Patents

Literature

34 results about "Fuzzy predictive control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for tracing arm motion in real time video tracking system

InactiveCN101256673AIn line with daily behaviorInput/output for user-computer interactionImage analysisControl signalNatural state

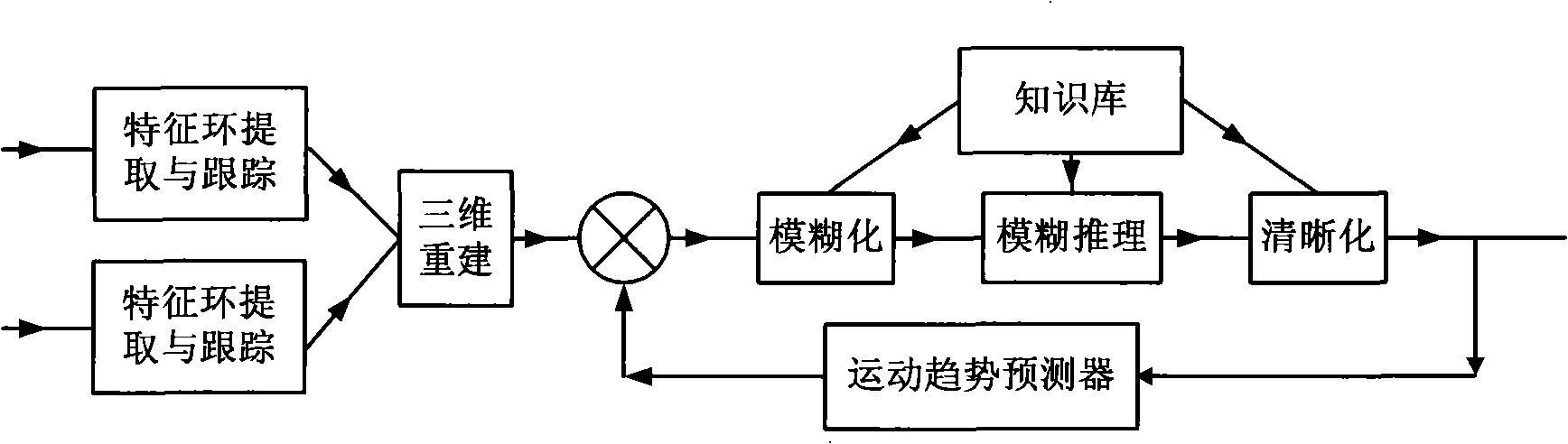

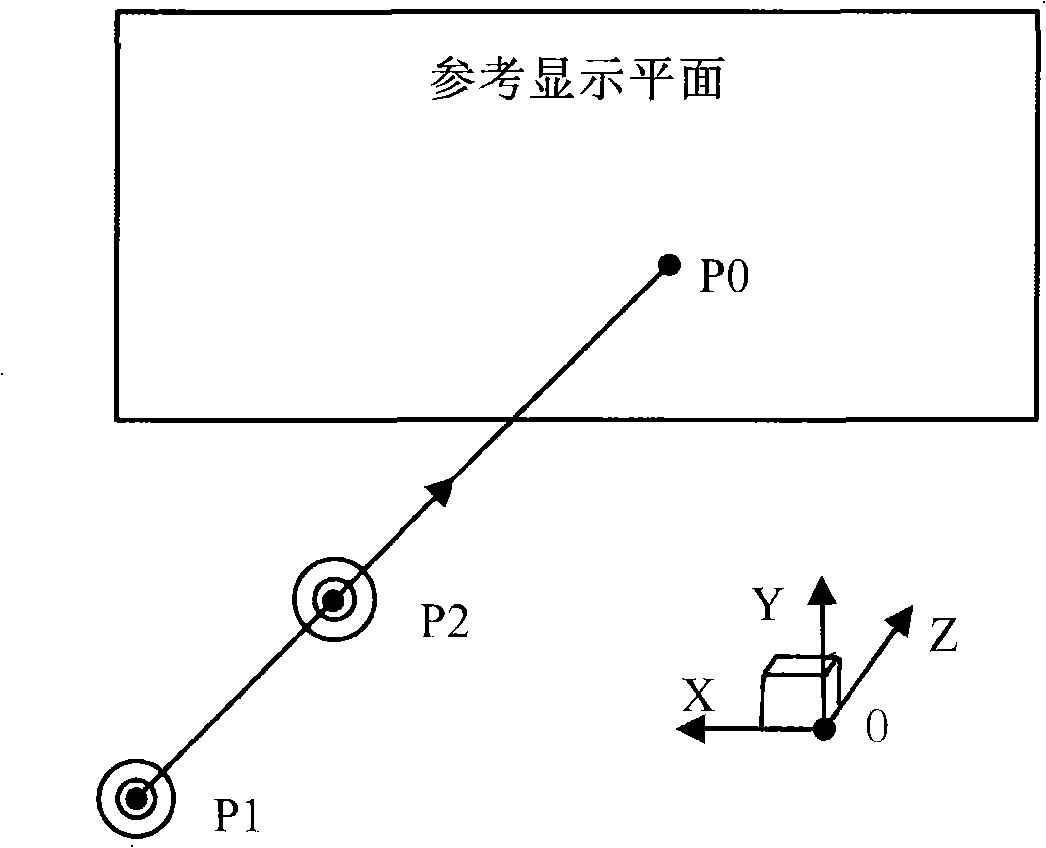

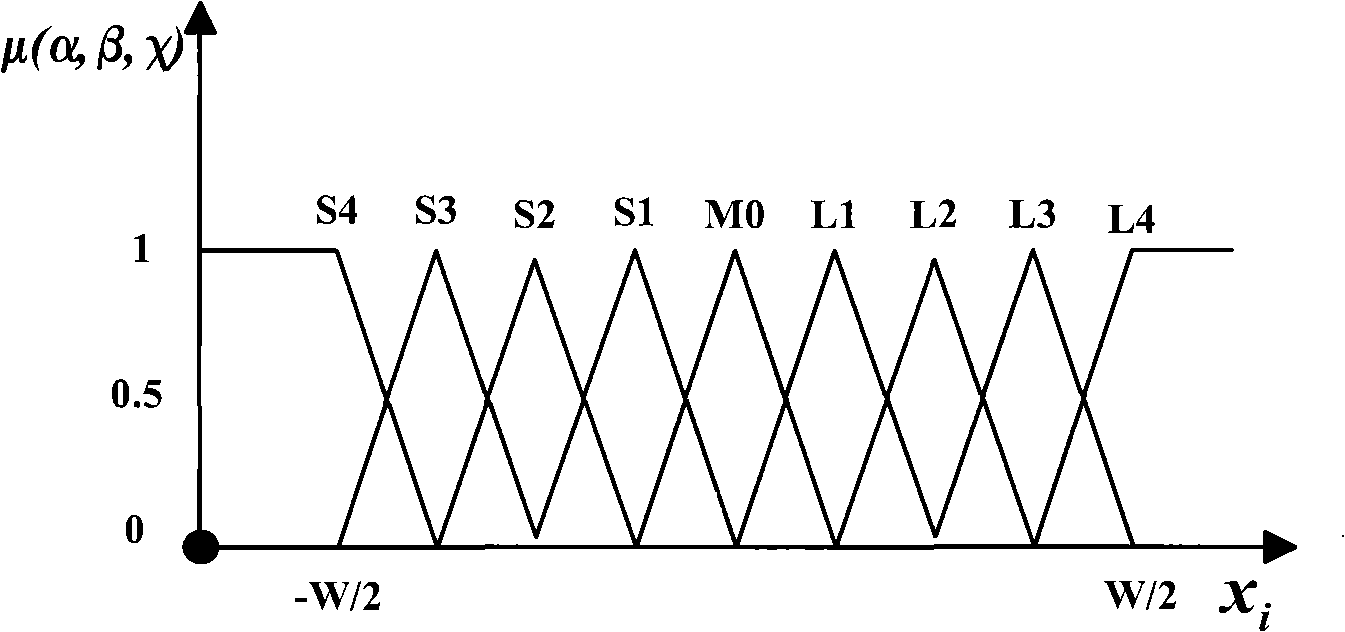

The invention relates to a method of realizing the visualization of track arm movement in fields such as immersion interactive game, dangerous industrial control, virtual reality, etc. The current method is not very much in line with human daily interaction habits. The method of the invention is: roughly locating the target window for arm position through analyzing the central logo color information of wrist and elbow in real-time image sequence; then carrying out central logo extraction and three-dimensional reconstruction of characteristic points for the rough target window from two synchronized camera; lastly carrying out robust control with the three-dimensional characteristic points of wrist and elbow based on fuzzy predictive control technology, and generating stable navigation control signals. The method of the invention can realize six degrees of freedom arm navigation operation, thus human arms and hands can be in a natural state when interacting, the operator can carry out human-computer interaction in a natural way, which is much more in line with human daily interaction habits.

Owner:CHINA JILIANG UNIV

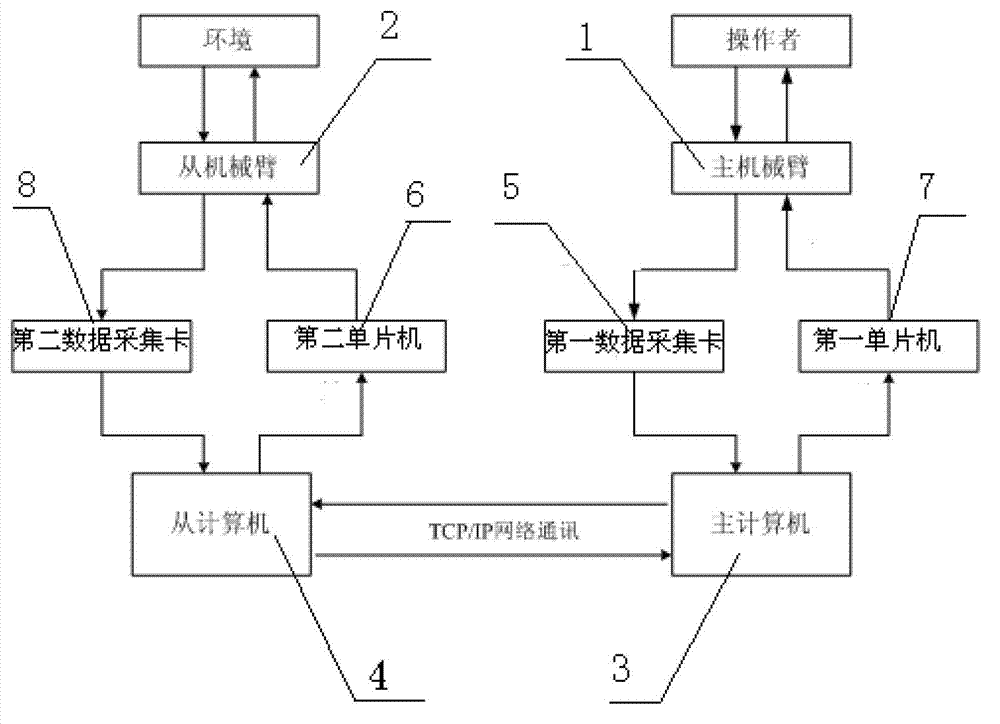

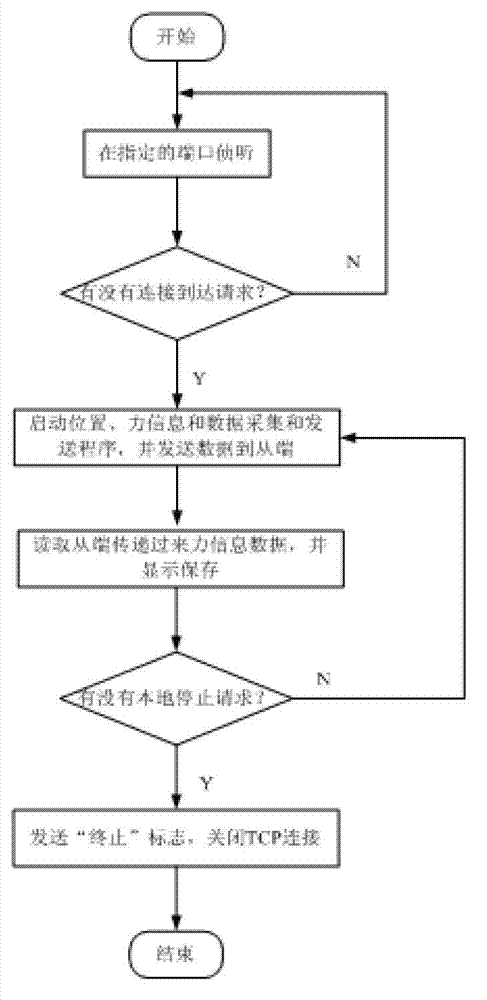

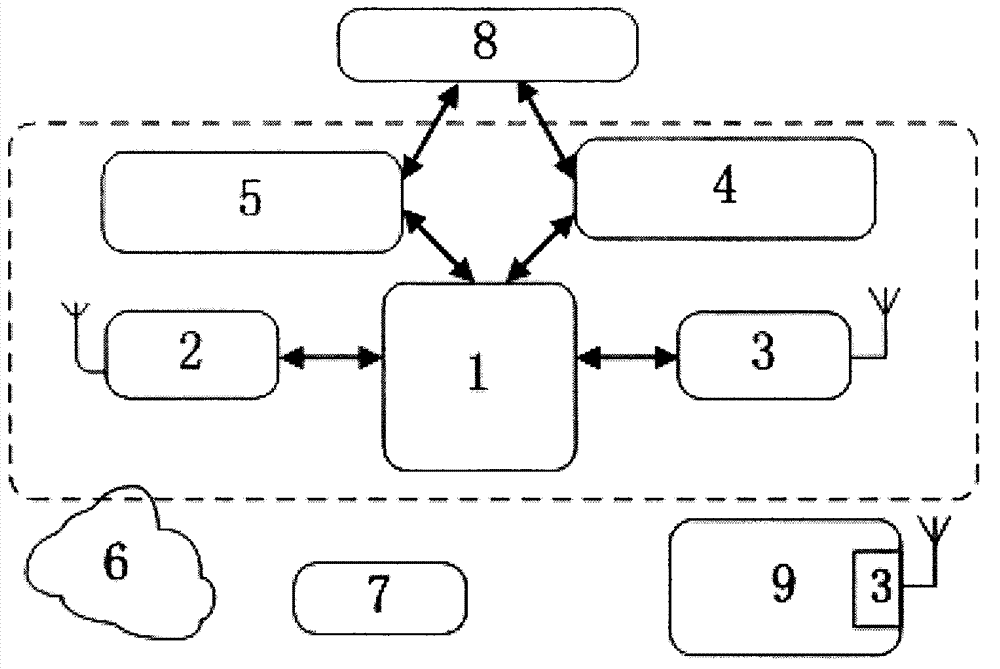

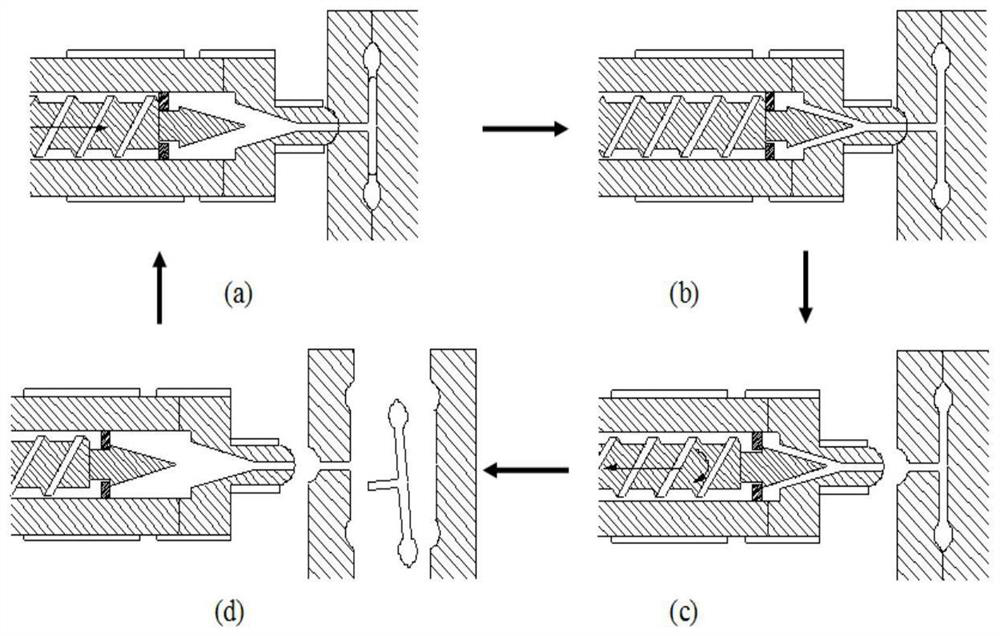

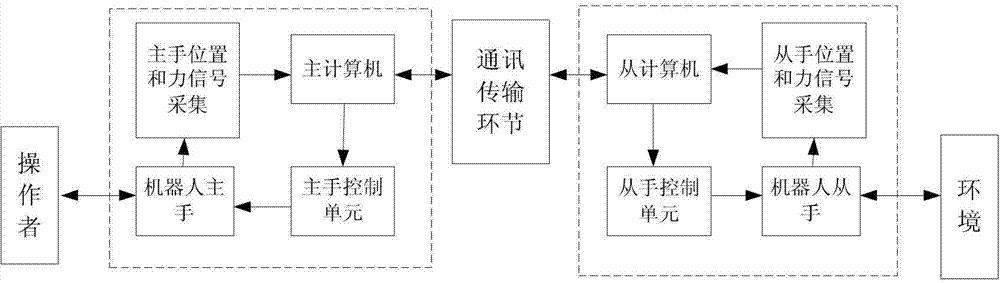

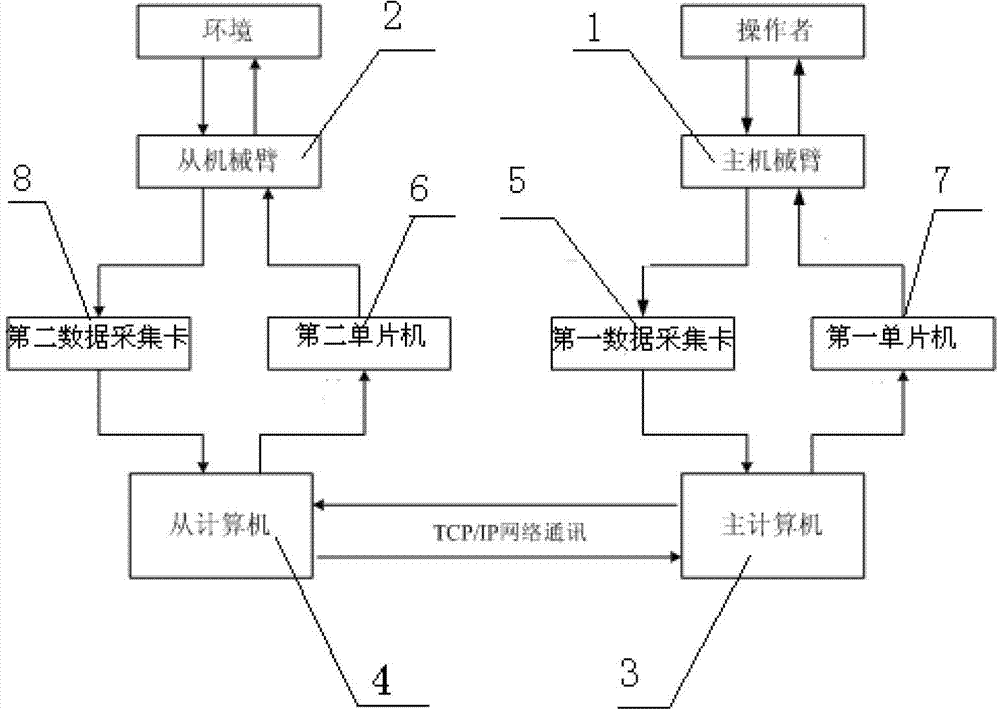

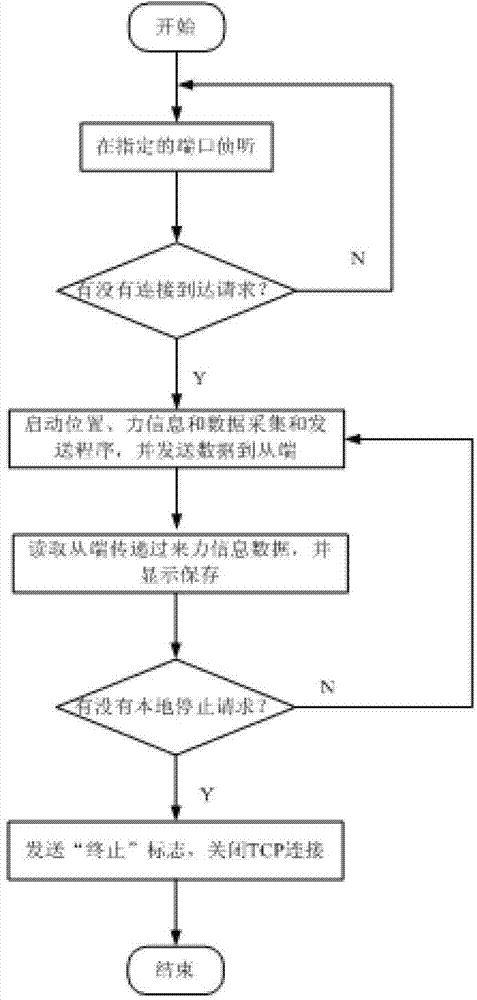

Network teleoperation robot system and time delay overcoming method

InactiveCN102825603AGuaranteed stabilityImprove robustnessProgramme-controlled manipulatorRobotic systemsTime delays

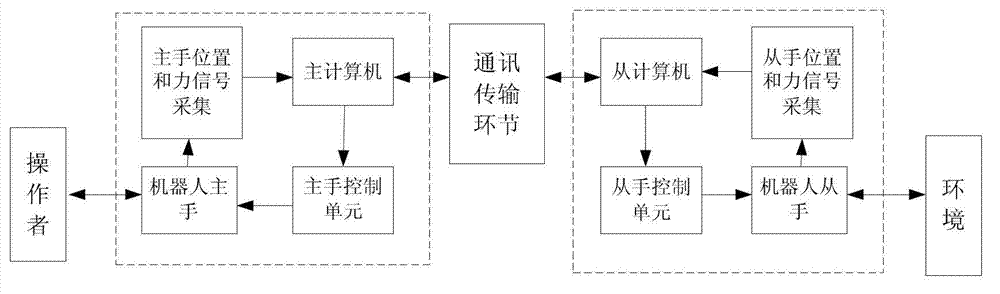

The invention discloses a network teleoperation robot system and a time delay overcoming method. The system is formed by linking two manipulators with the same structure and symmetrical functions through a network communication link. A main manipulator is operated by an operator so that the main manipulator is acted; the main manipulator transmits an action signal to a secondary manipulator through force and angle displacement sensors, and a communication control link, so that the secondary manipulator can move in the same direction along the main manipulator. When the secondary manipulator is affected by the environment, the secondary manipulator can return the signal to the main manipulator along the original path, thus, the main manipulator can feel the same action of the environment and feed back to the operator. By adopting a modeling method based on an event and a fuzzy predictive control algorithm, the system has good robustness on the model mismatch; therefore, the system can overcome the influence caused by the network time delay.

