Patents

Literature

53results about How to "Solve temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing isocyanates in the gaseous phase

ActiveCN101205197AHigh operating hoursSolve temperature controlOrganic compound preparationIsocyanic acid derivatives purification/separationGas phaseContact time

Owner:COVESTRO DEUTSCHLAND AG

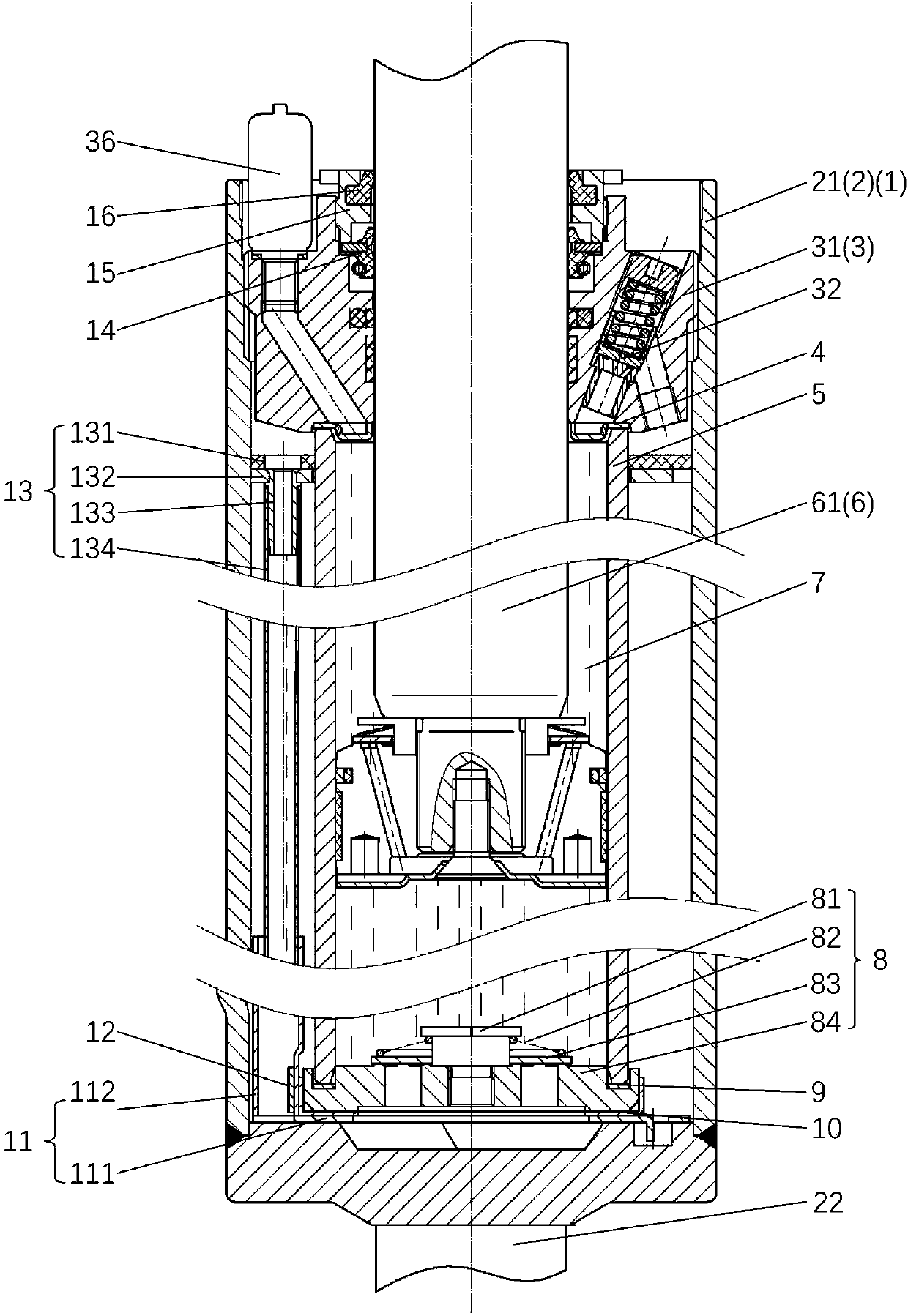

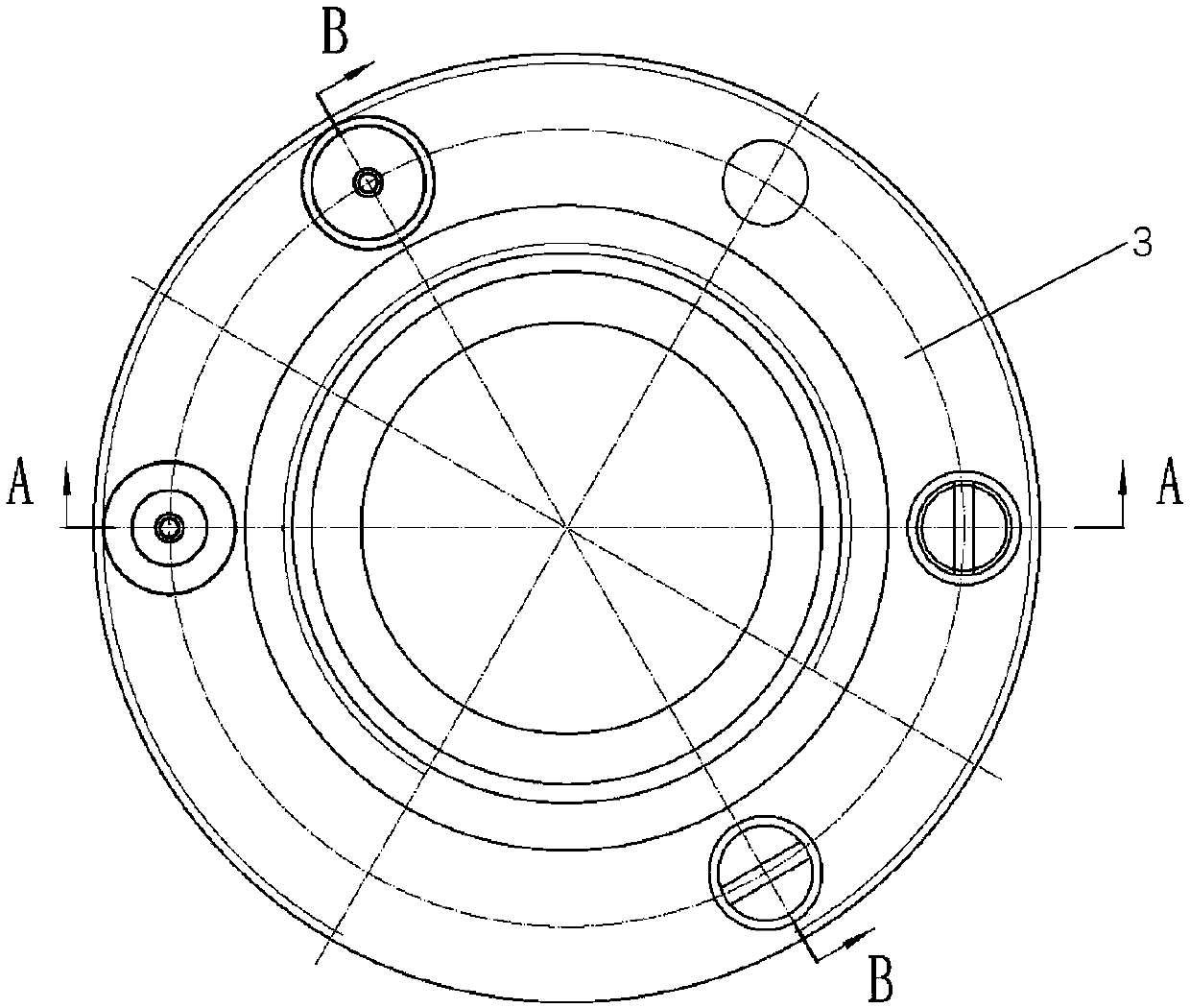

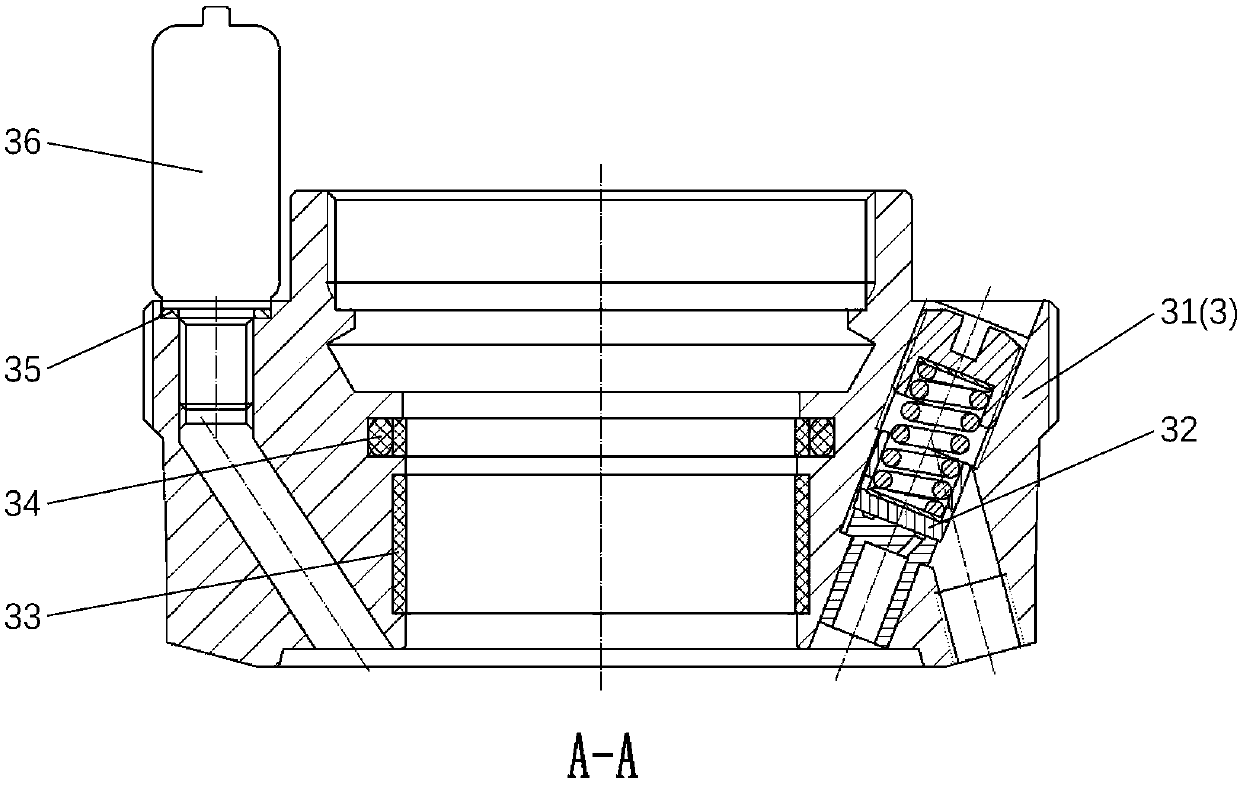

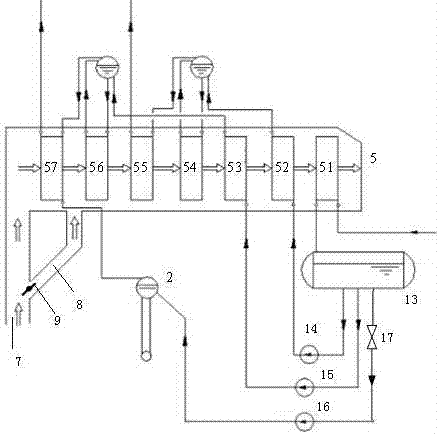

Test module, system and test method for testing damping valve of oil damper

The invention provides a test module, a system and a test method for testing the dynamic characteristic of the damping valve of an oil damper at high / low temperature. The test module includes an oil storage cylinder component, a guide component, a guide exhaust plate, a pressure cylinder, a piston-piston rod component, hydraulic oil, a bottom valve component, a pressure cylinder gasket, a bottom valve gasket, an oil guide plate component, a magnet, an oil return component, a framework oil seal, a screw cap, and a dustproof ring. The test module integrates the hydraulic oil, an oil supply mechanism, a tested damping valve and a sensor through the principle of integrated design. The entire test module can be placed in a high / low-temperature box. The problem on how to control the oil temperature of the tested damping valve can be conveniently, effectively and accurately solved. An automatic test system based on the test module and a related test method are further provided.

Owner:DONGGUAN UNIV OF TECH

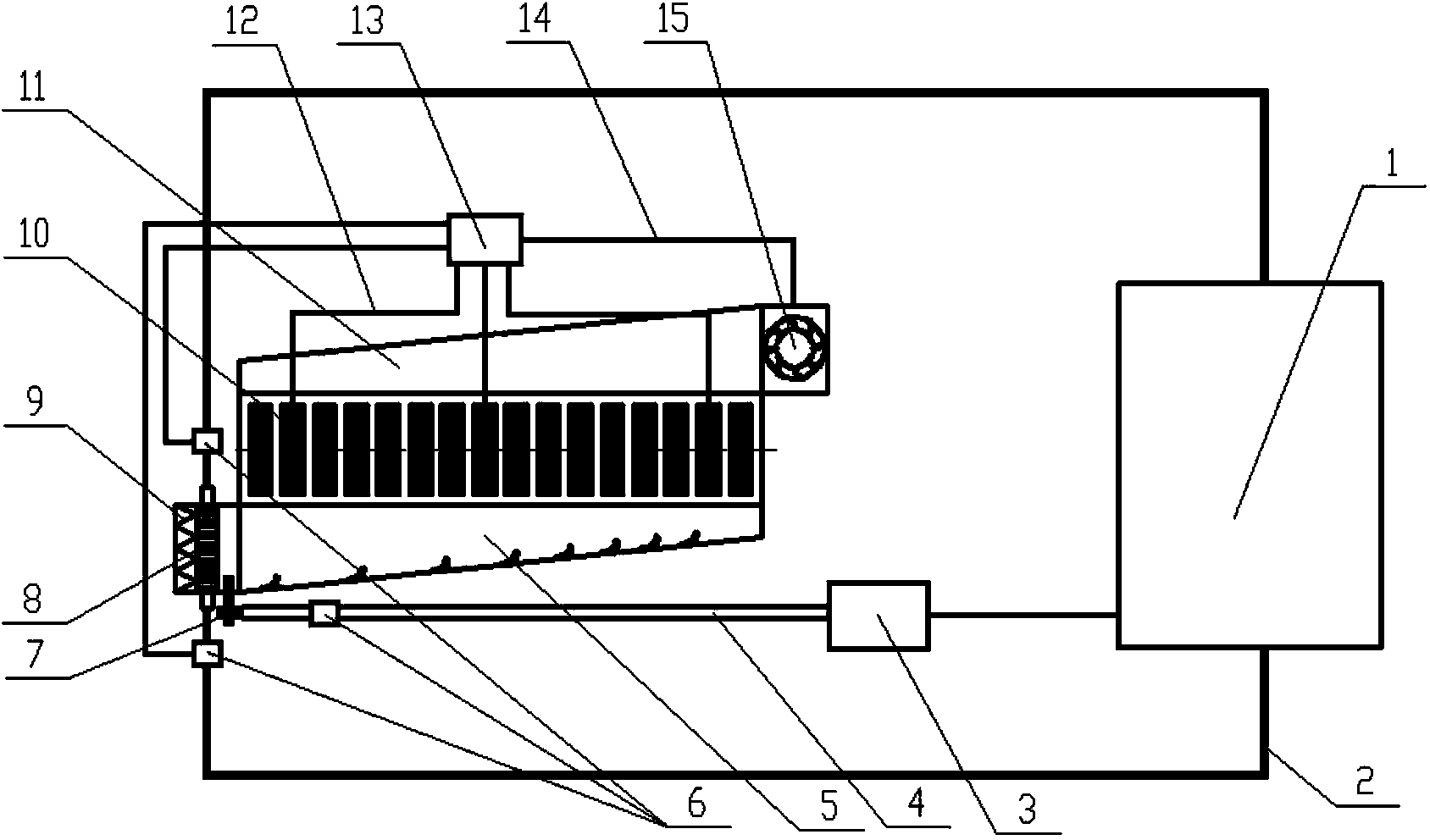

Power battery module temperature control system for new energy coach

ActiveCN103825068ASolve temperature controlHeat dissipation fastSecondary cellsBatteriesTemperature controlPower battery

The invention discloses a power battery module temperature control system for a new energy coach, which comprises a battery module, wherein the battery module is connected with a battery management controller through a temperature collecting wire; a battery inlet air guide hood is fixed on one side of the battery module in a sleeving manner; a battery outlet air guide hood is fixed on the other side of the battery module in a sleeving manner; a heating panel and a vortex pipe are fixed at the inlet of the battery inlet air guide hood; a vortex pipe is sequentially connected with a blast pump and a motor through a corresponding electromagnetic valve. According to the power battery module temperature control system for the new energy coach, based on the integral heat management and control of the whole coach, the compressed gas output from the blast pump and motor cooling water heat in the moving coach are mixed as an energy source; the cold gas and hot gas are provided for the battery through the vortex pipe and the heating panel; the temperature control of battery module is realized; the requirement that the battery can work in an optimal temperature range in a cold winter and in a hot summer is satisfied.

Owner:ZHONGTONG BUS HLDG

Culture method for chlorella

ActiveCN102311920ASolve the problem of slow growth or even failure to growIncrease concentrationUnicellular algaeMicroorganism based processesChlorellaBioreactor

The invention discloses a culture method for chlorella, which comprises the following contents: the volume of chlorella seed liquid in a bioreactor accounts for 5 to 15 percent of the total volume of a culture medium; a gas containing 5 to 15 volume percent of CO2 is introduced, the volume of introduced gas is 0.1 to 1.0vvm; and the culture temperature is reduced to 0 to 15 DEG C from 25 to 40 DEG C within 0.5 to 10 days, and chlorella is continuously cultured at a constant temperature of 0 to 15 DEG C for 5 to 15 days. The method disclosed by the invention can allow microalgae to grow normally at a low temperature, and the accumulated amount of fat and CO2 utilization rate of microalgae can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

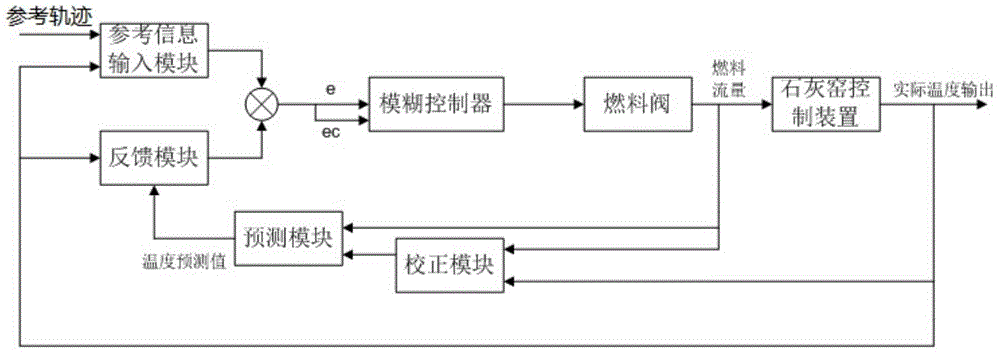

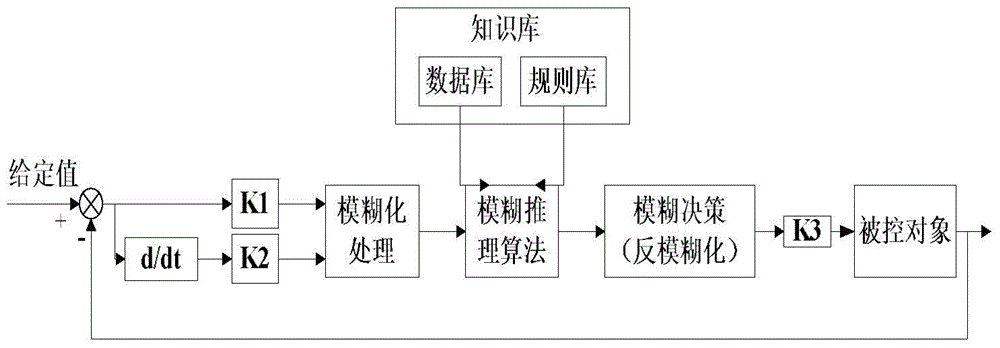

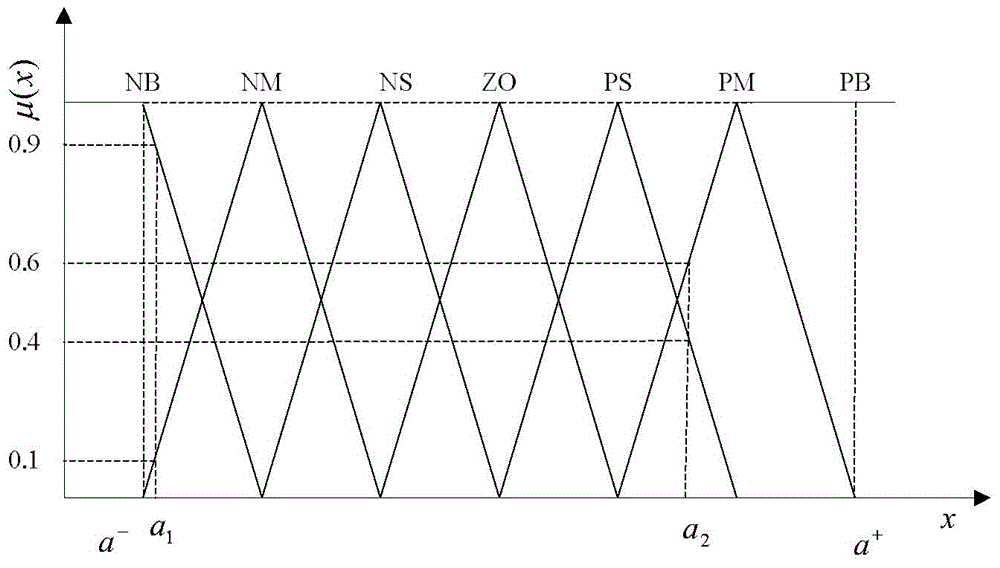

Fuzzy predictive control system for combustion process of lime kiln as well as control method of system

InactiveCN104950681ASolve temperature controlHigh activityAdaptive controlOptimal controlEngineering

The invention discloses a fuzzy predictive control system for a combustion process of a lime kiln as well as a control method of the system and belongs to the field of control on the combustion process. The fuzzy predictive control system comprises a reference information input module, a fuzzy controller, a fuel valve, a lime kiln control device, a prediction module, a feedback module and a correction module. A combustion temperature control system of the lime kiln has the characteristics of nonlinearity, time variability, model structure uncertainty and the like, a predictive control and fuzzy decision combined control method is adopted, an advanced prediction function of predictive control and the optimal control effect of fuzzy control in a large deviation range are integrated, and the temperature control problem of a large-time-delay nonlinear system is solved; the system can be put into actual production operation, the dynamic quality in the lime calcining temperature adjustment process is effectively improved, and the good actual application effect is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

