High-efficiency online drying system for grain moisture

A drying system and grain technology, applied in the direction of testing food, material inspection products, etc., can solve the problems of inability to realize automatic control of grain drying process, reduce drying efficiency, energy waste, etc., and achieve the effect of improving reliability and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

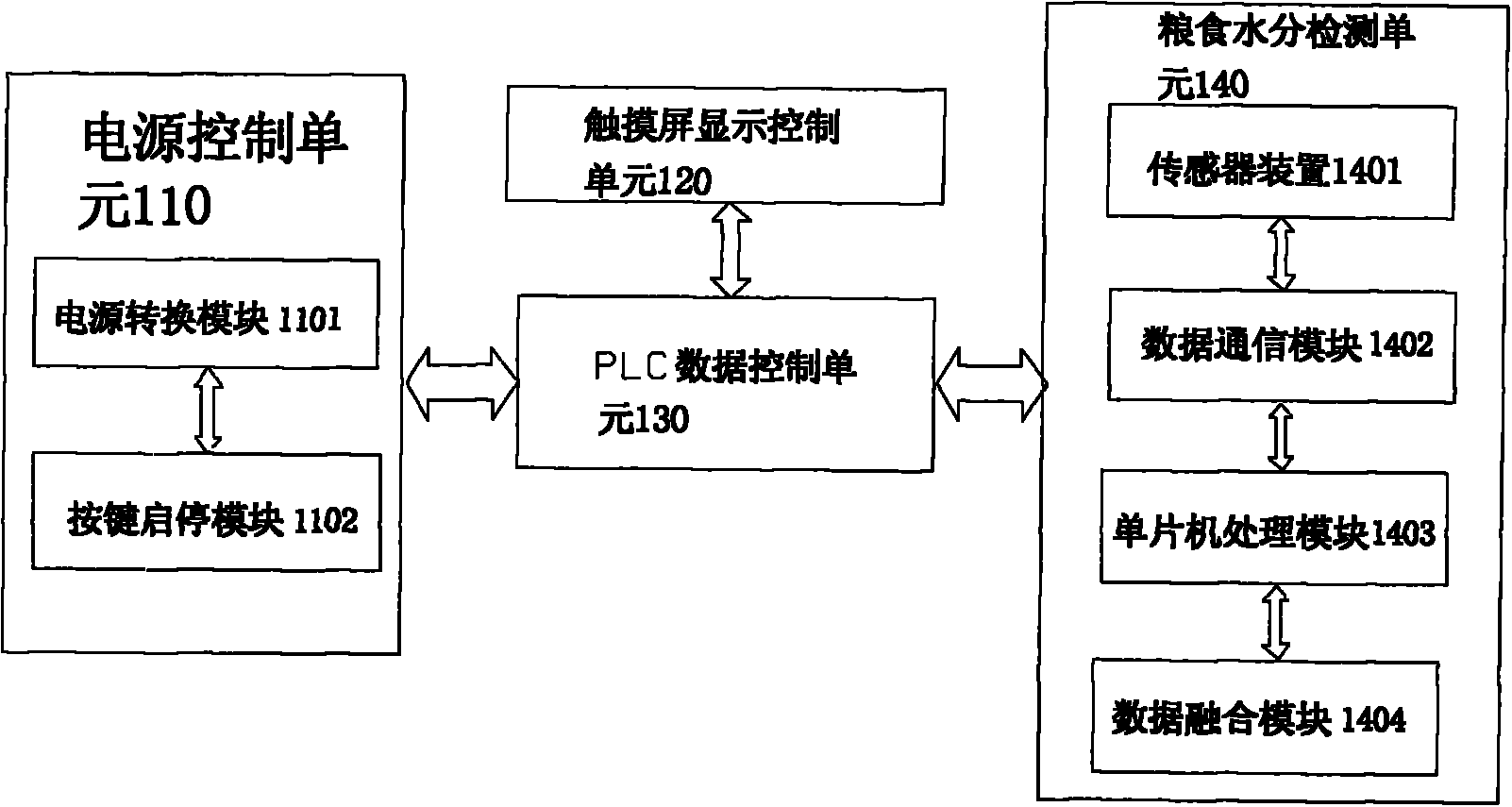

[0017] Reference Figure 1-4 , This specific embodiment adopts the following technical solutions: it includes a power control unit 110, a touch screen display control unit 120, a PLC data control unit 130, and a grain moisture detection unit 140. The PLC data control unit 130 and the touch screen display control unit 120 respectively, power control The unit 110 and the grain moisture detection unit 140 are connected to each other.