Owner:JIANGSU UNIV OF SCI & TECH

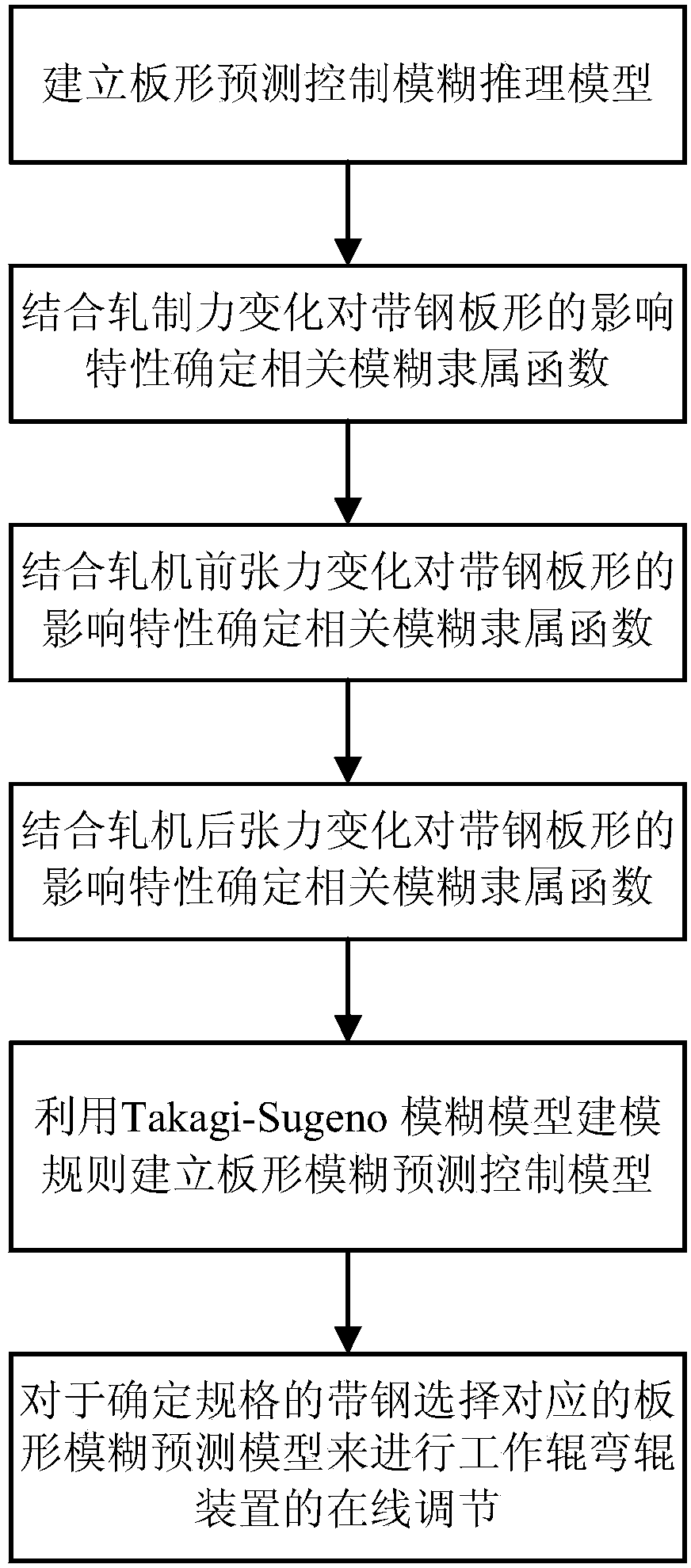

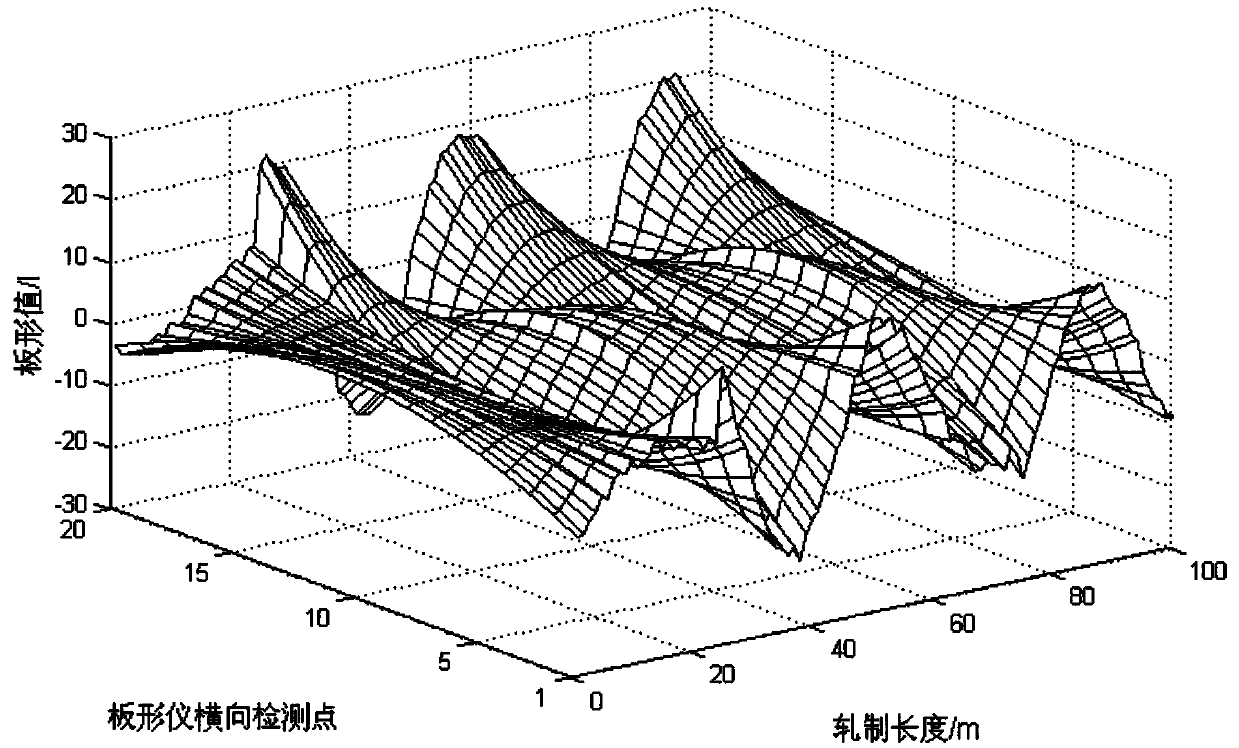

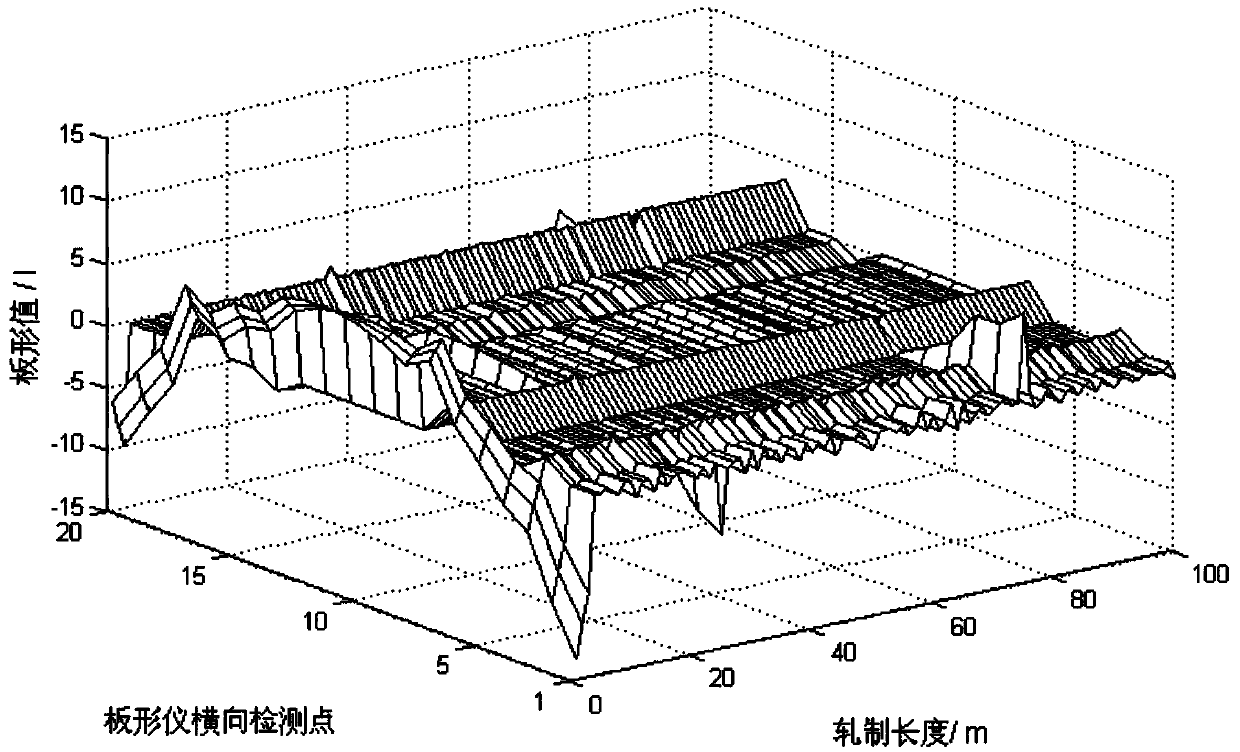

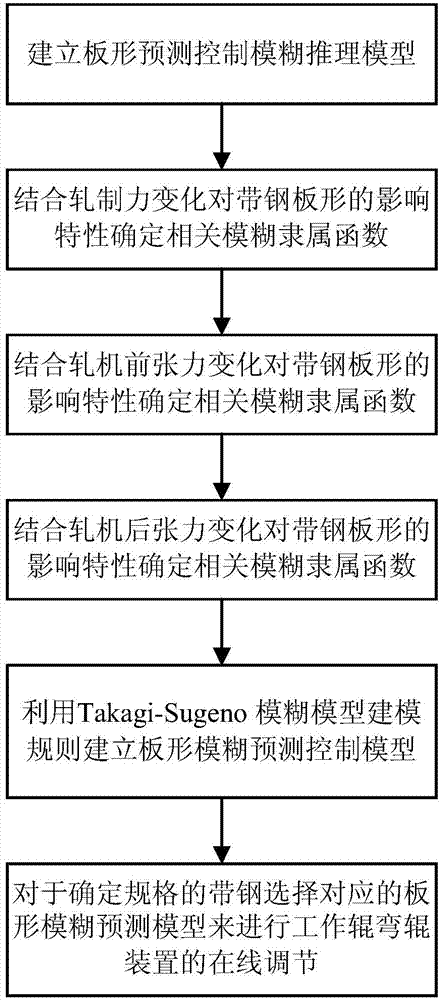

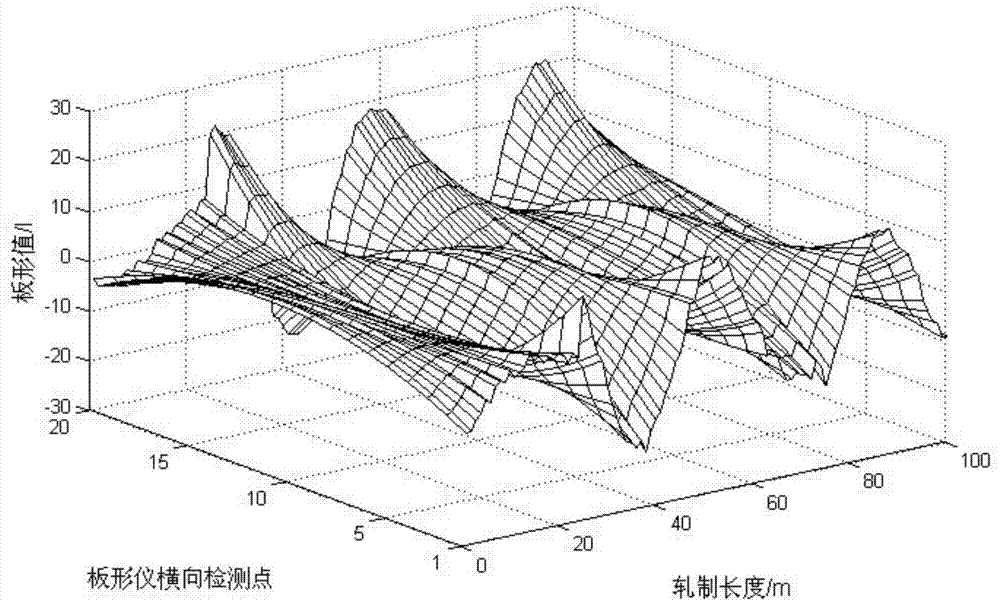

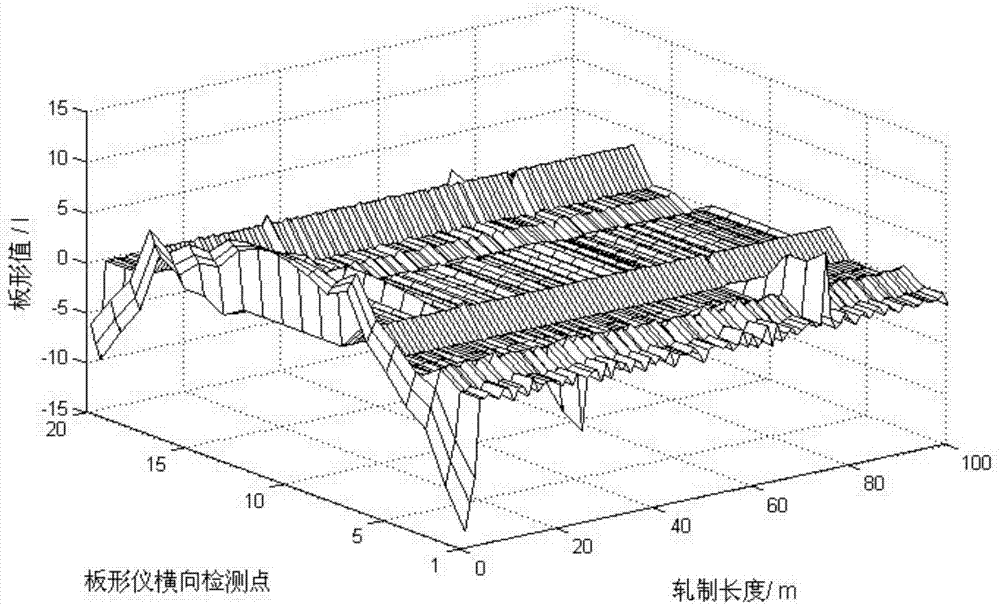

Cold-rolled strip steel plate shape prediction control method

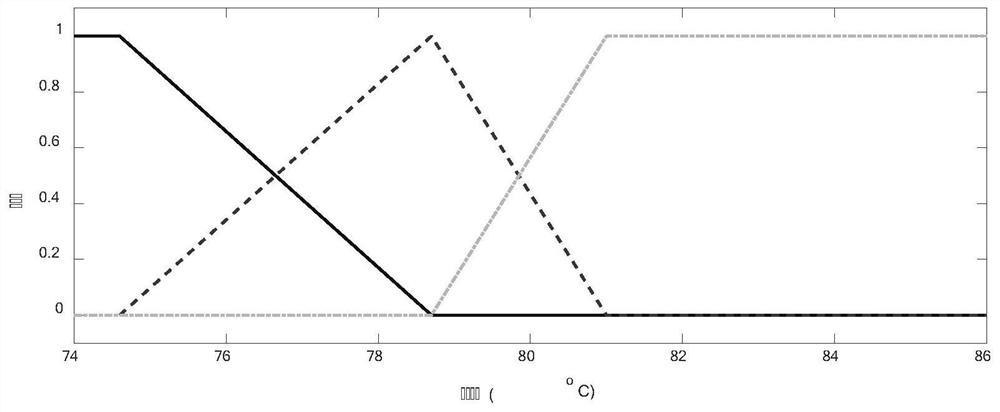

ActiveCN103418619AEliminate common shape defectsReduce negative impactProfile control deviceTakagi sugenoFuzzy membership function

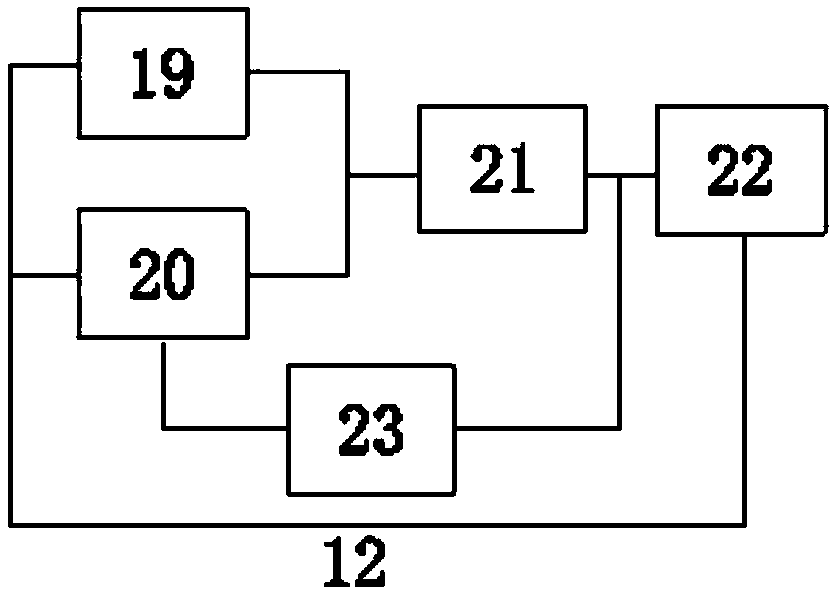

The invention provides a cold-rolled strip steel plate shape prediction control method, comprising the following steps: for cold-rolled strip steel of the same specification, establishing a corresponding plate shape prediction control fuzzy reasoning model; setting fuzzy membership functions of various parameters in the plate shape prediction control fuzzy reasoning model by being combined with the characteristics of influence of rolling force change on the strip steel plate shape; establishing plate shape fuzzy prediction control models by utilizing a Takagi-Sugeno fuzzy model modeling rule; selecting a corresponding plate shape fuzzy prediction control model to carry out online adjustment on a working roller bending device. A dynamic relationship is established among rolling force variation, forward pull variation of a roll mill, backward pull variation of the roll mill, and online adjustment variable of the working roller bending device by using a fuzzy modeling method, the adverse effect of transmission time lag existing between the roll mill body and a plate shape instrument on the plate shape control at the outlet of the cold-rolled strip steel, and two familiar plate shape defects of intermediate waves and edge waves existing in the cold-rolled strip steel products are effectively overcome.