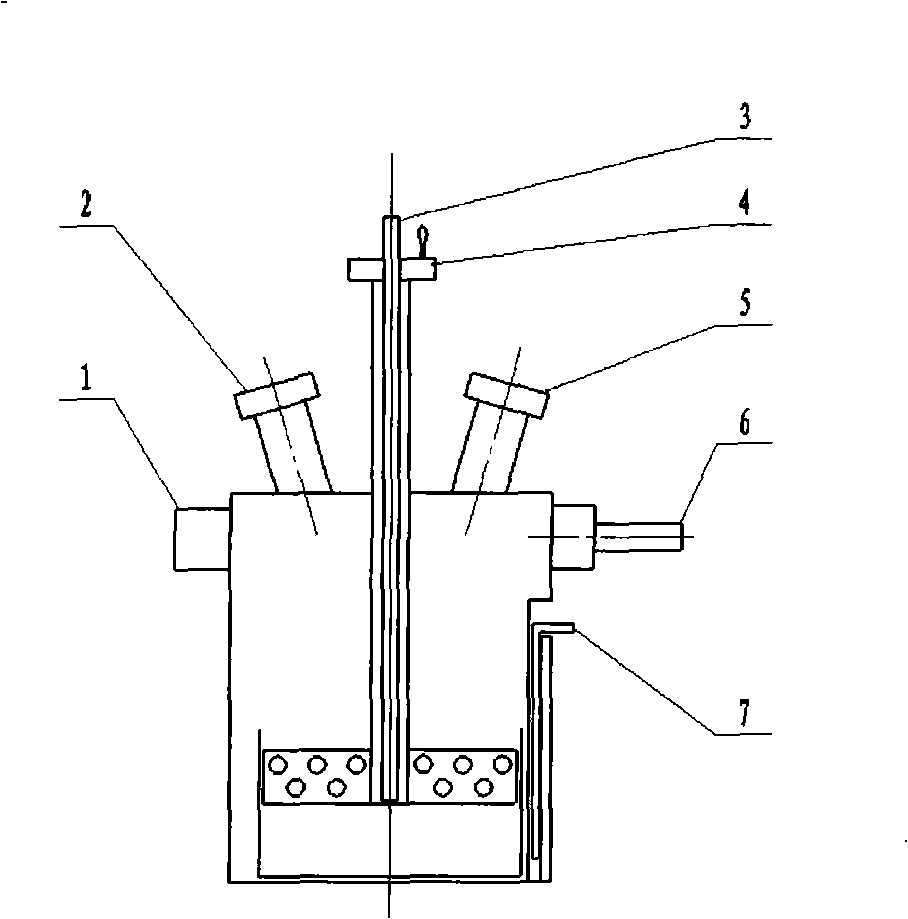

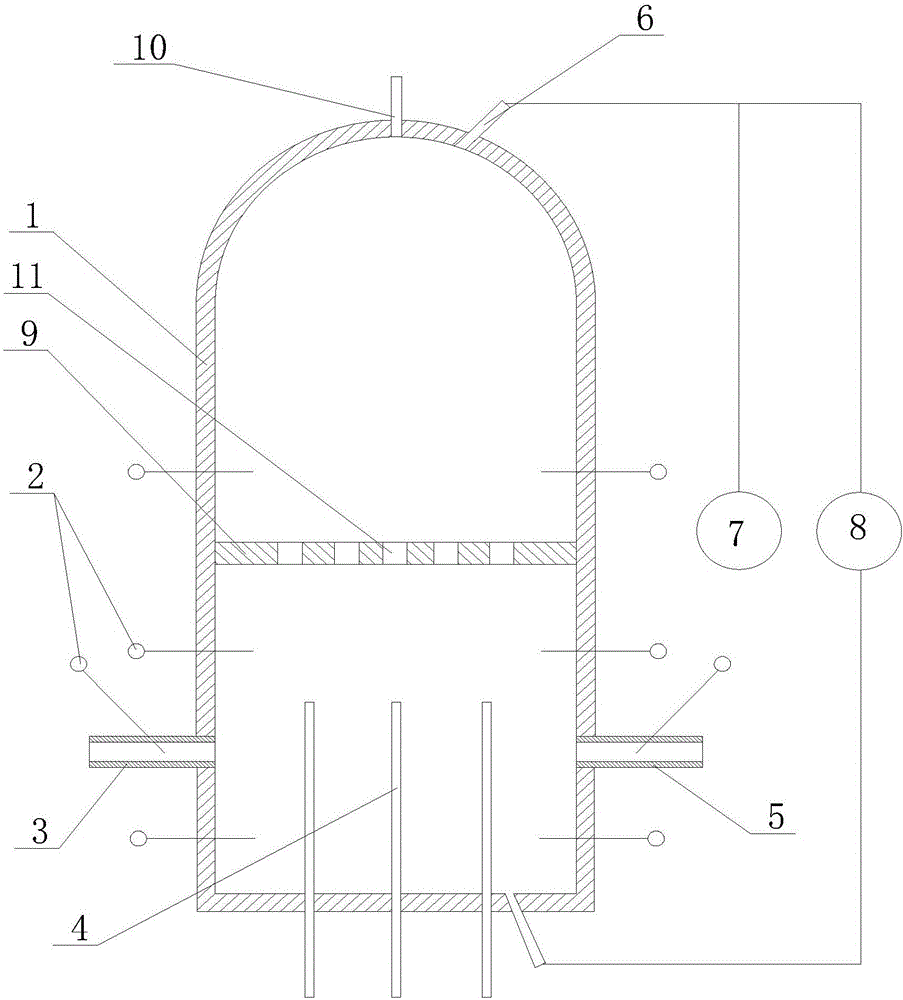

Method and apparatus for preparing Li-B alloy by vacuum smelting

InactiveCN101353734AReduce performanceFlat surfaceCrucible furnacesTemperature controlVacuum pumping

The invention discloses a method and a device for preparing Li-B alloy by vacuum smelting, pertaining to the metallurgy technology field. The device is a vacuum smelting furnace, a temperature-control thermocouple is arranged at the outer side of a crucible, a stirring paddle is arranged at the central position of the smelting furnace, a temperature thermocouple is arranged at the bottom end of the stirring paddle, an incident light port and an observation port are arranged on the upper surface of the furnace cover, a vacuum-pumping and argon channel is arranged at the upper end of the side of the furnace body, and an air-cooling device is arranged at the corresponding position of the argon channel. Li and B powder are put into the iron crucible, protected in high vacuum atmosphere, heated to 400 DEG C and then kept for 10min to 2h, the B powder is introduced with Ar gas to carry out protection when being fully dissolved in the melting of the Li; temperature rise is continued and stirring is reinforced, melt is solidified at the temperature of 530 DEG C, and after the alloy is fully solidified, the temperature rises to 650 DEG C, and the alloy is cooled with the furnace and treated with air-cooling after the temperature of 400 DEG C. The method and the device of the invention have compact and reasonable structure, simple technology, safe use, convenient operation and high-efficient production, thus having generalization and application value.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

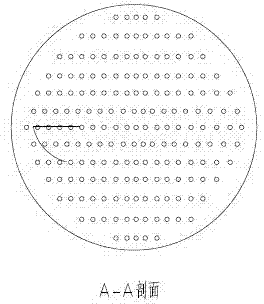

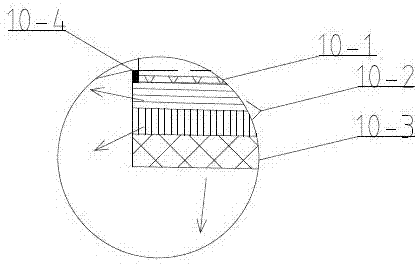

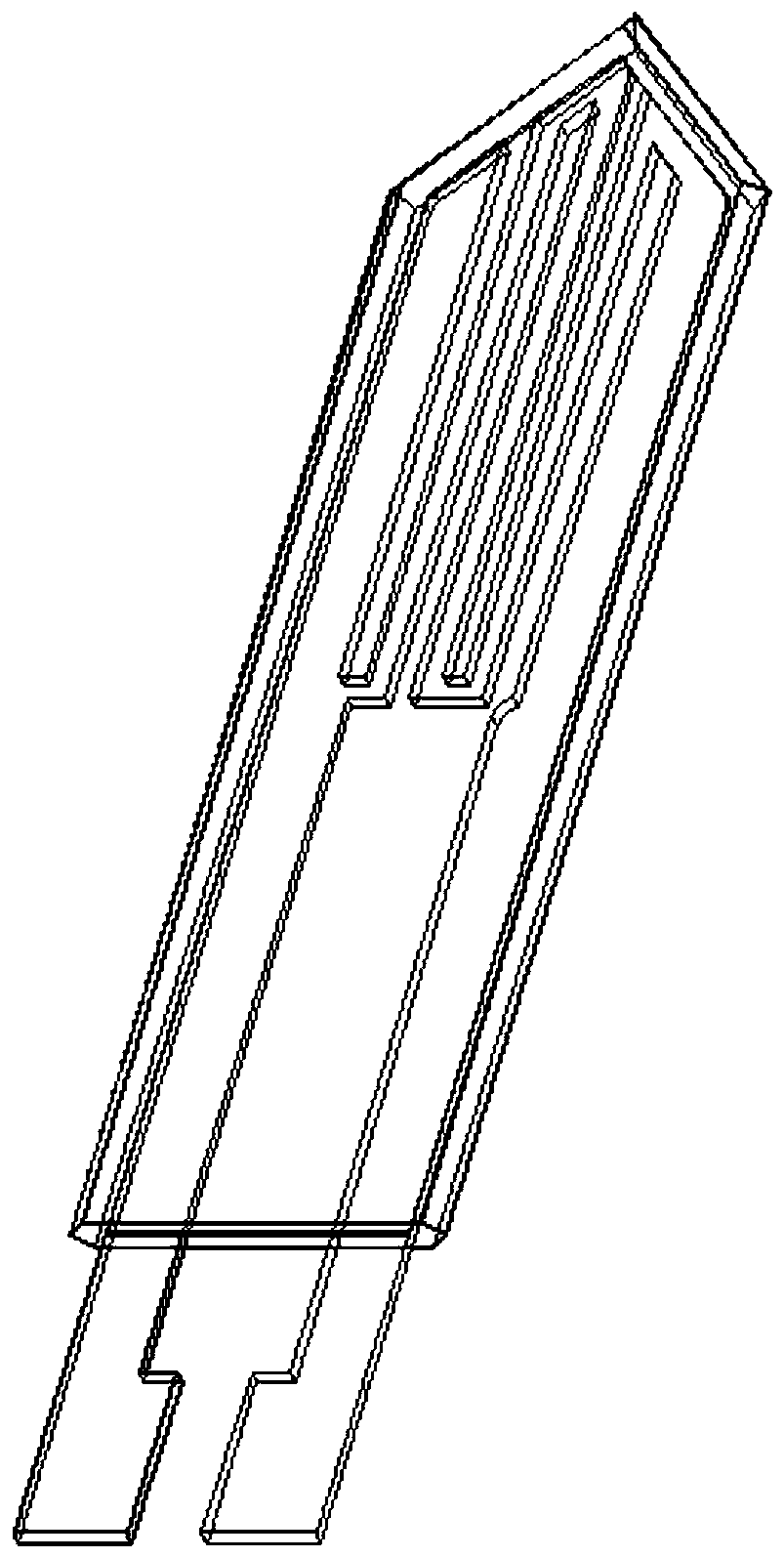

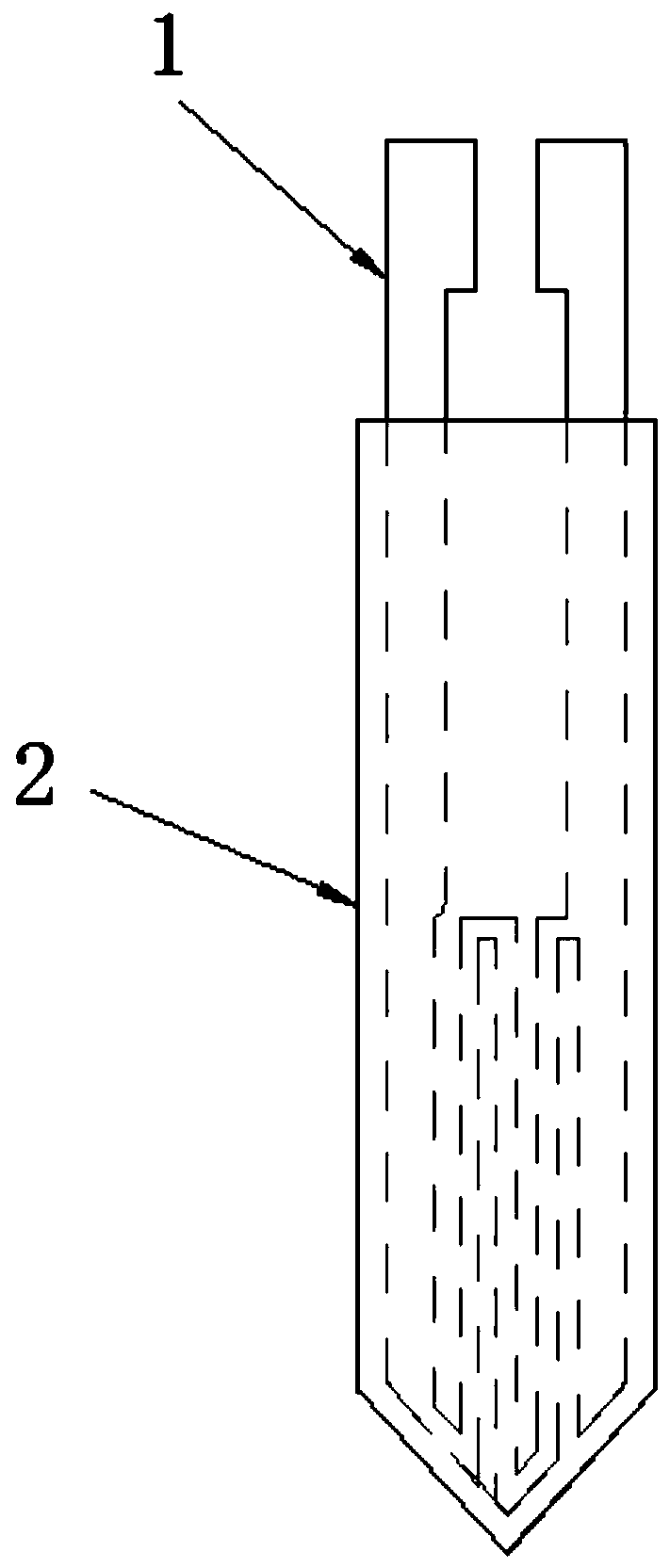

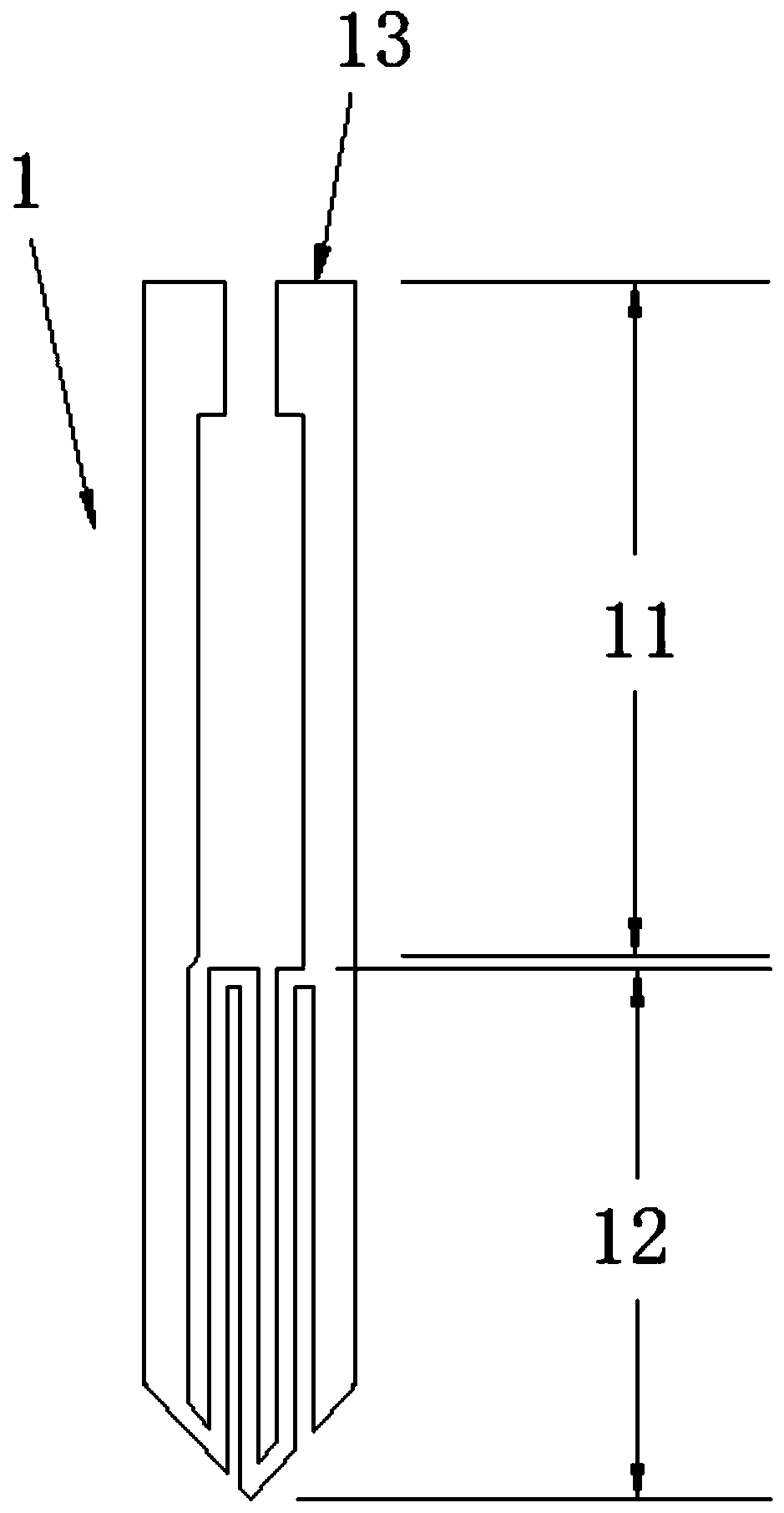

Magnetic fluid micro-channel thermal control system of microsatellite standalone

InactiveCN105578850AImprove heat transfer efficiencyReduce energy consumptionCooling/ventilation/heating modificationsTemperature controlActive cooling

The invention provides a magnetic fluid micro-channel thermal control system of a microsatellite standalone, relates to a micro-channel-based thermal control system applied to a microsatellite, and solves the problems that existing microsatellite thermal control systems are poor in temperature control performance and poor in standalone active cooling and cannot realize effective thermal utilization in the microsatellite. The magnetic fluid micro-channel thermal control system of the microsatellite standalone comprises an electromagnetic pump, magnetic fluid pipelines, a hot-end magnetic fluid micro-channel and a cold-end magnetic fluid micro-channel. The outlet of the electromagnetic pump is communicated with the inlet of the hot-end magnetic fluid micro-channel through the magnetic fluid pipeline. The inlet of the electromagnetic pump is communicated with the outlet of the cold-end magnetic fluid micro-channel through the magnetic fluid pipeline. The outlet of the hot-end magnetic fluid micro-channel is communicated with the inlet of the cold-end magnetic fluid micro-channel through the magnetic fluid pipeline. The magnetic fluid micro-channel thermal control system of the microsatellite standalone is used for spacecrafts.

