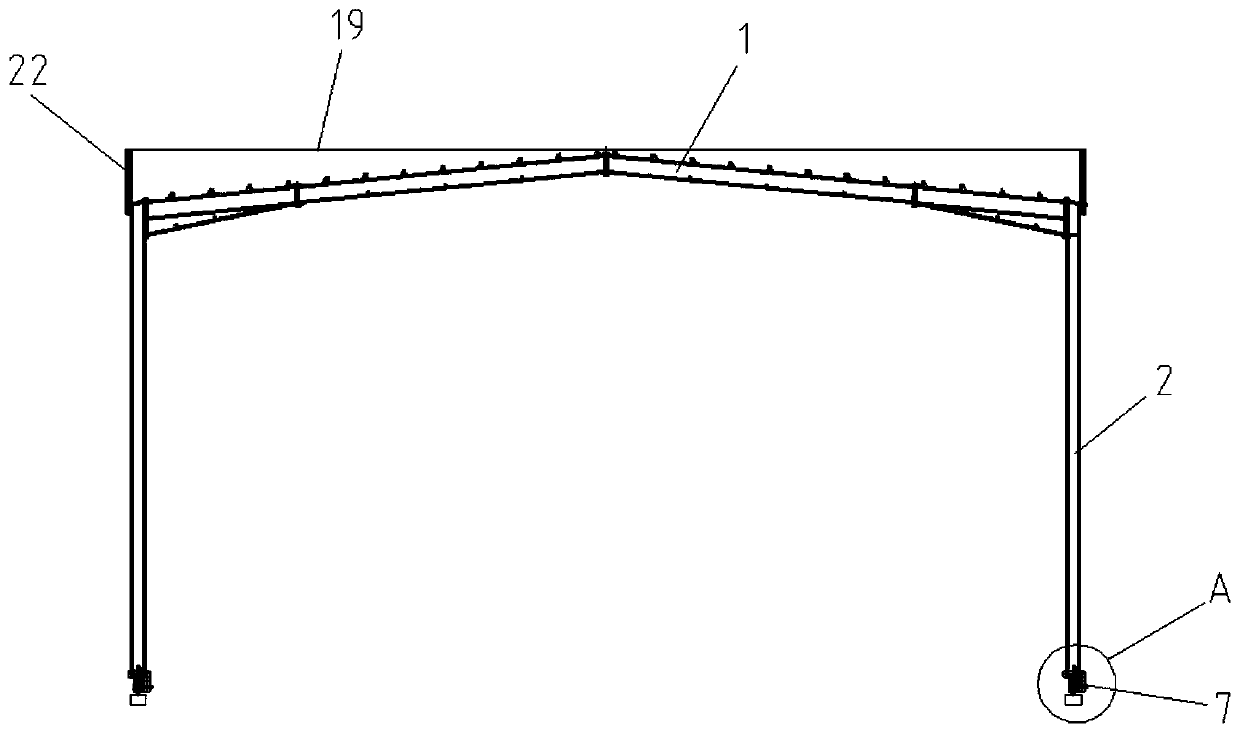

Whole-sealing combined type multifunctional moving work shed system

A combined and multi-functional technology, which is applied in the processing of building materials, construction, building types, etc., can solve the problems of high cost of complete closure, long construction period, and impact on construction period, and achieve temperature control problems, good construction environment, and reduced The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

