Heating appliance heating element and preparation method thereof

A technology for heating elements and heating appliances, which is applied to tobacco and other directions, can solve the problems of difficult control of resistance, poor temperature uniformity, and low resistance value accuracy, and achieve the effects of preventing corrosion damage, improving product performance, and facilitating temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Another object of the present invention is to provide a method for preparing a heating element of a heating appliance, the structural form adopts the aforementioned heating element of a heating appliance, and the preparation method includes the following steps:

[0041] Step 1, making the heating sheet 1, engraving the heating circuit on the body of the heating sheet 1 by means of laser engraving.

[0042] Step 2, configure the insulating base material;

[0043] According to the weight ratio, the composition of the insulating base material is as follows: silicon dioxide: 30-60%, aluminum oxide: 3-20%, calcium oxide: 2-20%, boron oxide: 1-10%, barium oxide: 1-10% %, zirconia: 1-10%;

[0044] Weigh the required weight of raw materials according to the above ratio, and the particle size of the raw materials is controlled at 1um-20um, preferably 2um, and then mixed and dried; the formula of the insulating base material here is the key to determine the combination of the in...

Embodiment 1

[0053] The present invention is implemented according to the following steps:

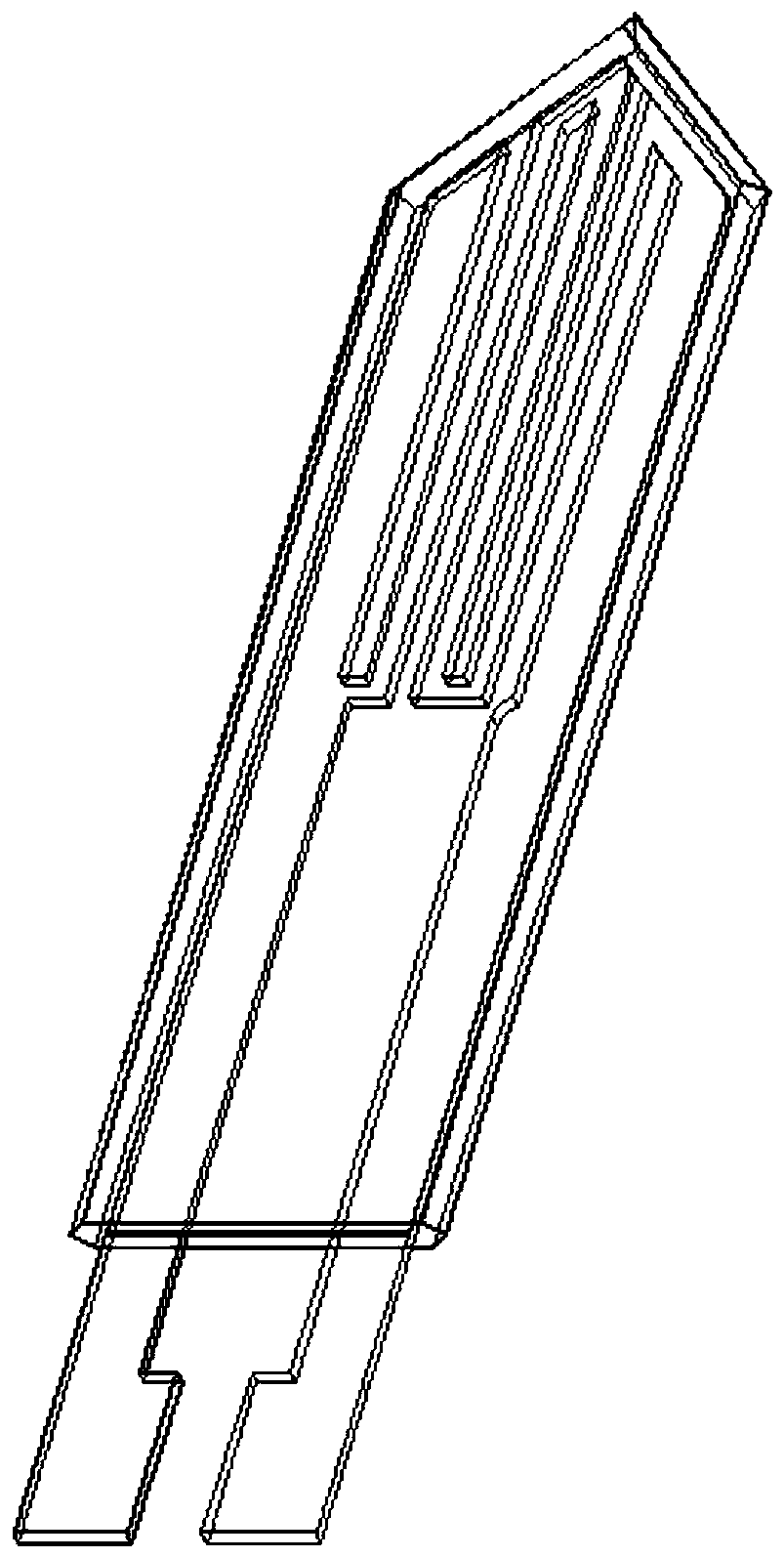

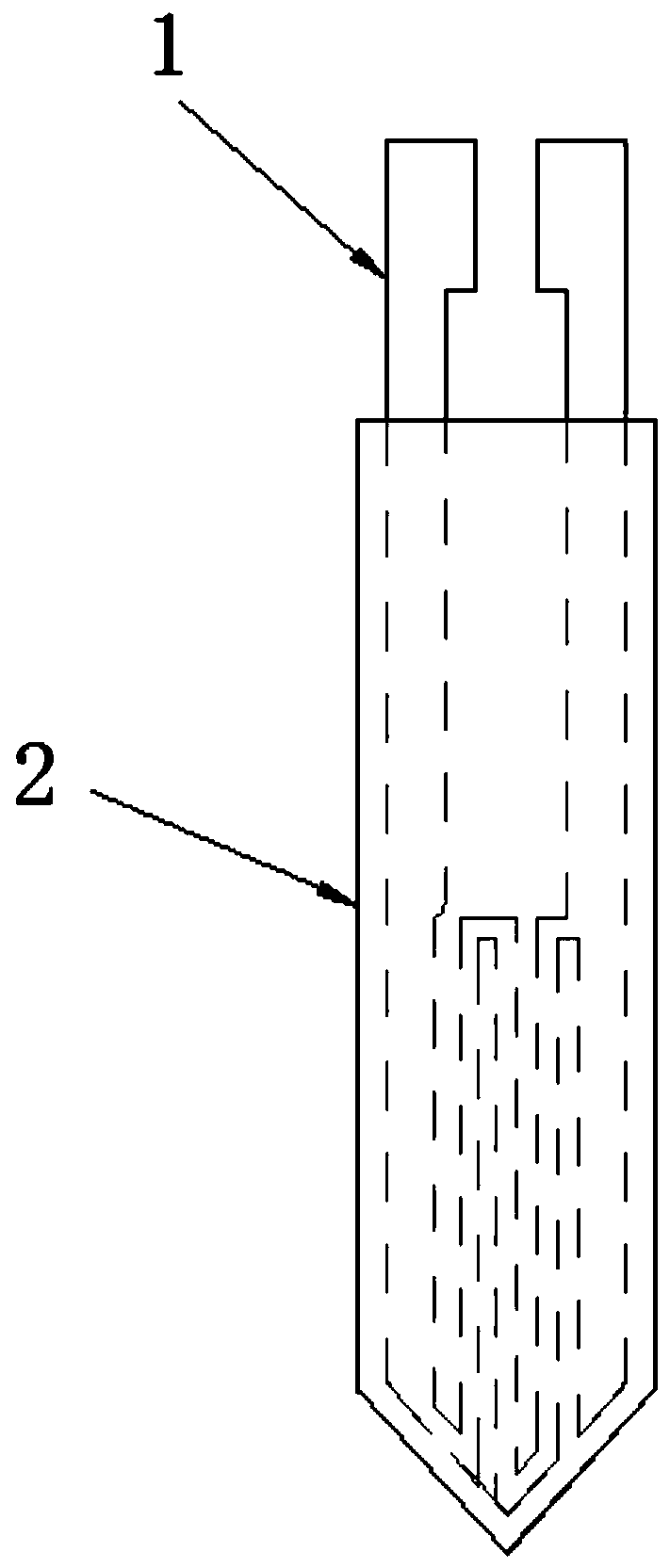

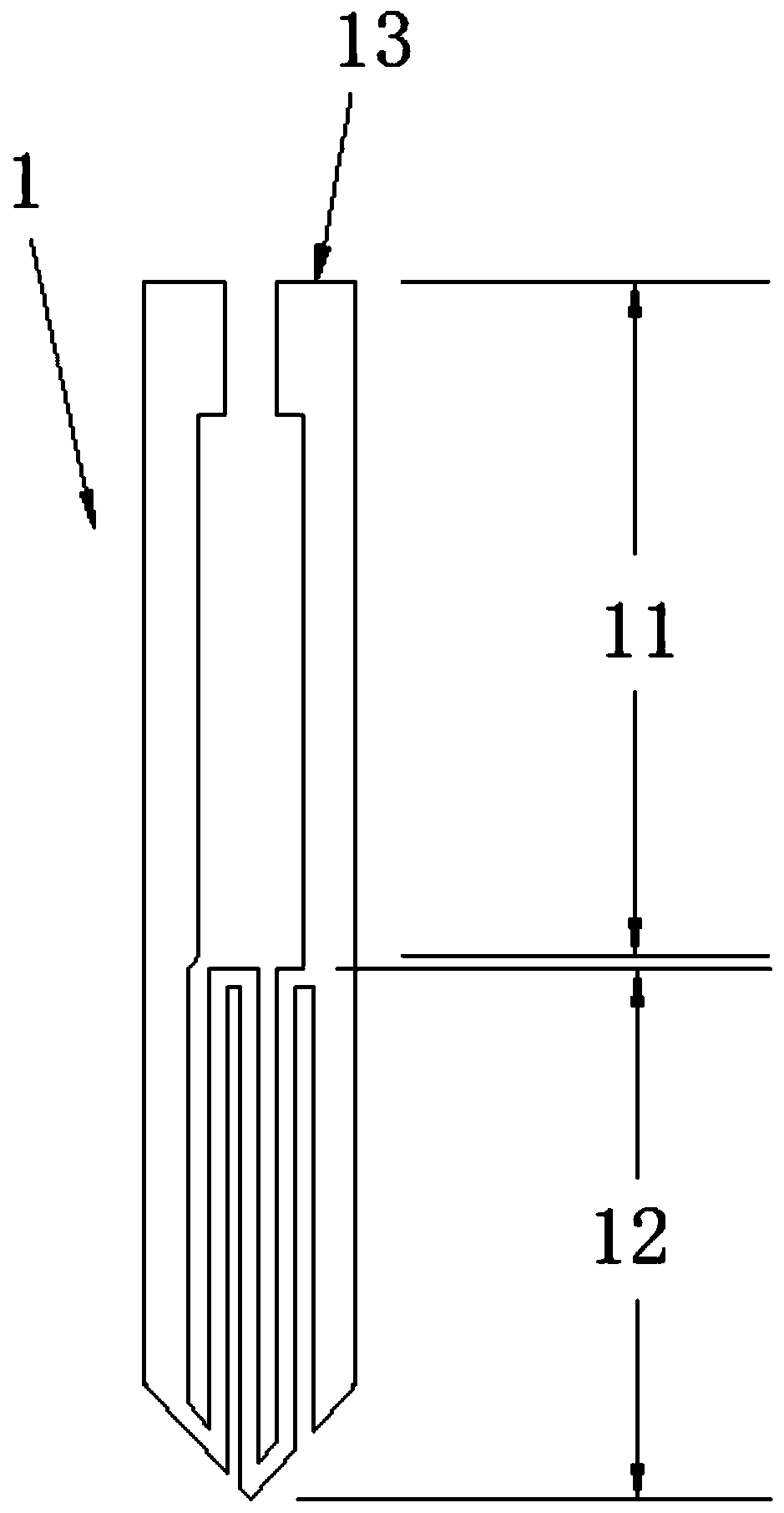

[0054]In step 1, nickel-iron alloy is used as a heating sheet; laser resistance adjustment is performed on the nickel-iron sheet. According to the required resistance of 0.9 ohms, the circuit of the heating area and the electrode area is designed, and then the circuit is processed on the nickel-iron alloy sheet by laser. The alloy sheet is set in a pointed shape, mainly for the convenience of inserting into the shredded tobacco during use; the circuit of the electrode area is thicker than that of the heating wire, mainly to reduce the calorific value of the electrode area, thereby reducing the energy loss and electrode temperature of the electrode area. Laser processing is used to precisely control the resistance. Afterwards, clean the resistance-adjusted heating element: ultrasonic cleaning with alcohol, mainly to clean the impurities on the surface, so as not to affect the combination of the hea...

Embodiment 2

[0063] In step 1, nickel-iron alloy is used as a heating sheet; laser resistance adjustment is performed on the nickel-iron sheet. According to the required resistance of 1.1 ohms, the circuit of the heating area and the electrode area is designed, and then the circuit is processed on the nickel-iron alloy sheet by laser. The alloy sheet is arranged in a pointed shape, and the circuit in the electrode area is thicker than the circuit in the heating wire. Afterwards, use alcohol to ultrasonically clean the blocked heating element.

[0064] Step 2, configure the insulating base material: according to the designed weight ratio, weigh the required weight of raw materials, the particle size is 1-20um, preferably 2um, and then mix and dry. The composition of the insulating base material is as follows: silicon dioxide: 58%, aluminum oxide: 18%, calcium oxide: 7%, boron oxide: 7%, barium oxide: 4%, zirconium oxide: 6%.

[0065] Step 3, configuring the colloid, weighing terpineol 61%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com