Owner:HARBIN INST OF TECH

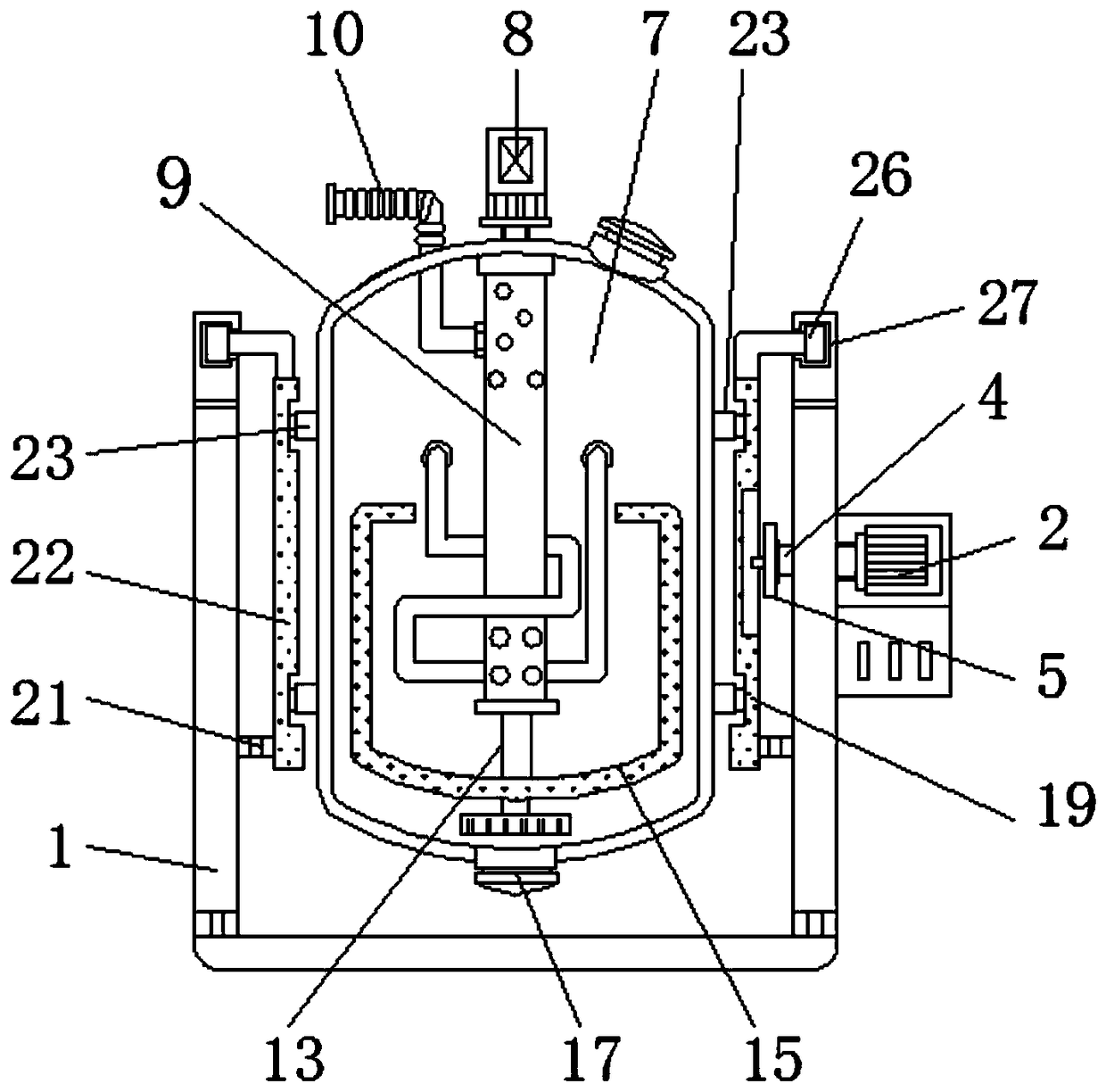

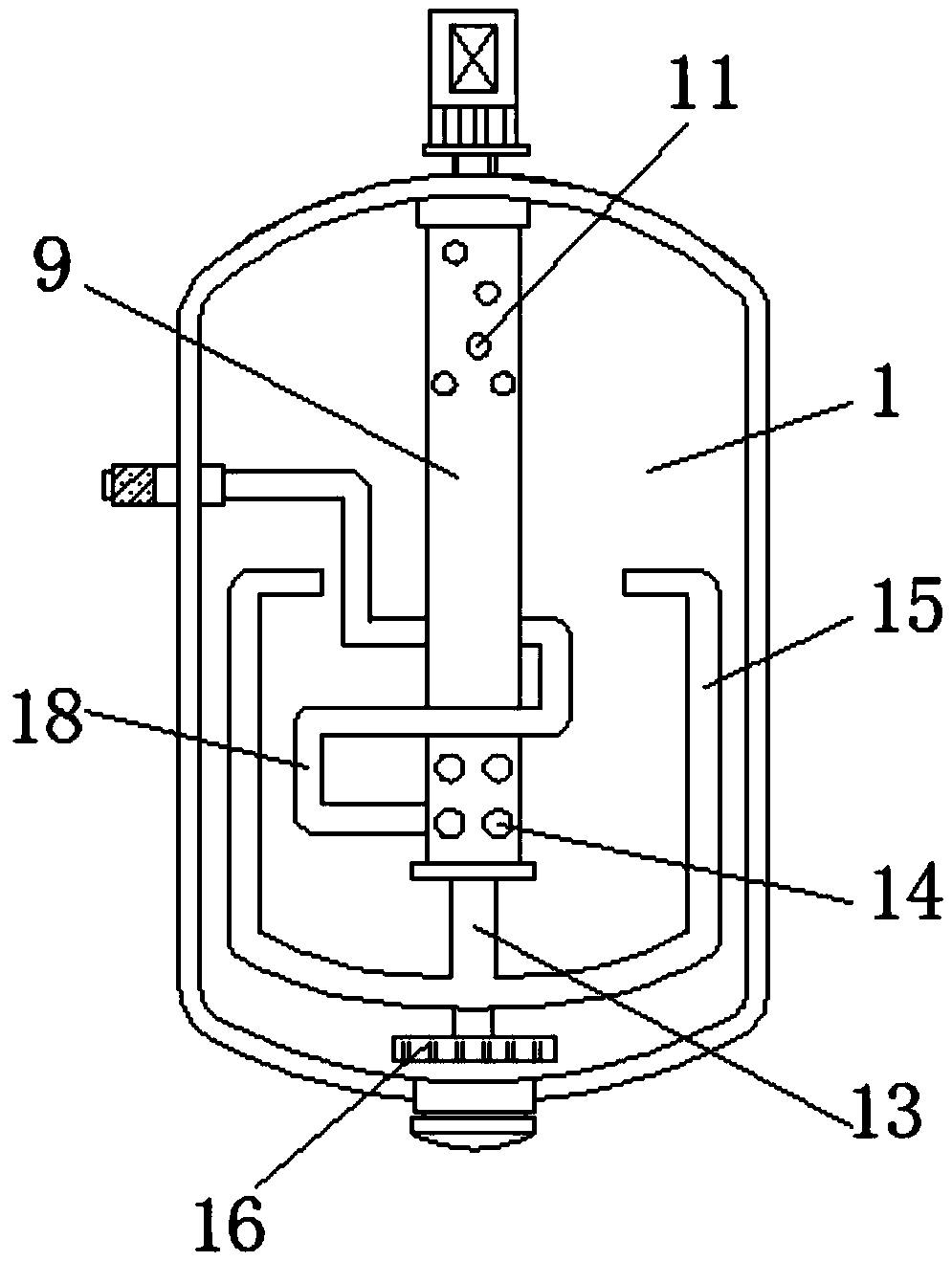

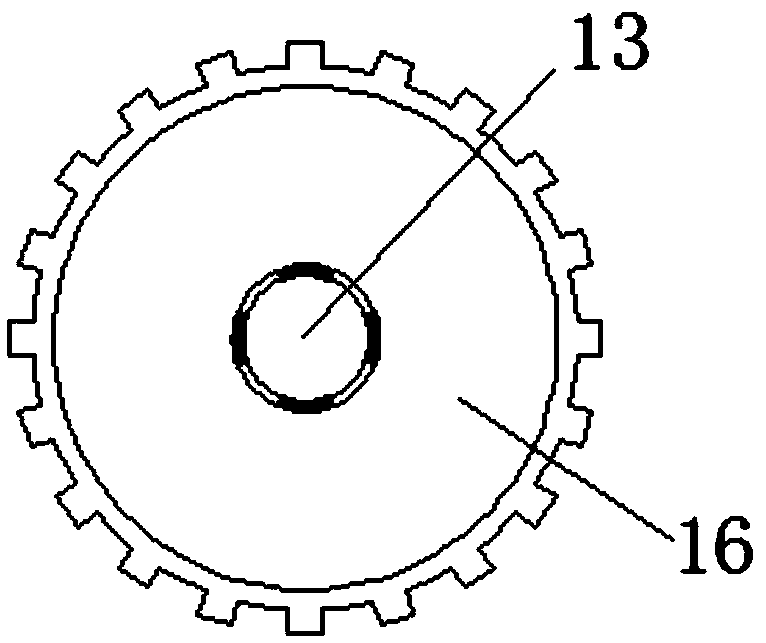

Oscillating type reaction kettle convenient for gas-liquid reaction

InactiveCN108636334AEasy temperature controlImprove mixing efficiencyFeed devicesChemical/physical/physico-chemical moving reactorsGas liquid reactionControl engineering

The present invention discloses an oscillating type reaction kettle convenient for a gas-liquid reaction. The oscillating type reaction kettle comprises a support machine frame, a kettle body, a protective sleeve cylinder and a circulation pipeline. A first motor is arranged on the left side of the support machine frame; besides, the lower side of the first motor is provided with a control switch;the middle place of the lower surface of the kettle body is provided with a material outlet; two pipe mouths of the circulation pipelines are penetrated from the surface of the kettle body; a surfaceof a first rotating arm is provided with a limited sliding groove; the first rotating arm and a second rotating arm are both connected with the support machine frame via outside bearing shafts; fixing sliding blocks and a horizontal sliding rail are connected to each other; and the horizontal sliding rail is located on the surface of the support machine frame. The oscillating type reaction kettleconvenient for the gas-liquid reaction is provided with two motors as a whole; besides, the two motors are arranged vertically; so that when a stirring shaft inside the kettle body is used for stirring, the whole kettle body can be oscillated back and forth on the support machine frame, thus improving the mixing efficiency inside the kettle body.

Owner:ZHEJIANG RONGKAI TECH DEV

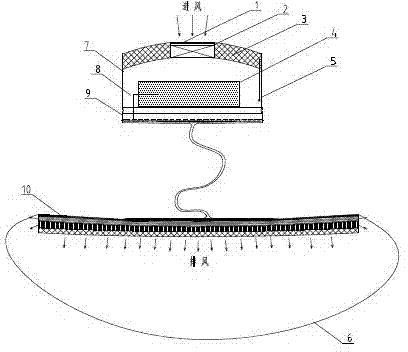

Domestic type portable moxa-moxibustion physiotherapy instrument

ActiveCN104771310AUtilize thermal efficiencyClose contactDevices for heating/cooling reflex pointsTemperature controlSpecial design

The invention discloses a domestic type portable moxa-moxibustion physiotherapy instrument. The physiotherapy instrument is composed of an adjusting air valve, a miniature fan, an electric appliance module, a temperature sensor, a moxa-moxibustion box tank body, composite cloth and the like. By means of the composite cloth in the special design, moxa-moxibustion smoke is filtered, the composite cloth can be in tight contact with different parts of the body, and multiple functions are truly achieved through the physiotherapy instrument. The miniature fan is used for active air supplying, and moxa-moxibustion can be suitable for multiple environments. The temperature sensor is matched with the adjusting air valve, and temperature display and temperature control become easy. The physiotherapy instrument is a breakthrough in the field of moxa-moxibustion convenience and domestication.

Owner:中山市子午智能医疗科技有限公司

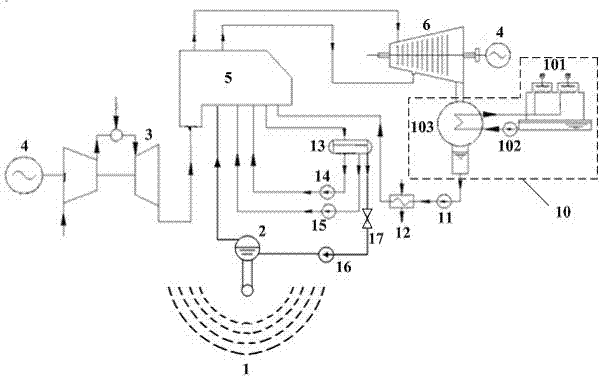

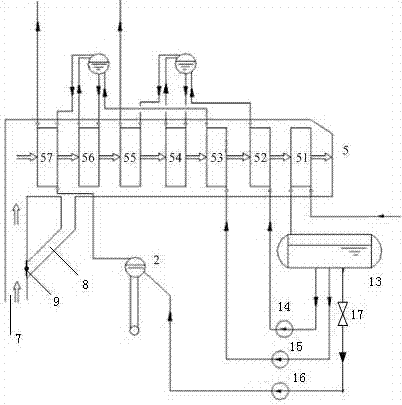

Tower type solar energy-steam combustion gas combined cycle power generation system

ActiveCN102966495AAvoid overheatingSolve temperature control problemsSuperheating controlFrom solar energyFlueSuperheater

The invention relates to a tower type solar energy-steam combustion gas combined cycle power generation system, which comprises a solar energy heat absorber, a combustion gas turbine, a residual heat boiler and a steam turbine. The residual heat boiler is connected with the combustion gas turbine; the solar energy heat absorber is connected with a superheater unit of the residual heat boiler; a fume outlet of the combustion gas turbine is communicated with a main flue of a fire hole section of the residual heat boiler; a bypass pipeline is arranged on the main flue; a fume distributing device is arranged on the bypass pipeline; when solar energy reaches a preset value, the fume distributing device closes the bypass pipeline; and when the solar energy does not reach the preset value, the fume distributing device opens the bypass pipeline. By using the tower type solar energy-steam combustion gas combined cycle power generation system, through arranging the bypass pipeline on the main flue and the fume distributing device, the flexible regulation of a superheated steam temperature is realized; the defect that the power generation by using pure solar energy is unstable is overcome; the power generation efficiency and the power generation quality are improved; the consumption of a fuel can be effectively decreased; and the purposes of energy saving and emission reduction are achieved.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

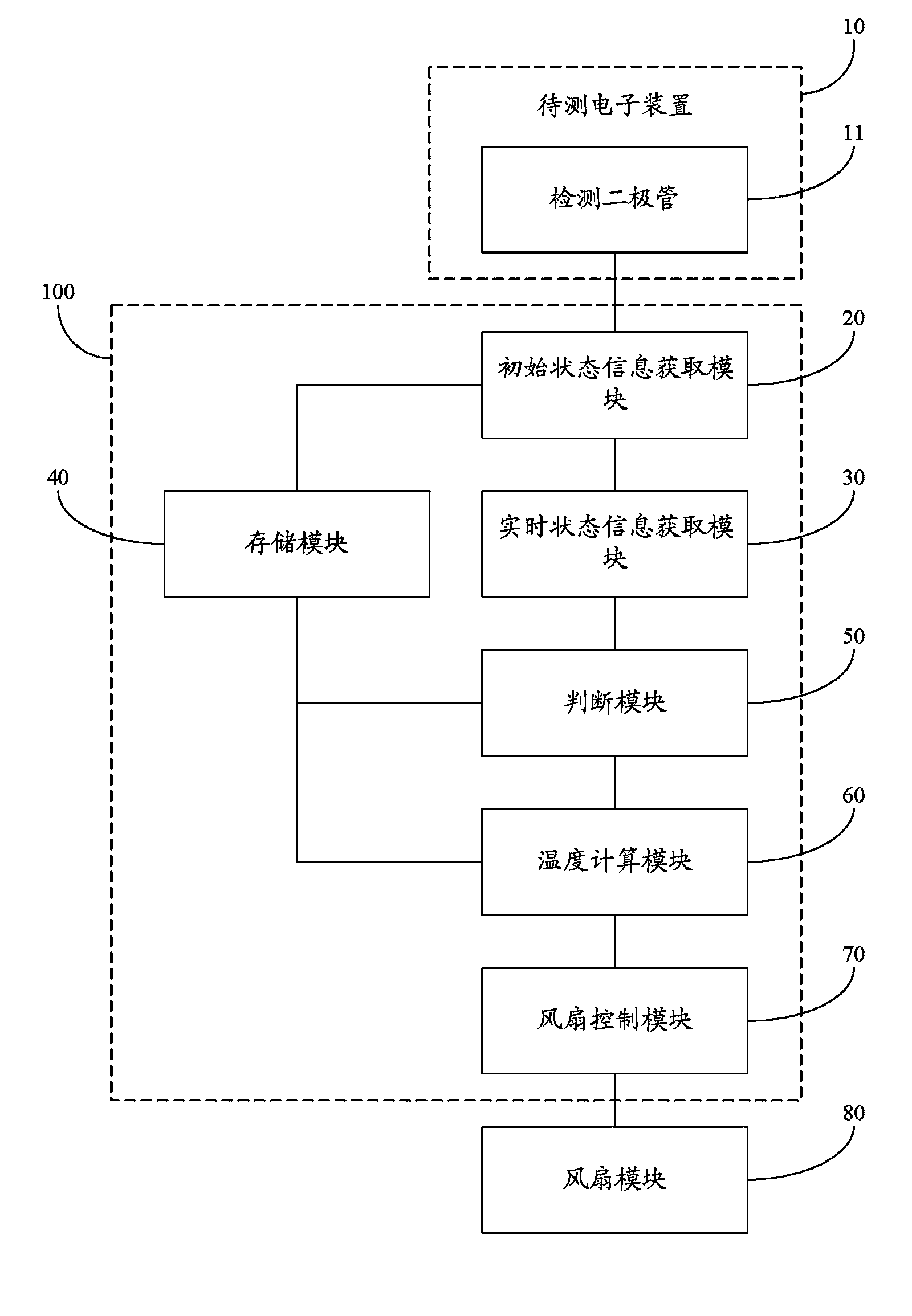

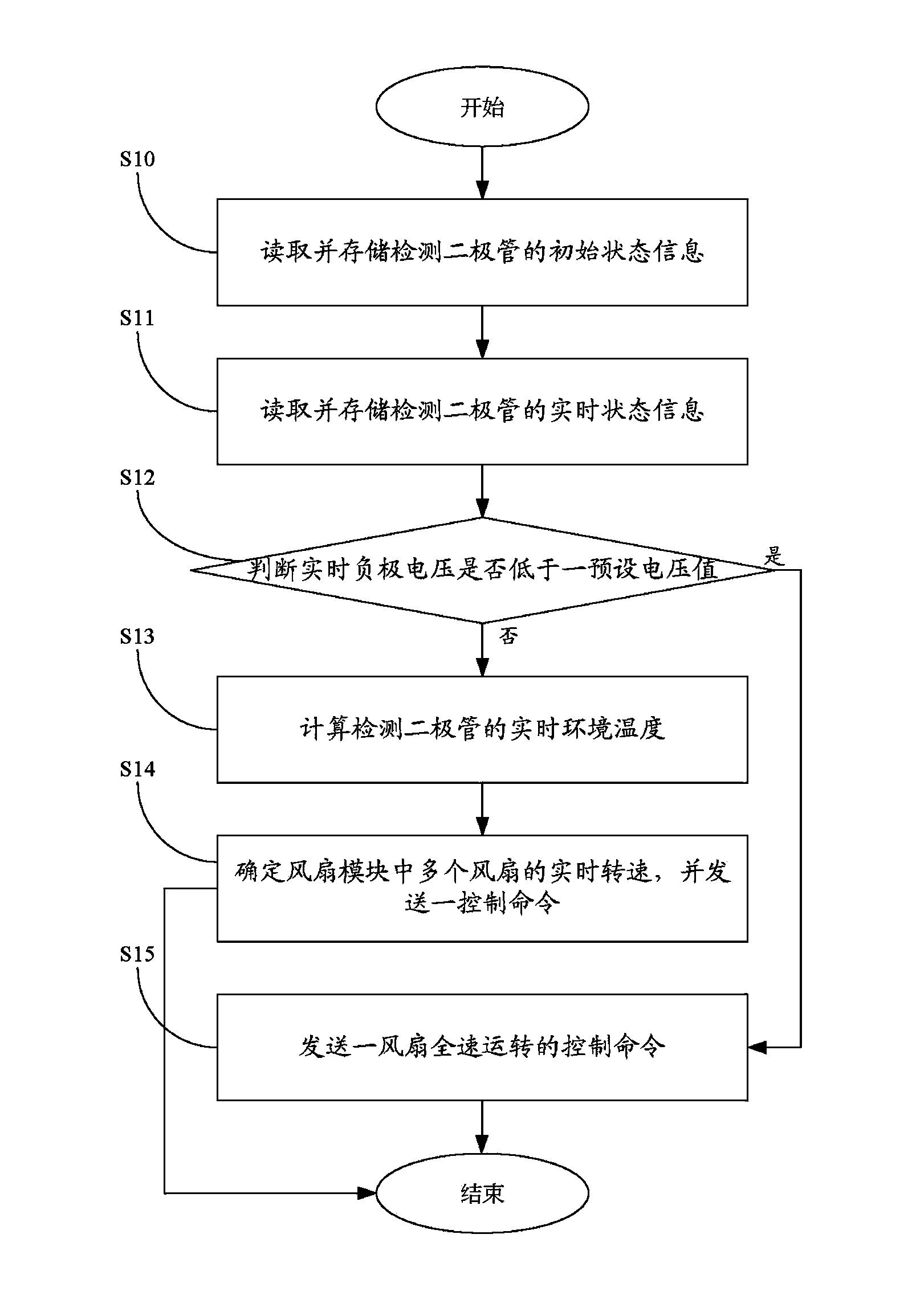

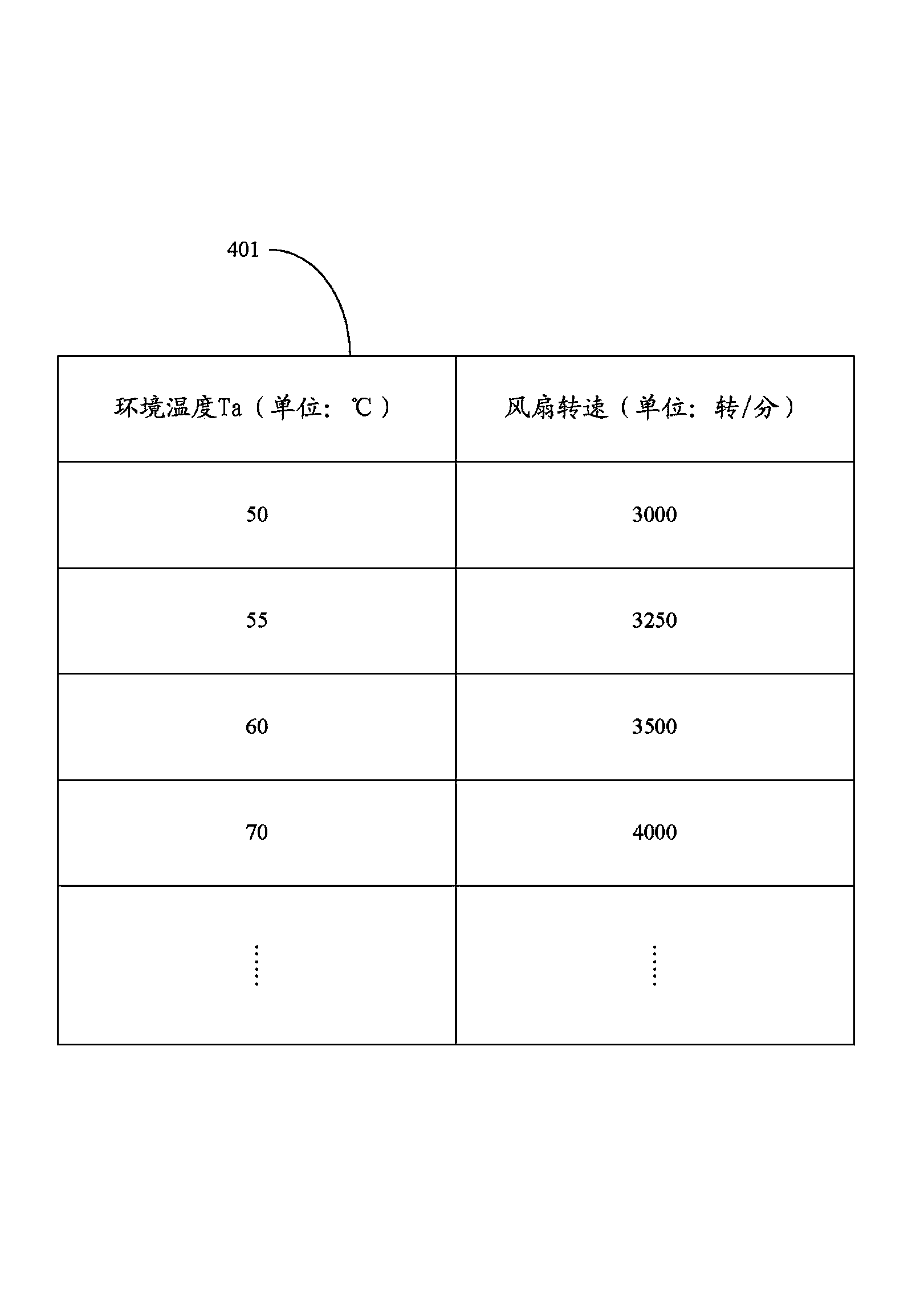

Temperature control device and method for electronic device

InactiveCN104281174ASolve temperature controlLow costTemperatue controlTemperature controlControl system

The invention provides a temperature control device for an electronic device. The temperature control device is connected with the electronic device to be detected and a fan module, the control system comprises an original state information obtaining module, a real-time state information obtaining module, a storage module, a judgment module, a temperature computation module and a fan control module. The electronic device to be detected comprises at least one detection diode. The temperature control device controls the environment temperature of the detection diode by detecting the state information of the diode, and then controls the work temperature of the electronic device to be detected. The problem of control of line temperature is solved, and cost of a large number of special temperature sensors in use is reduced. The invention further provides a temperature control method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

