Bidirectional rotational flow mixing device for heat exchanger of air source system

A technology of swirl mixing and heat exchanger, which is applied in the field of aircraft environmental control system, can solve the problems of short distance from the outlet of the precooler to the branch of the downstream pipeline, the uncertainty of the temperature of the air conditioner and anti-icing, and solve the problem of temperature control , to achieve the effect of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing, set forth more details in the following description so as to fully understand the present invention, but the present invention can obviously be implemented in many other ways different from this description, Those skilled in the art can make similar promotions and deductions based on actual application situations without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

[0039] In the following description, upstream and downstream refer to the flow direction of the airflow from the precooler to the downstream pipeline, the front side / front end refers to the side or end near the precooler, and the rear side / rear end refers to the side near the downstream The side or end of a pipe, unless otherwise characterized.

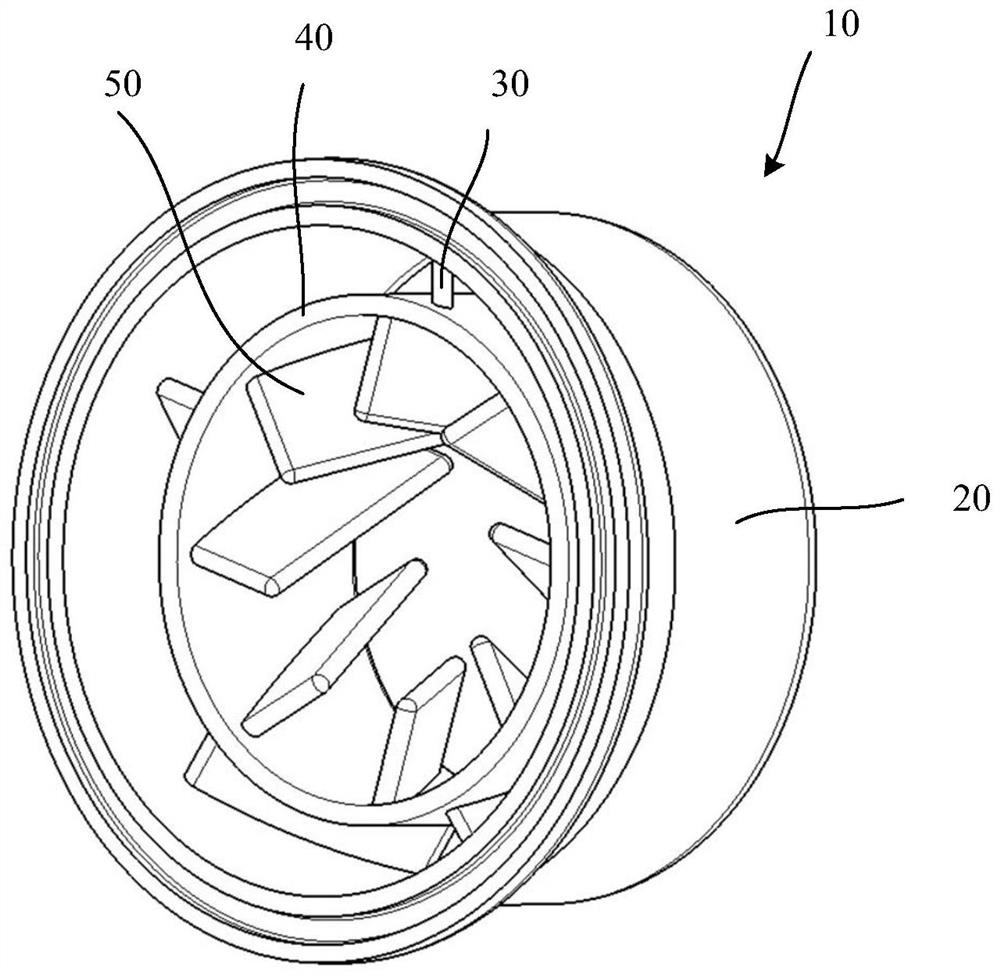

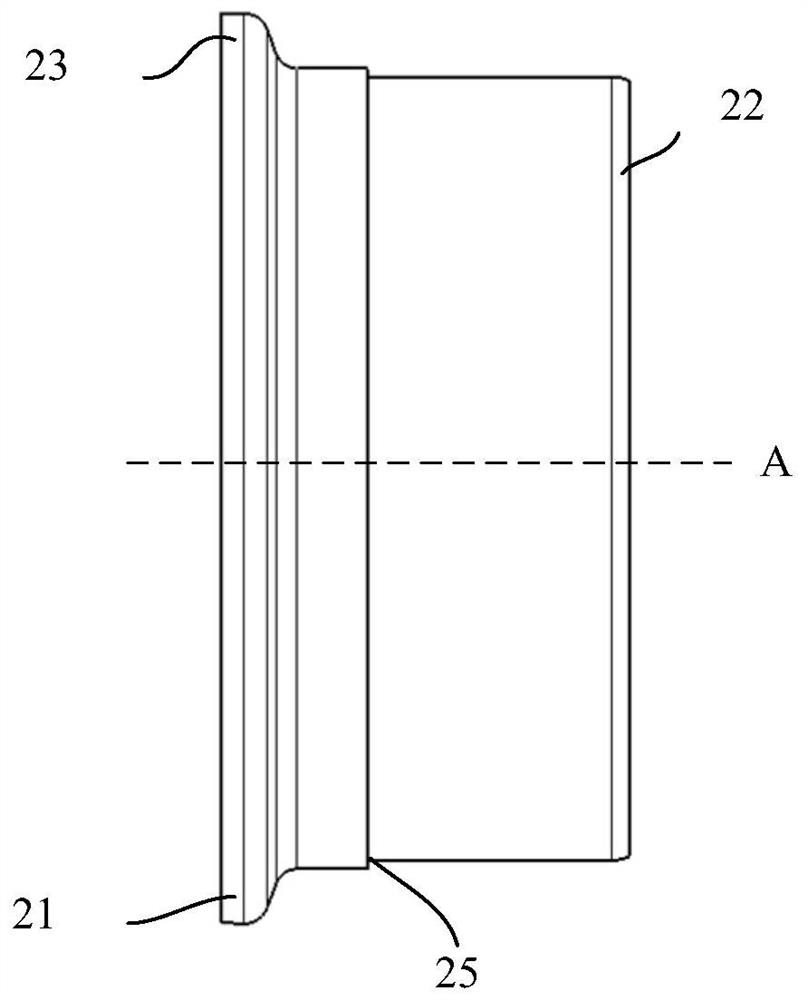

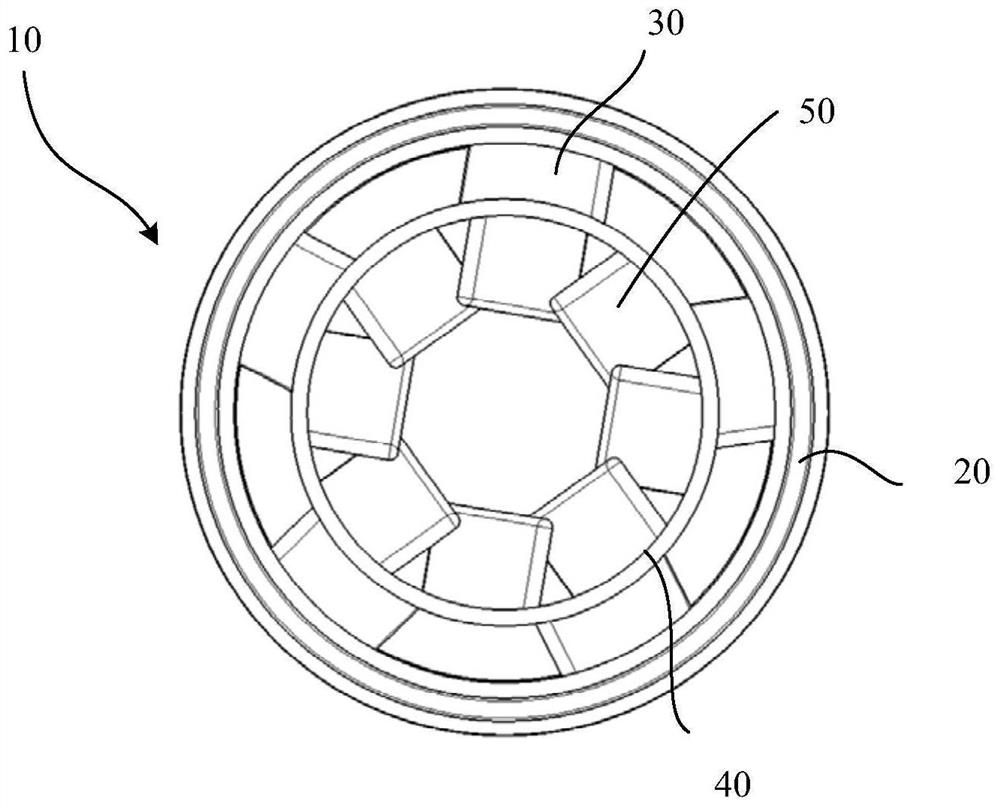

[0040] figure 1 , figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com