Patents

Literature

264 results about "Grain moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

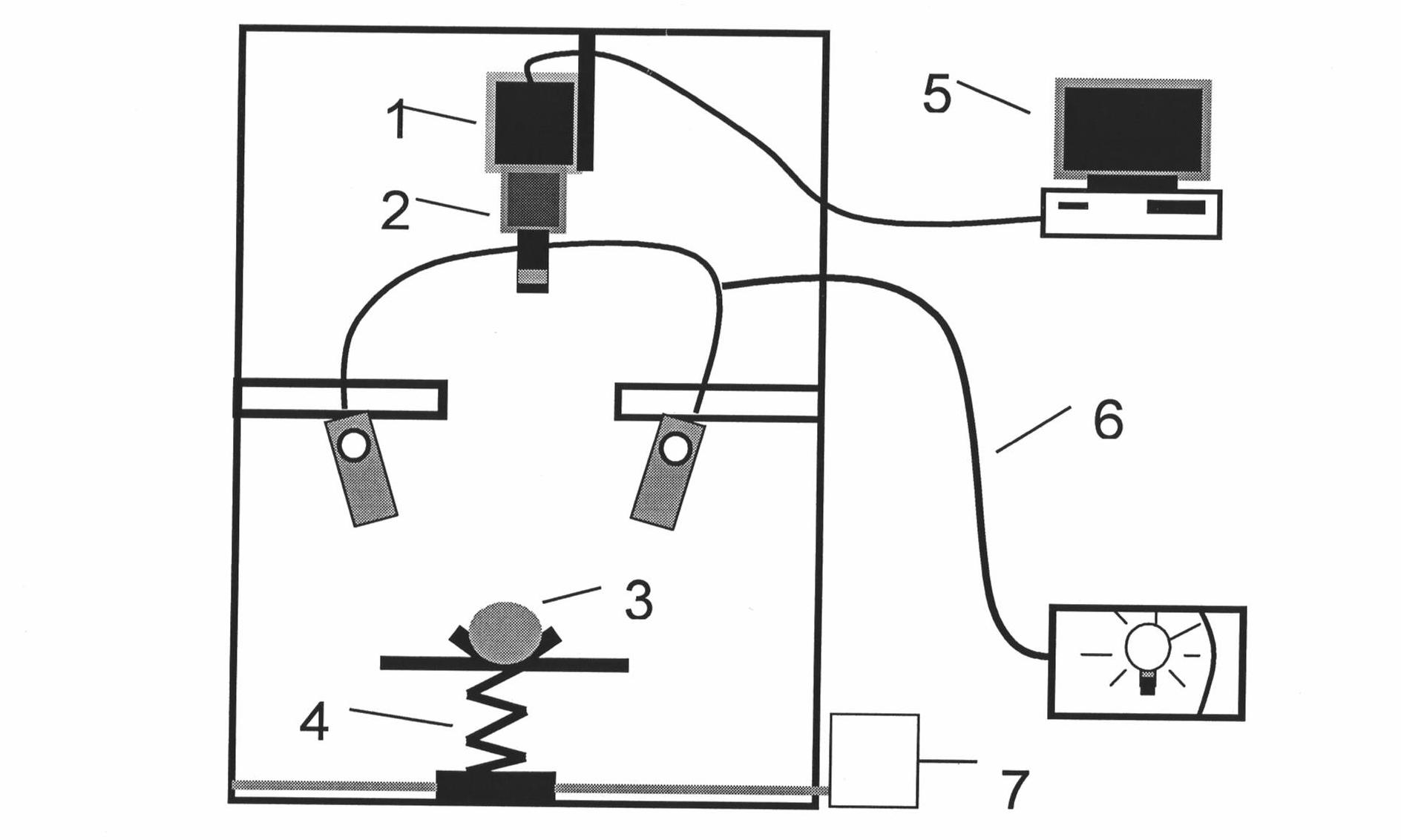

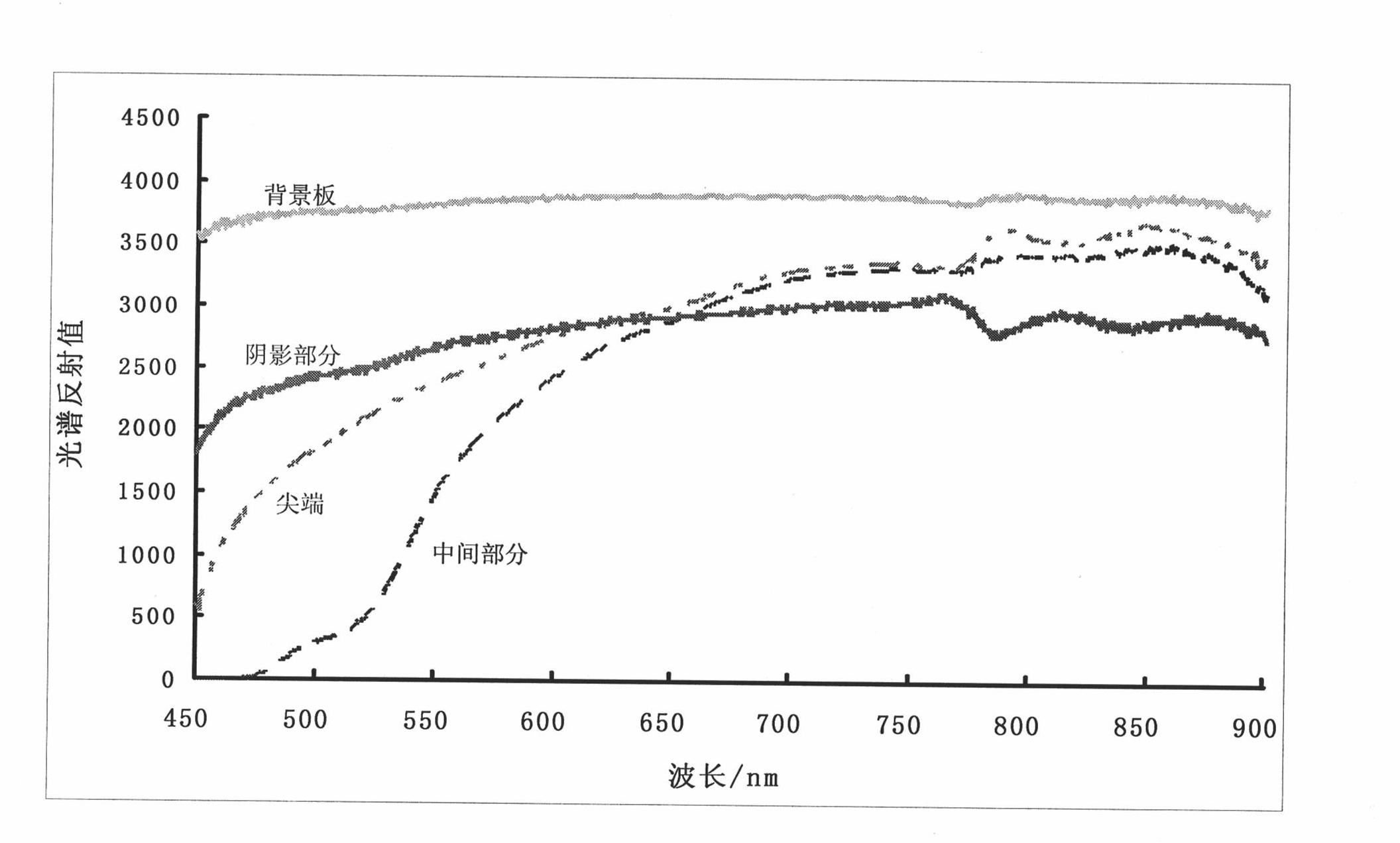

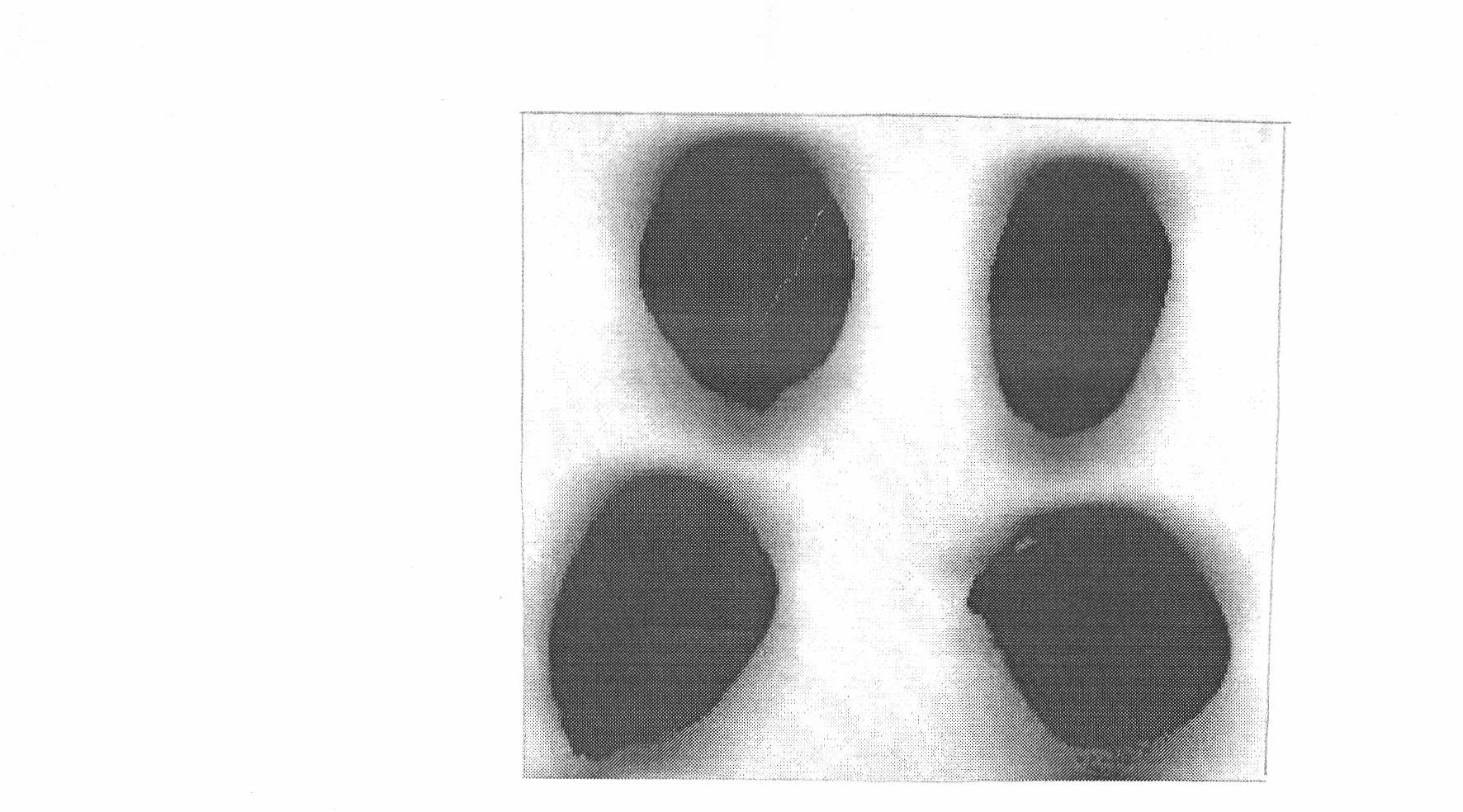

Grain moisture content detecting method based on hyperspectral image technology

InactiveCN102033043AFast wayMethod stableBiological neural network modelsColor/spectral properties measurementsMoving averagePattern recognition

The invention discloses a grain moisture content detecting method based on a hyperspectral image technology, which comprises the following steps: respectively acquiring an all black calibrated image B, an all white calibrated image W and a hyperspectral original data image I of grains the moisture content of which is given; carrying out reflection spectral correction on the hyperspectral original data image I of grains by the all black calibrated image B and the all white calibrated image W to obtain a corrected image R of grains; extracting the grain image from the corrected image R; carrying out spectral correction by a moving average method and multiplicative scatter correction; calculating the correlation coefficients of spectral reflection values and the moisture content; selecting a correlation coefficient as the maximum spectral reflection value to be input into an artificial neural network; and establishing a grain moisture prediction model. In the invention, the grain moisture content is detected by the artificial neural network according to the spectral signature of the grains caused by the moisture content, a quick stable method is provided, and the detecting efficiency is improved.

Owner:ZHEJIANG UNIV

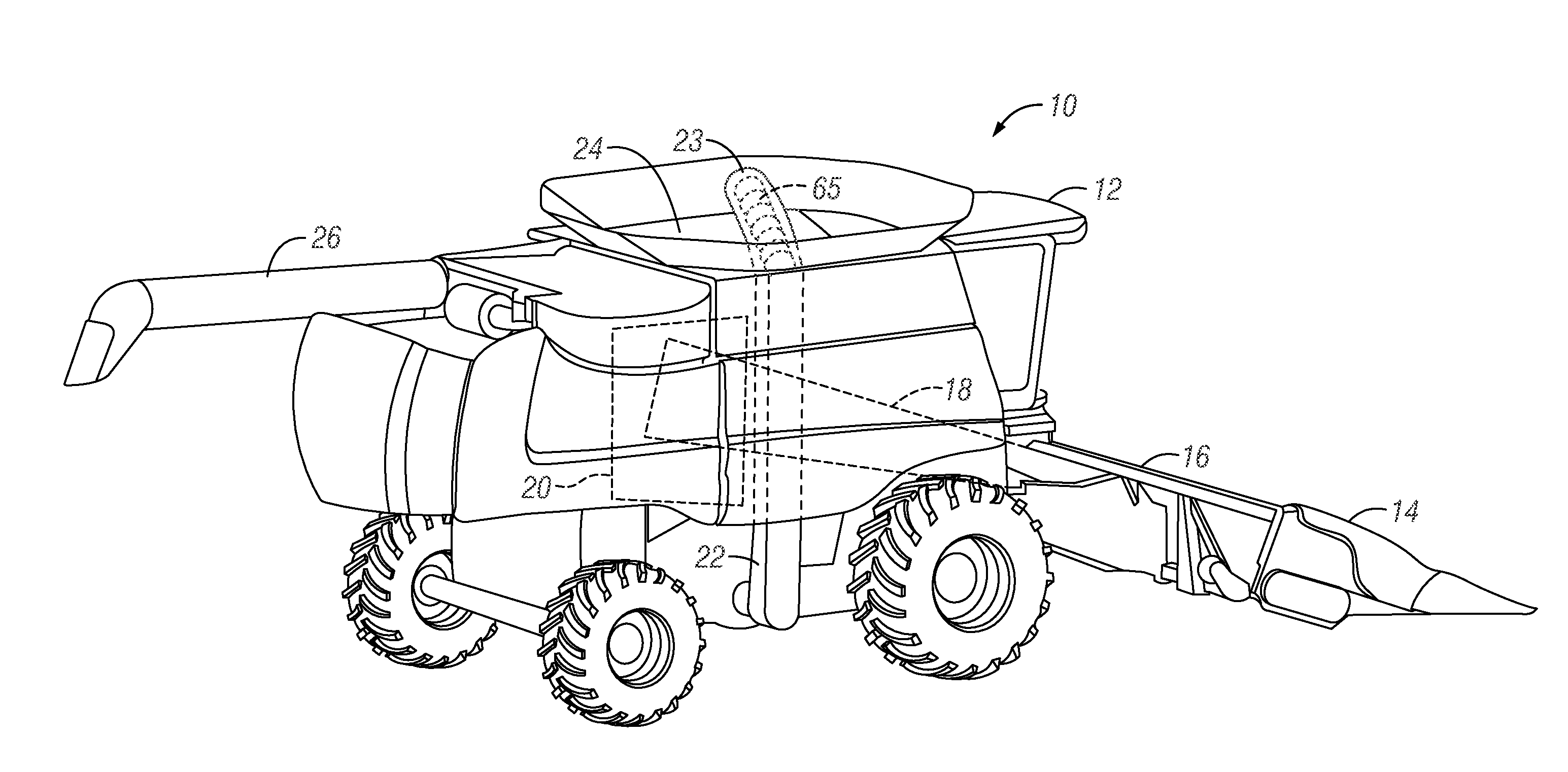

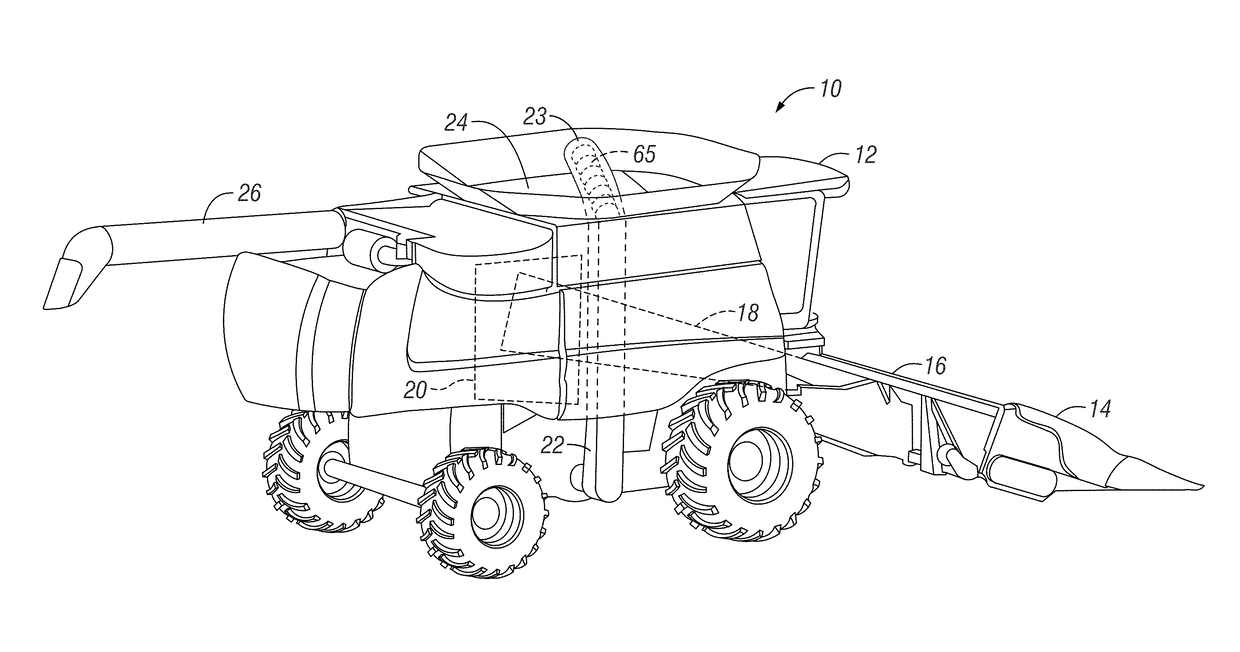

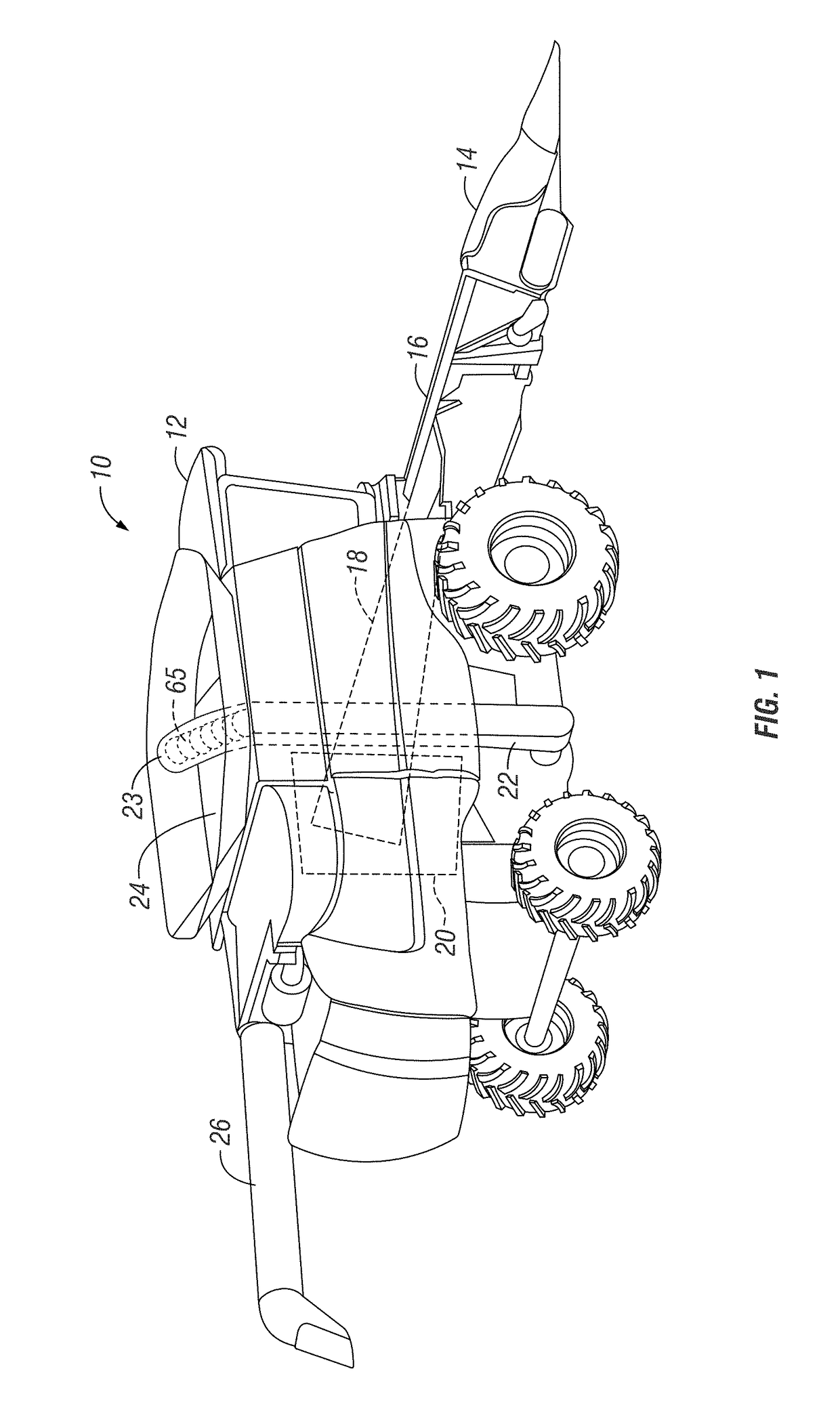

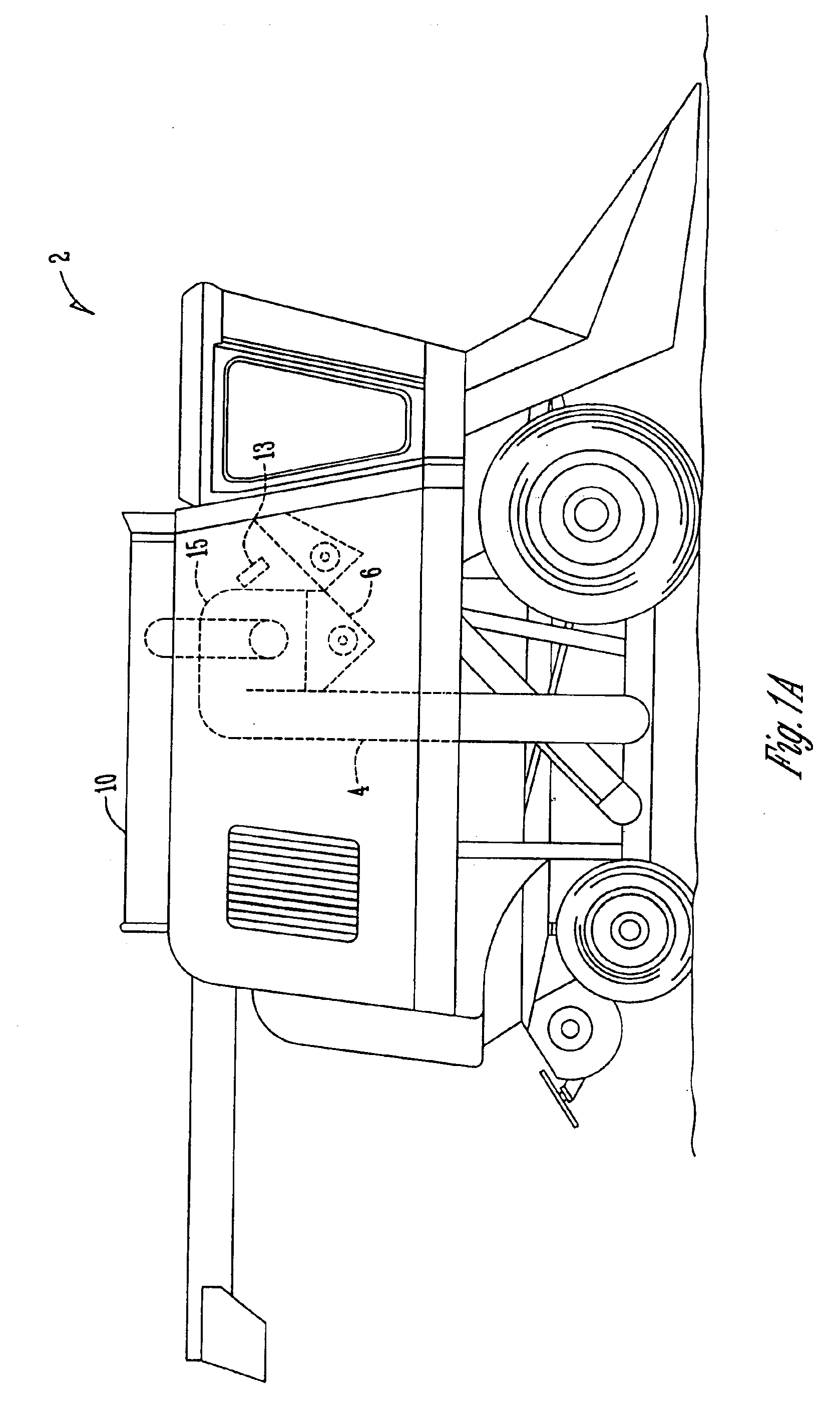

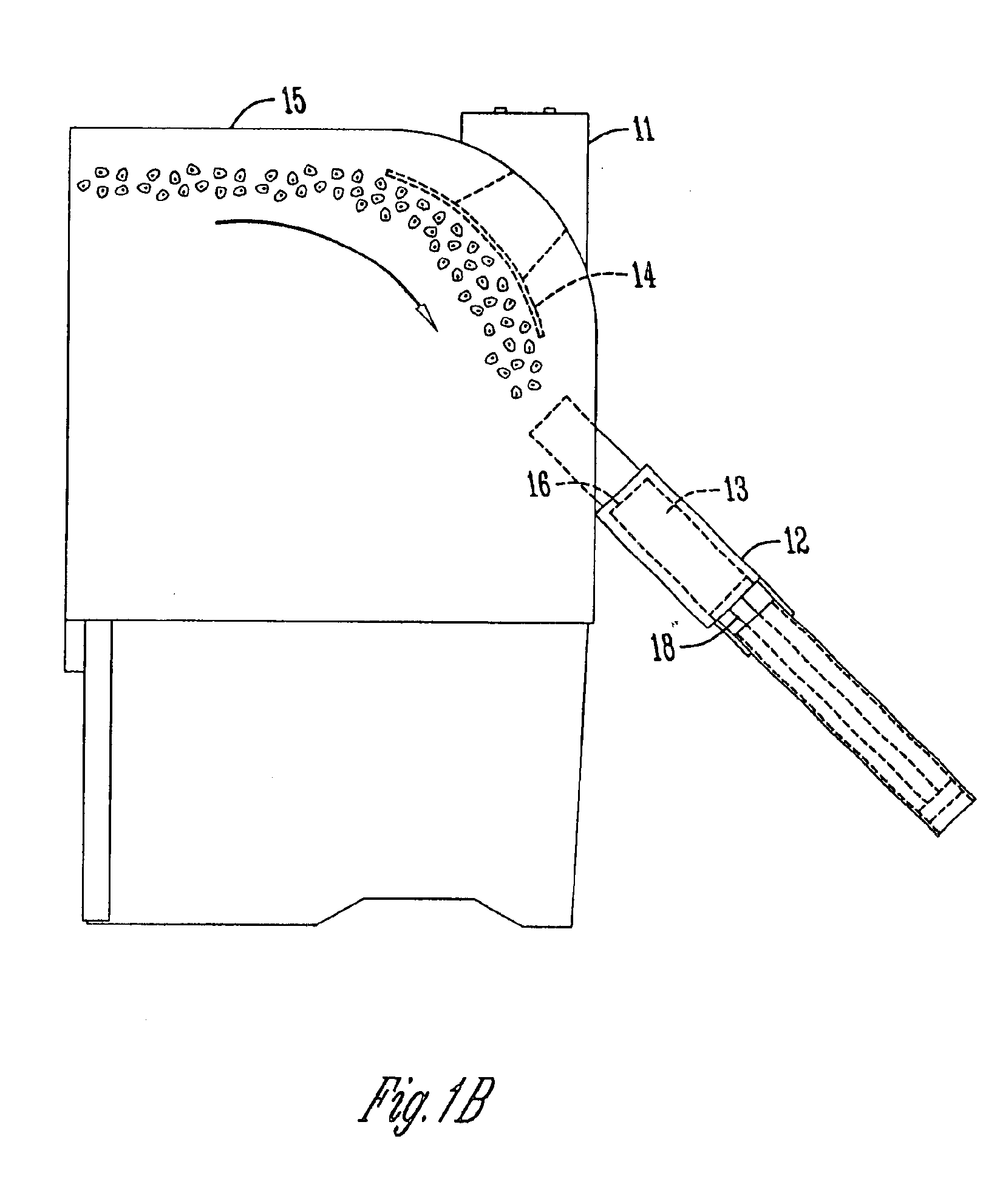

Automatic compensation for the effect of grain properties on mass flow sensor calibration

ActiveUS20150168187A1Minimize changesMowersVolume/mass flow by dynamic fluid flow effectEngineeringGrain moisture

A yield monitor system is configured to determine how the calibration characteristics of a grain mass flow sensor on an individual combine are affected by grain moisture content and / or other grain parameters which can be measured instantaneously or periodically by the yield monitor system or its operator, or which can be observed by the operator, or which can be determined from other reference information, such as maps of where different grain varieties or hybrids were planted. Other systems, methods, and apparatuses are also provided.

