Conveying and impurity-removing device of on-line grain moisture meter

A grain moisture and cleaning device technology, applied in the direction of material resistance, material capacitance, etc., can solve the problems of inaccurate moisture value of moisture meter, abnormal basic data, damage of moisture meter, etc., to prevent blockage, improve accuracy, and avoid occurrence of abnormal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

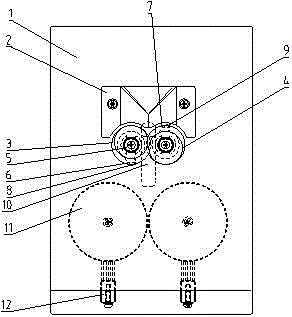

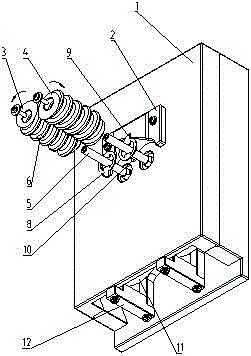

[0021] The on-line grain moisture meter conveying and impurity removal cleaning device of the present embodiment, such as figure 1 to Figure 5 As shown, it includes a pair of counter-rotating horizontal power output shafts 5 installed on both sides of the feed port of the moisture meter body 1. The axial direction of the output shaft 5 is installed with rotatable cleaning scrapers 8, 9 and screw output shafts from inside to outside. Material rollers 3 and 4 (commonly known as feeding screw feeding rollers), the spiral of the left spiral feeding roller 3 has at least one left screw feeding roller mixing groove 6, and the spiral of the right screw feeding roller 4 has at least one The miscellaneous groove 7 of the right spiral conveying roller at the center, the miscellaneous scrapers 8 and 9 have radial cutting edges, the two spiral conveying rollers 3 and 4 mesh with each other at the staggered positions corresponding to the miscellaneous grooves 6 and 7, and the moisture me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com