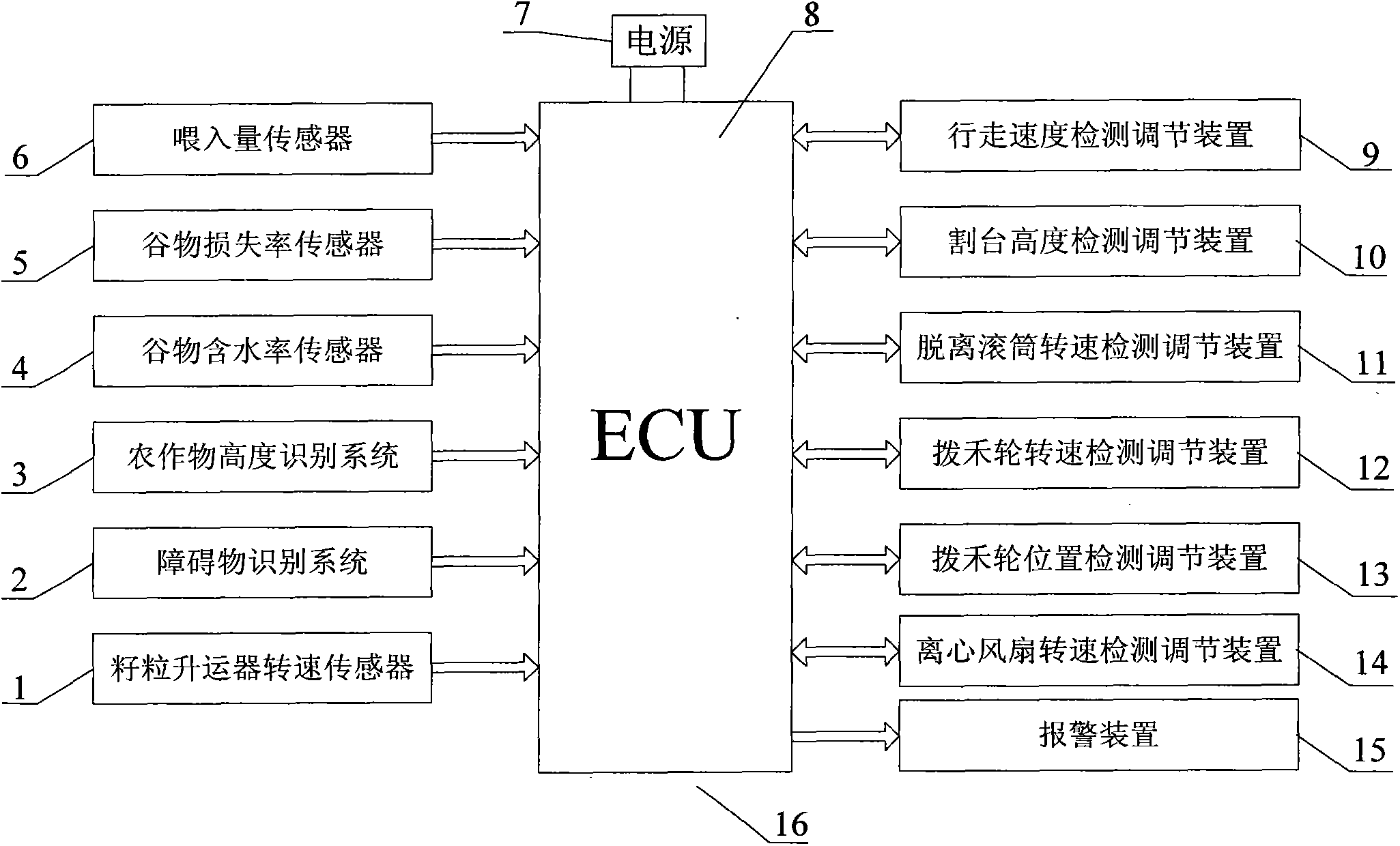

Electrically-driven intelligent combine-harvester control system

A combine harvester and control system technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as harsh working conditions, low intelligence, and poor reliability, so as to reduce labor intensity and facilitate intelligentization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