[0018] The power control unit 110 includes a key start / stop module 1102 and a power conversion module 1101. The key start / stop module 1102 and the power conversion module 1101 are connected to each other.

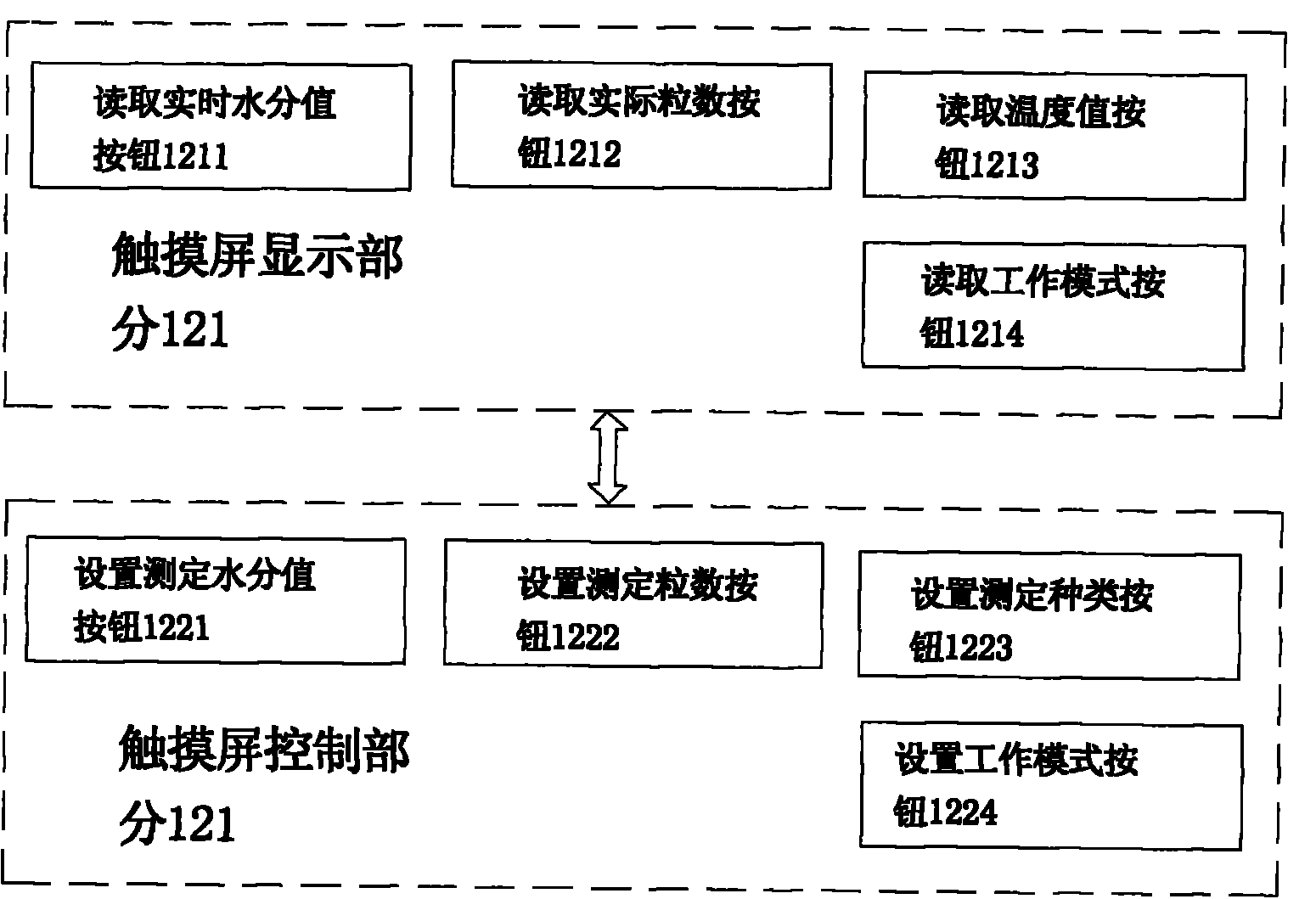

[0019] The touch screen display control unit 120 is mainly composed of a touch screen display part 121 and a touch screen control part 122. The touch screen control part 122 sets the measured moisture value button 1221, the set measurement button 1222, the set measurement type button 1223 and the setting The operation of the working mode button 1224...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com