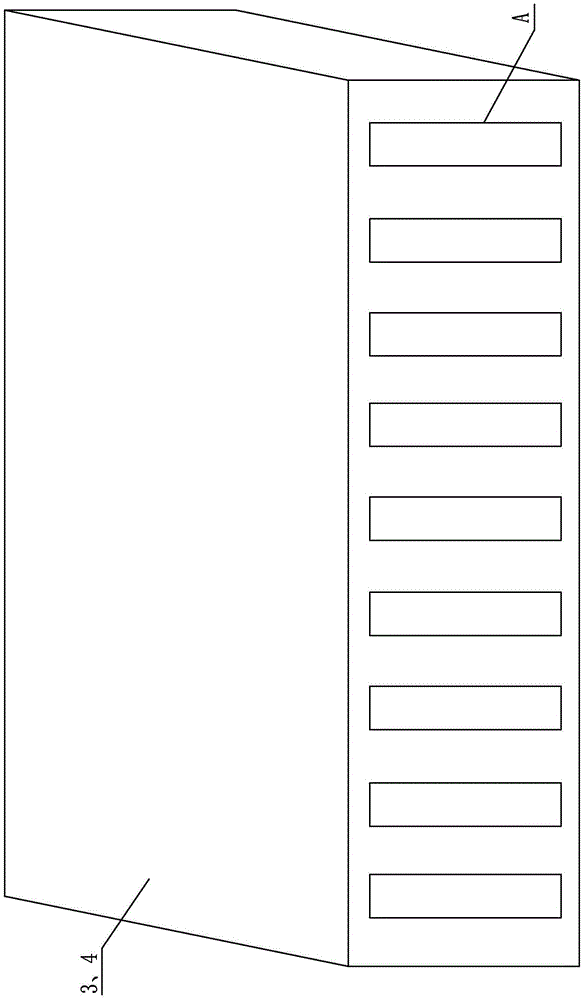

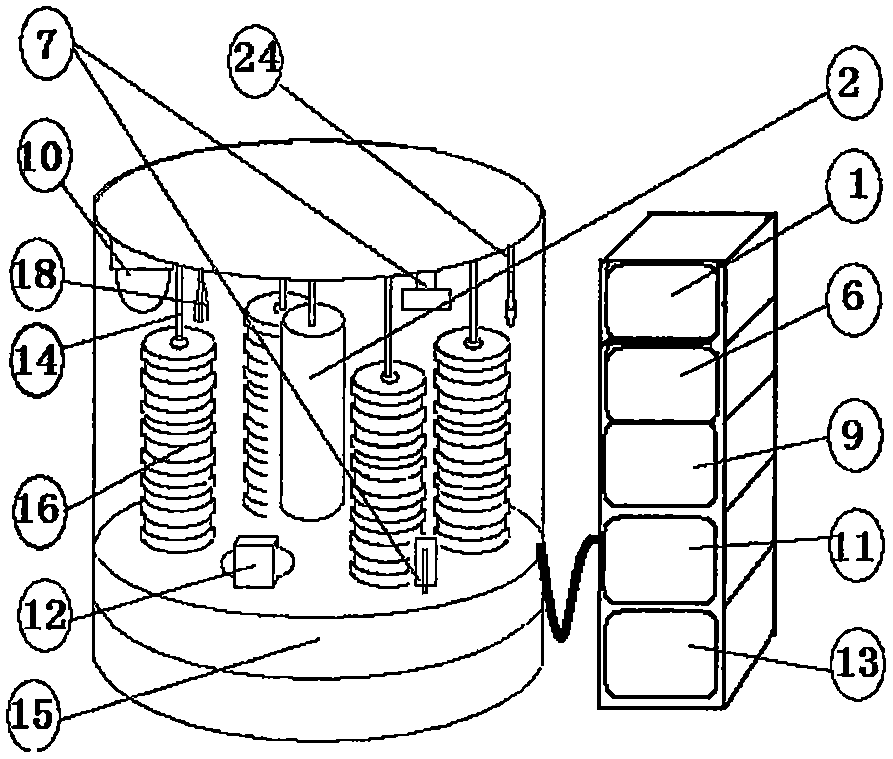

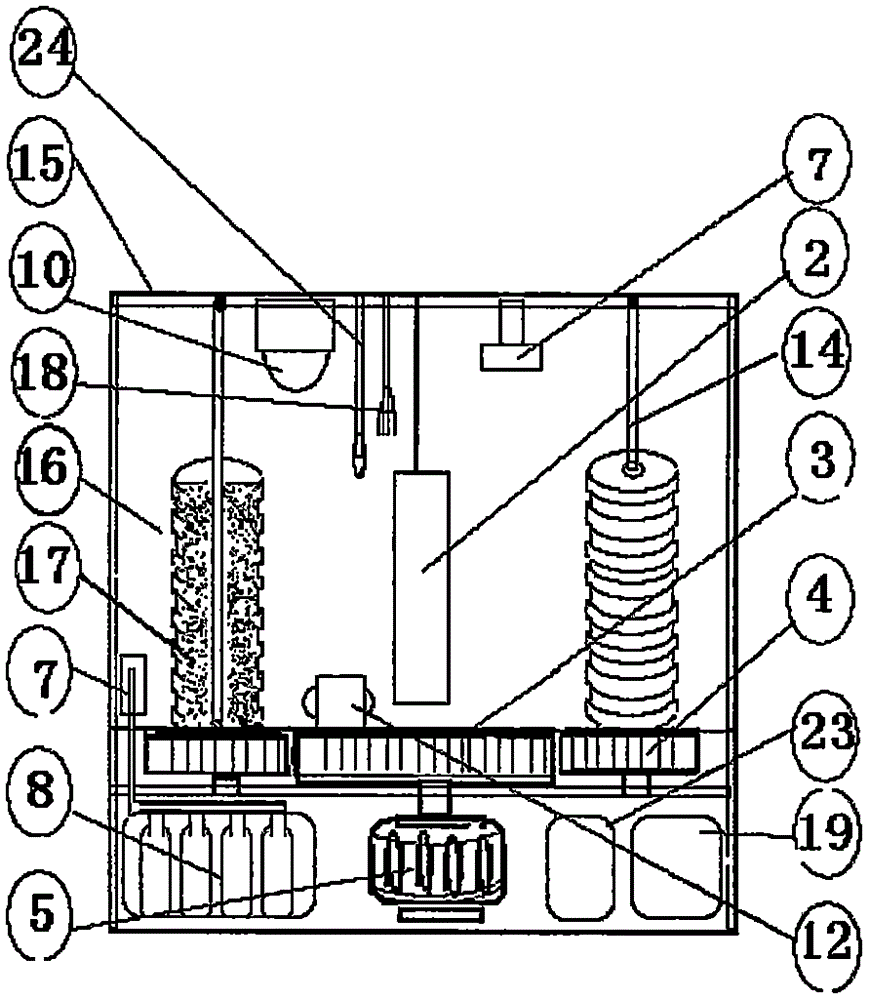

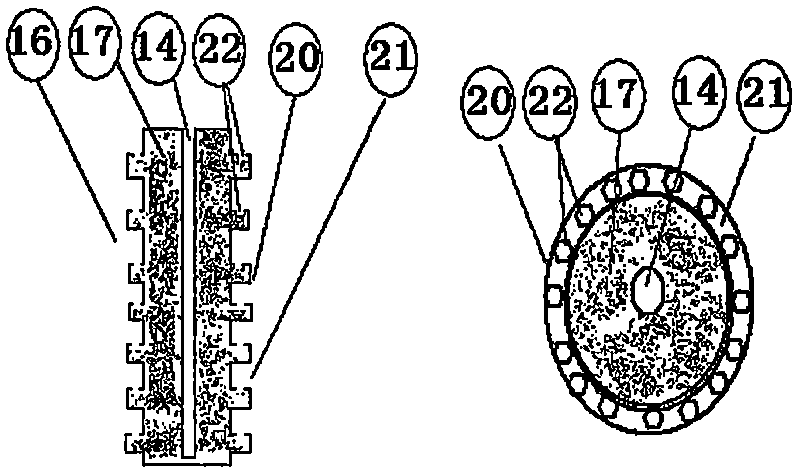

Plant fast-growing device

InactiveCN105454024AHigh speedPromote early maturityAgriculture gas emission reductionCultivating equipmentsGrowth plantPlant factory

A plant fast-growing device is composed of a light regulating system, an air regulating system, a humidity regulating system, a temperature regulating system, a fertilizer regulating system and a planting system. The plant fast-growing device is a plant factory which is designed by means of air regulating, humidity regulating, light regulating, fertilizer regulating, temperature regulating and drip irrigation technologies and can provide an artificial optimized environment for plant growth, shorten the plant growth cycle and increase the yield. The closed plant factory is not limited by the natural environment and has multiple guaranteeing devices suitable for fast growth of plants; for example, an adopted upright cylindrical planting field (16) can rotate on its axis, so that plants planted on the side face of the cylindrical planting field (16) can acquire vertical illumination from an artificial light source (2) conveniently, and the photoperiod characterized in alternation of day and night can be shortened through autorotation, and then plants can become ripe more rapidly. Therefore, the plant factory not only can increase the growth speed of plants, but also can be used for growing plants in a severe environment or in space. The plant fast-growing device belongs to the field of modern agricultural production.

Owner:刘南林

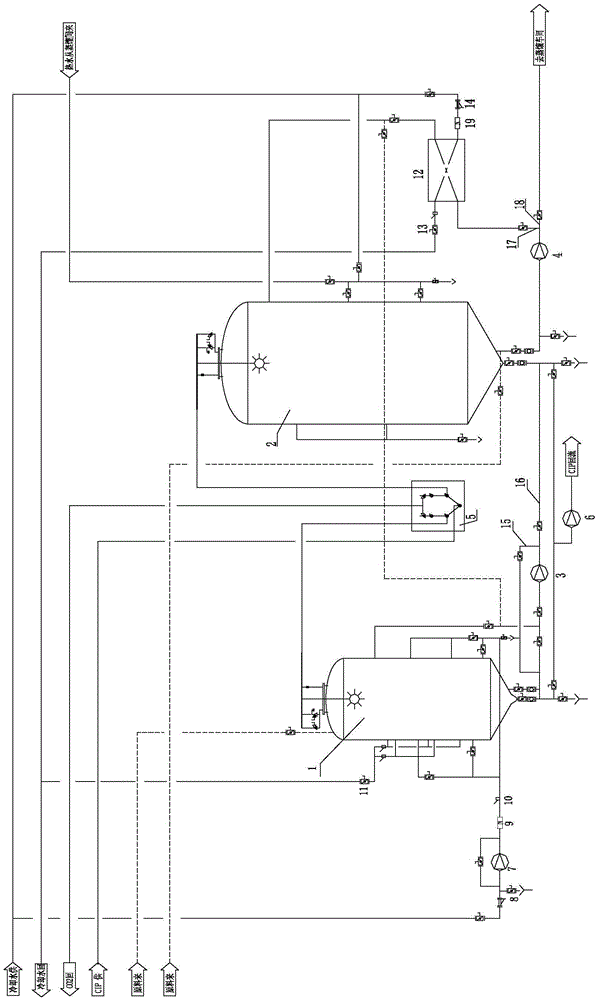

Integrated plant and method for rice wine semi-solid fermentation

ActiveCN105586212AIncrease fermentationGood liquidityAlcoholic beverage preparationAgricultural engineeringSemi solid

The invention discloses an integrated plant for rice wine semi-solid fermentation. The integrated plant comprises a prior-fermentation tank set and a later-fermentation tank set. The prior-fermentation tank set comprises at least one main fermentation tank, a cooling coiler arranged in the main fermentation tank and a circulation feeding pump arranged outside the main fermentation tank. A raw material feed port is formed in the top of the main fermentation tank, a main fermentation circulation discharging pipe is arranged on the upper portion of a body of the main fermentation tank, and a main fermentation tank returning / discharging pipe is arranged on the bottom of the body of the main fermentation tank. The later-fermentation tank set comprises at least one later-fermentation tank, a cooling heat exchanging device arranged outside the later-fermentation tank and a later-fermentation tank mash pump. Rice wine fermentation is divided into a prior fermentation period and a later fermentation period, the problem of semi-solid fermentation is solved through the prior-fermentation tank, the volume of the prior-fermentation tank is about one fourth that of the total fermentation volume, the later-fermentation tank is simplified, the volume of the later-fermentation tank is about three fourths that of the total fermentation volume, the prior-fermentation tank needing cooling for temperature reducing and the later-fermentation tank needing temperature keeping are arranged in a separated mode, the feeding difficulty of semi-solid materials is lowered, the equipment investment and the workshop investment are reduced, the temperature controlling effect is improved, and the energy consumption is reduced.

Owner:CHINA GDE ENG

Heating appliance heating element and preparation method thereof

ActiveCN111528529AEasy to achieve corrosion damageAvoid corrosion damageTobaccoTemperature controlLaser engraving

The invention belongs to the technical field of tobacco heating appliances, and relates to a heating appliance heating element and a preparation method thereof. The heating element comprises a metal heating sheet, and the heating circuit of the heating sheet is formed by laser engraving. According to the metal heating element, ferro-nickel alloy with a high resistance temperature coefficient is used as a heating sheet, and then an insulating layer is sintered on the surface of the heating sheet. The heating element has the advantages of uniform heating, stable resistance, convenience in temperature control and the like; and the arranged insulating layer can protect the heating piece and can prevent the heating piece from being corroded and damaged, the insulating base material proportion is optimized, after the sintering process is combined, the heating piece can be well matched with the ferro-nickel alloy, the product performance is improved, and the advantages of being high in strength and long in service life are achieved.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

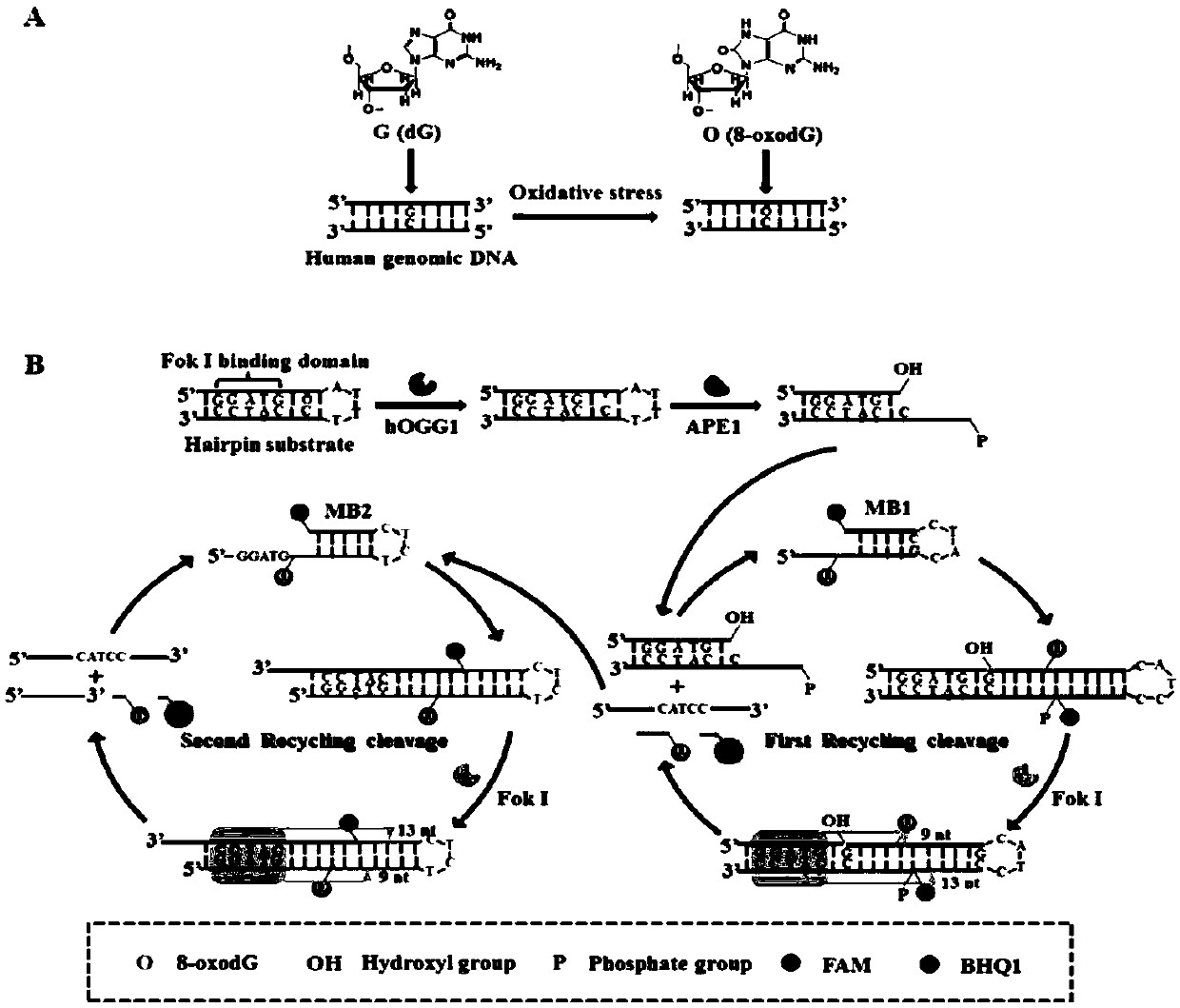

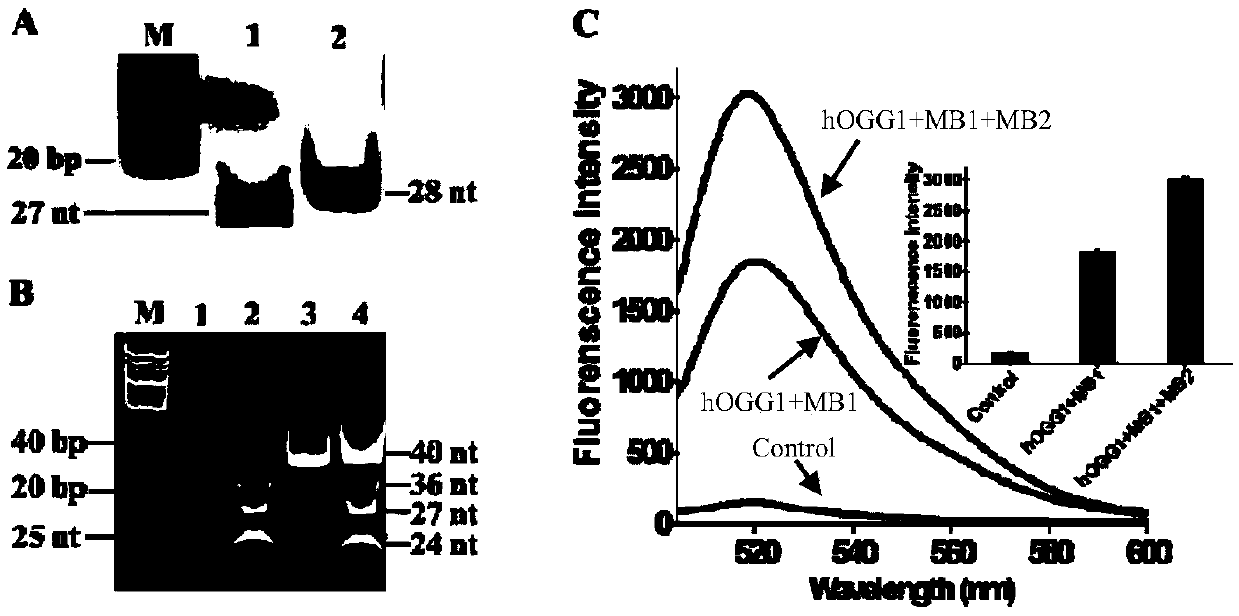

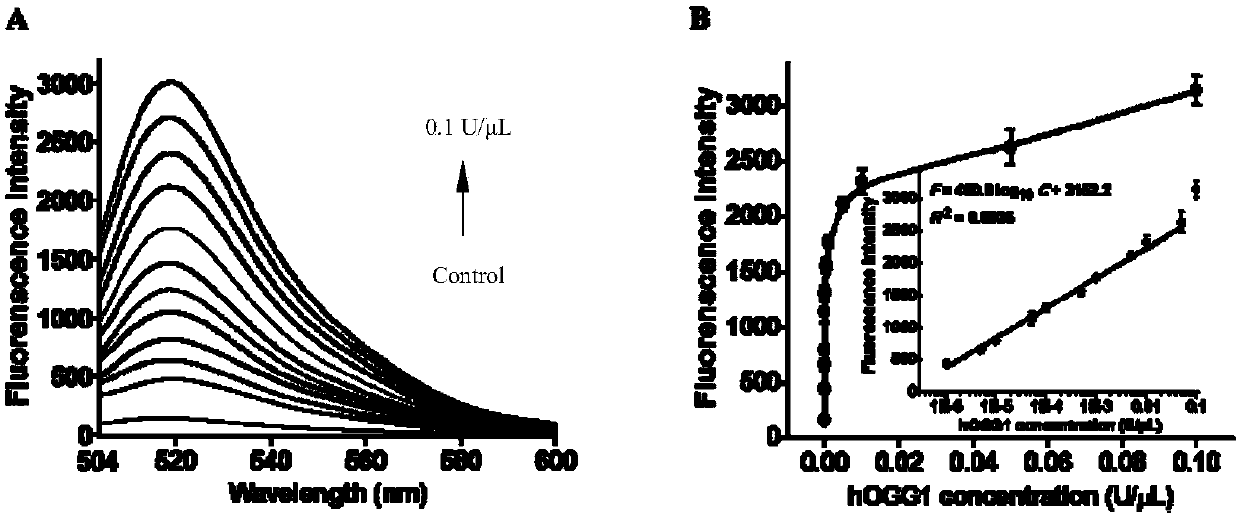

Method for detecting human 8-hydroxyl guanine DNA glycosylase activity through circular signal amplification based on autocatalytic replication mediation

InactiveCN109628556AHigh sensitivityHigh sensitivity detectionMicrobiological testing/measurementBiological material analysisSense strandSignal amplification

The invention discloses a method for detecting human 8-hydroxyl guanine DNA glycosylase activity through circular signal amplification based on autocatalytic replication mediation. A biological sensorcomprises a hairpin substrate, MB1, MB2, Fok I and APE1. A damaged guanine and palindromic sequence is designed in a sense strand or an antisense strand of the hairpin substrate, a damaged guanine islocated between the palindromic sequence and a ring, and a cytosine matched with the damaged guanine is designed at the other strand; MB1 is of a stem ring structure with the protruding 5' end, the palindromic sequence is designed at the ring of MB1, a sequence complementary for the ring of the hairpin substrate is designed on the 5'-tail end DNA sequence protruding from MB1, and fluorescent molecules and quenching molecules are modified on the MB1 and the MB2. The method can achieve easy, convenient, high-sensitive and high-specific detection of hOGG1.