Owner:LEADER TECH

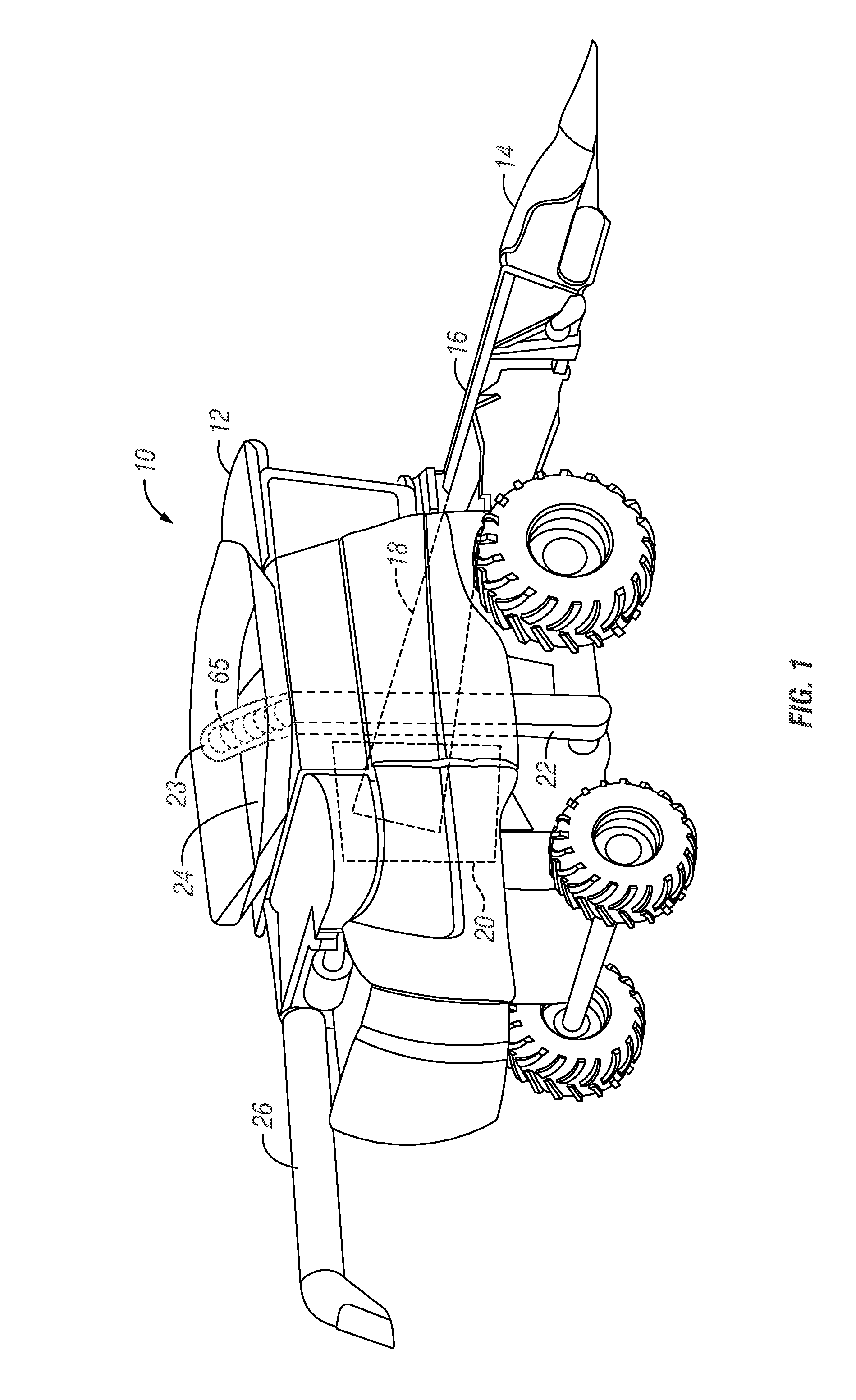

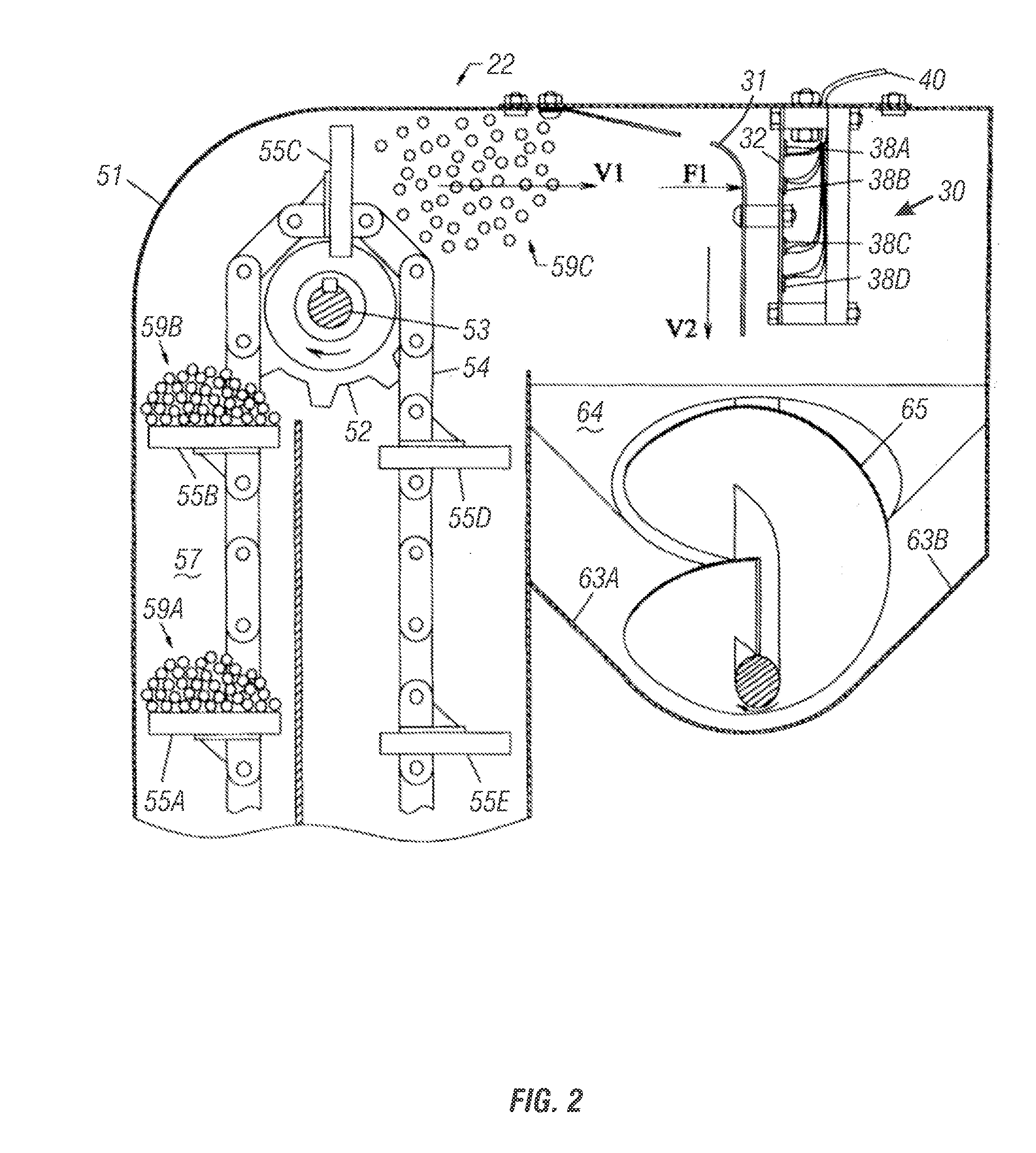

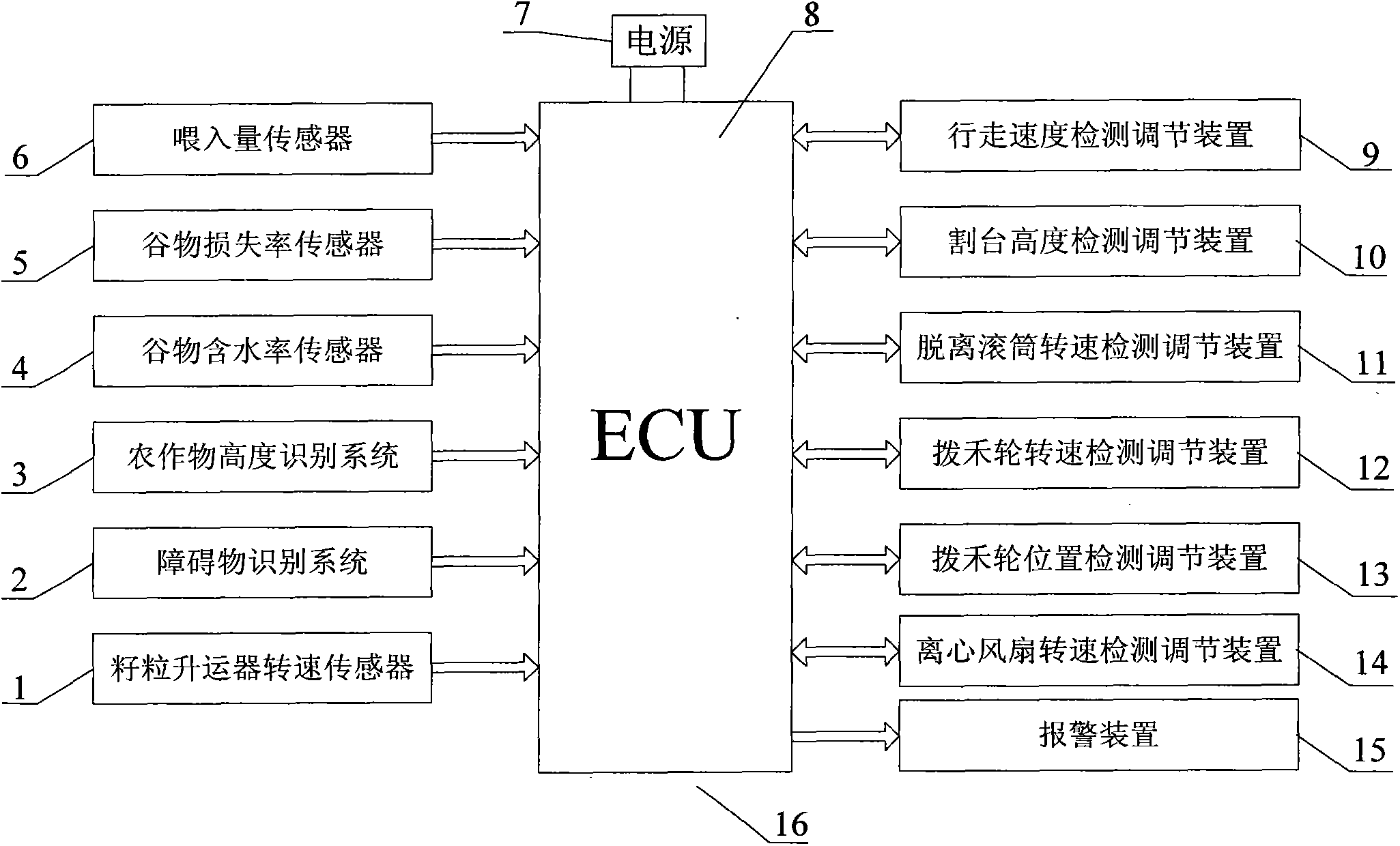

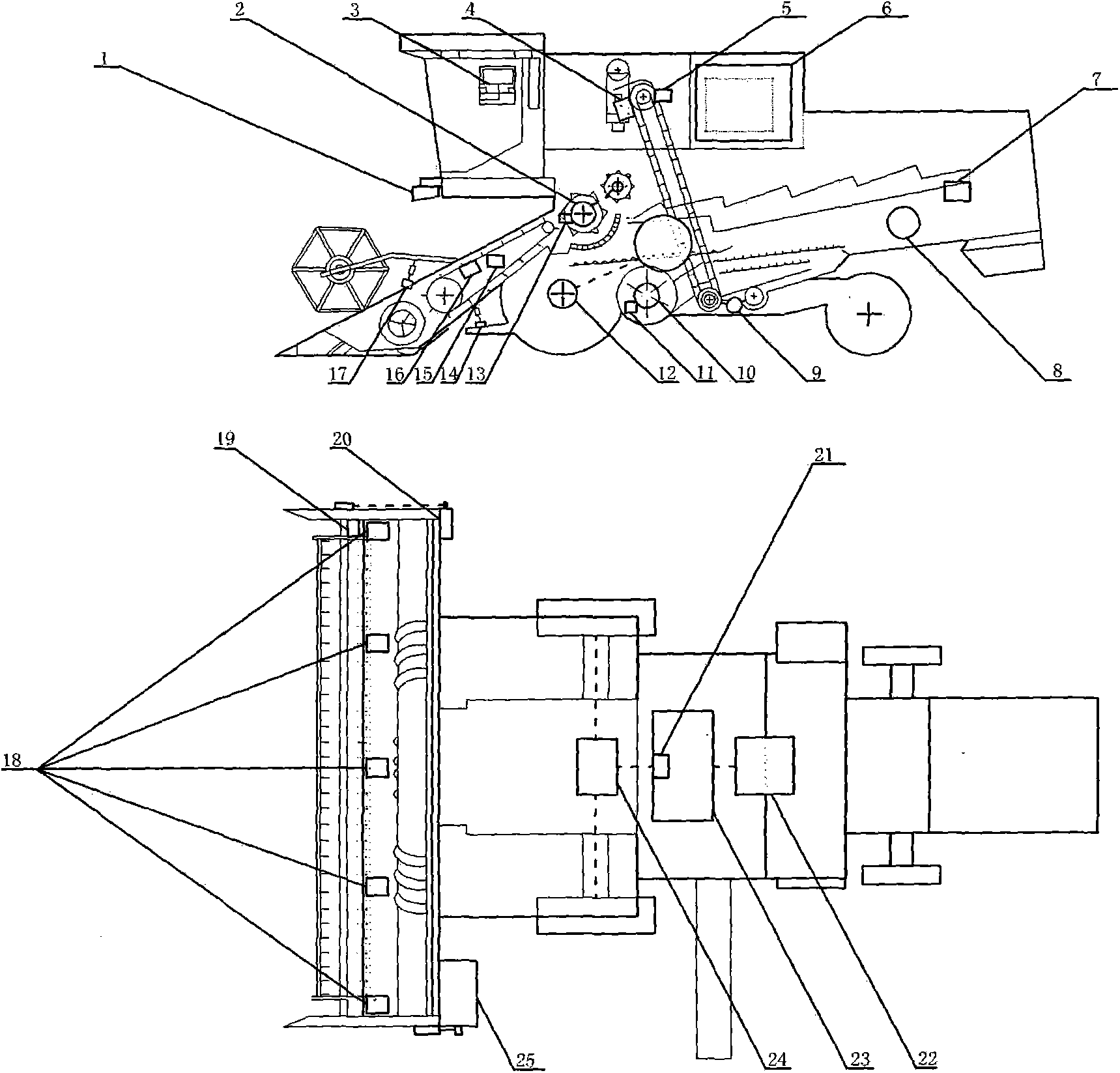

Electrically-driven intelligent combine-harvester control system

The invention relates to an electrically-driven intelligent combine-harvester control system, and belongs to the field of agricultural machinery. Different sensors are used for detecting feed quantity signals, grain loss rate signals, grain moisture content signals, crop height signals, barrier existing situation signals, seed lift conveyer rotation speed signals, traveling speed signals, header height signals, threshing drum rotation speed signals and winder position and rotation speed signals of a harvester, measured values are sent to an ECU, after the compared processing is carried out between the measured values and setting values, the ECU sends out control commands, automatic adjustment on the traveling speed, the header height, the threshing drum rotation speed, the winder rotation speed and position and the centrifugal fan rotation speed is respectively carried out, corresponding alarm devices are started, and the harvester works in the best state. The intelligent level is improved, the grain losses are reduced, and the labor strength of a driver is greatly relieved.

Owner:NORTHWEST A & F UNIV

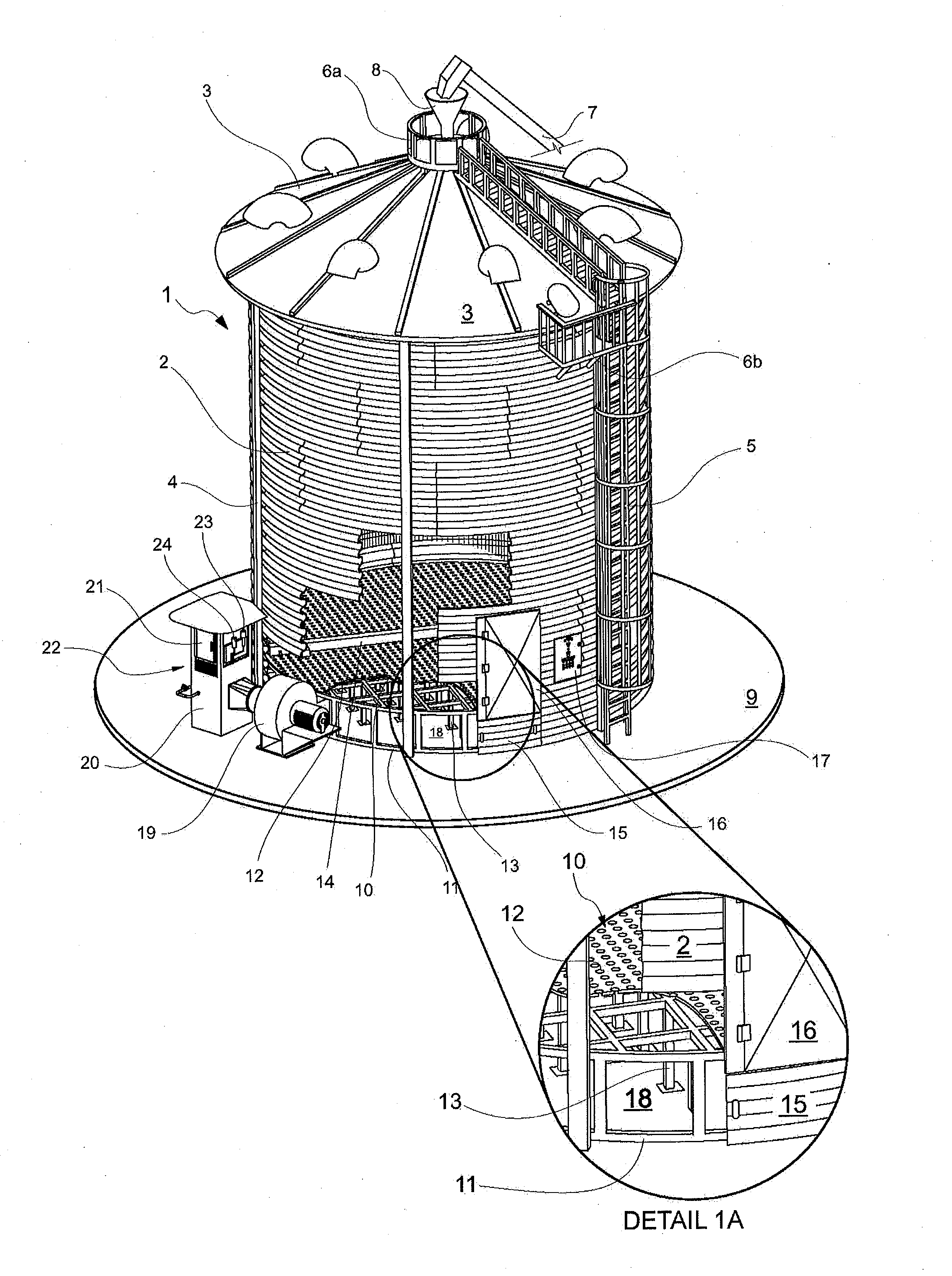

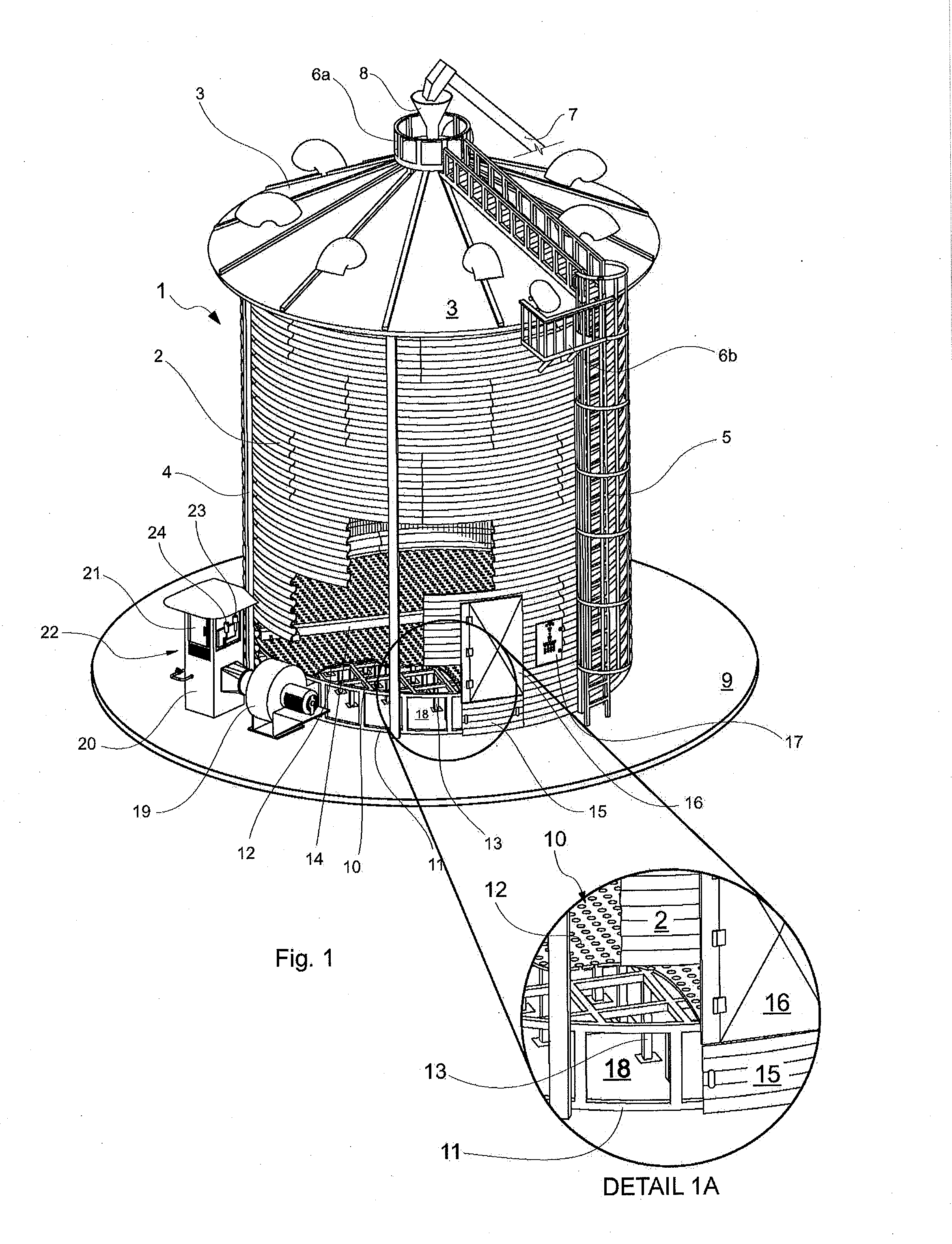

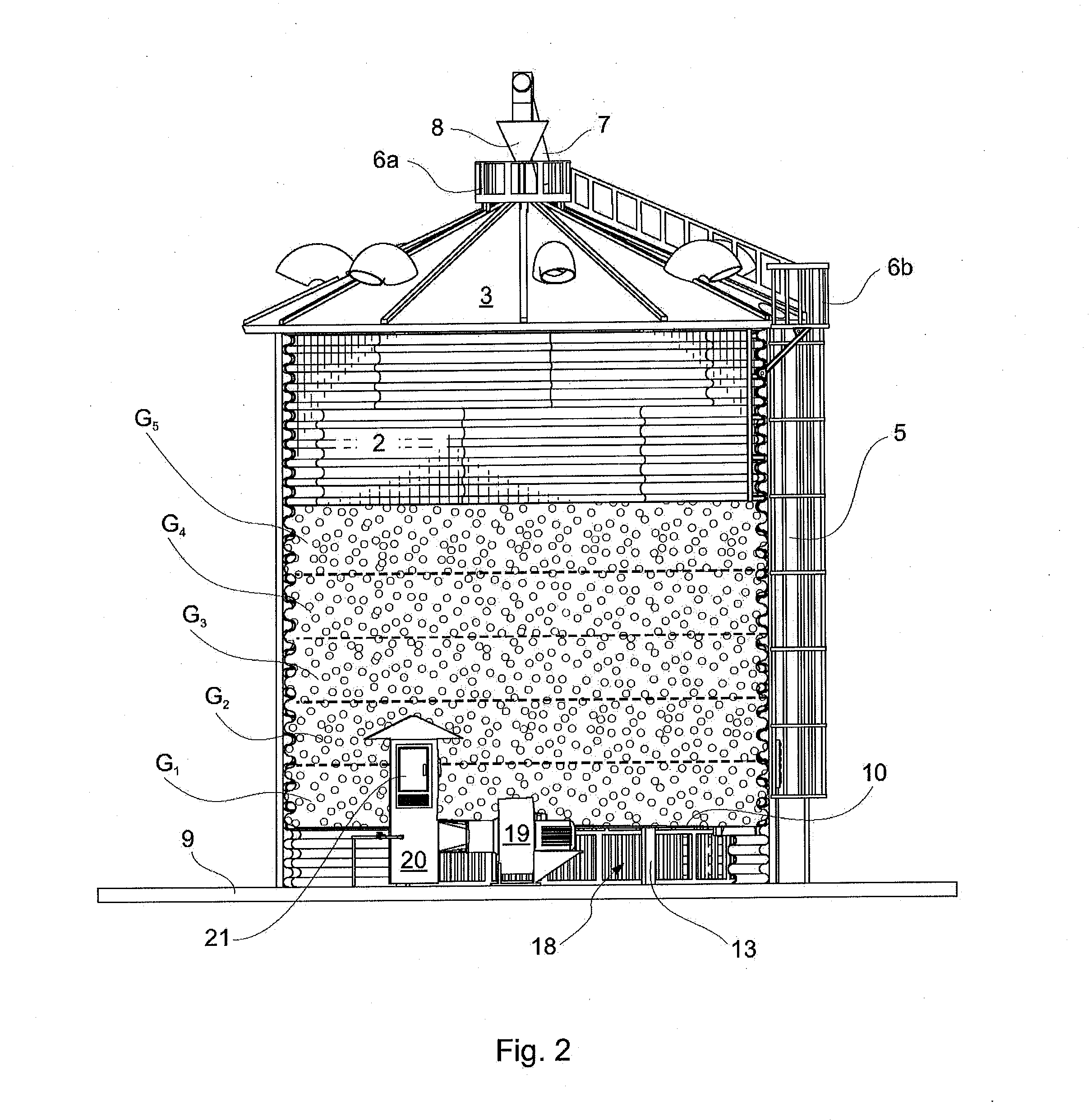

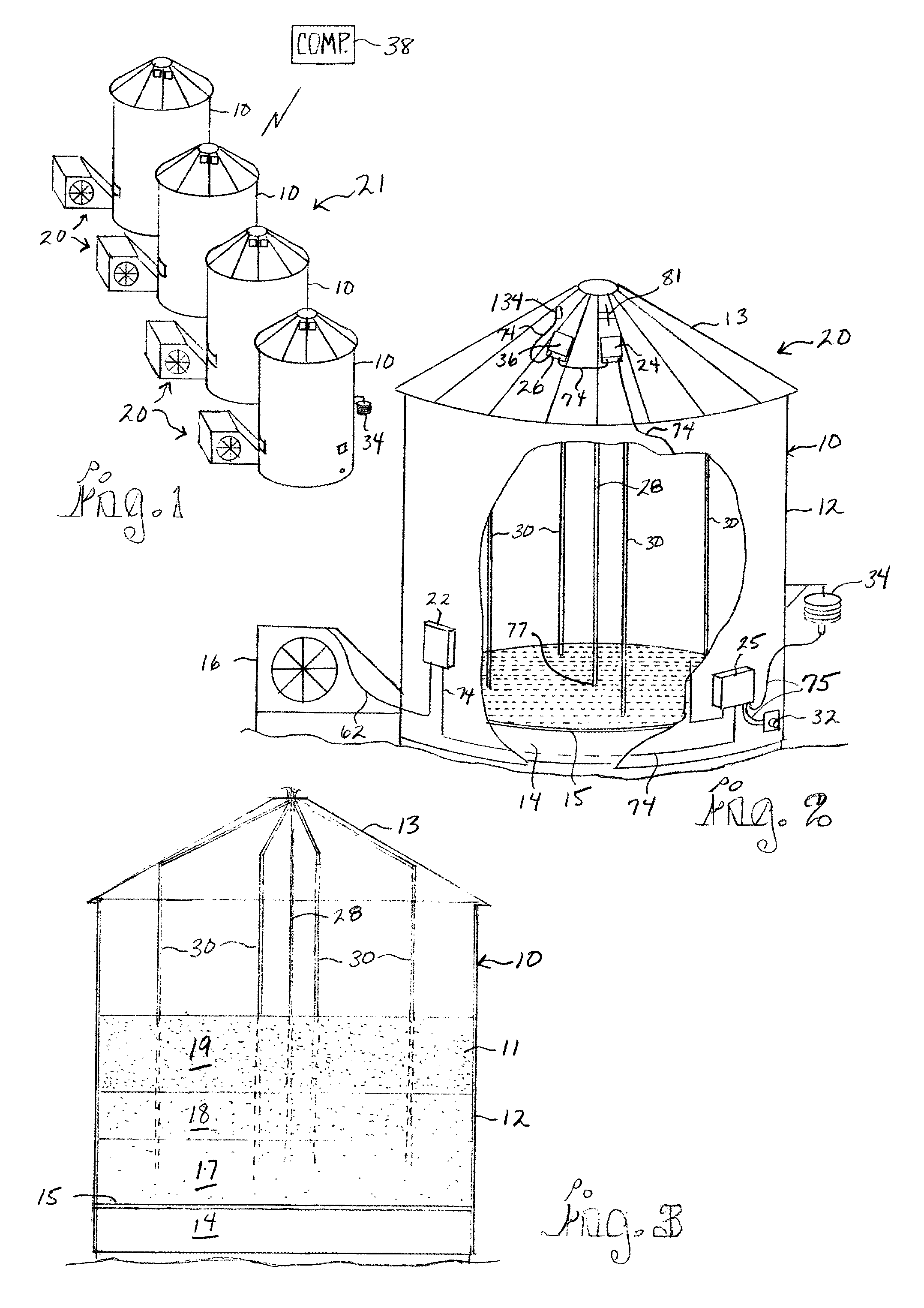

Procedure and facility for grain moisture control

ActiveUS20140360045A1The process is simple and effectiveEasy to set upAgriculture tools and machinesDrying solid materials with heatGrain storageEngineering

A facility for controlling the grain moisture provided with a grain storage silo conveniently installed on a hard flat floor and inside of which an elevated floor comprising air passageways is provided, determining an air chamber inside the silo and below the perforated floor, into which previously conditioned air is blown by an air heater, wherein the control of hot air blowing times is determined based on means of modeling and calculating on and off times applied through an electronic control means, with the ability to read and record manual input data entered by an operator and reading data from a temperature sensor in the air chamber, below the perforated floor, further aided with an ambient temperature and moisture sensor, thereby causing the application of different stages of drying, re-humidification and maintenance of the grain moisture.

