Intelligent energy-saving control system of grain drying tower

An energy-saving control system and drying tower technology, applied in drying, food processing, drying solid materials, etc., can solve the problems of unreasonable control of grain level in the grain storage section, potential safety hazards, waste of heat and electricity, etc. Achieve the effects of prolonging the service life of equipment, solving waste problems, and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

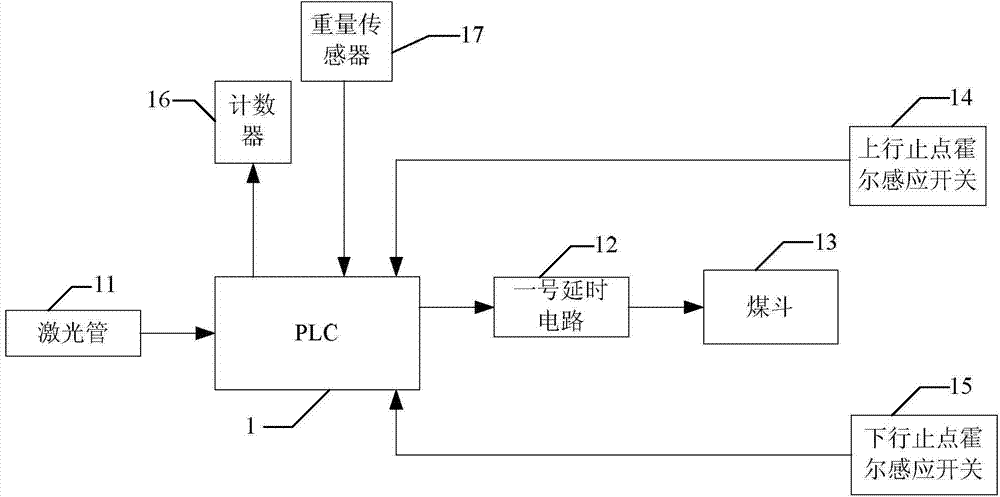

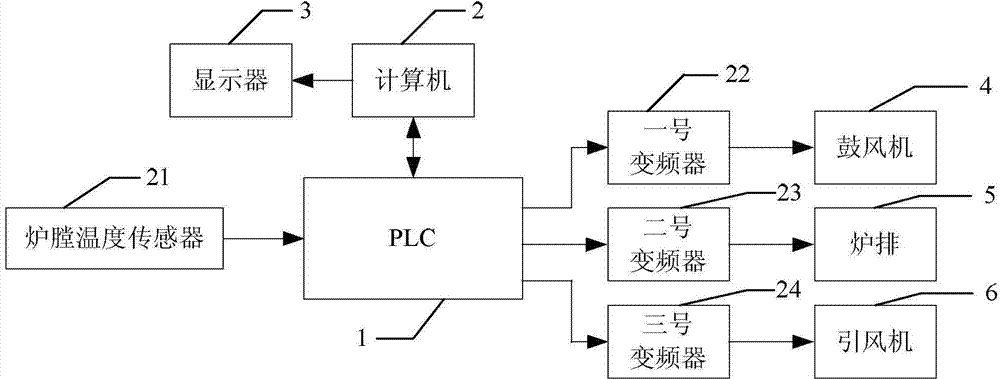

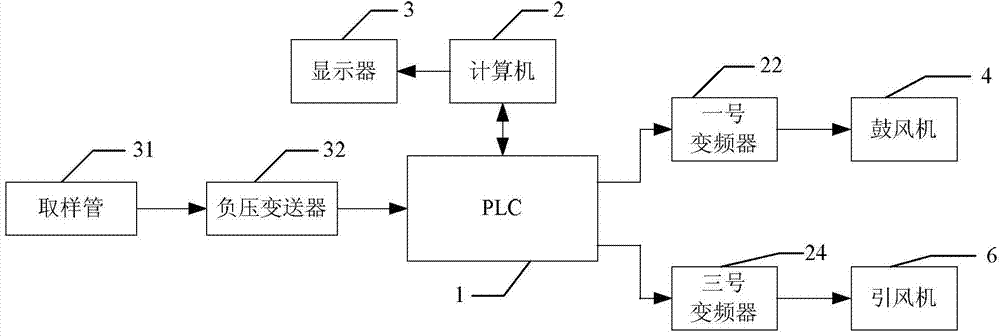

[0073] Specific implementation mode 1. Combination Figure 1 to Figure 15 Describe this specific implementation mode, the intelligent energy-saving control system of grain drying tower, which includes the upper coal hopper control unit of the hot blast stove, the furnace temperature detection and control unit of the hot blast stove, the negative pressure value detection and control unit of the furnace, and the temperature of the front end and the rear end of the heat exchanger. Detection and control unit, gradient air supply temperature detection and control unit of each hot air blower, grain level control unit in the grain storage section, grain temperature and moisture detection and control unit in each drying section, exhaust steam temperature, humidity and temperature at the exhaust outlet of each drying section Exhaust wind speed detection and control unit, grain temperature detection and control unit in the cooling section, grain moisture detection and control unit in the...

specific Embodiment approach 2

[0106] Embodiment 2. The difference between this embodiment and the grain drying tower intelligent energy-saving control system described in Embodiment 1 is that the furnace temperature sensor 21 is realized by a corundum temperature sensor.

specific Embodiment approach 3

[0107] Embodiment 3. The difference between this embodiment and the grain drying tower intelligent energy-saving control system described in Embodiment 1 is that the sampling pipe 31 is realized by a section of DN20 pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com