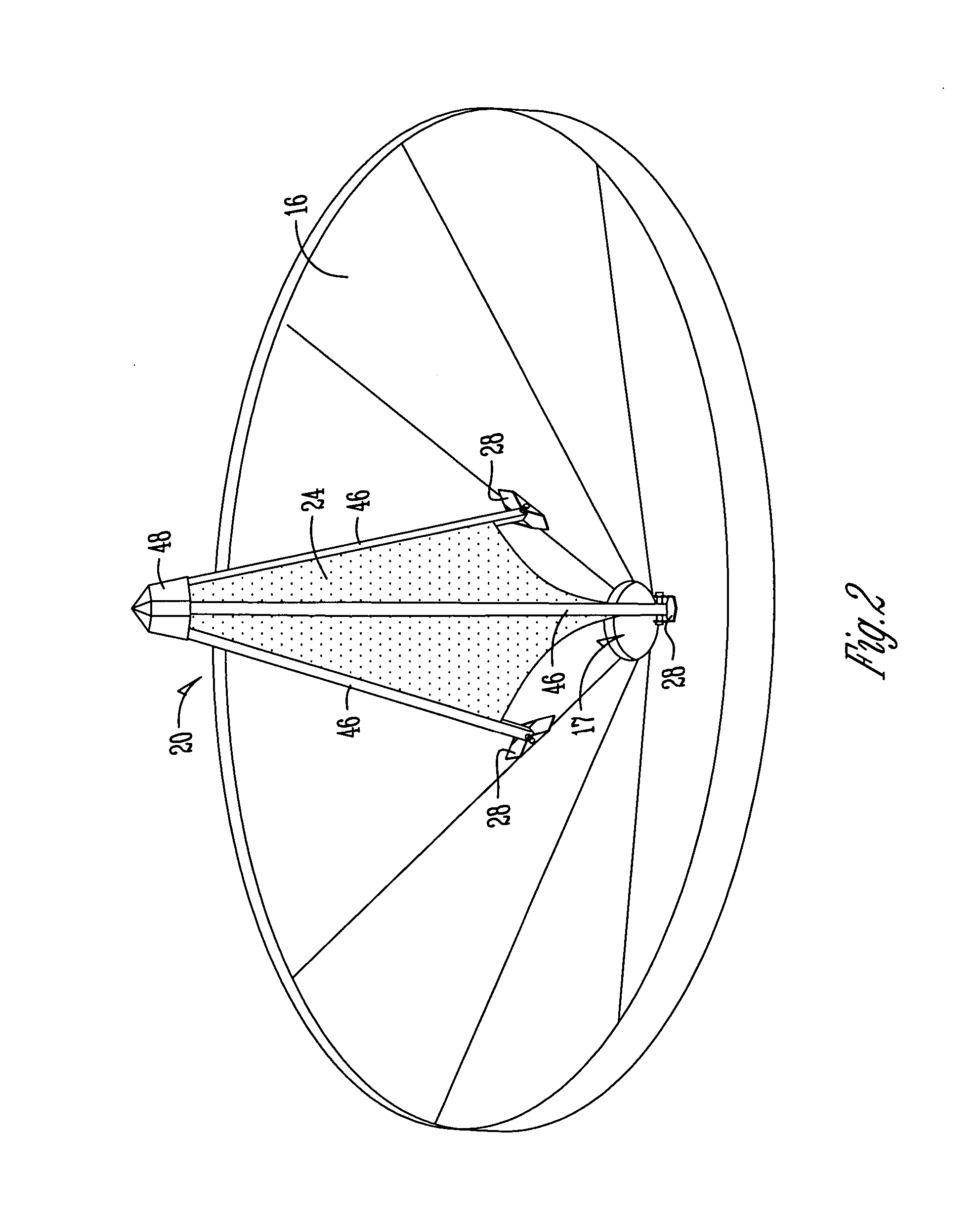

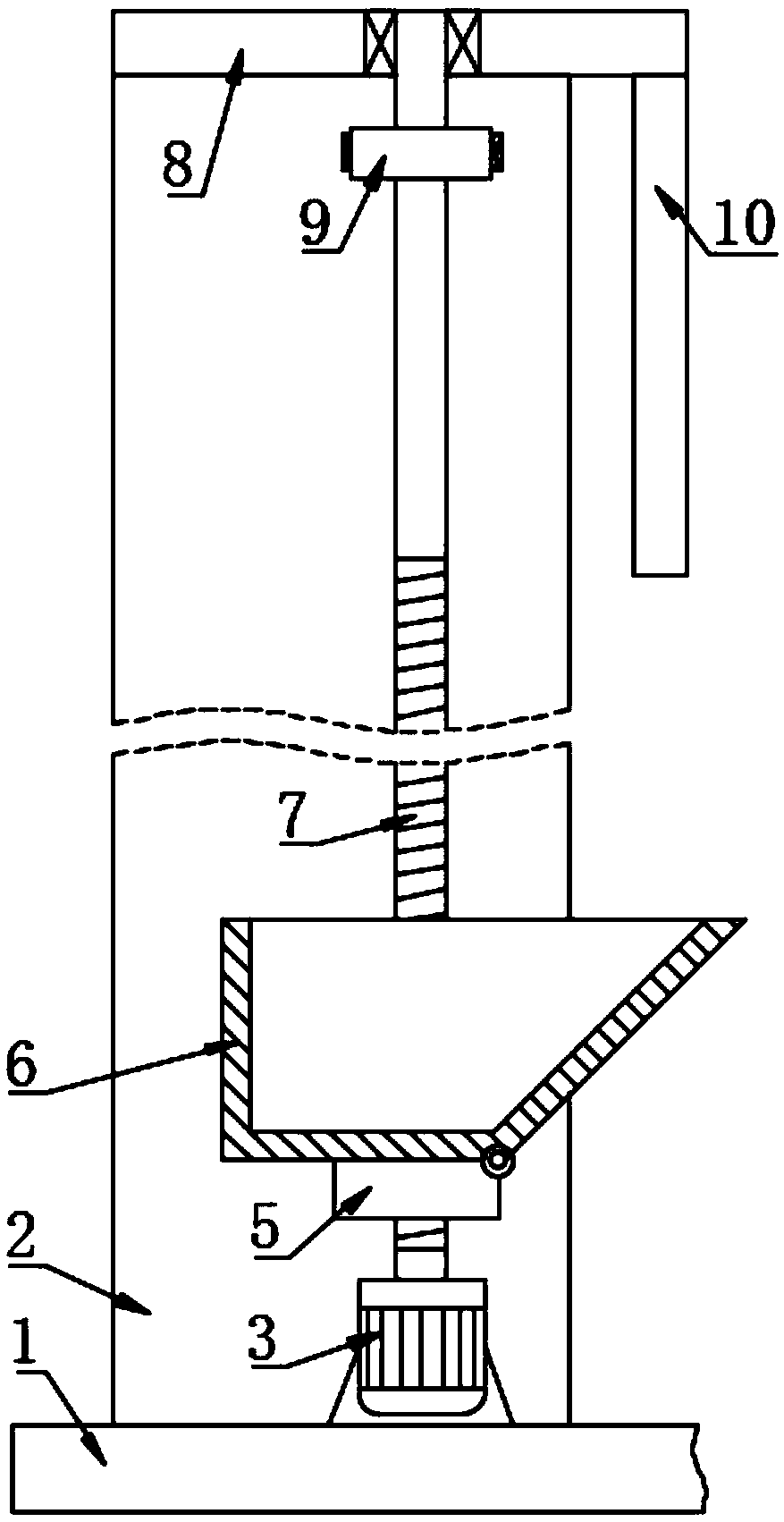

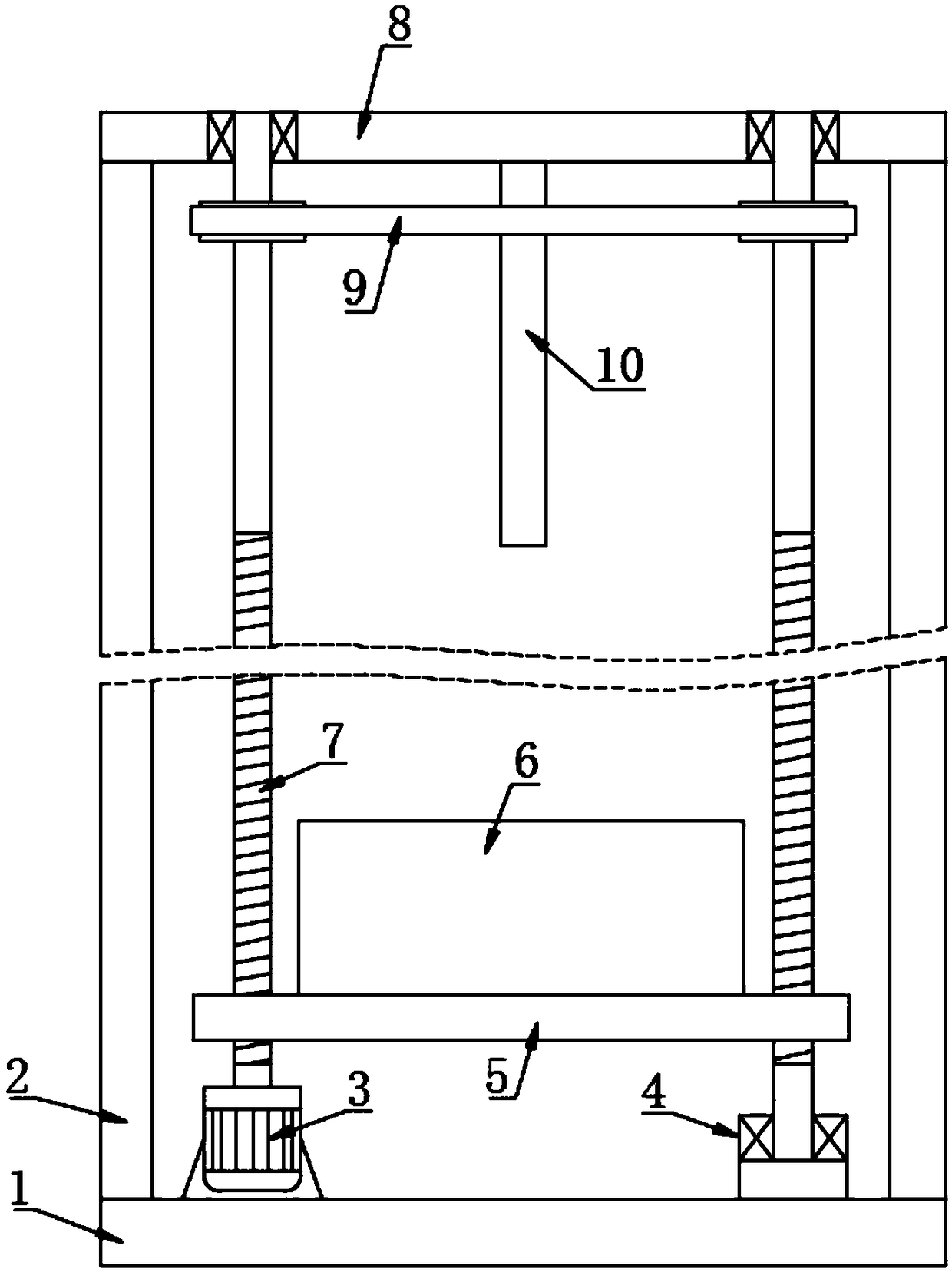

Grain drying aeration system

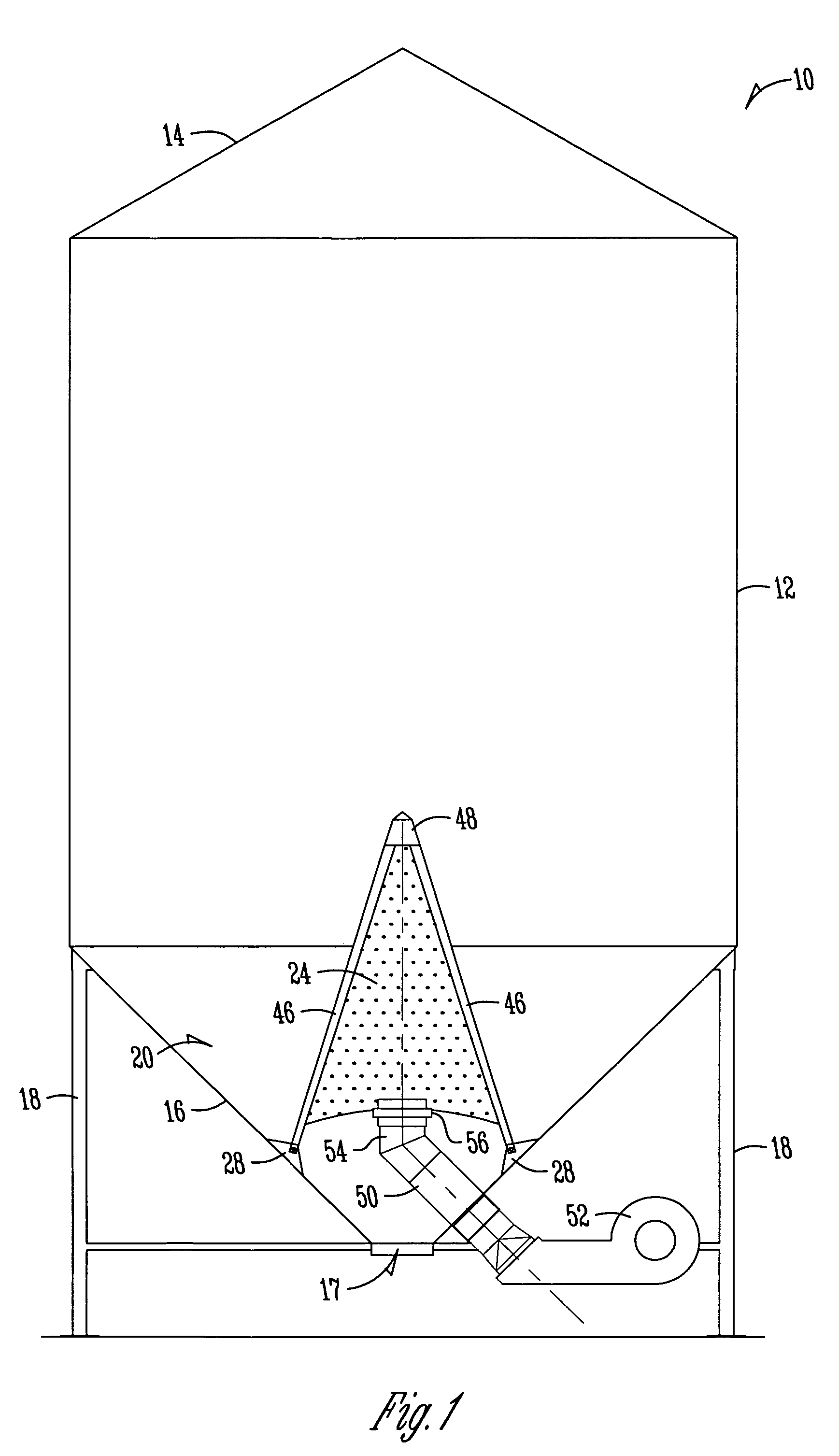

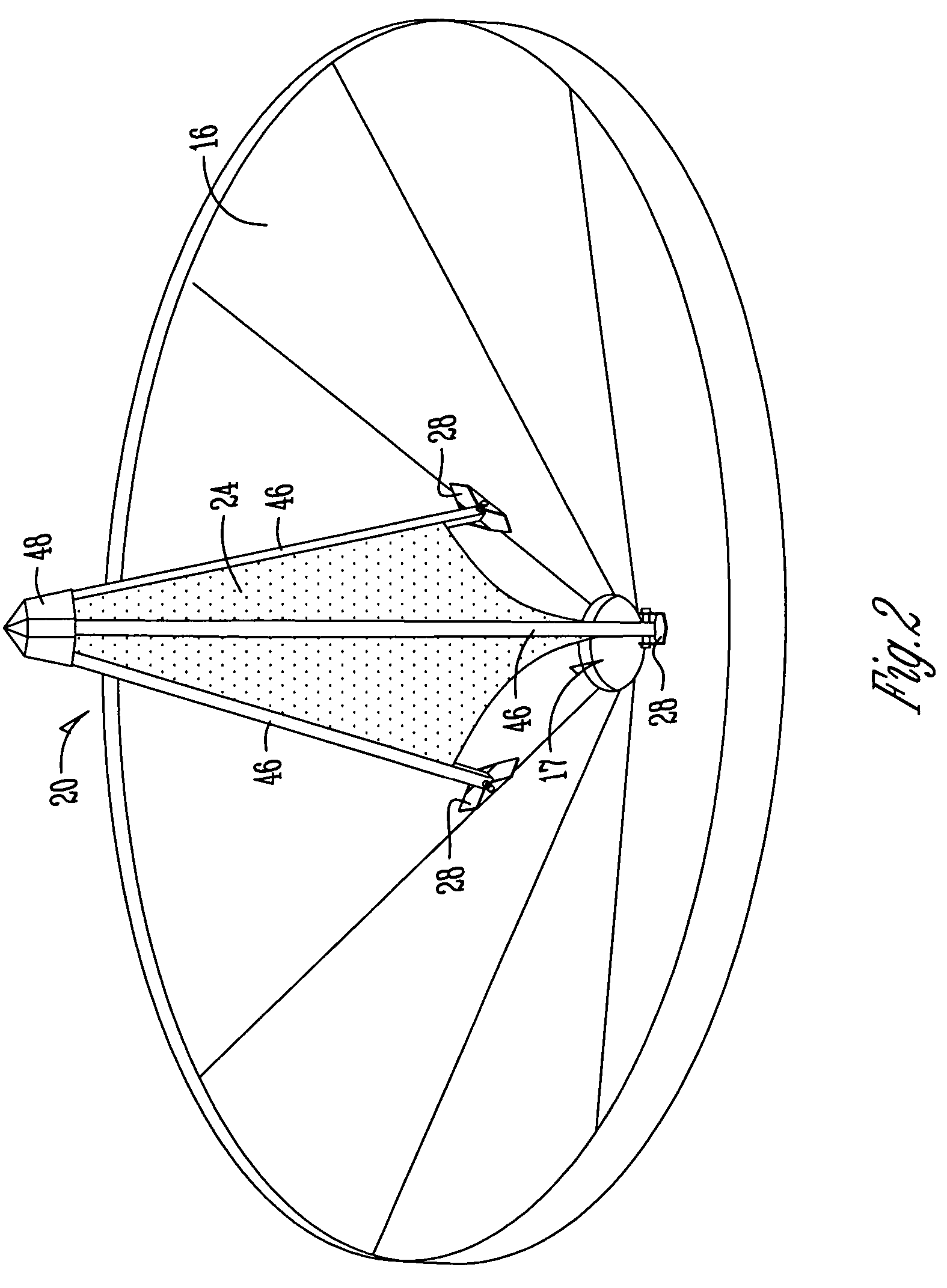

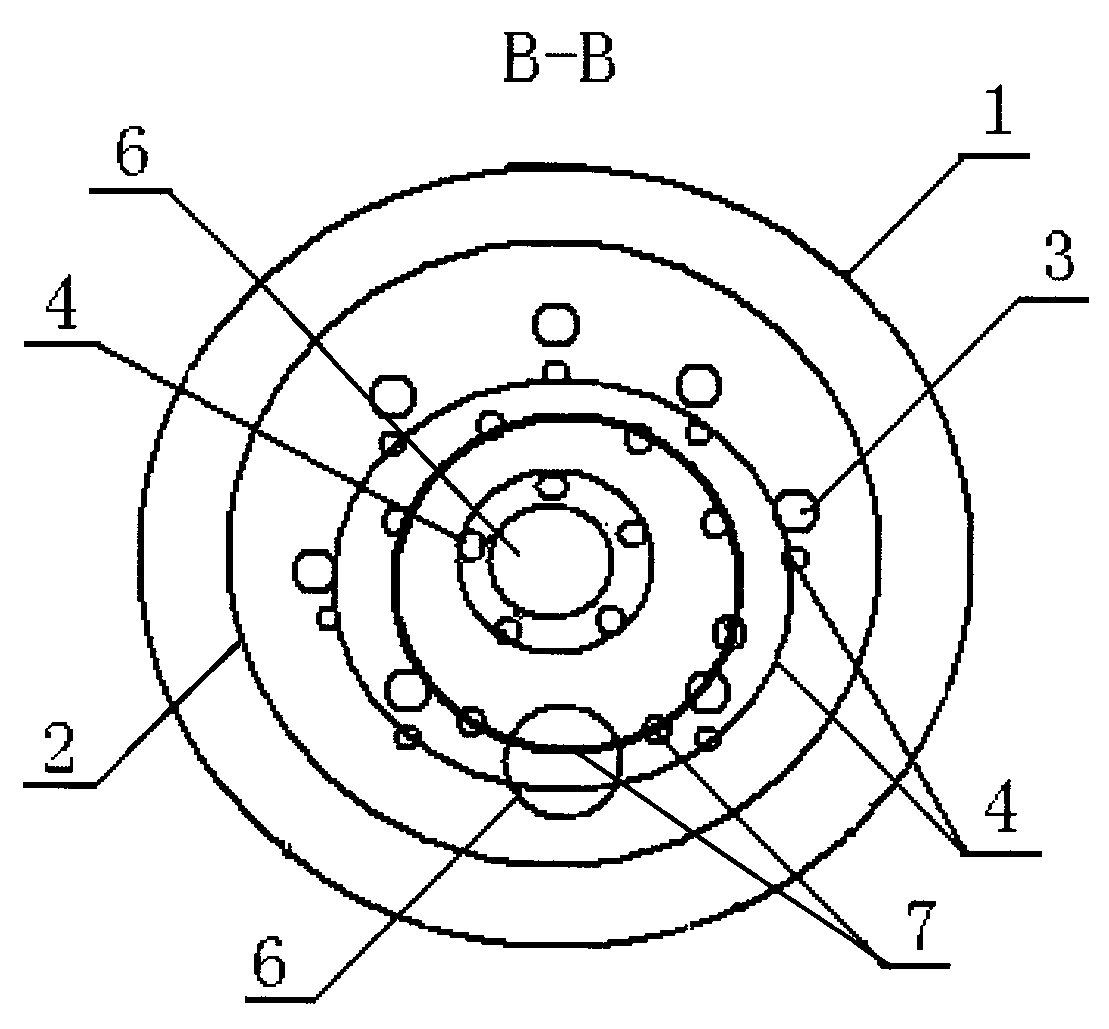

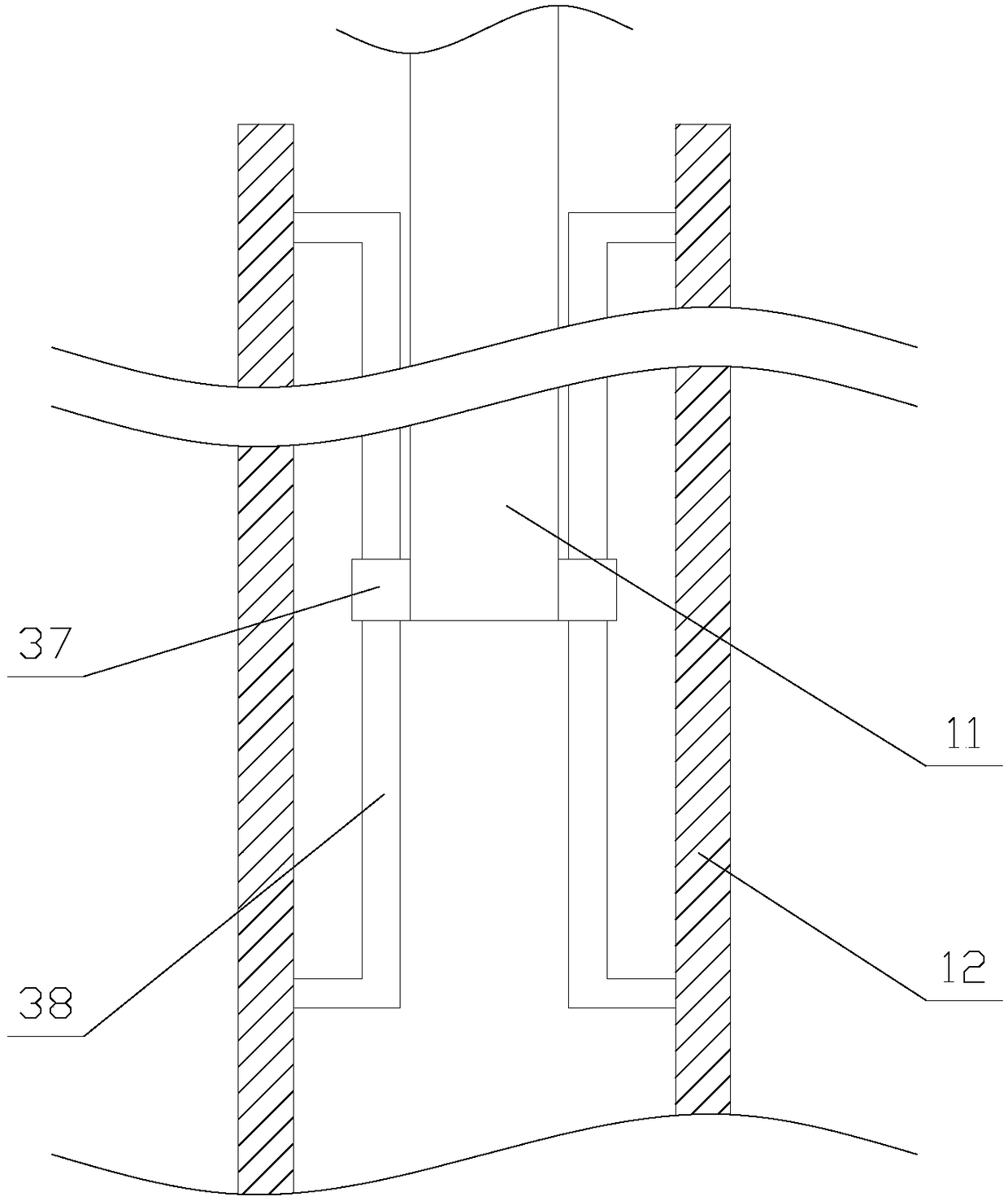

InactiveUS7568297B2Drying solid materials with heatDrying chambers/containersAeration systemWaste management

An improved vertical aeration system is provided for a grain bin having a sloped hopper bottom with a discharge opening. A pyramid frame includes legs with lower ends attachable to the hopper bottom. Concave perforated walls are attached to the legs. Braces extending between the legs provide structural support for the walls. An air duct extends upwardly and centrally into the interior of the frame, to supply air into the aeration system for flow outwardly through the perforated walls.