Owner:INST NACIONAL DE TECNOLOGIA AGROPECUARIA

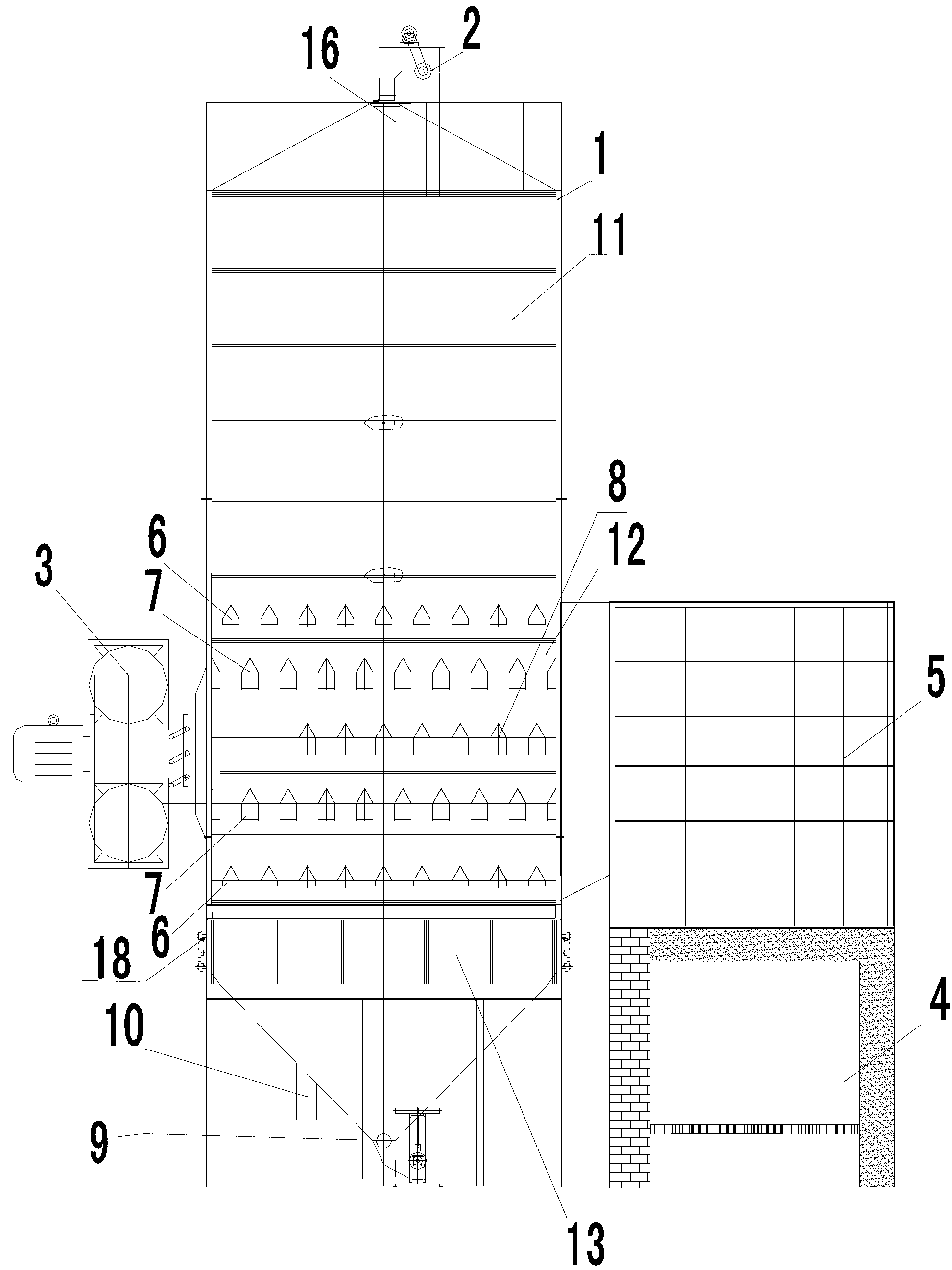

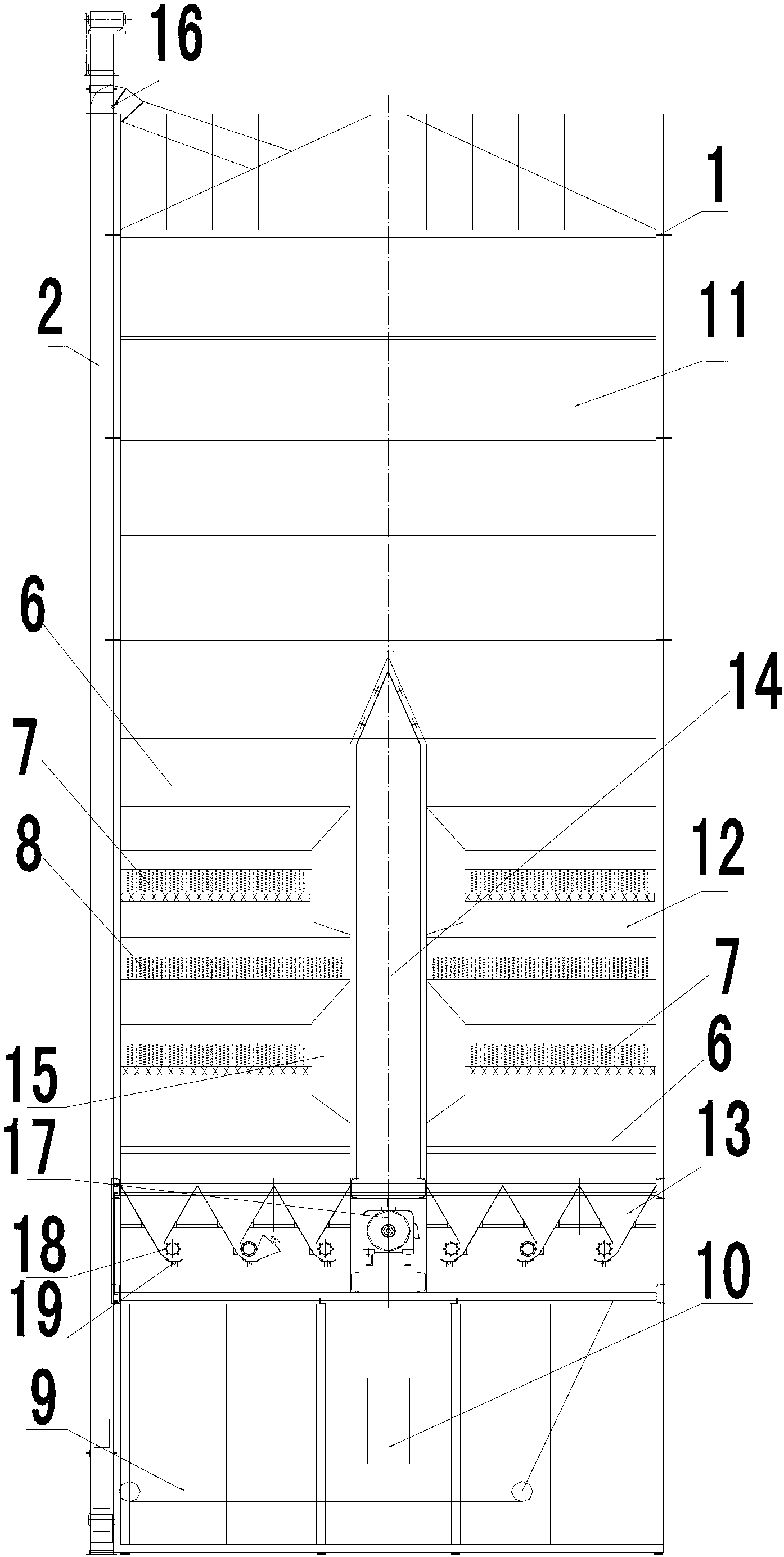

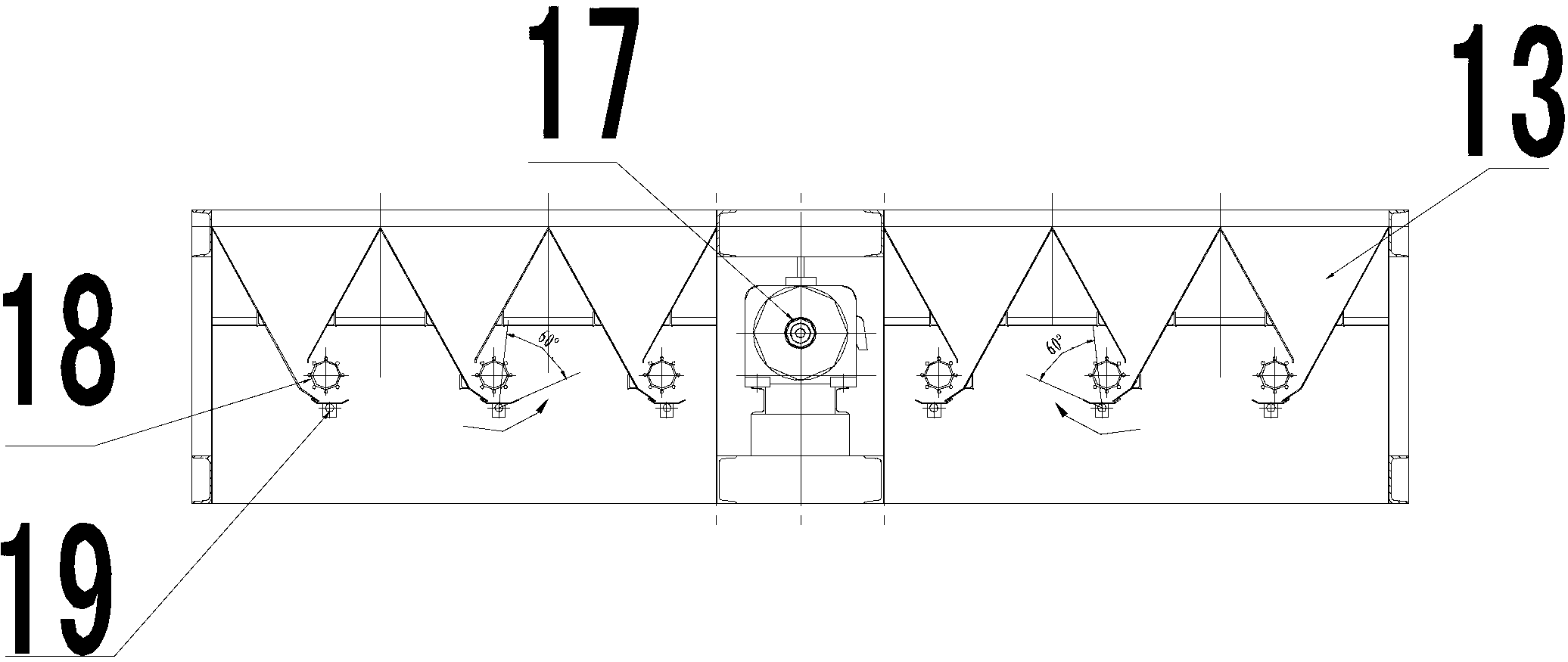

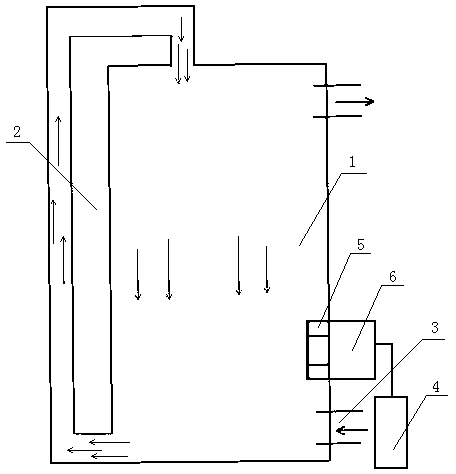

Low-temperature circulation dryer for crop seeds

InactiveCN103070232ARealize cycleImprove uniformityDrying gas arrangementsSeed preservation by dryingHigh energyEngineering

The invention discloses a low-temperature circulation dryer for crop seeds, which comprises a dryer body, a hoister, a draught fan, a hot-blast furnace, a heat exchanger, small air inflow angle boxes, air exhaust angle boxes, air inflow angle boxes, a grain discharge device, a delivery machine under the dryer and a grain-moisture and drying-temperature on-line detector. The low-temperature circulation dryer solves the problems of uneven material drying, higher energy consumption, a low annual utilization rate and the like in the prior art effectively, and has the characteristics of simple structure, simplicity in operation, high applicability, high-quality, efficient, safe and energy-saving low-temperature quick drying and the like.

Owner:SOUTH CHINA AGRI UNIV

Automatic compensation for the effect of grain properties on mass flow sensor calibration

ActiveUS9714856B2Minimize changesMowersVolume/mass flow by dynamic fluid flow effectEngineeringGrain moisture

Owner:LEADER TECH

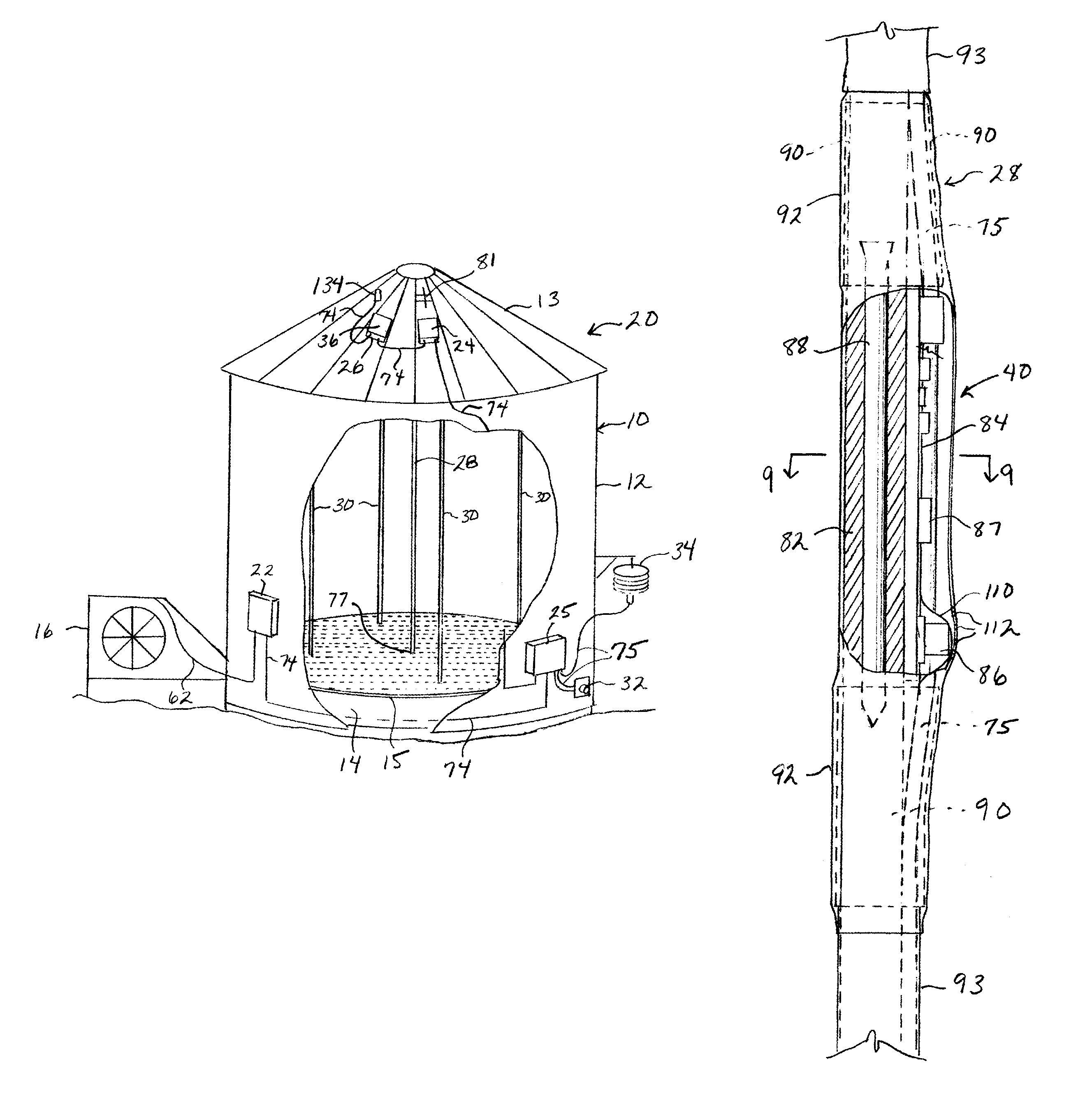

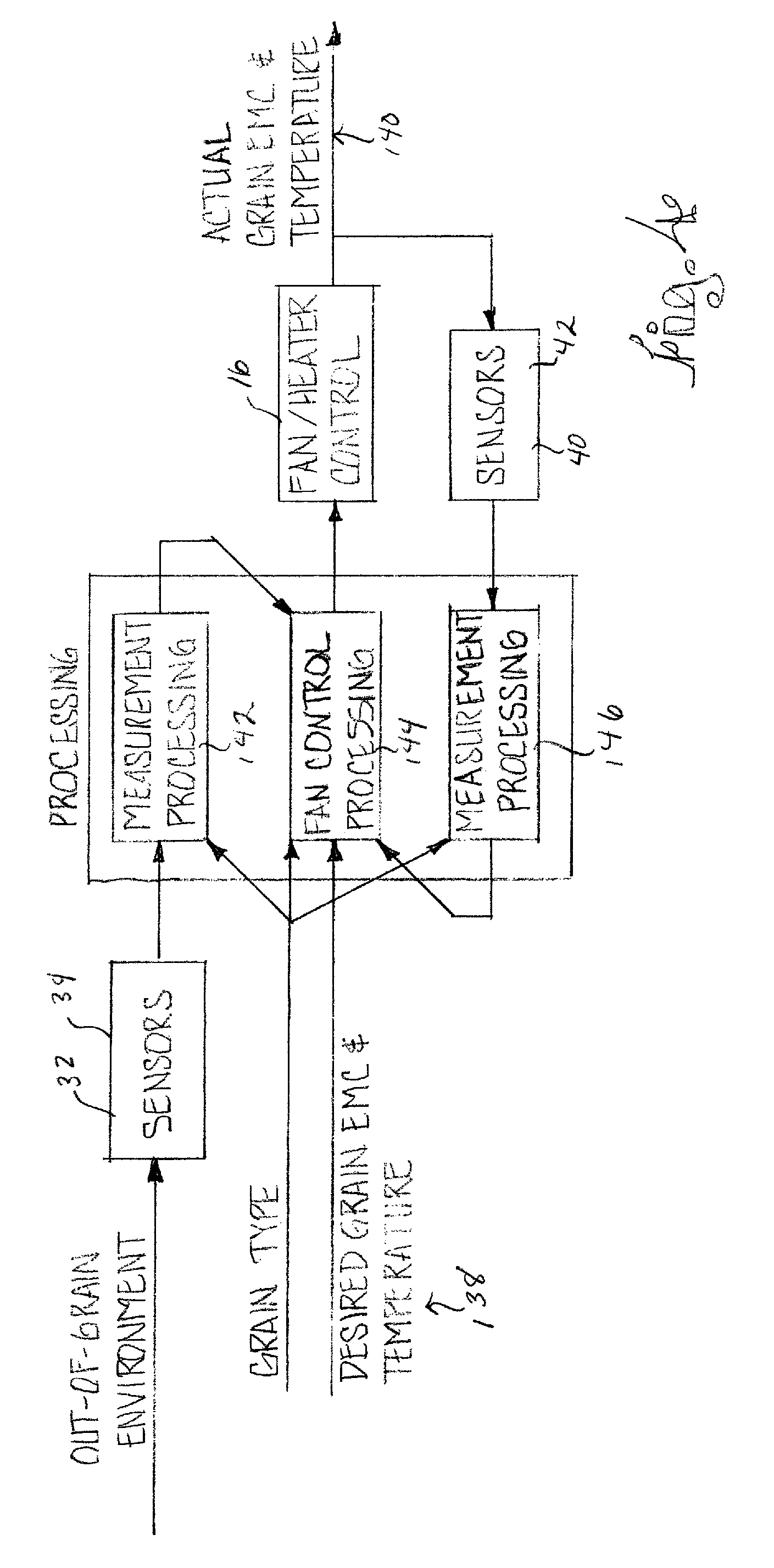

Grain drying system

ActiveUS8806772B1Accurately determinedEasy to determineDrying solid materials with heatDrying gas arrangementsModem deviceGrain storage

A grain drying system includes a master control unit external to the grain storage bin which is preprogrammed with a desirable grain moisture content or EMC. Condition sensor assemblies mounted within the grain bin determine the relative humidity and the temperature of the grain within the grain bin. Also, sensors mounted in the bin's plenum determine temperature, relative humidity and air pressure. A weather station mounted externally of the grain bin determines the outside air temperature and relative humidity. Depending on the conditions determined by the sensor assemblies and the weather station, the master control unit selectively activates the grain bin's drying fan when needed and when it is efficient and effective to do so. A radio or cellular modem allows for communication of the grain's condition. The internal sensor assemblies are preferably secured to flexible cables hung within the grain bin. The cable and rigid rod-like members support the sensors. The sensors may be secured in a spaced relationship along the cable so that the grain condition can be determined throughout the grain bin.