Owner:SHANDONG NORMAL UNIV

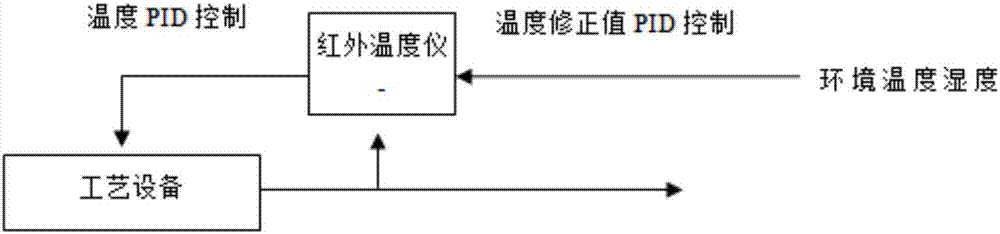

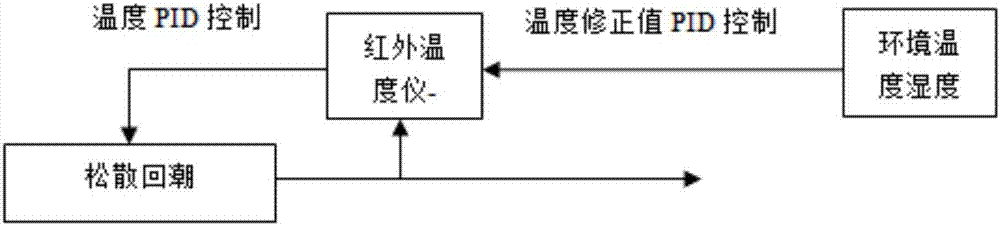

Double-thermometer linkage control technology

InactiveCN106942776AControl operationImproved temperature control stabilityTobacco preparationTobacco treatmentTemperature controlAgricultural engineering

The invention discloses a dual-thermometer linkage control technology, which detects the ambient temperature and humidity, forms a mathematical correction model based on the influence of the ambient temperature and humidity on the material temperature detected by the online infrared temperature instrument, and corrects the infrared thermometer in real time according to the mathematical correction model Test results. The beneficial effects of the present invention are: the present invention can be applied in the process of temperature control in the tobacco industry thread making line or threshing and re-baking line, including shredded leaves, shredded stem drying, re-roasting of leaves, moistening and re-moisturizing of leaves, and adding materials to moistening leaves. In this link, it can significantly improve the stability of temperature control. By improving the stability of temperature control, the quality stability of processed materials can be improved, and the level of cigarette production control can be improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

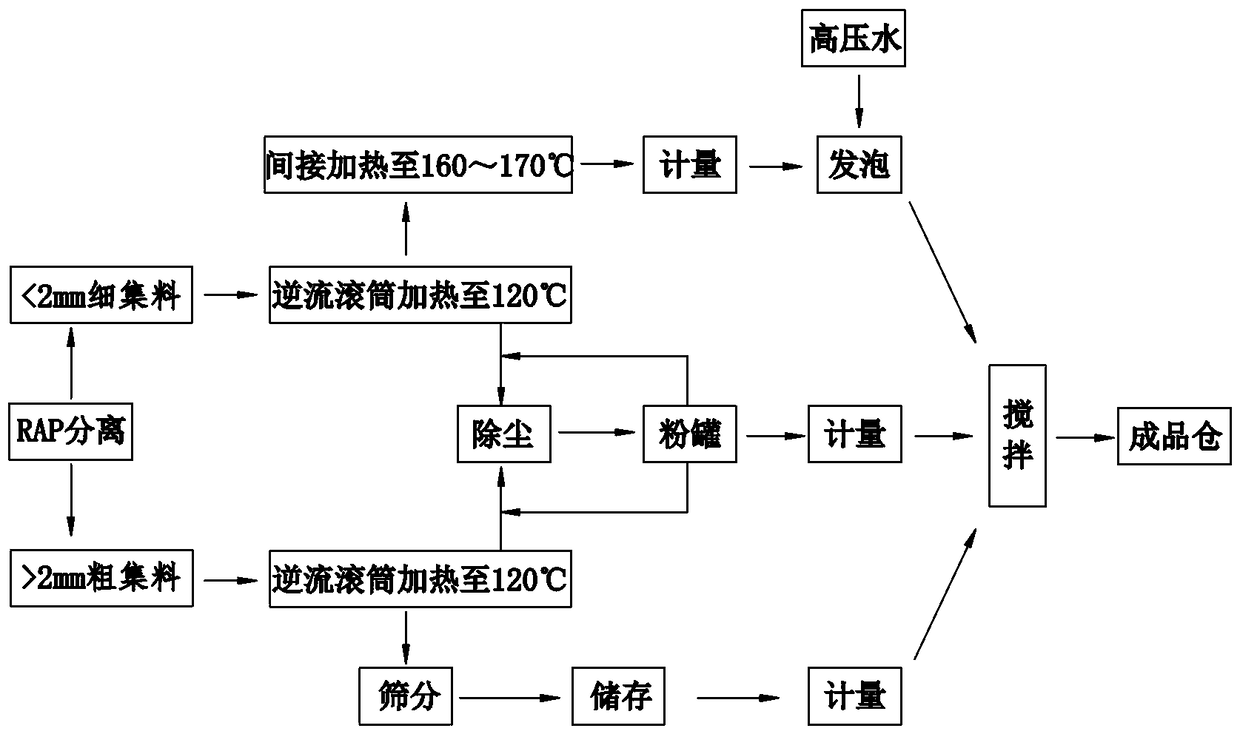

Hot mix plant recycling method capable of realizing RAP full-recycling

ActiveCN108411738AControl agingSolve temperature controlClimate change adaptationRoads maintainenceEmulsionAsphalt

A hot mix plant recycling method capable of realizing RAP full-recycling comprises the following steps of (1) grading RAP into fine aggregates with particle sizes of less than 2 mm and coarse aggregates with particle sizes of more than 2 mm; (2) heating the fine aggregates to 160-170 degrees centigrade by using a two-stage heating mode so that the fine aggregates are melted into an emulsion shape,and directly heating the coarse aggregates to 120 degrees centigrade; (3) after screening, storing and metering the heated coarse aggregates, putting the screened, stored and metered coarse aggregates into a mixing main machine together with a filling material; and (4) enabling the fine aggregates, which are heated to 160-170 degrees centigrade, to be produced into foamed asphalt emulsion by using a foaming device, and spraying the foamed asphalt emulsion into the mixing main machine according to grading gradation parameters to be mixed together with the coarse aggregates so as to produce a warm mix full-recycled asphalt mixture with temperature of not exceeding 140 degrees centigrade. The hot mix plant recycling method capable of realizing the RAP full-recycling has the advantages that low temperature mixing can be realized, the coarse aggregates are uneasy to adhere, and the RAP full-recycling is realized.

Owner:FUJIAN TIETUO MACHINERY

Sand-free automatic temperature control incubation technique for soft-shelled turtles

InactiveCN102578038AImprove hatch qualityImprove hatchabilityAnimal husbandryTemperature controlUv disinfection

The invention discloses a sand-free automatic temperature control incubation technique for soft-shelled turtles, which includes the processes: firstly, building an incubation room; secondly, collecting and selecting eggs; thirdly, performing ultraviolet sterilization; fourthly, placing the eggs in the incubation room; fifthly, allowing the eggs to incubate at constant temperature; and sixthly, collecting fry. The sand-free automatic temperature control incubation technique for soft-shelled turtles is high in safety, highly operably, high in fry incubation quality, high in incubating rate, effective and well worthy of application.