Owner:WOODHAVEN CAPITAL

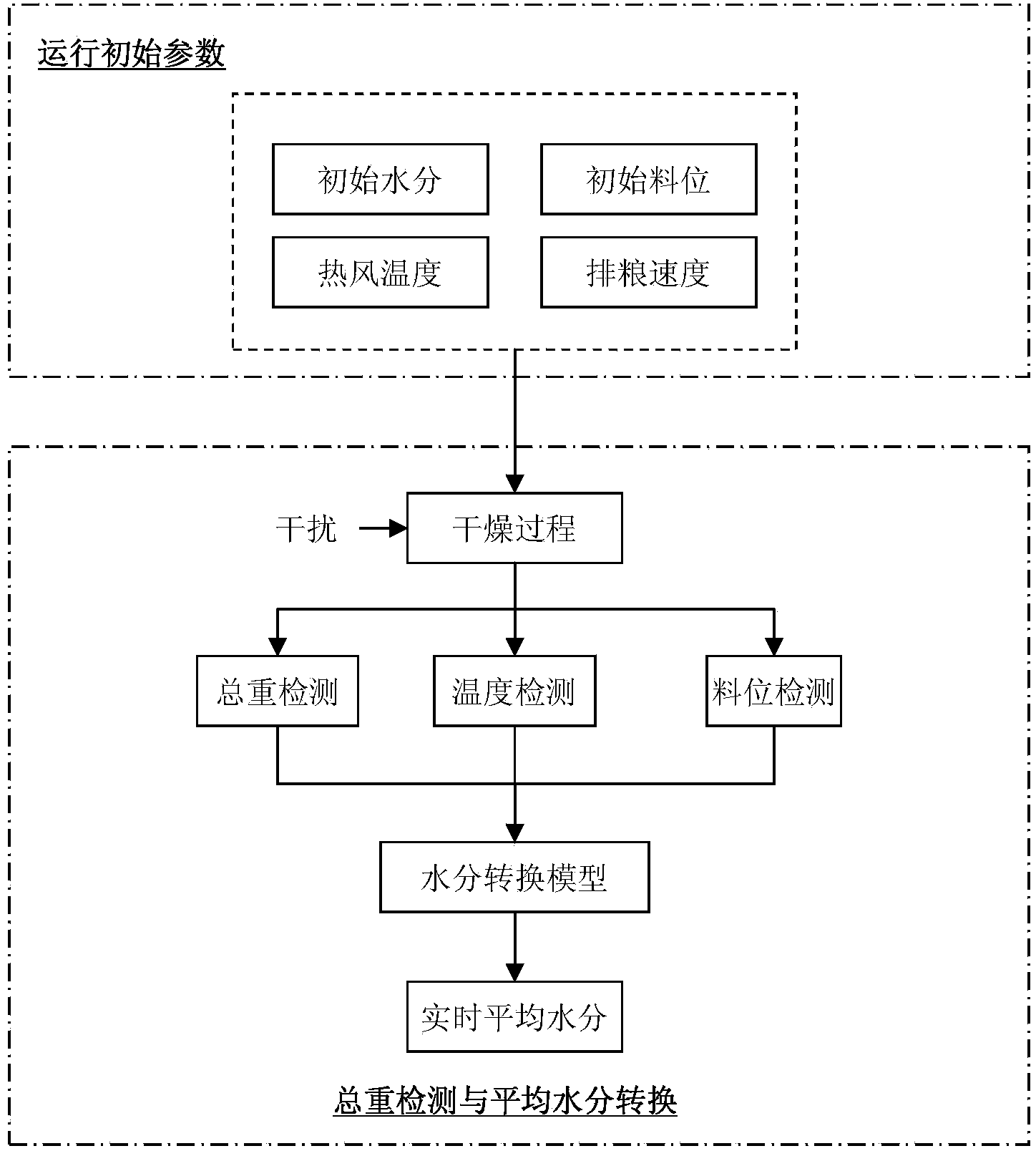

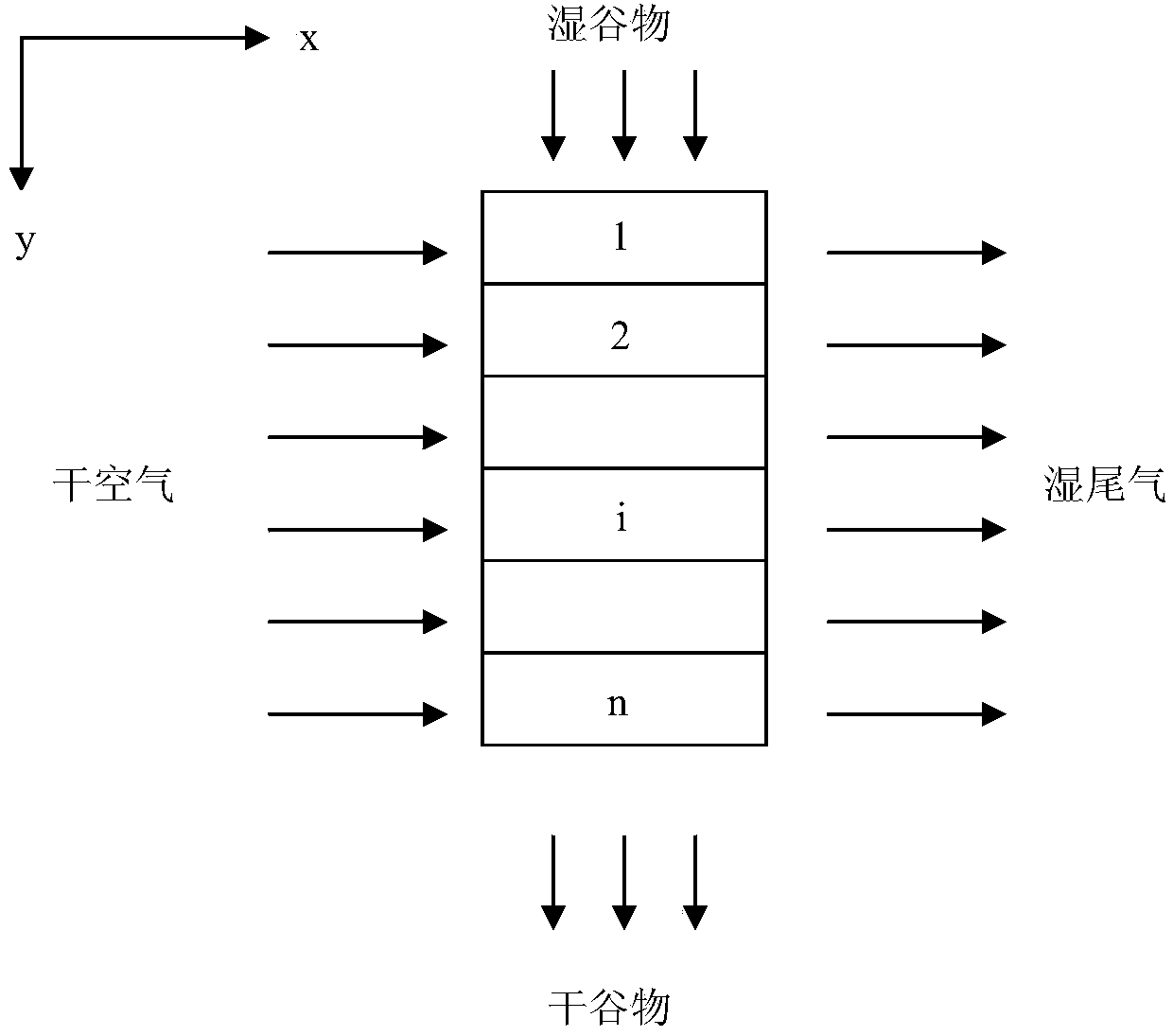

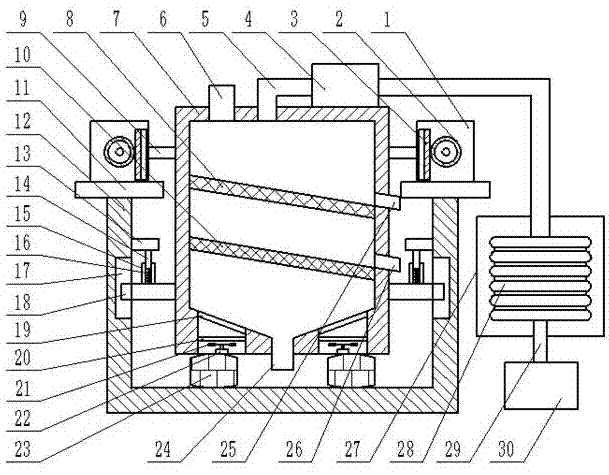

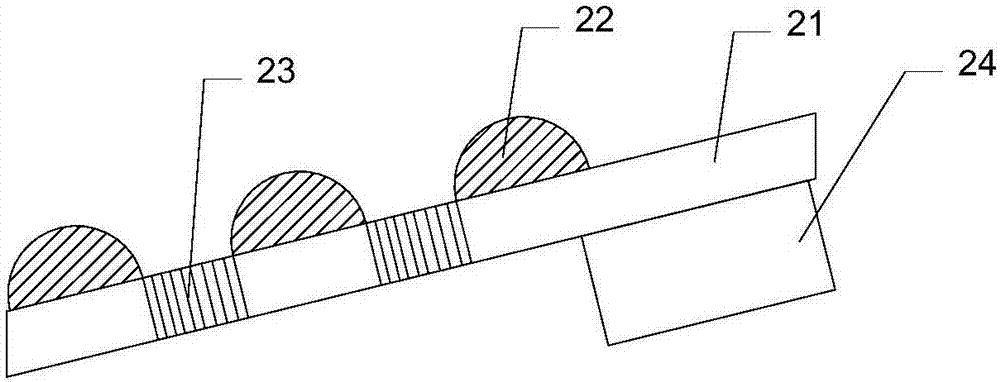

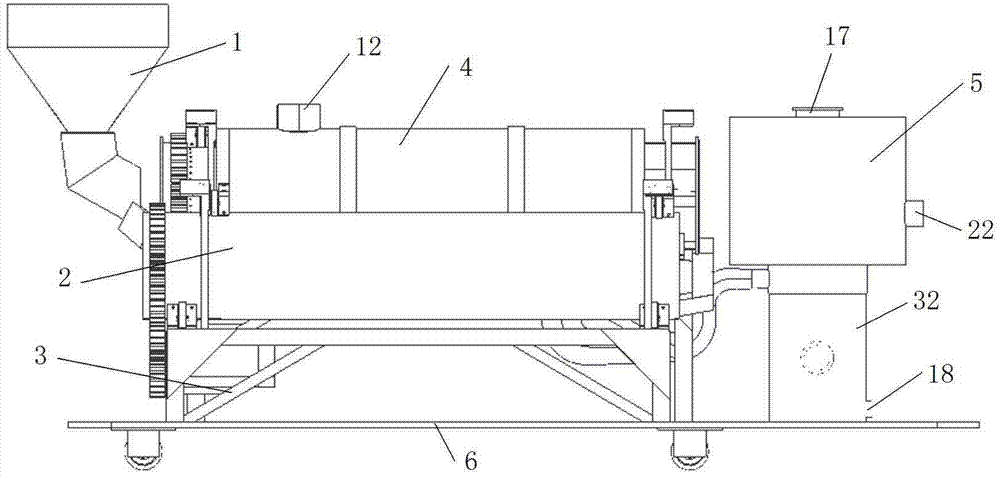

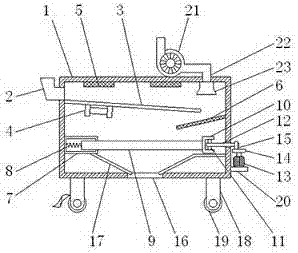

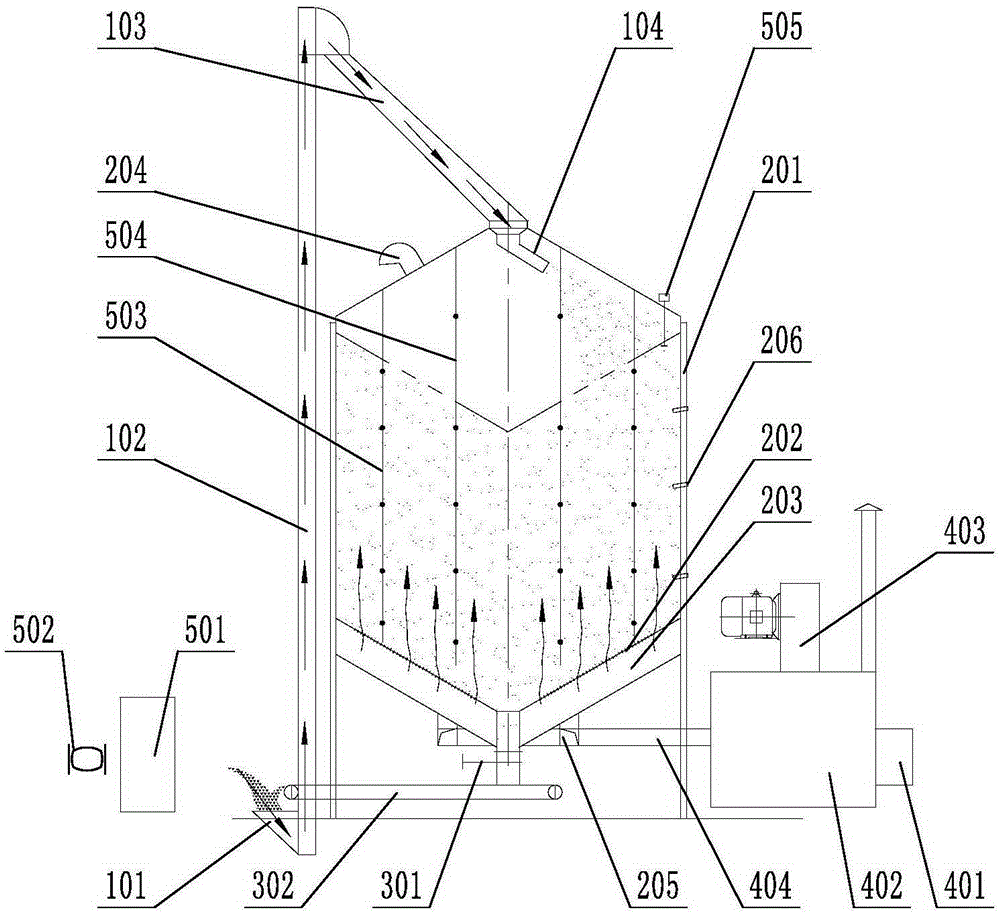

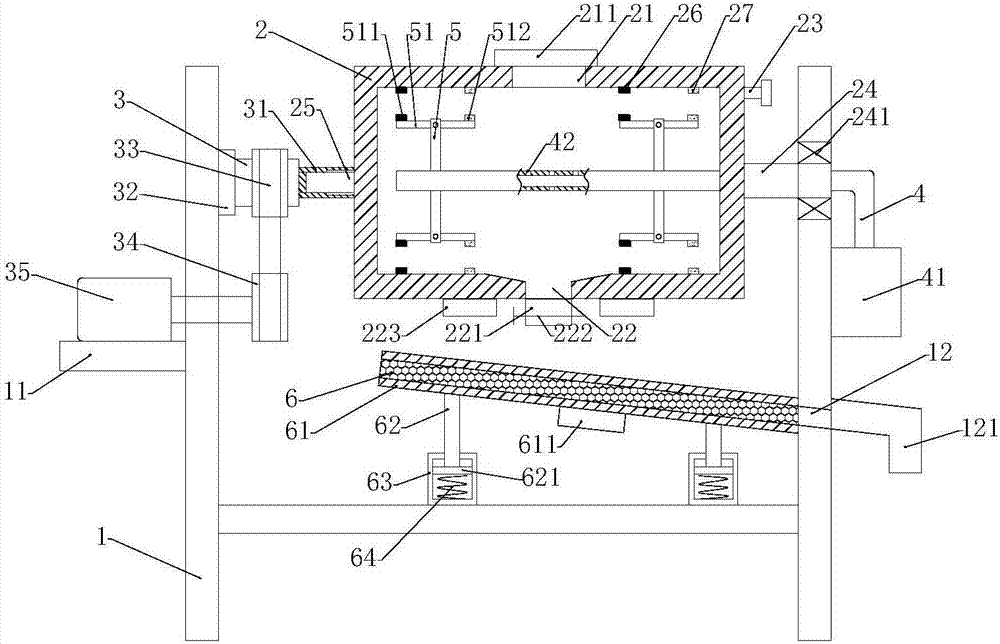

Online detection method for water in continuous grain drying process

ActiveCN103808591AAvoid stabilityAvoid precisionDrying solid materialsDrying machines with local agitationEnvironmental engineeringGrain drying

The invention discloses an online detection method for water in a continuous grain drying process. Water is calculated by using a relation of water and volume weight. The online detection method has the advantages of simple structure, convenience in installation, simplicity in operation, strong interference resisting capacity, good environmental suitability and the like, is suitable for a continuous drying operation of crops such as corns, rice and wheat, and avoids main defects of detection of water in the prior art.

Owner:CHANGCHUN JIDA SCI INSTR EQUIP

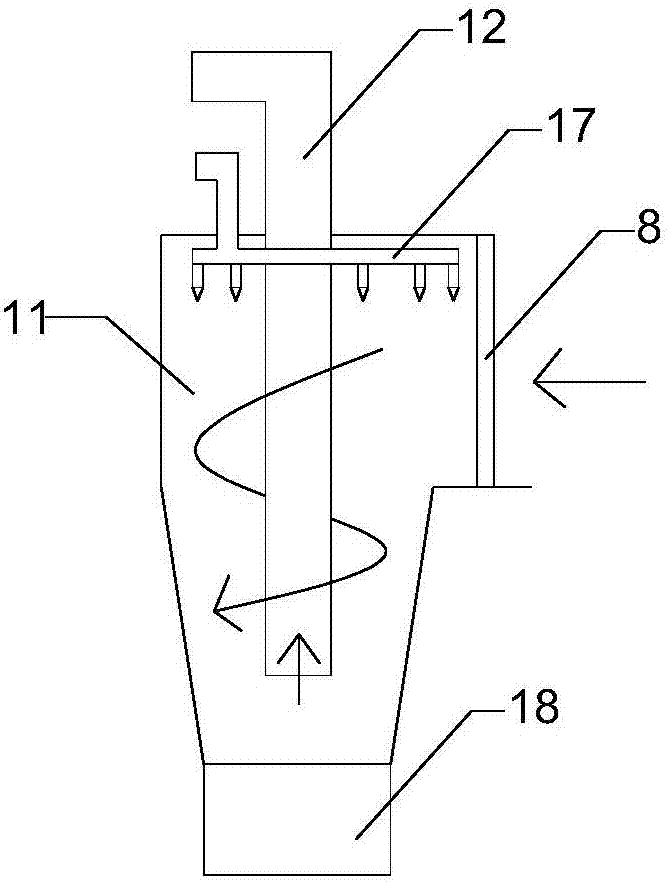

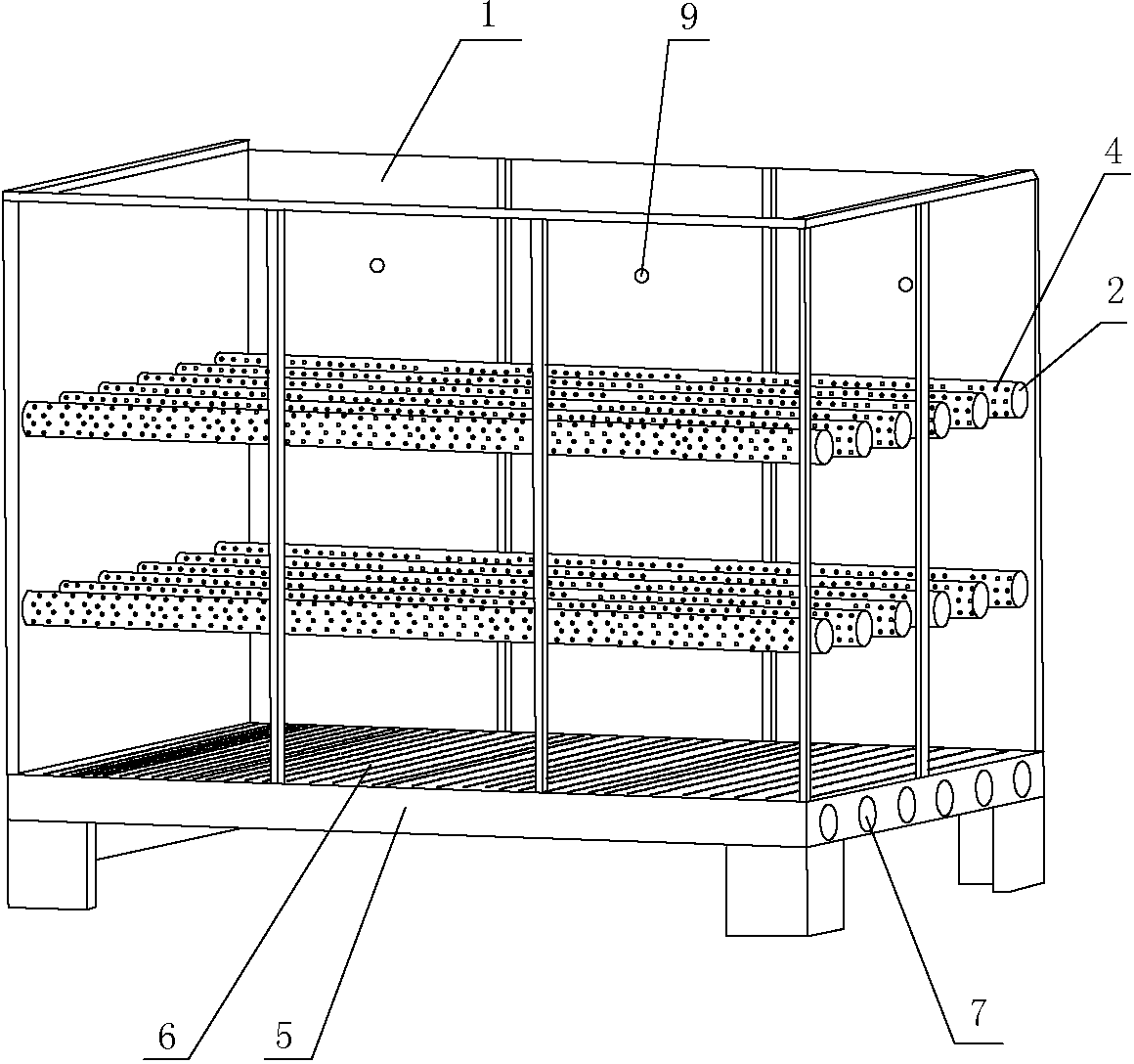

Circulating type grain drying machine

InactiveUS6318000B1Easy to operateShorten drying timeDrying solid materials with heatDrying gas arrangementsEngineeringControl theory

The circulating type grain drying machine is provided in which, at the grain filling operation, a controller causes a first heated air generator to operate and a second heated air generator to stop operating, and also causes, according to the detected values of the outside air humidity from an outside air humidity detector, an airflow control section to operate so as to change the quantity of the airflow by an air exhaust section. Also, at the drying operation, the controller controls the first heated air generator and controls the temperature of the heated air supplied into each heating pipe according to the detected values of the grain water content value, and controls the second heated air generator and controls the temperature of the temperature of the heated air supplied into the drying section according to the detected values of the grain water content values and the grain filling amount.