Owner:AGI SURETRACK LLC

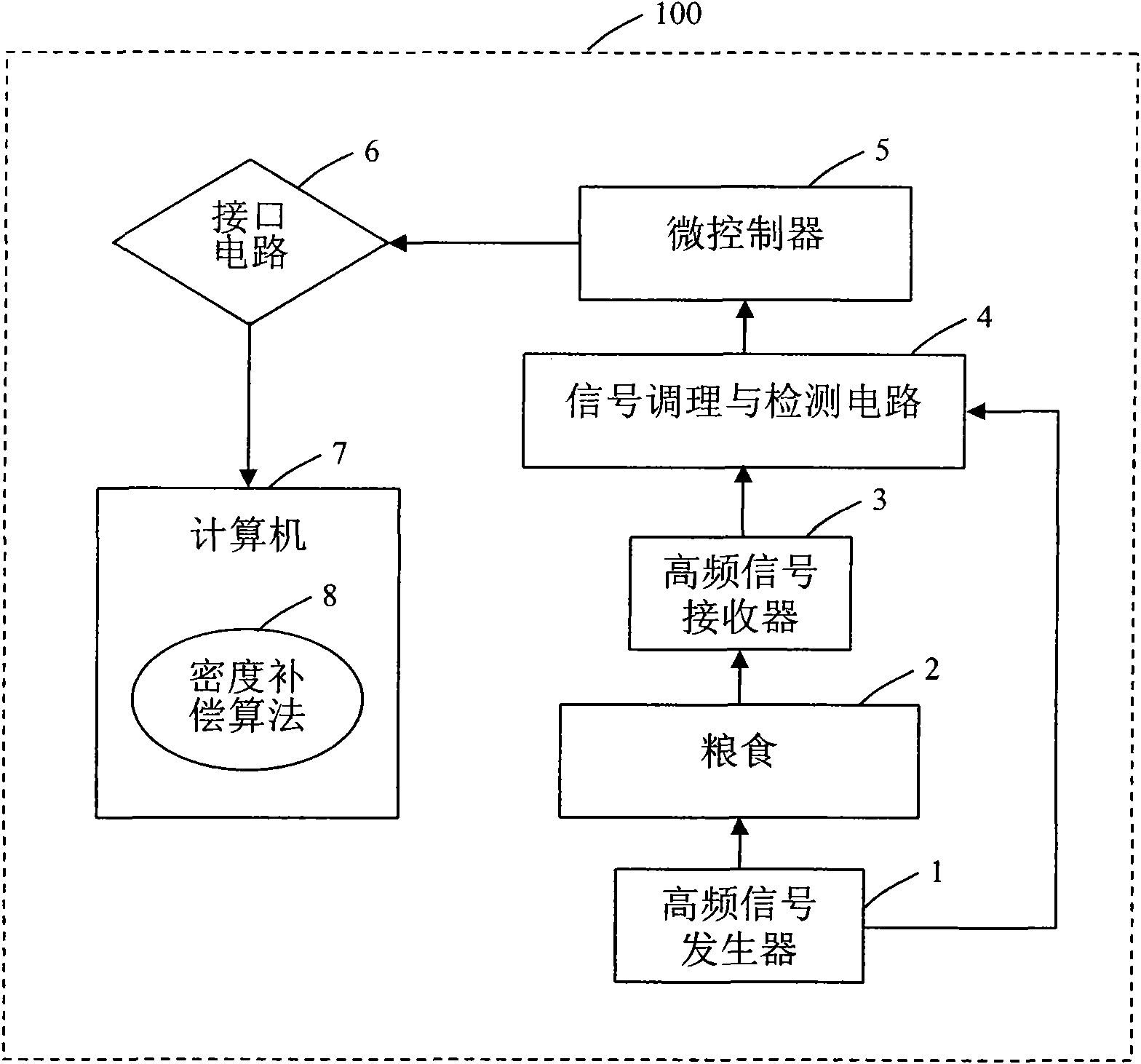

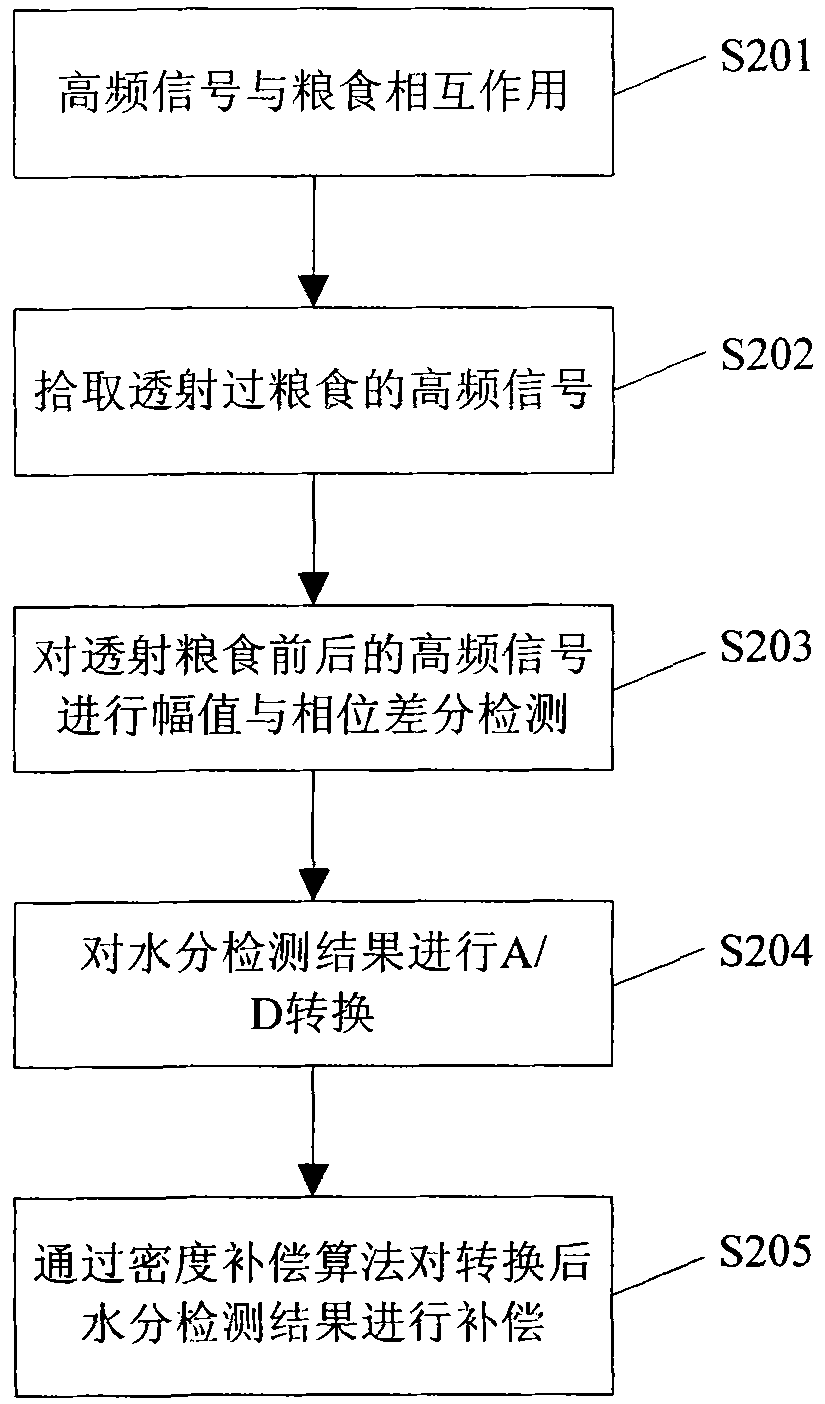

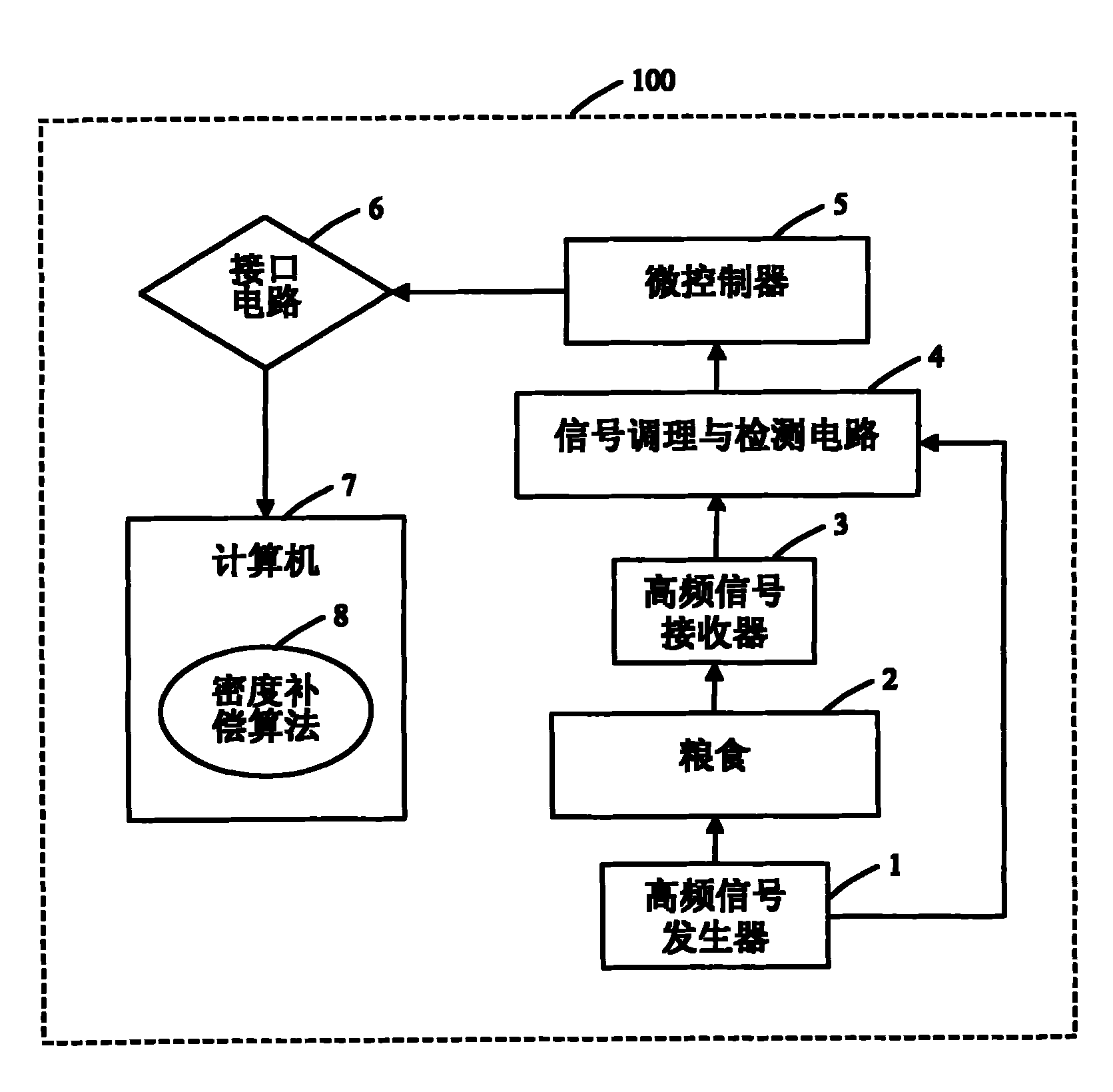

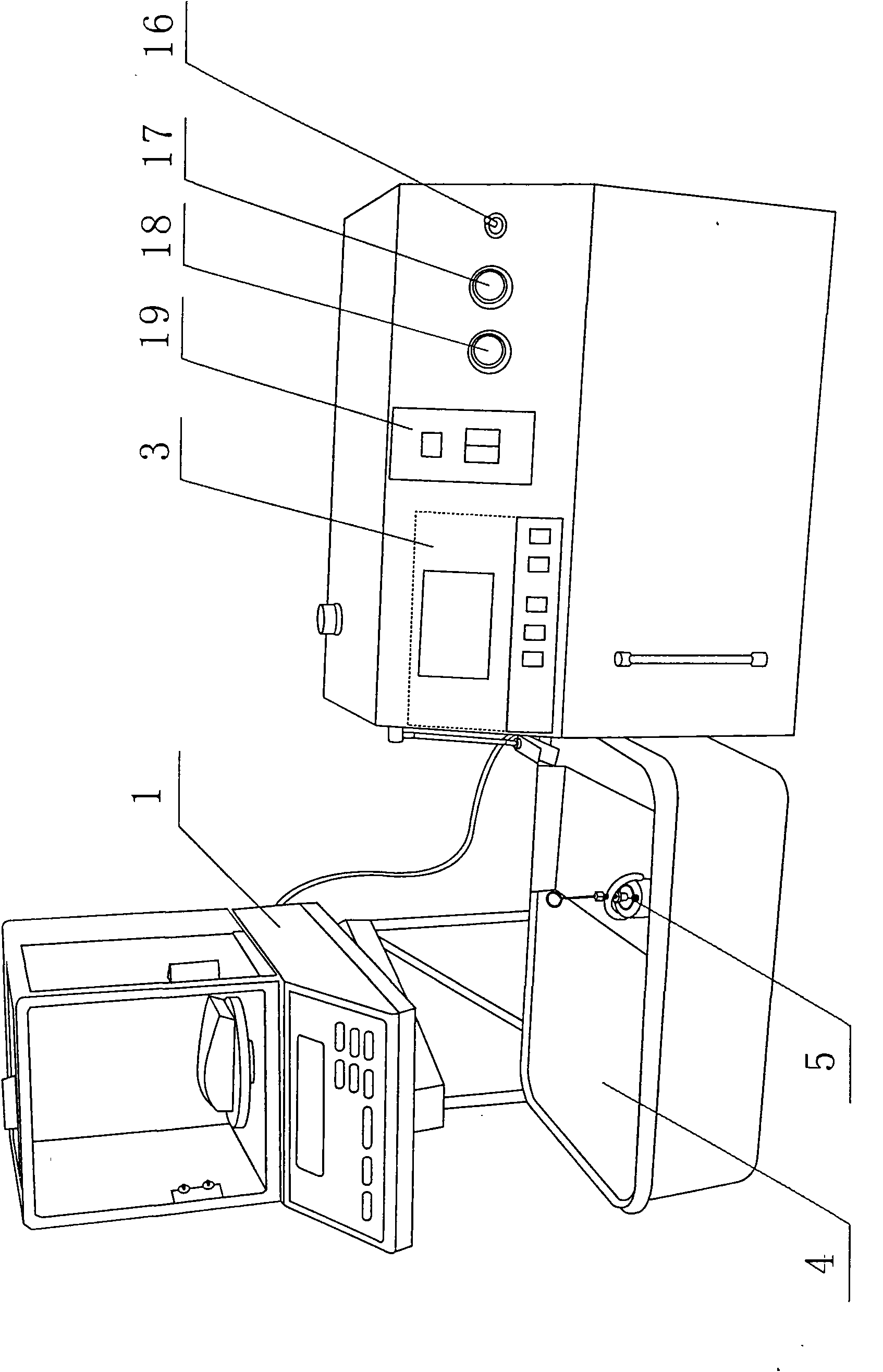

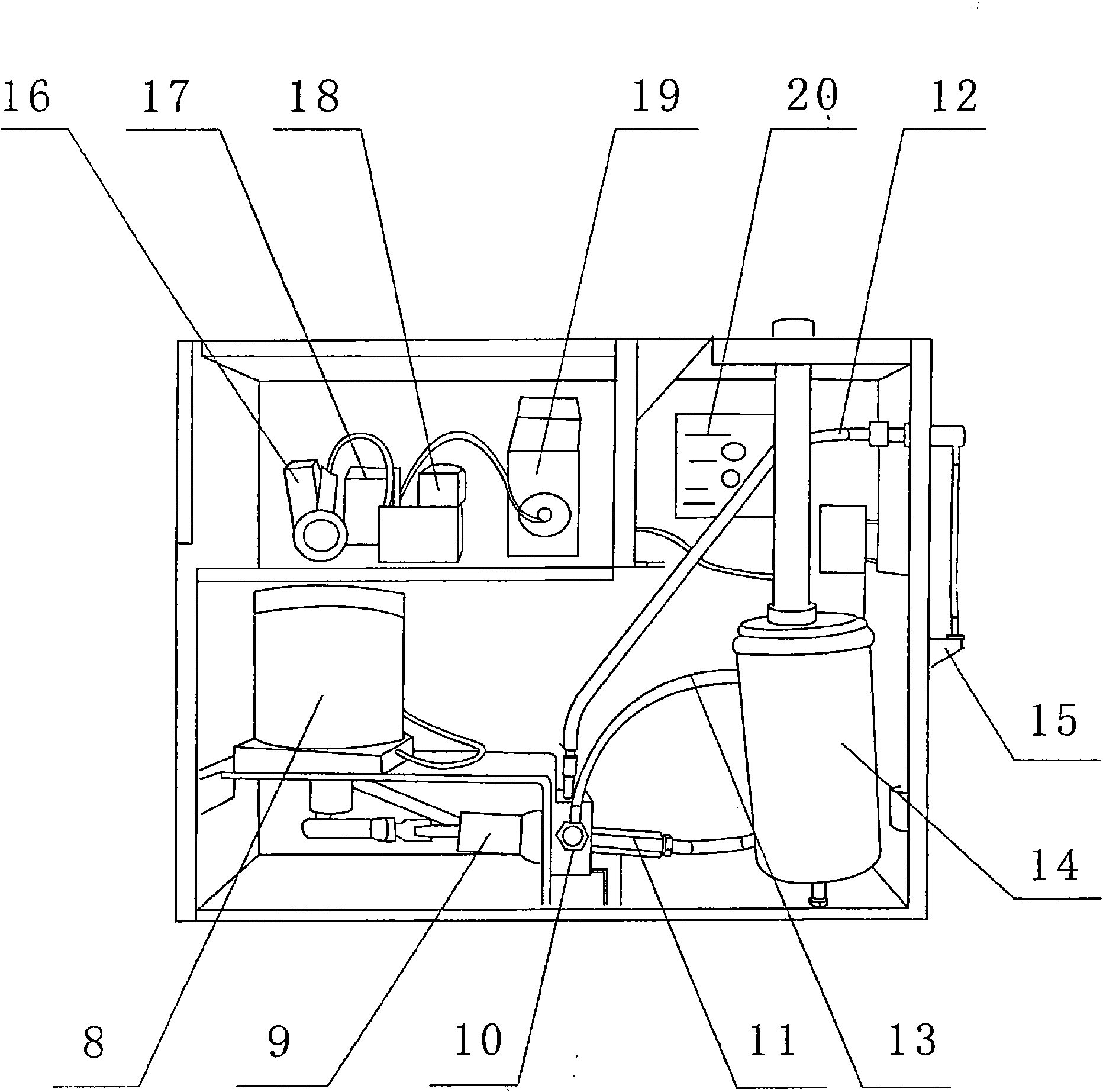

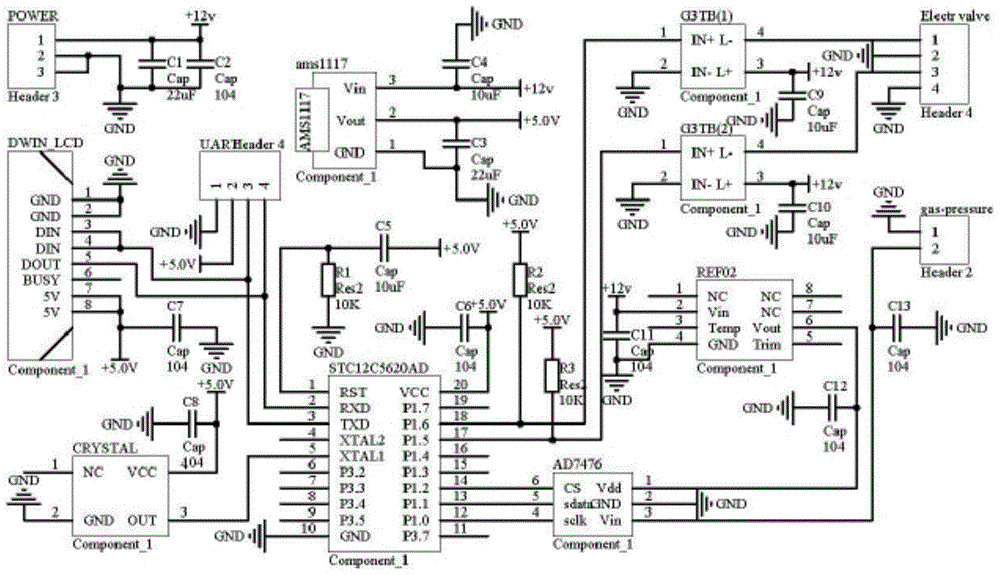

Microwave on-line grain moisture content detection device and method thereof

ActiveCN101776617ASolve the impactResolve sizeMaterial analysis by transmitting radiationMicrocontrollerMicrowave

The invention discloses a microwave on-line grain moisture content detection device and a method thereof. The device comprises a microcontroller, an interface circuit and a computer, which are sequentially connected with each other, and also comprises a high-frequency signal generator for generating a high-frequency signal, a high-frequency signal receiver for receiving the high-frequency signal which transmits through the grain, a signal regulation and detection circuit for detecting the amplitude value and phase difference of the high-frequency signal which is picked up by the high-frequency signal receiver and the high-frequency signal before transmitting through the grain and for transmitting the picked moisture content detection result to the computer through the microcontroller and the interface circuit, wherein the computer performs the density compensation for the moisture content detection result according to the density compensation algorithm. The auxiliary high-frequency signal amplitude value and phase difference detection technology and the density compensation algorithm are adopted to solve the density spacing influence of the grain particles.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

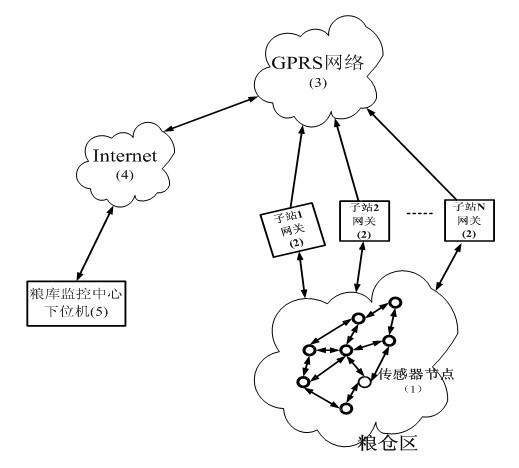

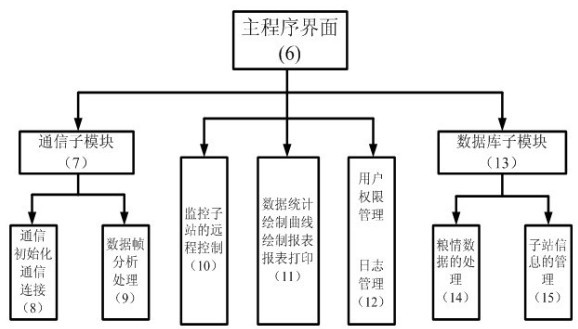

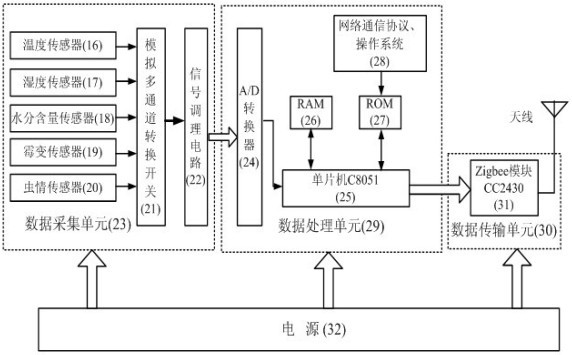

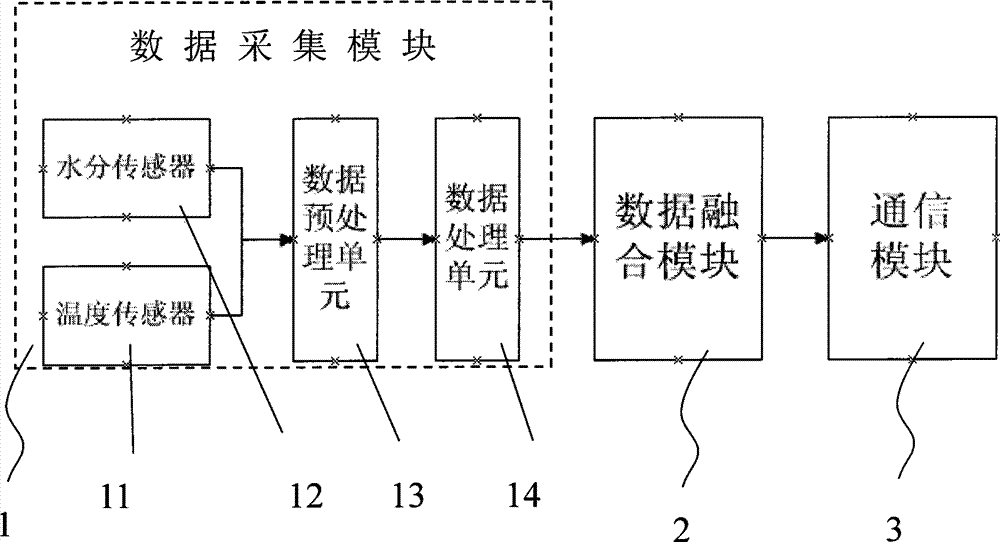

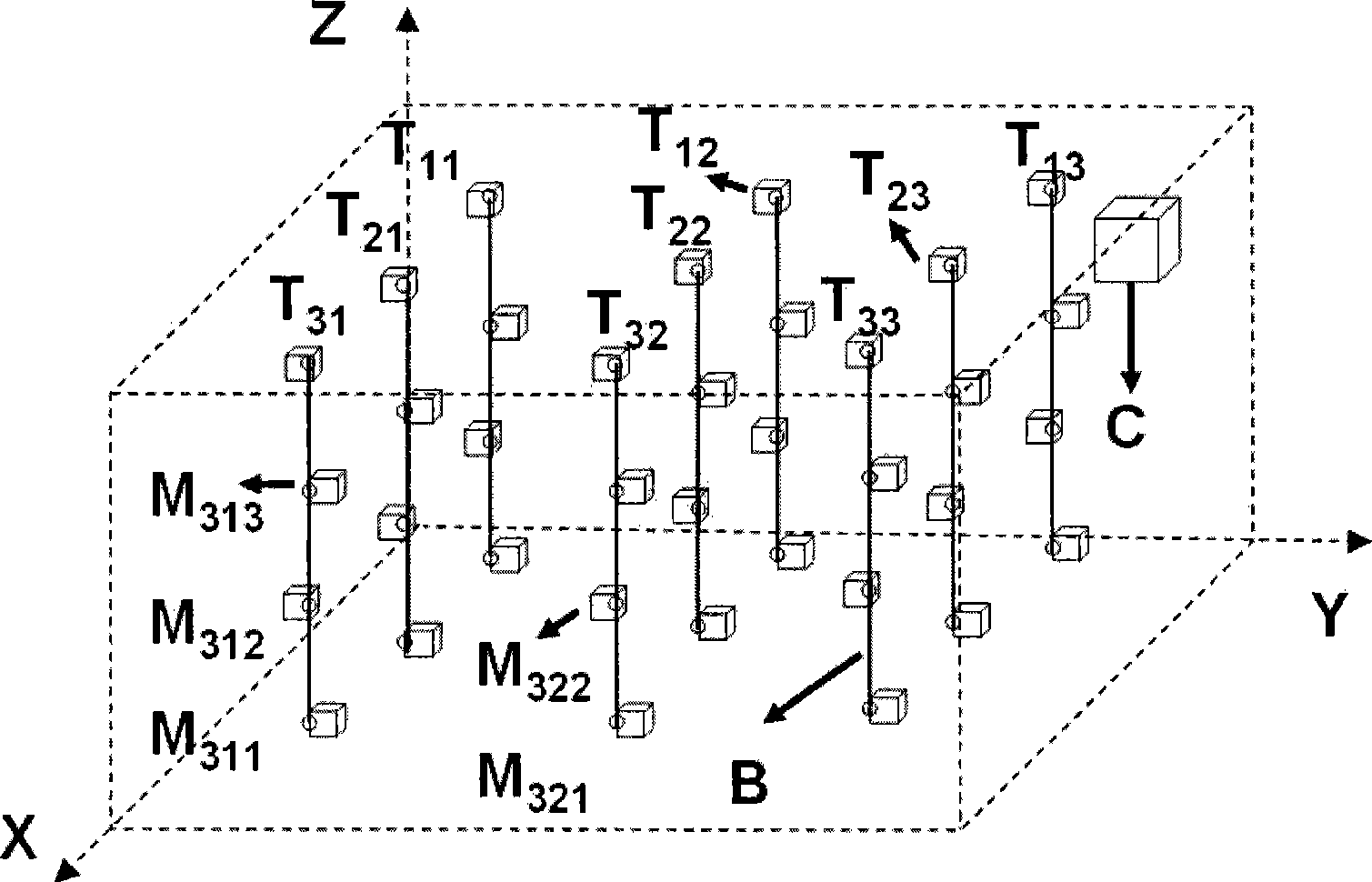

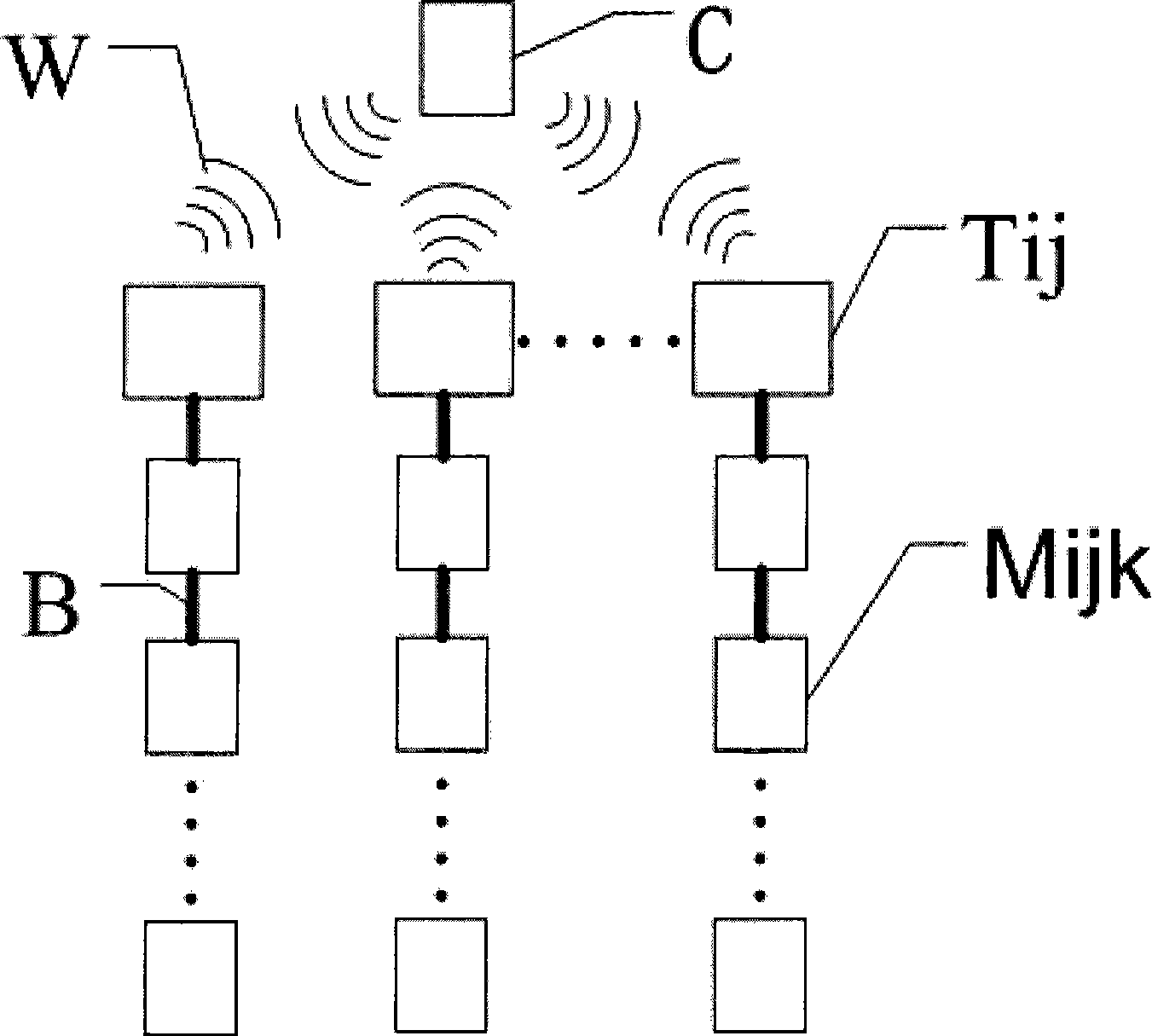

Wireless sensor network monitoring system for grain situation of grain depot

InactiveCN102004479AMonitor temperature in real timeHumidity real-time monitoringNetwork topologiesTotal factory controlGeneral Packet Radio ServiceThe Internet

The invention discloses a wireless sensor network monitoring system for the grain situation of a grain depot. The system comprises wireless sensor nodes, gateway nodes, a general packet radio service (GPRS) network, Internet and a monitoring center lower computer, wherein a group of wireless sensor nodes for acquiring grain situation parameters of the grain depot are connected with the GPRS network by a group of gateway nods; and the GPRS network is connected with the monitoring center lower computer by the Internet. The wireless sensor network monitoring system based on a ZigBee protocol can realize multi-parameter monitoring and monitor grain situation information such as temperature, humidity, grain moisture, mildew, insect pests and the like inside the grain depot in real time; and the GPRS network is connected with the Internet network, so the wireless sensor network monitoring system has low cost and high reliability, and is suitable for various grain storage depots.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Resistive grain moisture measurement system

InactiveCN104713910AQuick measurementAccurate measurementSeed preservation by dryingMaterial resistanceMicrocontrollerMicrocomputer

The invention discloses a resistive grain moisture measurement system. A moisture measurement method provided by the invention can perform grain moisture measurement continuously in a real-time manner and upload the grain moisture value and the temperature value of the grain environment in a real-time manner, and can also generate alarm information to remind users and automatically realize shutdown in time to avoid loss, so that the drying efficiency is improved by 12 to 15%. According to the method, the moisture measurement range can reach up to 11to 40%, and the temperature measurement range can reach up to minus 40 to 180 DEG C. According to the invention, the measured resistance signals are converted into frequency signals, and the grain moisture is measured by adopting a frequency measuring and period measuring method; an oscillating circuit is used to convert the collected signals, the measurement is performed by a single-chip microcomputer, linearization is carried out through a software optimization design and an appropriate algorithm, so that the moisture measurement can be performed quickly and accurately on samples of various types of food grains.