Owner:王高宽

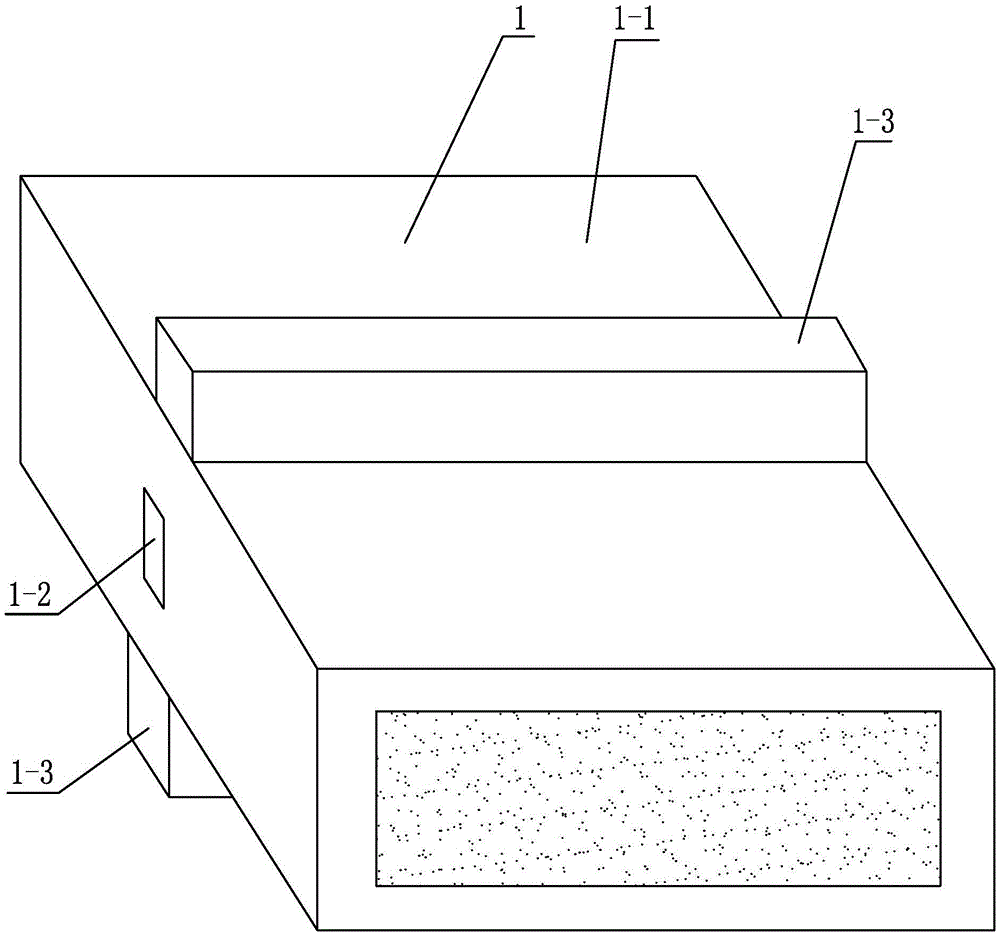

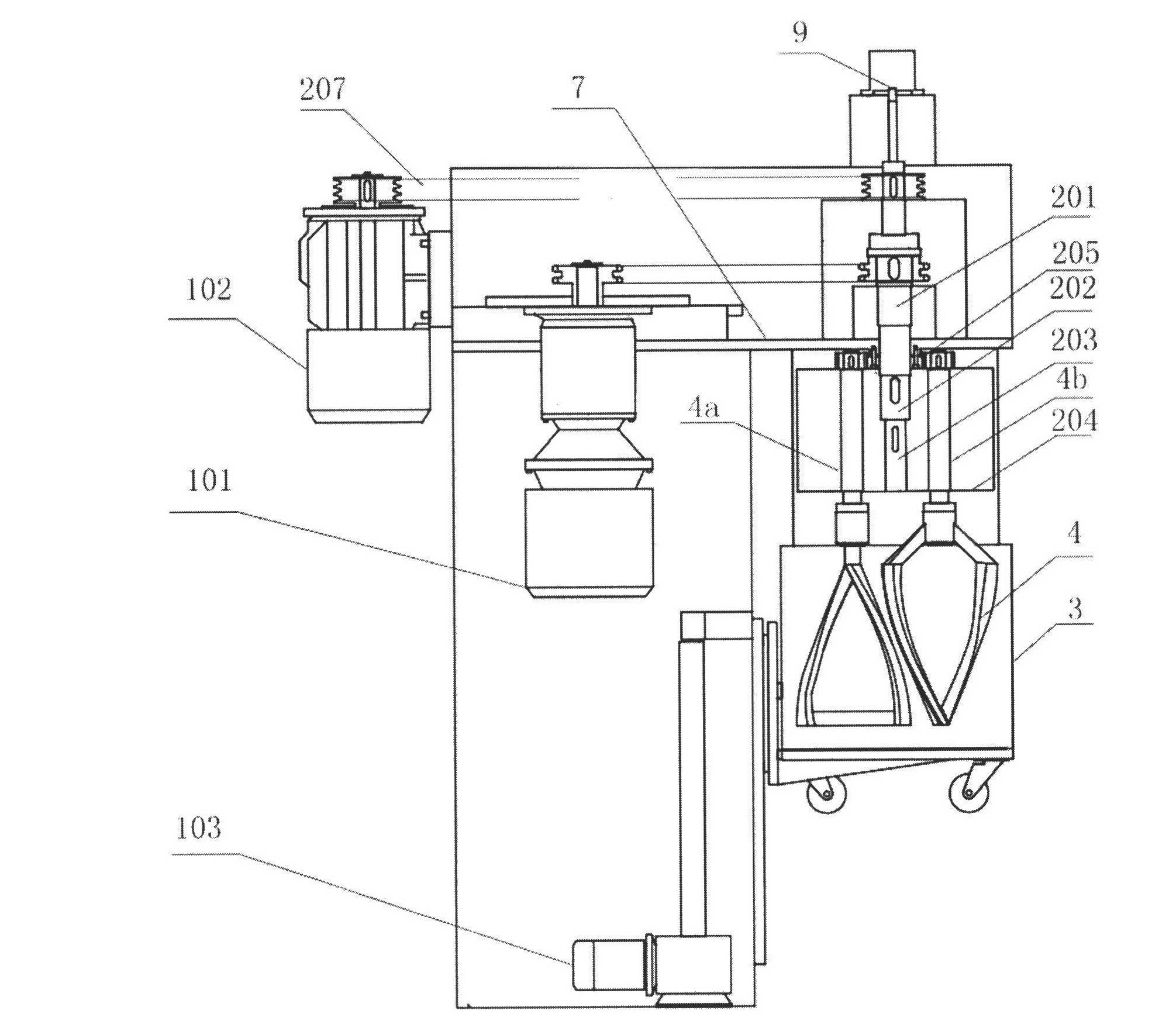

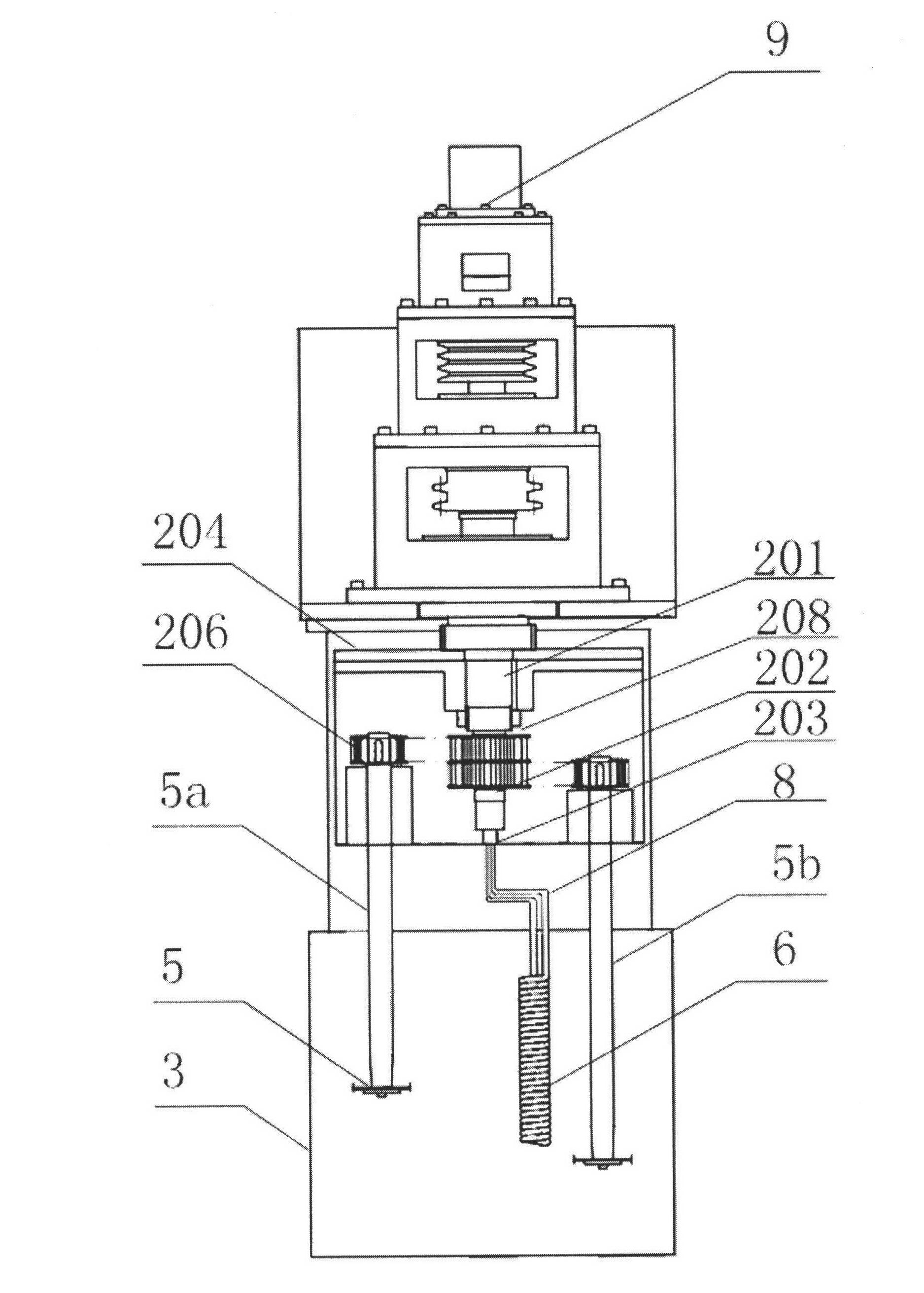

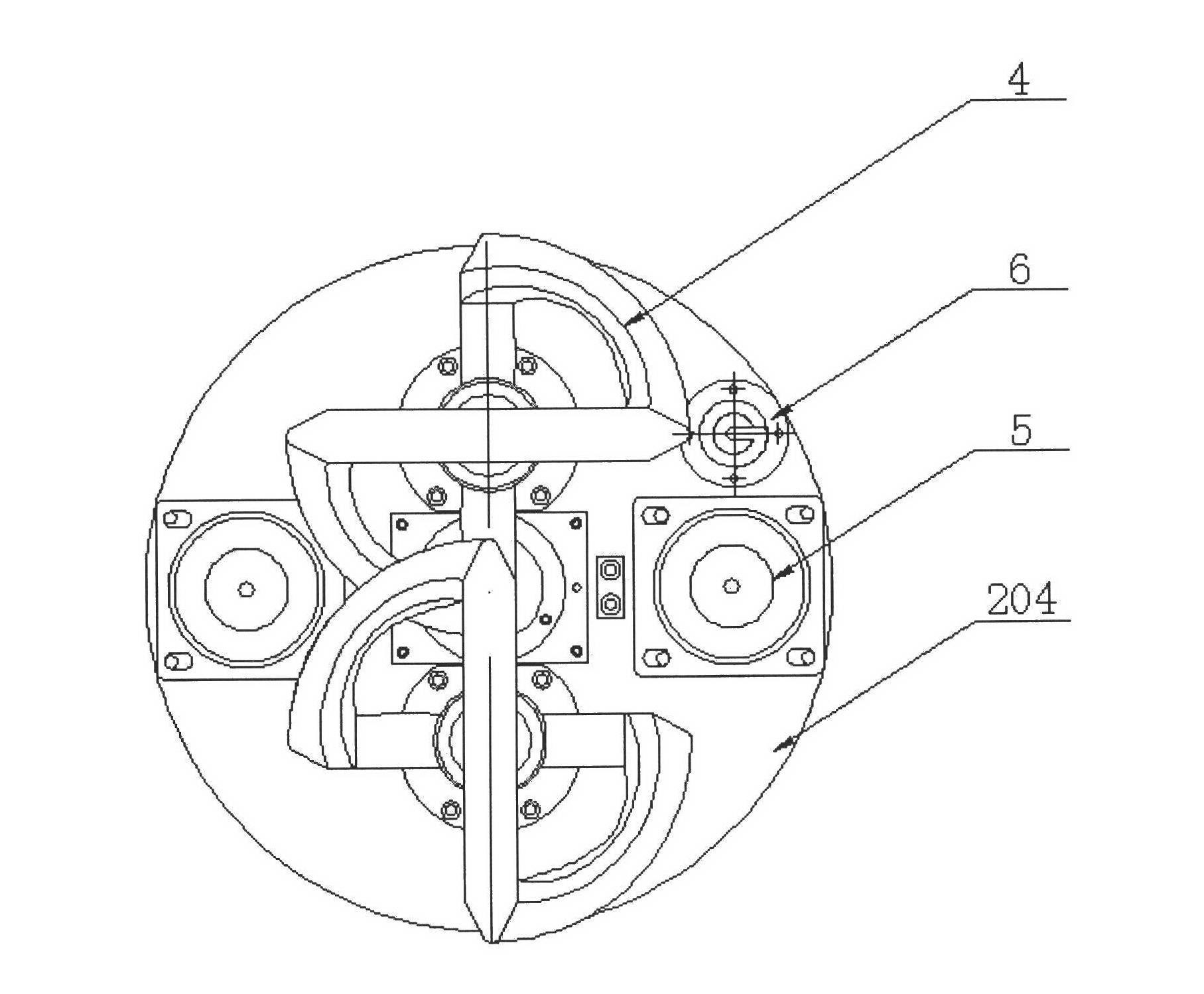

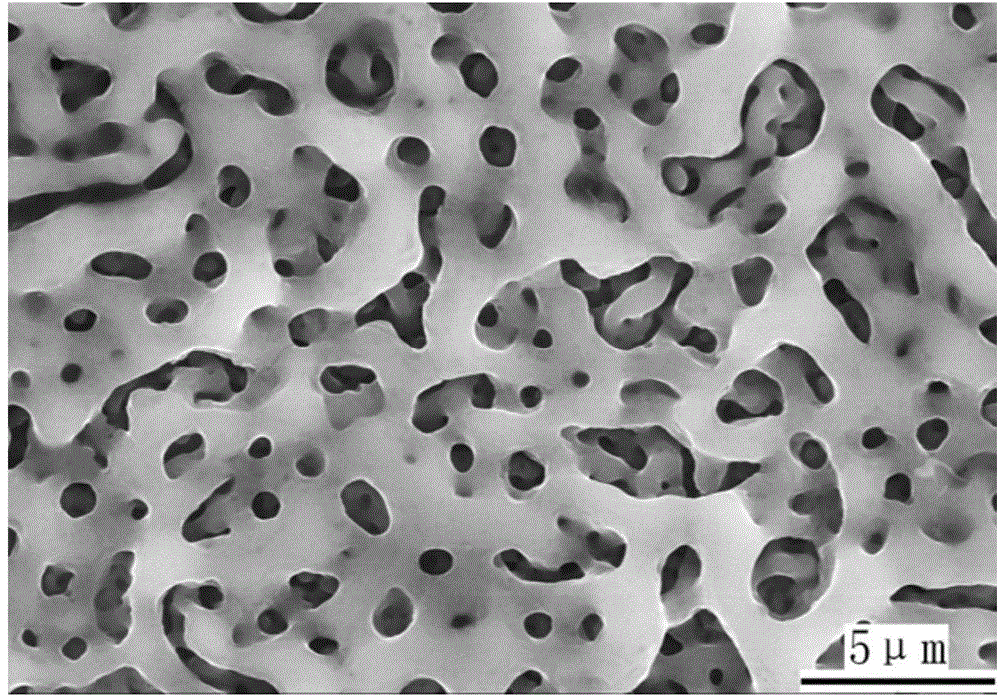

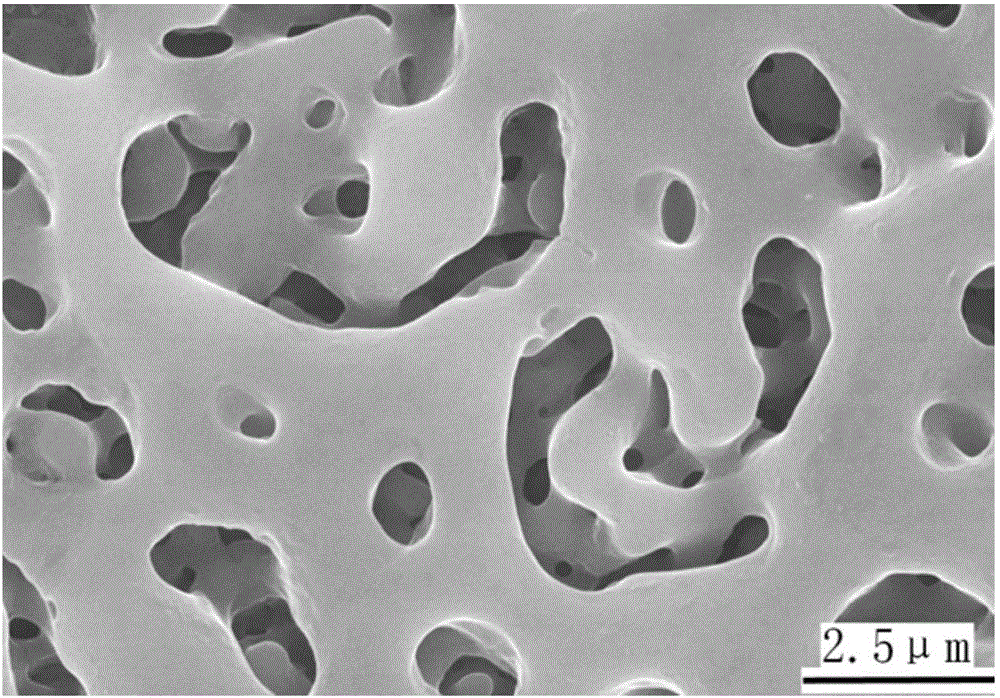

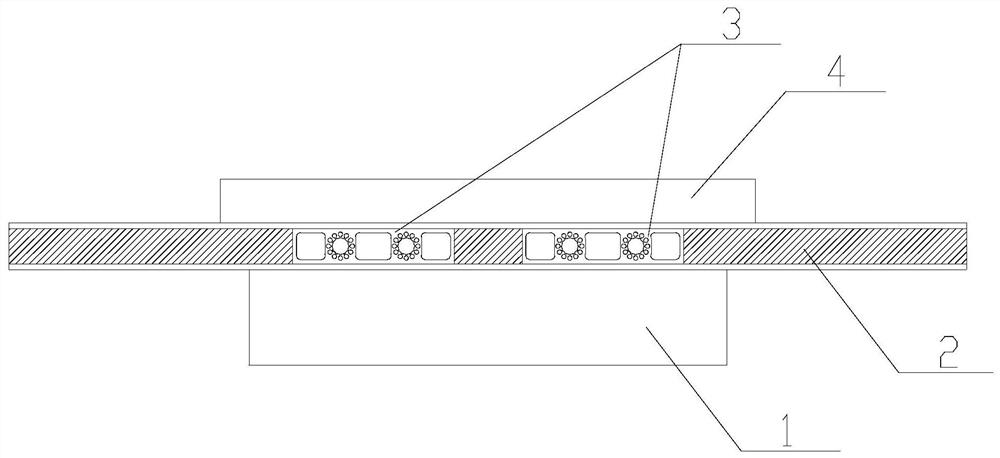

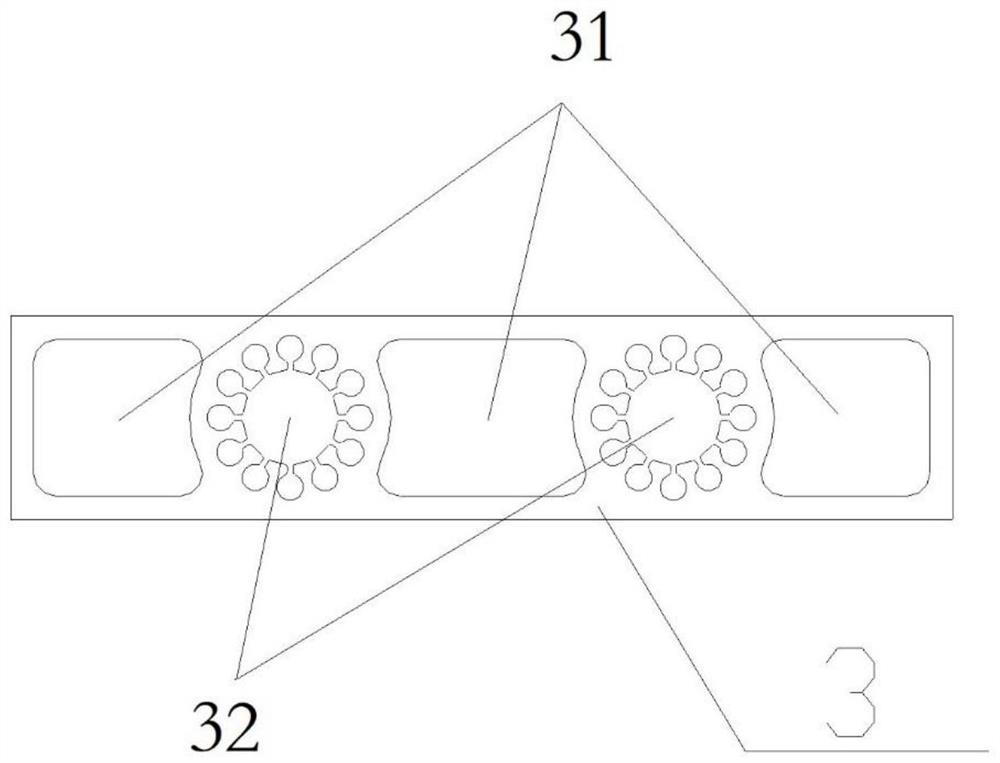

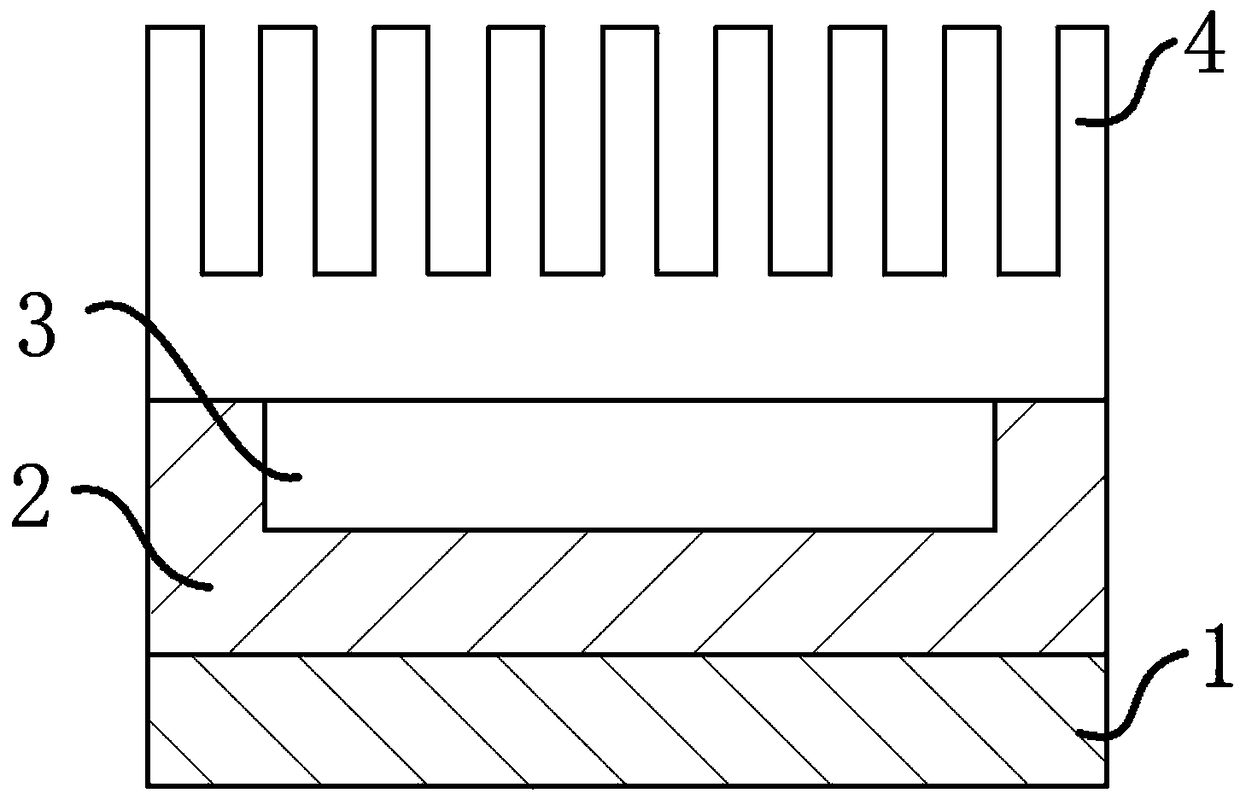

Device and method for preparing diffusion layer slurry of proton exchange membrane fuel cell

The invention relates to a device and method for preparing diffusion layer slurry of a proton exchange membrane fuel cell. The device comprises a power device, a transmission device, a mixing tank, a low-speed mixer, a high-speed disperser, internal cooling modules and the like, wherein the transmission device comprises a hollow low-speed transmission main shaft and a high-speed transmission shaft which is arranged in the hollow main shaft; the transmission device is arranged on the transmission shaft; the low-speed mixer, the high-speed disperser and the internal cooling modules are arranged on a rotary frame and rotate together along with the rotary frame; and meanwhile, the high-speed disperser is driven to rotate at high speed by the high-speed transmission shaft connected to the transmission device; and a circulating water pipeline is introduced by a pipeline shaft arranged in the hollow high-speed transmission shaft to realize an internal cooling function. The device provided by the invention has the internal cooling function during the slurry preparation process for the first time, and thereby, the demulsification problem caused by internal temperature rise in the high-viscosity slurry preparation is solved, and moreover, premixing treatment and high-speed dispersion are integrated into the same device, so that the device has the advantages of high handling capacity, wide applicable viscosity range, high efficiency, low cost, easiness in operation and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

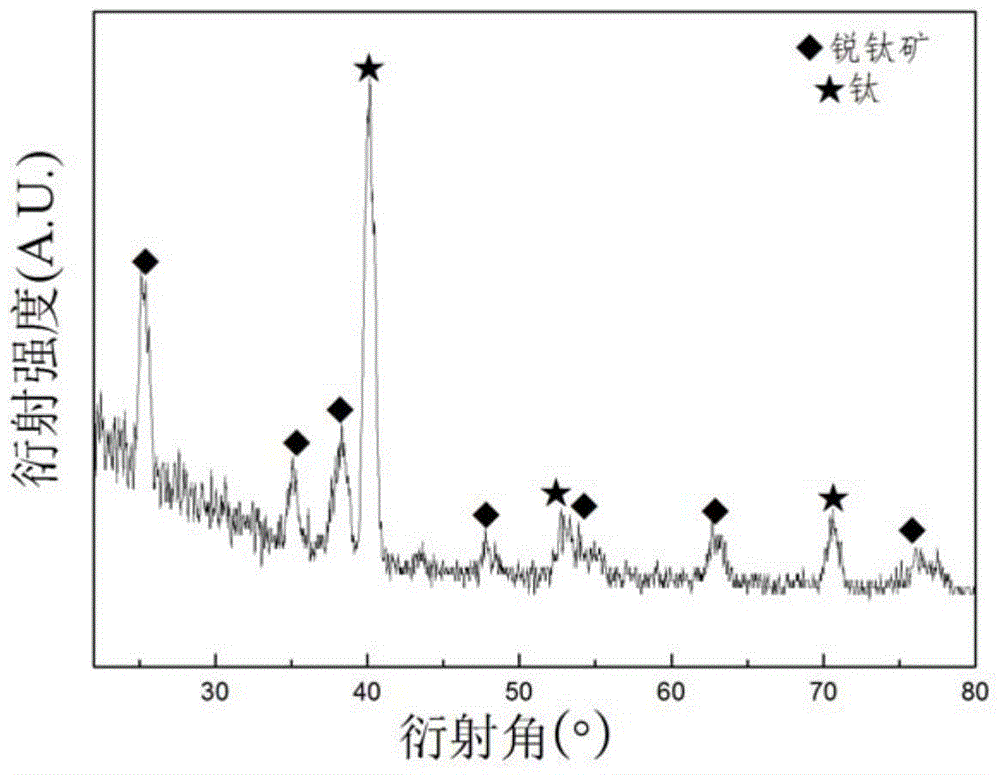

Method for preparing multilevel-hole structure with titanium surface containing calcium and phosphorus

InactiveCN104694992AAvoid violent discharge phenomenonSolve temperature controlSurface reaction electrolytic coatingMicro arc oxidationTitanium surface

The invention discloses a method for preparing a multilevel-hole structure with a titanium surface containing calcium and phosphorus. By means of the method, the purpose of conducting modification on the structure and ingredients of a titanium substrate at the same time is achieved, and a titanium implant body material with good comprehensive performance is obtained. A polished, cleaned and dried medical pure titanium sheet serves as the anode to be placed in a NaH2PO4.2H2O electrolyte, and a platinum electrode serves as the cathode to conduct micro-arc oxidation processing; after processing is conducted, the titanium sheet is taken out of the NaH2PO4.2H2O electrolyte and then serves as the anode to be placed into a (CH3COO)2Ca.H2O electrolyte, the platinum electrode serves as the cathode, and the micro-arc oxidation processing is conducted again; the multilevel-hole structure containing the calcium and the phosphorus is obtained on the titanium surface. According to the method, the multilevel-hole structure with holes of different sizes is prepared on the titanium surface through a step-by-step micro-arc oxidation technology, so that space is provided for deep growth of bone cells, meanwhile the calcium element and the phosphorus element in the electrolyte are led into anatase TiO2 at the same time, and the titanium implant body material is made to have good biological activity and biocompatibility.

Owner:TIANJIN UNIV OF COMMERCE

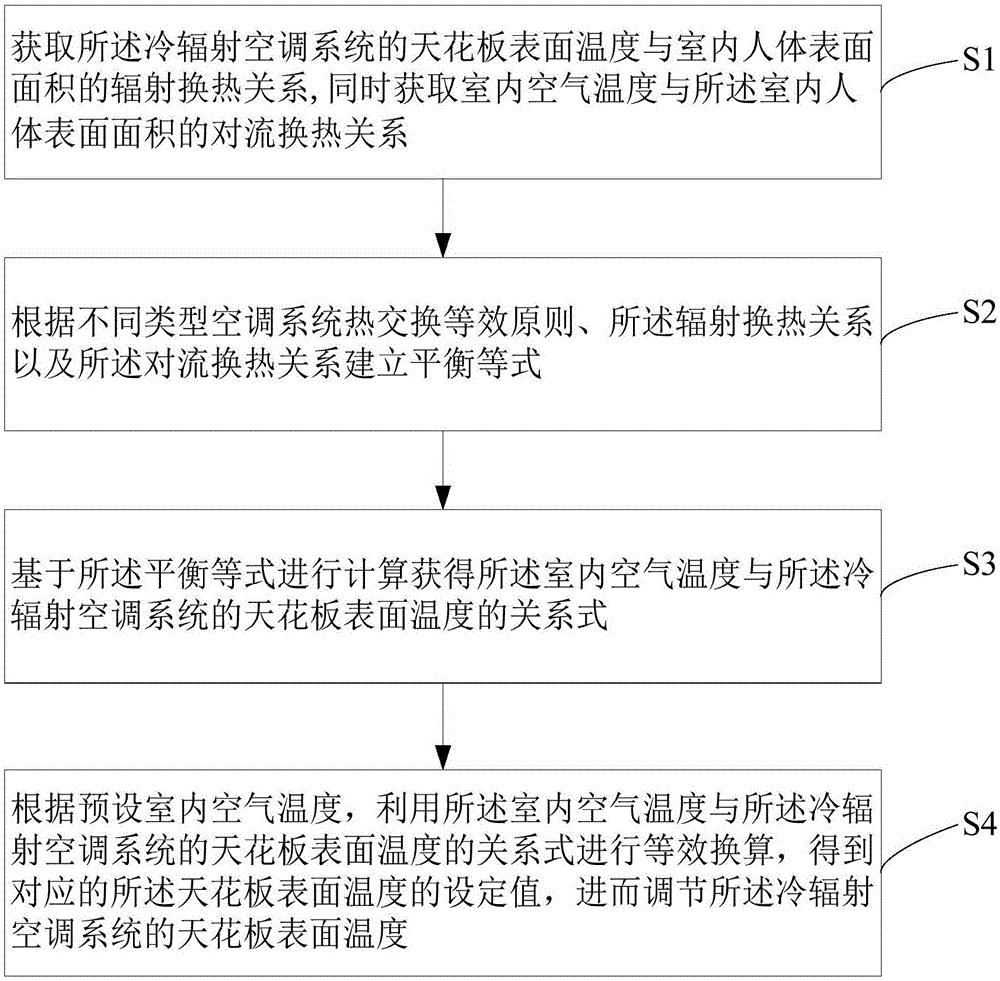

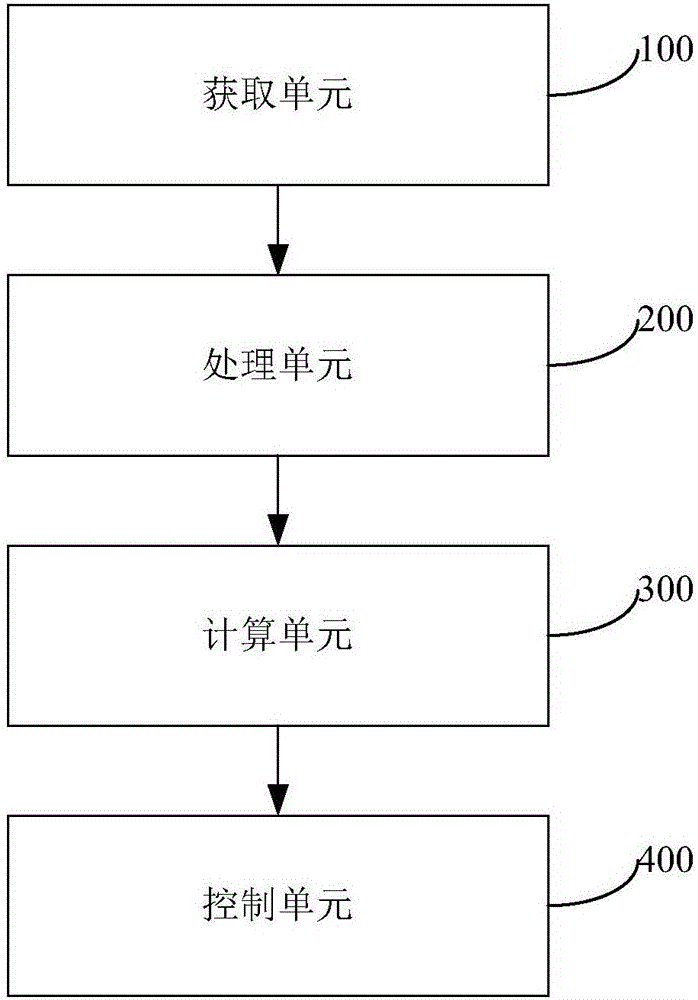

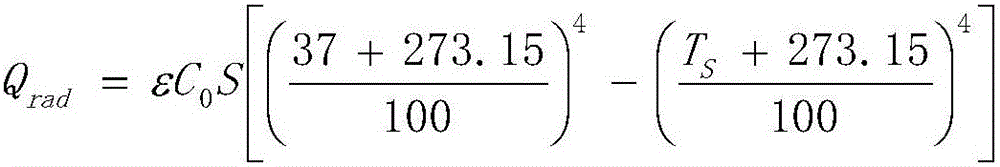

Temperature control method and device for cold radiation air conditioner system

ActiveCN106765869ASolve temperature controlImprove experienceMechanical apparatusSpace heating and ventilation safety systemsTemperature controlEngineering

The invention relates to a temperature control method and device for a cold radiation air conditioner system. The method includes the following steps that a radiation heat exchange relation between the ceiling surface temperature of the cold radiation air conditioner system and the indoor human body surface area is obtained, and meanwhile a convex heat exchange relation between the indoor air temperature and the indoor human body surface area is obtained; a balance equation is established according to the heat exchange equivalence principle, the radiation heat exchange relation and the convex heat exchange relation of different types of air conditioner systems; calculation is conducted according to the balance equation, and a relation between the indoor air temperature and the ceiling surface temperature of the cold radiation air conditioner system is obtained; equivalent conversion is conducted by means of the relation between the indoor air temperature and the ceiling surface temperature of the cold radiation air conditioner system according to the preset indoor air temperature, a set value of the corresponding ceiling surface temperature is obtained, and the ceiling surface temperature of the cold radiation air conditioner system is adjusted. According to the temperature control method and device for the cold radiation air conditioner system, the problem of control over the temperature in the practical running and operation process of a cold radiation air conditioner is solved, and a good experience of a user is ensured while energy is saved.