Owner:SATAKE CORP

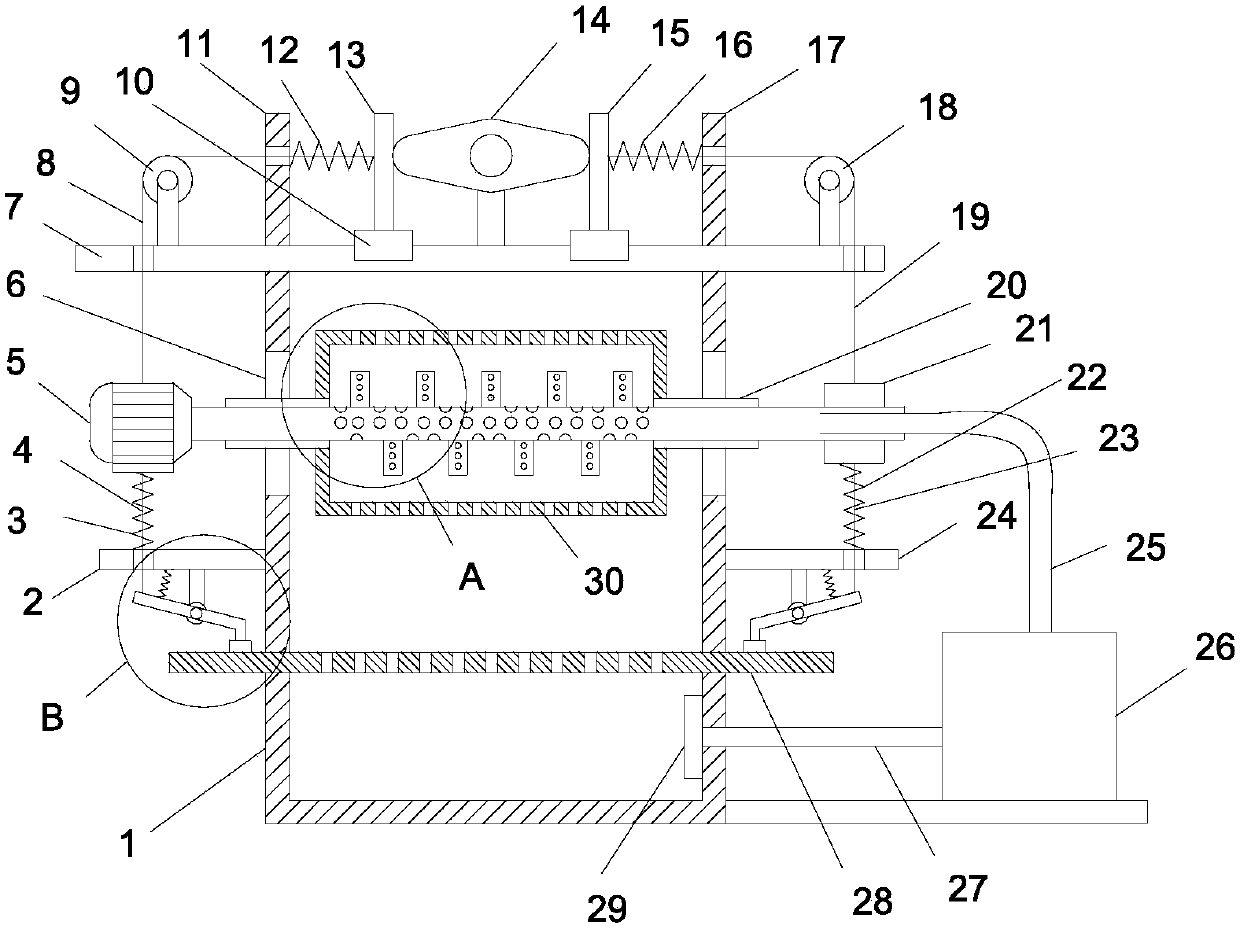

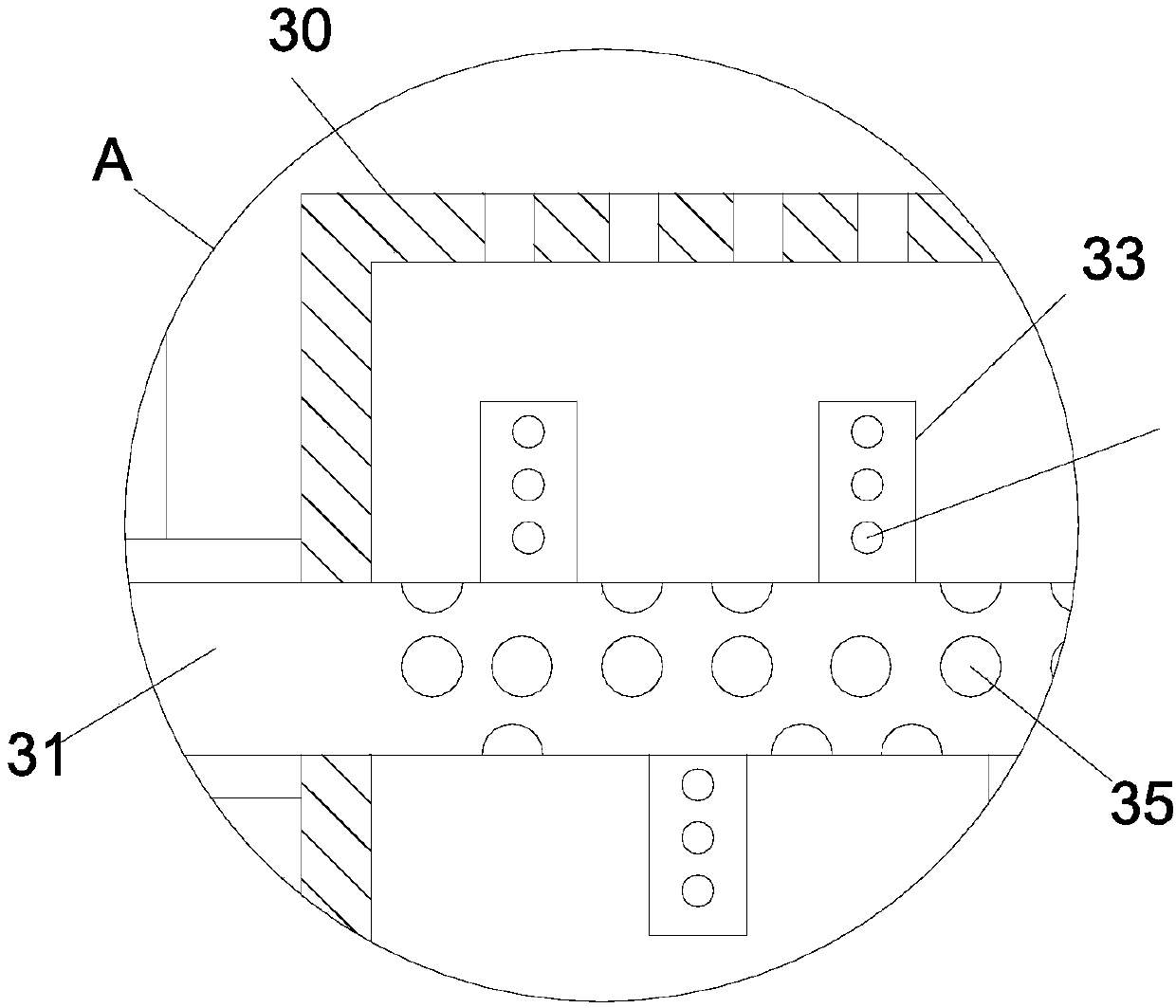

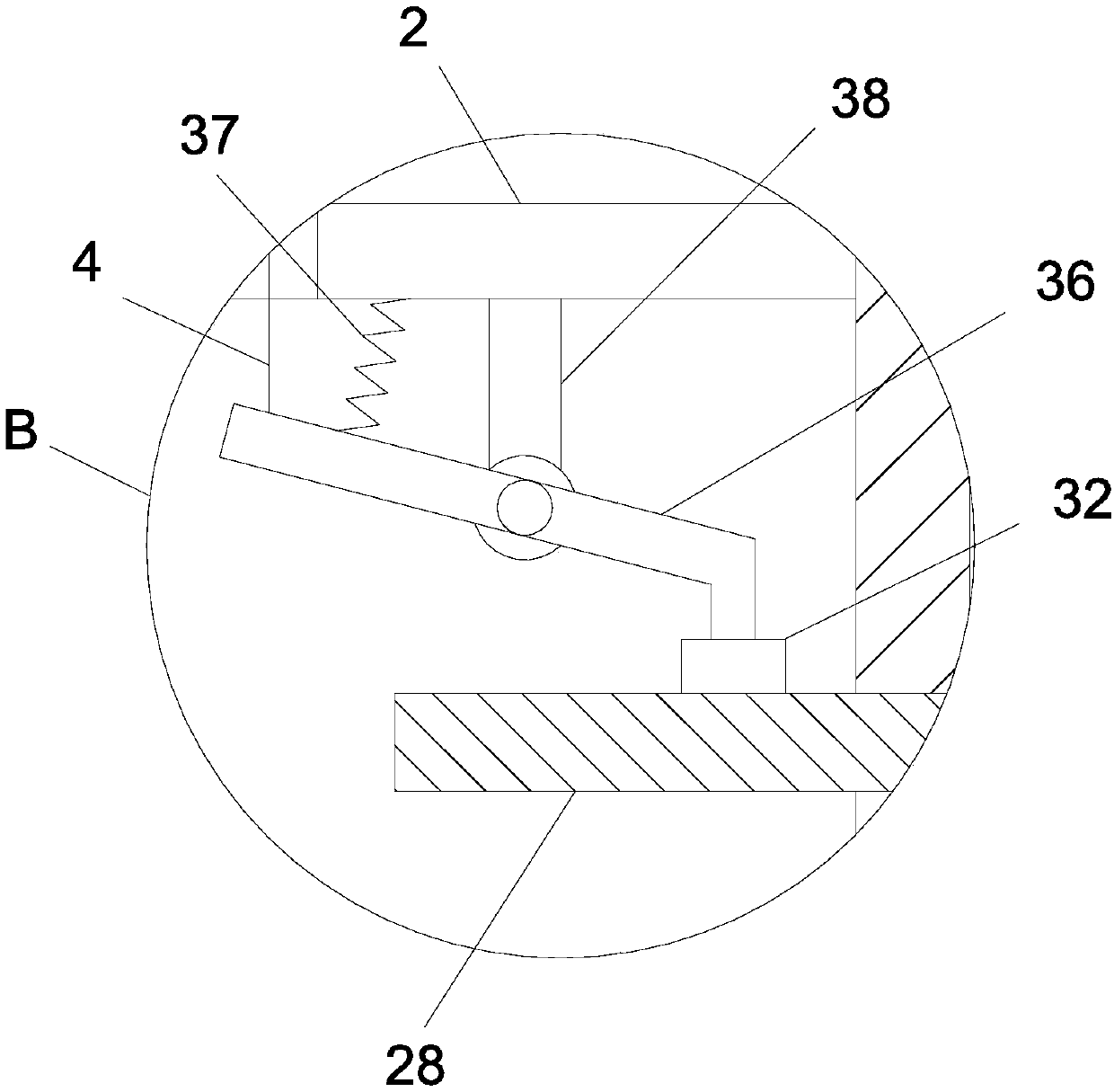

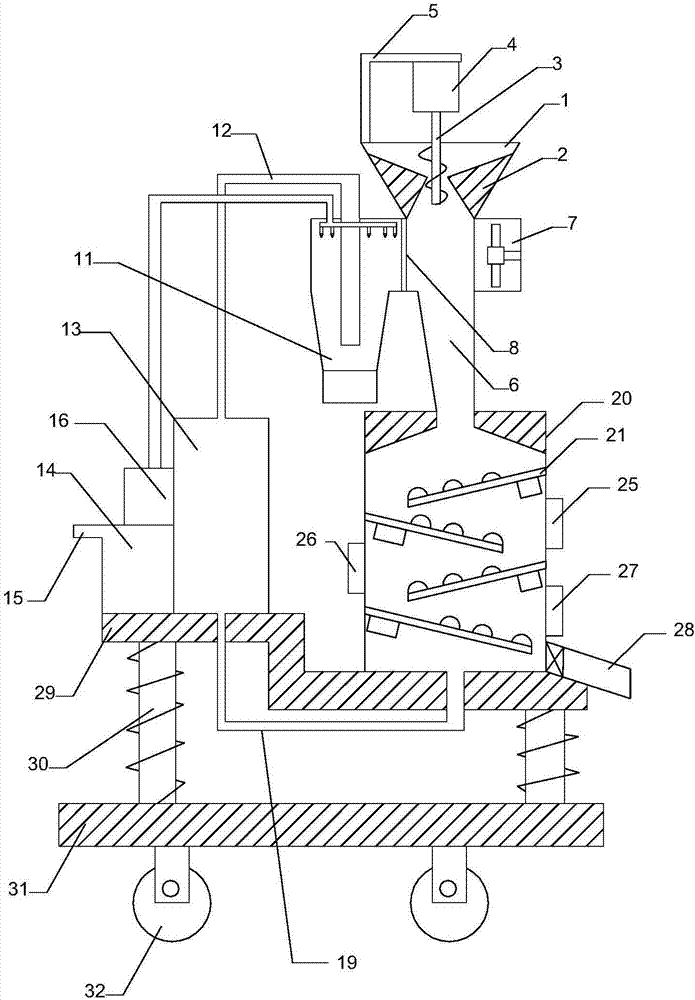

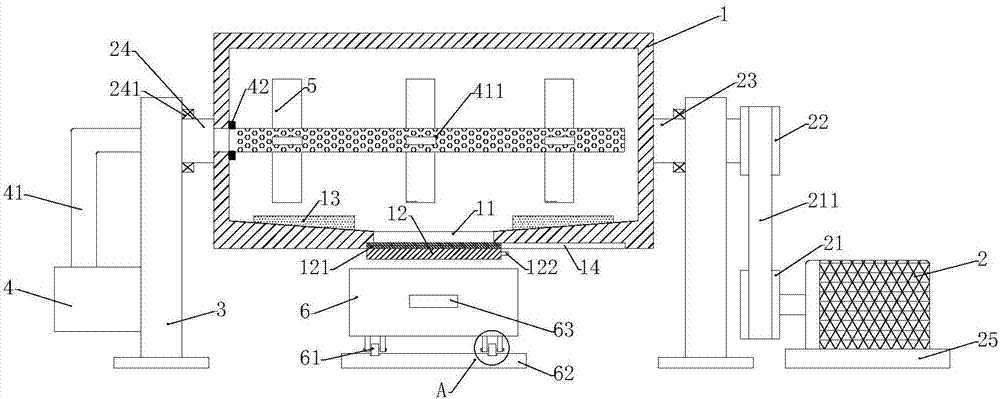

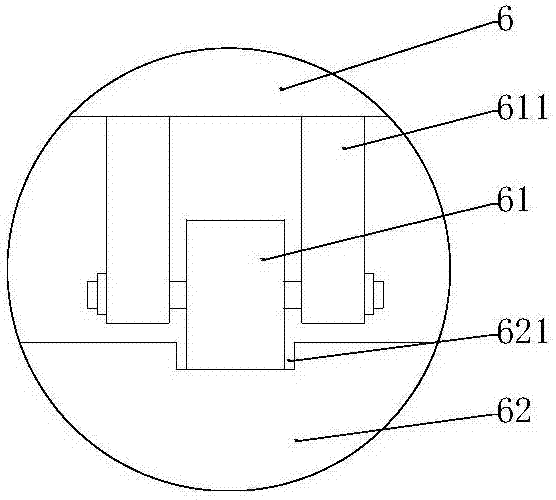

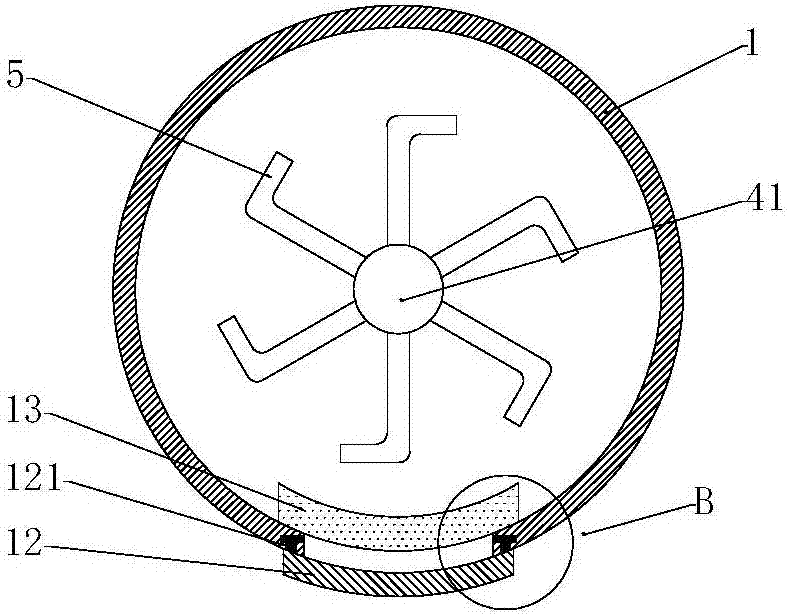

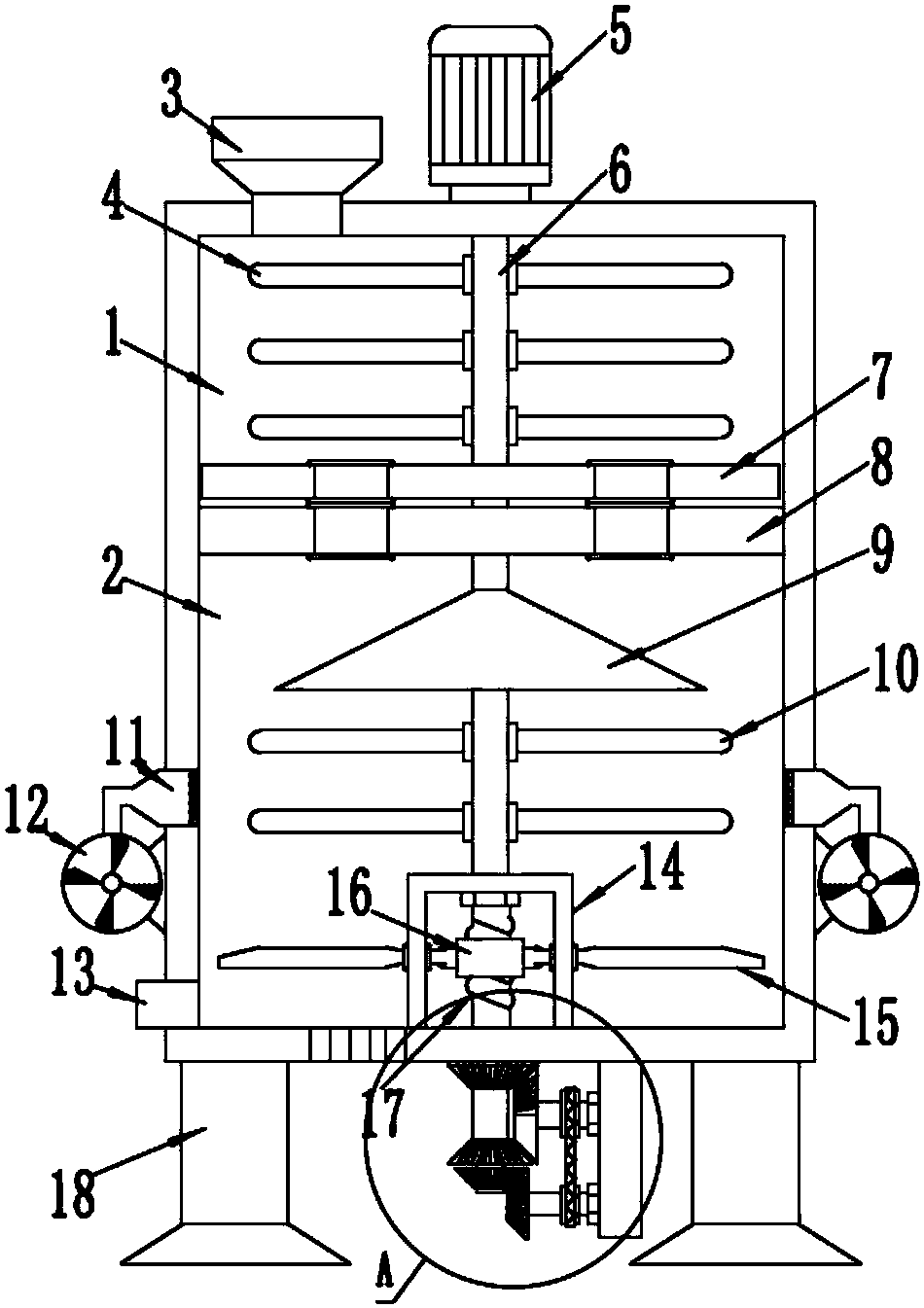

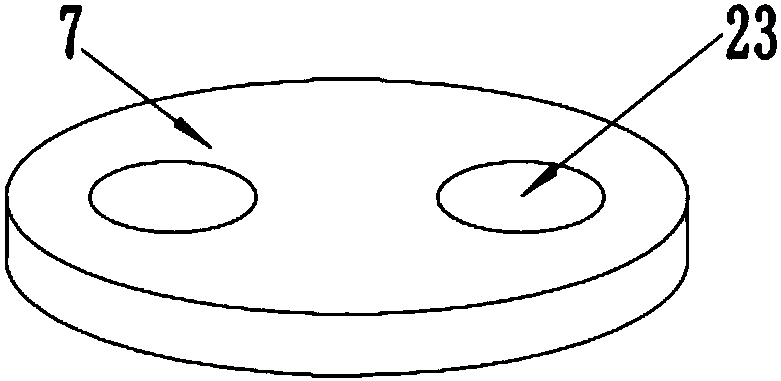

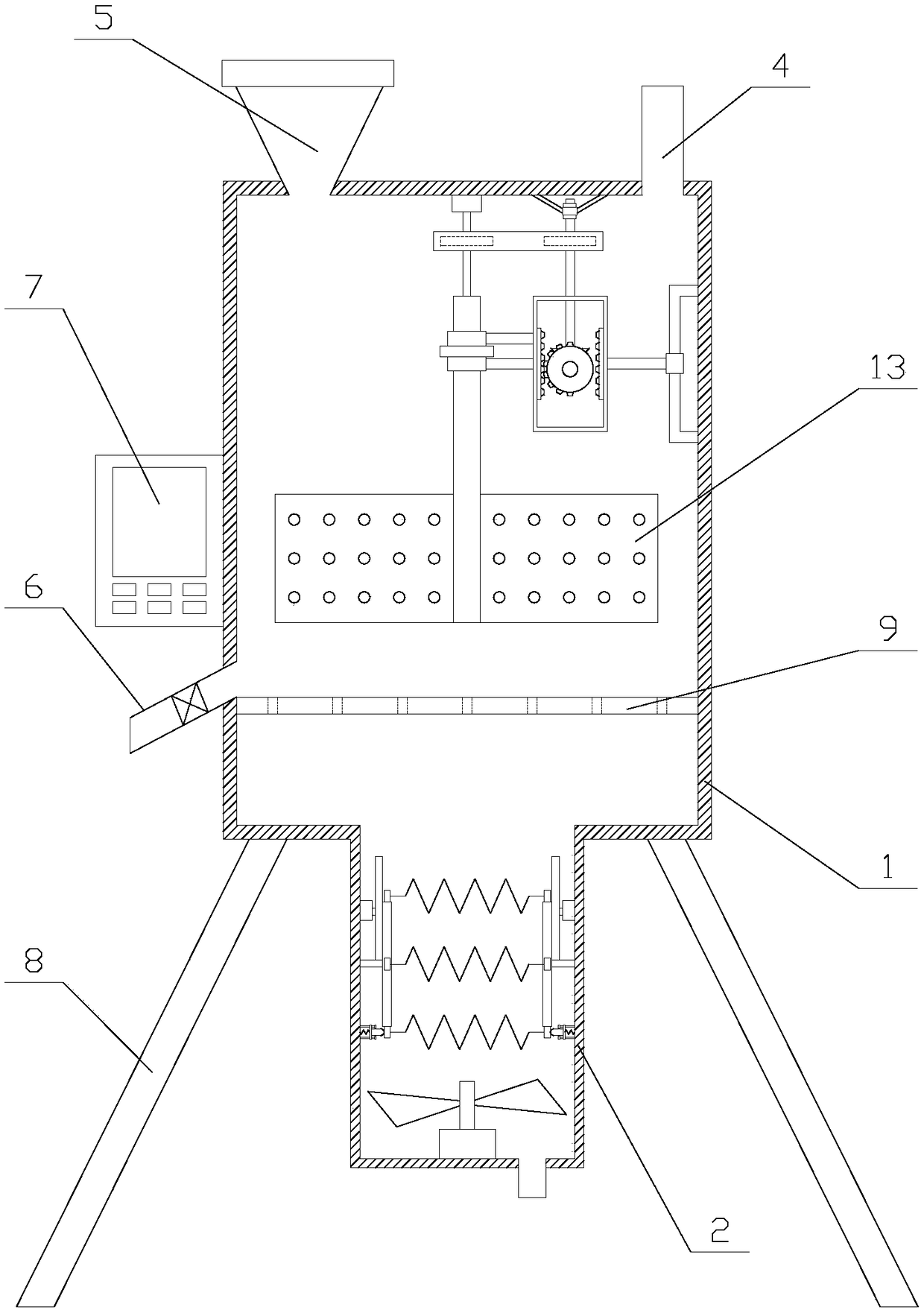

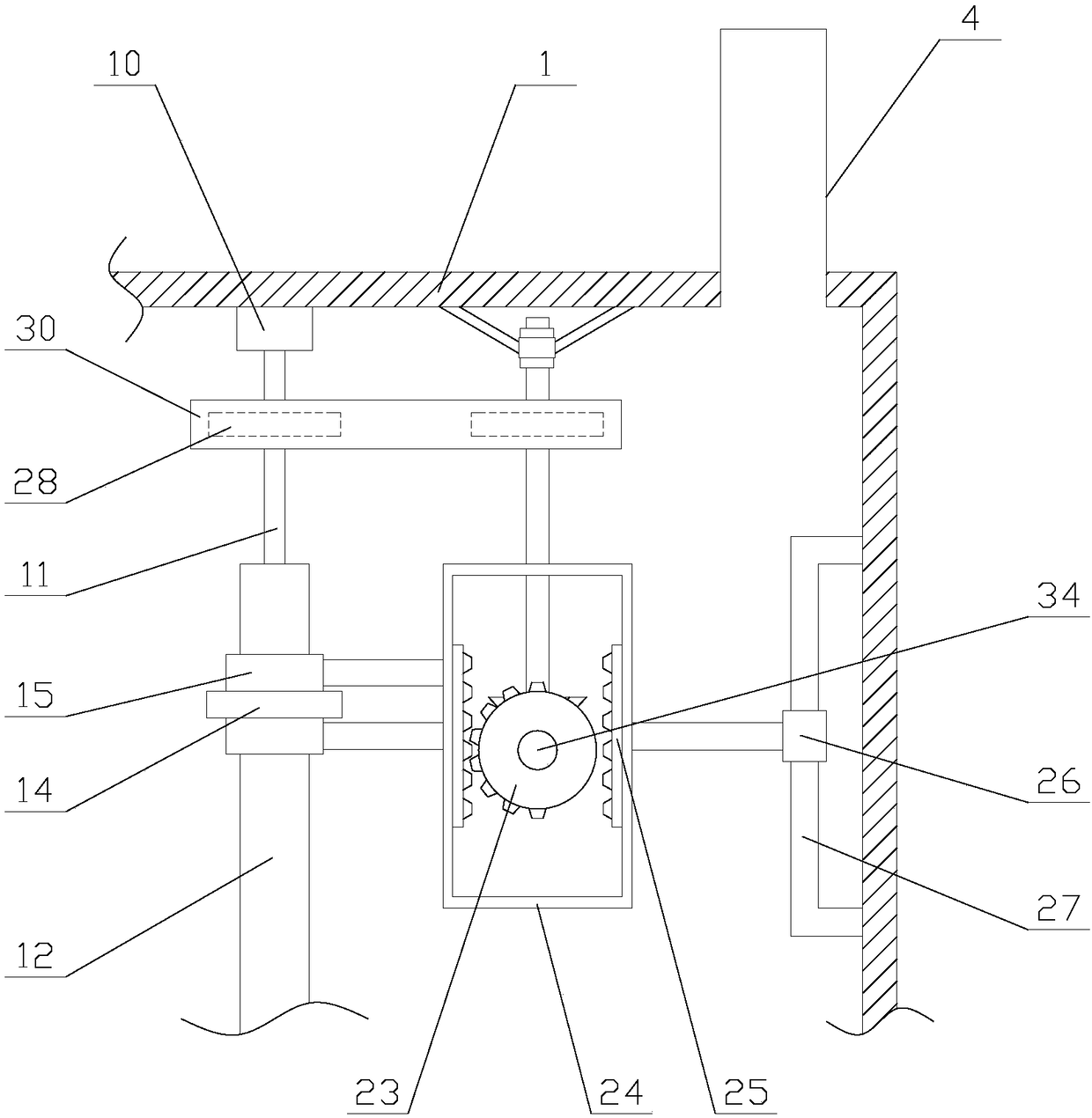

Grain screening and drying device for agriculture

The invention discloses an agricultural grain screening and drying device, which comprises a drying chamber, a limit chute is symmetrically arranged on the left and right side walls of the drying chamber, a drying screen cylinder is horizontally arranged in the drying chamber, and a right end of a rotating nozzle is provided. A limit bearing seat is sleeved; a horizontal plate is arranged on the drying chamber, a left vertical plate and a right vertical plate are symmetrically arranged on the horizontal plate, a driving device is installed on the elliptical cam, and left limit plates are respectively arranged on the left and right sides of the elliptical cam and the right limit plate, the bottom ends of the left limit plate and the right limit plate are both provided with guide sliders slidingly connected with the horizontal plate; both ends of the screen plate extend to the outside of the drying chamber, the first extension plate and the second extension plate The bottom surface is provided with a boom, and the boom is rotatably provided with a swing rod. The structure of the invention is ingenious. The rotating nozzle is driven by the driving motor and drives the stirring block to turn and stir the grains, so that the grains are more dispersed. The jetted hot air dries the grains by wind, which greatly improves the drying effect of the grains.

Owner:张宇霞

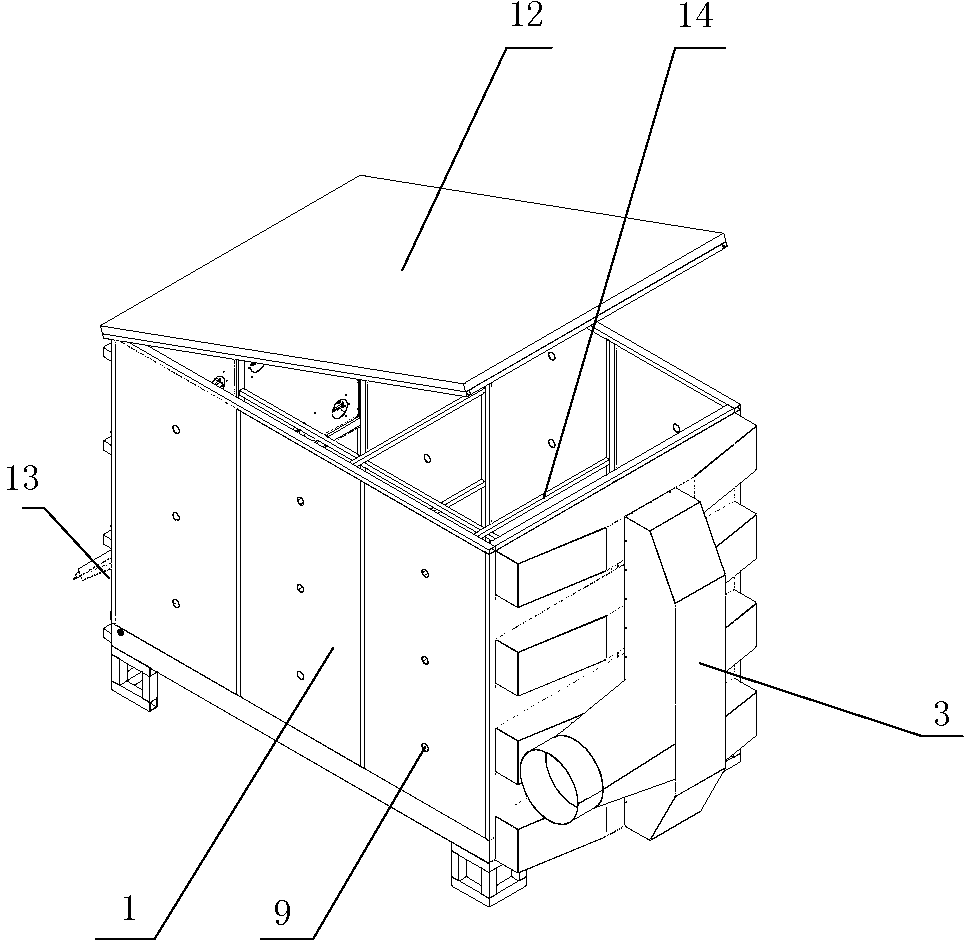

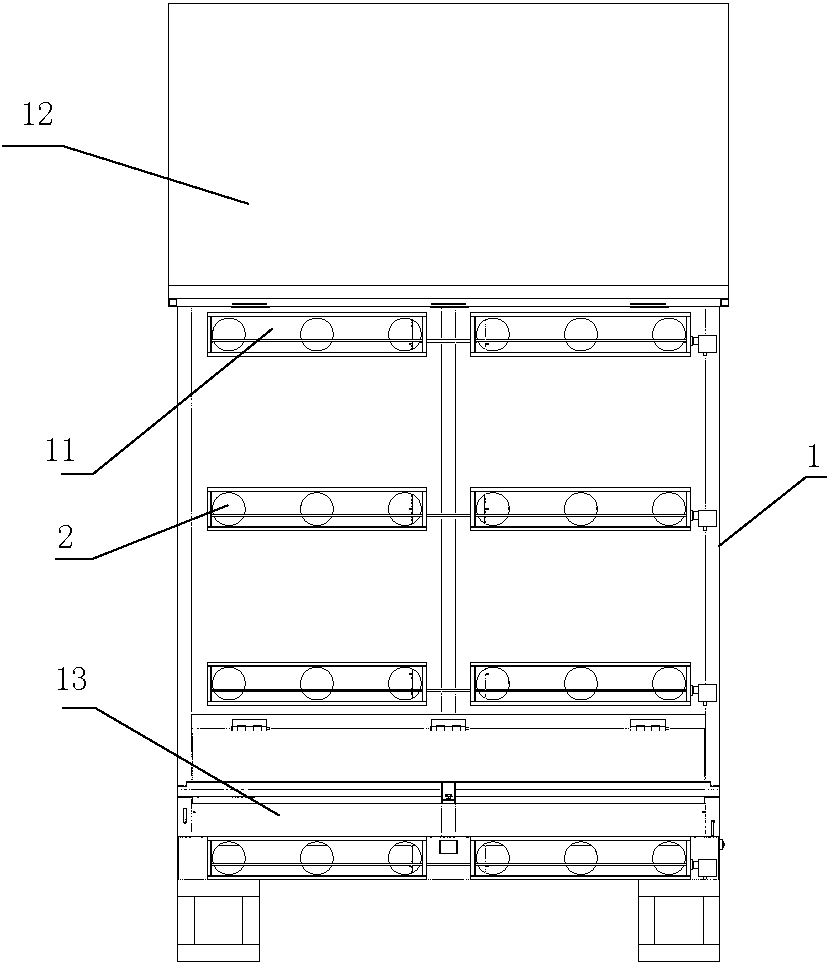

High-efficiency energy-saving grain drying machine and drying method

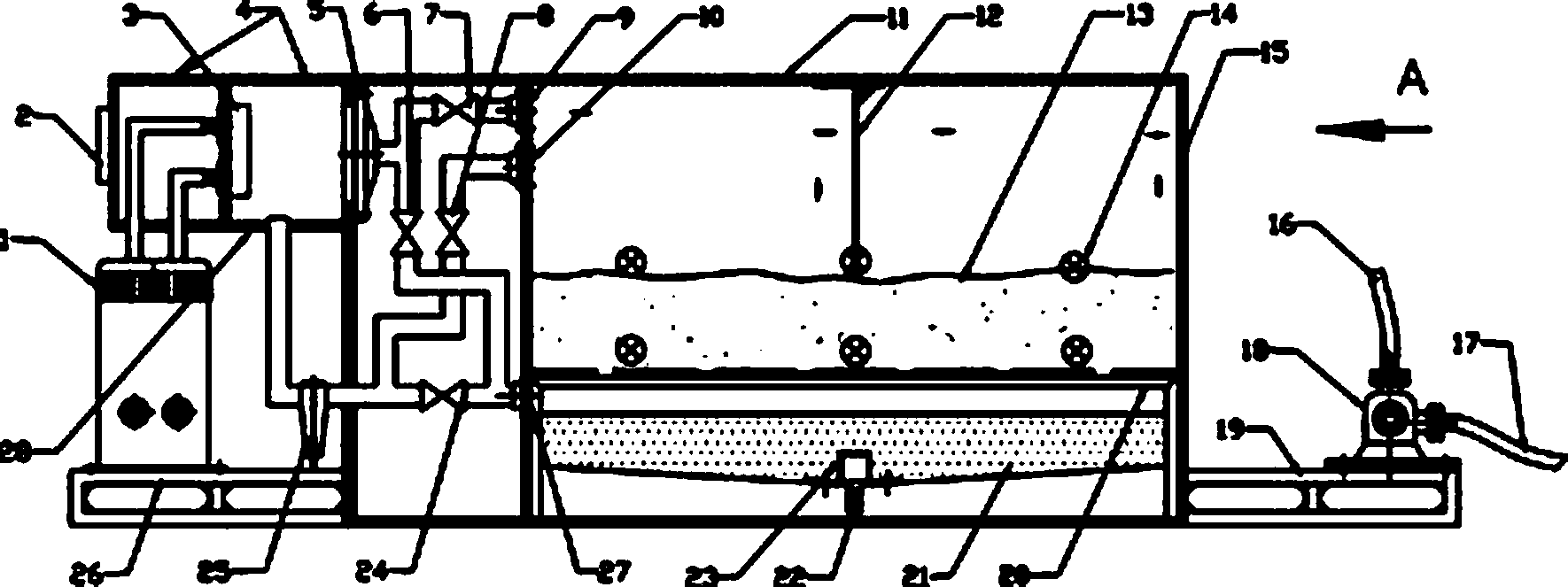

InactiveCN103749670AReduce drying costsHigh degree of intelligenceFood processingClimate change adaptationProcess engineeringMoisture sensor

The invention discloses a high-efficiency energy-saving grain drying machine and a drying method. The drying machine adopts a brand-new heat source design provided by an air energy heat pump. The high-efficiency energy-saving grain drying machine comprises an air energy dehumidifying pump, a main room body, an auxiliary room body, a heat exchanger, a fan, an intelligent controller, electromagnetic valves, a temperature-humidity sensor, a stacking bed, a dehumidifying mechanism and a cabin door; the intelligent controller is used for transmitting a multi-point average humidity-temperature signal inside a room obtained by the temperature-humidity sensor, and each electromagnetic valve is electrically connected with the intelligent controller so as to realize the intelligent operation of the drying machine. The high-efficiency energy-saving grain drying machine and the drying method are used for drying the grain, so that the characteristics of high efficiency, energy conservation, intelligentization in operation and good grain quality can be realized.