Owner:WISDRI ENG & RES INC LTD

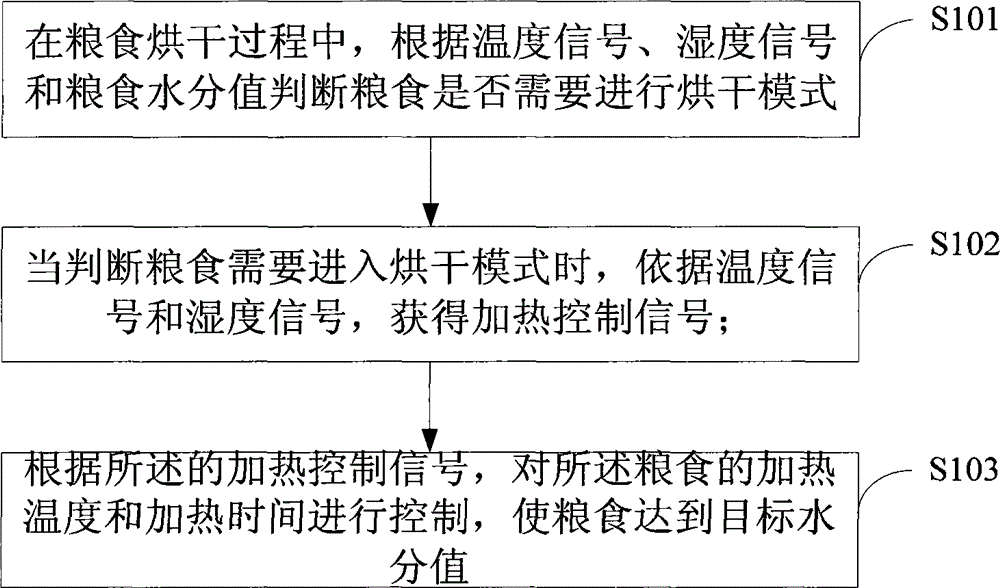

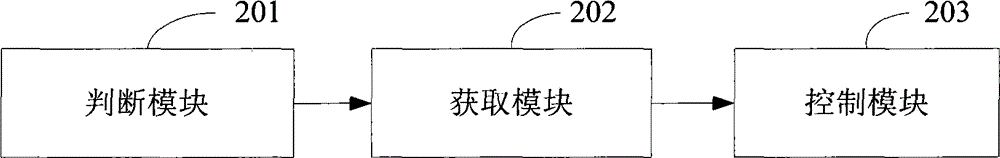

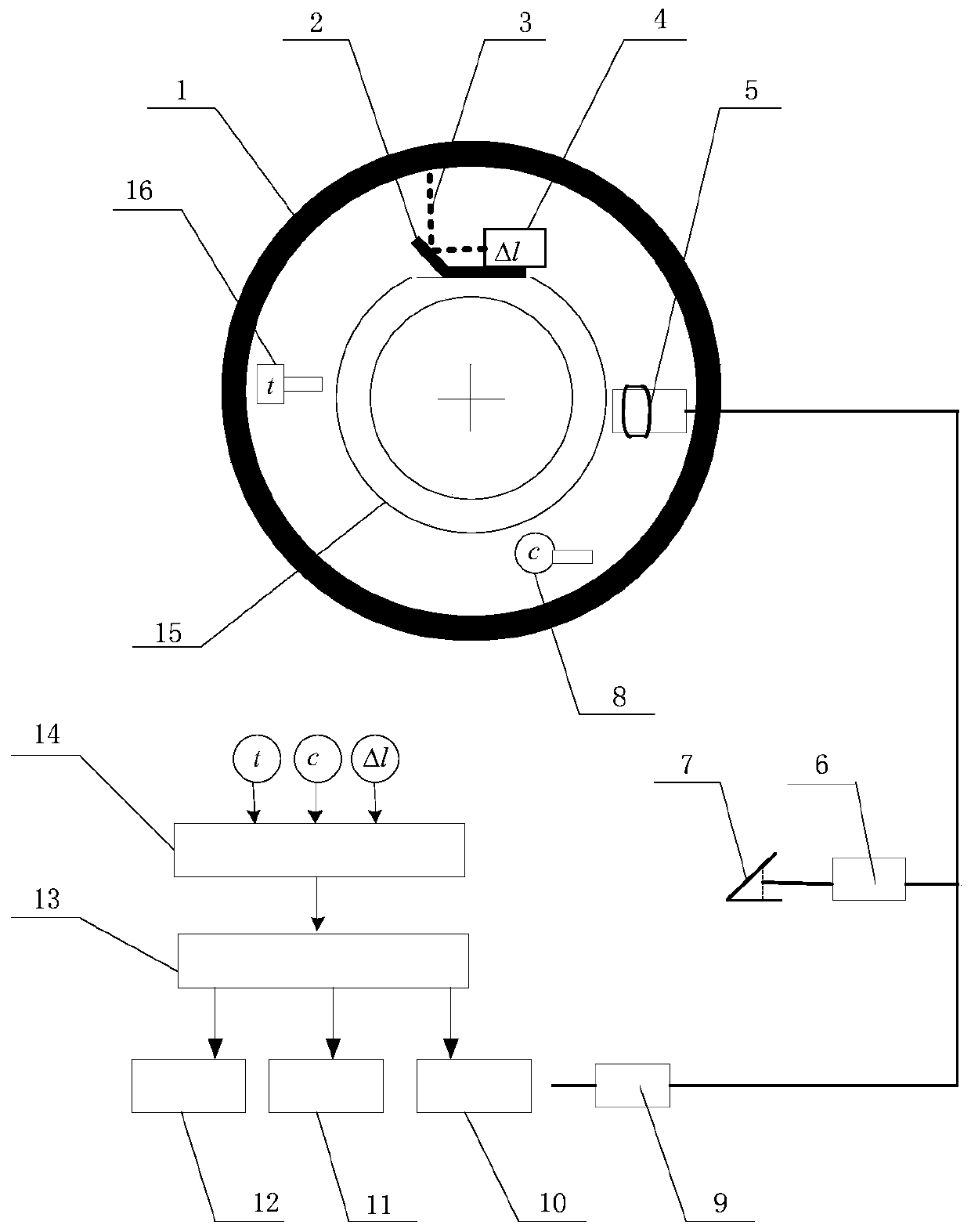

Intelligent grain drying control method

InactiveCN104663877ARealize intelligent managementEasy to controlSeed preservation by dryingControl signalAgricultural engineering

The invention discloses an intelligent grain drying control method. According to the method, a temperature signal, a humidity signal and a grain moisture value are utilized for judging whether delayed-mode drying is required to be performed on grains or not and a heating control signal is obtained or other modes are started according to the judgment result, so that finally a target moisture value of the grains can be achieved. The intelligent grain drying control method can be used for achieving the intelligent management in a drying process, controlling the drying process by utilizes a fuzzy predictive control method, and adjusting drying time in a predictive way to adjust and control the grain drying time relatively accurately; the intelligent grain drying control method can be used for effectively overcoming a large delay link, shortening the adjusting time and eliminating the systematic quiet error.

Owner:ANHUI OCEAN AUTOMATION EQUIP

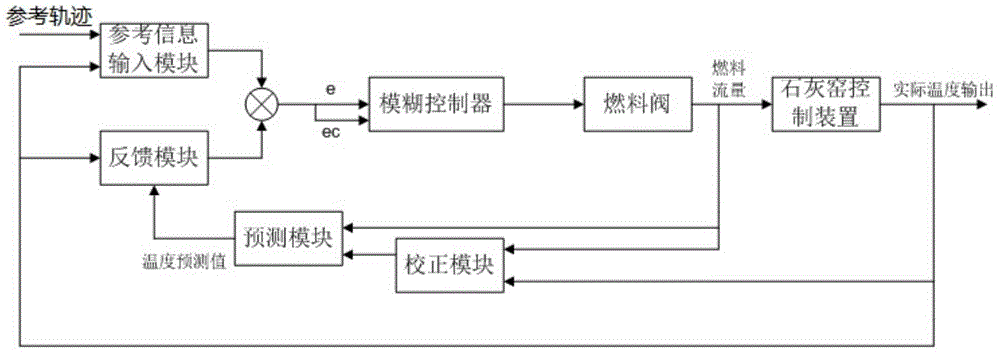

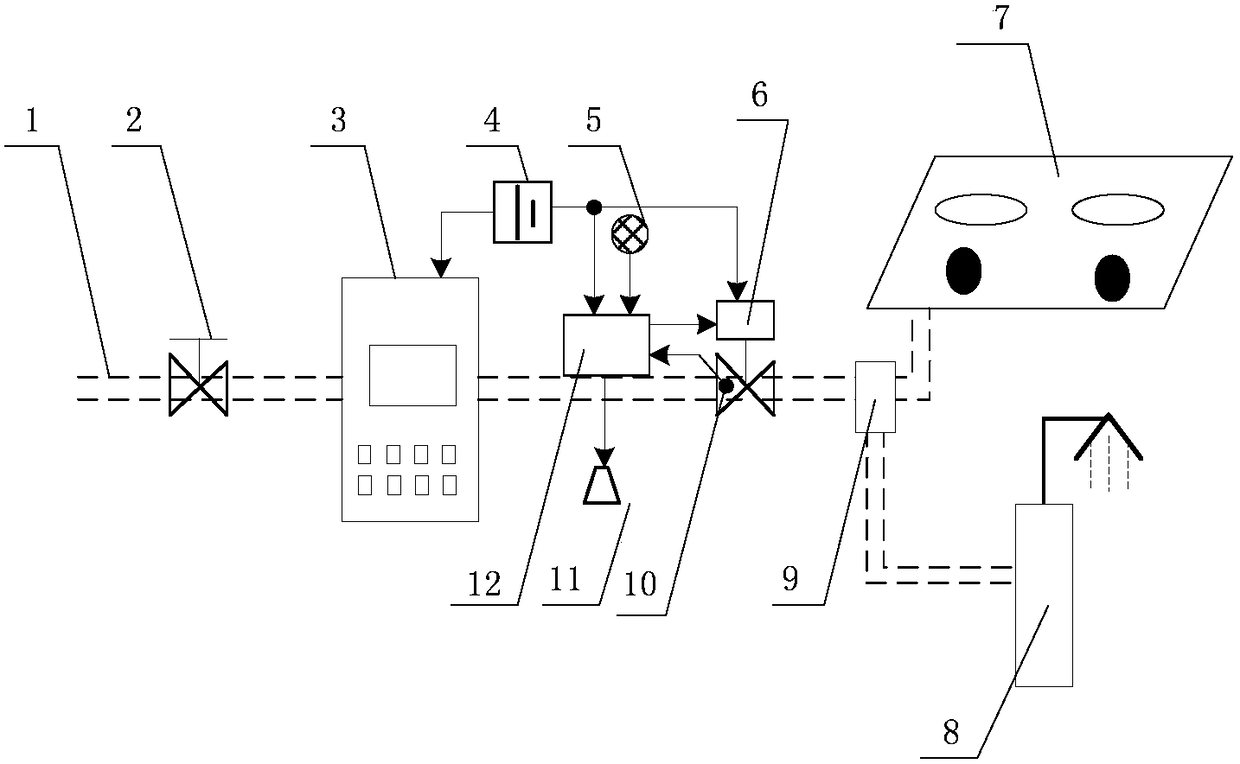

Fuzzy predictive control system for combustion process of lime kiln as well as control method of system

InactiveCN104950681ASolve temperature controlHigh activityAdaptive controlOptimal controlEngineering

The invention discloses a fuzzy predictive control system for a combustion process of a lime kiln as well as a control method of the system and belongs to the field of control on the combustion process. The fuzzy predictive control system comprises a reference information input module, a fuzzy controller, a fuel valve, a lime kiln control device, a prediction module, a feedback module and a correction module. A combustion temperature control system of the lime kiln has the characteristics of nonlinearity, time variability, model structure uncertainty and the like, a predictive control and fuzzy decision combined control method is adopted, an advanced prediction function of predictive control and the optimal control effect of fuzzy control in a large deviation range are integrated, and the temperature control problem of a large-time-delay nonlinear system is solved; the system can be put into actual production operation, the dynamic quality in the lime calcining temperature adjustment process is effectively improved, and the good actual application effect is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Nuclear power device two-loop multi-variable integrated model fuzzy predication control method

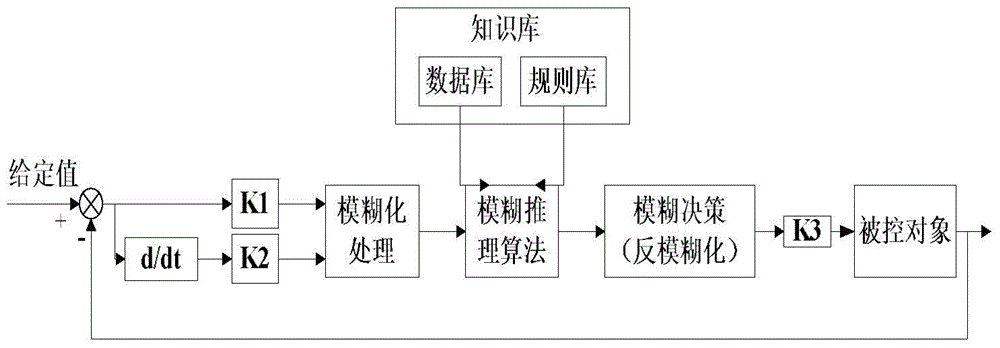

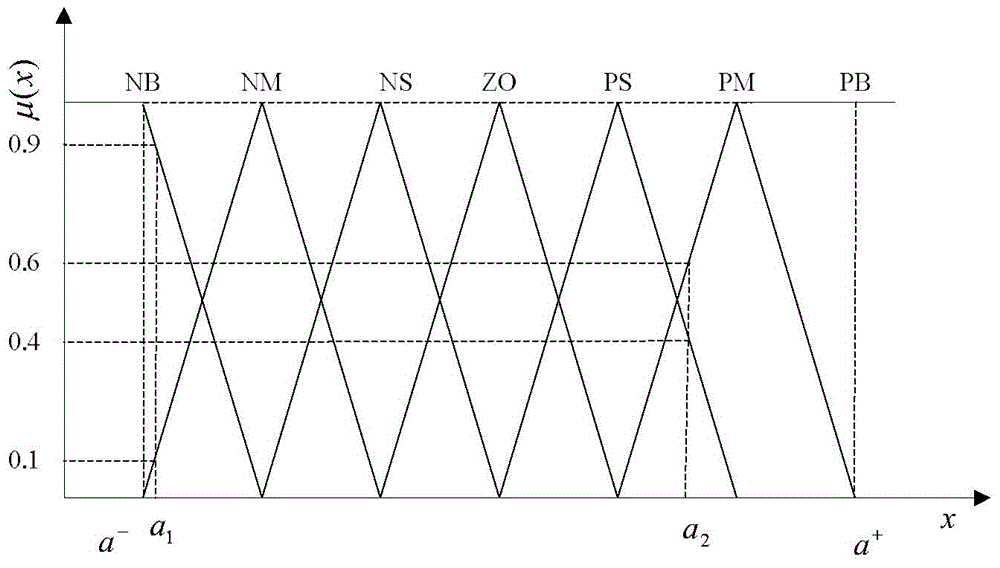

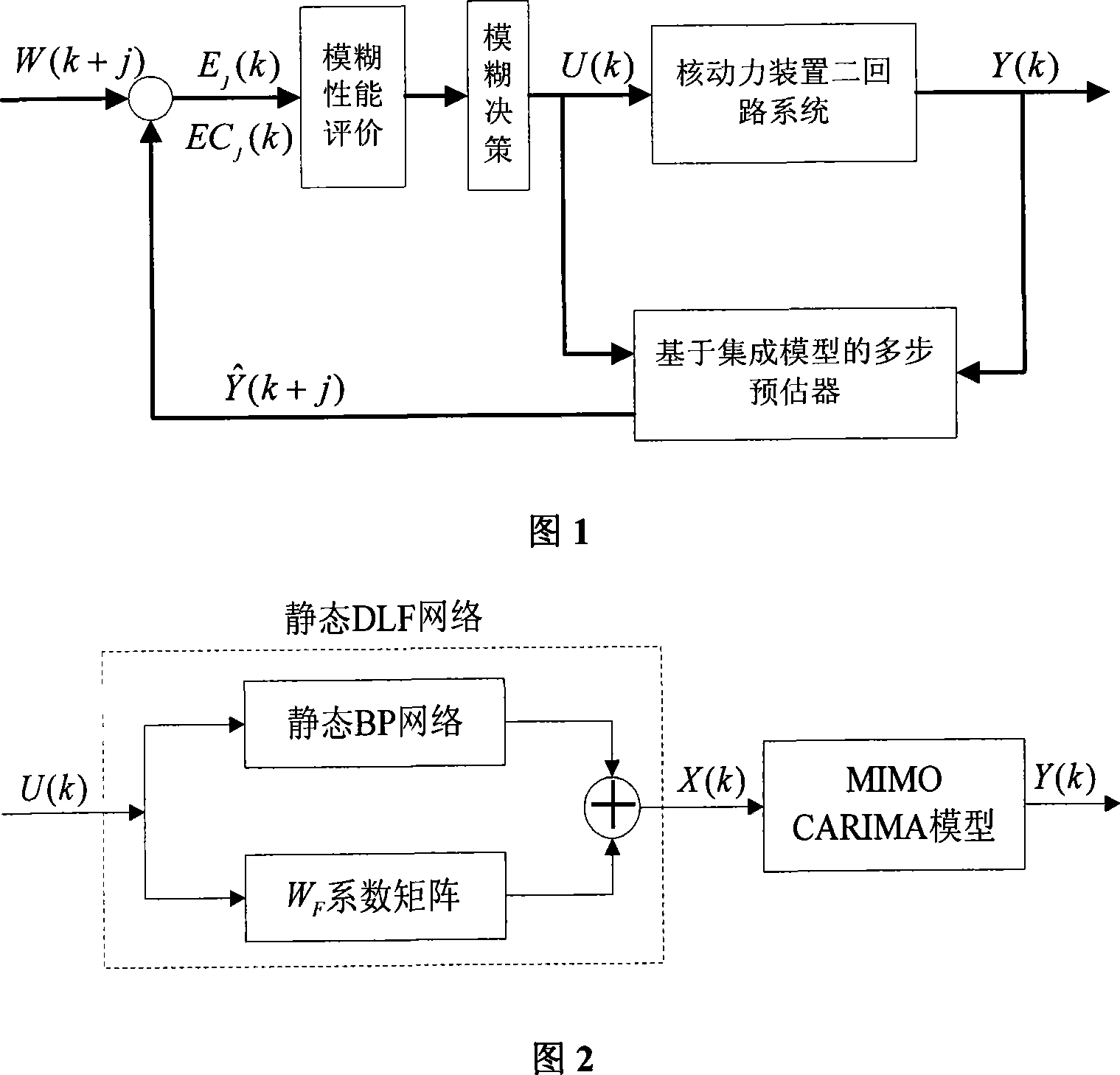

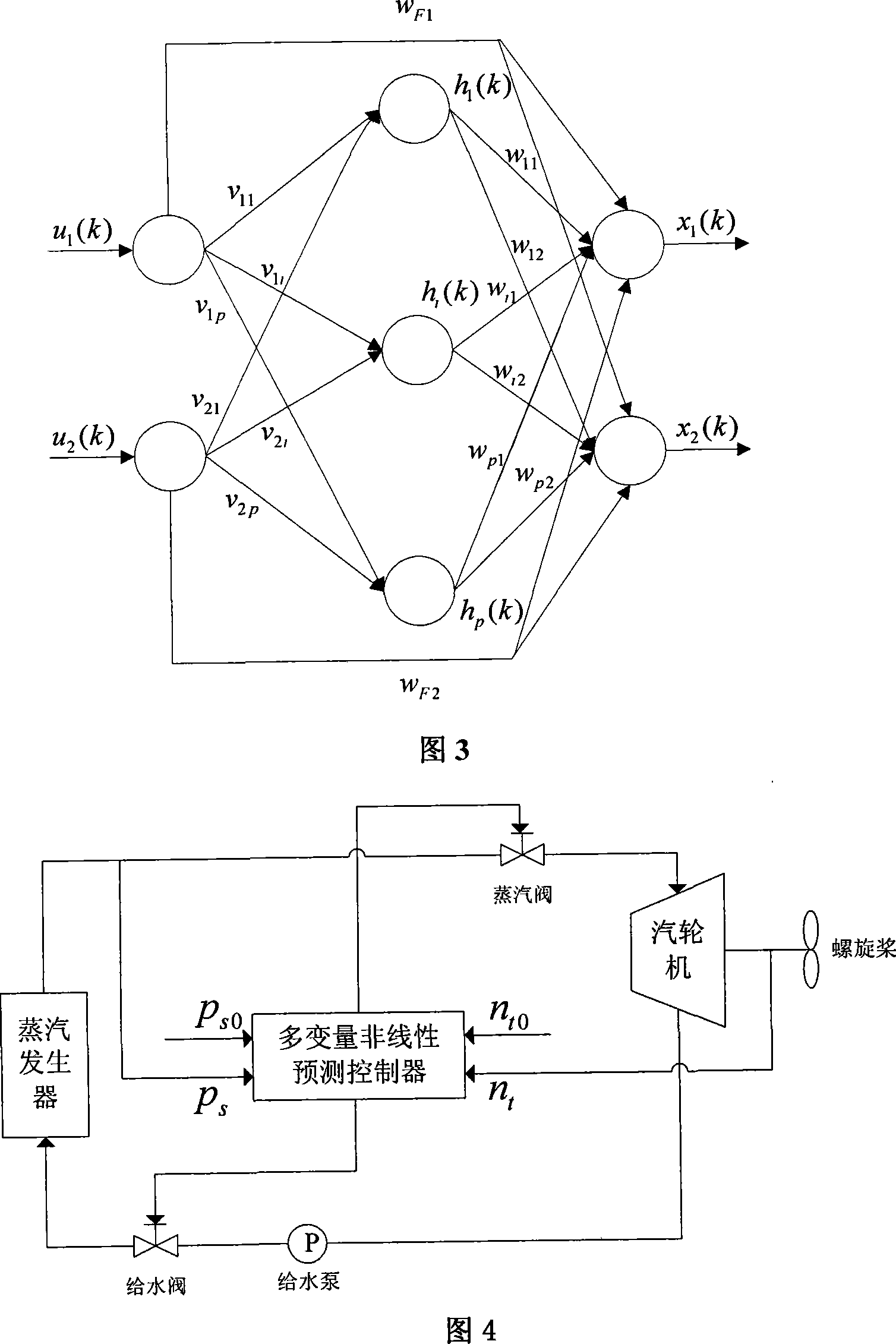

InactiveCN101169622AHigh control precisionImprove robustnessAdaptive controlNuclear powerControl signal

The invention provides a fuzzy forecasting and controlling method for the two-circuit multivariable integrated model of a nuclear power device. The state parameter information for the nuclear power device is measured out by utilizing a measuring system. The state parameter information is converted into digital signals, and then sent to a controller through a filter. The controller selects the optimum control input of the two-circuit system of the nuclear power device. The control signals generated by the controller are converted into analog signals through a digital-analog converter, strengthened by a signal amplifier and then output to an executing mechanism. The executing mechanism executes to transform the whole system to a specified working condition as commanded. The invention is applicable to a system like a nuclear power device that has serious non-linearity, coupling and time-variation. The invention has high control precision and good robustness.