Owner:HEFEI AIRUIDE ELECTRICAL

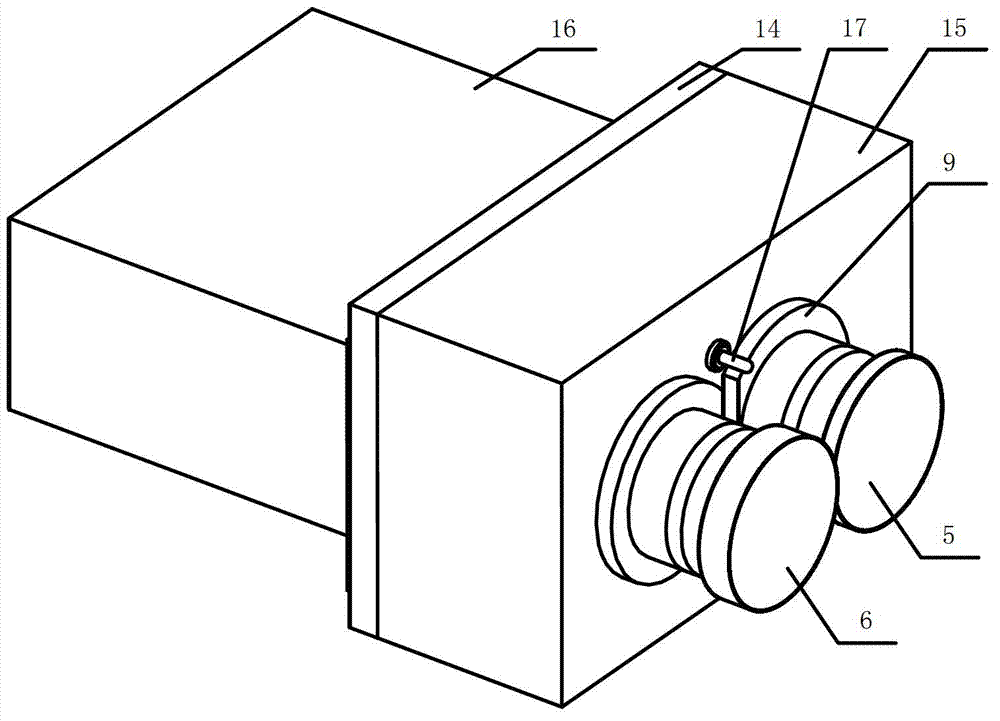

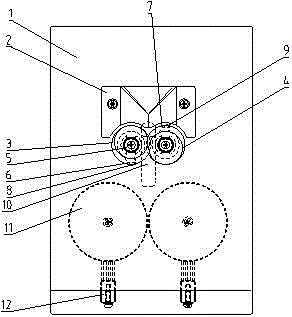

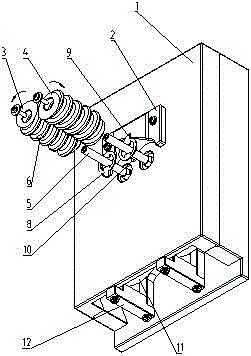

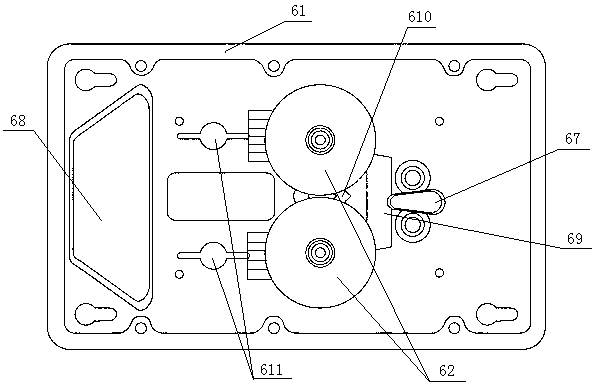

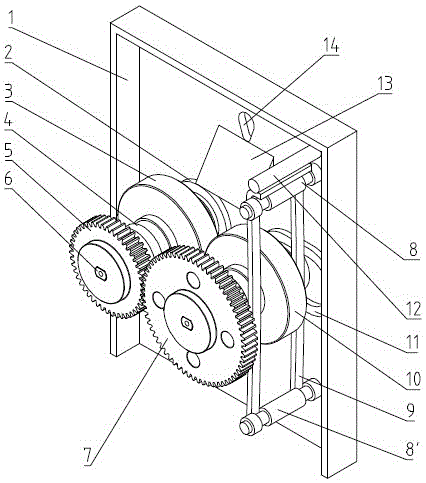

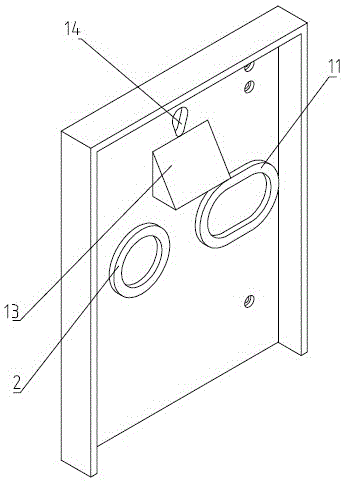

On-line resistance type moisture sensor

ActiveCN102809585ARealize real-time controlReduce mistakesWithdrawing sample devicesMaterial resistanceLine resistanceEngineering

The invention discloses an on-line resistance type moisture sensor, and relates to detection equipment for grain moisture. The moisture sensor comprises a sampling device and a detection control device, wherein the sampling device consists of a motor provided with a motor gear and two roller components provided with rolling gears; roller components are meshed with each other via the rolling gears, the motor gear is meshed with one rolling gear; a signal board is arranged between the two roller components; both the signal board and the motor are electrically connected with the detection control device; one ends of the two roller components are provided with one rolling gear, and the other ends of the two roller components are respectively provided with a small rolling wheel and a large rolling wheel; and a gap between the small rolling wheel and the large rolling wheel is 0.3 mm to 1 mm, the width of the periphery of the small rolling wheel is 4 mm to 10 mm, and the width of the periphery of the large rolling wheel is 12 mm to 40 mm. The moisture sensor disclosed by the invention can automatically detect grain crops, is high in accuracy of detection of grain crop moisture, and is longer in service life and lower in application cost.

Owner:武汉凯特复兴科技有限责任公司

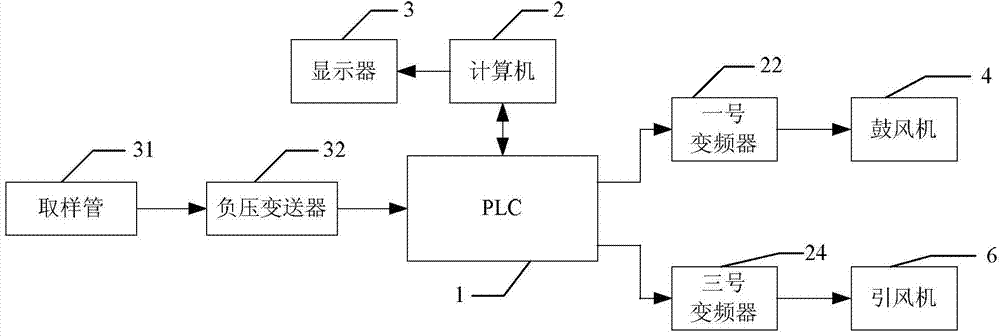

High-efficiency online drying system for grain moisture

InactiveCN103760312AImprove reliabilityHigh measurement accuracyTesting foodReal-time Control SystemElectrical resistance and conductance

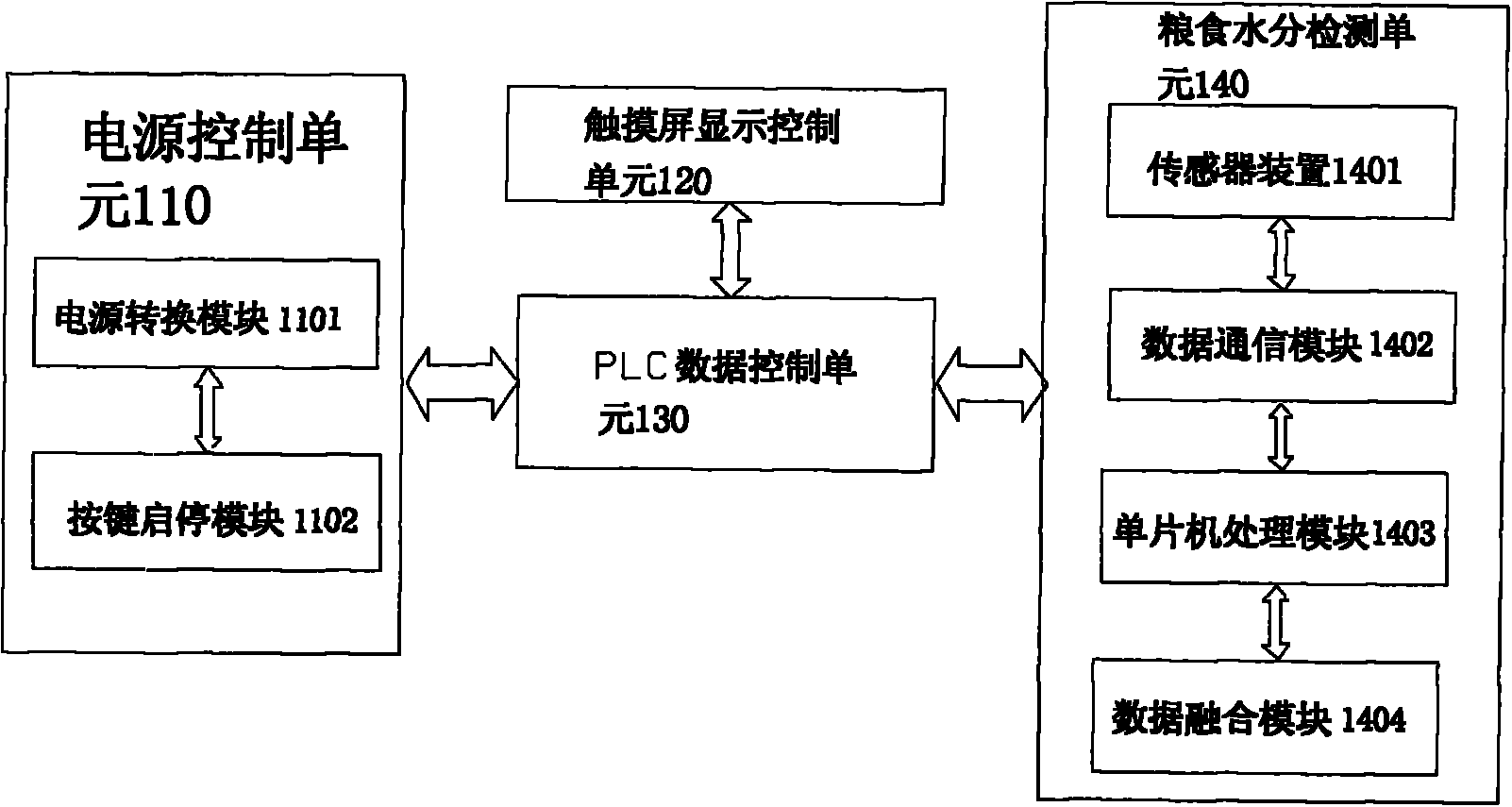

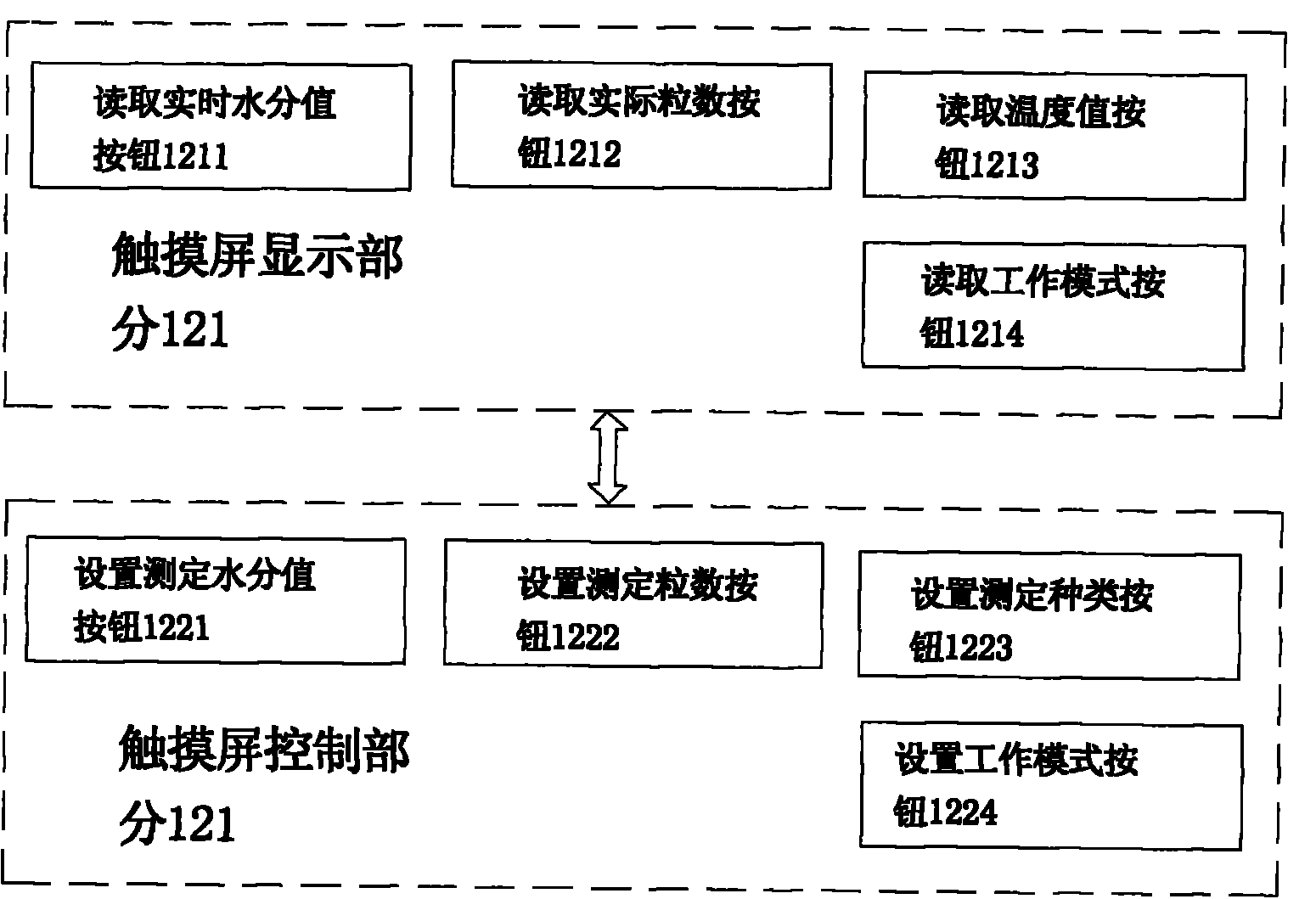

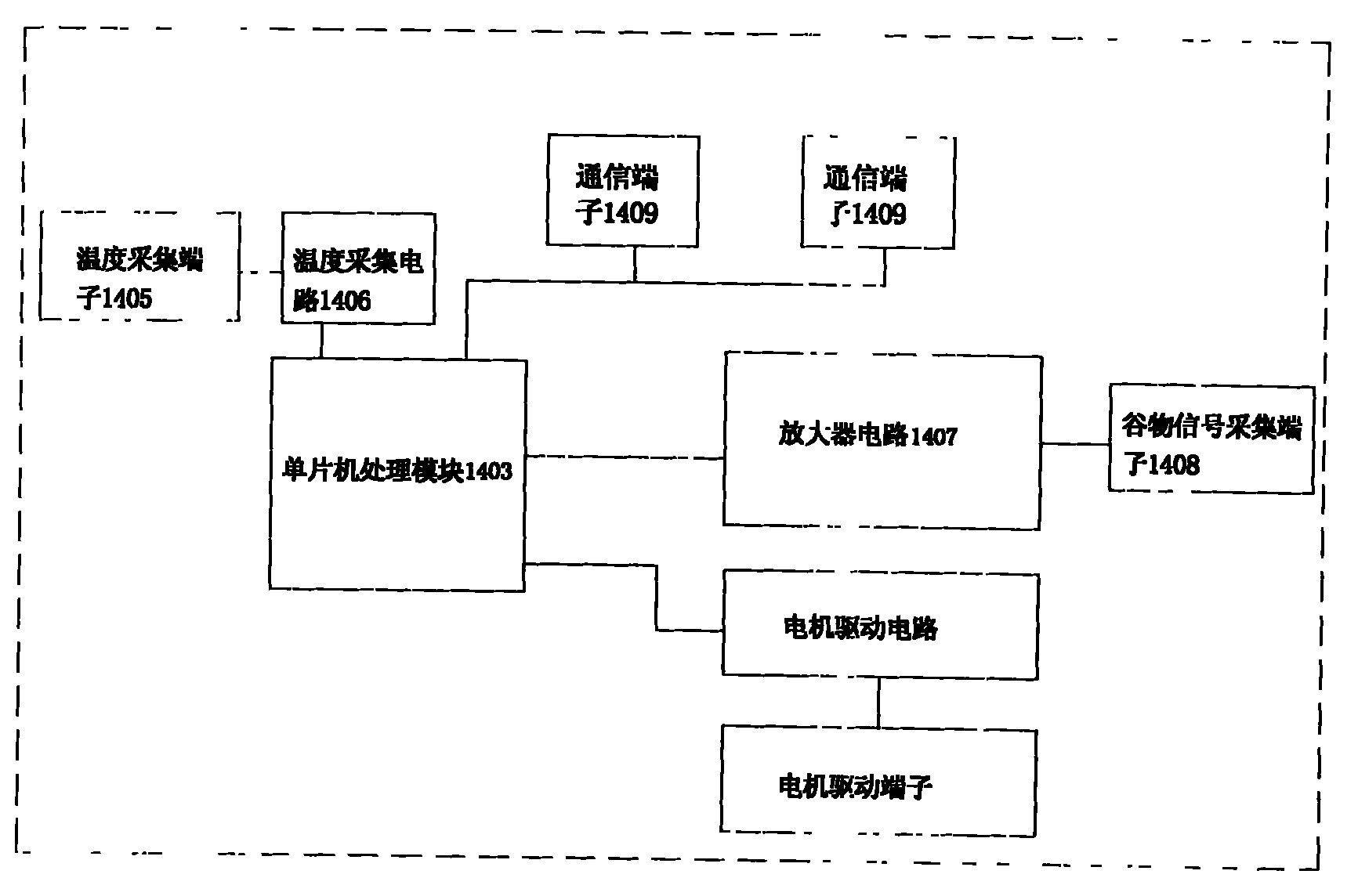

The invention discloses a high-efficiency online drying system for grain moisture, and relates to the technical field of drying equipment. The high-efficiency online drying system for the grain moisture comprises a power supply control unit (110), a touch screen display control unit (120), a PLC (Programmable Logic Controller) data control unit (130) and a grain moisture detecting unit (140), wherein the PLC data control unit (130) is respectively interconnected with the touch screen display control unit (120), the power supply control unit (110) and the grain moisture detecting unit (140). On the basis of the resistance moisture detecting method, the high-efficiency online drying system for the grain moisture applies the nonlinear processing capacity of an RBF (Radial Basis Function) neutral network algorithm to fuse the measured data, and can automatically implement various corrections and error compensations for the measured value, so that the reliability and measurement precision of the grain moisture detecting system are improved; meanwhile, a real-time control system based on a PLC and matched with grain drying equipment is independently researched and developed to realize the functions of automatic control, online display, fault alarming and grain moisture detection in the grain drying process.

Owner:ANHUI OCEAN AUTOMATION EQUIP

Grain condition monitoring system of sensor

InactiveCN101441805AIncrease flexibilityImprove scalabilityTransmission systemsData switching by path configurationSurface layerMonitoring system

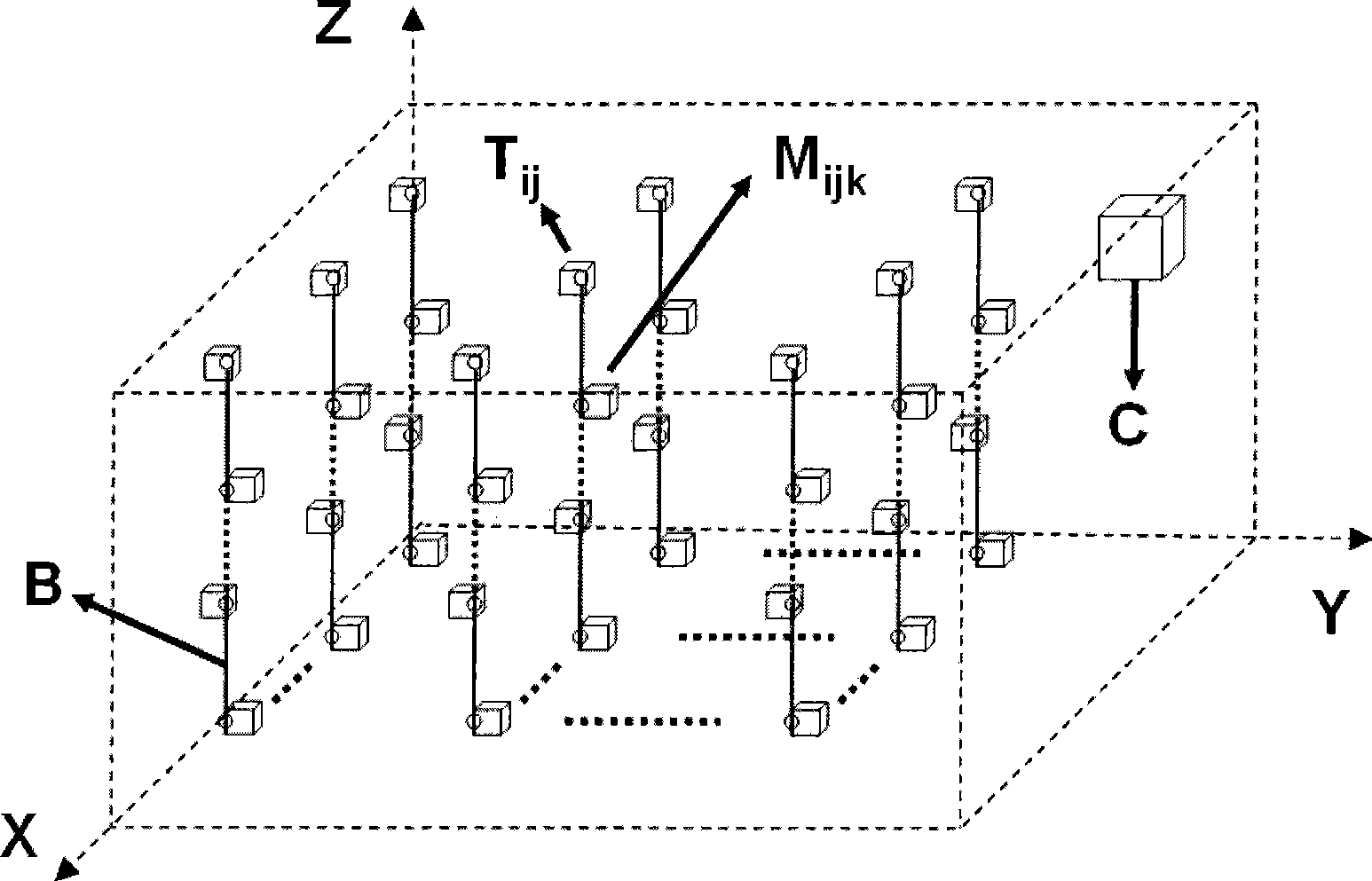

The invention provides a sensor network grain situation monitoring system based on a bus and a wireless structure, which can monitor grain situation information in a granary such as temperature, humidity, grain moisture and insect damage in real time. The monitoring system consists of grain situation parameter monitoring nodes which are buried into grains in the granary, relay nodes on a grain surface layer in the granary, and granary main control nodes, wherein a plurality of grain situation parameter monitoring nodes are connected and communicated with each other through a bus-organized structure and the relay nodes which are arranged on the top layer, and the relay nodes are communicated with the main control nodes for managing the granary through a wireless network; and the grain situation monitoring nodes are responsible for acquiring grain situation parameters in the granary such as the temperature, the humidity, the grain moisture and the insect damage, and the grain situation parameter information acquired by various monitoring nodes is transmitted to the granary main control nodes through the relay nodes on the top layer.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

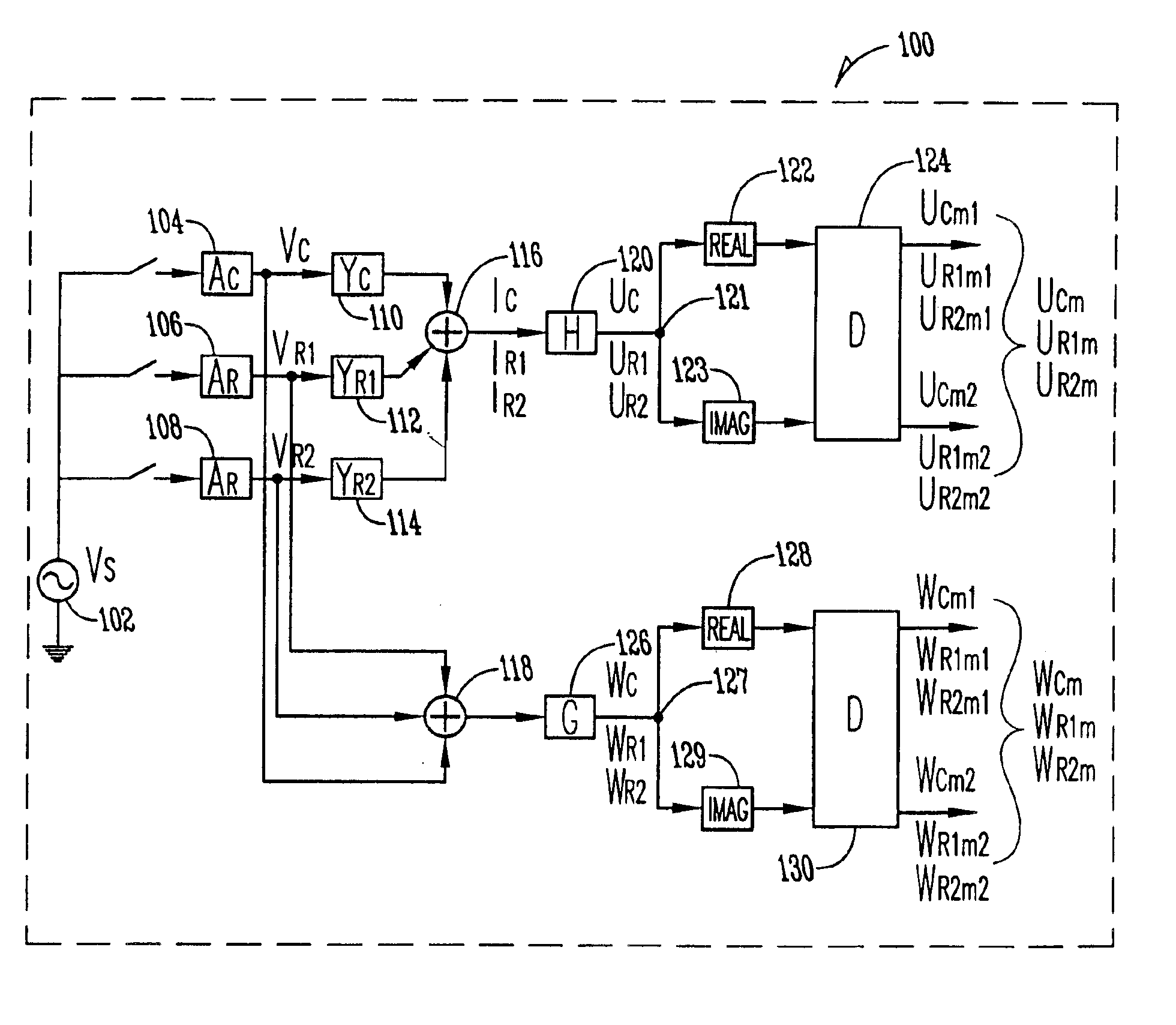

Multiple frequency grain moisture sensor for combines

InactiveUS6917206B2Reduce edge effectsEqual sensitivityTesting starch susbtancesResistance/reactance/impedencePermittivityGrain moisture

A grain moisture sensor having a sensor cell that includes a driven plate, a sense plate proximate to and substantially parallel with the driven plate for capacitive measurement across a spacing between the driven plate and the sense plate, and a fill plate adjacent the sense plate and substantially parallel with the driven plate for sensing whether the spacing is filled with grain. The grain moisture sensor provides for measuring real and imaginary components of an excitation voltage applied to the driven plate, measuring real and imaginary components of a sense current sensed at the sense plate, calculating a complex admittance of the cell, calculating a complex admittance of a reference admittance, and calculating a grain complex permittivity.