Owner:SHENZHEN DAS INTELLITECH CO LTD

Nitrogen pressure stabilizing experiment device with controllable outlet fluid temperature in moving condition

ActiveCN106652726APrecise temperature controlSmall fluctuationEducational modelsElectricityStreaming instability

The invention discloses a nitrogen pressure stabilizing experiment device with a controllable outlet fluid temperature in a moving condition. The nitrogen pressure stabilizing experiment device comprises a closed experiment device. The experiment device is internally provided with a separator plate which divides the inner chamber of the experiment device into an upper chamber and a lower chamber. The separator plate is provided with a plurality of through holes. The top of the experiment device is provided with a nitrogen introducing pipe. The sidewall of the lower chamber of the experiment device is provided with an inlet connecting pipe and an outlet connecting pipe. A plurality of electric heating rods are mounted in the lower chamber of the experiment device. The nitrogen pressure stabilizing experiment device settles problems of natural circulation loop pressure controlling and heating experiment segment inlet fluid temperature controlling in the moving condition, and furthermore satisfies a requirement of carrying out a natural circulation loop flow unstability experiment in the moving condition. Furthermore relative to the structure in which a surge tube is connected with a voltage stabilizer, the nitrogen pressure stabilizing experiment device has advantages of simple structure, easy realization and great reduction of simulation experiment cost.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

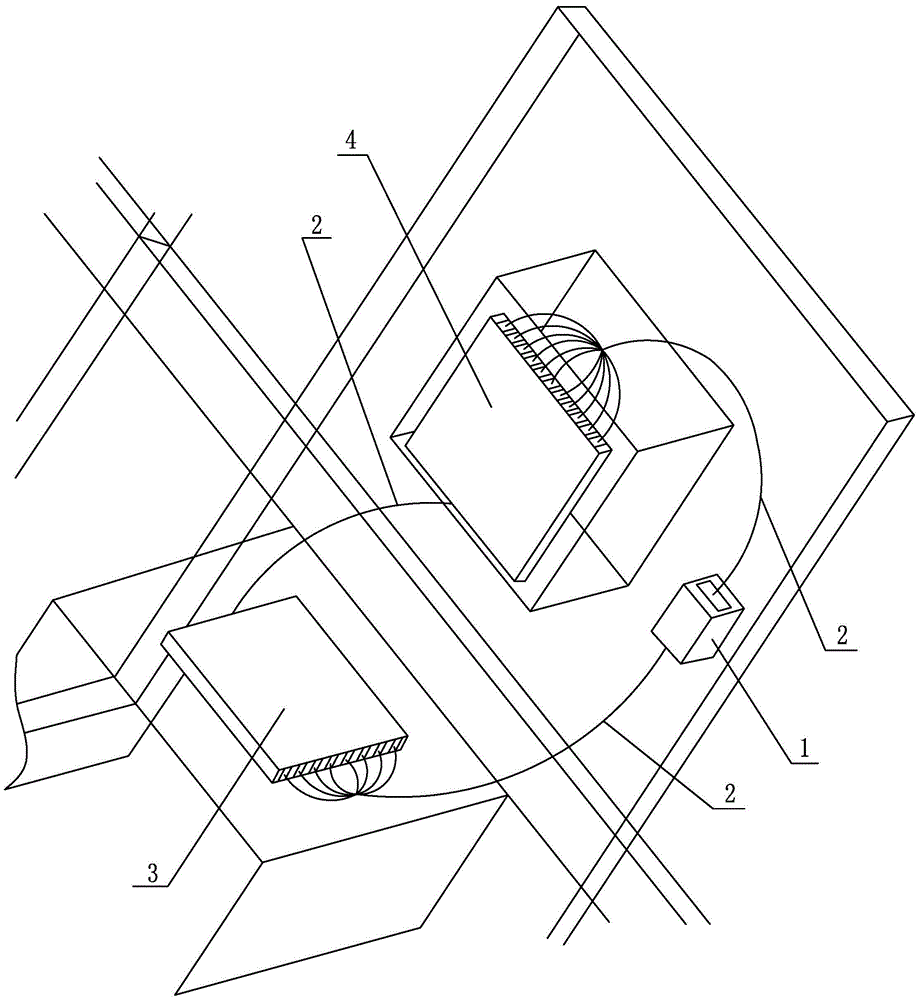

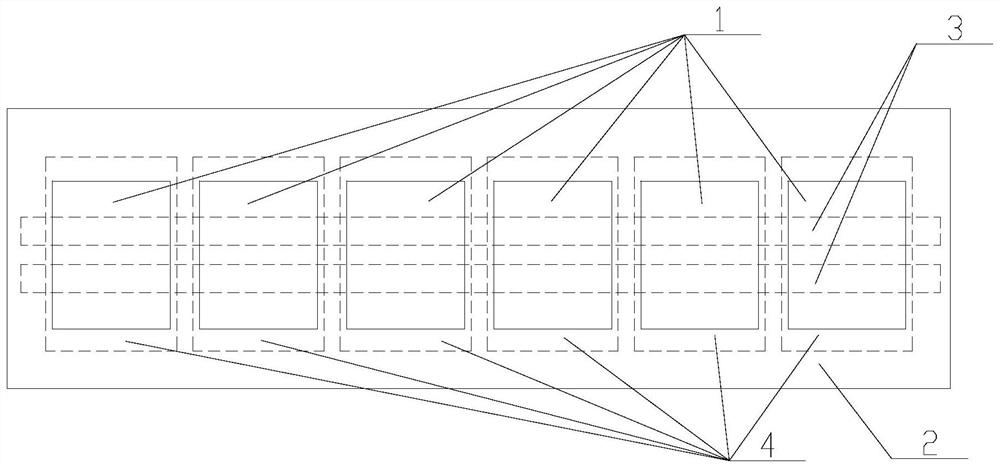

Heat transfer device suitable for space equipment group

PendingCN111918526AInhibit temperature riseSuppresses temperature rise when starting upModifications using liquid coolingModifications by conduction heat transferPower equipmentEngineering

The invention provides a heat transmission device suitable for a space equipment group. The heat transmission device comprises the equipment group (1), an aluminum honeycomb plate (2), a phase changeheat pipe (3), and a phase change energy storage box (4). The equipment group (1) is installed on the front face of the aluminum honeycomb plate (2), the phase change heat pipe (3) is pre-buried in aninterlayer of the aluminum honeycomb plate (2), and the phase change energy storage box (4) is installed on the back face of the aluminum honeycomb plate (2). Through the method of combining the phase change heat pipe with the phase change energy storage box, the temperature rise of the short-time high-power equipment group in the working period is effectively inhibited, the startup temperature rise of the short-time high-power equipment group is effectively inhibited, the temperature control problem of the short-time high-power equipment group is solved, and the beneficial effects of high reliability, large phase change material filling amount, good temperature control effect and the like are achieved.

Owner:SHANGHAI SATELLITE ENG INST

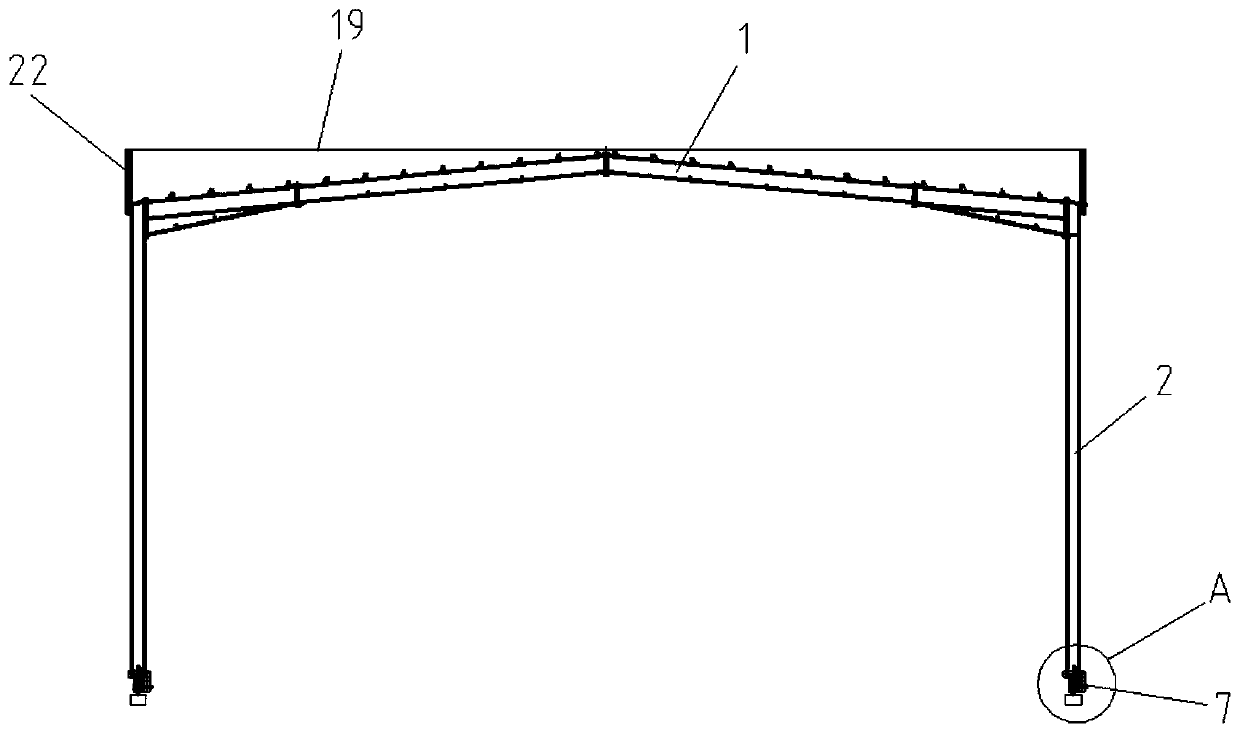

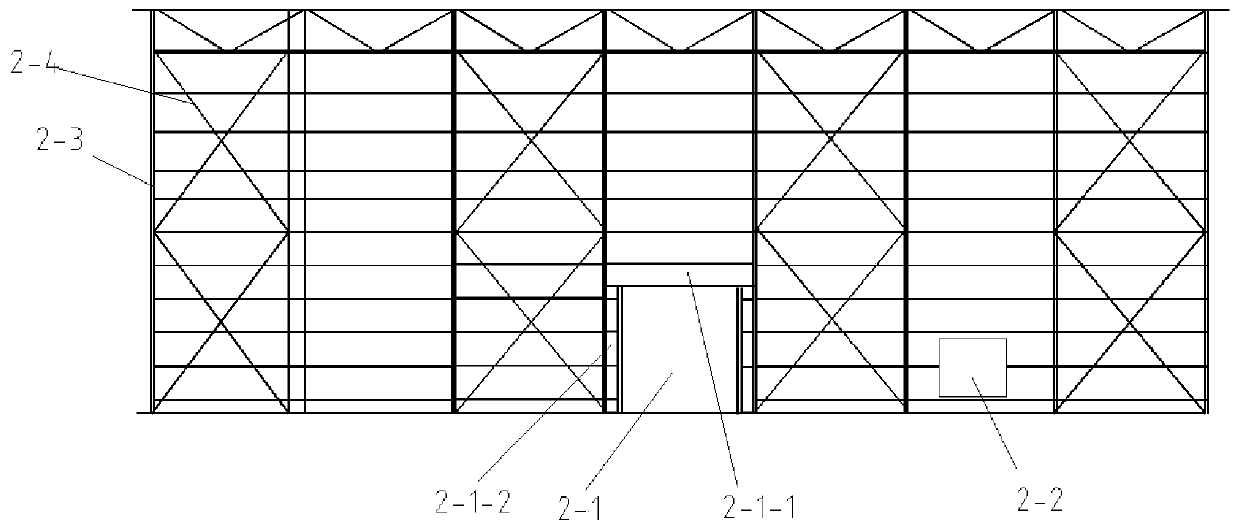

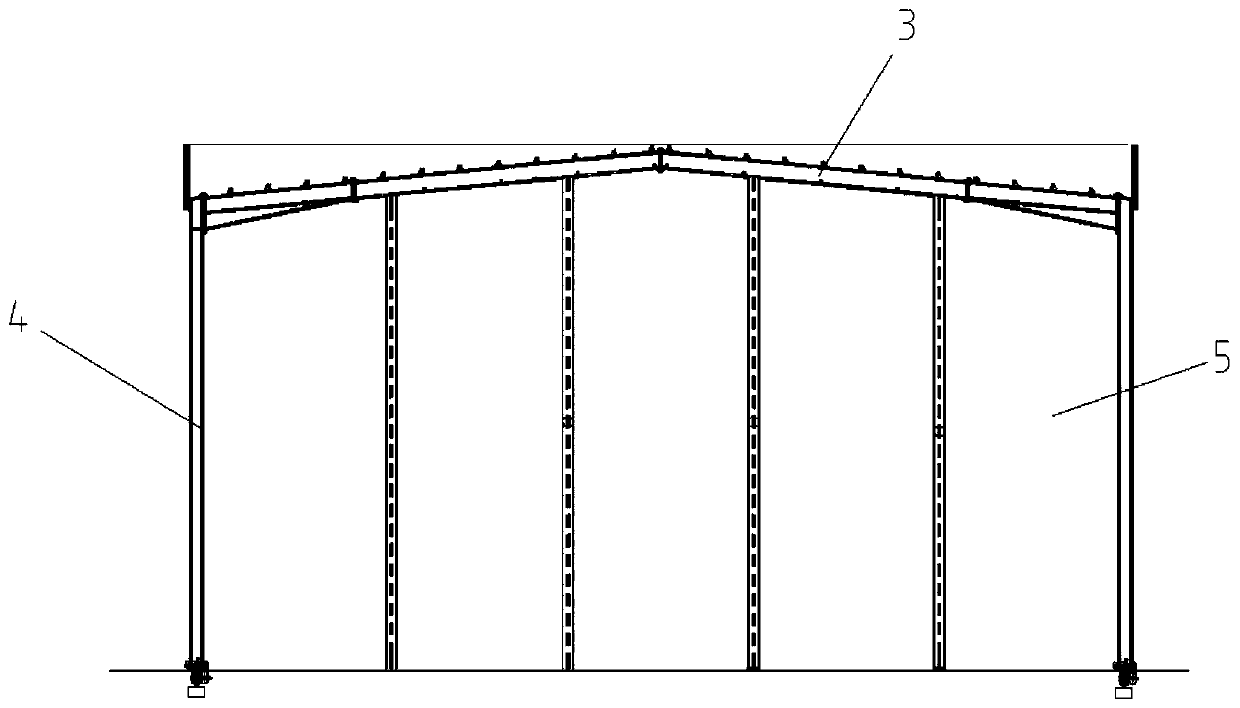

Whole-sealing combined type multifunctional moving work shed system

PendingCN110593606AQuarantine pollutionAvoid influenceSpecial buildingBuilding material handlingArchitectural engineeringBuilding construction

The invention relates to a whole-sealing combined type multifunctional moving work shed system which comprises a body part and blocking parts located on the two sides of the body part. A sealed construction space can be formed by the body part and the blocking parts. The bottoms of the body part and the blocking parts are supported by a first rail, and driving mechanisms and fixing mechanisms arearranged at the bottoms of the body part and the blocking parts. The driving mechanisms are used for driving the body part and the blocking parts to move along the first rail, and the fixing mechanisms are used for locking and fixing the body part and the blocking parts on the first rail. By the adoption of the work shed system, the surroundings cannot be affected by construction, demounting and repeated mounting are not needed during moving, the construction period is shortened, and the construction cost is reduced.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD +1

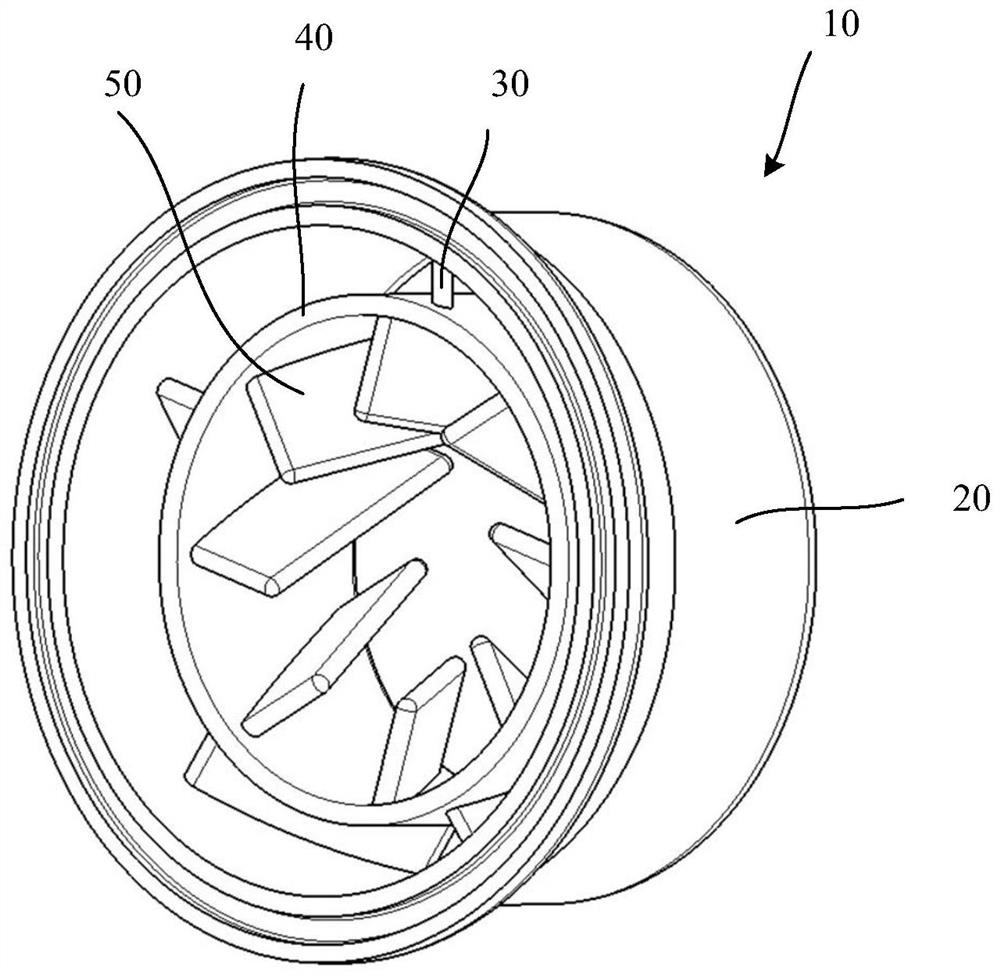

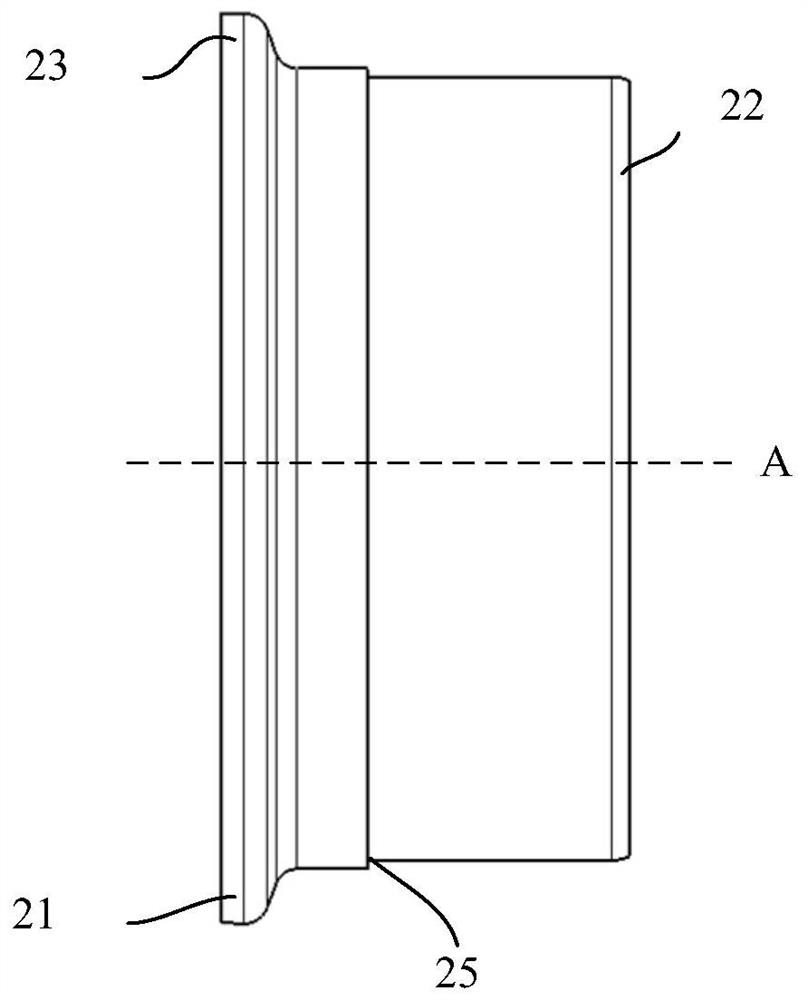

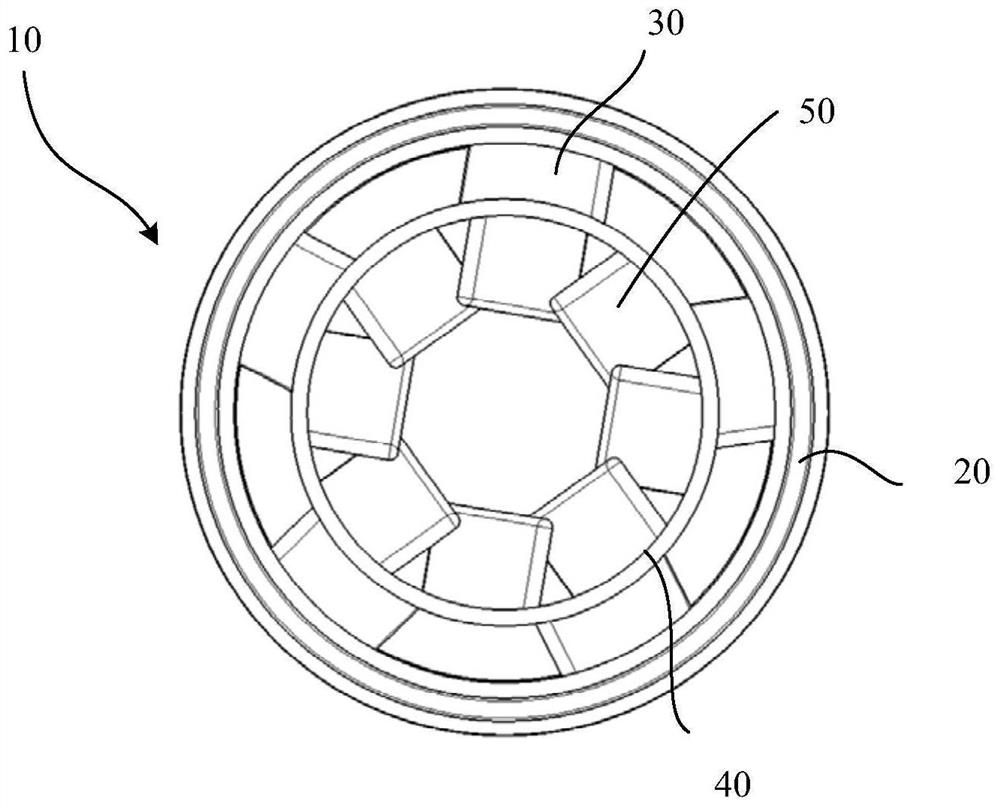

Bidirectional rotational flow mixing device for heat exchanger of air source system

PendingCN114180070AAchieve homogenizationSolve temperature controlAir-treatment apparatus arrangementsEngineeringMechanical engineering

The invention discloses a bidirectional rotational flow mixing device for a heat exchanger of an aircraft air source system, the mixing device comprises an outer sleeve and an inner sleeve, the inner sleeve is located in the outer sleeve, and the two sleeves are spaced from each other; the mixing device further comprises a plurality of outer ring stator blades, and the outer ring stator blades are fixedly connected with the inner wall face of the outer sleeve and the outer wall face of the inner sleeve at intervals. The plurality of inner ring stator blades are fixedly connected with the inner wall surface of the inner sleeve in a mutually separated manner; the outer ring stator blades and the inner ring stator blades are arranged at different angles relative to the longitudinal axis of the inner sleeve. When the outer-ring blades and the inner-ring blades incline in opposite directions relative to the longitudinal direction, the two-way rotational flow mixing device can enable air flows passing through the inner-ring blades and the outer-ring blades to rotate in opposite directions, so that the two air flows are wound and mixed with each other, and the purpose of quickly and efficiently realizing temperature field homogenization is achieved.