Owner:LONGYAN CHENGDE AGRI MACHINERY

Self-vibrating grain drying and sieving equipment

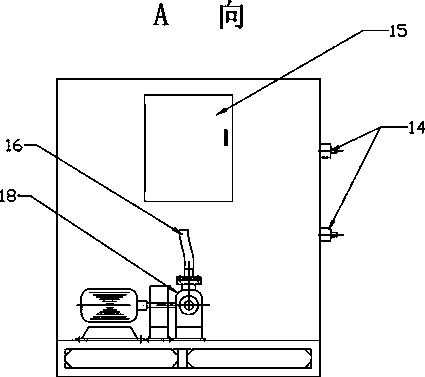

InactiveCN107339878AImprove the vibration effectPrevent fallingSievingScreeningEngineeringVacuum pump

The invention discloses self-vibrating grain drying and sieving equipment. The equipment comprises a shell, a support and a condensation chamber; the support is arranged outside the shell, sliding blocks are fixedly connected to the middle of the outside of the shell, sliding grooves are formed in both sides of the support, and the sliding blocks are connected with the sliding grooves in a sliding mode; connecting plates are arranged at the upper ends of the sliding grooves, the connecting plates are fixedly connected with the support, and floating devices are arranged between the connecting plates and the sliding blocks; a first sieving net and a second sieving net are fixedly connected to the inner side wall of the shell from top to bottom in sequence, a dehumidification pipe is arranged at the upper end of the shell, a vacuum pump is connected to the middle of the dehumidification pipe, one end of the dehumidification pipe is communicated with the interior of the shell, and the other end of the dehumidification pipe is connected with a condensation pipe in the condensation chamber. According to the self-vibrating grain drying and sieving equipment, the structure is simple, the design is reasonable, sieving of grain is completed through self-vibrating of the shell, and the sieving quality and efficiency are improved; meanwhile, drying equipment is added, the functionality of the device is enhanced, and rapid dehumidification can be conducted, so that the drying efficiency is improved.