Owner:HARBIN ENG UNIV

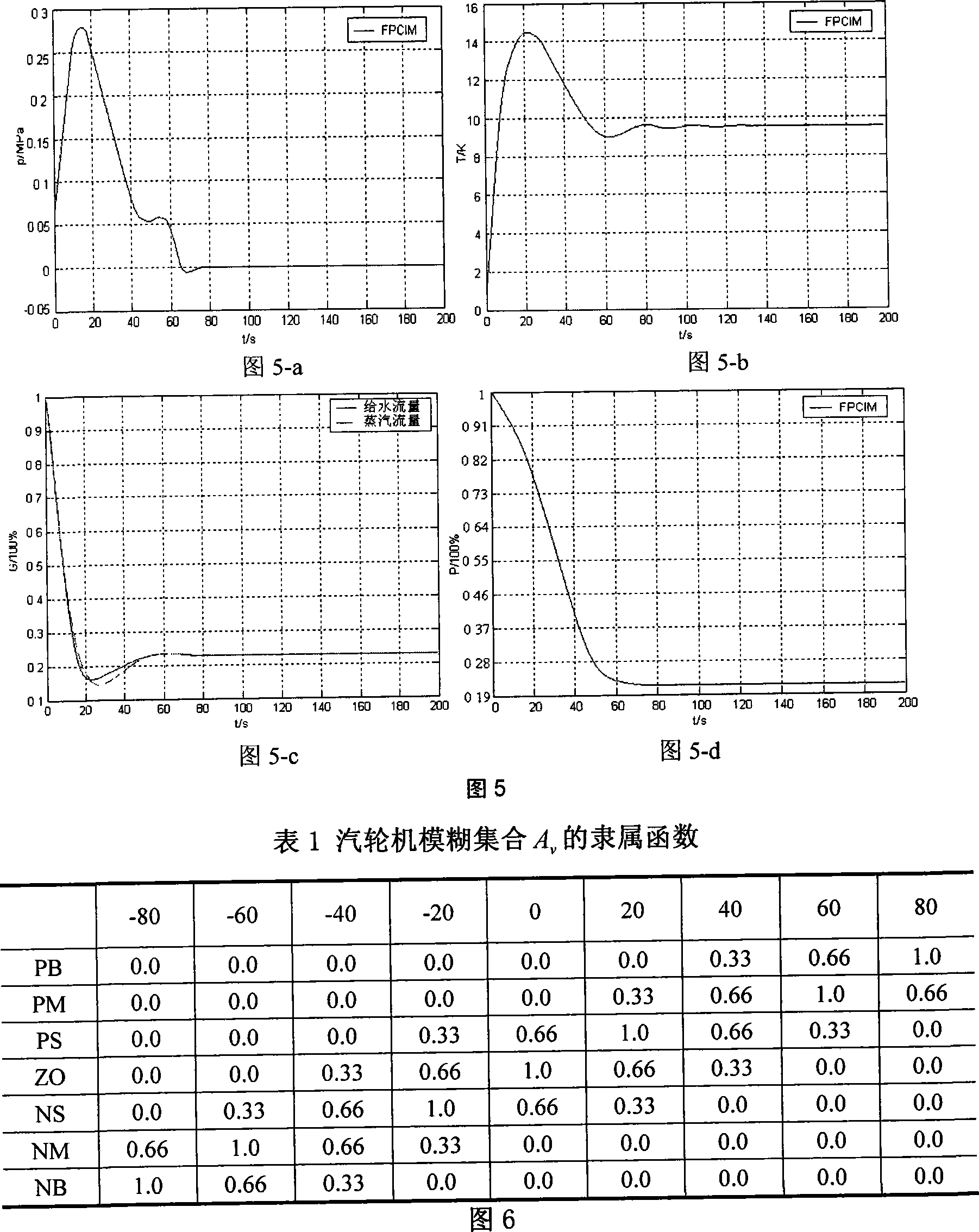

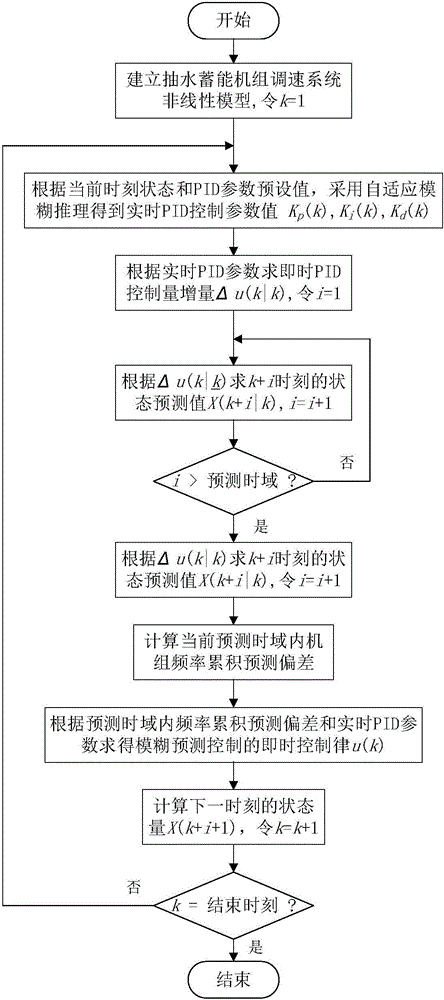

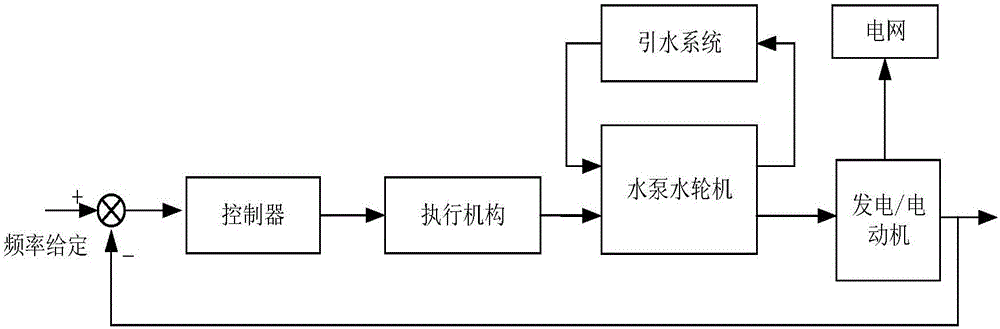

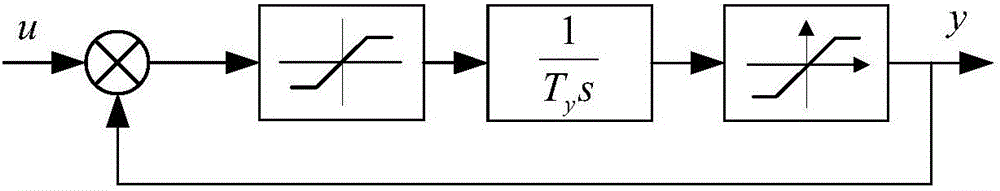

Quick non-linear fuzzy predictive control method for speed regulating system of pumped storage unit

ActiveCN106014849AEasy to adjustGood working condition adaptabilityActive/predictive/anticipative controlHydro energy generationTransient stateFuzzy pid control

The invention discloses a quick non-linear fuzzy predictive control method for a speed regulating system of a pumped storage unit. The quick non-linear fuzzy predictive control method includes the three steps of fuzzy PID parameter self-adaption, online rolling prediction and control law computing. By the adoption of the control method, the function that the fuzzy PID control parameters are adjusted automatically along with the working conditions is achieved, the future system state is predicted through a pumped storage unit speed regulating system non-linear model built in a controller by means of the online rolling prediction method, and the future system state quantity deviation information is considered when a real-time control law is set. By the adoption of the quick non-linear fuzzy predictive control method, the requirements of the control process of the pumped storage unit under different working conditions can be met, the control precision of the unit is improved effectively, and the transient state performance of the operating process of the unit is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

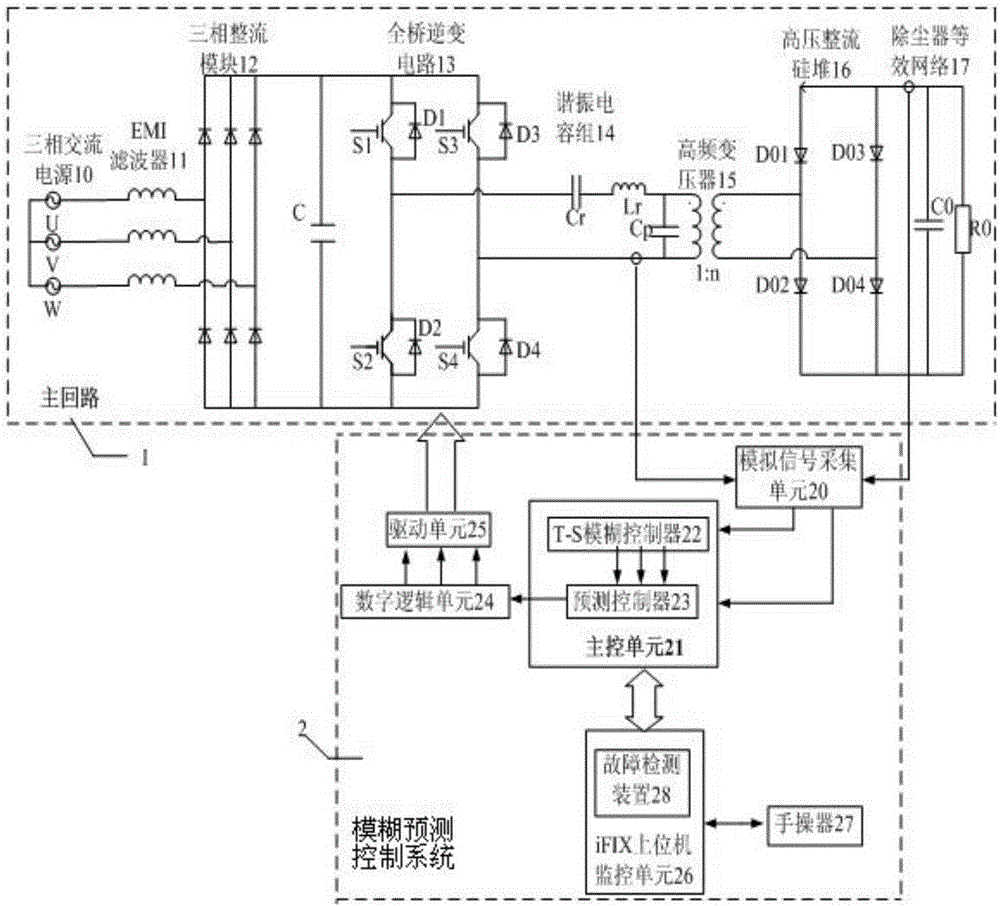

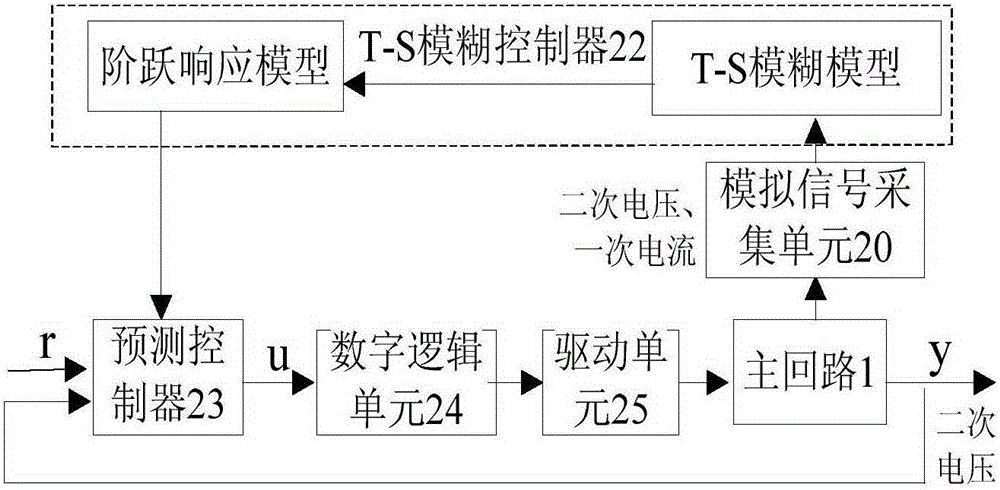

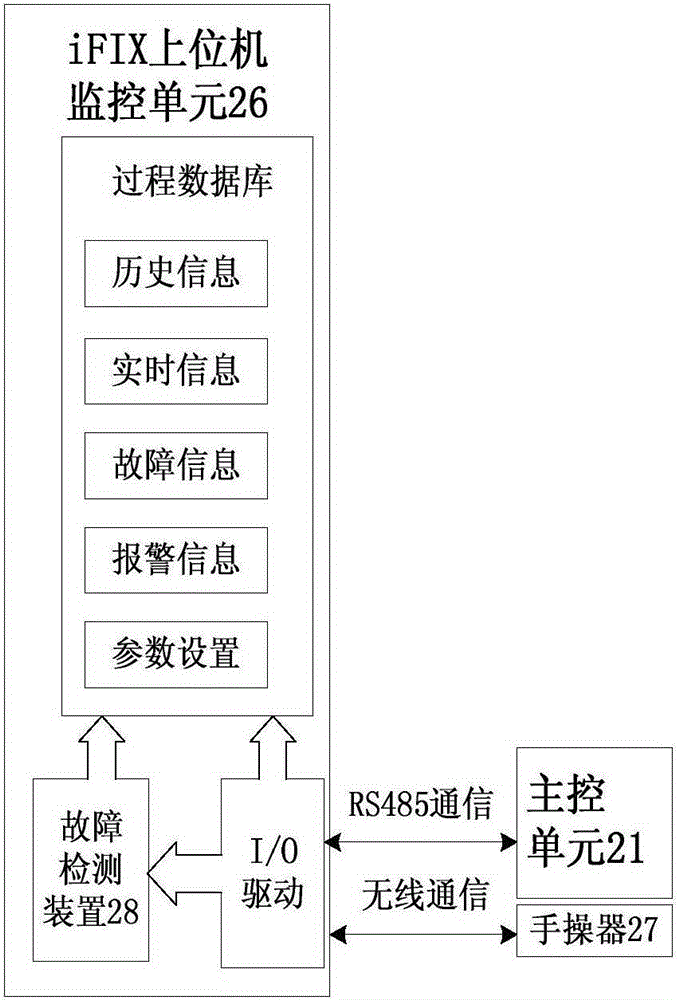

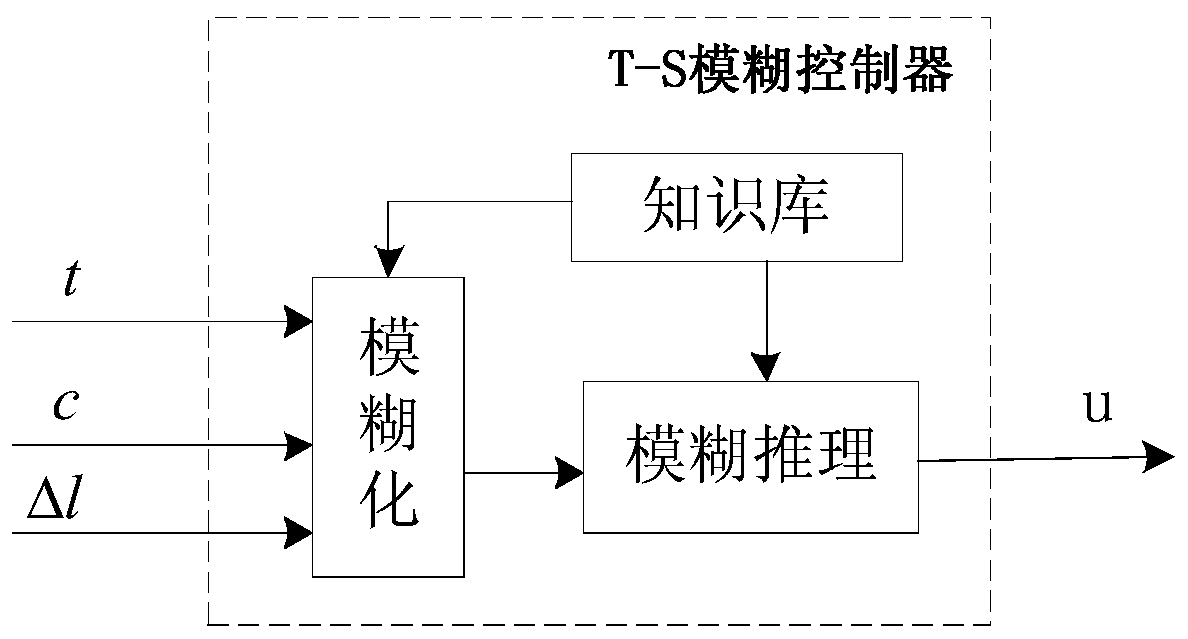

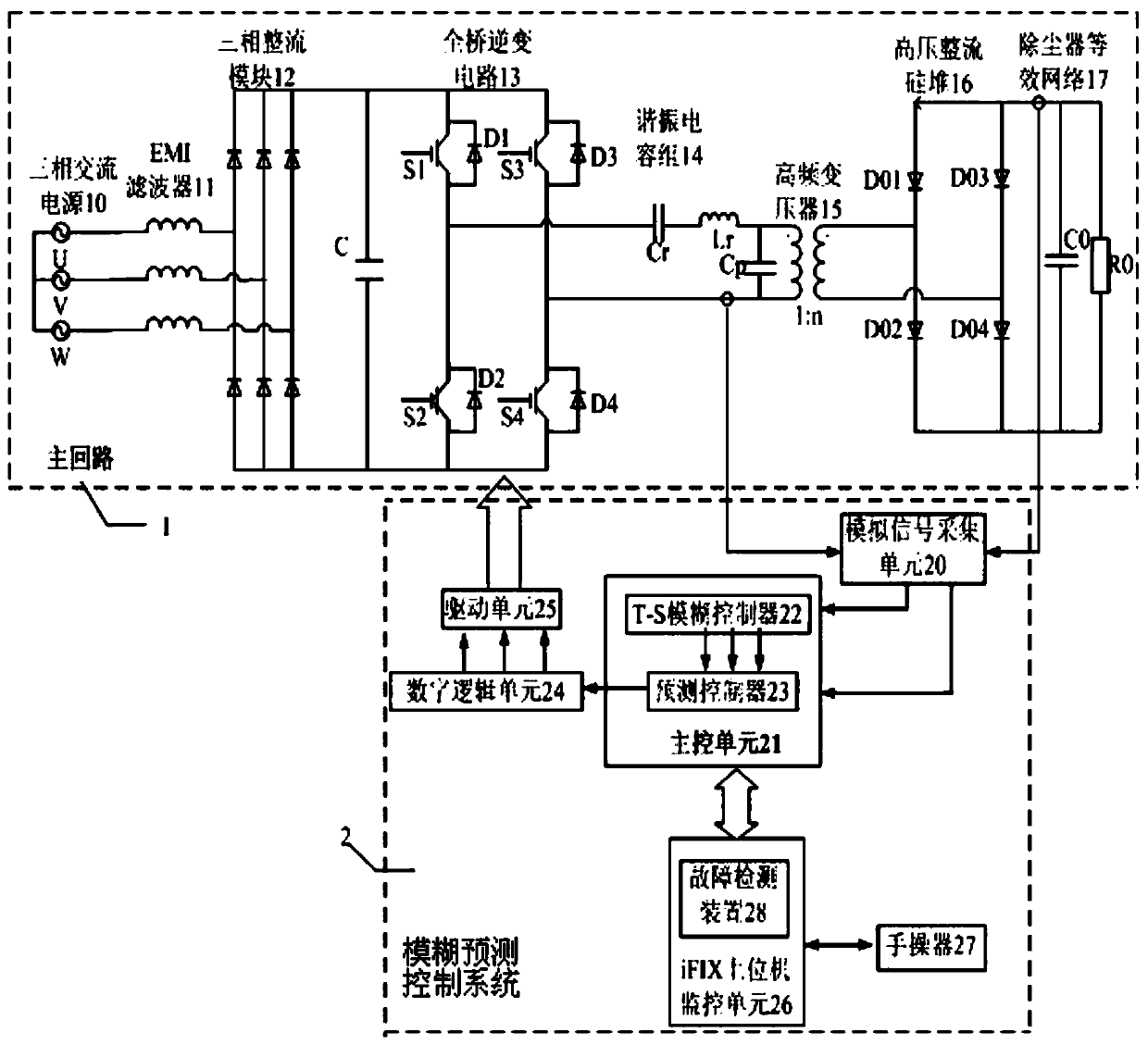

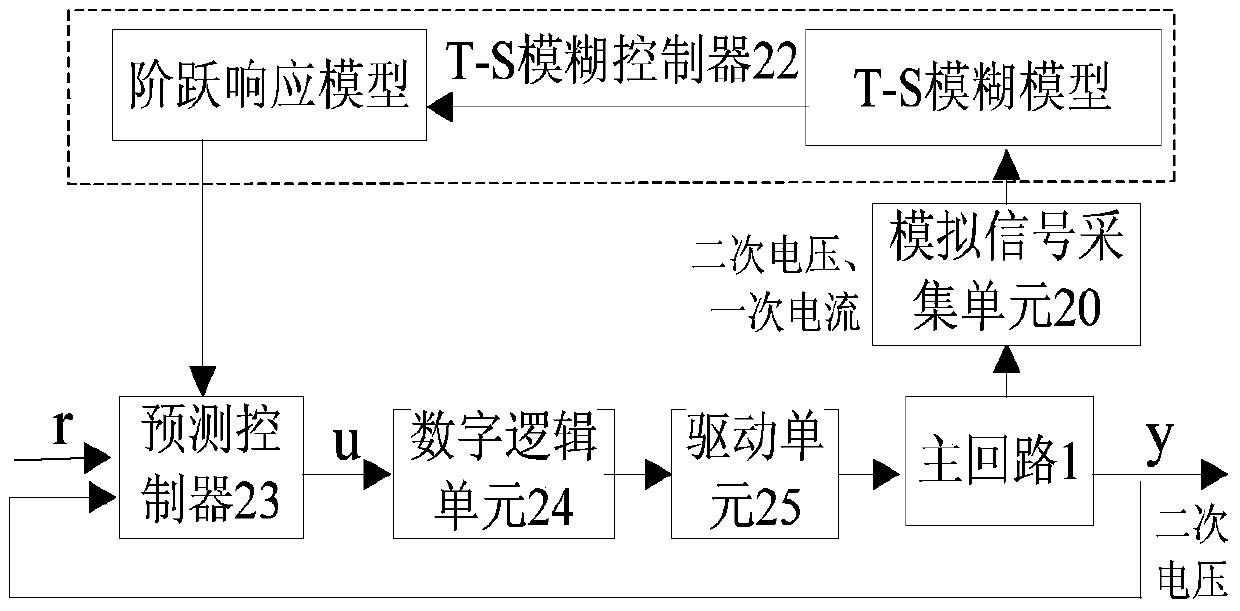

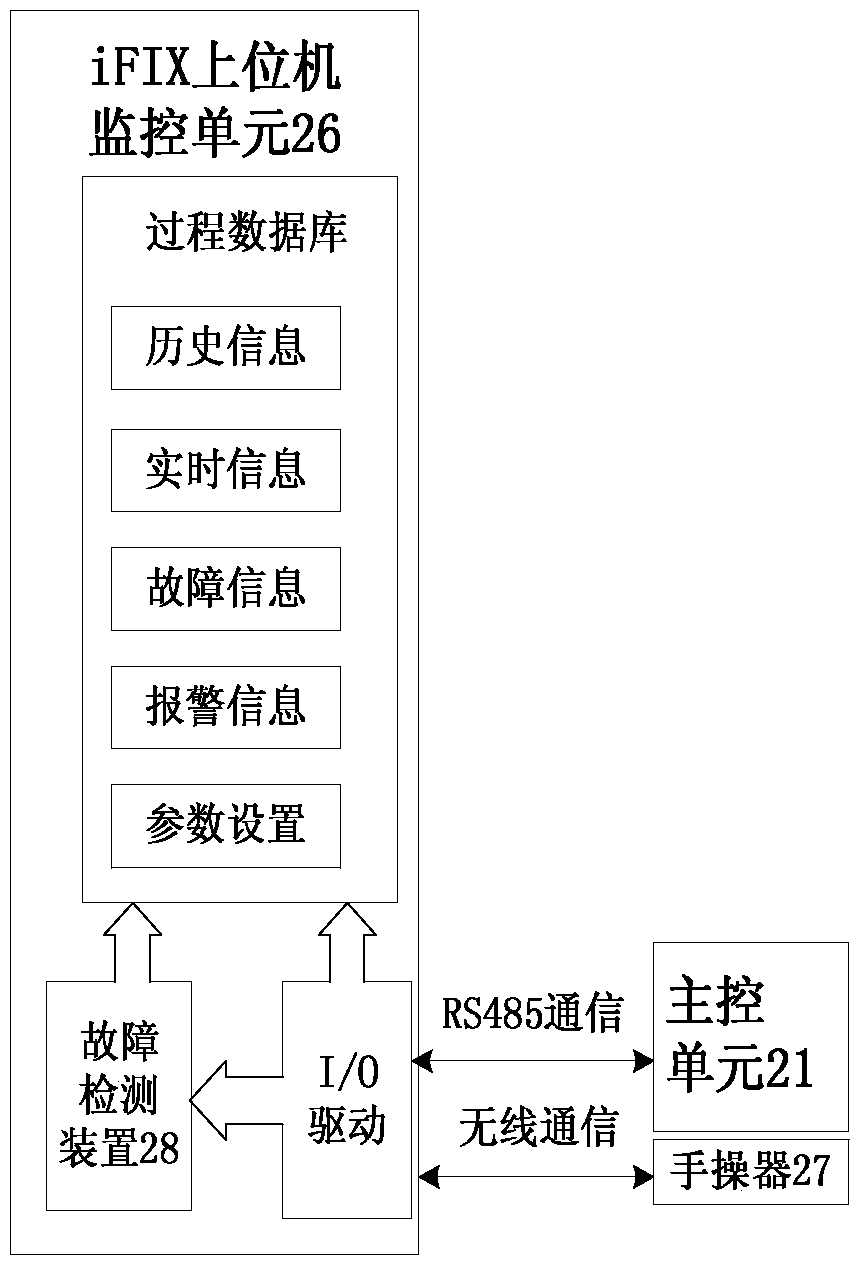

Fuzzy prediction control system of power supply for electrostatic dust collection and control method of fuzzy prediction control system

