Robust Fuzzy Predictive Control Method for Asynchronous Switching Process of Nonlinear Injection Molding

An injection molding, fuzzy prediction technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems affecting control performance, the controller cannot perform optimal control, model deviation, etc., to improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0186] Plastic products are widely used in daily life due to their low cost and strong plasticity. The plastic industry occupies a very important position in today's world. In recent years, the production technology of plastic products has developed rapidly. As one of the important methods of plastic product processing, injection molding has been more and more widely used in the production of plastic products due to its advantages of fast production speed, high efficiency, accurate product size, and easy replacement.

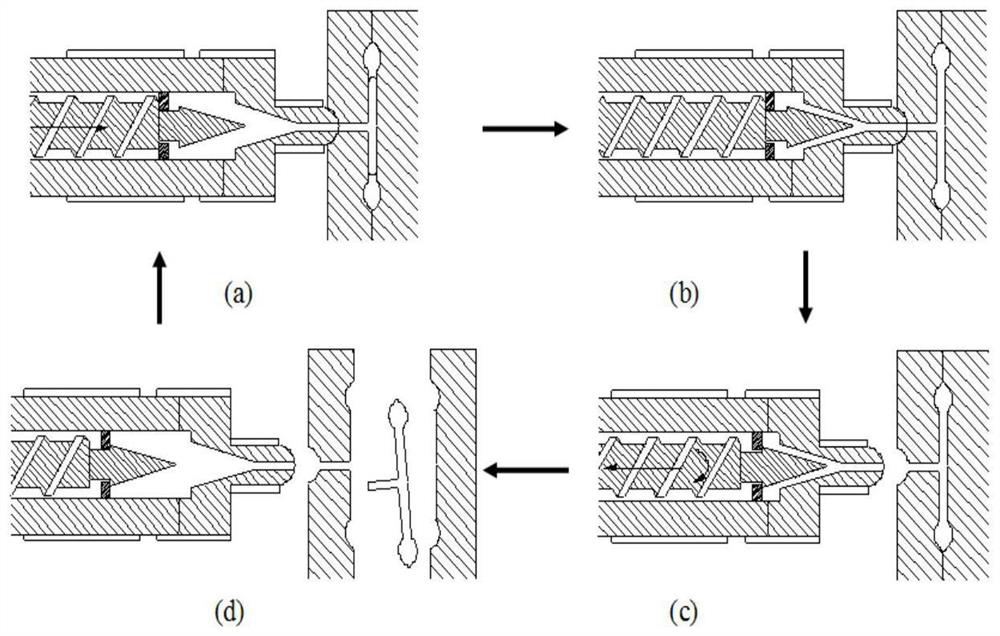

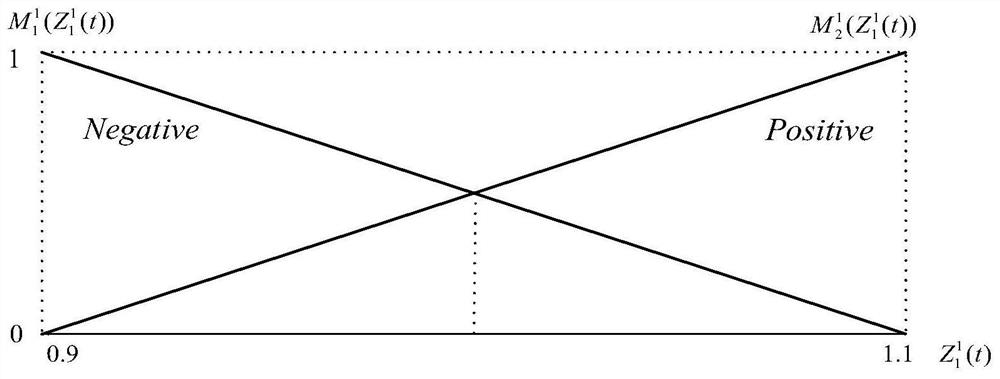

[0187] It is well known that the injection molding process is a common nonlinear multi-stage batch process. figure 1 It is the physical picture of the reciprocating screw injection molding machine, figure 2 In the figure, a is injection, b is pressure holding, c is cooling and d is demoulding. The injection and pressure holding stages have a great influence on the product quality. In order to ensure the uniform filling of the material in the injection stage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com