Owner:俞纪洪

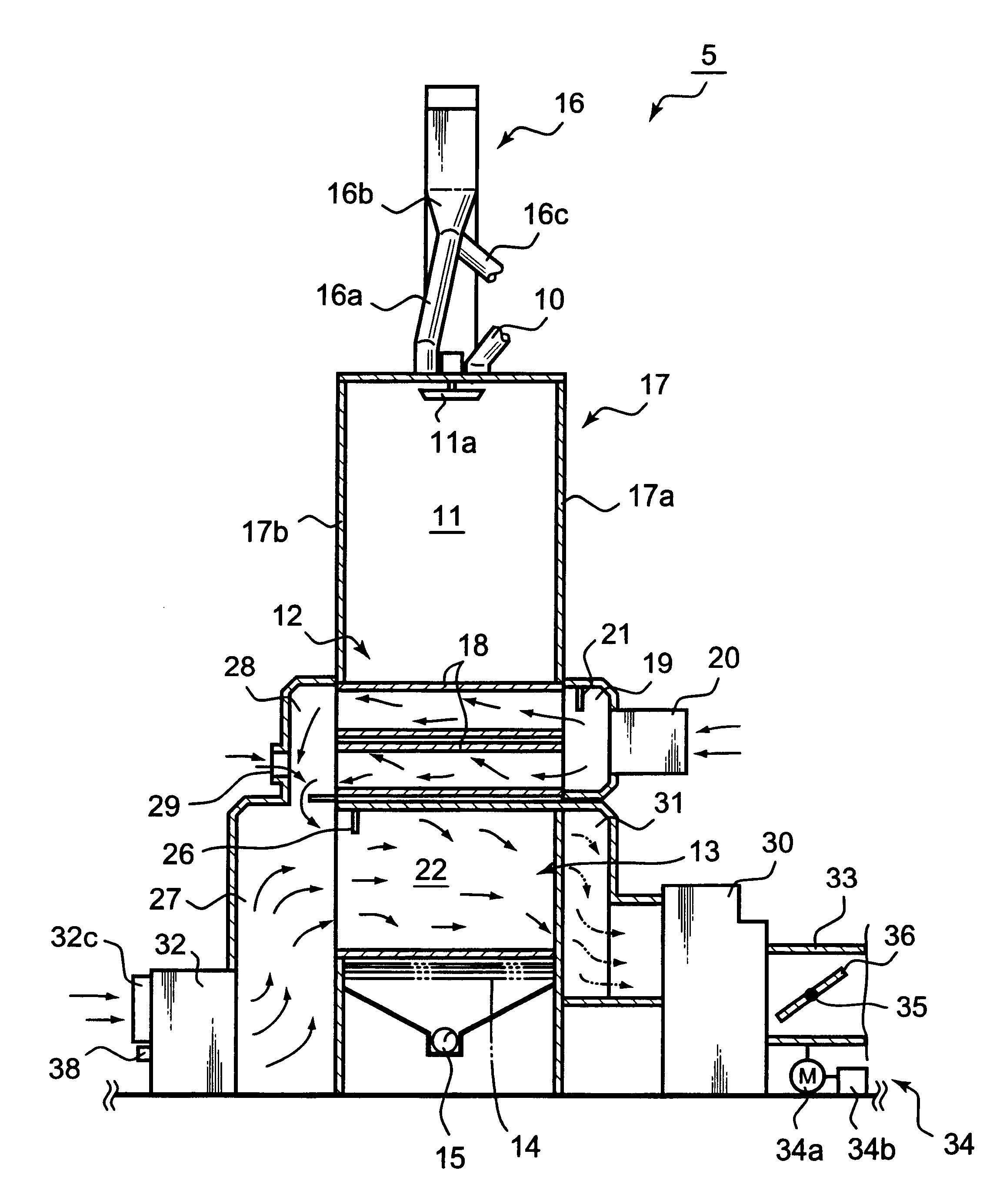

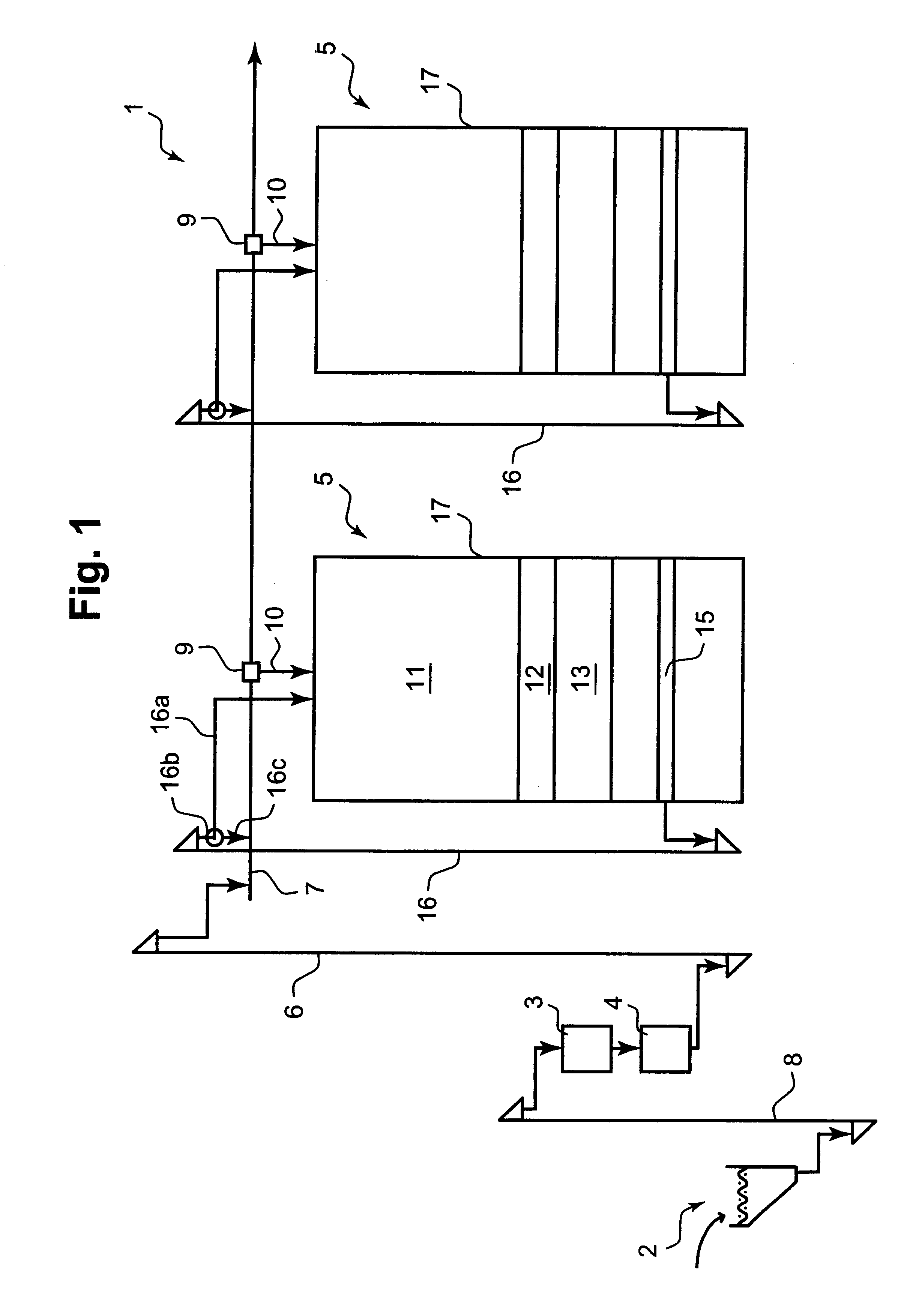

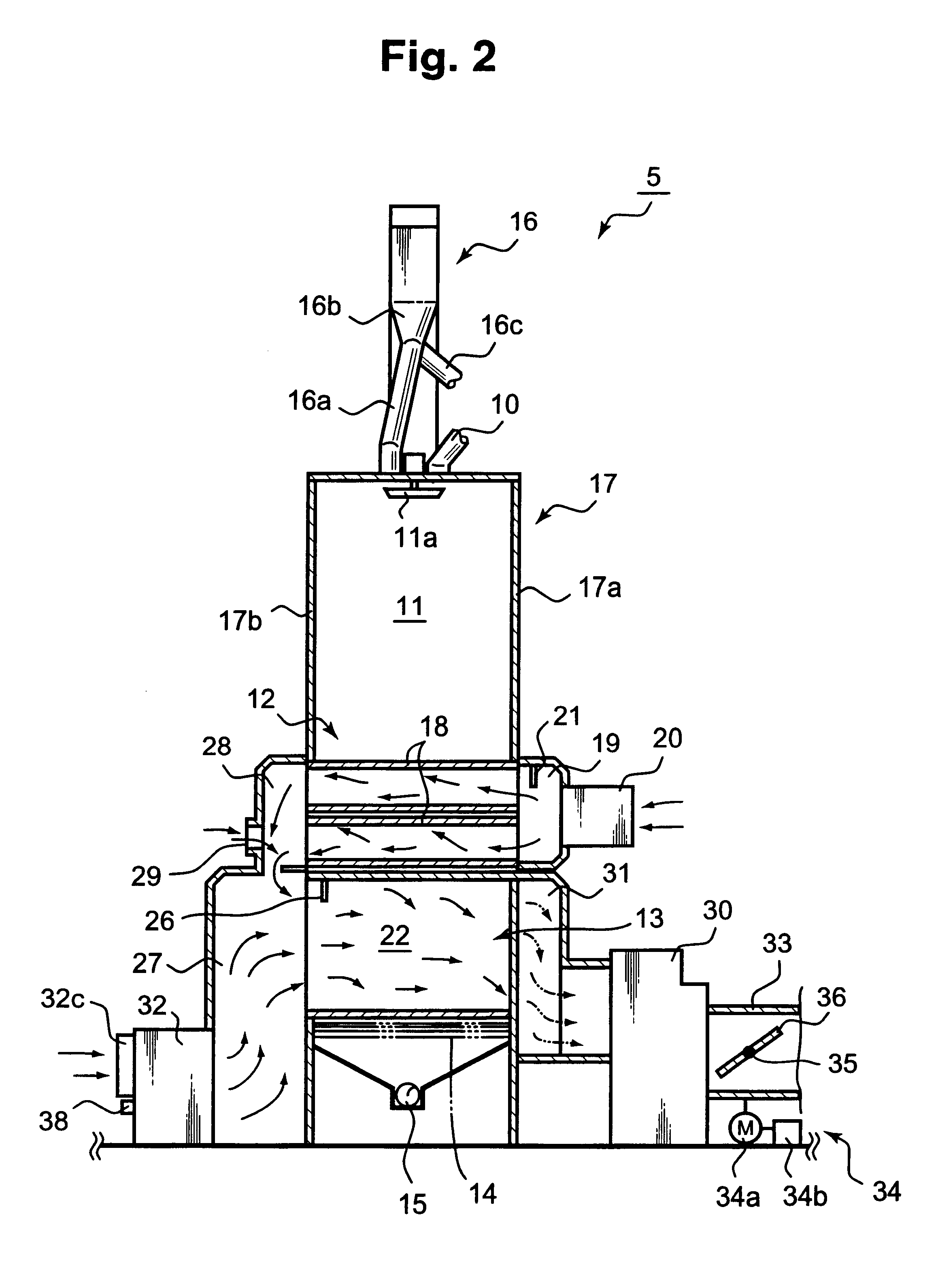

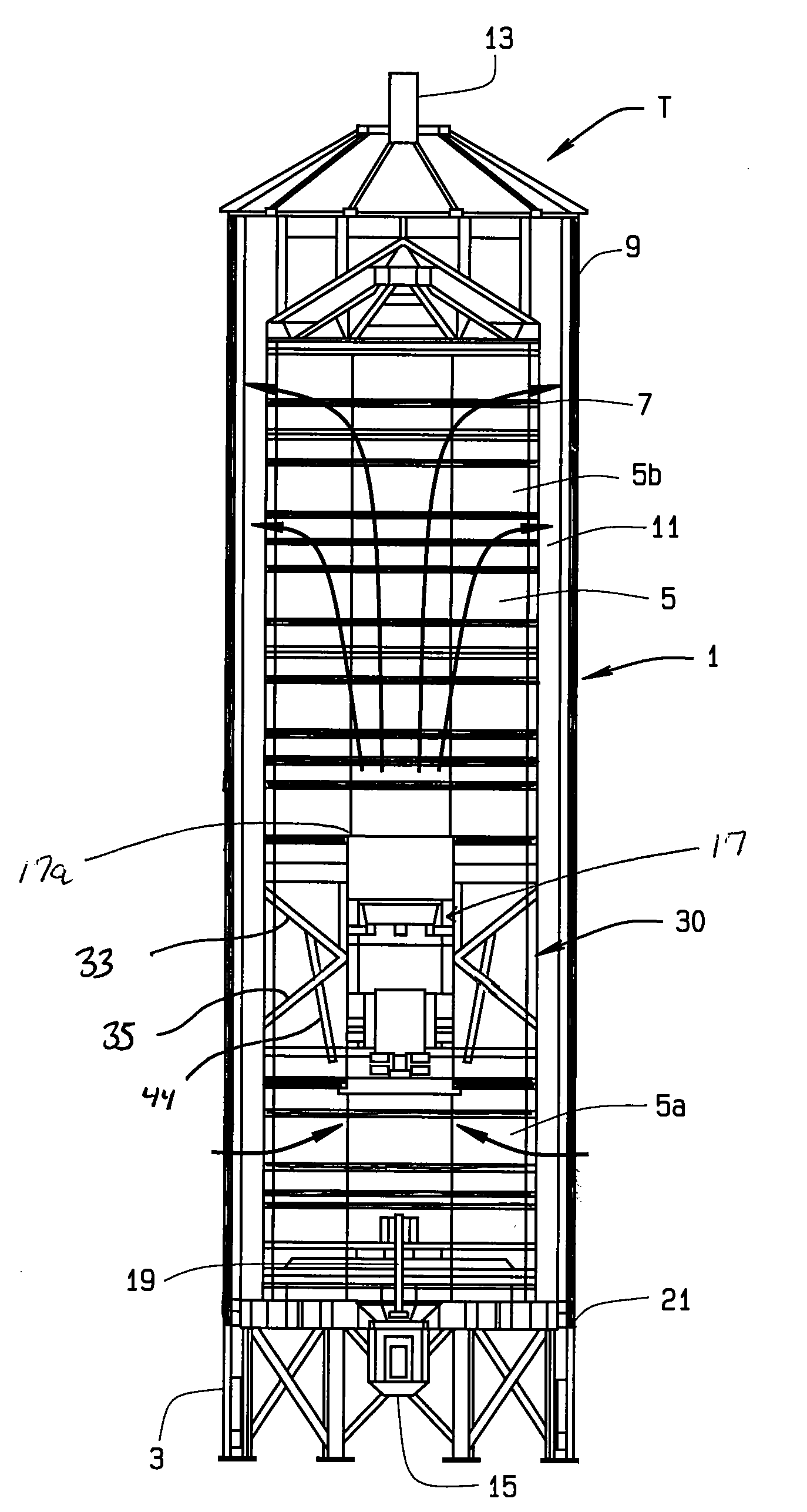

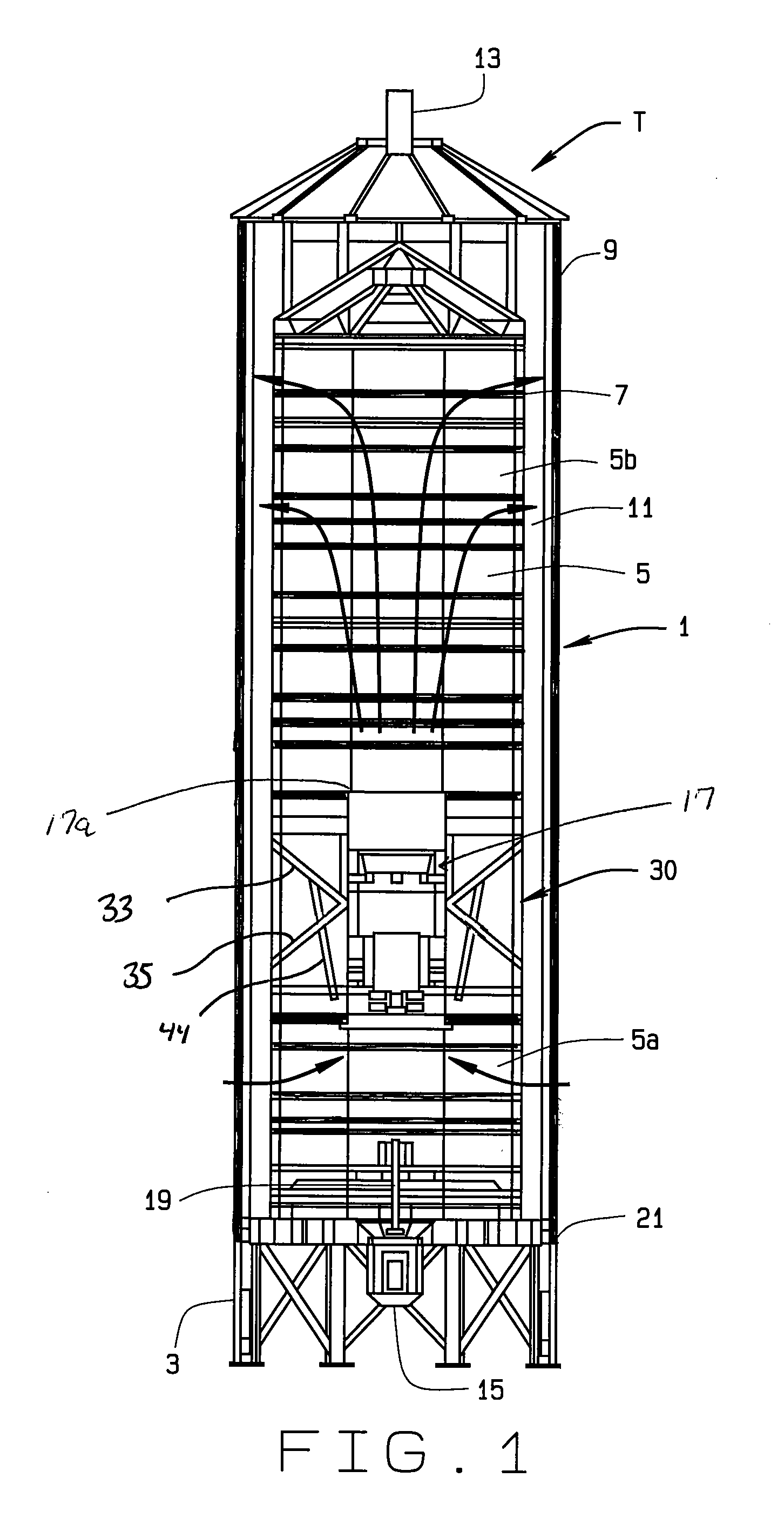

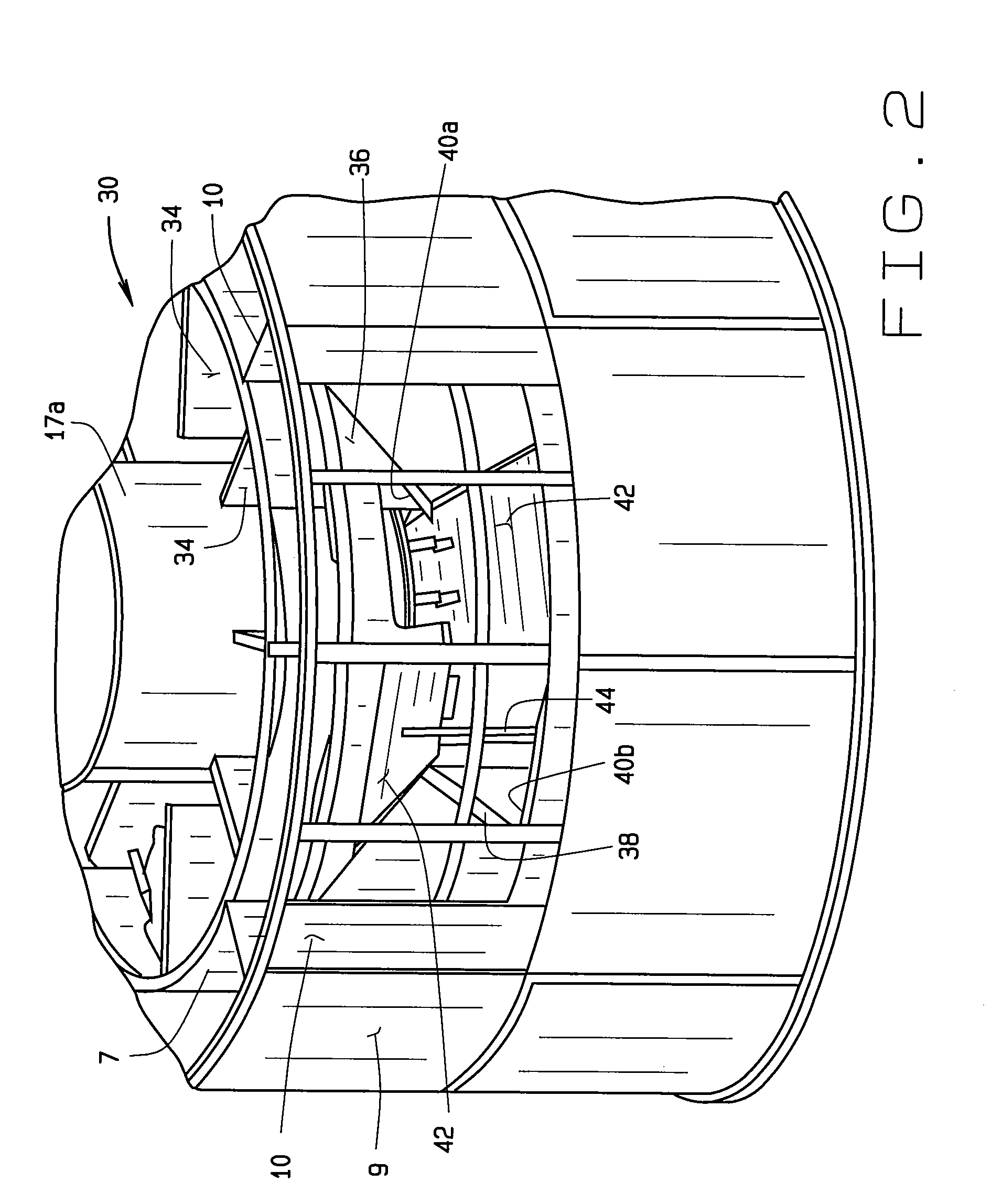

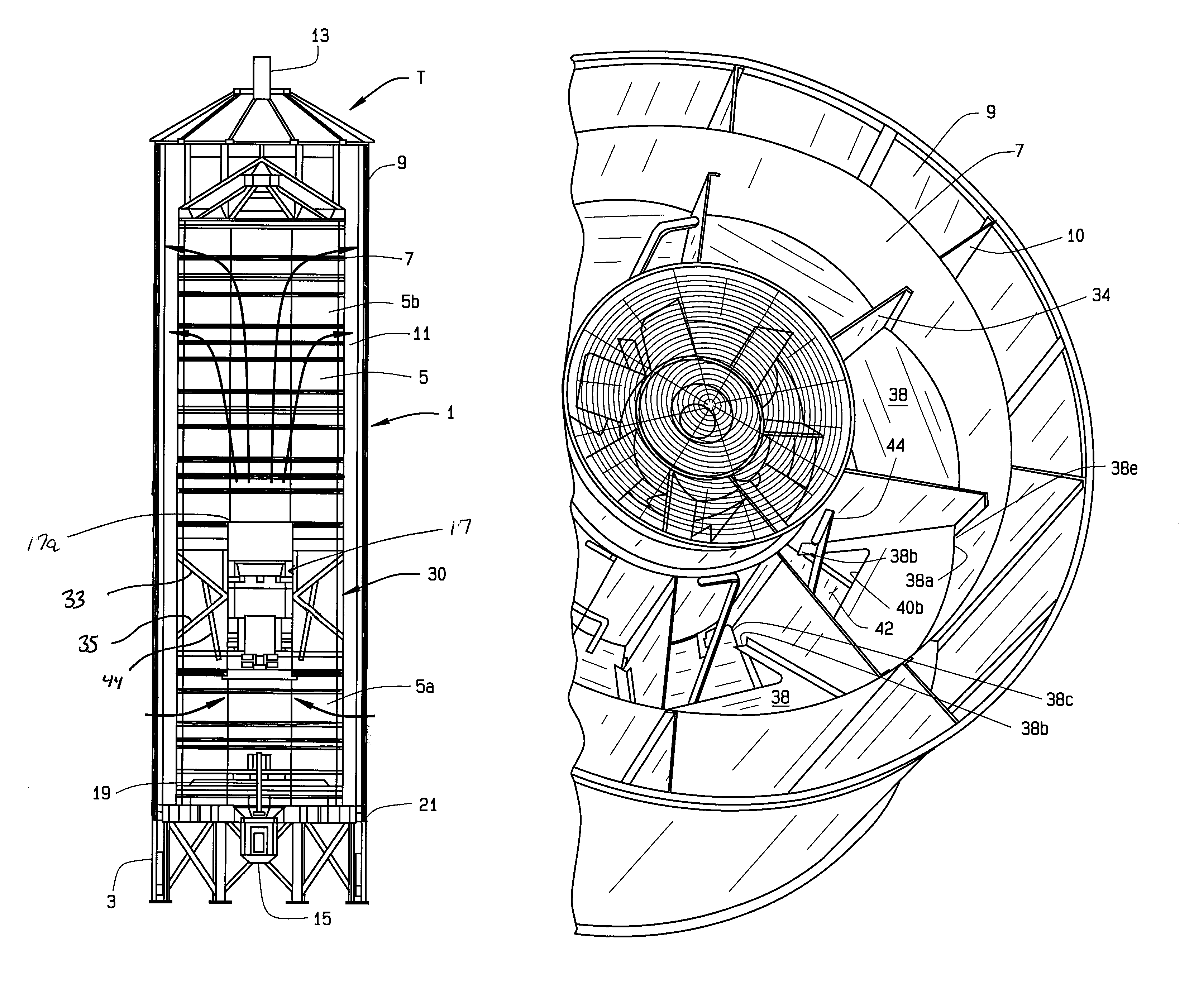

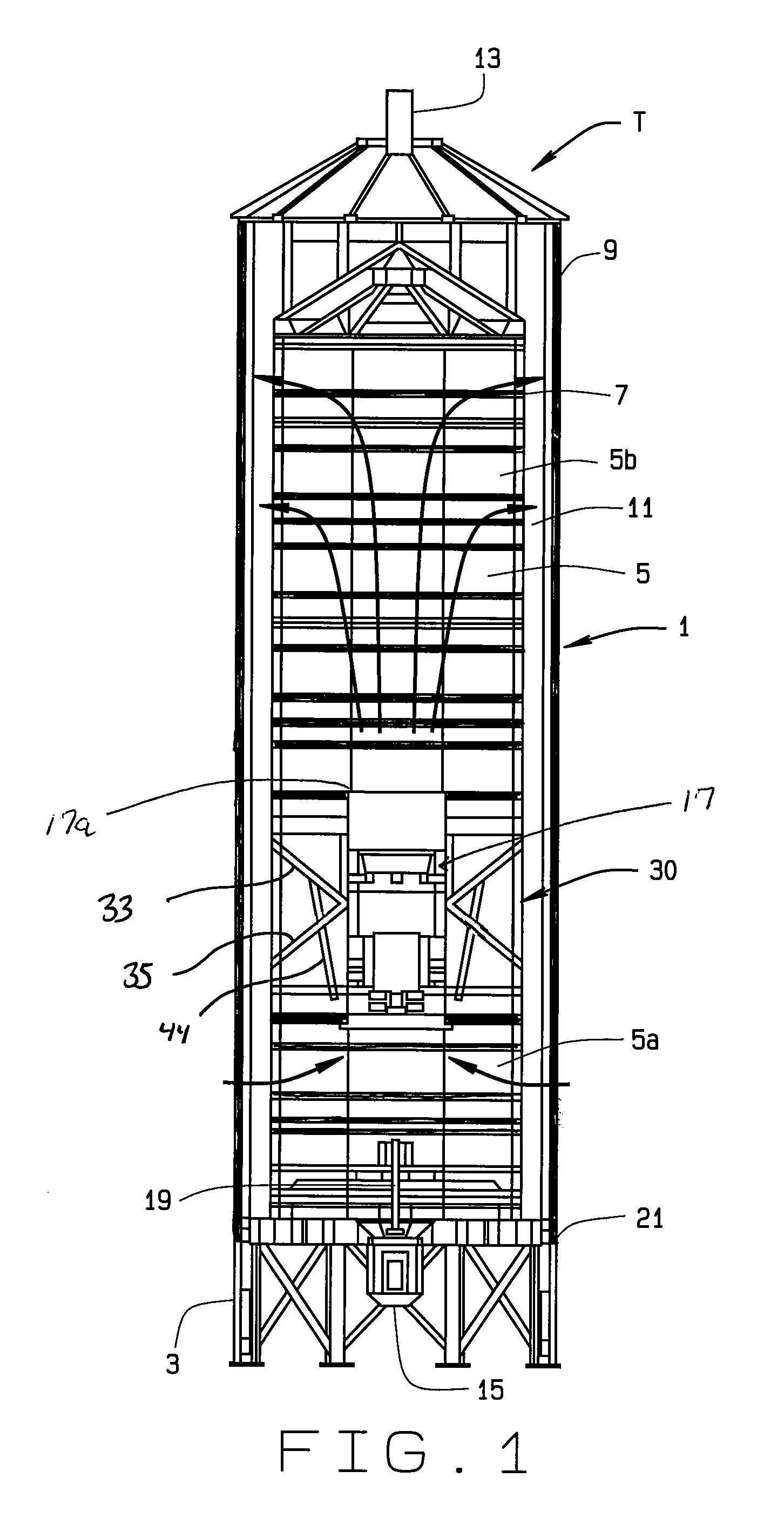

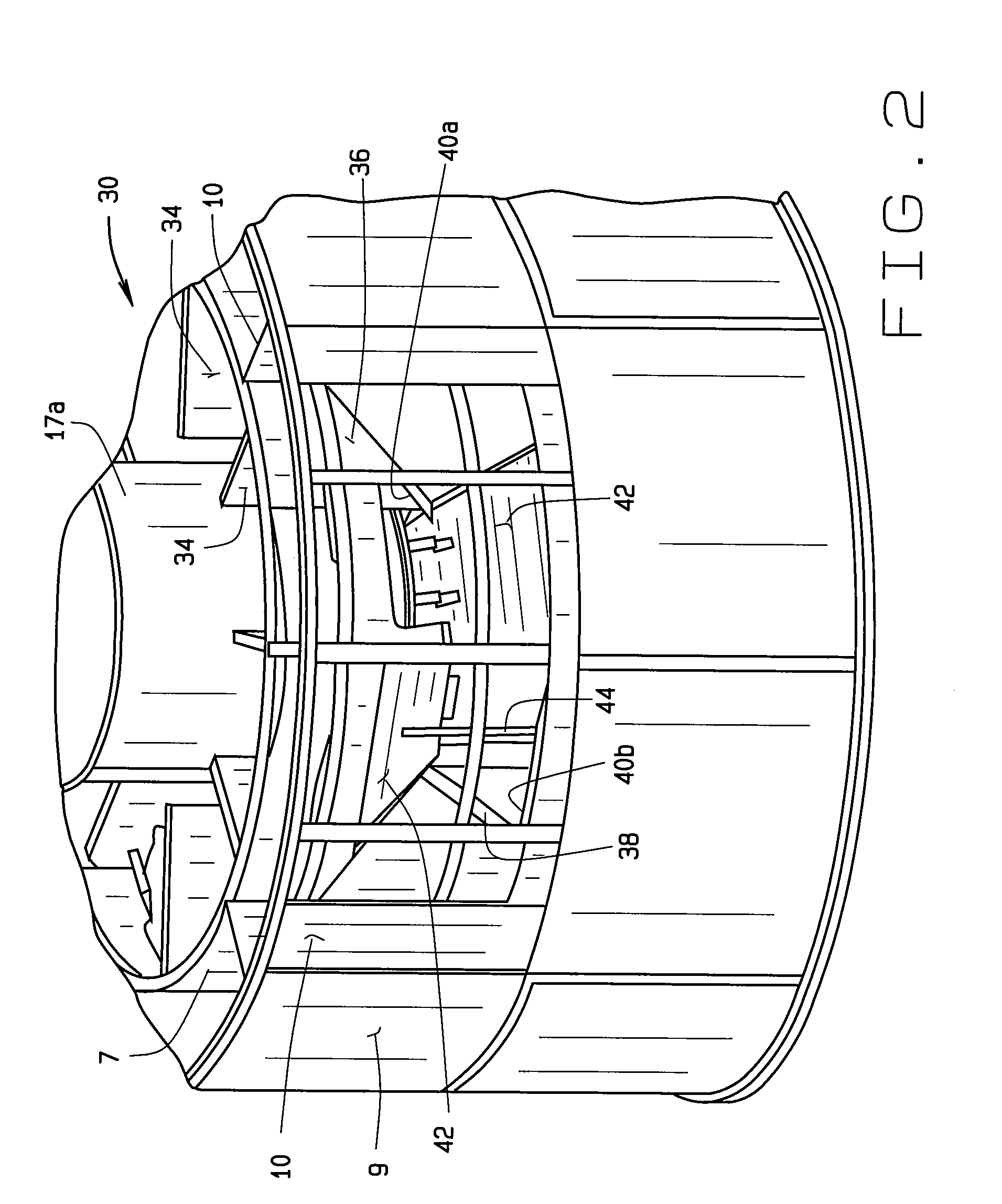

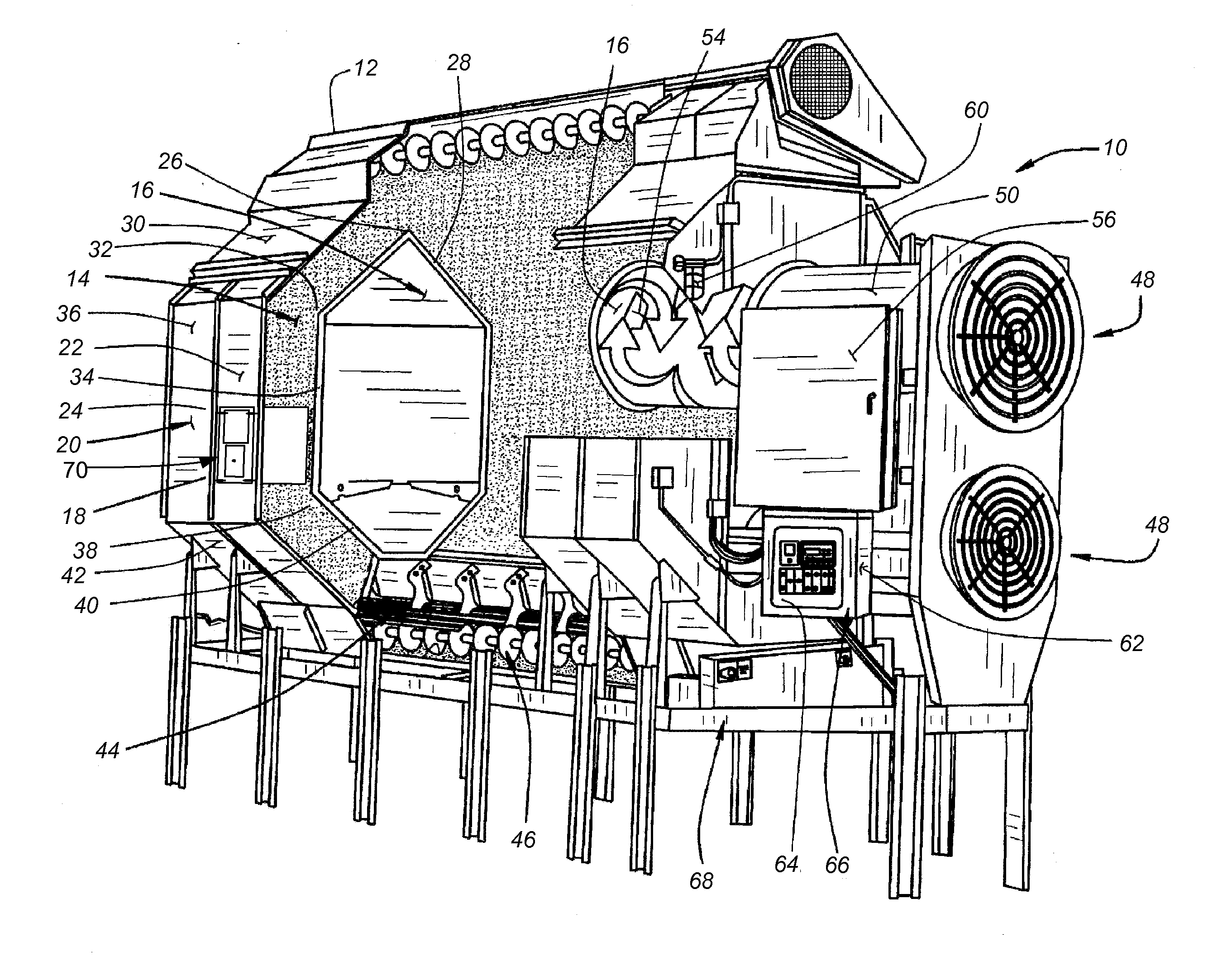

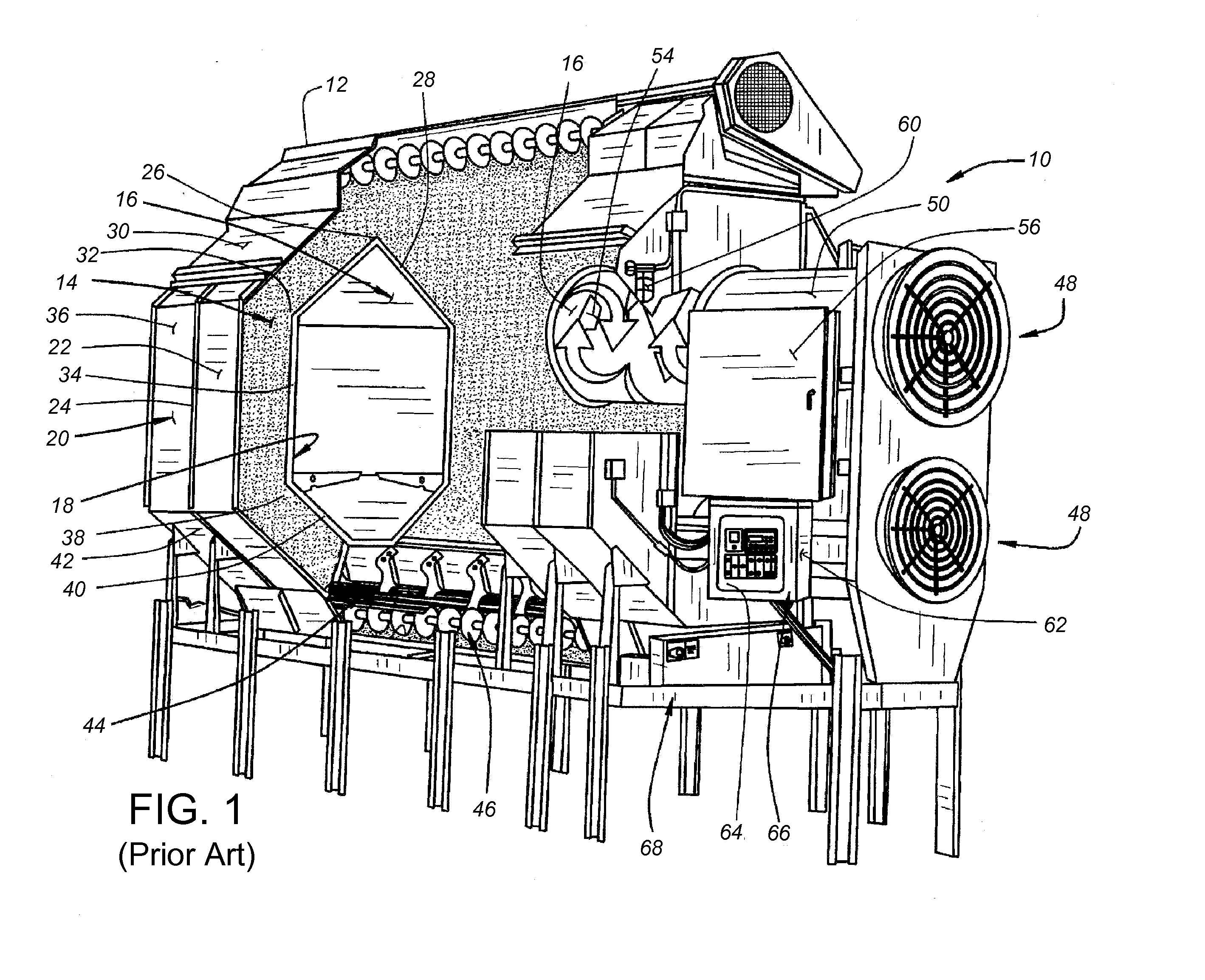

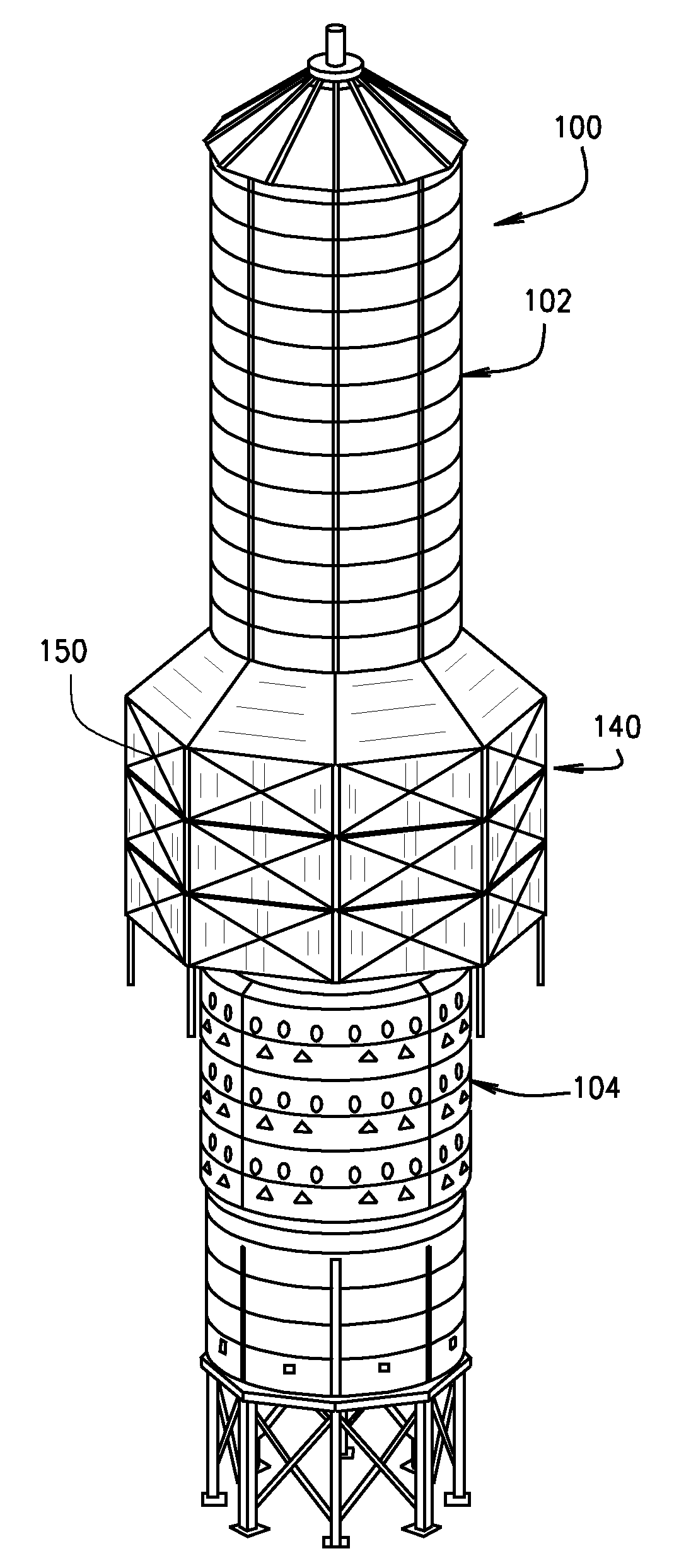

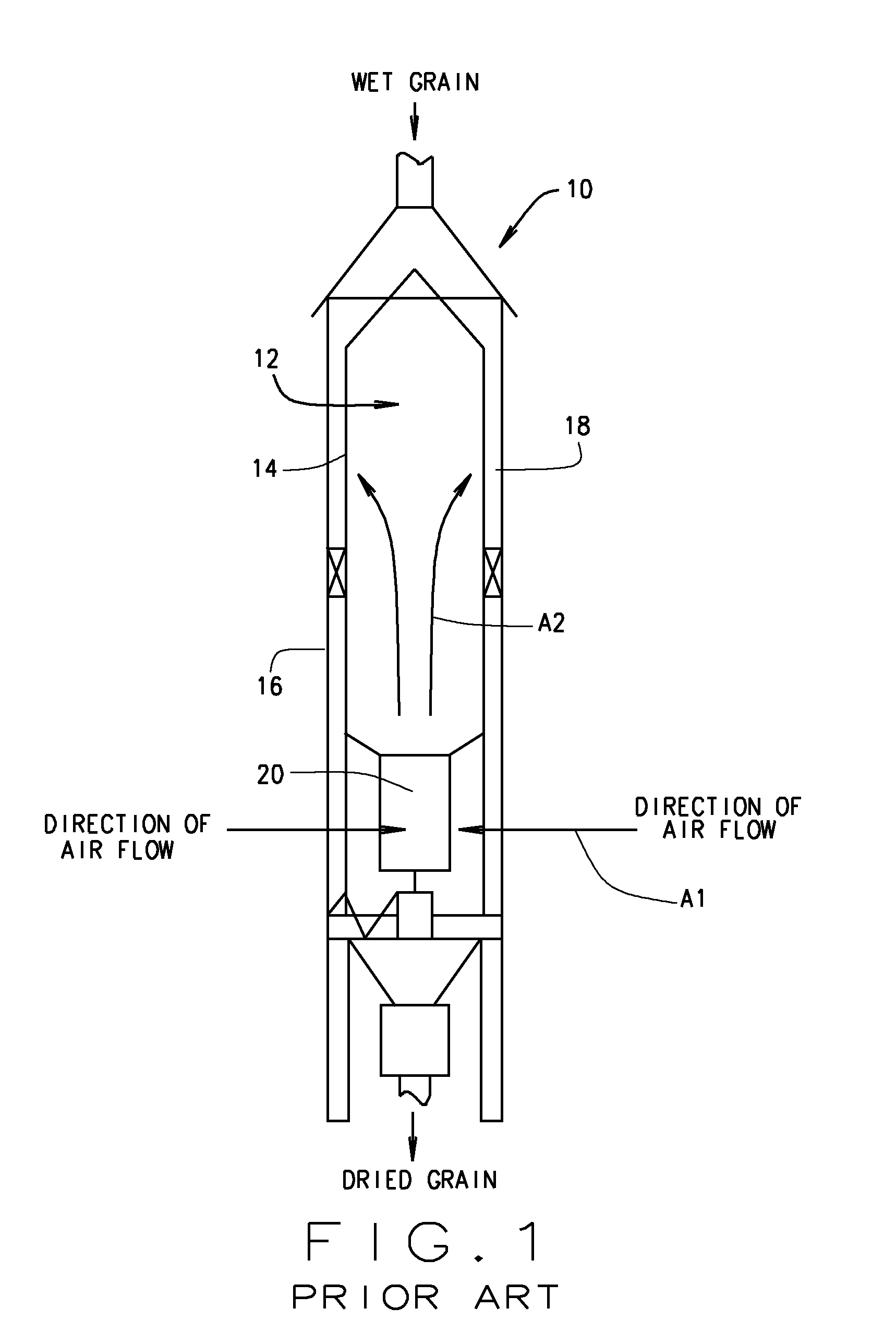

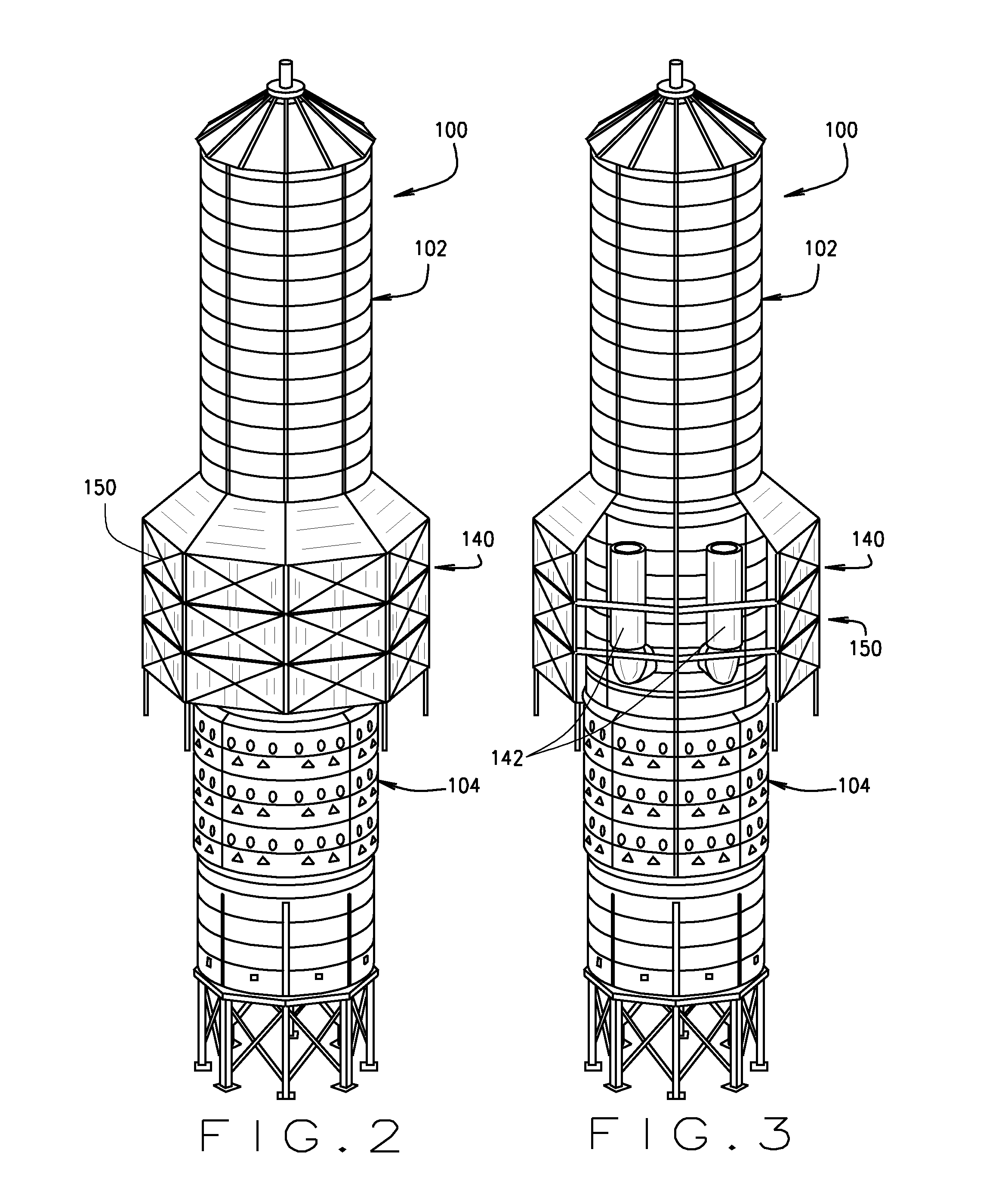

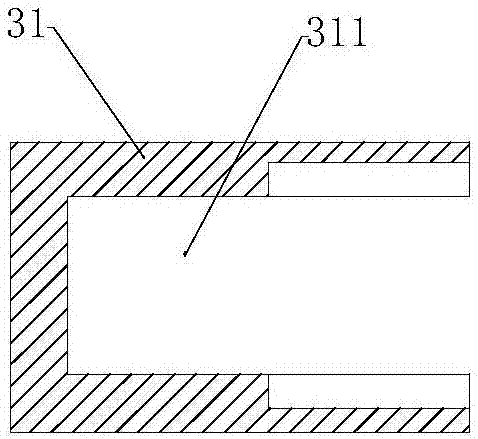

Adjustable divider/hopper for a grain tower dryer

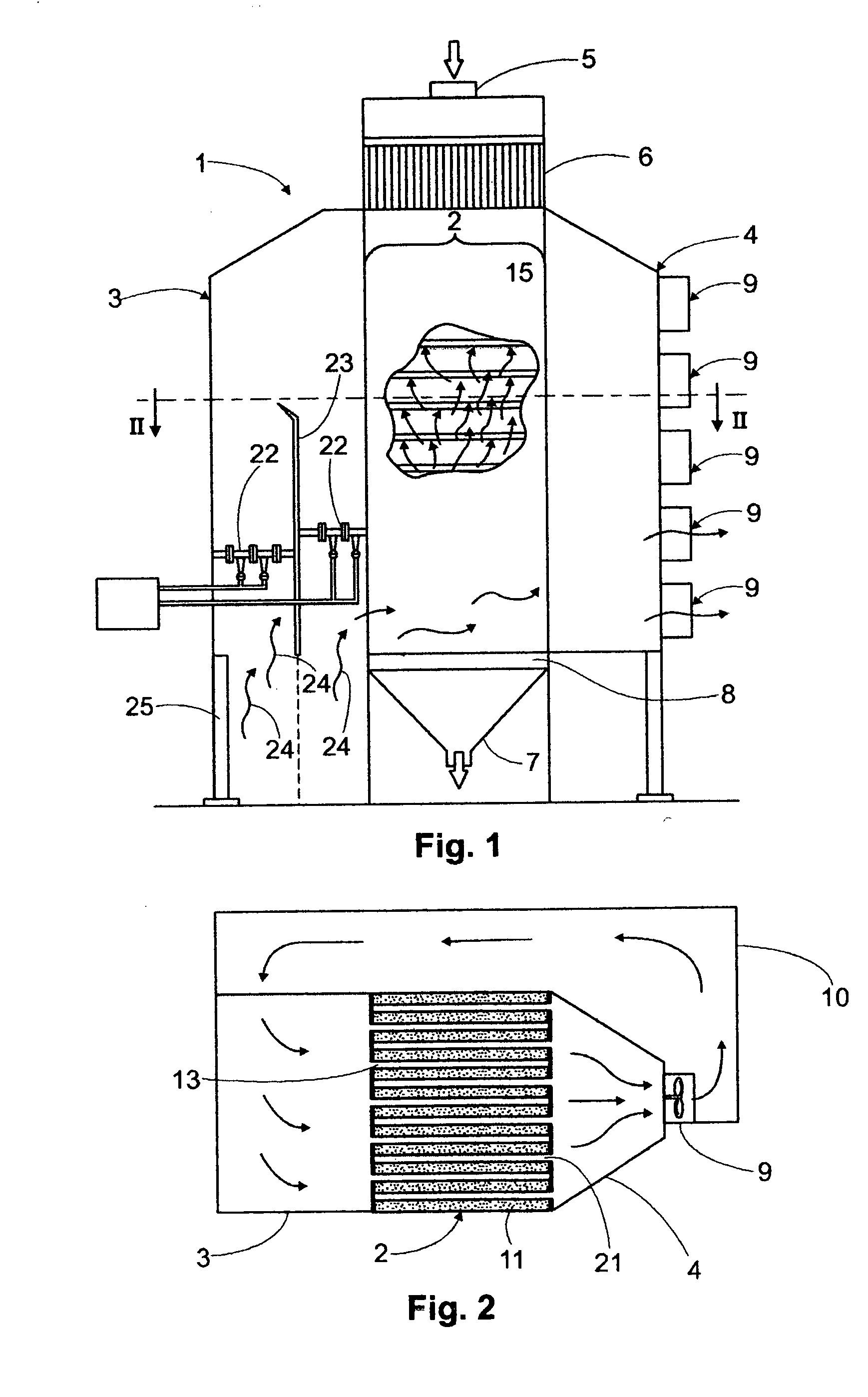

ActiveUS20100223800A1Drying solid materials with heatGas current separationTowerMechanical engineering

A combined plenum divider / hopper is provided for a grain drying tower. The divider / hopper is positioned in the drying tower proximate the heater for the drying tower and is operable to adjust the ratio of the length of the heating portion of the plenum to the length of the cooling portion of the plenum.

Owner:THE GSI GRP LLC

Hot air circulation grain drying device

InactiveCN107156291AImprove qualityReduce churnDrying gas arrangementsSeed preservation by dryingEngineeringHeat losses

The invention discloses a hot gas circulation grain drying equipment, which comprises a dehumidifier and a drying box; a dust removal channel is arranged above the drying box, and a winnowing device is arranged on the right side of the dust removal channel; the dust removal channel is connected with a cyclone dust collector A drying box is connected under the dust removal channel; a drying plate is arranged in the drying box; a first hot air blower, a second hot air blower and a third hot air blower are arranged between the drying plates. The present invention realizes the full utilization of the hot air and separate drying of the grains with different drying degrees by providing a circulating hot air drying device and hot air blowers with different powers, reducing heat loss and saving energy; the present invention is provided with staggered distribution The drying plate improves the drying efficiency and the drying effect; the invention is equipped with a high-school dust removal device to remove dust and shriveled grains in the grain, improves the quality of the grain, and saves storage space.

Owner:惠安益源信息技术咨询有限公司

Grain drying system

ActiveUS8806772B1Accurately determinedEasy to determineDrying solid materials with heatDrying gas arrangementsModem deviceGrain storage

A grain drying system includes a master control unit external to the grain storage bin which is preprogrammed with a desirable grain moisture content or EMC. Condition sensor assemblies mounted within the grain bin determine the relative humidity and the temperature of the grain within the grain bin. Also, sensors mounted in the bin's plenum determine temperature, relative humidity and air pressure. A weather station mounted externally of the grain bin determines the outside air temperature and relative humidity. Depending on the conditions determined by the sensor assemblies and the weather station, the master control unit selectively activates the grain bin's drying fan when needed and when it is efficient and effective to do so. A radio or cellular modem allows for communication of the grain's condition. The internal sensor assemblies are preferably secured to flexible cables hung within the grain bin. The cable and rigid rod-like members support the sensors. The sensors may be secured in a spaced relationship along the cable so that the grain condition can be determined throughout the grain bin.

Owner:AGI SURETRACK LLC

Efficient grain drying device capable of achieving feeding easily

InactiveCN106979674AFully contactedGuaranteed drying effectDrying gas arrangementsSeed preservation by dryingAgricultural engineeringStacker

The invention discloses a high-efficiency and easy-to-cut grain drying device, which includes a drying cylinder, a motor, symmetrically arranged support columns, a hot air blower and a material receiving frame; the drying cylinder is arranged between two support columns; The center position of the bottom of the drying cylinder is provided with a discharge opening, and a cover plate is arranged on the discharge opening, and the bottom of the drying cylinder is located on both sides of the discharge opening, and counterweights are fixed symmetrically; the hot air blower is installed on the left side On the supporting column, the hot air blower is connected to the hot air pipe, and the hot air pipe runs through the connecting shaft from the axis of the connecting shaft and goes deep into the right side of the drying cylinder. The hot air pipe is densely provided with air outlets; the hot air pipe is deeply dried A plurality of turning plates are fixed on the periphery of the tube body of the cylinder; a material receiving frame is arranged at the position directly facing the discharge opening under the drying cylinder. The grain drying device of the present invention has good drying effect and is convenient for unloading.

Owner:合肥智慧殿机械设计有限公司

Adjustable divider/hopper for a grain tower dryer

A combined plenum divider / hopper is provided for a grain drying tower. The divider / hopper is positioned in the drying tower proximate the heater for the drying tower and is operable to adjust the ratio of the length of the heating portion of the plenum to the length of the cooling portion of the plenum.

Owner:THE GSI GRP LLC

Small grain dryer

InactiveCN104719461AShorten the lengthReduce volumeDrying gas arrangementsSeed preservation by dryingCombustionAgricultural engineering

The invention discloses a small grain dryer comprising a feed hopper. The feed hopper is connected to the inlet of a drying rolling drum; the outlet of the drying rolling drum is connected to the inlet of a cooling rolling drum, the outlet of the cooling rolling drum is connected to a discharge hopper, and the air inlet of the drying rolling drum is connected to a hot air outlet of a straw combustion furnace; the drying rolling drum comprises an outer heat insulation drum, the outer heat insulation drum is provided with an inner rolling drum inside, asymmetric copy boards are distributed on the wall of the inner rolling drum circumferentially, the inner rolling drum is provided with hot air flowing holes, and the inner rolling drum and the outer heat insulation drum are sealed through a sealing sleeve; the outer heat insulation drum is fixed, and the inner rolling drum is capable of rotating; the inner rolling drum is provided with a temperature sensor, a humidity sensor and a microprocessor inside, the temperature sensor and the humidity sensor transmit the acquired data to the microprocessor, and the microprocessor transmits the data to an upper computer; the drying rolling drum, the cooling rolling drum and the straw combustion furnace are arranged on a trailer. By the aid of the small grain dryer, the problems of rural straw combustion and grain drying can be solved.

Owner:WUHAN UNIV OF TECH

Grain drying device with intermittent feeding function

InactiveCN108444254APrevent drying effectRealize the function of intermittent feedingDrying gas arrangementsSeed preservation by dryingAgricultural engineeringThreaded rod

The invention discloses a grain drying device with intermittent feeding function. The device comprises a stirring chamber, a drying chamber, a motor, a tapered throwing plate and a transmission chamber, wherein the stirring chamber is arranged at the upper end of the drying chamber and is separated through a separating plate; a feeding bucket is arranged at the upper end of the stirring chamber, and the motor is arranged at the right side of the feeding bucket; the output end of the motor is fixedly connected to a rotating shaft; the rotating shaft passes through the stirring chamber and the drying chamber and is fixedly connected to a bevel gear C; the transmission chamber in which a threaded rod is arranged is formed in the middle of the bottom part of the drying chamber; a threaded sleeve is in thread connection with the threaded rod at the inner side of the transmission chamber; shifting plates are symmetrically hinged with two sides of the threaded sleeve. The device is novel in design; the arranged threaded rod can positively and negatively rotate to drive the shifting plates swing up and down in a reciprocating manner through the threaded sleeve; grain at the bottom part ofthe drying chamber can be raised again by the shifting plates, so that the contact area between the grain and hot air is further increased, and as a result, the grain drying effect is improved.