Owner:COMAC +1

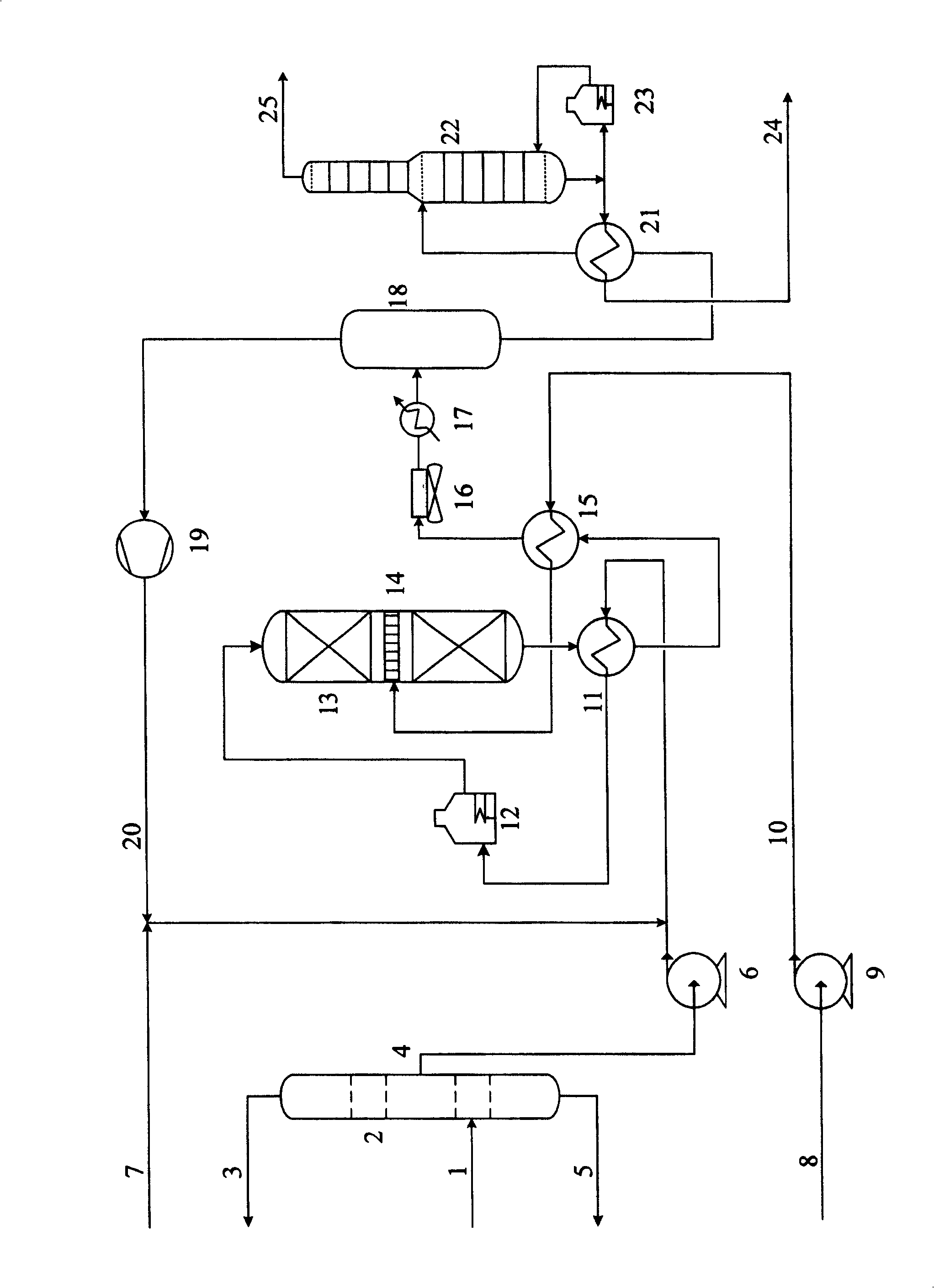

Hydrogenation method for producing catalytic reforming raw material

ActiveCN100425675CSolve temperature controlLow costRefining to eliminate hetero atomsCatalytic reformingNaphtha

Owner:CHINA PETROLEUM & CHEM CORP

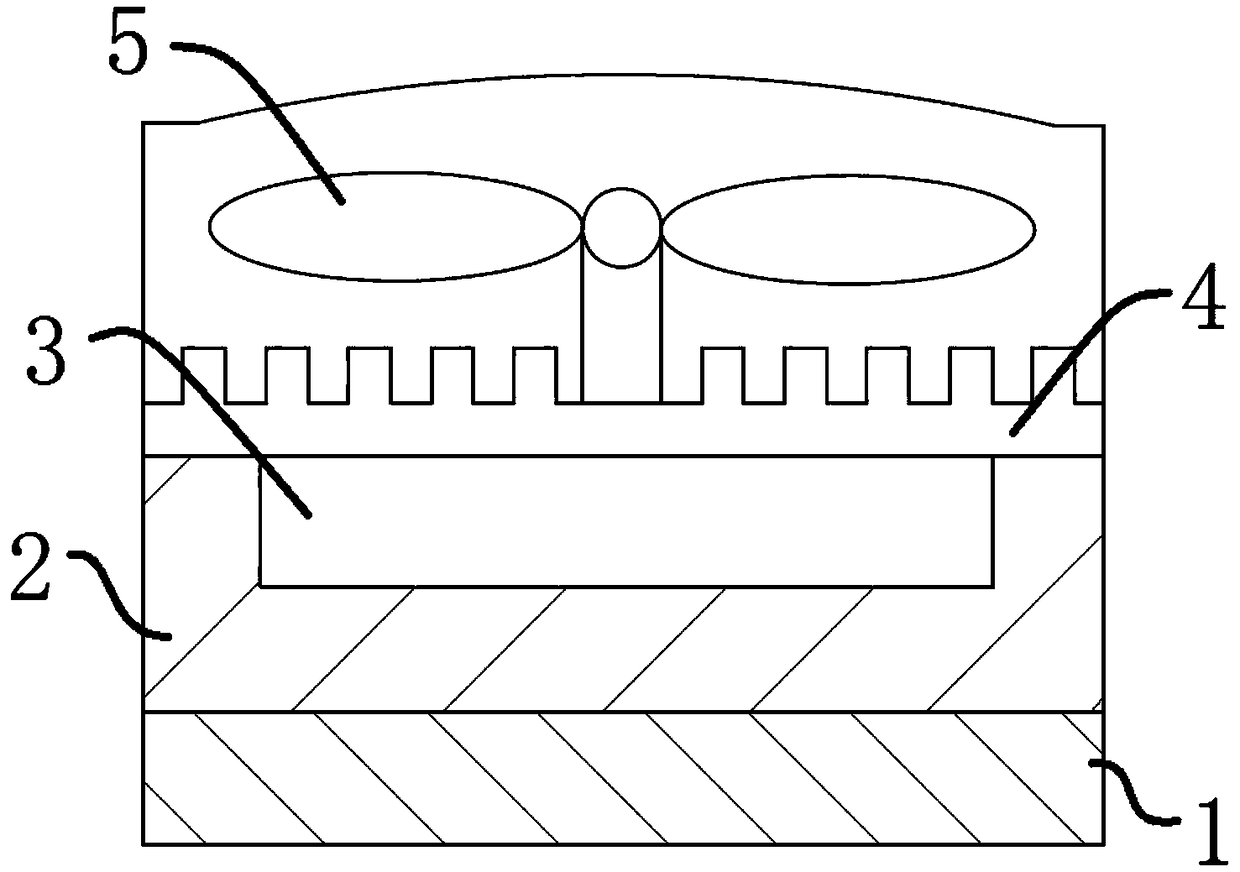

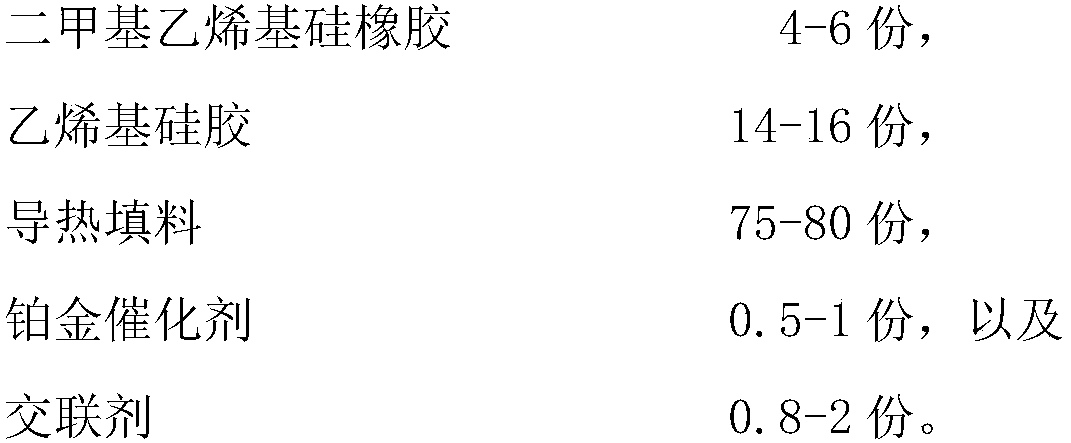

Heat conduction and storage composite, preparation method thereof and heat conduction, storage and dissipation device

InactiveCN108728046AHigh energy storage densityNearly constant temperatureSemiconductor/solid-state device detailsSolid-state devicesVulcanizationMetal foil

The invention discloses a heat conduction and storage composite, a preparation method thereof and a heat conduction, storage and dissipation device based on the heat conduction and storage composite,and relates to the technical field of heat conduction materials. The method comprises the following steps: raw materials are prepared: a, a piece of metal foil is taken, b, a heat conduction silica gel base material is taken, and c, a phase-change material base material is taken; the outer surface of one side of the metal foil is coated with the heat conduction silica gel base material, the metalfoil is placed in a tunnel furnace for vulcanization, and a heat conduction silica gel layer is formed after vulcanization; the outer surface of the other side of the metal foil is coated with the phase-change material base material, hot coating temperature is controlled at 80-90 DEG C, and a phase-change material layer is formed; finally, the heat conduction and storage composite is obtained. Byaid of the phase-change energy storage conduction technology, the heat conduction and storage composite stores and releases energy by physical state transformation and has the advantages that energy storage density is large, temperature is approximately constant, phase-change temperature conduction can be realized, and rapid cooling can be realized.

Owner:苏州矽美科导热科技有限公司

Phase change heat dissipation structure and manufacturing method thereof

InactiveCN108307606AImprove thermal conductivityImprove flame retardant performanceFireproof paintsModifications by conduction heat transferAluminium hydroxideSilica gel

The invention discloses a phase change heat dissipation structure and a manufacturing method thereof. The phase change heat dissipation structure includes aluminium foil. The top side of the aluminiumfoil is coated in a flame-retardant heat conduction silica gel layer, and the bottom side of the aluminium foil is coated in a phase change material layer. The flame-retardant heat conduction silicagel layer is prepared by the following raw materials by weight: 2-8 parts of methyl vinyl silicone rubber, 15-20 parts of vinyl silica gel, 18-25 parts of dimethicone, 0.5-2 parts of hydrogen-containing silicone oil, 0.5-1 parts of platinum catalyst, 20-40 parts of aluminium hydroxide, 20-40 parts of magnesium hydroxide, 10-20 parts of nano silicon dioxide, and 10-20 parts of hollow glass bead. The phase change heat dissipation structure has the characteristics of exhibiting good thermal conductivity and good flame resistance and being flexible and compressible, and also has the phase change energy storage characteristic.

Owner:ZHANJIANG ZHENGXIN TECH SERVICE CO LTD

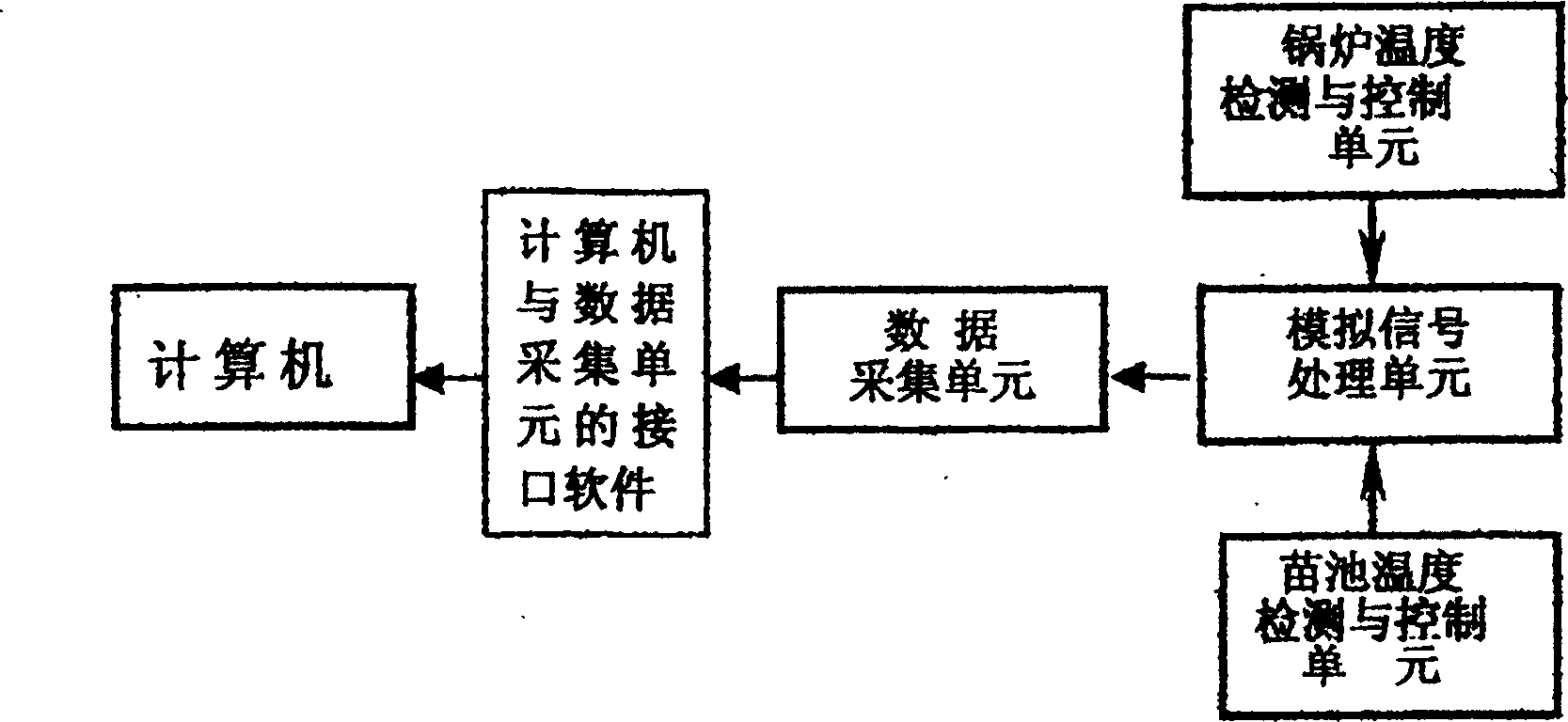

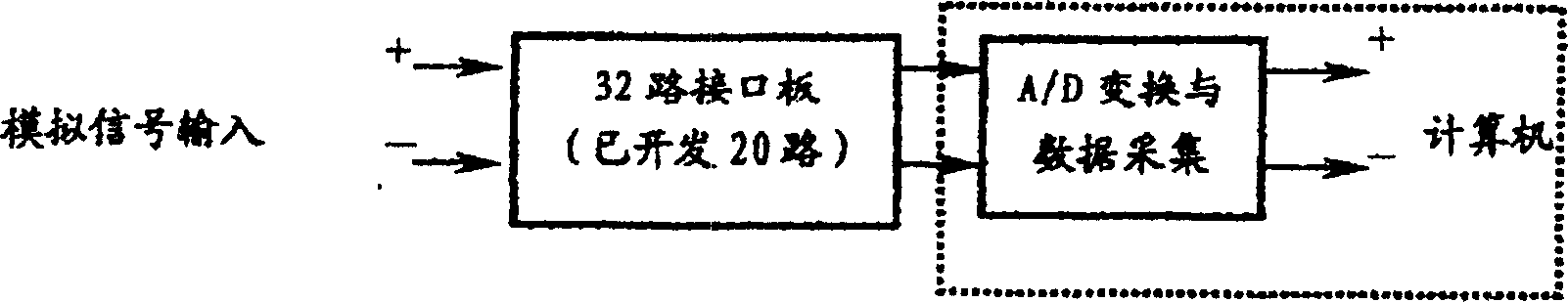

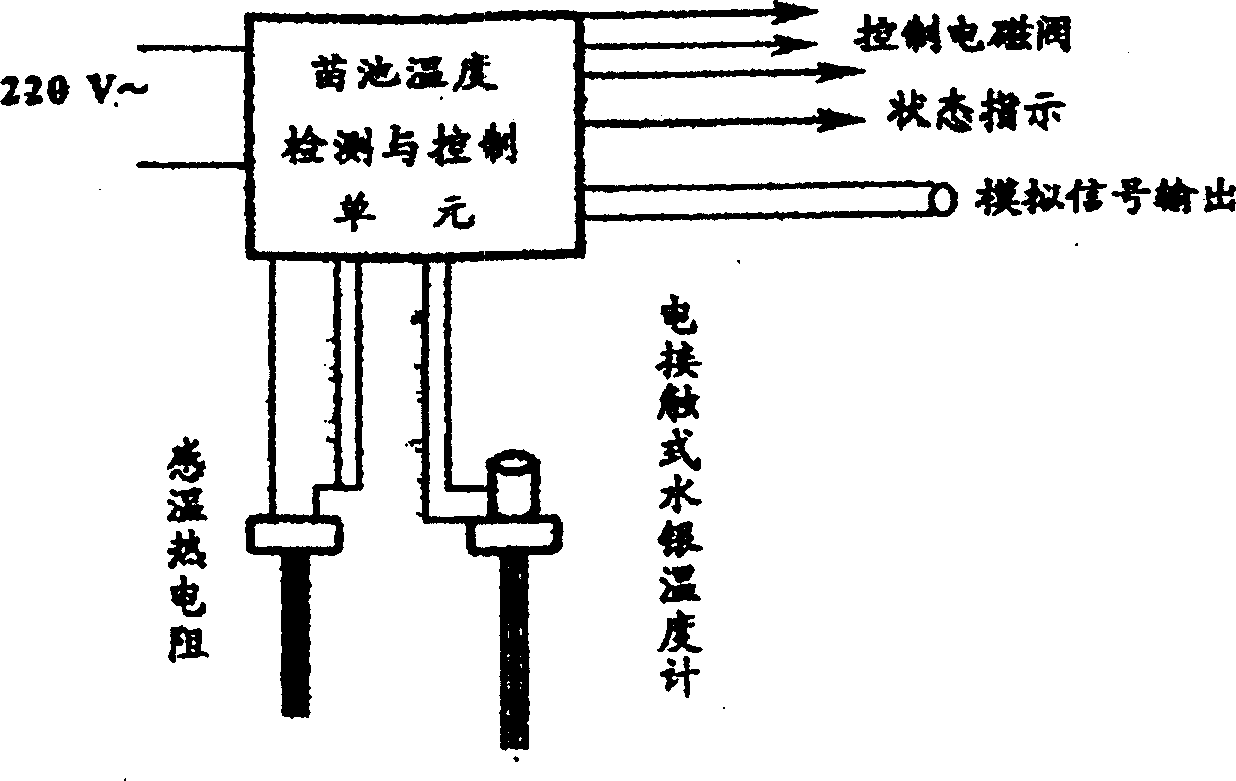

Computer monitor system for temp of industrially culturing pool

InactiveCN1152203CSolve temperature controlImprove survival rateClimate change adaptationPisciculture and aquariaMicrocomputerAutomatic control

A computer monitor system for the temp of industrially culturing pools is composed of automatic measuring and controlling unit for the water in boiler, automatic measuring and controlling unit for the water in pools, and microcomputer monitoring and processing unit. The water in pools can be heated by the circulating hot water of boiler via heat exchanger of heat radiator. Its advantages include automatic control, sound-light alarm, high performance stability, high reliability and no pollution.

Owner:GUANGDONG OCEAN UNIVERSITY

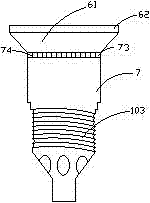

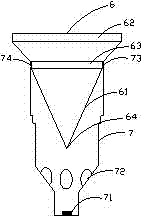

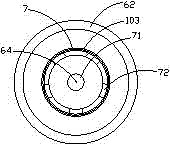

Mixed liquid gasification burner and nozzle-free water cooling gasification furnace end comprising same

The invention relates to the technical filed of gasification furnace ends and discloses a mixed liquid gasification burner and a nozzle-free water cooling gasification furnace end comprising the same. The mixed liquid gasification burner consumes 4kg of mixed liquid fuel per hour, a flame turns cyan gradually from the bottom to the top of the flame sequentially according to the power and is centralized in the direction perpendicular to the first plane. The outer flame temperature of the flame can reach 1550-1600 DEG C. The problem of kitchen waste blockage is solved, meanwhile, the mixed liquid fuel can be burned more fully, the consumption of the mixed liquid fuel can be lower, and the flame of the mixed liquid fuel can be more centralized. The nozzle-free water cooling gasification furnace end is provided with the mixed liquid gasification burner, the situation that a gas nozzle is directly exposed in the environment is avoided, the problem that the gas nozzle in the furnace end is liable to be blocked is solved, the using performance of the furnace end is improved greatly, and potential safety hazards are avoided. A tapered part and a protective part are matched, through the structure design, the temperature of the furnace end is increased, the fuel consumption is reduced, and the flame is more centralized.

Owner:株洲蓝宝新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com