On-line resistance-type grain moisture tester and control method thereof

A technology of grain moisture and control method, which is applied in the direction of drying solid materials, storing seeds through drying, lighting and heating equipment, etc., can solve problems such as low precision, loss of grain protein, troublesome operation, etc., to ensure normal operation and improve The effect of high measurement accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

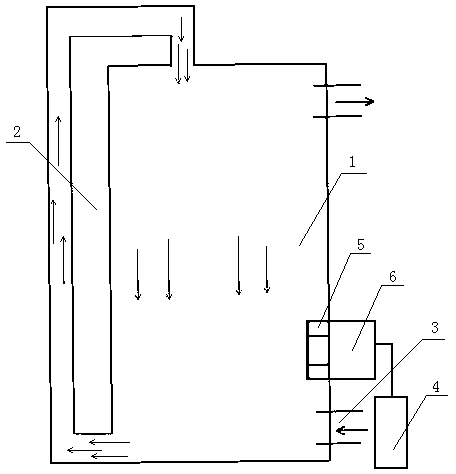

[0033] see figure 1 , On-line resistance type grain moisture tester, including conveying device and detection control device 6;

[0034] see Figure 4 , The conveying device selects two conveying wheels 5, the two conveying wheels 5 are arranged in the drying chamber 1, and their outer ends are fixed on the housing 61 of the detection control device 6, and the gap between the two conveying wheels 5 is the conveying channel;

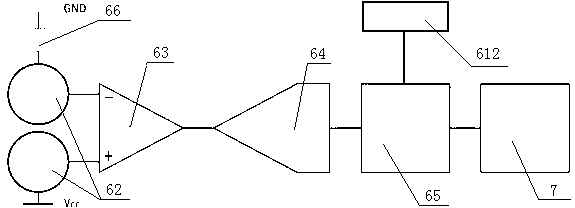

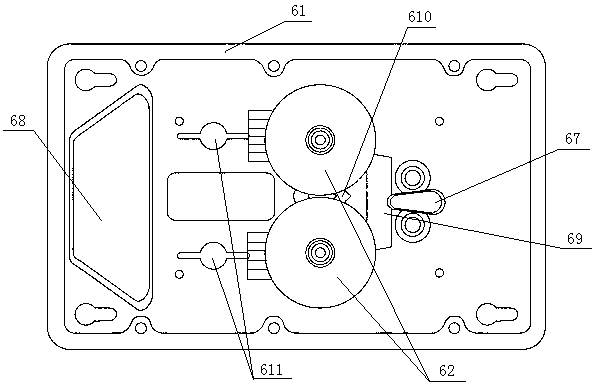

[0035] The detection control device 6 is arranged outside the drying chamber 1; the detection control device 6 includes a housing 61, two rolling wheels 62, an operational amplifier 63, an A / D converter 64, and a central processing unit 65 arranged in the housing 61 , Fixed value resistor 66, rolling chamber inlet 67, rolling chamber outlet 68, downwardly inclined isolation plate 69, guide device 610 and cleaning brush 611, arranged outside the housing 61 and with the central processing 65 Connected display 612; see image 3 , The rolling chamber inlet 67 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com