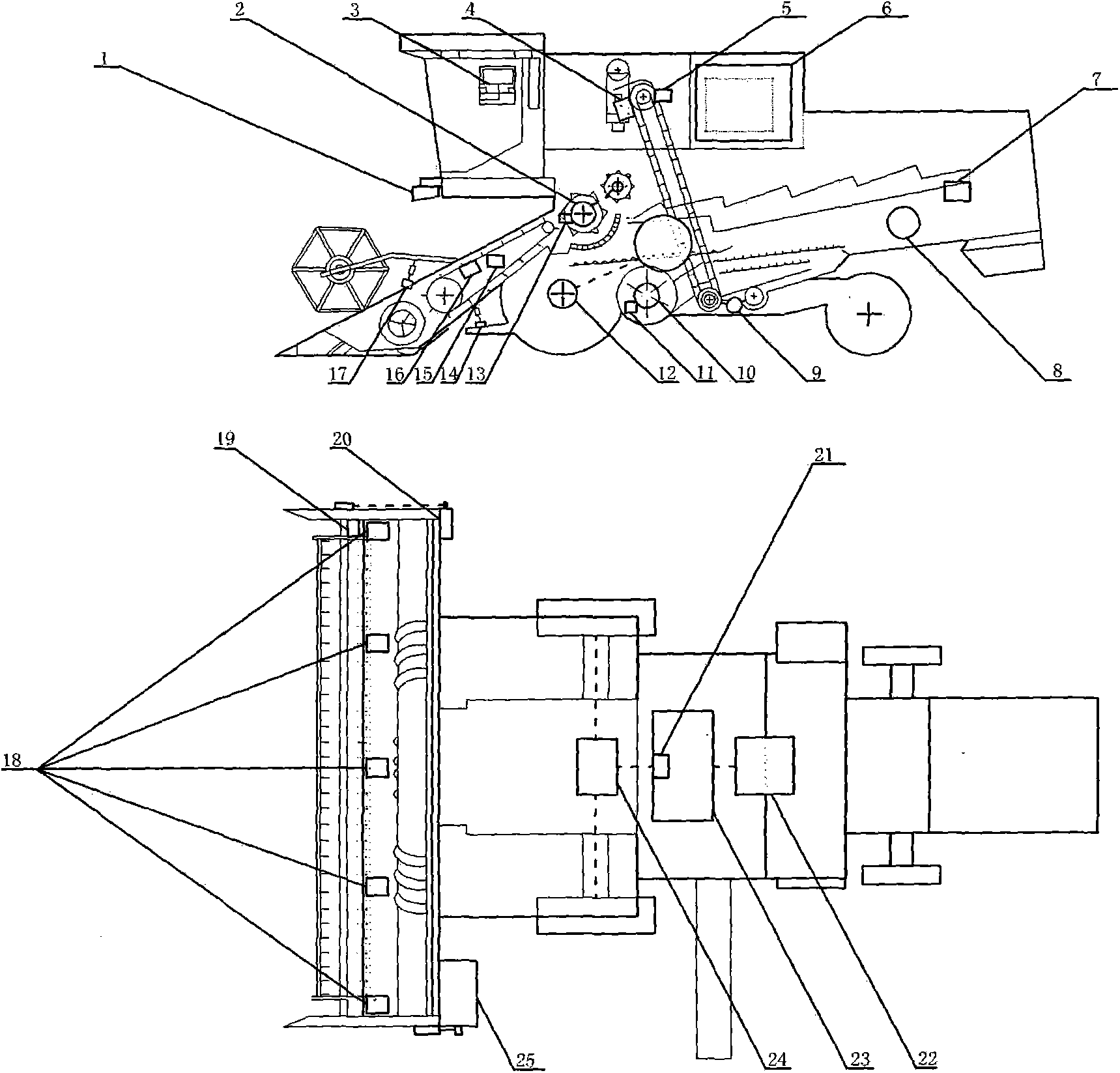

Method used

Image

Examples

Embodiment Construction

[0013] The obstacle recognition system detects whether there are obstacles in front of the machine, and sets a safe distance of 3m. When there is an obstacle ahead and the measured distance is less than 3m, the alarm device is activated to remind the driver to take corresponding measures; when there is no obstacle ahead or the measured distance is greater than 3m, the harvester continues to work.

[0014] The crop height recognition system detects the current crop height and its lodging situation, and the hydraulic cylinder position sensor detects the current position signal of the header. When the crop height is low or encounters lodging crops, the height of the control header is lowered; on the contrary, the height of the header is raised.

[0015] The grain moisture content sensor and the feed amount sensor respectively detect the grain moisture content, crop straw moisture content and feed amount signals in real time, and send them to the ECU together with the threshing dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com