Owner:DEERE & CO

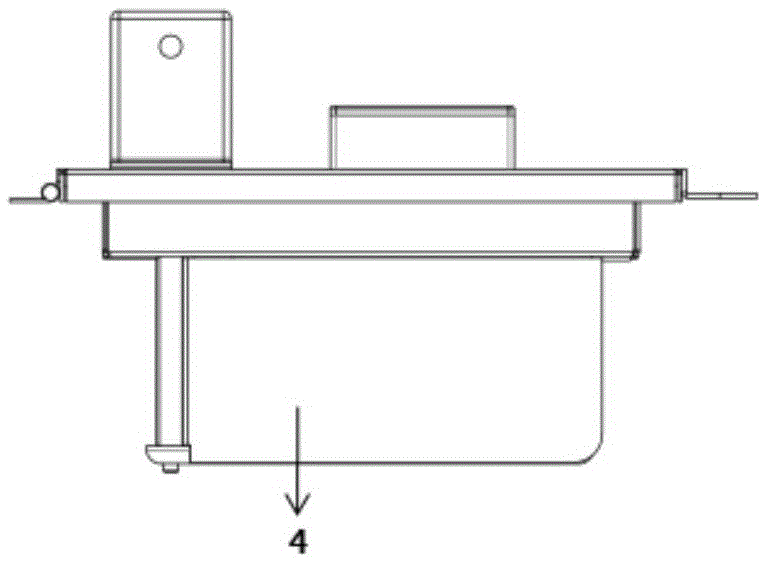

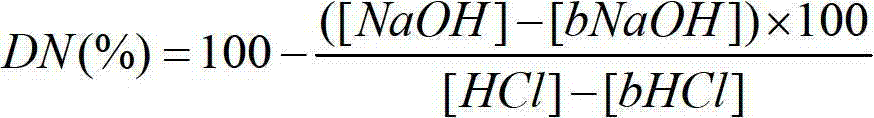

Buoyancy method for rapidly measuring grain moisture and tester thereof

The invention relates to a buoyancy method for rapidly measuring grain moisture and a tester thereof. The measuring method is realized by five steps of dish box liquid injection and suppressing tare weighing, sample preparation, sample weighing, liquid injection and suppressing gross weight weighing and result calculation. The tester comprises an electronic balance, a liquid injection and suppressing device, a data processing display device, a water groove and a dish box. By adopting the grain moisture measuring method and the special tester thereof, the invention utilizes the principle of Archimedes buoyancy law, overcomes the disadvantages of long operation time of a drying method, untimely guidance and slightly great error of other rapid moisture testers, has both the accuracy of the drying method and the characteristic of rapid measurement of various moisture testers, has wide moisture measuring range and multiple measuring varieties, is not influenced by factors such as grains, temperature, and the like, and is widely suitable for grain storage business and the field of grain processing.

Owner:田志和

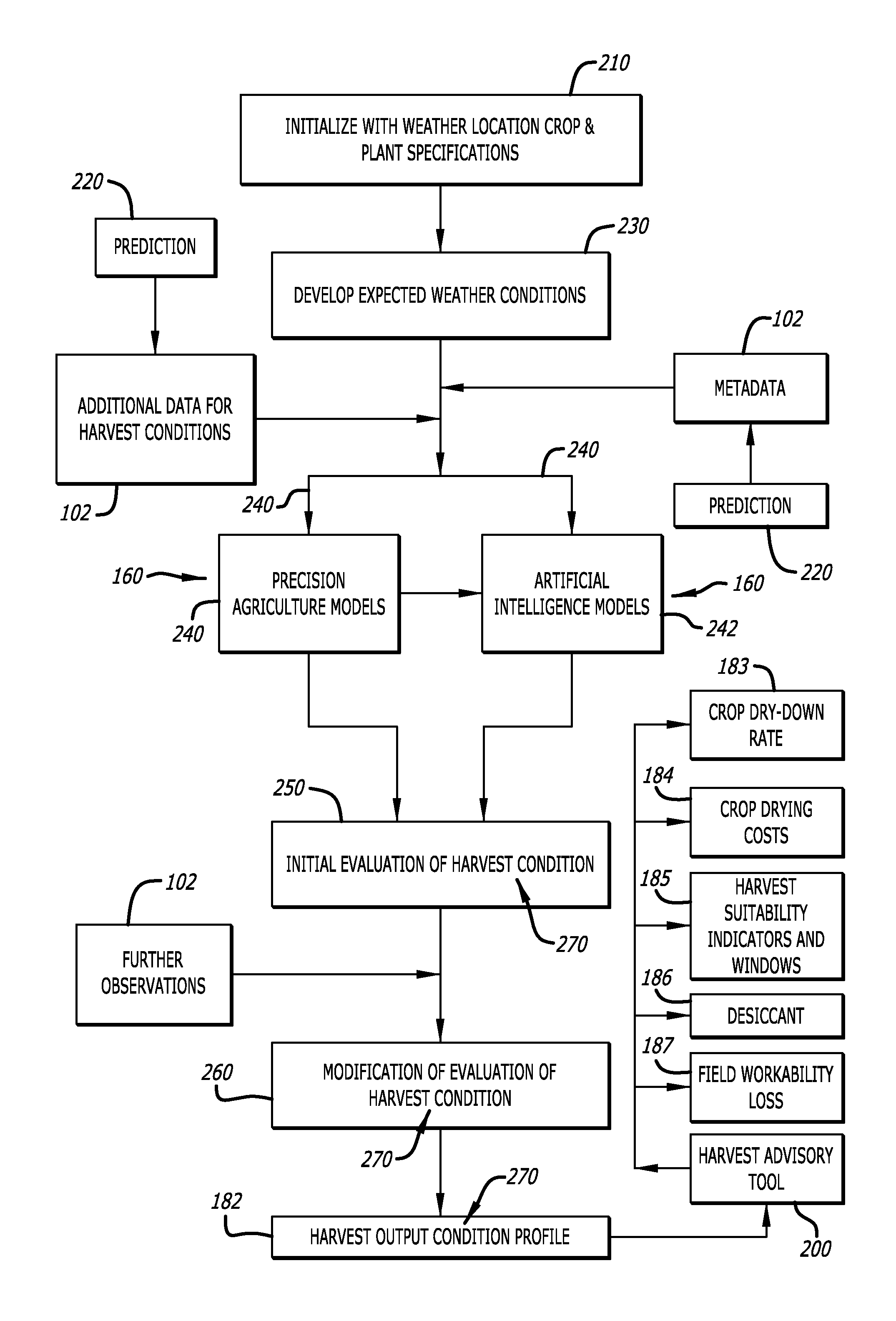

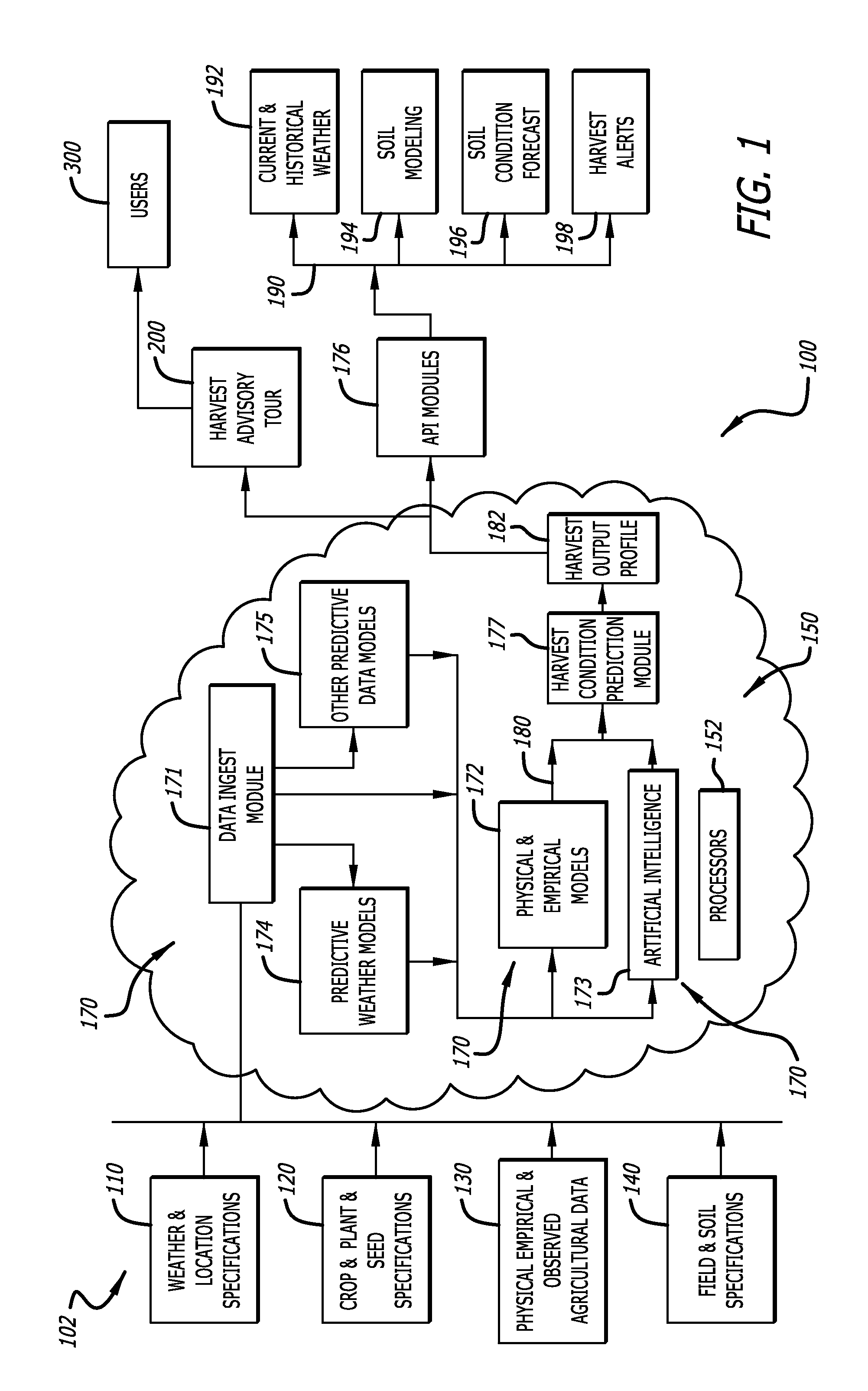

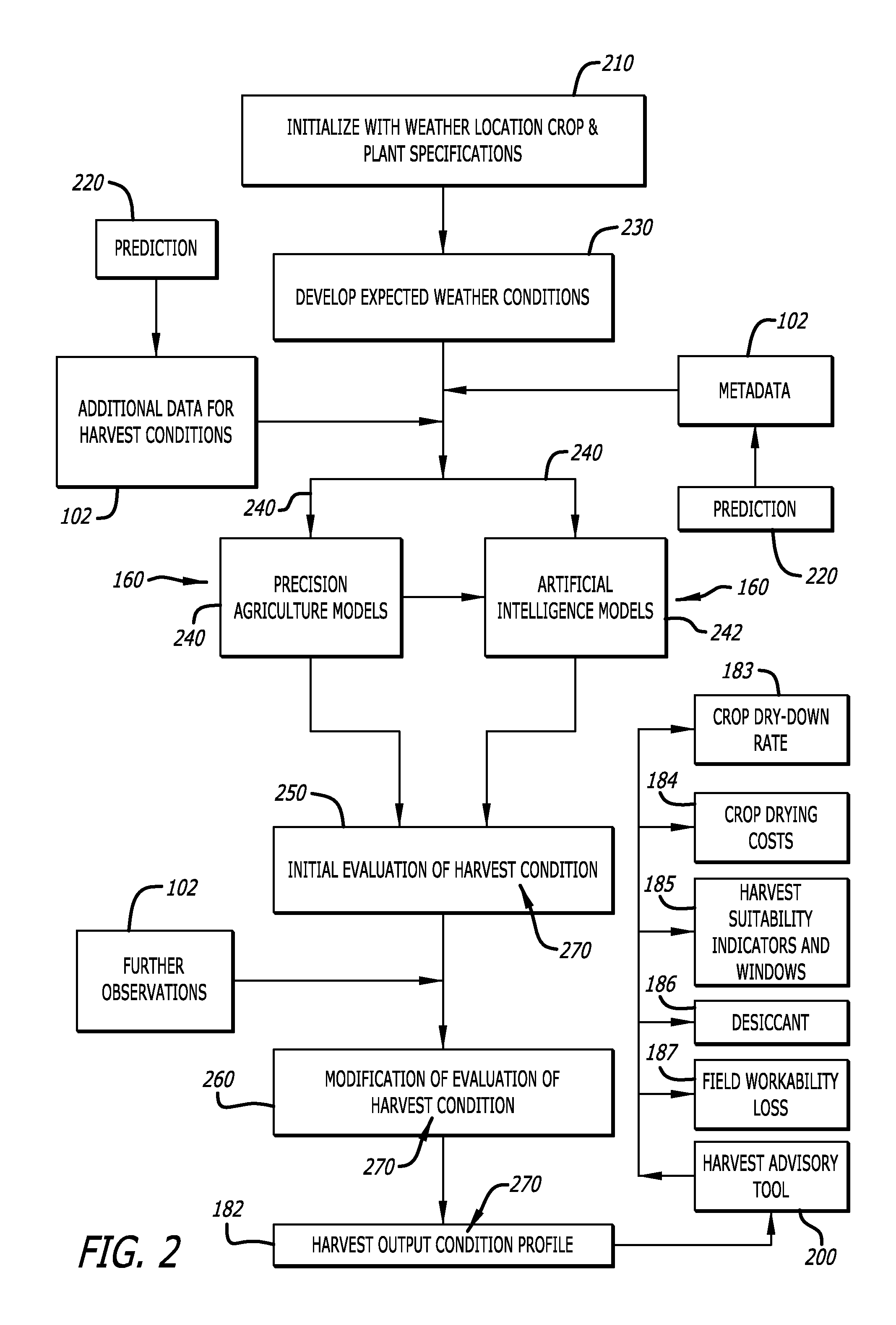

Modeling of time-variant grain moisture content for determination of preferred temporal harvest windows and estimation of income loss from harvesting an overly-dry crop

ActiveUS9311605B1Facilitate decision-makingEasy to operateLighting and heating apparatusWeather condition predictionAgricultural engineeringGrain moisture

A modeling framework for evaluating the impact of weather conditions on farming and harvest operations applies real-time, field-level weather data and forecasts of meteorological and climatological conditions together with user-provided and / or observed feedback of a present state of a harvest-related condition to agronomic models and to generate a plurality of harvest advisory outputs for precision agriculture. A harvest advisory model simulates and predicts the impacts of this weather information and user-provided and / or observed feedback in one or more physical, empirical, or artificial intelligence models of precision agriculture to analyze crops, plants, soils, and resulting agricultural commodities, and provides harvest advisory outputs to a diagnostic support tool for users to enhance farming and harvest decision-making, whether by providing pre-, post-, or in situ-harvest operations and crop analysis.

Owner:DTN LLC

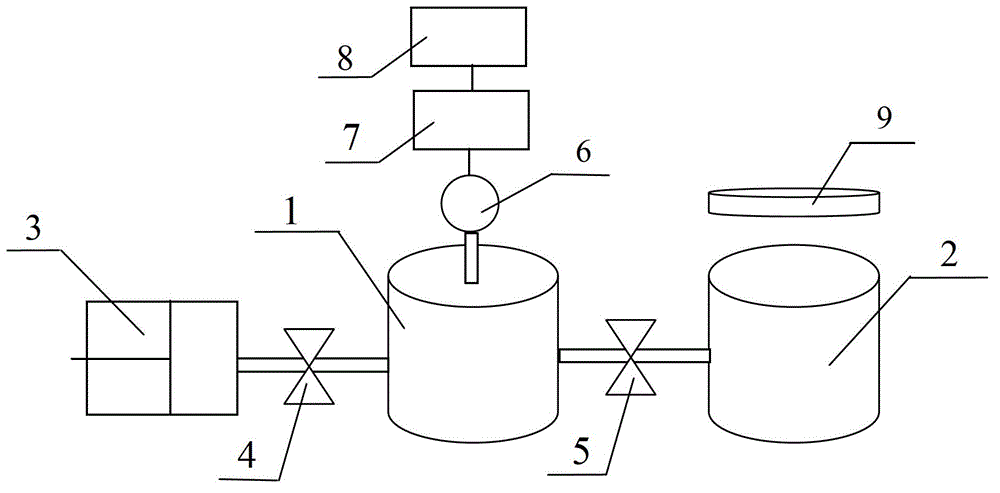

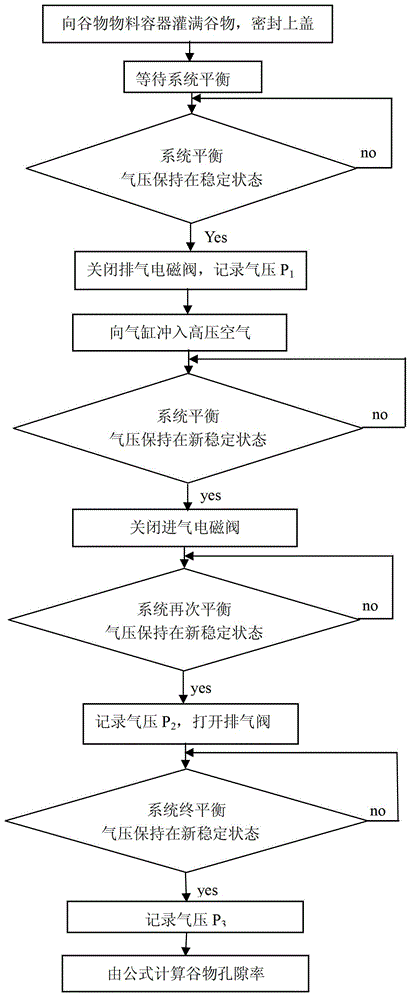

Grain porosity measurement apparatus and measurement method thereof

InactiveCN103335927APhysical propertiesInhibit hygroscopicityPermeability/surface area analysisPorosityMeasurement device

The invention discloses a grain porosity measurement apparatus, which comprises an air compressor, pipelines, a gas inlet valve, a gas cylinder, a gas exhaust valve, a grain container, a pressure measurement device and a control display device, wherein the gas cylinder is respectively connected with the air compressor and the grain container through pipelines, the gas inlet valve is installed on a pipeline between the air compressor and the gas cylinder, the gas exhaust valve is arranged on a pipeline between the grain container and the gas cylinder, the pressure measurement device is arranged on the gas cylinder, and is connected with the control display device, and the gas inlet valve and the gas exhaust valve are connected with the control display device. The invention further discloses a measurement method of the grain porosity measurement apparatus. According to the present invention, the structure is simple, operations are convenient, and workload is reduced; and the used medium is air so as to avoid influence of grain moisture absorption or organic solvent volatility, increase measurement result accuracy, and ensure measurement result reliability.

Owner:SOUTH CHINA AGRI UNIV

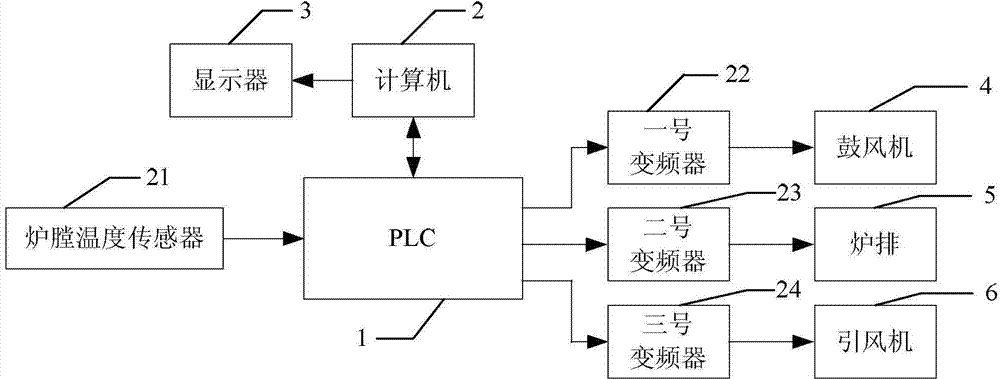

Intelligent energy-saving control system of grain drying tower

ActiveCN104729276ASolve the problem of baking food based on personal experience without basisSolve irregularFood processingSeed preservation by dryingCombustion chamberGrain moisture

The invention discloses an intelligent energy-saving control system of a grain drying tower, and relates to the field of intelligent energy-saving control over the grain drying tower. The purpose is to solve the problems that according to an existing grain drying tower, fuel and electric energy are wasted, the service life of a heat exchanger can not be guaranteed, and all drying sections can not achieve gradient temperature air delivery. The intelligent energy-saving control system comprises a hot blast heater coal feeding hopper control unit, a hot blast heater combustion chamber temperature detection and control unit, a combustion chamber negative pressure value detection and control unit, a heat exchanger front end and rear end temperature detection and control unit, a detection and control unit for gradient air delivery temperature of air heaters, a grain storage section grain position control unit, a detection and control unit for grain temperature and moisture of all the drying sections, a detection and control unit for dead steam temperature and humidity and steam exhausting air speed of steam exhausting ports of all the drying sections, a cooling section grain temperature detection and control unit and a drying tower grain discharging part grain moisture detection and control unit. The intelligent energy-saving control system performs intelligent control based on a PLC and is suitable for intelligent energy-saving control over the grain drying tower.