InactiveCN105170333AImprove adaptabilitySolve problems that are difficult to model mathematicallyElectric supply techniquesMathematical modelControl signal

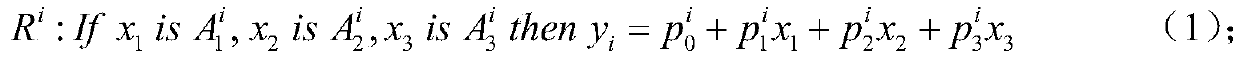

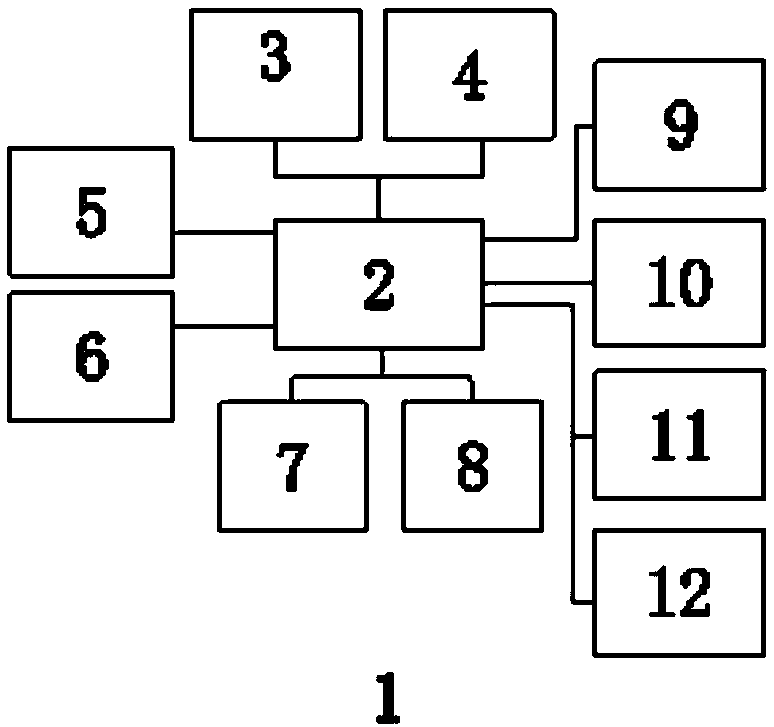

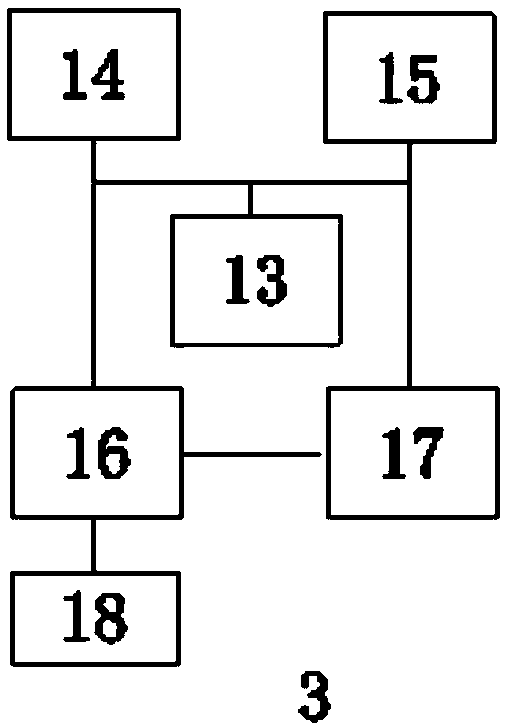

The invention discloses a fuzzy prediction control system of a power supply for electrostatic dust collection and a control method of the fuzzy prediction control system. The control method comprises the steps that an analog signal acquisition unit converts an acquired analog signal to an electrical signal, and outputs the electrical signal to a T-S fuzzy controller after carrying out conditioning such as filtering on the electrical signal, and the T-S fuzzy controller first recognizes a first component and a conclusion part of a T-S fuzzy model according to the conditioned signal, obtains the T-S fuzzy model, then converts the T-S fuzzy model to a step response model, and outputs the step response model to a prediction controller 23 to act as a prediction model; the prediction controller takes the step response model as the prediction model, carries out rolling optimization and feedback compensation, and outputs a control signal to a digital logic unit; and the control signal passes the digital logic unit and then acts as a driving signal of a control driving unit to carry out fuzzy prediction control on the power supply. The problem that a mathematical model can not be established easily for an electrostatic dust collection system is solved, and the dependence of the prediction controller on the accurate mathematical model is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

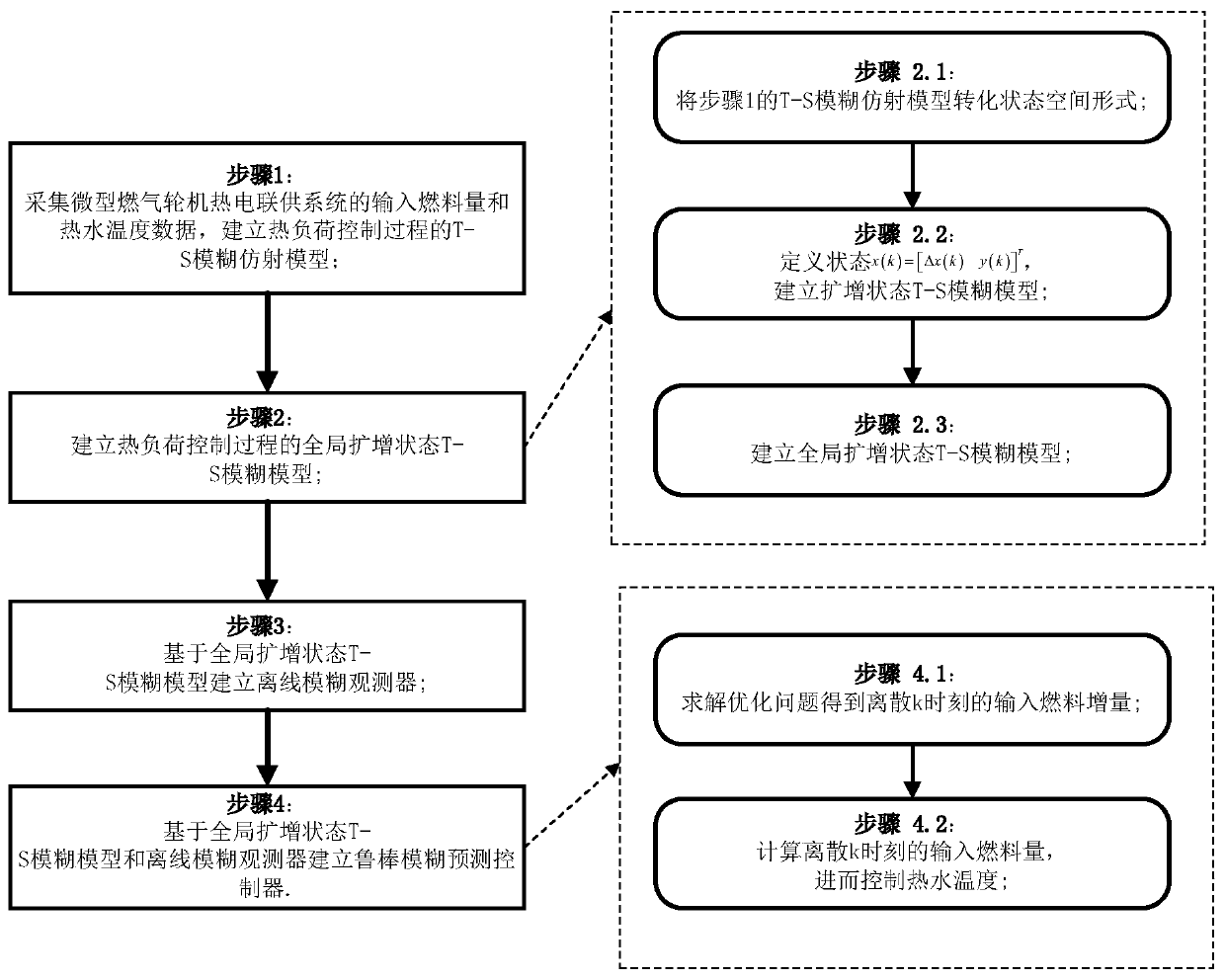

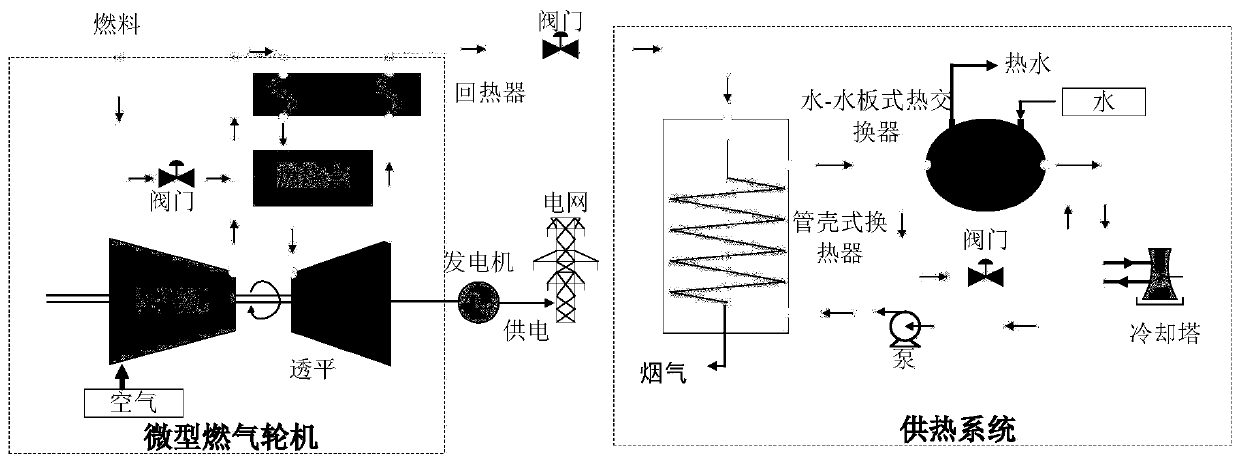

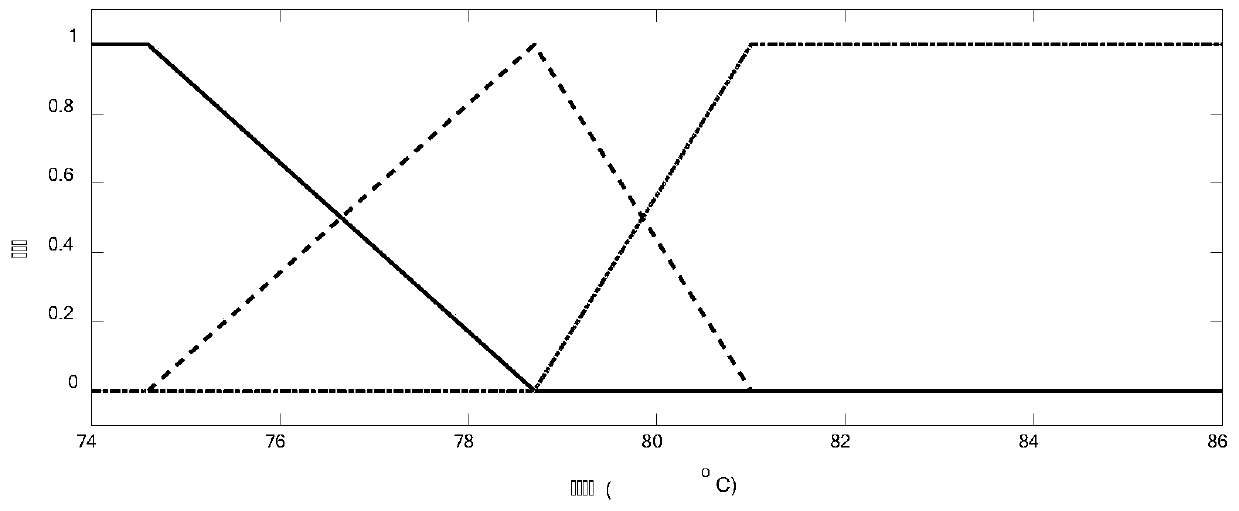

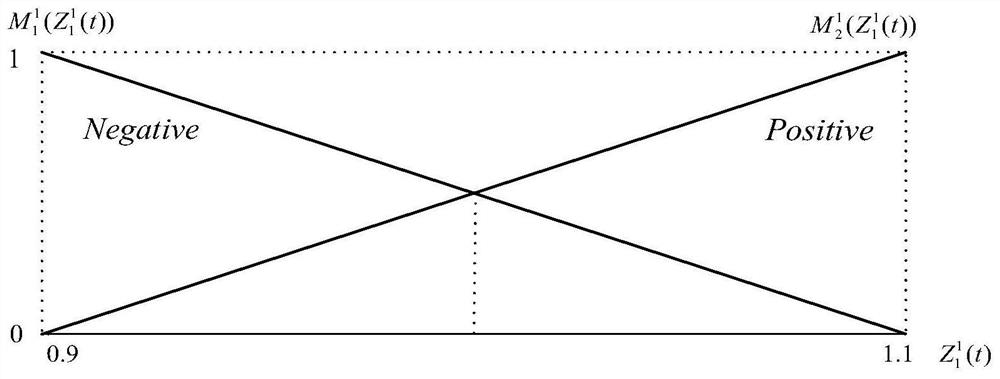

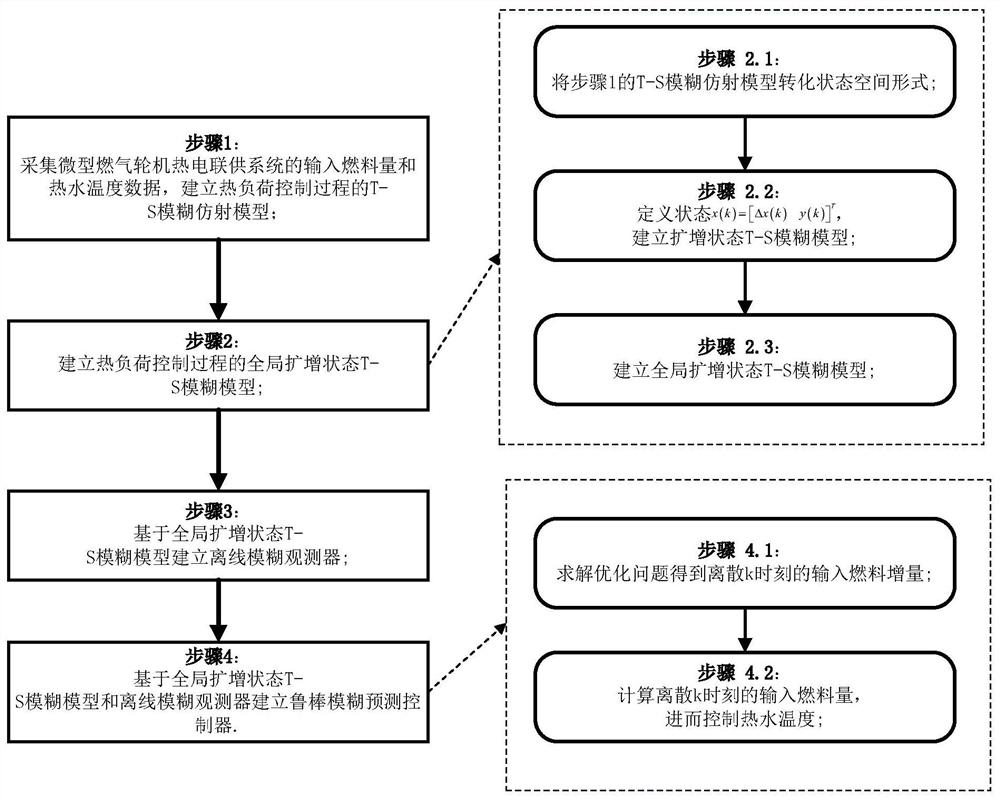

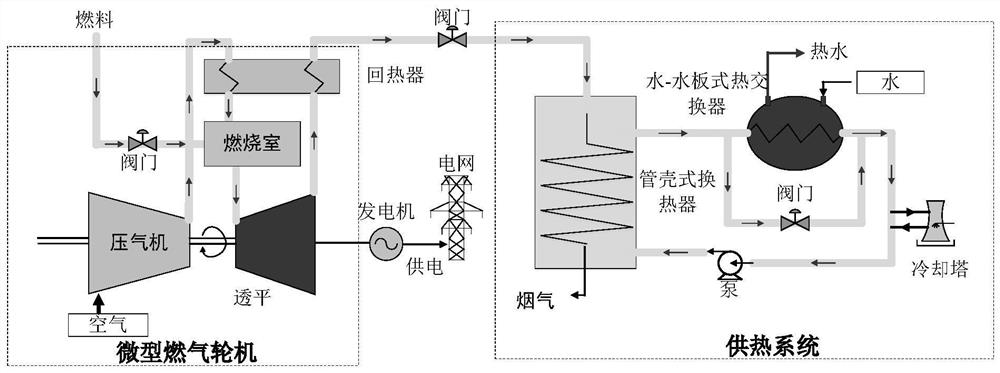

Thermal load control method for combined heat and power supply system of micro gas turbine based on robust fuzzy prediction control

ActiveCN110488610AIncrease freedomOvercoming the problem of unmeasurable stateAdaptive controlMicro gas turbineControl theory

The invention discloses a thermal load control method for a combined heat and power supply system of a micro gas turbine based on robust fuzzy prediction control, which comprises the steps of acquiring input fuel quantity and hot water temperature data of the combined heat and power supply system of the micro gas turbine, and establishing a T-S fuzzy affine model of the thermal load control process; establishing a global amplification state T-S fuzzy model of the thermal load control process; establishing an off-line fuzzy observer based on the global amplification state T-S fuzzy model; and establishing a robust fuzzy prediction controller based on the global amplification state T-S fuzzy model and the off-line fuzzy observer. According to the method, the influence of system nonlinearityon the controller is weakened by using the T-S fuzzy model, the problem that the state cannot be measured is solved by using the observer, steady-state errors are overcome by using state amplification, the degree of freedom of the controller is enhanced, and the method is a high-quality stable model prediction control method suitable for an actual complex industrial process.