Owner:台州来智科技有限公司

Bright green cold firework composition and production method thereof

The invention discloses a bright green cold firework composition and a preparation method thereof. The composition comprises the following ingredients by weight percentage: 25-40% of boron powder, 5-15% of magnalium powder, 6-12% of titanium powder, 8-15% of barium nitrate, 6-10% of 52# chlorinated paraffin, 15-20% of nitrocotton and 15-20% of ammonium perchlorate. The preparation method of the composition comprises the steps of fuel mixing, fuel granulation, fuel grain drying and composition mixing. A cold firework produced by the composition can emit bright green light, the color variety of the cold firework is enriched, and the enjoyment effect of the cold firework is improved.

Owner:NANJING UNIV OF SCI & TECH

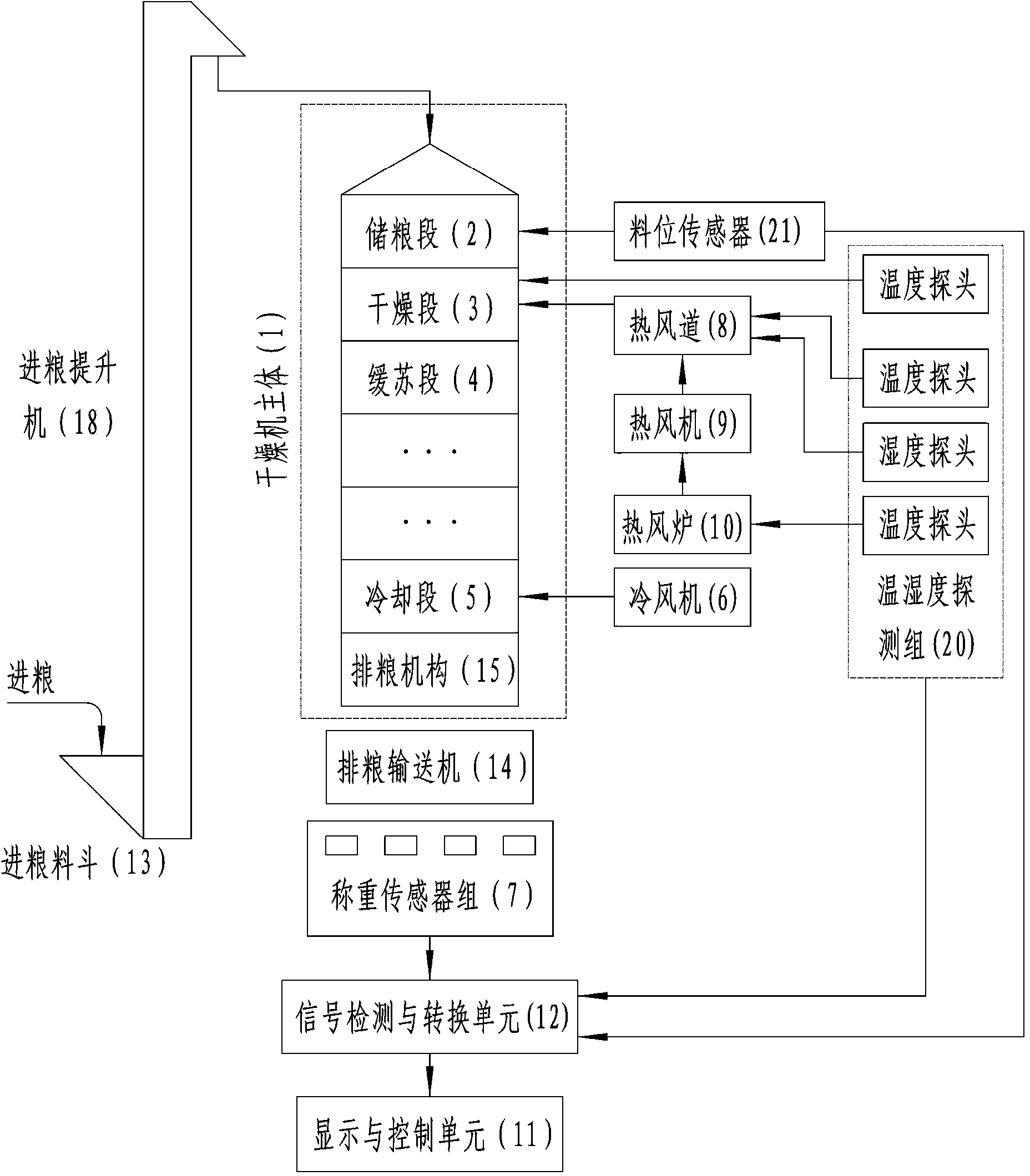

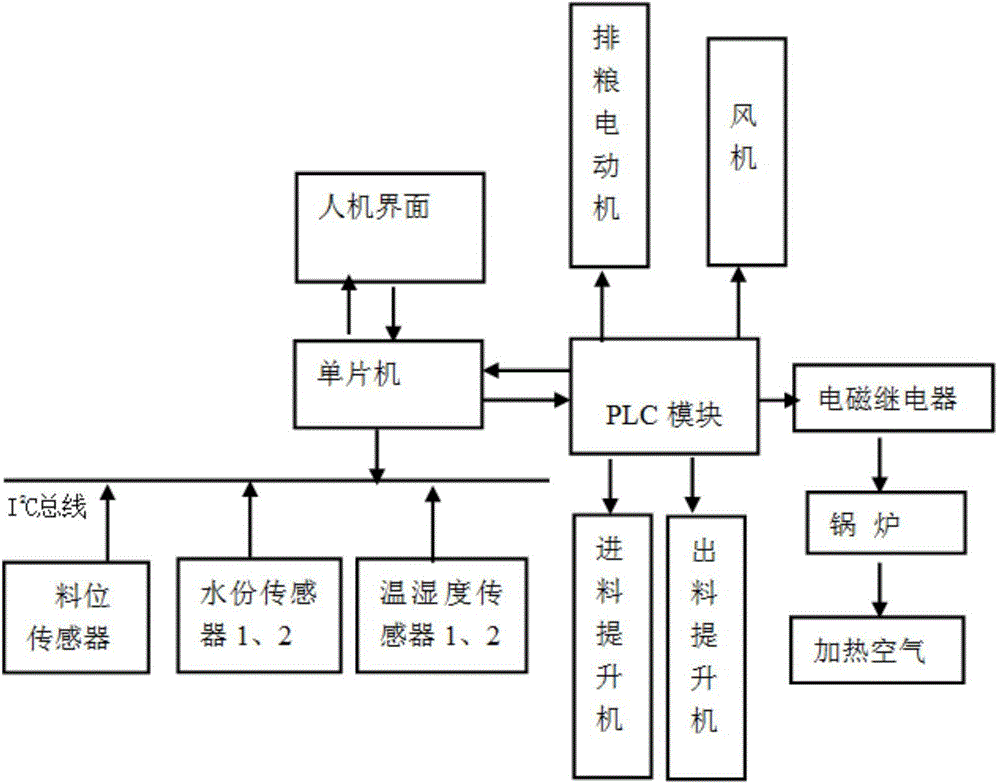

Cereal drying control system

InactiveCN104154733ARealize intelligent controlEconomically flexibleDrying solid materialsHuman–machine interfaceControl system

The invention discloses a cereal drying control system which is characterized in that a human-computer interface, a single chip microcomputer, a sensor and a PLC module are included, the human-computer interface and the sensor are connected with the single chip microcomputer, the sensor comprises a material position sensor, a moisture sensor and a temperature-humidity sensor, the PLC module is connected with the single chip microcomputer, a grain discharging motor, a fan, a feeding lifter, a discharging lifting and an electromagnetic relay, and the electromagnetic relay is connected with a boiler. Compared with the prior art, the cereal drying control system has the advantages of being stable, reliable, economical and flexible, the parts such as the single chip microcomputer, the PLC module and the sensors are matched, and cereal drying intelligent drying is achieved.

Owner:JIAMUSI UNIVERSITY

Grain drying aeration system

InactiveUS20070234587A1Drying solid materials with heatDrying chambers/containersAeration systemWaste management

An improved vertical aeration system is provided for a grain bin having a sloped hopper bottom with a discharge opening. A pyramid frame includes legs with lower ends attachable to the hopper bottom. Concave perforated walls are attached to the legs. Braces extending between the legs provide structural support for the walls. An air duct extends upwardly and centrally into the interior of the frame, to supply air into the aeration system for flow outwardly through the perforated walls.

Owner:WOODHAVEN CAPITAL

Agricultural grain drying device

InactiveCN107238273AImprove slipSolve the problem of drying efficiencyDrying gas arrangementsDrying solid materialsAgricultural engineeringConvenience food

The invention discloses an agricultural grain drying device, which comprises a machine body, the top of the left side of the machine body is connected with a feeding hopper, the top of the left side of the inner cavity of the machine body is fixedly connected with a connecting plate, and the bottom of the connecting plate is fixedly connected with There is a vibrating motor, a dryer is fixedly connected to both sides of the top of the body, and a baffle is fixedly connected to the right side of the inner cavity of the body. The invention can dry the grain through the setting of the dryer, through the setting of the vibrating motor and the connecting plate, it is convenient for the grain to slide down, and at the same time, the uniformity of drying is increased. Through the setting of the motor, the turntable and the fixed rod can be driven to rotate, Through the setting of movable rods, connecting rods and movable racks, the sieve can be driven to shake and the grain can be screened. At the same time, it solves the problem of uneven drying when drying the grain and the impossibility of screening the impurities in the grain, which reduces the The problem of drying efficiency of grain.

Owner:乐陵市鑫地园金银花种植专业合作社

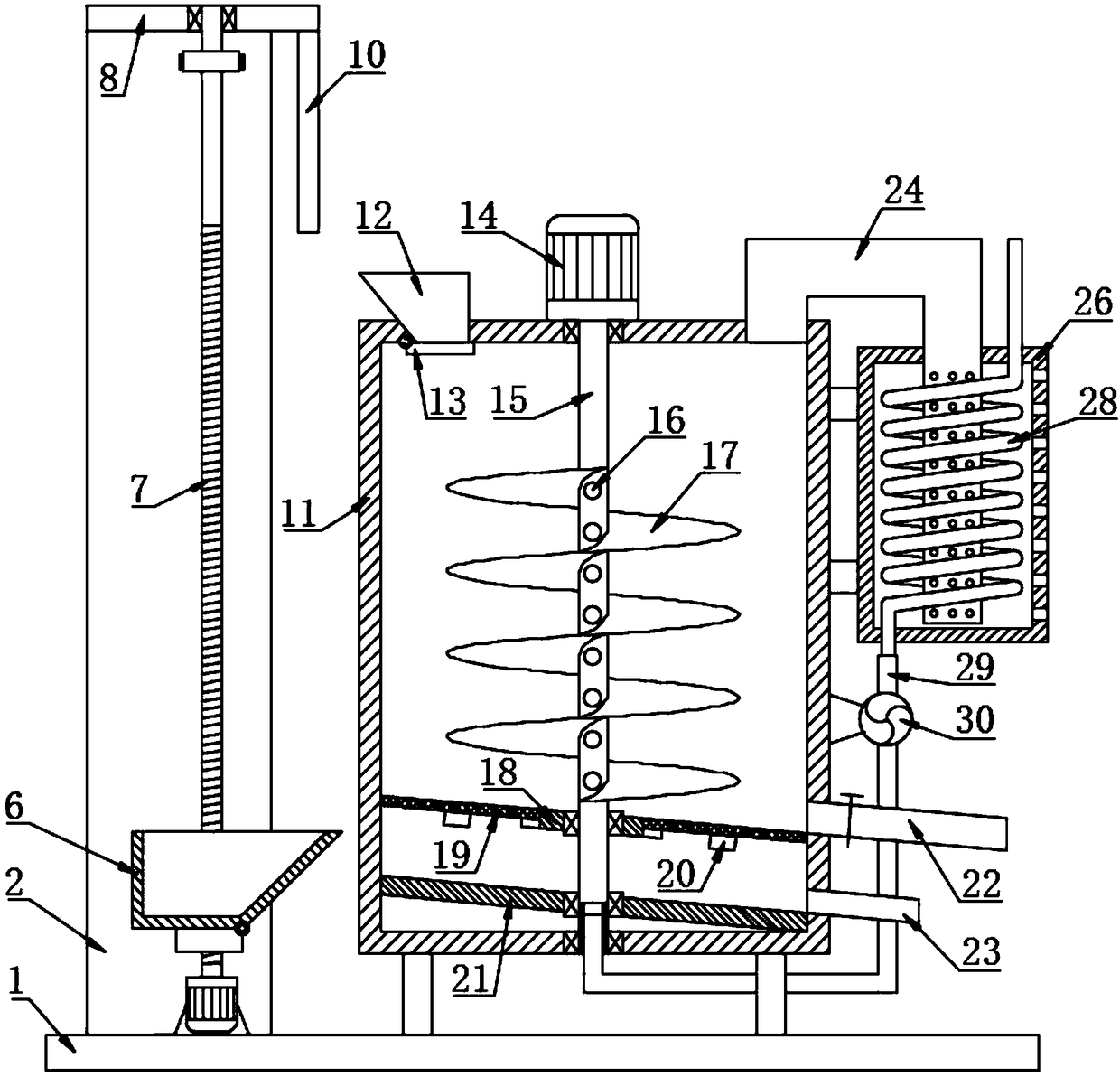

Self-feeding type energy-saving grain drying device

InactiveCN108800832AEvenly heatedImprove drying effectFood processingDrying gas arrangementsSpiral bladePulp and paper industry

The invention discloses a self-feeding type energy-saving grain drying device comprising a base. A drying barrel is fixed to the top of the base through a support, a rotating tube is arranged in the center in the drying barrel, and the upper end and the lower end of the rotating tube are rotationally connected with the top wall and the bottom wall of the drying barrel correspondingly. A second speed reducing motor is fixedly arranged at the center of the top of the drying barrel, a motor shaft at the bottom end of the second speed reducing motor is fixedly connected with the top end of the rotating tube, and spiral blades are fixedly mounted at the tube section, located above a screen plate, of the rotating tube. A plurality of one-way air outlet holes are uniformly formed in the tube section, between the spiral blades, of the rotating tube. A hot air blower is fixedly arranged at the right part of the side wall of the drying barrel, the air inlet end and the air outlet end of the hotair blower are connected with hot air tubes correspondingly, and the air outlet end of each hot air tube is connected into the rotating tube. The hot air blower is used for introducing hot air into the rotating tube, the hot air is discharged from the one-way air outlet holes to dry grains, and the heat is uniformly distributed; and the spiral blades are driven by the rotating tube to rotate to drive the grains to roll, so that the grains are heated more uniformly when dried, and the drying effect is good.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

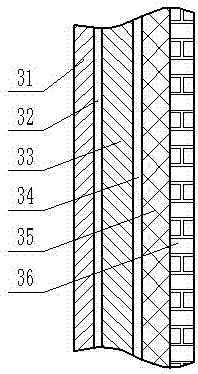

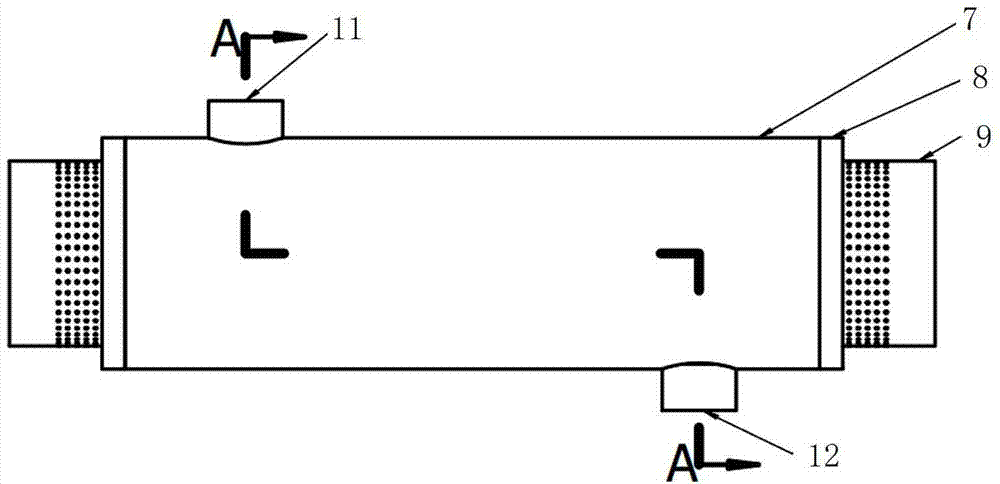

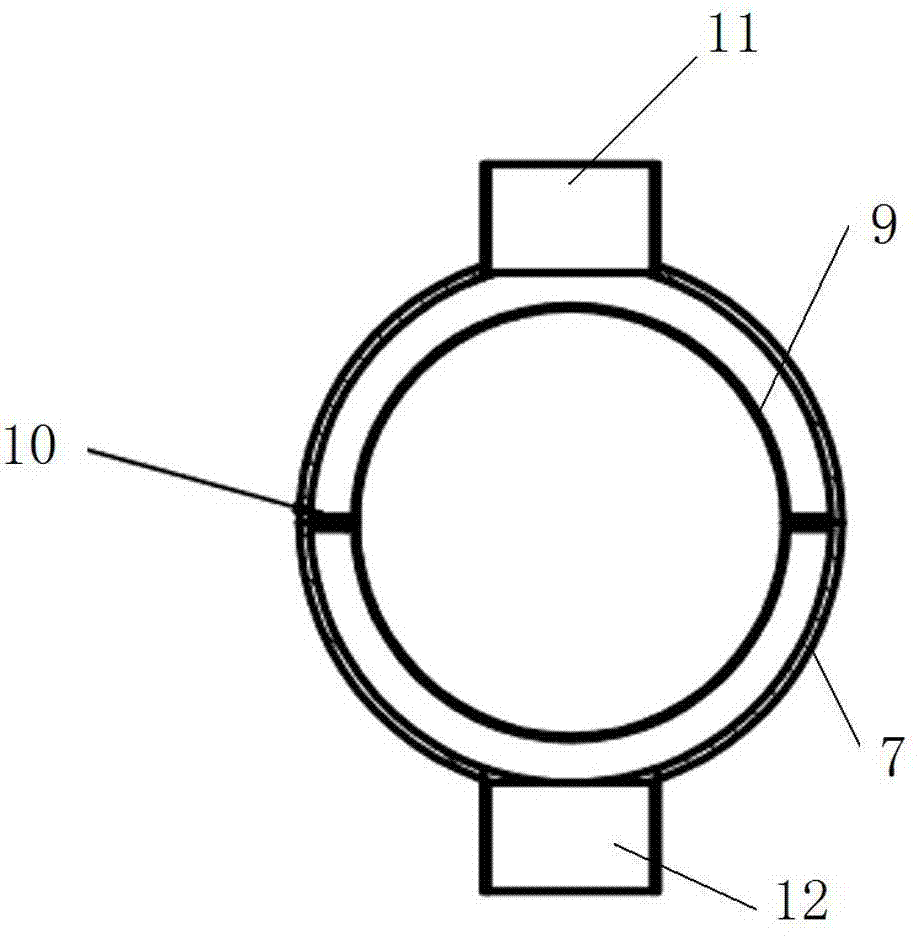

Horizontal convection integral grain drying machine

The invention discloses a horizontal convection integral grain drying machine, relating to a grain drying machine. By using the horizontal convection integral grain drying machine, the problems of high cost, low efficiency, low temperature, low warming speed, large energy consumption and pollutant discharge are solved. The stator reels of the grain drying machine are symmetrically arranged on two ends of a drying cylinder; a superconductive tube is arranged in the drying cylinder; the right end of the superconductive tube is arranged in the combustion chamber of a heat supply furnace by the stator reels; an air tube is arranged below the superconductive tube; the air tube and the superconductive tube are arranged in a hot-proof cyclone cover below which a hot wind port is arranged; and a dust catcher is arranged between a flue and a discharge flue. The horizontal convection integral grain drying machine has the advantages of compact design, small volume, simple structure, low cost, high efficiency and low cost, and is convenient in installation, is energy-saving, environment-friendly, wherein the grain drying machine can save energy by 30-40% and save electricity by 20-30% if compared with the existing drying equipment under the same condition, and improve efficiency by 15-20% if compared with the existing drying equipment, and the cost of the grain drying machine is 60-70% of that of the existing equipment.