Owner:七台河市双益节电有限公司

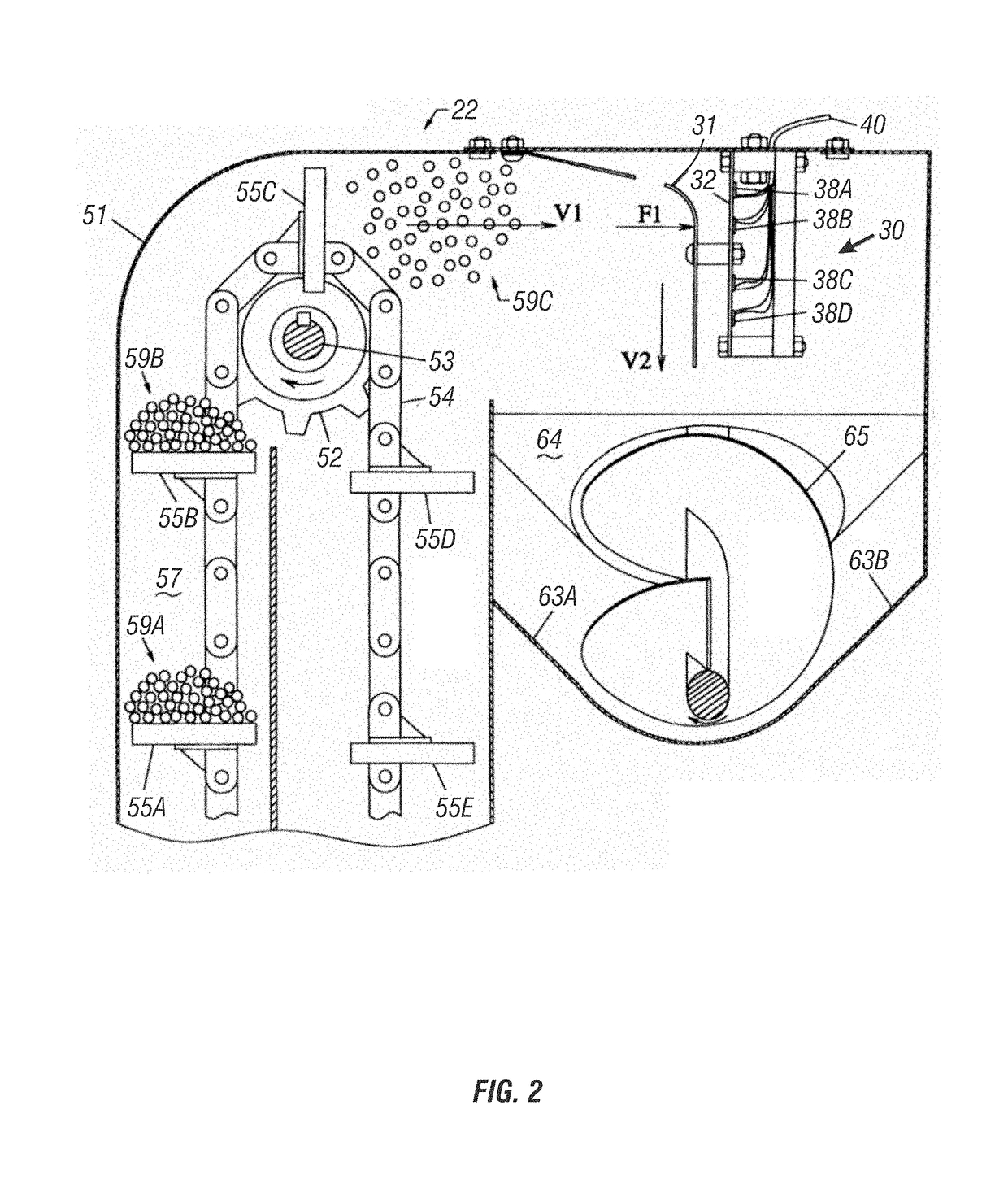

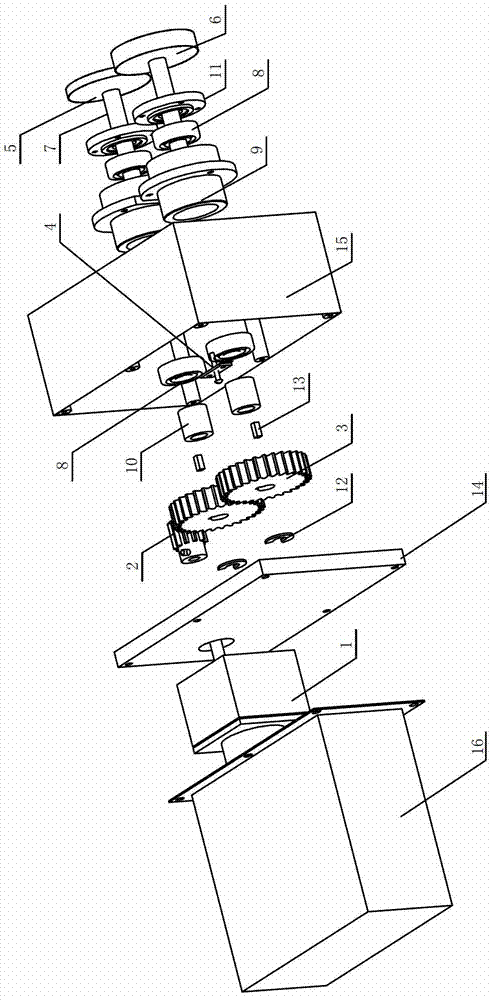

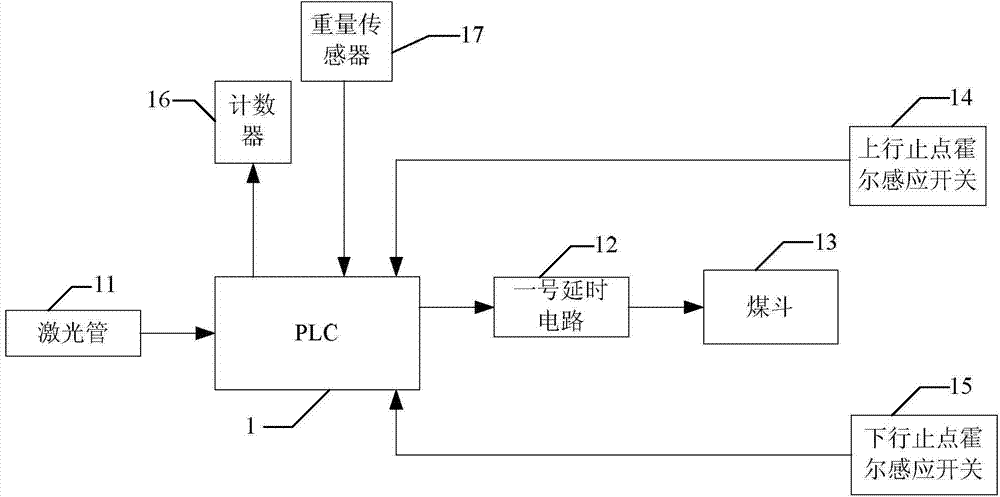

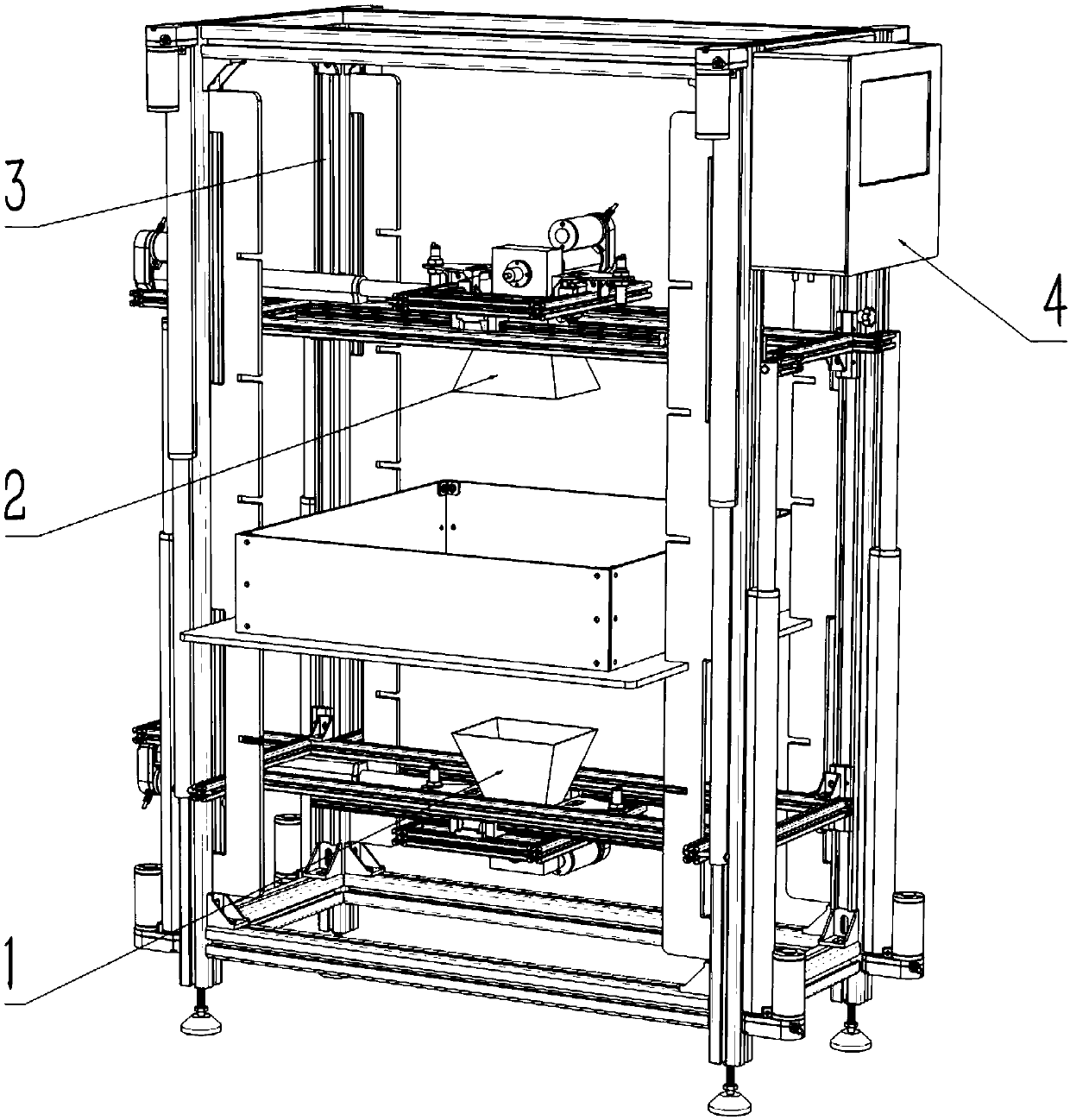

Conveying and impurity-removing device of on-line grain moisture meter

ActiveCN104634828AEfficient removalReal-time cleaningMaterial resistanceMaterial capacitanceGrain moistureCounter rotation

The invention relates to a conveying and impurity-removing device of an on-line grain moisture meter. The conveying and impurity-removing device comprises a pair of horizontal power output shafts, wherein the horizontal power output shafts are arranged on two sides of a feed opening of a moisture meter body and rotate in opposite directions; rotatable impurity-removing scrapers and screw conveying rollers are mounted from inside to outside in the axial directions of the horizontal power output shafts; at least one impurity-removing groove is formed in the screw of each screw conveying roller; the impurity-removing scrapers have radial cutting edges; the two screw conveying rollers are meshed with each other in such a way that the corresponding impurity-removing grooves are staggered; an impurity-removing stop block is mounted on the moisture meter body in a position above the meshing point of the two screw conveying rollers; the middle of the impurity-removing stop block extends axially to the horizontal power output shafts to form a wedge-shaped extension end above the meshing point of the screw conveying rollers; and inclined impurity-separating side surfaces, which are located above the meshing point of the screw conveying rollers respectively, are formed on the wedge-shaped extension end. According to the conveying and impurity-removing device, various impurities doped in a material can be removed effectively, the feed opening is cleaned in time, blockage is prevented, the grain moisture meter is free of an abnormal sampling value, and the precision of a measured value is improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

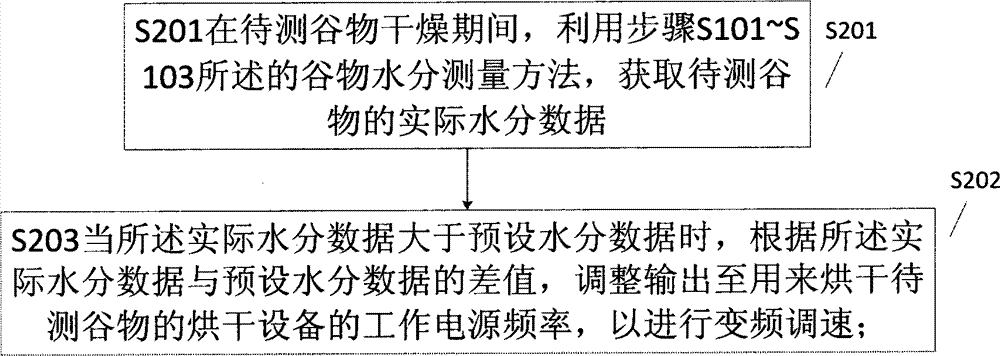

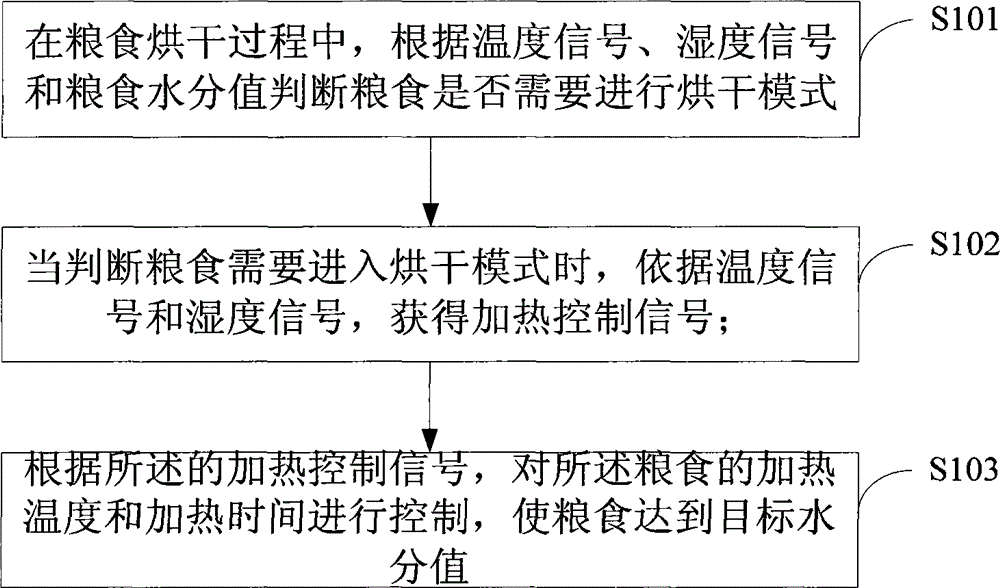

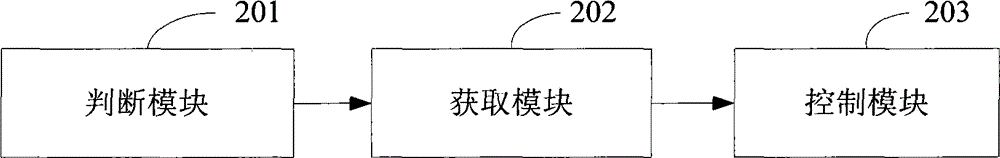

Intelligent grain drying control method

InactiveCN104663877ARealize intelligent managementEasy to controlSeed preservation by dryingControl signalAgricultural engineering

The invention discloses an intelligent grain drying control method. According to the method, a temperature signal, a humidity signal and a grain moisture value are utilized for judging whether delayed-mode drying is required to be performed on grains or not and a heating control signal is obtained or other modes are started according to the judgment result, so that finally a target moisture value of the grains can be achieved. The intelligent grain drying control method can be used for achieving the intelligent management in a drying process, controlling the drying process by utilizes a fuzzy predictive control method, and adjusting drying time in a predictive way to adjust and control the grain drying time relatively accurately; the intelligent grain drying control method can be used for effectively overcoming a large delay link, shortening the adjusting time and eliminating the systematic quiet error.

Owner:ANHUI OCEAN AUTOMATION EQUIP

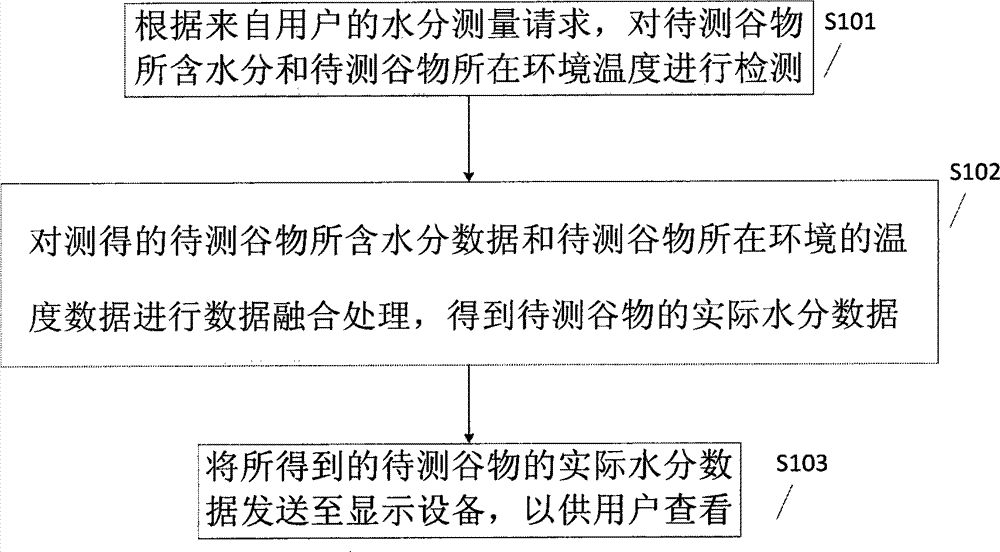

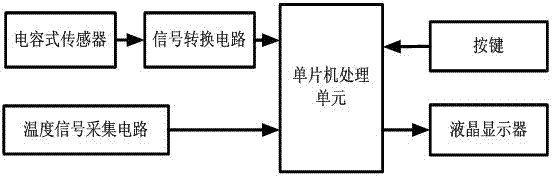

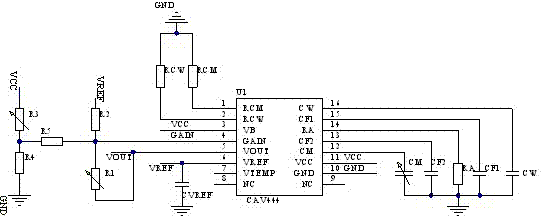

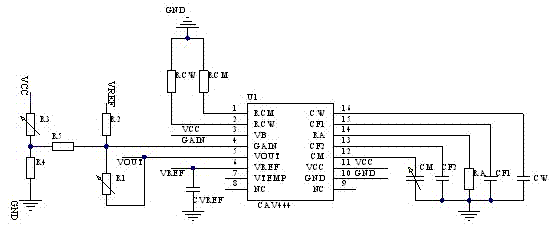

On-line grain moisture measuring device

The invention discloses an on-line grain moisture measuring device which comprises a capacitance sensor, a signal converting circuit, a temperature signal acquiring circuit, a singlechip processing unit, a key and a liquid crystal display, wherein the capacitance sensor is connected with the singlechip processing unit through the signal converting circuit; the temperature signal acquiring circuit is directly connected with the singlechip processing unit; and the key and the liquid crystal display are respectively connected with the singlechip processing unit. The on-line grain moisture measuring device has the advantages that the circuits are simple, only an AT89S5X series chip and simple peripheral components are used, the influences of factors such as temperature and grain species on the moisture content measurement are considered by utilizing software compensation coefficients, and the device has higher flexibility and practical applicability. The practical and low-price on-line gain moisture measuring device is capable of measuring agricultural granular products, such as paddy, rice, soybean, barley, wheat, corn, and the like.

Owner:ZHEJIANG UNIV

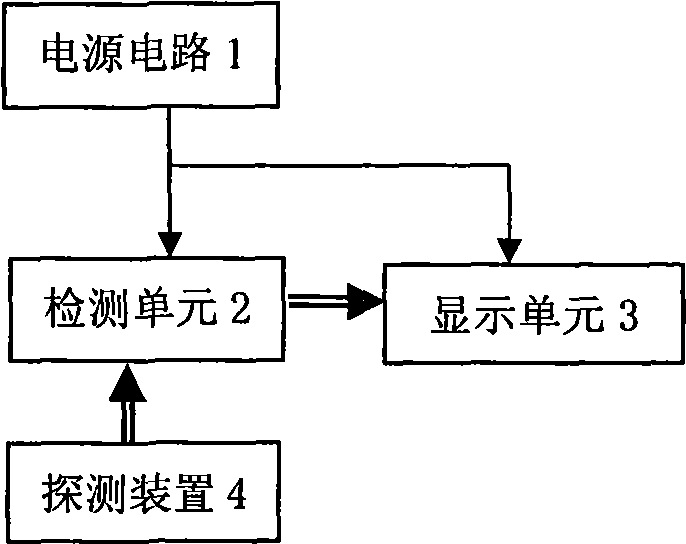

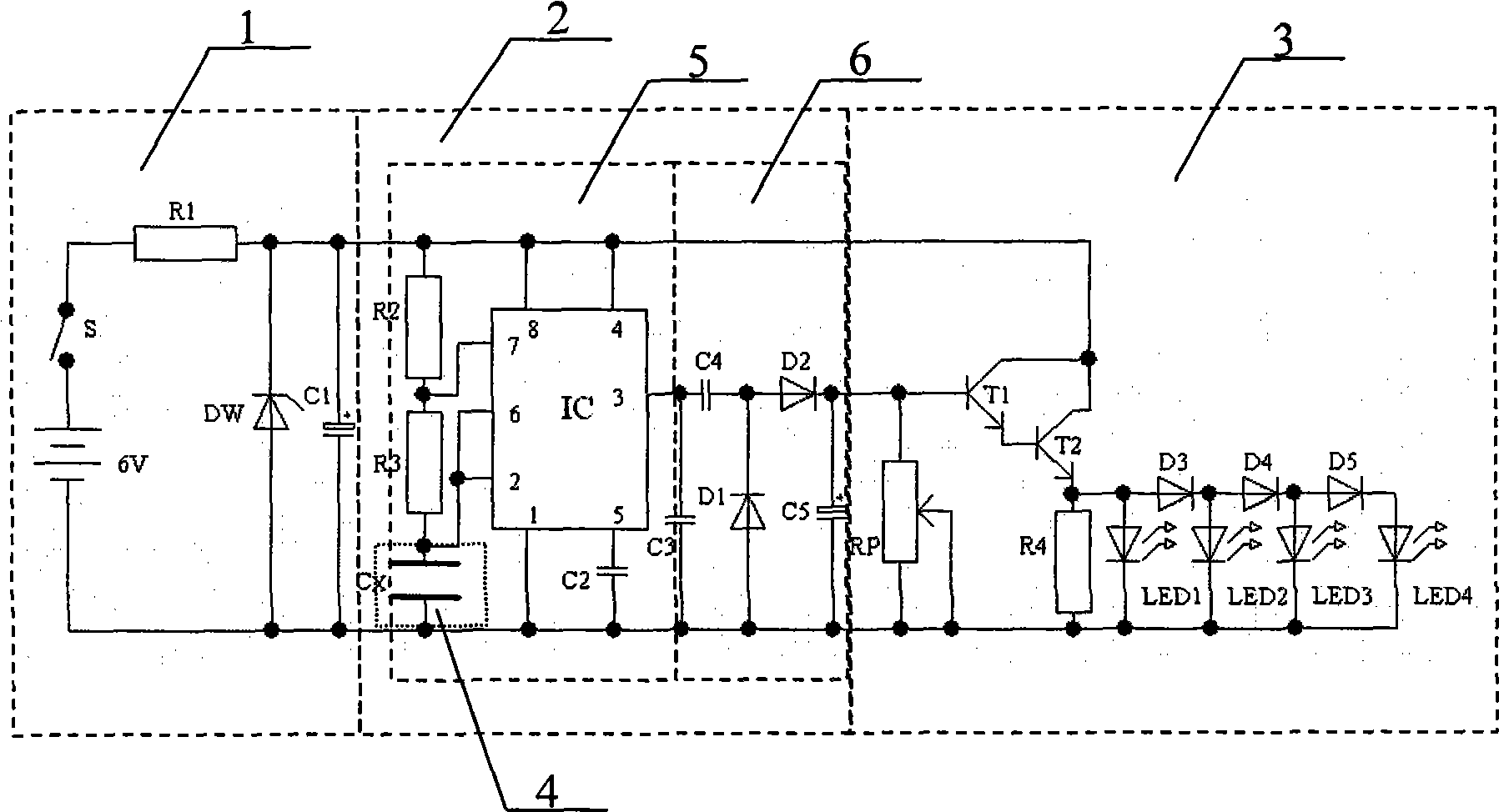

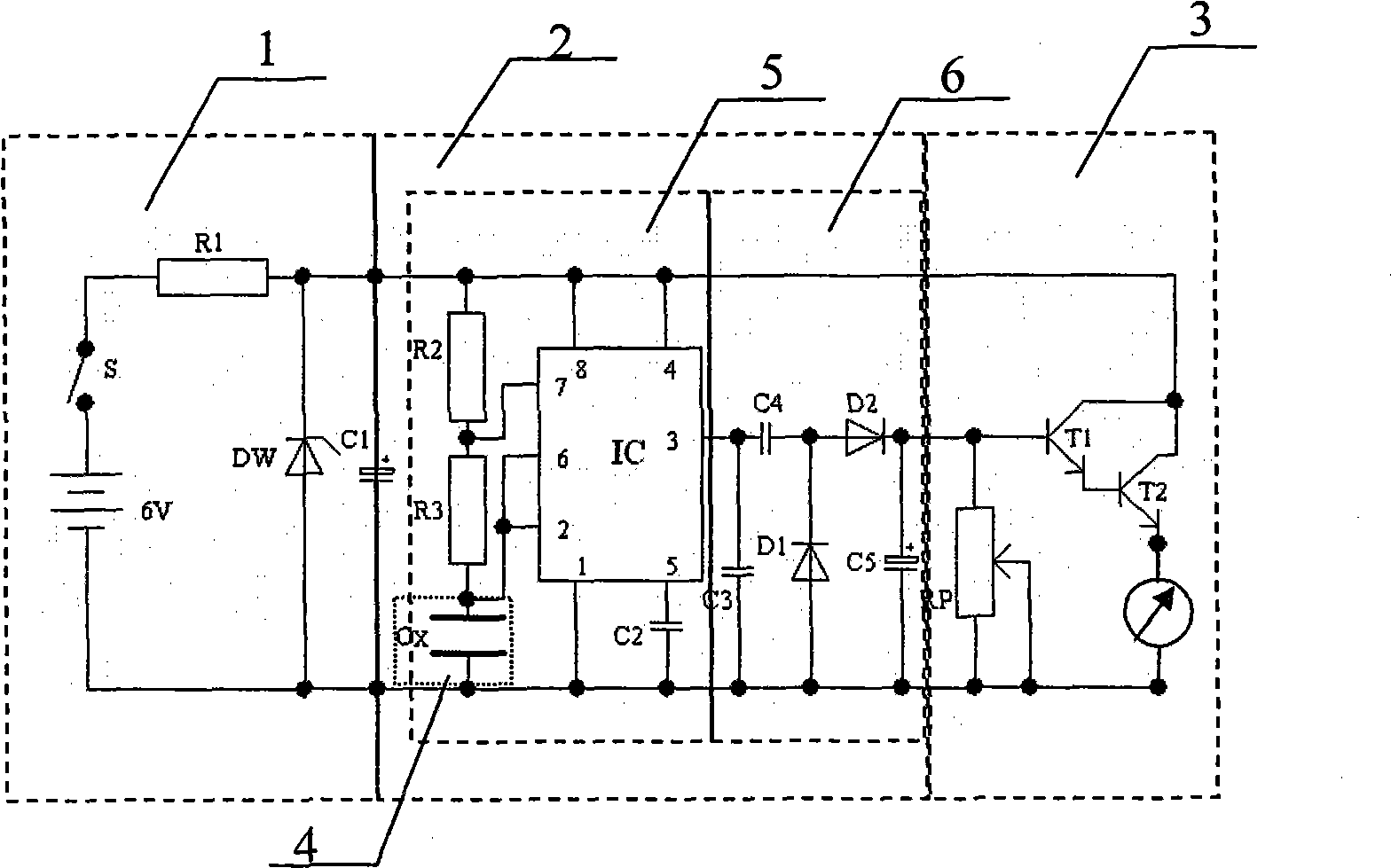

Grain moisture detector

InactiveCN101509884AGuaranteed measurement accuracyEasy to operateMaterial capacitanceCurrent sheetParallel plate

The invention relates to a grain moisture detector, belonging to the technical field of electronic detection. The grain moisture detector consists of a power circuit 1, a detection unit 2, a detection device 4 connected with the input of the detection unit 2, and a display unit 3 connected with the output of the detection unit 2, and is characterized in that the detection device 4 is a box-typed parallel-plate capacitor, and copper plates or aluminum plates are taken as two parallel plates of the capacitor and respectively positioned inside two opposite surfaces of a portable box made of insulation materials; and the detection device 4 is the box-typed parallel-plate capacitor, the copper plates or aluminum plates with the thickness being 3 to 4mm are taken as the two parallel plates of the capacitor, and the two sides and the bottom surface of the capacitor are made of the insulation materials. A parallel-plate capacitor probe in the grain moisture detector has simple operation, and is firm and durable. The degree of humidity is displayed by the quantity of lights emitted by a light-emitting diode, thus being intuitive and clear; or the degree of humidity is displayed by using a voltmeter, an ammeter or liquid crystal, thus being intuitive and precise.

Owner:BEIJING UNION UNIVERSITY

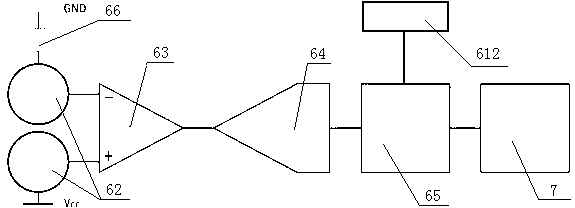

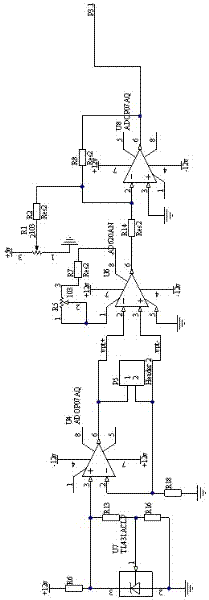

On-line resistance-type grain moisture tester and control method thereof

InactiveCN103211008AAvoid churnHigh measurement accuracySeed preservation by dryingDrying solid materialsElectrical resistance and conductanceLine resistance

The invention discloses an on-line resistance-type grain moisture tester and a control method thereof. The tester comprises a transporter and a detection control device, wherein the detection control device comprises two grinding wheels on the rear end of the transporter, an operational amplifier the reverse input end and the syntropy input end of which are respectively connected with the two grinding wheels, an A / D (analog-digital) converter the input end of which is connected with the output end of the operational amplifier, and a control end connected with the output end of the A / D converter, wherein one grinding wheel connected with the reverse input end of the operational amplifier is connected in series with a fixed value resistor, and the control end is connected with a dryer controller. The on-line resistance-type grain moisture tester provided by the invention adopts intelligent automation operation; and when a grain drying machine operates, the tester can automatically carry out periodic detection on grain moisture and the inner temperature of the dryer according to parameters set by users and compare the detected result with the preset parameters, and other related operations are also automatically executed.

Owner:安徽世龙电子技术有限公司

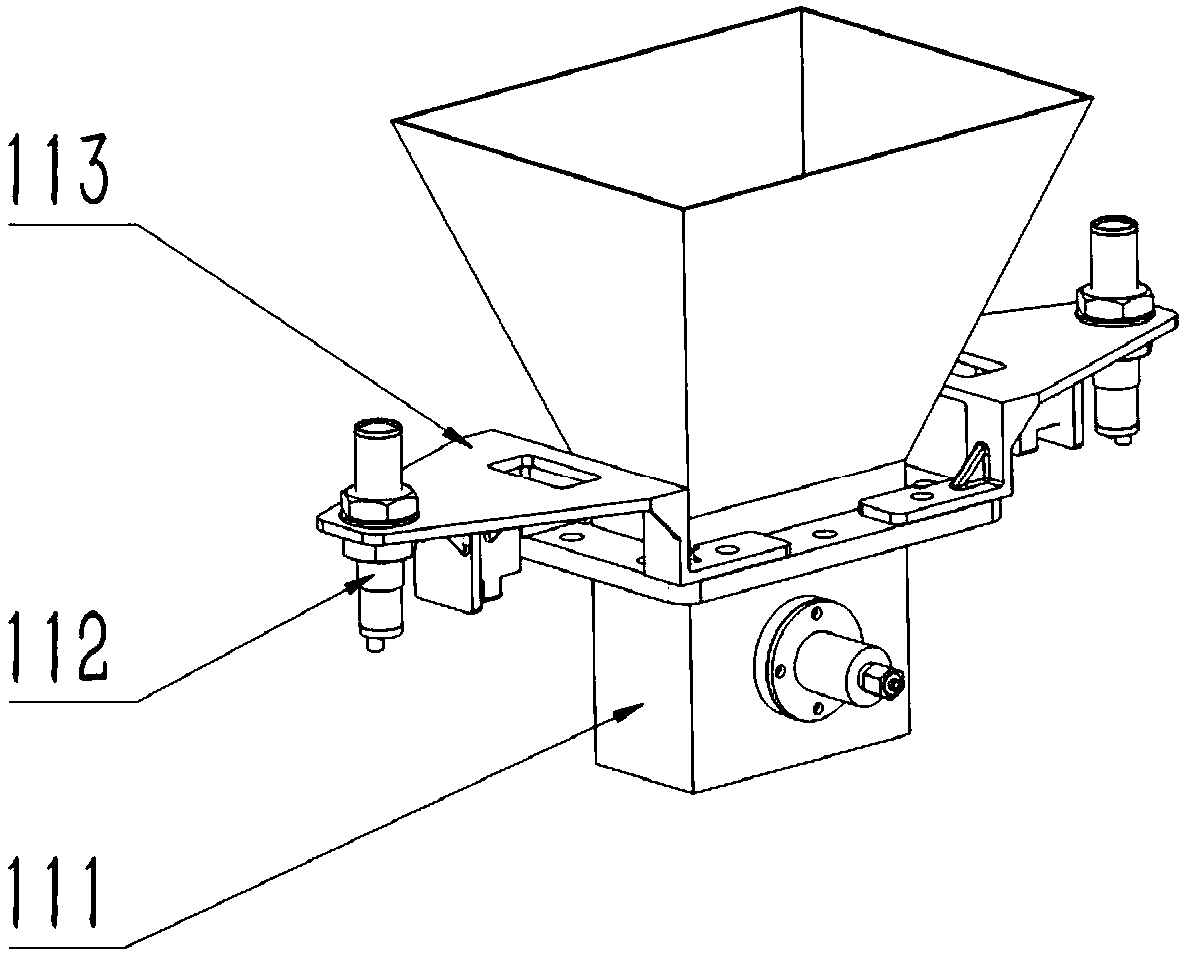

Grain moisture analysis meter and method and grain drying system

ActiveCN105548287AHigh measurement accuracyAvoid wear and tearMaterial capacitanceMoisture analysisConductive materials

The invention relates to a grain moisture analysis meter which comprises a hopper, a plastic plate, a sensor plate, a base plate, a base plate motor and a control circuit. The hopper is vertically placed, the top of the hopper is provided with an opening used for receiving grains, the bottom of the hopper is sealed by the base plate, the base plate opens and closes the hopper under the drive of the base plate motor, at least one side wall of the hopper is provided with a slot, the plastic plate is embedded into the slot, the sensor plate is attached to the plastic plate to be arranged on the outer side of the hopper and insulates from the hopper, and the hopper and the sensor plate are made of conductive materials and form a positive electrode and a negative electrode of the capacitive grain moisture analysis meter. The invention further relates to grain moisture analysis method and a grain drying system.