Owner:SOUTHEAST UNIV

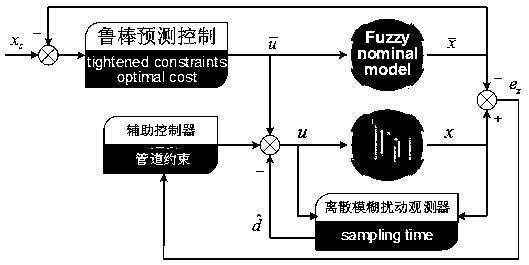

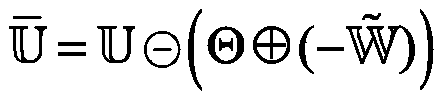

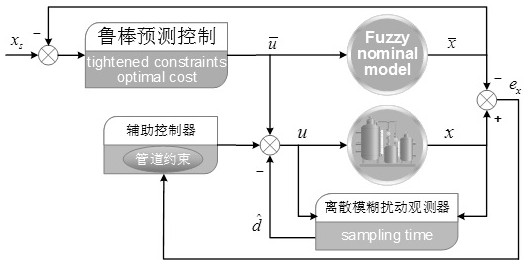

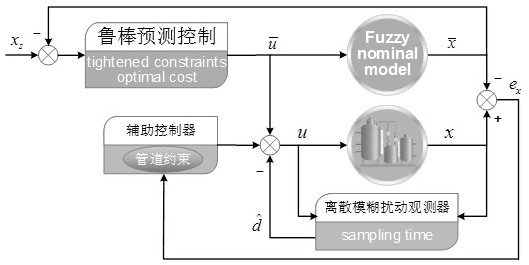

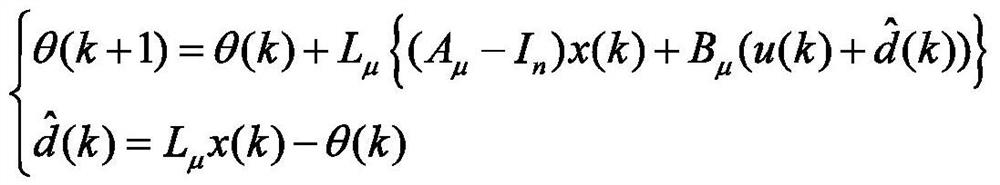

Fuzzy predictive control method capable of enhancing robustness based on disturbance observer

The invention provides a fuzzy predictive control method capable of enhancing robustness based on a disturbance observer. The method comprises the following steps: 1) establishing a discrete fuzzy disturbance observer model, an auxiliary controller and a robust predictive controller; 2) solving a feedback gain of the auxiliary controller and a gain of the disturbance observer to obtain a minimum robust invariant set, and calculating a tight constraint set of control input and state variable of the robust predictive controller; 3) initializing the system state variable and assigning a value tothe state variable of a nominal model; 4) for the current nominal model state variable, solving the optimization problem that minimizes the upper bound gamma of predictive control performance, and obtaining a current disturbance estimated value; 5) calculating control input of the system and applying the control input to a controlled object; 6) applying the control input of a nominal system to thenominal model and calculating output of the current state and current state quantity output of a sampling system; and 7) performing substituting and setting k=k+1, and then, skipping to the step 4).The stability of a predictive control system is improved.

Owner:NANJING INST OF TECH

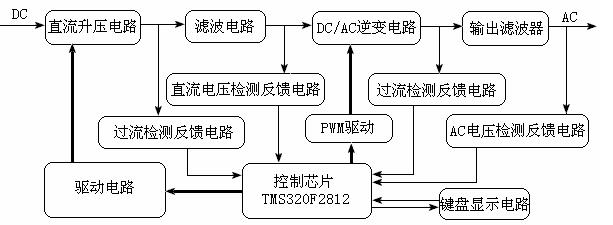

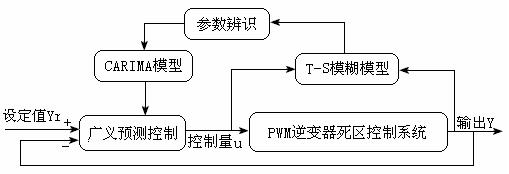

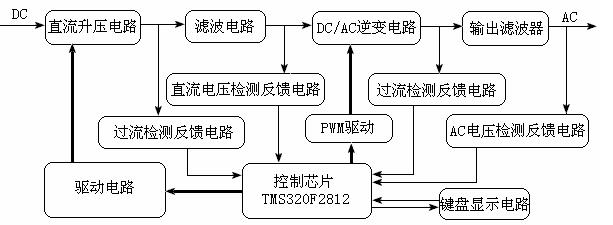

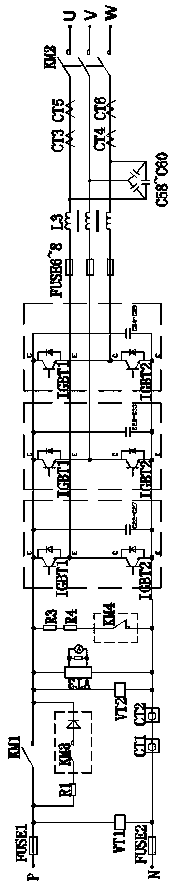

Pulse-width modulation (PWM) inverted power supply system and algorithm based on fuzzy predictive control technology

InactiveCN102185508AImprove output waveformImprove robustnessDc-ac conversion without reversalOvervoltageWind driven

The invention discloses a pulse-width modulation (PWM) inverted power supply system and a PWM inverted power supply algorithm based on a fuzzy predictive control technology. The input is direct current (DC) voltage, and the input passes through a DC booster circuit, is subjected to ripple wave removal through a filtering circuit and passes through a DC / alternating current (AC) inversion circuit; the output is high-voltage AC, an AC voltage detection feedback circuit, an overcurrent detection feedback circuit, a DC detection feedback circuit, a DC voltage detection feedback circuit and other protection circuits are arranged in the circuit, when overcurrent and overvoltage are detected, a control chip obtains a reasonable dead-zone predictive control scheme through an algorithm according to data which is acquired in real time, the PWM driving pulse waveform is changed, and the working reliability of a switching device is effectively guaranteed; meanwhile, the conversion efficiency of a PWM inverter system is high, and the distortion rate of output waveform is reduced. The invention is applicable to fields of switching power supply inverters, solar inverted power supplies, small wind driven generator inverted power supplies and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

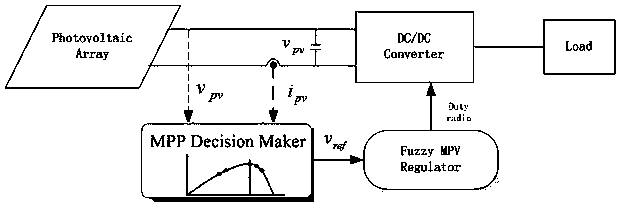

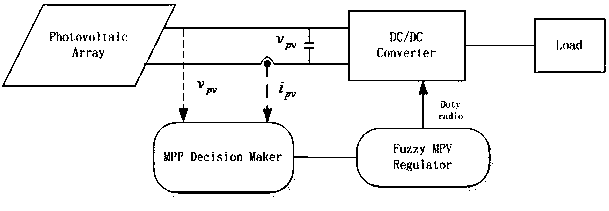

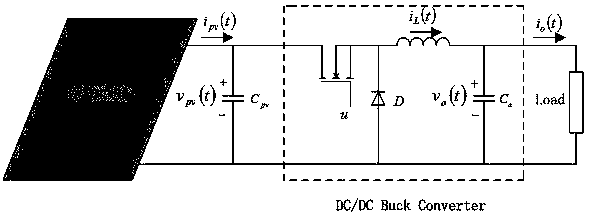

Maximum power point fuzzy prediction control method for uncertain photovoltaic system

InactiveCN109144164AThe maximum power point reachesPhotovoltaic energy generationElectric variable regulationFuzzy predictive controlMaximum power principle

A maximum power point fuzzy prediction control method for an uncertain photovoltaic system comprises the following steps: firstly, introducing MPV and DMP fuzzy control configurations with PV voltageand power slope as control outputs; secondly, using a T-S fuzzy model representation method to represent the two fuzzy MPPT control configurations as output adjustment problems in a unified form; then, for the deviation of a DC / DC converter, proposing a predictive PDC control law based on an integral fuzzy observer to directly drive the system to reach the maximum power point. The proposed fuzzy prediction controller can ensure that the photovoltaic system reaches the maximum power point within a limited time. The maximum power point fuzzy prediction control method for an uncertain photovoltaic system can solve the controller and the observer gain online by the newly developed LMI type control algorithm with no need to perform coordinate transformation and calculation on the maximum powerpoint of the converter, and compared to the conventional MPPT method, allows for strict stability analysis and online control design of the system in the event of rapid atmospheric changes.

Owner:NANJING UNIV OF POSTS & TELECOMM

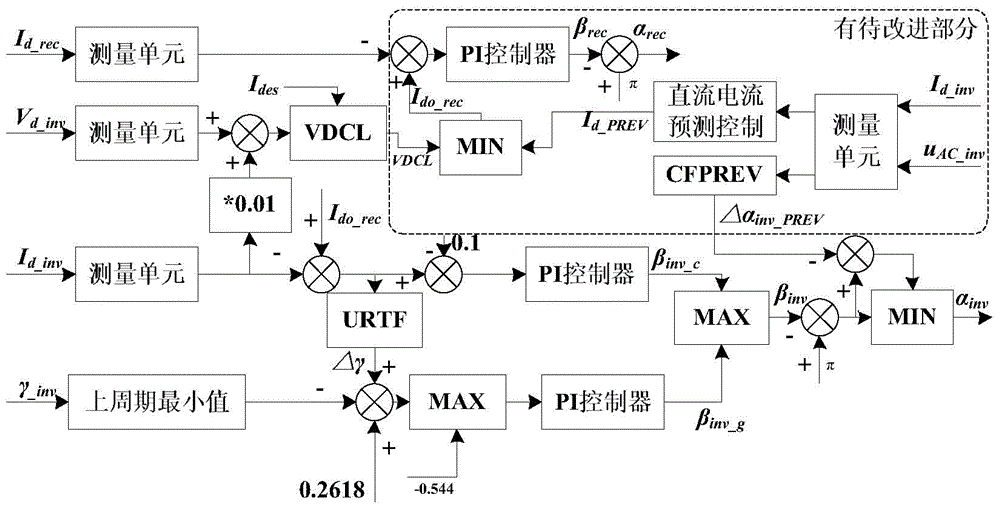

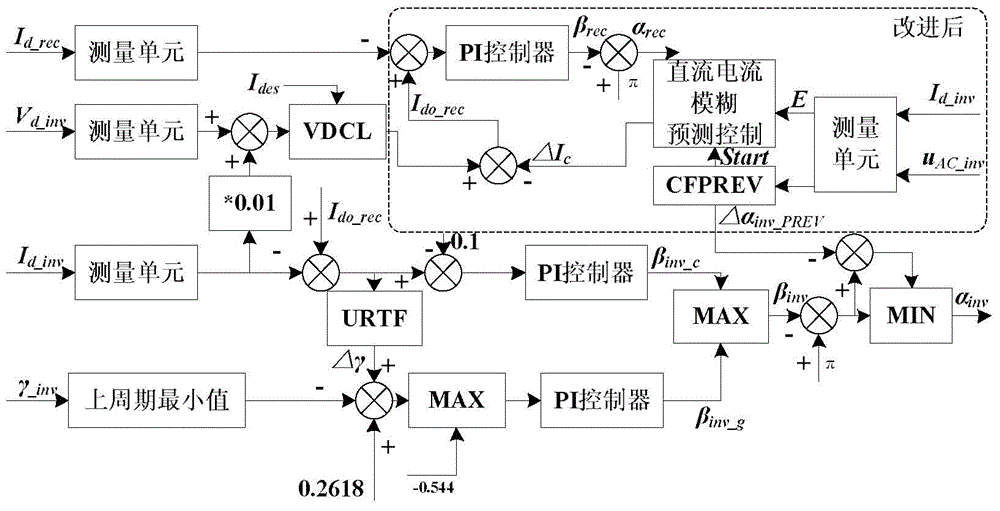

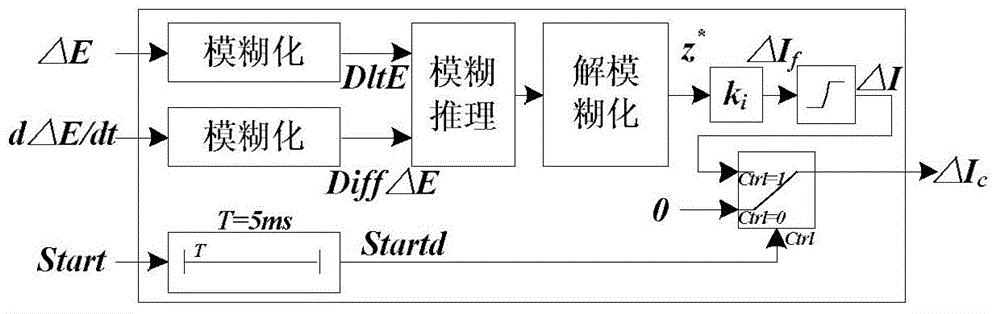

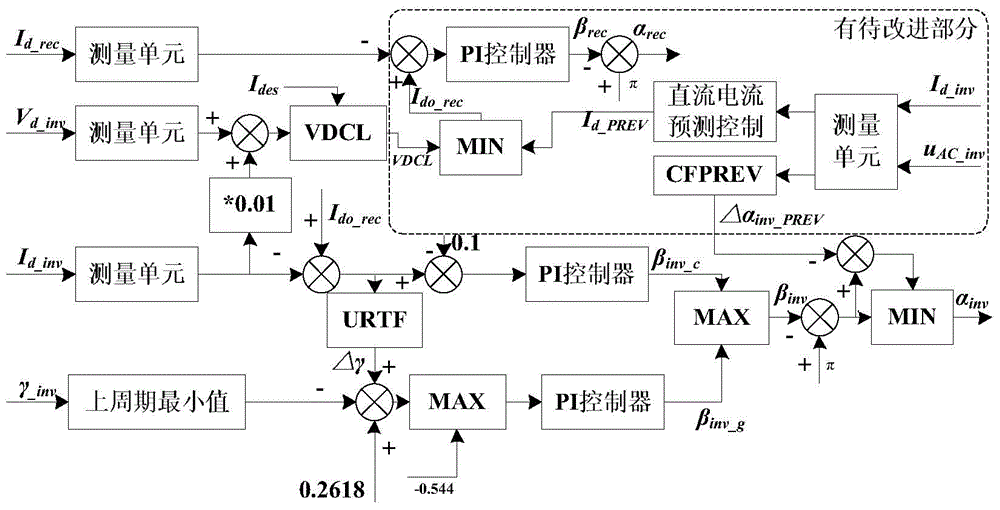

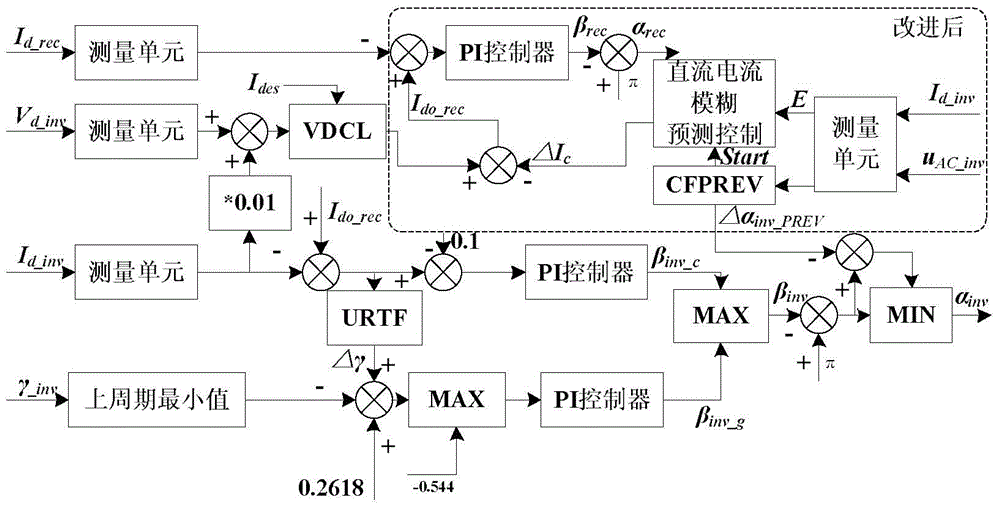

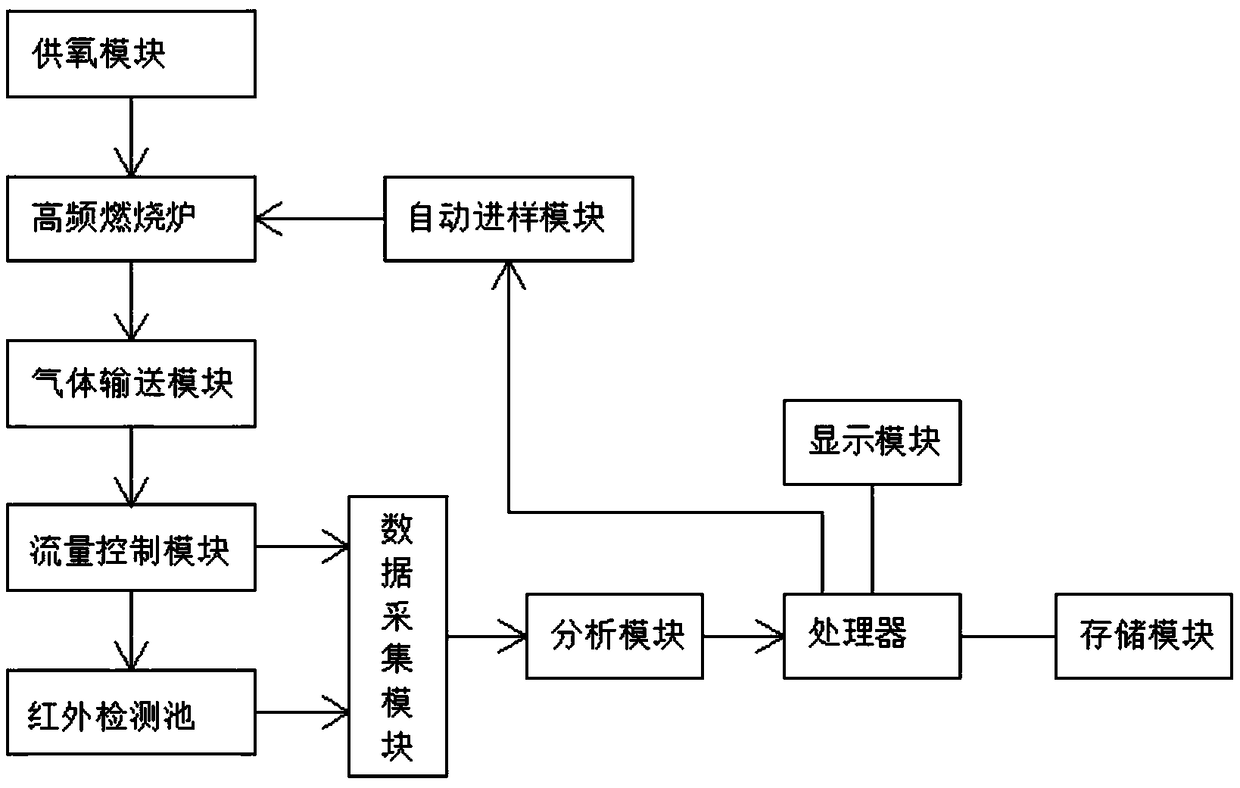

Commutation failure prevention method based on direct current fuzzy predictive control

InactiveCN104810847AOvercoming the Limitations of RandomnessReduce the DC current on the rectifier sideElectric power transfer ac networkFailure preventionDc current

The invention discloses a commutation failure prevention method based on direct current fuzzy predictive control. In view of a direct current predictive control method in which limitation exists in a parameter k random value in a direct current predication setting valve calculation formula and direct current at a rectifier side is reduced for a long time, limitation of slow current recovery of the direct current system is caused, a fuzzy controller is adopted to control the direct current predication setting valve, a direct current fuzzy predictive control method is brought forward, a control time duration T selected via a simulation result is set, and the direct current at the rectifier side is only reduced with a time duration T after a CFPREV module detects failure happens to an alternating current system. Through modeling and simulation, compared with the prior direct current predictive control method, effectiveness of restraining the commutation failure ability by the HVDC (high-voltage direct current) system is verified to be enhanced.