Owner:HARBIN ZHONGSHENGLONG HEATING EQUIP TECH DEV

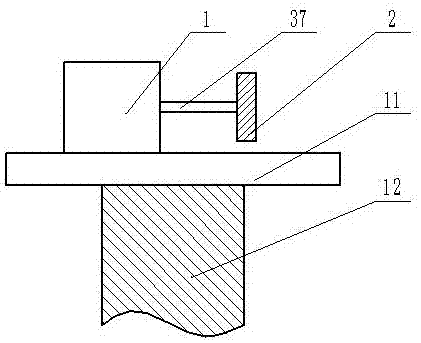

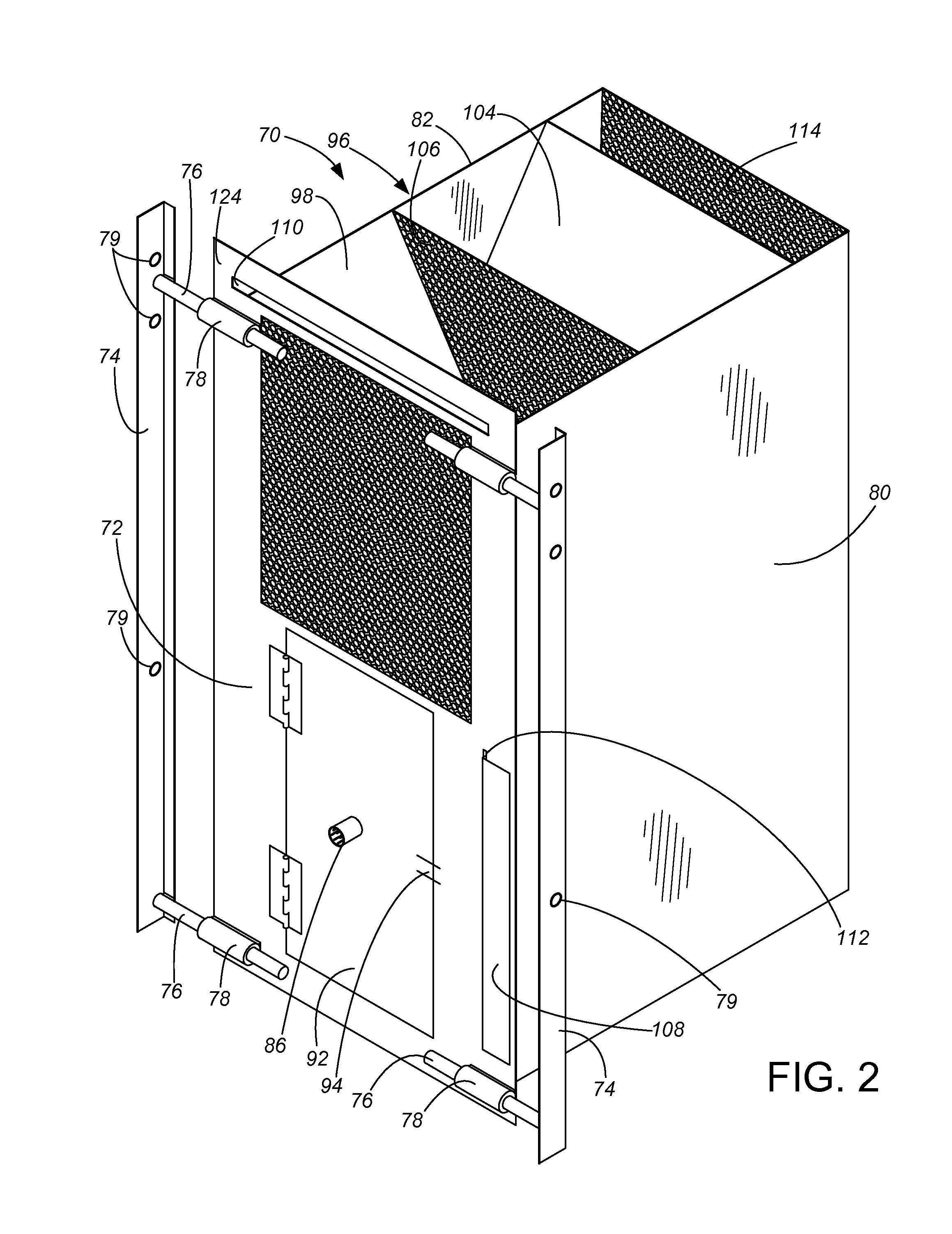

Retrofit Grain Dryer Moisture Controller

ActiveUS20100229421A1Easy to installSampled-variable control systemsComputer controlContinuous flowEngineering

A retrofit turner and sensor unit includes, on its upper portion, a grain turner for moving grain from a central portion in the grain pathway to a defined outer space for measurement. On its lower portion, the retrofit unit includes a moisture sensor and a temperature sensor provided in a plate configuration in line with the outer wall of the grain dryer for sensing moisture and temperature of grain in the defined space. In the preferred configuration, the plate sensor includes redundancies, and is mounted on a hinged door. The retrofit unit is easily installed into an existing grain dryer with columns and continuous flow capabilities, and electrically connected with a controller / processor and a motor for metering rolls which determine grain speed through the dryer.

Owner:SALISBURY NOBLE M

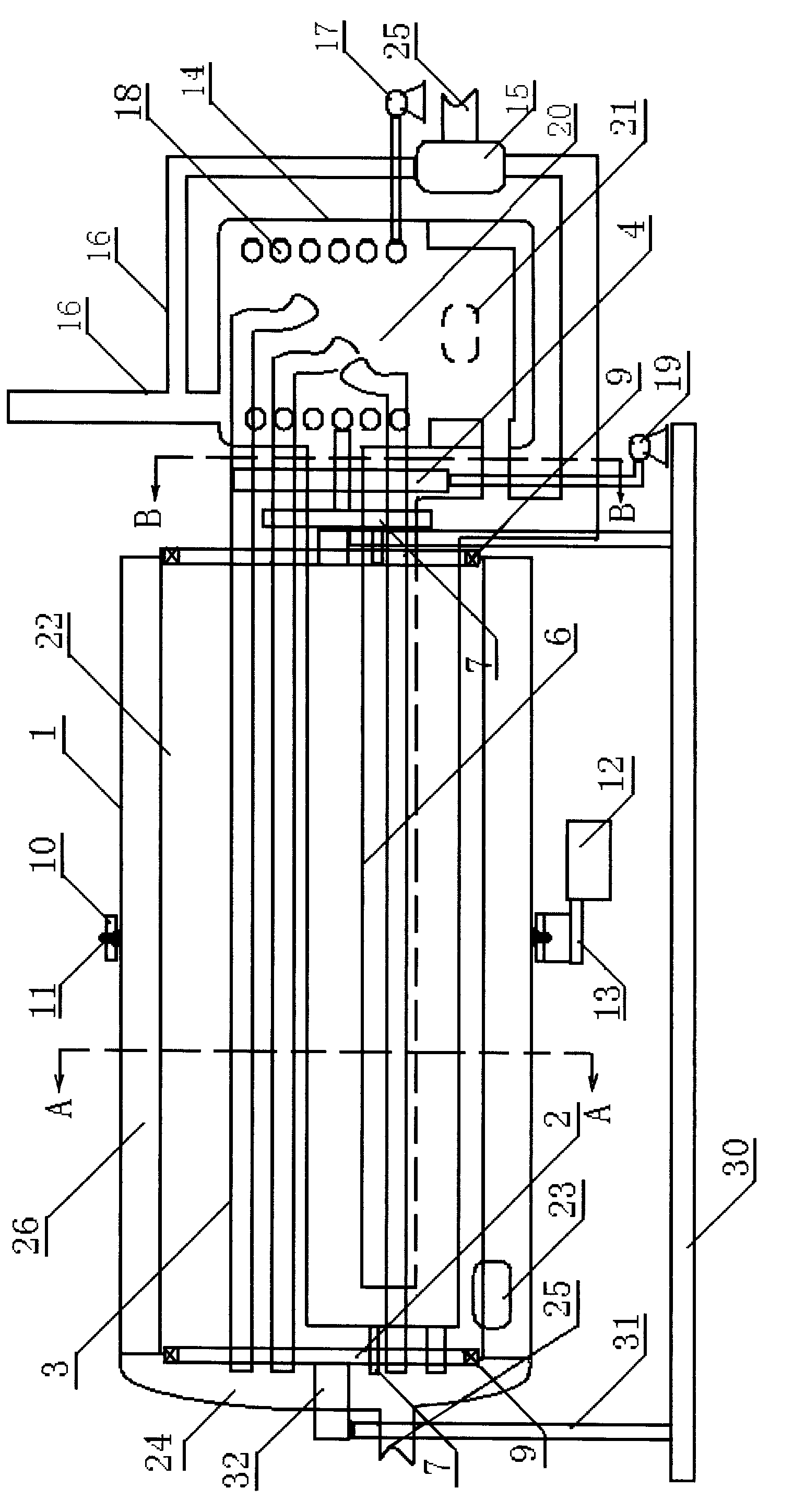

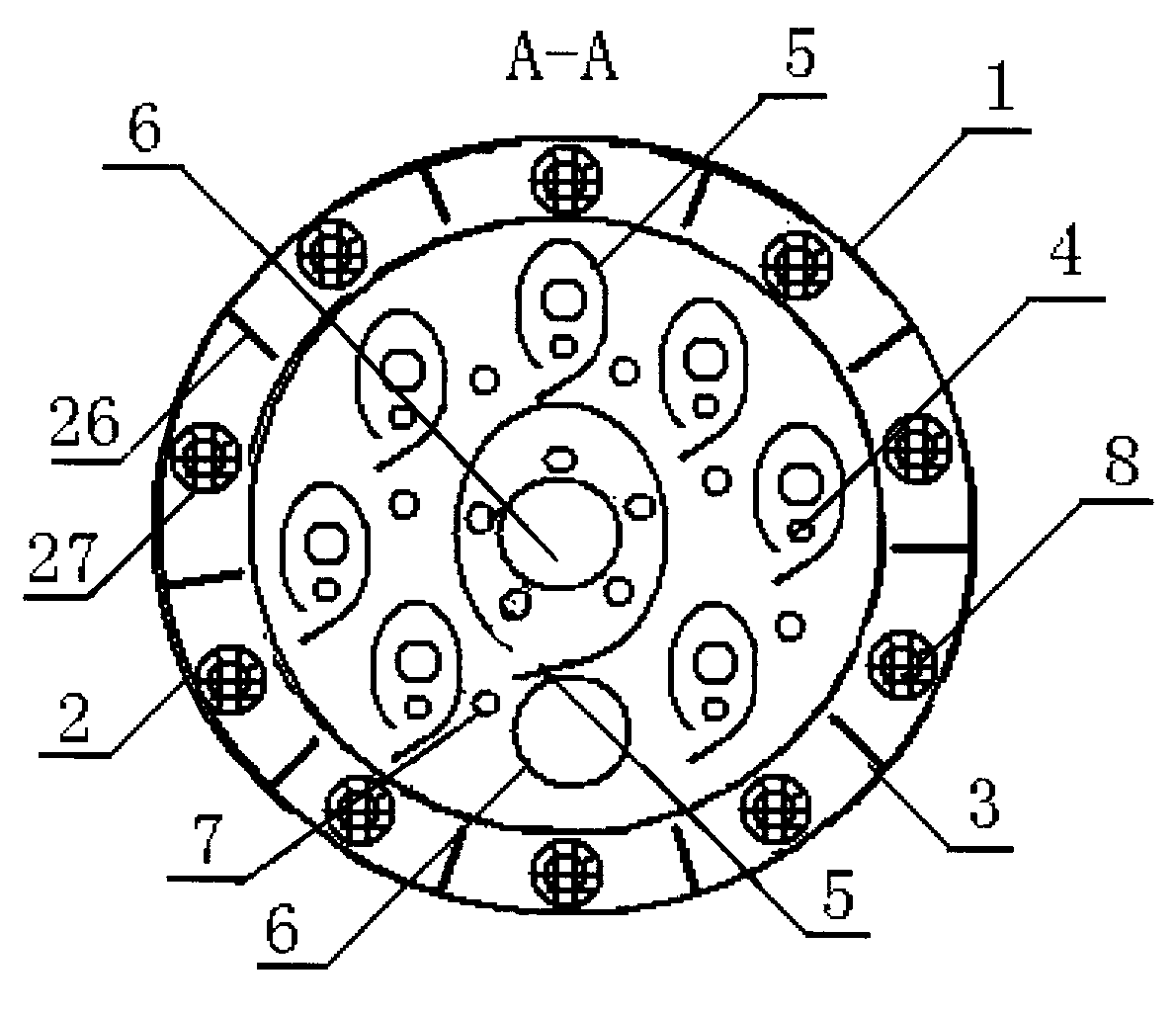

Grain intelligent baking storing integrated device

InactiveCN105341148AHigh degree of automationRealize automatic feedingAgriculture tools and machinesSeed preservation by dryingAgricultural engineeringIntelligent control

The invention relates to a grain intelligent baking storing integrated device with intelligent drying and storing functions, and belongs to the field of agricultural machinery grain drying and storing. The grain intelligent baking storing integrated device comprises a feeding unit, a storage unit, a discharging unit, an aeration-drying unit, and an intelligent control unit; the storage unit comprises a silo cell; the feed inlet of the silo cell is connected with the feeding unit; the feed outlet of the silo cell is connected with the discharging unit; the bottom of the silo cell is provided with an air passage; a wind chamber is arranged below the bottom of the silo cell; the wind chamber is communicated with the inner part of the silo cell via the air passage; the wind chamber is communicated with the aeration-drying unit via a wind passage; and the upper part of the silo cell is provided with an air exhausting device. According to the grain intelligent baking storing integrated device, grain drying and storing function are combined; automatic degree is high; the grain intelligent baking storing integrated device is safe and reliable to use; cost is reduced; grain drying and storing are not influenced by air factors; and the grain intelligent baking storing integrated device is suitable for small and medium-sized farmers, and big grain production households.

Owner:SHANDONG QUANGUAN MASCH TECH CO LTD

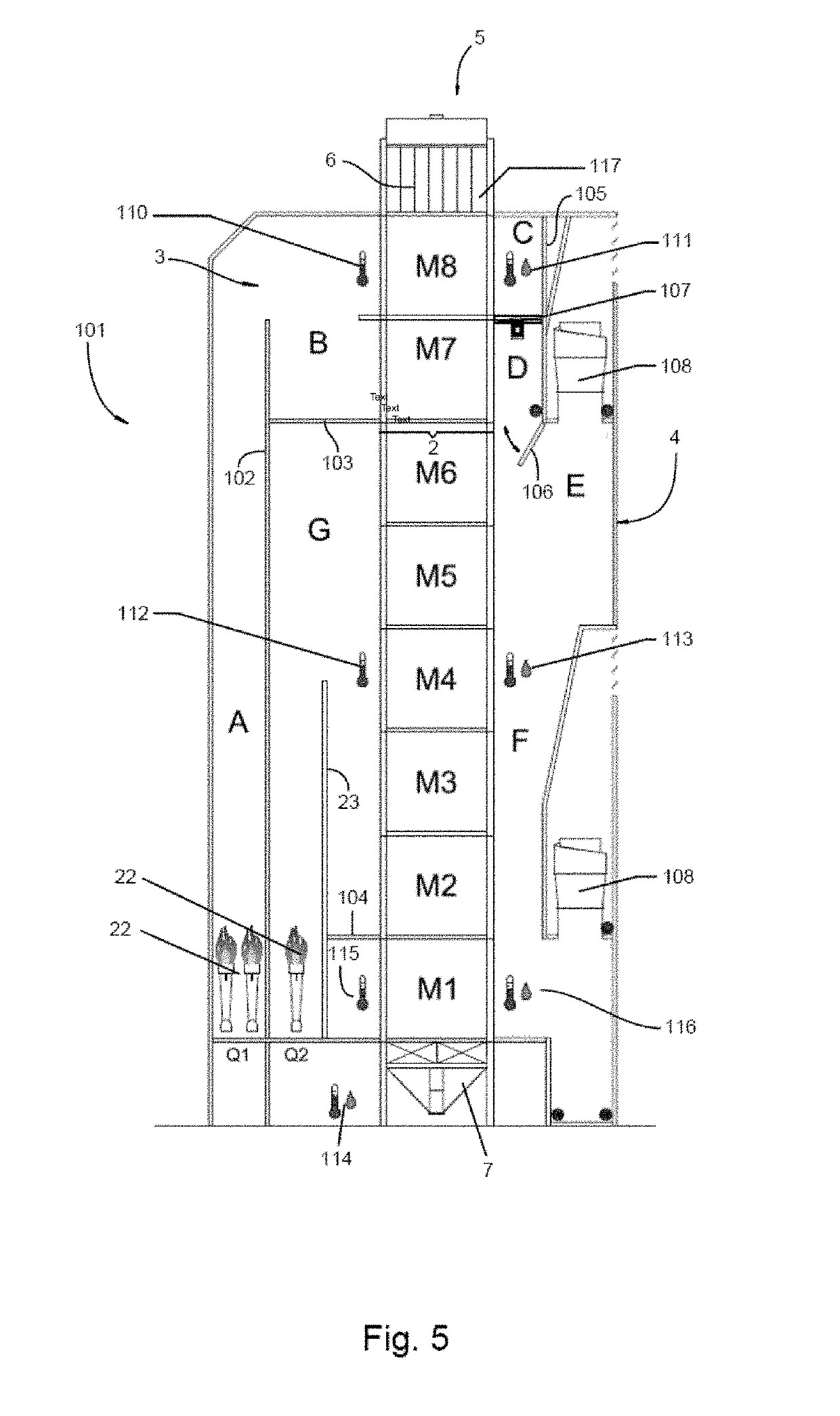

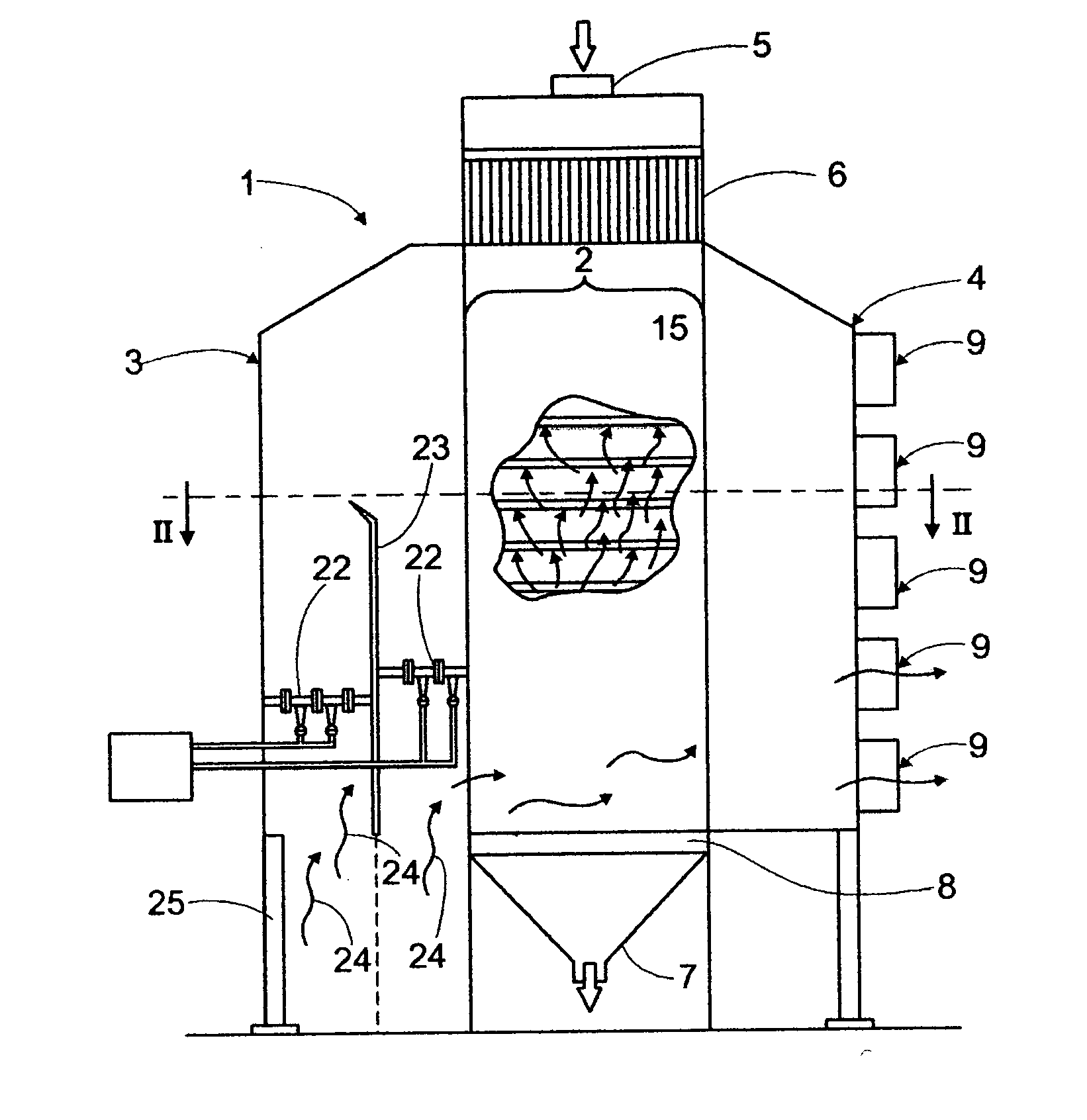

Grain dryer

ActiveUS20190174782A1Reduce energy consumptionEasy to handleThermometer detailsDrying gas arrangementsEngineeringMoisture

Grain dryer of the type comprising a vertical main structure consisting of a central body through which the grain to be dried passes, a front hot air intake chamber and a rear used air outlet chamber, being that the main body has in its upper part an entrance from where wet grains are loaded, underneath which there is a loading hopper that communicates with the central body, wherein the grain descends along the central body within which it is dried during its fall by a flow of hot air that passes through the mass of grain, finally exiting through a discharge hopper arranged at the lower end of the dryer, the dryer of the invention being characterized in that it allows to significantly reduce the energy consumption in order to obtain a better quality of grain and a process much faster than conventional ones due to the arrangement of one or more preheating chambers without extraction of moisture from the grain.

Owner:ING MEGA

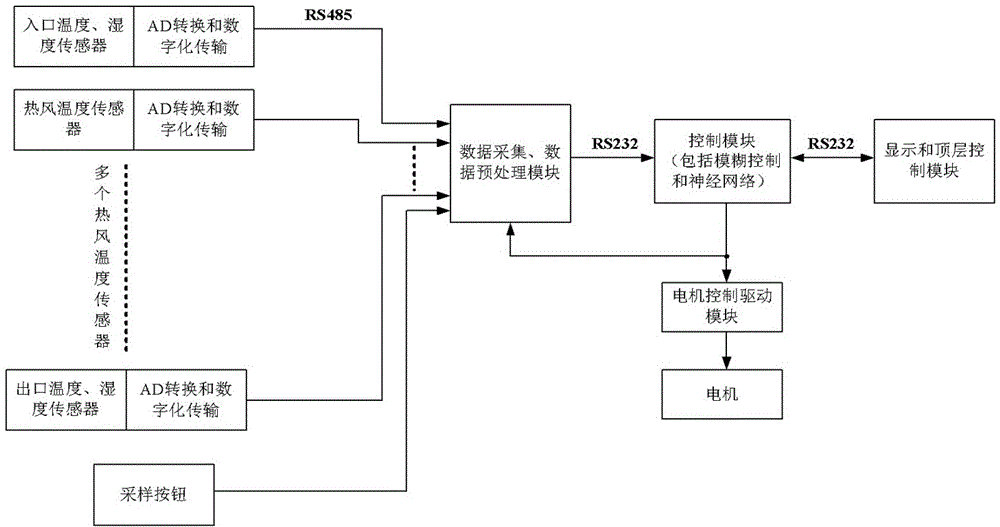

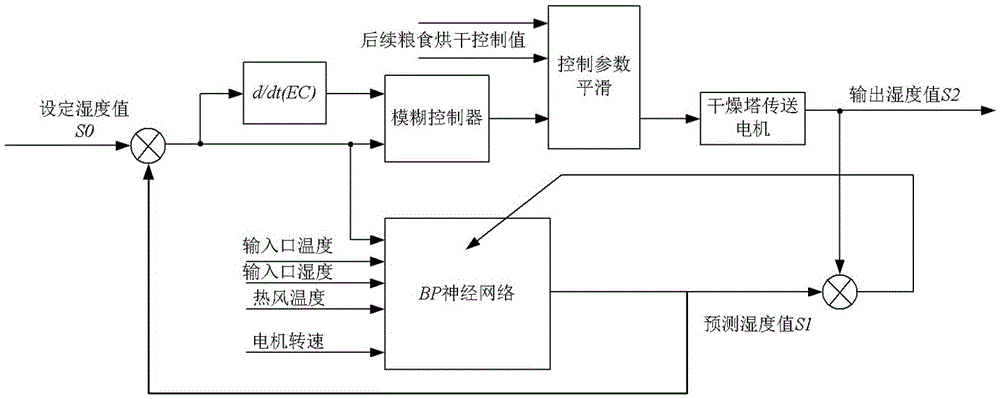

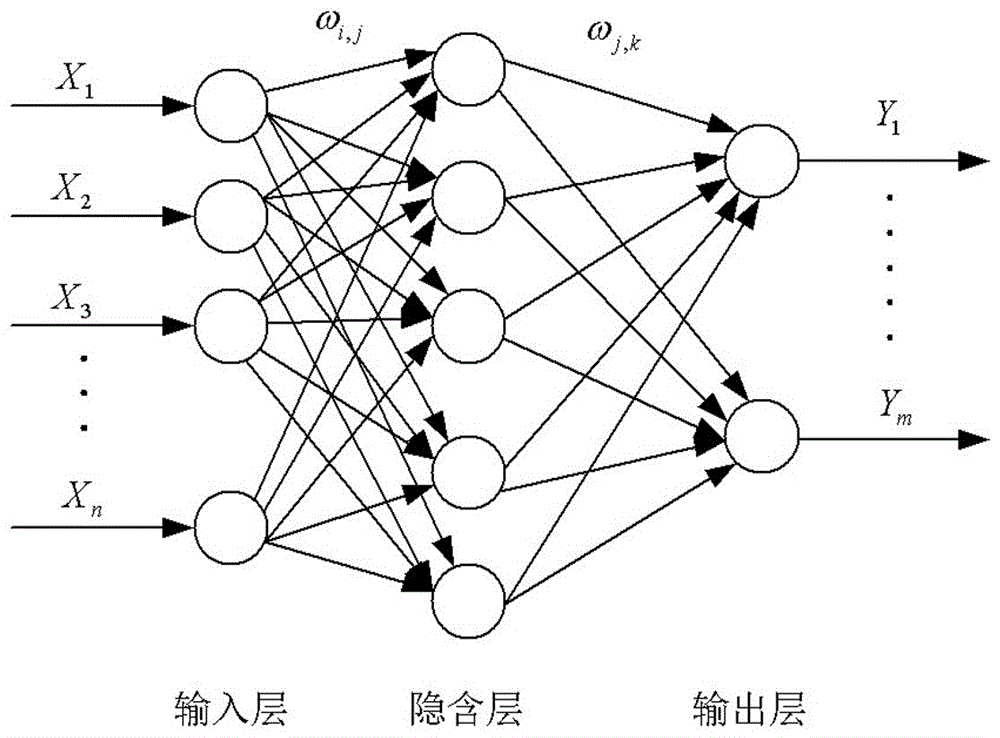

Intelligent control method for grain drying tower based on neural network and fuzzy control

InactiveCN106227038AReduce computing timeImprove robustnessBiological neural network modelsAdaptive controlInformation controlFuzzy control system

The invention belongs to the technical field of grain drying control and specifically relates to an intelligent control method for a grain drying tower based on neural network and fuzzy control. The hardware comprises a temperature / moisture sensor, a data collecting and treating module and an input and display module, wherein the temperature / moisture sensor is used for collecting temperature and moisture information; the data collecting and treating module is used for controlling the drying parameter according to the temperature and moisture information; the input and display module is used for performing man-machine interaction. The method comprises the following steps: 1) setting an initial value for the drying data according to a drying experience; 2) performing fuzzy control training on the system and drawing a control rule table; 3) sampling and correcting an error in the drying process. A drying tower is modeled according to the training data through the network; the error between a forecast moisture value after training and a moisture value calculated according to a model is small; the practical application requirement can be met; although a simple linear model is adopted, the training effect is excellent even if a higher order model is adopted.

