Material rolling device for online grain moisture meter

A moisture meter and material technology, which can be used in measurement devices, analytical materials, instruments, etc., to solve problems such as adhesion, reduction in reliability and success rate of rolling, and increase in energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

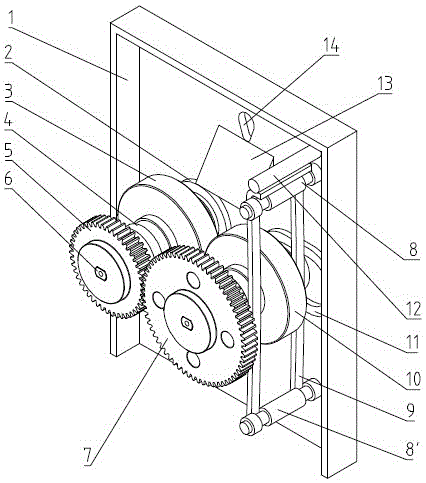

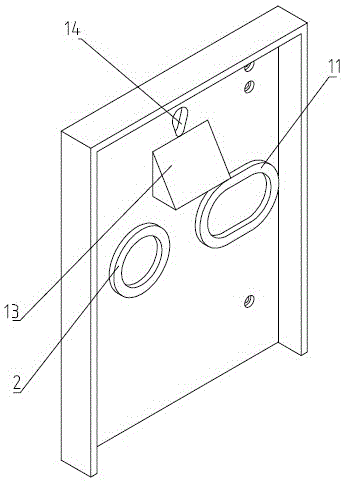

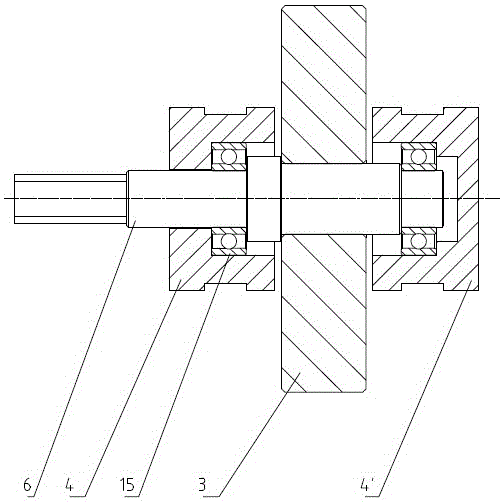

[0016] The material rolling device for the online grain moisture meter of this embodiment is as follows: Figure 1 to Figure 3 As shown, there is a feeding port 14 in the middle of the upper part of the housing 1 on one side, and an inclined material guide block 13 located under the feeding port is fixed inside the two pairs of combined housings 1 . The housings 1 on both sides under the material guide block 13 are respectively formed with a coaxial circular mounting hole 2 and a coaxial waist-shaped mounting hole 11 . The circular mounting holes 2 on both sides and the waist-shaped mounting holes 11 on both sides respectively support the corresponding transmission shaft 6 through the front and rear rubber shock absorbing sleeves 4, 4'. The positioning rolling wheel 3 and the floating rolling wheel 10 between the front and rear rubber shock absorbing sleeves 4, 4' are installed respectively on the two power transmission shafts 6, and the floating rolling wheel 10 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com