Owner:HOHAI UNIV

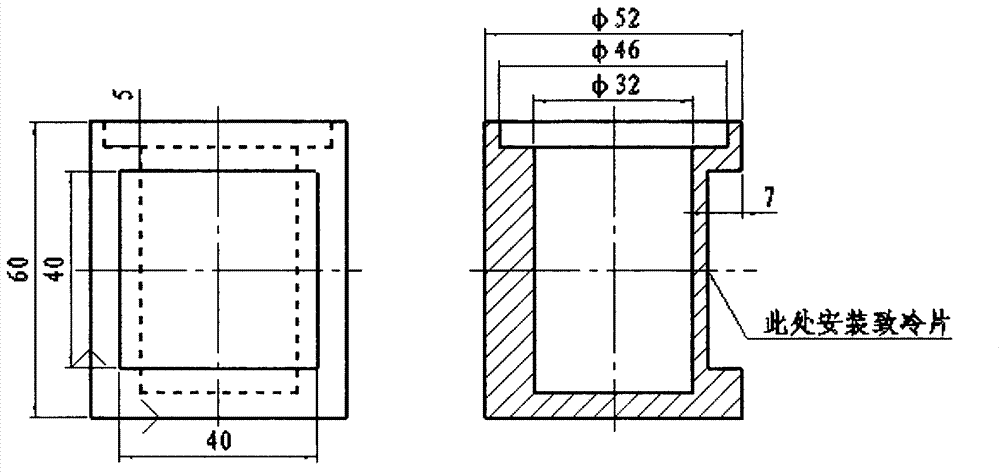

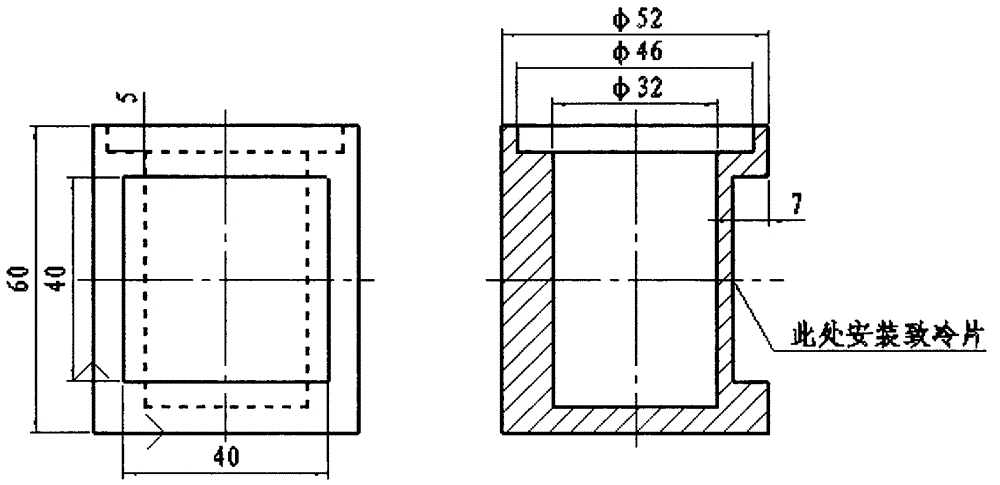

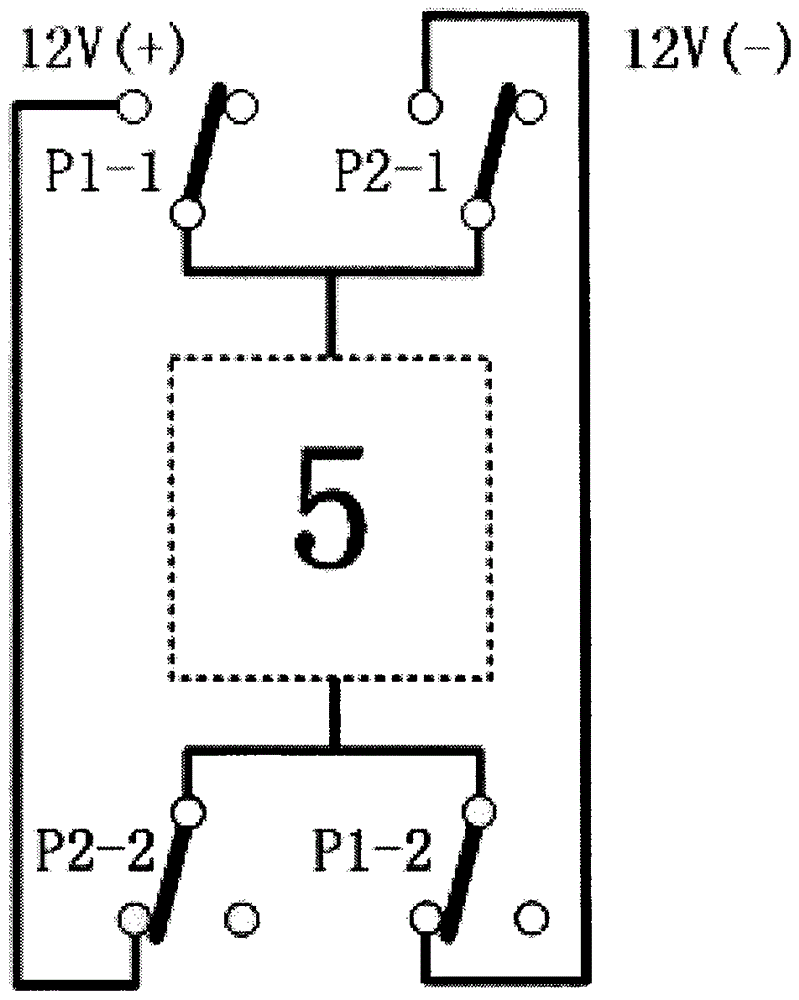

Intelligent temperature control device for infrared carbon-sulfur analyzer electric arc combustion furnace body

ActiveCN104729279AQuick analysisAccurate analysisLighting and heating apparatusWireless controlElectric arc furnace

The invention discloses an intelligent temperature control device for an infrared carbon-sulfur analyzer electric arc combustion furnace body. The intelligent temperature control device is composed of a DSP, a GPRS module, a Zigbee transmitting and receiving module, a temperature sensor, a semiconductor refrigeration and heating piece and a GPRS network. In the working process, the temperature sensor is installed on the electric arc combustion furnace body and transmits temperature signals to the DSP, the semiconductor refrigeration and heating piece is controlled by a fuzzy algorithm to make the temperature stabilized at 60 DEG C, and temperature information is transmitted to a smart phone through the GPRS module and the Zigbee transmitting and receiving module so that the infrared carbon-sulfur analyzer can be controlled to be started. Intelligent control is achieved through a fuzzy prediction control algorithm, and therefore the control process of the temperature of the electric arc combustion furnace body can be stabilized and reasonable; the Zigbee protocol wireless control is applied, connection lines are omitted, and multiple electric arc combustion furnaces can be detected through a wireless sensor network; the smart phone participates in furnace body temperature control so that the temperature of the furnace body can be more conveniently controlled.

Owner:南京华欣分析仪器制造有限公司

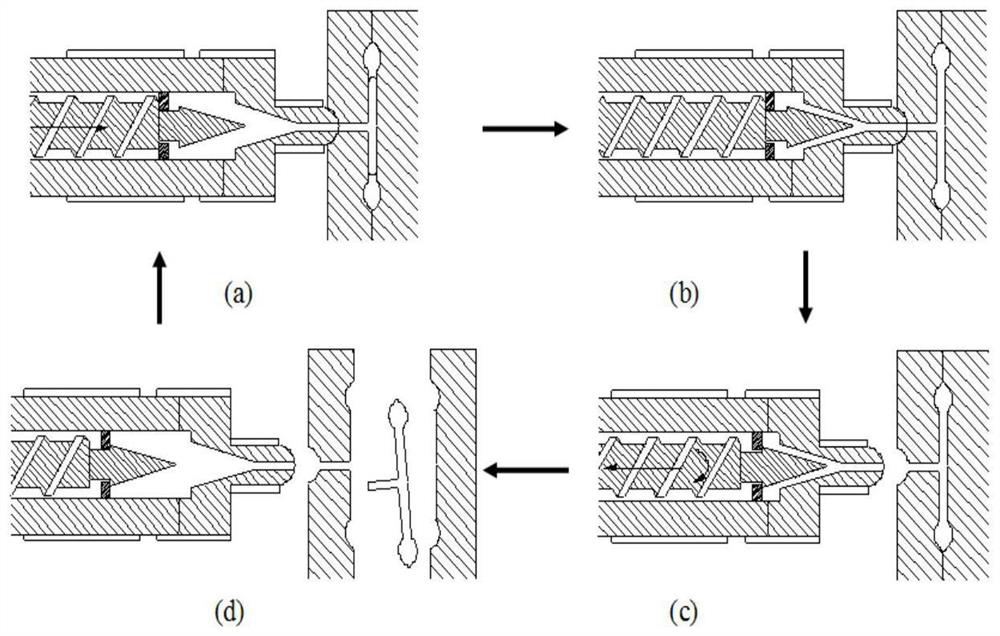

Robust fuzzy prediction control method for nonlinear injection molding asynchronous switching process

ActiveCN112180738AGuaranteed uptimeIncrease productivityAdaptive controlControl engineeringState space

A robust fuzzy prediction control method for a nonlinear injection molding asynchronous switching process belongs to the field of industrial process control, and comprises the following steps: 1, establishing a state space model of a nonlinear injection molding asynchronous switching system; 2, establishing a state space model of the nonlinear injection molding asynchronous switching system into aTS fuzzy state space model through a fuzzy criterion; 3, converting the built TS fuzzy state space model of the nonlinear injection molding asynchronous switching system into an extended TS fuzzy state space model; 4, designing a controller of the extended TS fuzzy state space model based on the nonlinear injection molding asynchronous switching system; 5, calculating the gain of the controller;6, calculating the average residence time of each stage. According to the invention, the influence of model mismatch caused by model linearization on the control effect of the injection molding systemcan be effectively avoided.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

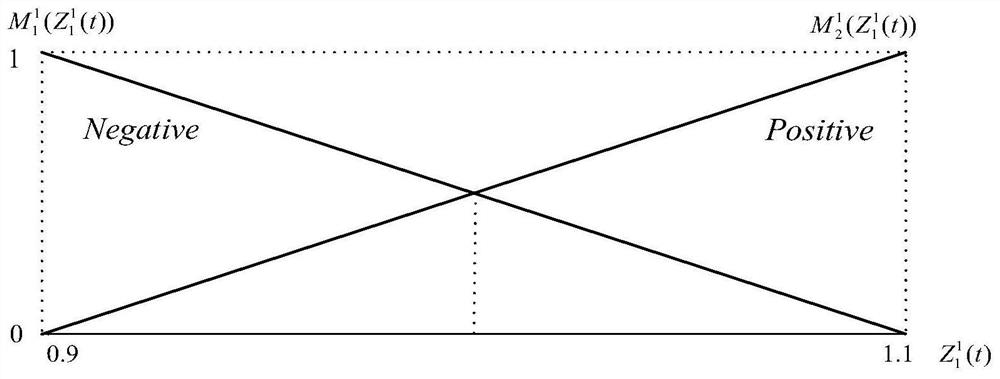

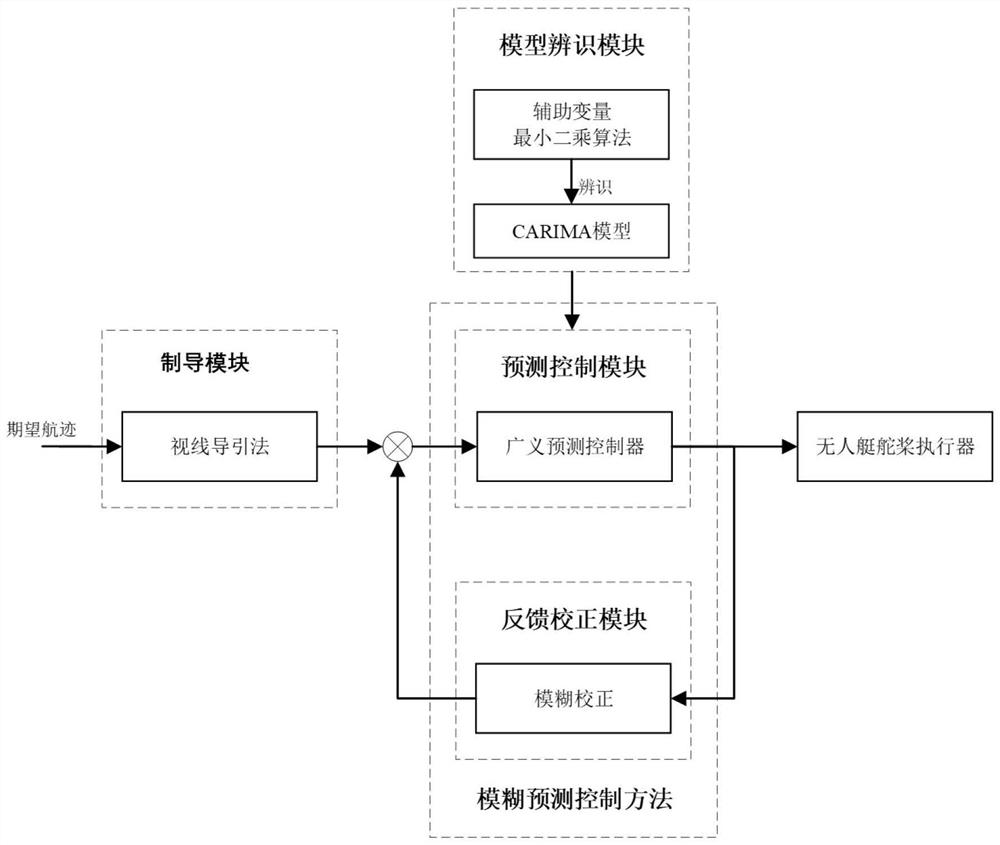

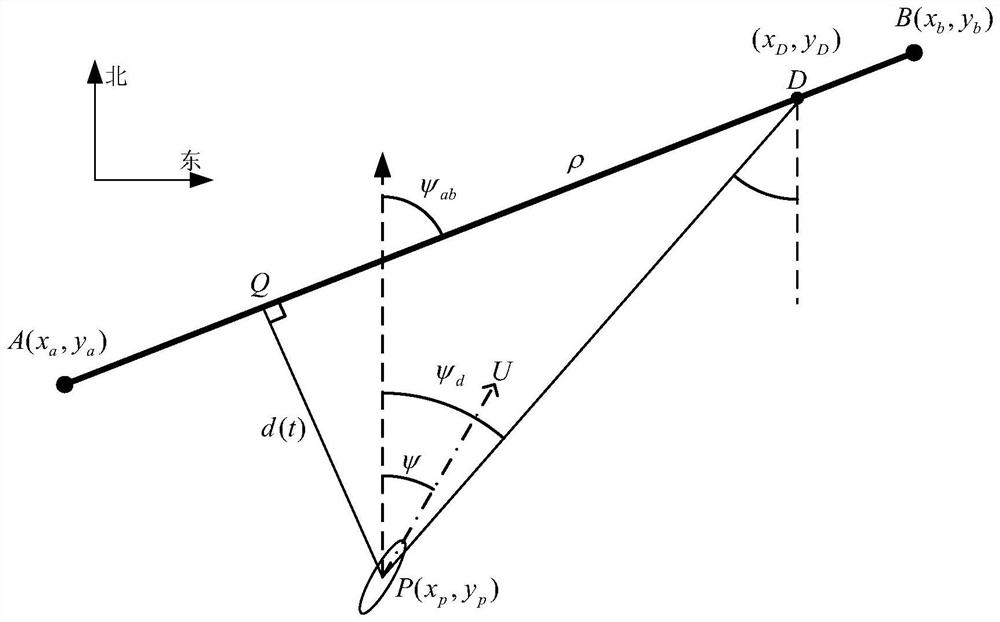

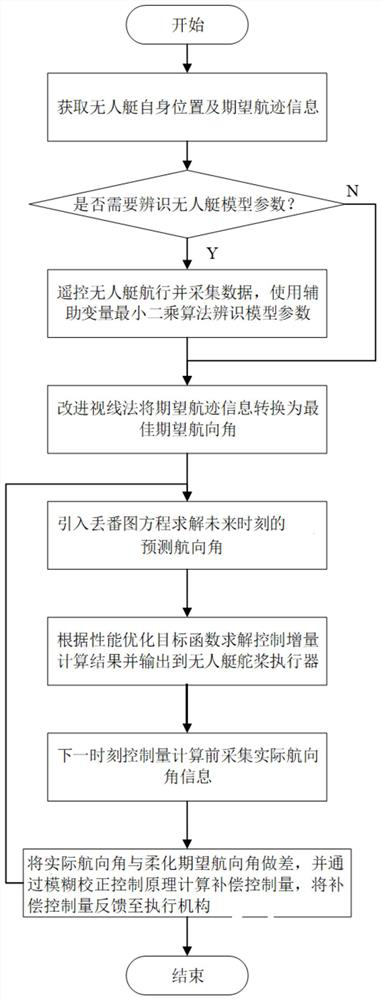

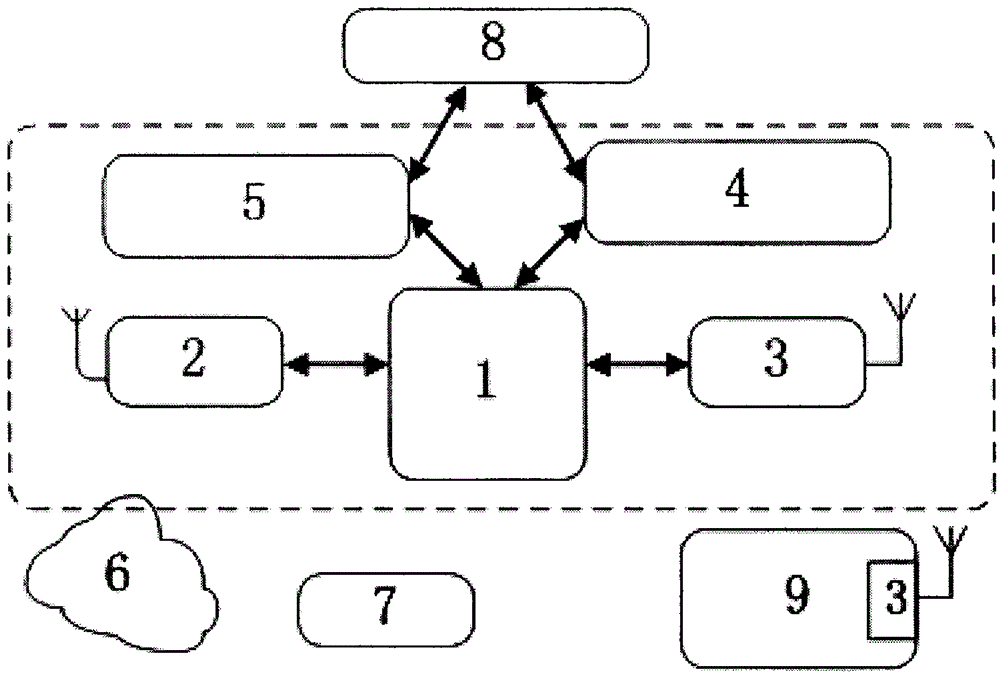

Unmanned ship fuzzy prediction control system and method

ActiveCN113960998AReduce the impactReduce the problem of biased estimationInternal combustion piston enginesPosition/course control in two dimensionsTime domainControl system

The invention provides an unmanned ship fuzzy prediction control system and method. The control system comprises a guidance module, a model identification module, a prediction control module and a feedback correction module. In the guidance module, an expected course angle is obtained through an adaptive foresight distance method; in the model identification module, an improved least square algorithm is adopted to identify model parameters, and in the predictive control module, the idea of rolling optimization in a generalized predictive control algorithm is applied, and an optimal control quantity is solved according to an optimization objective function in a finite time domain; in the feedback correction module, feedback compensation is designed by adopting a fuzzy principle; in conclusion, through the unmanned ship fuzzy prediction control system and method, the capability of accurately tracking an expected track of the unmanned ship is improved, and the unmanned ship fuzzy prediction control system still has relatively high control precision under complex sea conditions.

Owner:航天时代(青岛)海洋装备科技发展有限公司

A tire protection device and its control method based on intelligent prediction

ActiveCN108189628BComprehensive monitoring statusDriving safetyAutomatic initiationsTyre measurementsControl systemControl engineering

Owner:博蔓医疗科技(常州)有限公司

A braking control system of urban rail train based on fuzzy predictive control

InactiveCN109263680AFacilitate man-machine dialogueRailway hydrostatic brakesRailway hydrodynamic brakesRelay valveMathematical model

The invention discloses an urban rail train braking control system based on fuzzy predictive control, include a brake control system body, air brake mechanism, predictive control mechanism, a brake control system unit is arranged on the brake control system body, air brake mechanism, display, trunk interface module, communication module, balance controller, EP Control Switch Valve, brake controller, Brake, sensor set, predictive control mechanism, Master air cylinder, brake air cylinder IEP control. The invention adopts the fuzzy control foundation, does not need to establish the mathematicalmodel of the controlled object, adopts the rules of the knowledge base, facilitates the human-machine dialogue, and makes the calculation hardware more intelligent. The invention is characterized in that the air cylinder EP control, the first relay valve, the second relay valve, the distribution valve, the reference trajectory, the correction module, the data processing module, the output module,and the prediction model are used.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE +1

Robust Fuzzy Predictive Control Method for Asynchronous Switching Process of Nonlinear Injection Molding

ActiveCN112180738BGuaranteed uptimeIncrease productivityAdaptive controlControl engineeringState space

Aiming at the robust fuzzy predictive control method of nonlinear injection molding asynchronous switching process, which belongs to the field of industrial process control, the method includes the following steps: Step 1: Establish a state space model of nonlinear injection molding asynchronous switching system; Step 2: Through fuzzy Criterion, the state space model of the nonlinear injection molding asynchronous switching system is established as a T‑S fuzzy state space model; Step 3: Transform the T‑S fuzzy state space model of the nonlinear injection molding asynchronous switching system into an extended T‑S S fuzzy state-space model; Step 4: Design a controller based on the extended T‑S fuzzy state-space model of the nonlinear injection molding asynchronous switching system; Step 5: Calculate the controller gain Step 6: Calculate the average dwell time of each stage ; The present invention can effectively avoid the influence of the model mismatch problem caused by model linearization on the control effect of the injection molding system.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

A thermal load control method for micro gas turbine cogeneration system based on robust fuzzy predictive control

ActiveCN110488610BIncrease freedomOvercoming the problem of unmeasurable stateAdaptive controlMicro gas turbinePredictive controller

The invention discloses a heat load control method of a micro gas turbine combined heat and power system based on robust fuzzy predictive control, comprising the following steps: collecting input fuel quantity and hot water temperature data of the micro gas turbine combined heat and power system, and establishing a heat load control process The T‑S fuzzy affine model of the heat load control process is established; the global amplification state T‑S fuzzy model is established; the offline fuzzy observer is established based on the global amplification state T‑S fuzzy model; the global amplification state T‑S fuzzy model is established Model and Offline Fuzzy Observer to Build a Robust Fuzzy Predictive Controller. The method of the present invention utilizes the T-S fuzzy model to weaken the influence of the nonlinearity of the system on the controller, adopts the observer to overcome the problem of unmeasurable state, uses the state amplification to overcome the steady-state error, and strengthens the degree of freedom of the controller. A high-quality stable model predictive control method for practical complex industrial processes.