Owner:THE PLA INFORMATION ENG UNIV

Tower grain dryer with improved heat reclamation and counter-flow cooling section

A grain drying tower comprises a heater and blower separating a heating plenum and a cooling plenum. The dryer is provided with a heat reclamation / heat recycling system and / or counter-flow cooling to reduce the energy requirements of the tower dryer. The heat reclamation system comprises a chamber external to the outer wall of the tower and which is and located at a point along the drying path. The bottom of the chamber is open to the atmosphere. Hot exhaust air enters the heat reclamation chamber at the top of the chamber and is drawn back into the tower by the blower as the exhaust air exits the open bottom of the chamber. In the counter-flow, the walls defining the grain path of the in the cooling section are not air permeable, and air is drawn into the cooling section through outer wall ducts which are closed at the inner wall. The entering air travels up through heated grain to be warmed, and then enters the plenum through inner wall ducts, which are closed at the outer wall of the tower.

Owner:THE GSI GRP LLC

Uniformly-heated and convenient-to-choose intelligent grain dryer

InactiveCN108375294AEvenly heatedEasy to absorb heat and dryDrying gas arrangementsDrying solid materialsAgricultural engineeringGrain drying

The invention relates to a uniformly-heated and convenient-to-choose intelligent grain dryer, which comprises a drying tank, a hot air chamber, an air inlet pipe, an air outlet pipe, a hopper, a discharge pipe, a controller and a plurality of supporting legs, wherein an air guide mechanism is arranged in the hot air chamber, a mesh plate and an agitating mechanism are arranged in the drying tank,the agitating mechanism comprises a first motor, a first driving shaft, a rotary shaft, a transmission assembly and two agitating plates, the transmission assembly comprises a transmission unit, a reciprocating unit, a fixed plate and two collars, and the air guide mechanism comprises an air guide assembly, a plurality of electric heating wires and two switching assemblies. The uniformly-heated and convenient-to-choose intelligent grain dryer can use different specifications of electric heating wires by means of the air guide mechanism, so that the temperature of heated air can be convenientlycontrolled, and thereby the dryer can dry different types of grains; in addition, by means of the agitating mechanism, the agitating plates can reciprocate up and down in the process of rotation, consequently, piled grain can be thoroughly uniformly heated, the drying effect is improved, and the practicability of the dryer is increased.

Owner:南安市智德机械设备有限公司

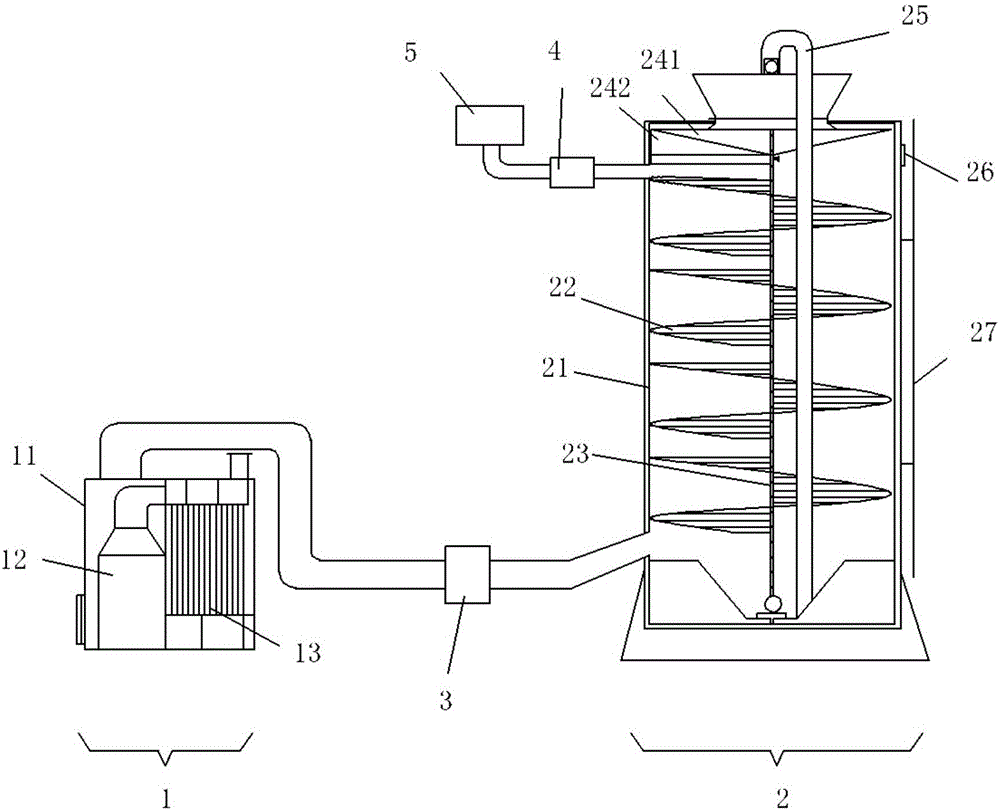

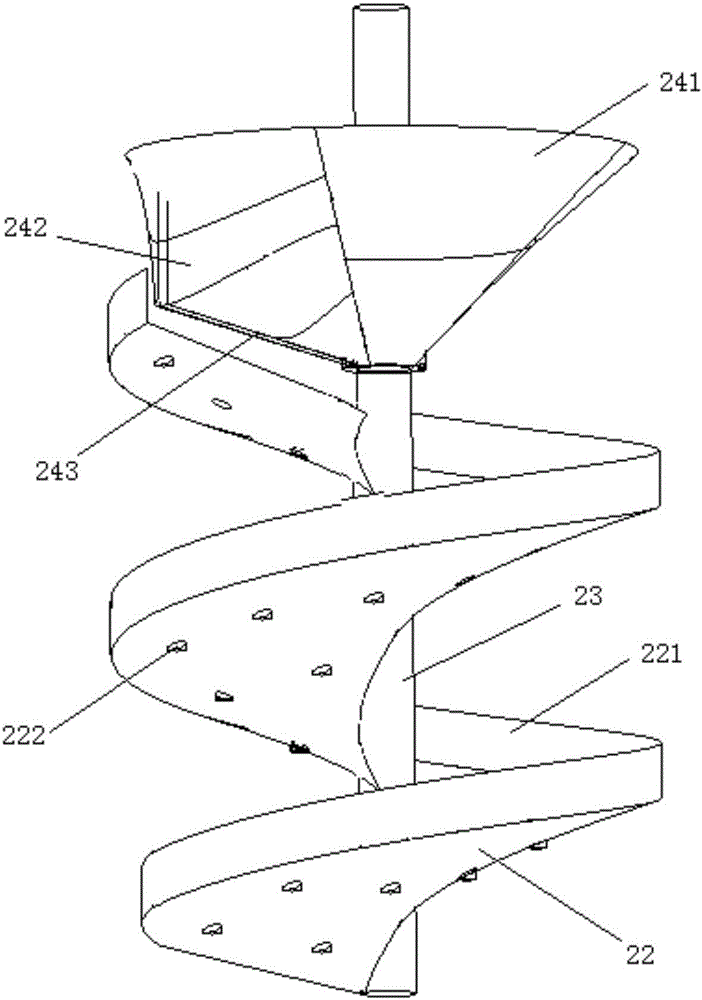

Grain drying device

ActiveCN107178987AExtended retention timeUniform qualityFood processingDrying gas arrangementsSpiral bladePorous medium

The invention discloses a grain drying device. The grain drying device comprises a hot-blast stove, an air blower and a drying tower, and is characterized in that a shaft rod is arranged in a tower body of the drying tower; spiral plates are arranged on the shaft rod; the spiral plates outwards extend from the surface of the shaft rod; two or more stages of spiral plates are arranged on the shaft rod; blowing holes are formed in the spiral plates, and penetrate through the surfaces of the spiral plates; and the hot-blast stove adopts the scheme of arranging heat exchange pipes in a pentagonal form and filling porous mediums in the heat exchange pipes. Compared with the prior art, the grain drying device has the following advantages: the drying speed can be adjusted through adjusting the rotating speed of a rotating shaft according to different grain characteristics; the overturning of materials is realized through multiple sections of spiral blades; the heat exchange efficiency is improved through arranging the heat exchange pipes in a pentagonal form and filling the porous mediums in the pipes; the problems of high production cost, energy consumption and low drying efficiency in the grain drying device can be effectively solved; and the grain drying device is used for drying grains, and reduces the drying cost, saves the energy, and improves the drying efficiency.

Owner:HEFEI UNIV OF TECH

Grain drying and storing granary

InactiveCN103283425ASolve drying problemsImprove qualityAgriculture tools and machinesLighting and heating apparatusAgricultural engineeringMoisture

The invention discloses a grain drying and storing granary which is characterized by comprising a grain storing case. A plurality of air pipes are arranged in the grain storing case, one end of each air pipe is connected with a ventilation pipeline, a plurality of ventilation holes are formed in each air pipe, the top of the grain storing case can be opened to be used as a grain inlet, a ventilation cavity is arranged at the bottom of the grain storing case, a sieve plate is arranged on the top surface of the ventilation cavity, air holes are formed in the ventilation cavity and respectively correspond to two ends of each air pipe, each air hole at one end of the corresponding air pipe is connected with the ventilation pipeline, the two ends of each air pipe and the air holes of the ventilation cavity can be opened and closed under the control of corresponding valves, and a grain outlet is arranged on the lower side of a side wall of the grain storing case. The grain drying and storing granary has the advantages that the grain drying and storing granary is simple and practical in structure, harvested high-moisture grains can be loaded into the grain drying and storing granary at one step, and grain piles can be stereoscopically bi-directionally dried at a low temperature in a multilayer manner, so that the safe storage requirement on the moisture content of the grains can be timely and quickly met, the high-moisture grains can be dried by the grain drying and storing granary, and the integrity of the grains can be guaranteed.

Owner:杨益荣

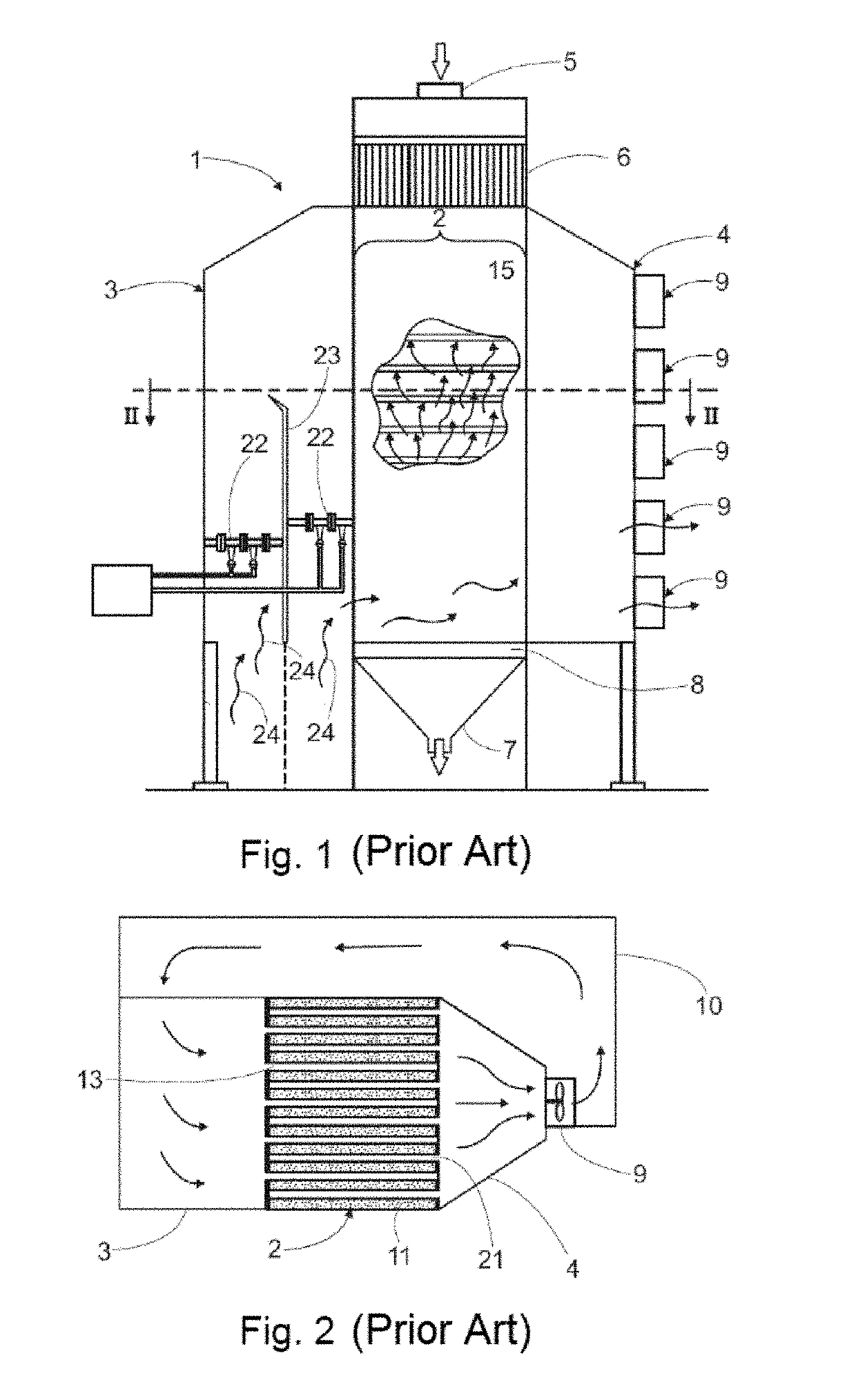

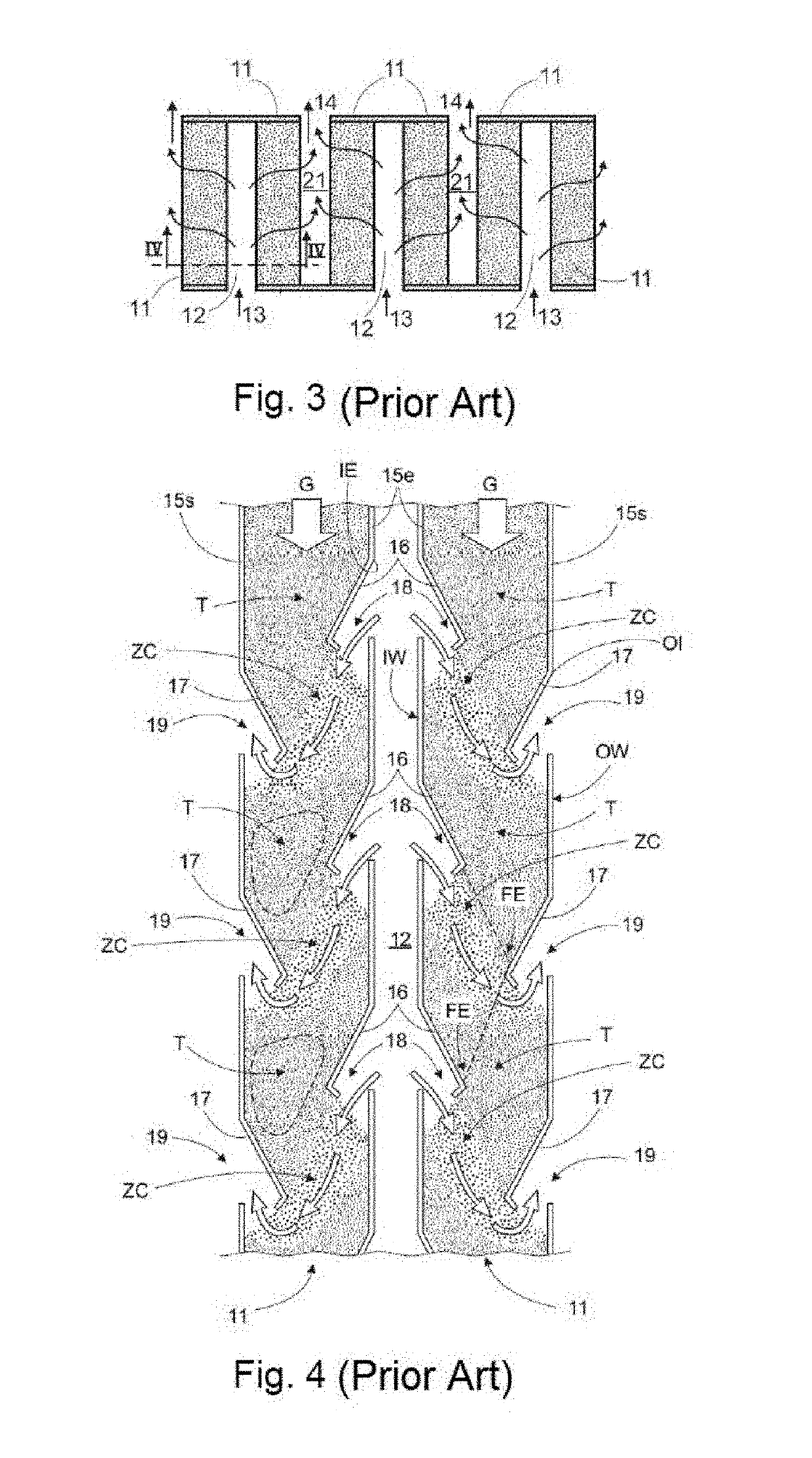

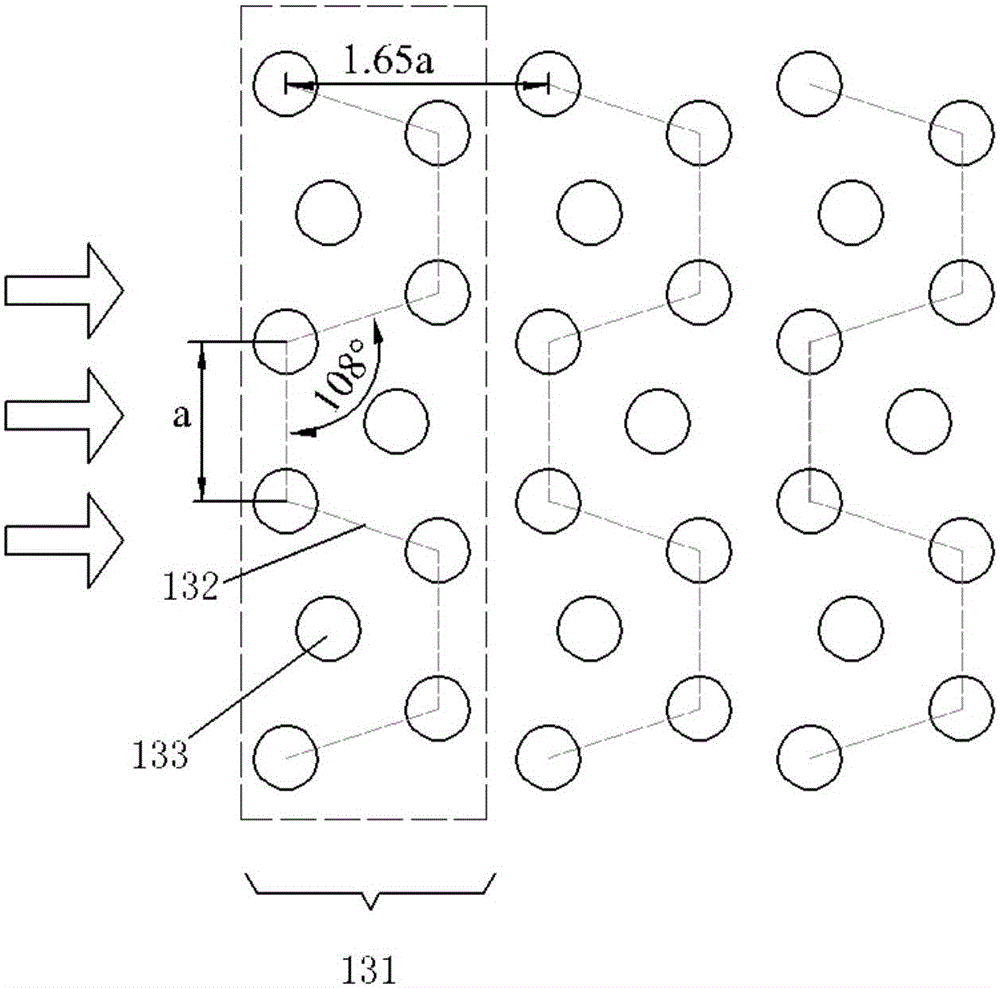

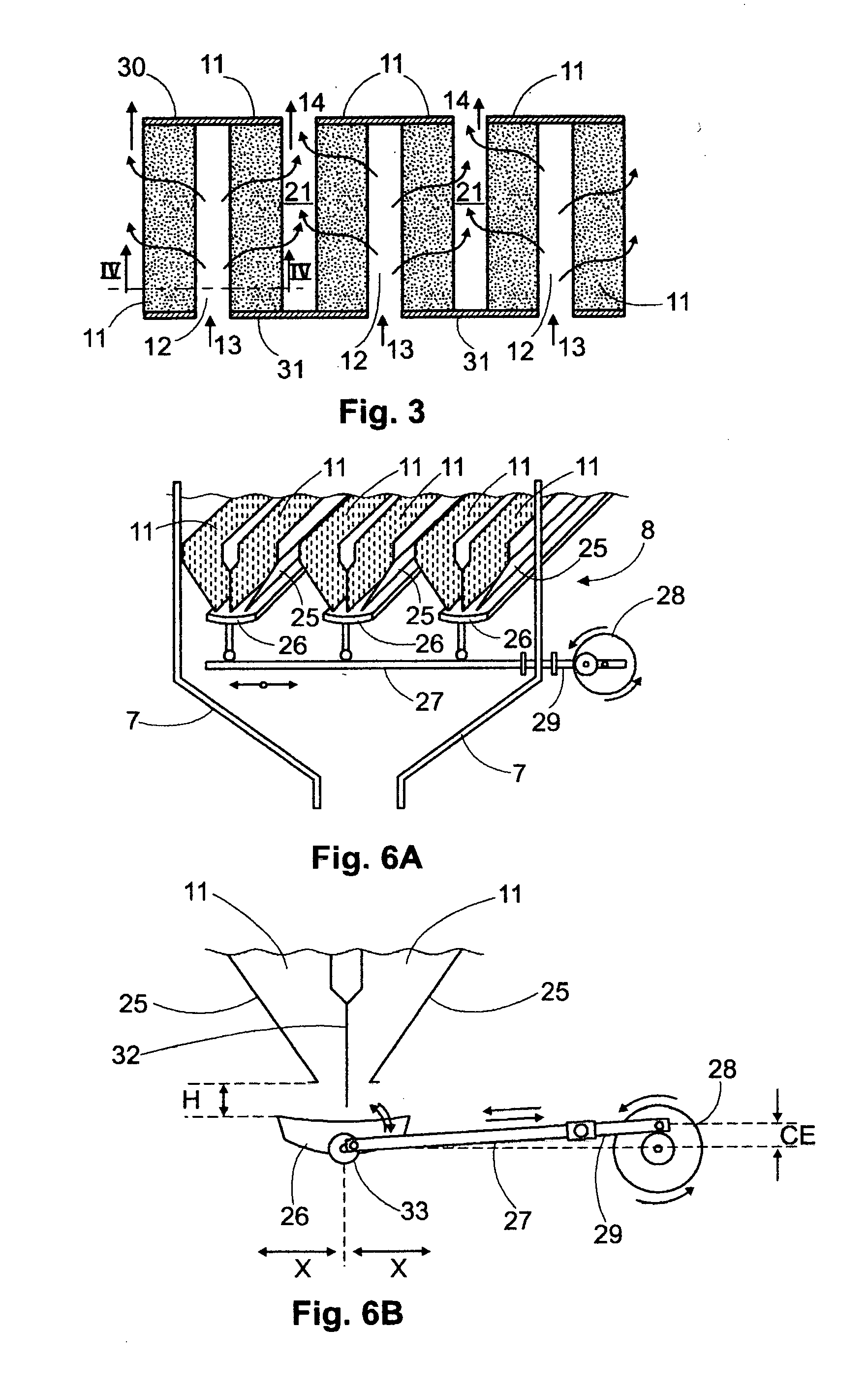

Continuous flow grain dryer

InactiveUS20060123655A1Drying using combination processesDrying solid materials with heatContinuous flowWaste management

A continuous flow grain dryer comprising a plurality of vertical columns for receiving and heating / drying grain, with each column having an inlet wall including side drying air inlets, and an opposite outlet wall including side exhausted air outlets, wherein the inlets and outlets are provided with diverters angularly extending towards a longitudinal axis of the column and defining a central clear region for permitting the free downward moving of the grain, with an air descending path being defined between an inlet and a downwardly adjacent outlet, and a tempering region being defined between a diverter and an associated opposite wall portion.

Owner:ING MEGA

Efficient grain drying and sieving-in-one machine

InactiveCN107356073AAvoid accumulationEvenly heatedDrying gas arrangementsSeed preservation by dryingEngineeringAir blower

The invention discloses a high-efficiency integrated grain drying and screening machine, which comprises a support frame, a drum, a hot air pipe, and a sieve plate; the drum is rotatably arranged in the support frame; Connect the feeding pipe; one end of the hot air pipe is connected to the hot air blower, and the other end passes through the right rotating shaft from the center of the right rotating shaft of the drum and penetrates into the drum. The hot air pipe is densely arranged on the drum body. Air outlet; the hot air pipe is located at both ends of the tube body of the drum, and a group of straight rods are arranged, each group of straight rods has two and symmetrically distributed, and the end of the straight rod away from the hot air pipe is rotated and connected with a turning rod; The sieve plate is arranged below the feeding port. The invention can turn the grains during the grain drying process, avoid the accumulation of the grains, make the grains heated evenly, thereby ensuring the drying effect; meanwhile, it also has the function of screening.

Owner:安庆海维环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com