Owner:LIAONING HAIDISHENG MECHANICAL

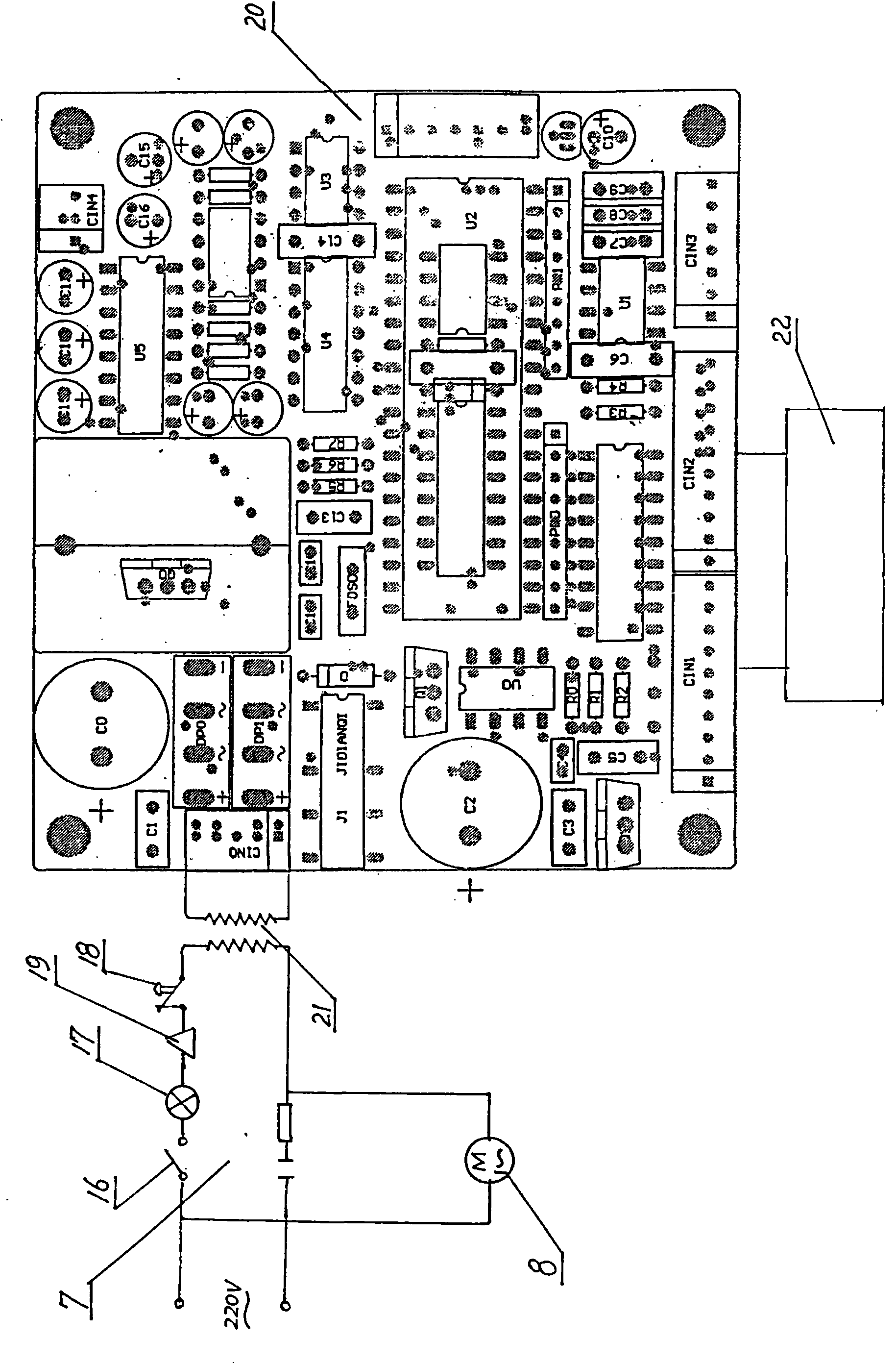

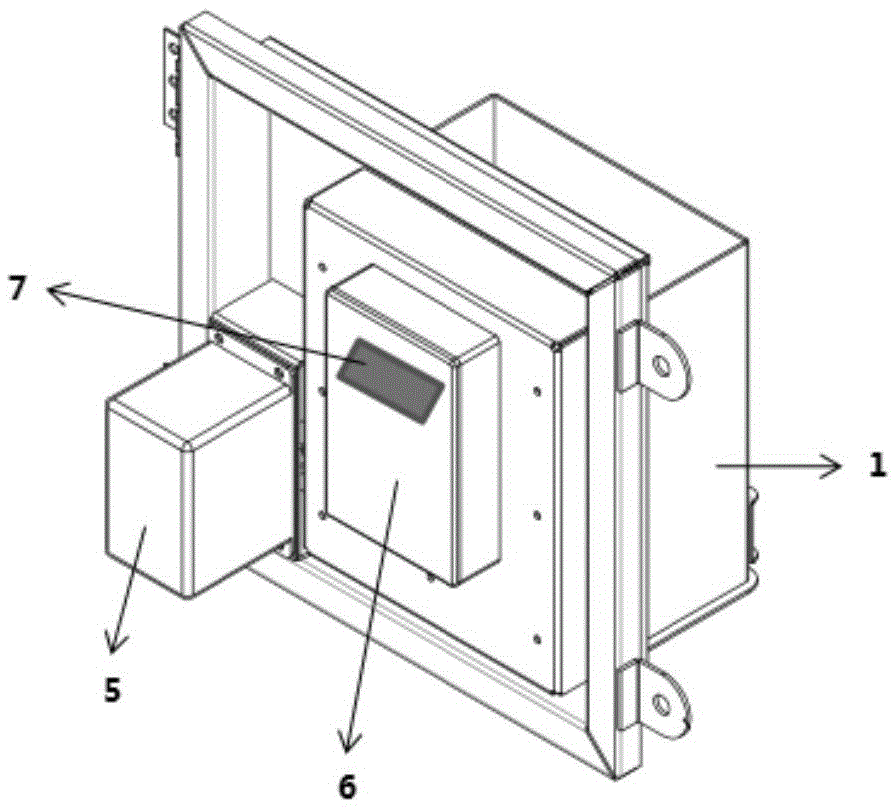

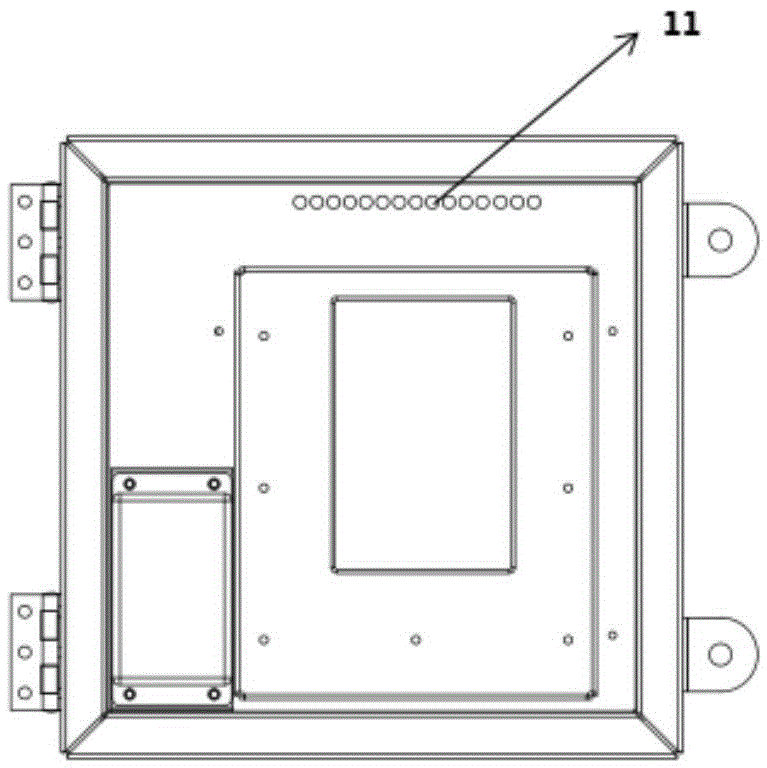

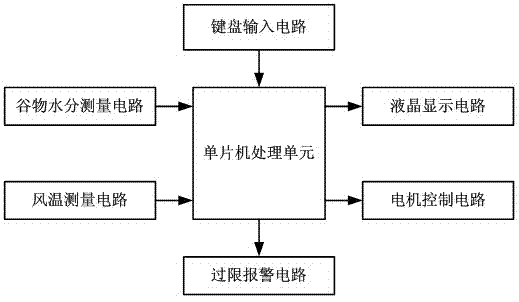

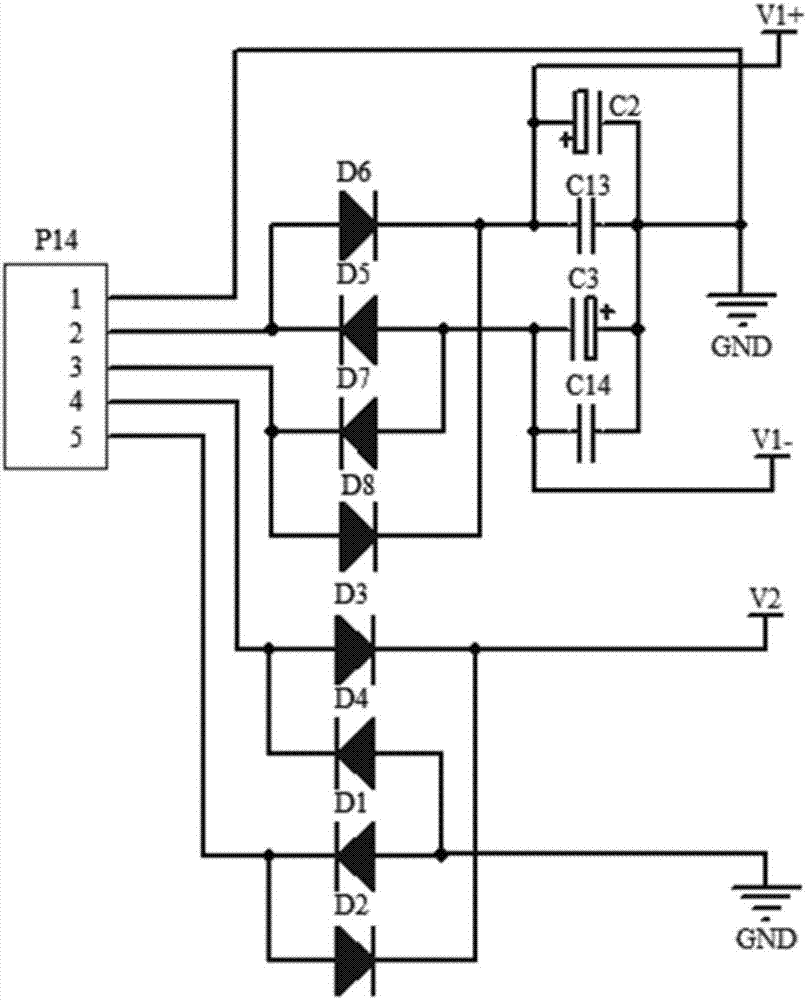

Intelligent controller of grain drier

InactiveCN102508448ALow priceIt has the function of alarm display when the drying condition exceeds the standardProgramme controlComputer controlMicrocontrollerMicrocomputer

The invention discloses an intelligent controller of a grain drier. The intelligent controller comprises a grain moisture measuring circuit, an air temperature measuring circuit, a single chip microcomputer processing unit, a keyboard input circuit, an over-limit alarm circuit, a liquid crystal display circuit and a motor control circuit, wherein the grain moisture measuring circuit is used for measuring moisture of grains at the outlet of the grain drier; the air temperature measuring circuit is used for measuring airflow temperature in the drier; the motor control circuit is used for controlling a grain discharging speed; and the grain moisture measuring circuit, the air temperature measuring circuit, the keyboard input circuit, the over-limit alarm circuit, the liquid crystal display circuit and the motor control circuit are respectively connected with the single chip microcomputer processing unit. An AT89S5X series chip and some peripheral devices are only used in the intelligent controller disclosed by the invention; the drying time is controlled by acquiring temperature of dry air and moisture content of grains at the outlet of the grain drier, so that the drying process is controlled; meanwhile, the intelligent controller also has an alarming and displaying function if drying conditions are excess and has higher flexibility and practicability; and the intelligent controller of the grain drier is installed on a universal grain drier and has a very low cost.

Owner:ZHEJIANG UNIV

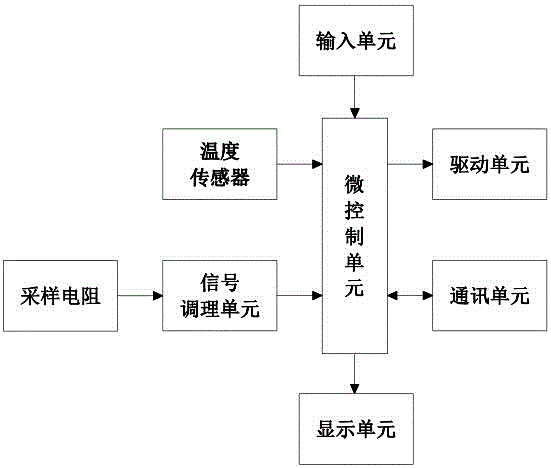

Resistance type grain moisture tester

InactiveCN106093143AReal-time measurementAccurate measurementMaterial resistanceElectrical resistance and conductanceCommunication unit

The invention discloses a resistance type grain moisture tester. The resistance type grain moisture tester comprises a temperature sensor, a sampling resistor, a signal conditioning unit, a micro-control unit, a driving unit, a communication unit, an input unit and a display unit. The resistance type grain moisture tester acquires a resistance value of grain through the sampling resistor, the resistance value is compared to a corresponding relation of preset moisture resistance of the micro-control unit to obtain a grain moisture measurement initial numerical value, meanwhile, the temperature sensor acquires a temperature numerical value of the grain, the temperature numerical value is transmitted to the micro-control unit to correct the grain moisture measurement initial numerical value so as to obtain a grain moisture measurement final numerical value, and therefore, grain moisture is measured accurately in real time. The resistance type grain moisture tester has the characteristics of high anti-interference capability, simple circuit structure and low cost.

Owner:CHENGDU HANKANG INFORMATION IND

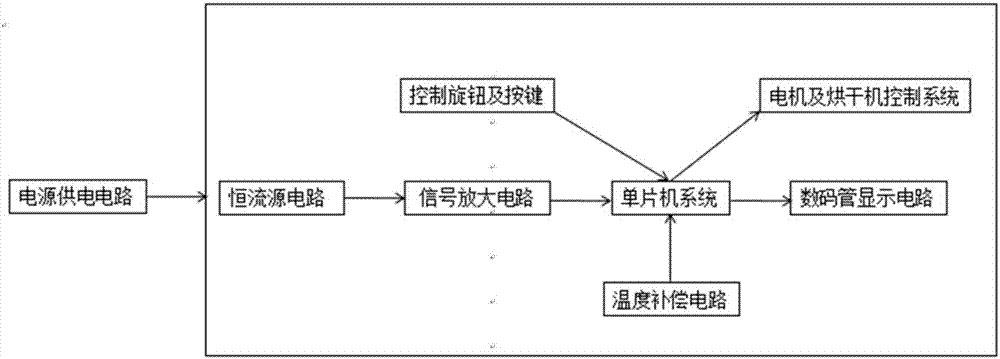

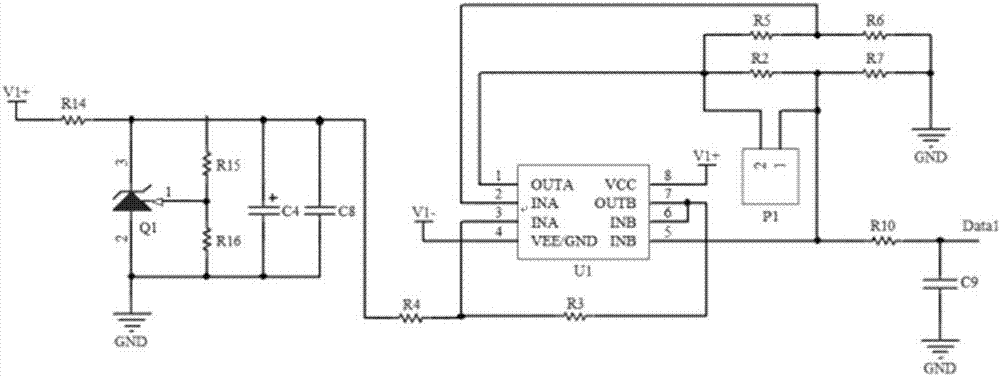

Grain moisture online detection circuit

InactiveCN106908483AFast measurement responseHigh precisionProgramme controlComputer controlMachine controlControl system

The invention discloses a grain moisture online detection circuit. The grain moisture online detection circuit comprise a power supply circuit, a constant-current source circuit, a single-chip microcomputer system, a signal amplification circuit, a Nixie tube display circuit, a motor anddrying machine control system, a control knob, a key circuit and a temperature compensation circuit, wherein the signal amplification circuit, the Nixie tube display circuit, the motor and drying machine control system, the control knob, the key circuit and the temperature compensation circuit are connected with the single-chip microcomputer system through data lines, the power supply circuit is connected with the other circuits, the constant-current source circuit is formed by connecting a voltage stabilizing circuit and a constant-current source measuring circuit, and the output end of the constant-current source circuit is connected with the signal amplification circuit. The grain moisture online detection circuit has the advantages that the measuring response speed is high, precision can be as high as + / -0.5%, manpower source waste can be reduced, the production cost is reduced, measuring results are accurate and the practicality is high.

Owner:WUHAN UNIV OF TECH

Method for measuring grain moisture content based on microwave frequency sweep technology

ActiveCN109632834AMoisture content investigation using microwavesUltrasound attenuationField conditions

The invention discloses a method for measuring the grain moisture content based on a microwave frequency sweep technology. The measuring method adopts a grain moisture content measuring device based on a frequency sweep microwave penetration method. The method mainly comprises the steps of setting an initial microwave frequency sweep signal MSS according to the characteristics of different kinds of grains, removing poor frequency points corresponding to a great reflection coefficient [Gamma] and standing-wave ratio [Rho] in the MSS by taking the automatic alignment of microwave antennas as a basis to obtain an optimized frequency sweep signal MSS'; determining and adjusting to the optimum measurement distance and inter-antenna distance according to three conditions such as an antenna far field condition, the representativeness of the moisture content measurement result and microwave space transmission loss reduction; mutually interacting the radiation optimized frequency sweep signal MSS' and the grain to be measured, inputting the microwave attenuation A and the microwave phase shift [Phi] into a grain moisture content prediction model to calculate the grain moisture content measurement result. The method not only uses the microwave frequency sweep technology, but also optimizes the used frequency sweep signal, is comprehensive in consideration when the microwave attenuation is calculated, and improves the accuracy of the grain moisture content measurement.

Owner:ZHEJIANG UNIV

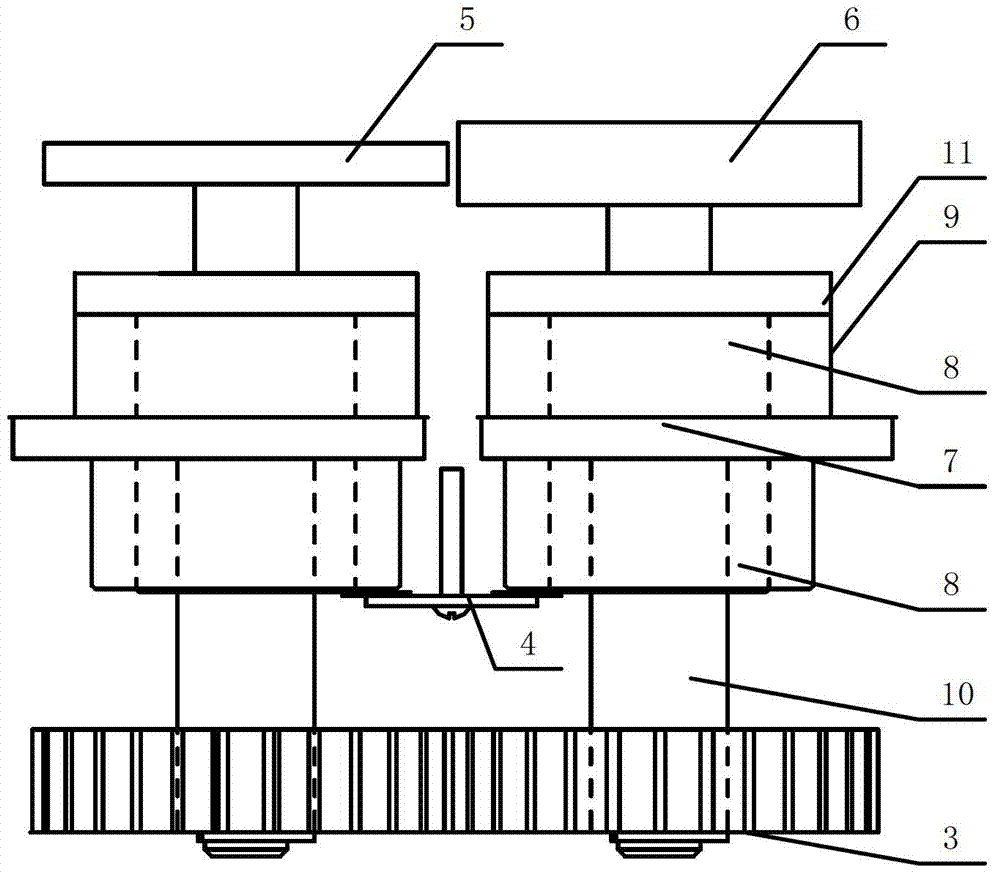

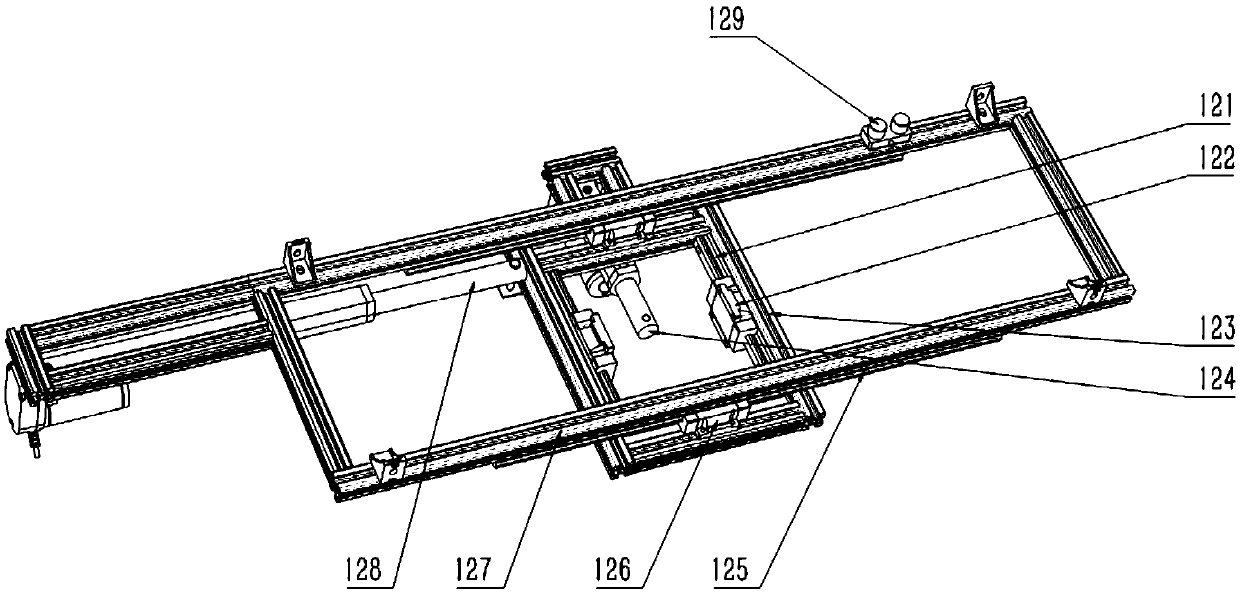

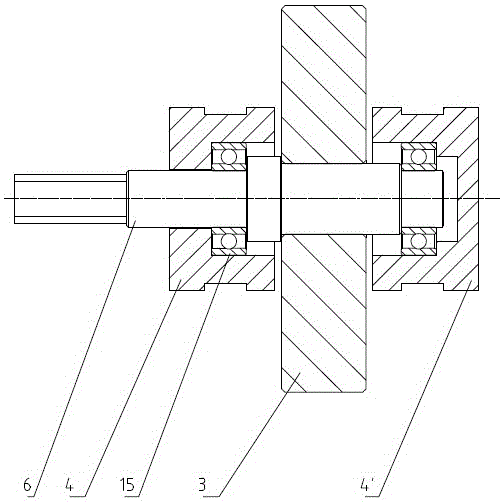

Material rolling device for online grain moisture meter

ActiveCN106680329ADeformable and stablePlay a role in elasticityPreparing sample for investigationMaterial resistanceForeign matterDrive shaft

The invention relates to a material rolling device for an online grain moisture meter, and belongs to the technical field of agricultural testing devices. The device comprises a shell with a feeding hole, wherein a material guide block below the feeding hole is fixed in the shell; coaxial round installation holes and coaxial kidney-shaped installation holes are formed at two sides of the shell under the material guide block respectively; the round installation holes and the kidney-shaped installation holes in two sides support corresponding transmission shafts through front and back rubber damping sleeves respectively; the two transmission shafts are provided with locating rolling wheels and floating rolling wheels between the front rubber damping sleeve and the back rubber damping sleeve; and one side, far away from a fixing rolling wheel, of each floating rolling wheel is provided with an elastic part for pressing the fixing rolling wheel. According to the material rolling device for the online grain moisture meter, an ''adhesion'' phenomenon is effectively avoided while the rolling stability is significantly improved and a ''jump'' phenomenon is removed; and shifting of the floating rolling wheels on a kidney-shaped installation seat can be overcome by increasing rolling force when a hard foreign matter passes through the rolling wheels, and thus the damage to the rolling wheels is avoided and the foreign matter is timely discharged.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Preparation method for high-performance absorbent resin

ActiveCN102731713AImprove permeabilityExcellent comprehensive properties such as permeability <30sPolymer scienceOxidation-Reduction Agent

The invention relates to a preparation method for high-performance absorbent resin. The preparation method comprises the following steps that: (1) wide super-absorbent resin gel with the water content being 50wt% which is obtained by free radical polymerization reaction on a continuous cycle belt is pelleted and a redox initiator is added during gel pelleting; (2) after pelleting, the gel grains are evenly distributed on a circulating air belt-type machine for drying, the drying process is divided into three stages of drying constant speed stage, drying speed reduction stage and drying cooling stage and the temperature and the air speed of hot air of a drier are adjusted according to the change of the water content of the gel at different drying stages; and (3) the dried materials which are obtained are crushed, grinded and screened to obtain the grains with qualified grain diameter; the surface of the super-absorbent resin grains with qualified grain diameter is coated with a superficial cross-linking agent; and the grains are heated and an anti-yellowing assistant and a grain moisture-proof clustering agent are added during the process that the materials are cooled. The absorbent resin gel prepared by the method provided by the invention has excellent physical usability.

Owner:SHANGHAI HUAYI NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com