Owner:SOUTHEAST UNIV

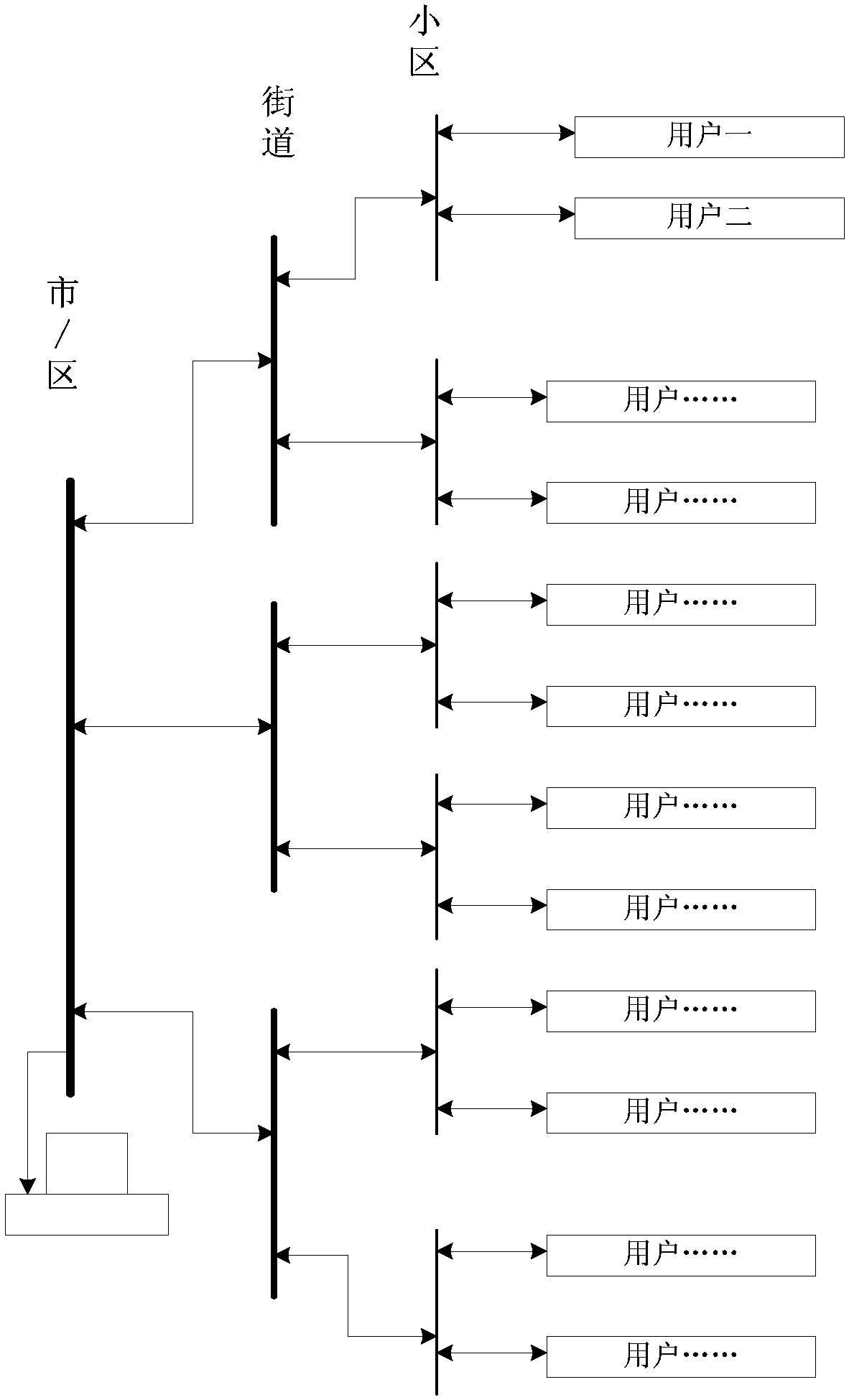

Fuel gas intelligent early warning centralized control device, centralized control system and monitoring method

PendingCN108267993AAvoid accidentsWith forecastProgramme controlComputer controlElectricityControl system

The invention discloses a fuel gas intelligent early warning centralized control device, a centralized control system and a monitoring method. The control device comprises a controller, a monitoring mechanism, an execution mechanism, an alarming mechanism and a power supply mechanism, wherein the detection mechanism comprises a fuel gas concentration sensor and a pressure sensor, and is connectedwith the controller; the execution mechanism comprises a manual control valve, an electric control valve and a communication valve; a user connection end opening of the fuel gas supply pipeline is connected with the input of the fuel metering meter through the manual control valve; the output of the fuel metering meter is connected with the input of the communication valve through the electric control valve; the output of the controller is respectively connected with the electric control valve and the warning mechanism; the two output openings of the communication valve are respectively connected with the input of a fuel gas water heater and a gas-cooker; the power supply mechanism provides electricity for the controller, the electric control valve and the fuel gas meter. The fuel gas using safety grade of the user can be obtained through the fuzzy prediction control; the prediction and control function is realized; the accidents of the fuel gas in various aspects can be effectively prevented.

Owner:NANJING XIAOZHUANG UNIV

A Commutation Failure Prevention Method Based on DC Current Fuzzy Predictive Control

InactiveCN104810847BOvercoming the Limitations of RandomnessReduce the DC current on the rectifier sideElectric power transfer ac networkFailure preventionPrevention approach

The invention discloses a commutation failure prevention method based on direct current fuzzy predictive control. In view of a direct current predictive control method in which limitation exists in a parameter k random value in a direct current predication setting valve calculation formula and direct current at a rectifier side is reduced for a long time, limitation of slow current recovery of the direct current system is caused, a fuzzy controller is adopted to control the direct current predication setting valve, a direct current fuzzy predictive control method is brought forward, a control time duration T selected via a simulation result is set, and the direct current at the rectifier side is only reduced with a time duration T after a CFPREV module detects failure happens to an alternating current system. Through modeling and simulation, compared with the prior direct current predictive control method, effectiveness of restraining the commutation failure ability by the HVDC (high-voltage direct current) system is verified to be enhanced.

Owner:HOHAI UNIV

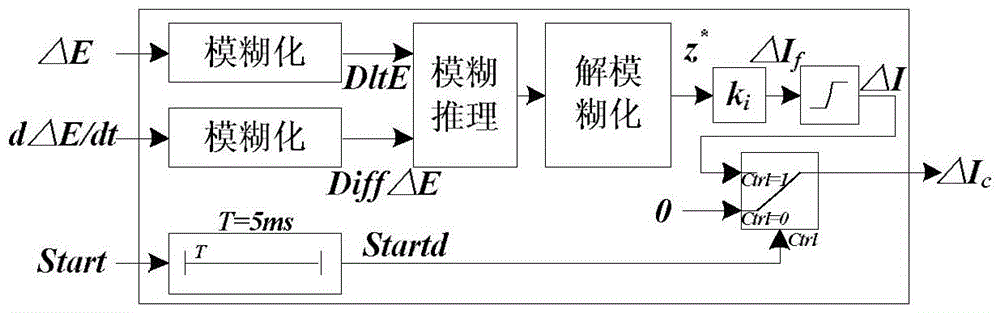

Fuzzy prediction control analysis system of infrared carbon and sulfur analyzer

ActiveCN109444068AImprove accuracyHigh precisionMaterial analysis by optical meansData acquisitionGas concentration

The invention discloses a fuzzy prediction control analysis system of an infrared carbon and sulfur analyzer. The fuzzy prediction control analysis system is used for overcoming effects of different environment temperatures, partial pressures, sample weights and analysis air flows on analysis results and the problem of errors of measurement result caused by ageing of a detection unit after long-time use. The fuzzy prediction control analysis system comprises an automatic sampling module, a high-frequency combustion furnace, an oxygen supply module, a gas conveying module, a flow control module, an infrared detection tank, a data acquisition module, an analyzing module, a processor, a display module and a storage module. A formula of ZCi=Ci+Ci*ln[(Qi-Qb)*k1+(Ti-Tb)*k2+(Pi-Pb)*k3+Gi*k4]u1 isutilized to obtain an actual value ZCi of the concentration of CO2 gas; by means of the obtained actual value of the gas concentration, the effects of the environment temperatures, the gas partial pressures, the sample weights and the air flows on the analysis results are reduced, and accuracy and precision of the analysis results are improved; a correction factor u1 is obtained through a fuzzy prediction formula, so that errors of measurement result caused by ageing of the detection unit after long-time use are reduced.

Owner:郎溪杰博电器科技有限公司

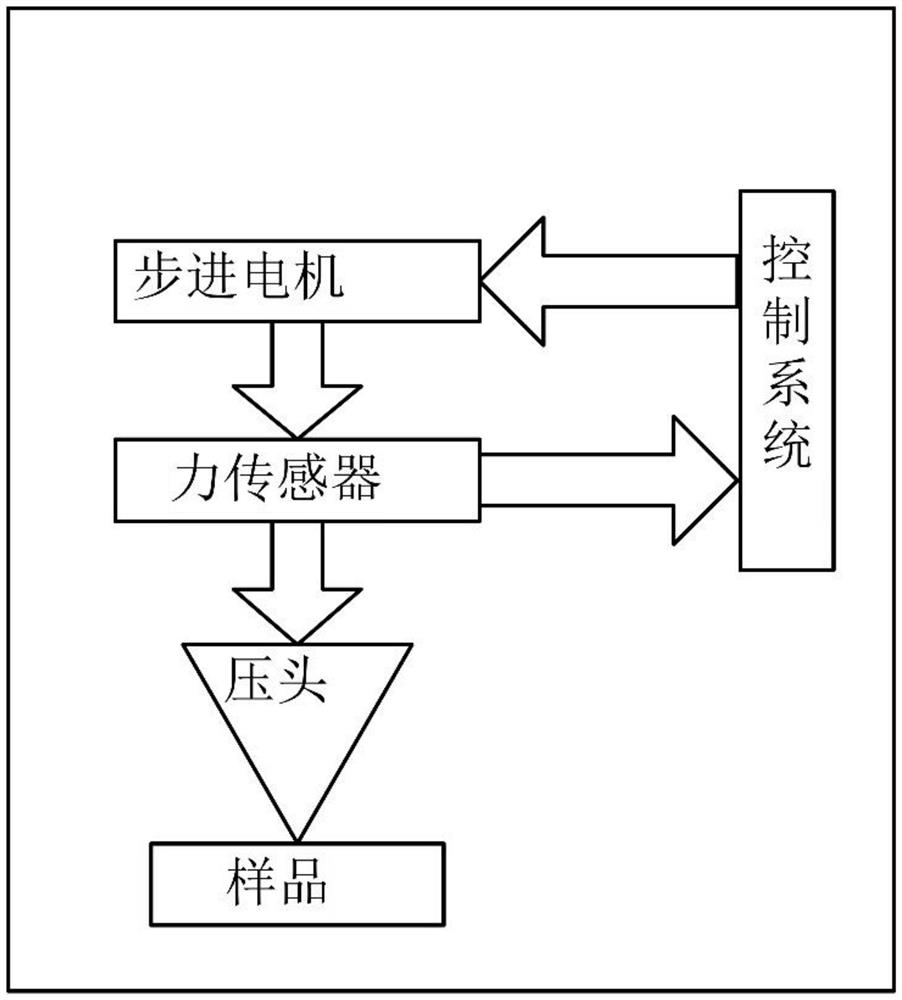

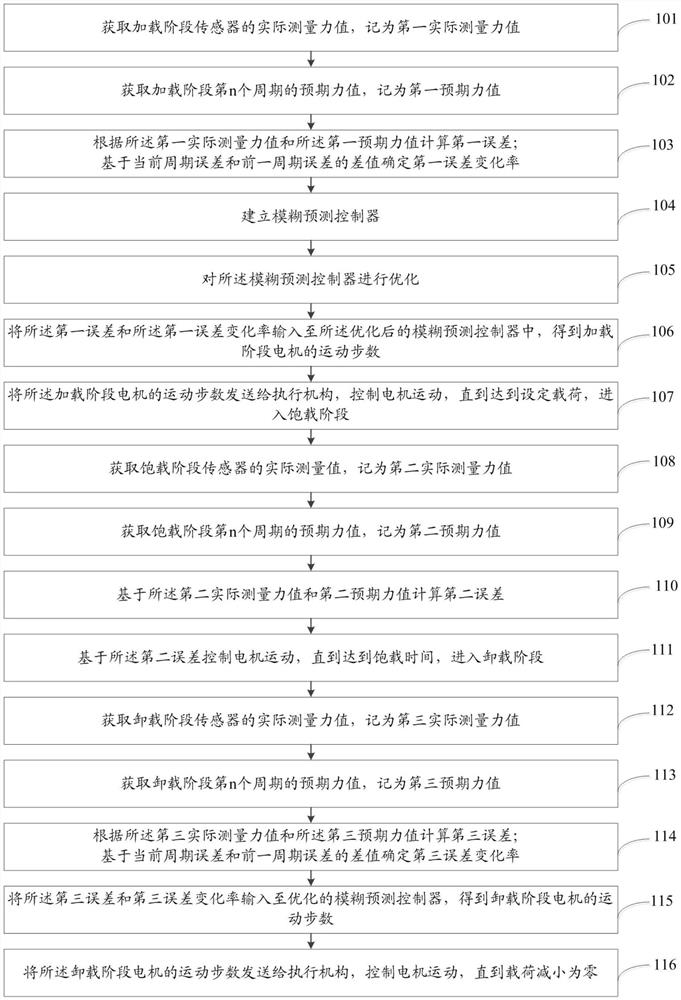

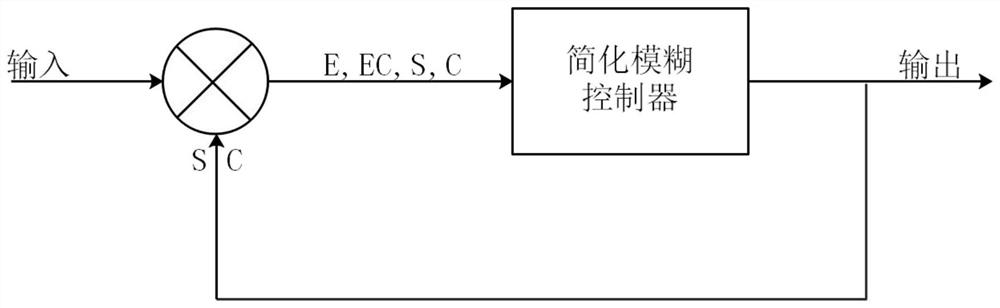

Indentation instrument load control method and system based on fuzzy predictive control

ActiveCN112799300AAvoid damageImprove experienceMaterial strength using tensile/compressive forcesInference methodsControl engineeringElectric machinery

The invention relates to an indentation instrument load control method and system based on fuzzy predictive control. The method comprises the following steps: acquiring an actual measurement force value of a sensor in a loading stage; acquiring an expected force value of the nth period in the loading stage; calculating a first error and a first error change rate; establishing and optimizing a fuzzy prediction controller; determining the motion step number of a motor in the loading stage; acquiring an actual measurement value of the sensor in the full load stage; obtaining an expected force value of the nth period in the full load stage, and calculating a second error; controlling the motor to move based on the second error; acquiring an actual measurement force value of the sensor in the unloading stage; acquiring an expected force value of the nth period in the unloading stage; calculating a third error and a third error change rate; and determining the motion step number of the motor in the unloading stage. The method has the characteristics of high precision, small deviation and simple algorithm.

Owner:XIANGTAN UNIV

Cold-rolled strip steel plate shape prediction control method

ActiveCN103418619BEliminate common shape defectsReduce negative impactProfile control deviceTakagi sugenoFuzzy membership function

The invention provides a cold-rolled strip steel plate shape prediction control method, comprising the following steps: for cold-rolled strip steel of the same specification, establishing a corresponding plate shape prediction control fuzzy reasoning model; setting fuzzy membership functions of various parameters in the plate shape prediction control fuzzy reasoning model by being combined with the characteristics of influence of rolling force change on the strip steel plate shape; establishing plate shape fuzzy prediction control models by utilizing a Takagi-Sugeno fuzzy model modeling rule; selecting a corresponding plate shape fuzzy prediction control model to carry out online adjustment on a working roller bending device. A dynamic relationship is established among rolling force variation, forward pull variation of a roll mill, backward pull variation of the roll mill, and online adjustment variable of the working roller bending device by using a fuzzy modeling method, the adverse effect of transmission time lag existing between the roll mill body and a plate shape instrument on the plate shape control at the outlet of the cold-rolled strip steel, and two familiar plate shape defects of intermediate waves and edge waves existing in the cold-rolled strip steel products are effectively overcome.

Owner:WISDRI ENG & RES INC LTD

Fuzzy predictive control system and method for power supply for electrostatic dust removal

InactiveCN105170333BImprove adaptabilitySolve problems that are difficult to model mathematicallyElectric supply techniquesControl signalMathematical model

The invention discloses a fuzzy prediction control system and method for a power supply for electrostatic dust removal. The analog signal acquisition unit converts the collected analog signal into an electrical signal, performs filtering and other adjustments, and then outputs it to a T-S fuzzy controller. The T-S fuzzy The controller first identifies the antecedent and conclusion part of the T-S fuzzy model according to the conditioned signal, obtains the T-S fuzzy model, then converts the T-S model into a step response model, and outputs the step response model to the prediction The controller 23 is used as a predictive model; the predictive controller uses the step response model as a predictive model to perform rolling optimization and feedback correction, and output the control signal to the digital logic unit; the control signal is used as a drive signal for controlling the drive unit after passing through the digital logic unit. Fuzzy predictive control of the power supply; solves the problem that the electrostatic precipitator system is difficult to establish a mathematical model, and reduces the dependence of the predictive controller on the precise mathematical model.

Owner:JIANGSU UNIV OF SCI & TECH

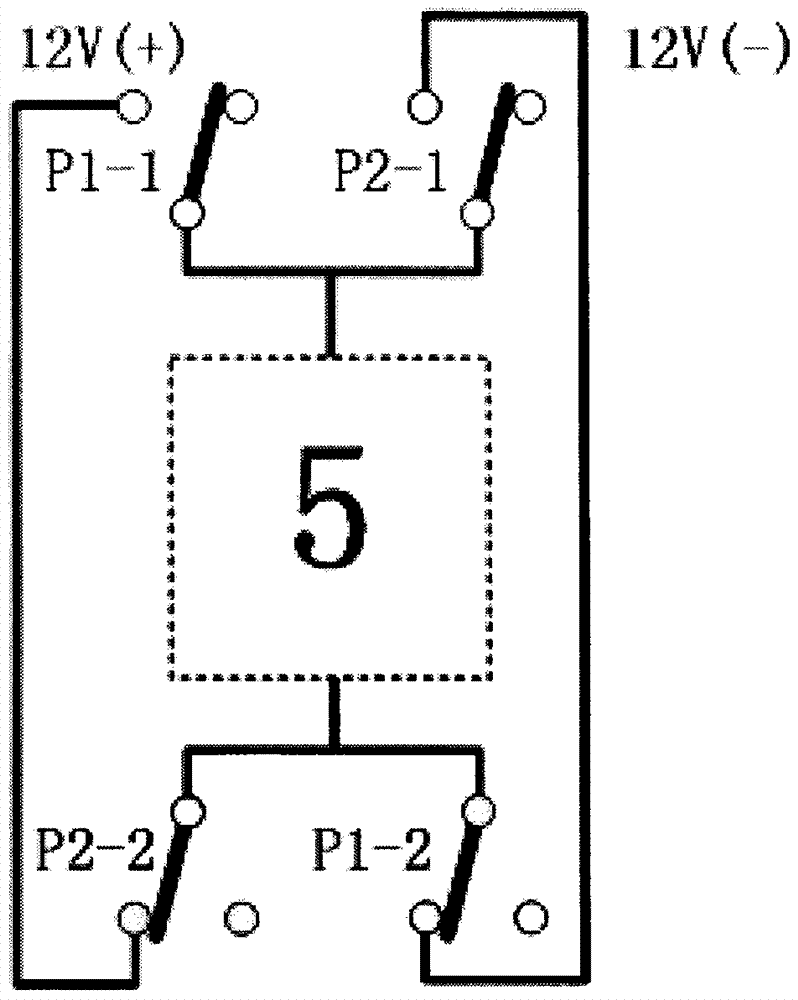

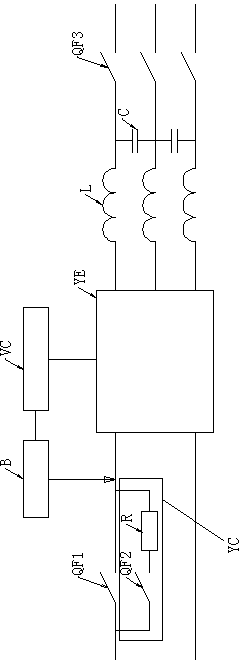

Electric vehicle braking follow-type fuzzy prediction starting and stopping control circuit

InactiveCN104714410ASimple topologyImprove output waveform qualityAdaptive controlEngineeringAlternating current

The invention relates to the technical field of electric vehicle starting and stopping, in particular to an electric vehicle braking follow-type fuzzy prediction starting and stopping control circuit. The electric vehicle braking follow-type fuzzy prediction starting and stopping control circuit comprises a direct current contactor QF, a precharge branch YC, alternating current contactors QF3, a recognition unit B, a fuzzy prediction control unit VC, a drive and executing device YE, electric reactors L and a capacitor V. The recognition unit B and the fuzzy prediction control unit VC are connected with an electric tractor power supply through the direct current contactor QF1 and the precharge branch YC, the rear end of the recognition unit B and the rear end of the fuzzy prediction control unit VC are connected with the drive and executing device YE, the rear end of the drive and executing device YE is connected with the electric reactors L and capacitors C, the rear ends of the electric reactors L and the rear ends of the capacitors C are connected with the alternating current contactors QF3, and the alternating current contactors QF3 are connected to an electric grid. According to the electric vehicle braking follow-type fuzzy prediction starting and stopping control circuit, the main circuit topology is simple, control is flexible and convenient, and the quality of output waveforms is good.

Owner:JIANGSU MINGWEI WANSHENG TECH CO LTD

An intelligent temperature control device for an arc combustion furnace body of an infrared carbon and sulfur analyzer

ActiveCN104729279BQuick analysisAccurate analysisLighting and heating apparatusFurnace temperatureWireless control

Owner:南京华欣分析仪器制造有限公司

A fuzzy predictive control method with enhanced robustness based on disturbance observer

The present invention provides a fuzzy predictive control method based on the enhanced robustness characteristic of a disturbance observer. The steps are as follows: 1. Establish a discrete fuzzy disturbance observer model, an auxiliary controller and a robust predictive controller; 2. Solve the feedback gain of the auxiliary controller and the gain of the disturbance observer, obtain the minimum robust invariant set, and calculate the tight constraint set of the control input and state variables of the robust predictive controller; 3. Initialize the system state variables and assign them to the state variables of the nominal model; 4. For the The current nominal model state variables, solve the optimization problem that minimizes the upper bound γ of the predictive control performance, and obtain the current disturbance estimation value; 5. Calculate the control input of the system and act on the controlled object; 6. Apply the control of the nominal system The input acts on the nominal model and calculates the output of the current state, and the output of the current state quantity of the sampling system; 7. Substitute with and set k=k+1, and then jump to step 4. The present invention improves the stability of the predictive control system.

Owner:NANJING INST OF TECH

Network teleoperation robot system and time delay overcoming method

InactiveCN102825603BGuaranteed stabilityImprove robustnessProgramme-controlled manipulatorRobotic systemsTime delays

The invention discloses a network teleoperation robot system and a time delay overcoming method. The system is formed by linking two manipulators with the same structure and symmetrical functions through a network communication link. A main manipulator is operated by an operator so that the main manipulator is acted; the main manipulator transmits an action signal to a secondary manipulator through force and angle displacement sensors, and a communication control link, so that the secondary manipulator can move in the same direction along the main manipulator. When the secondary manipulator is affected by the environment, the secondary manipulator can return the signal to the main manipulator along the original path, thus, the main manipulator can feel the same action of the environment and feed back to the operator. By adopting a modeling method based on an event and a fuzzy predictive control algorithm, the system has good robustness on the model mismatch; therefore, the system can overcome the influence caused by the network time delay.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com