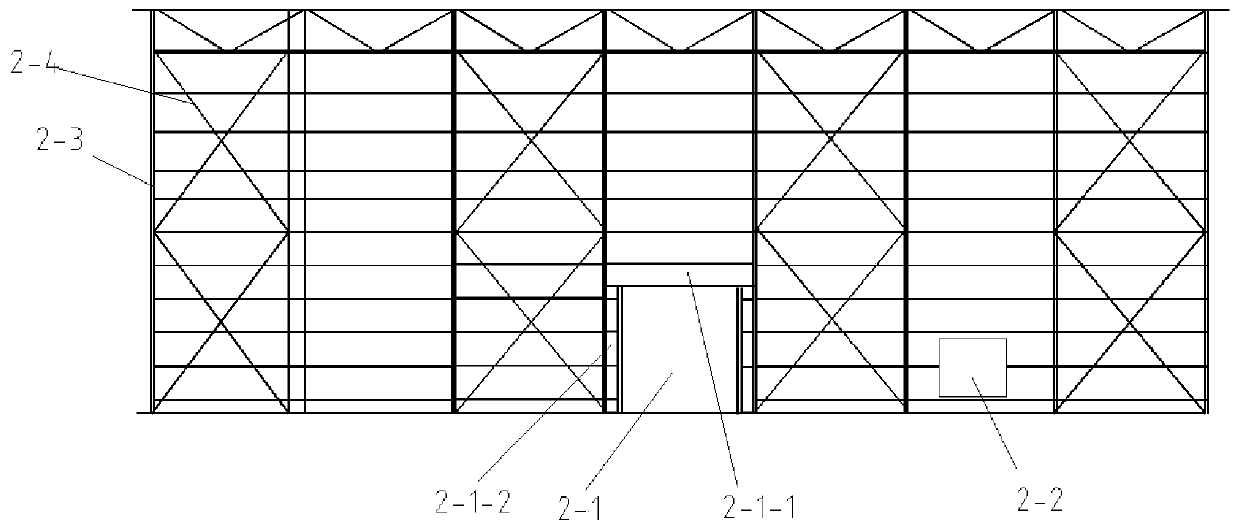

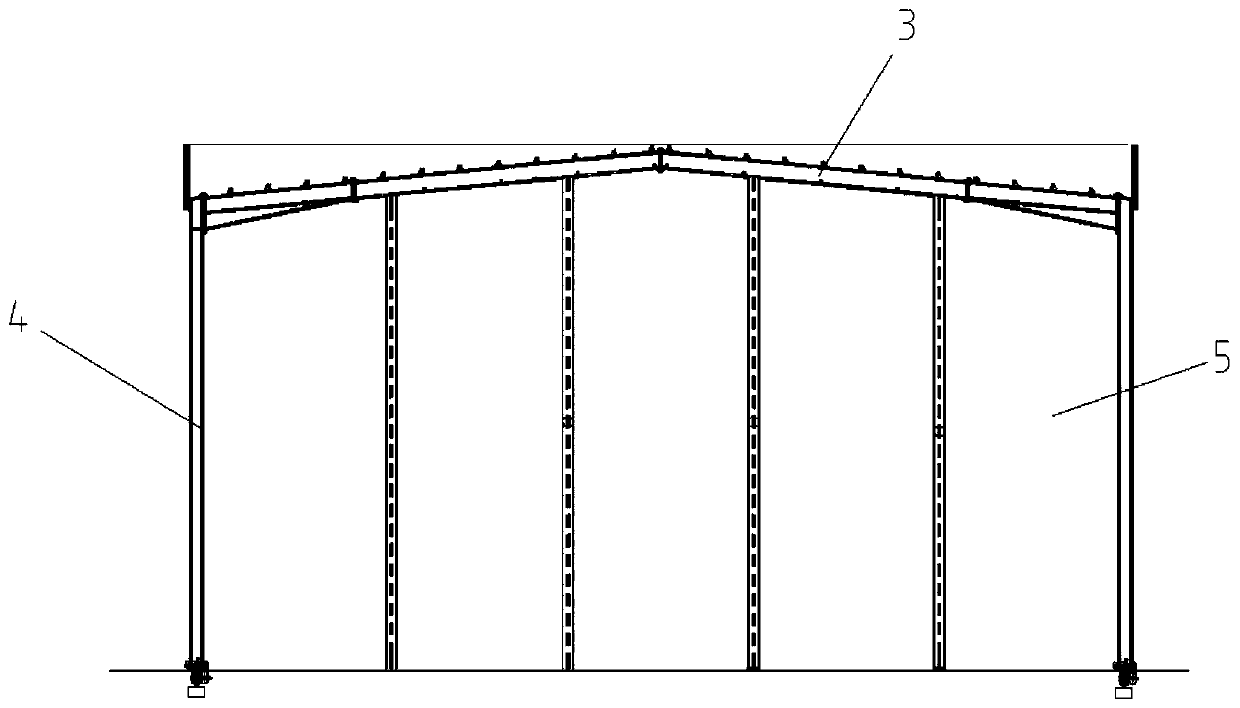

[0065] This embodiment discloses a working method of a fully enclosed combined mobile shed system. The motor drives the walking wheel to rotate, drives the middle part and the blocking part to move along the first track, and the blocking part moves to both ends of the middle part to form a fully enclosed In the construction space, the operator turns the handle to make the first clamp and the second clamp move towards each other, clamp the first rail, and lock the middle part and the blocking part with the first rail. Construction in a closed construction space can effectively prevent the impact of noise, dust and light pollution on the surrounding environment and residents. The spray mechanism can spray clean water to reduce the dust generated during the construction process. When the location of the shed needs to be transferred , Lay the first track in advance, then loosen the first clamp and the second clamp, use the drive mechanism to move the middle part and the blocking par...

Embodiment 3

[0067] This embodiment discloses a construction method of a fully enclosed combined mobile shed:

[0068] The construction of the enclosure structure of the subway station is completed, and the surveying personnel will place the track lines of the shed and gantry crane at fixed points according to the design requirements. Treat the foundations of the shed and gantry crane track according to the requirements of the laying-out elevation, and carry out the acceptance inspection according to the design requirements.

[0069] Review the track foundation elevation and flatness, place the prefabricated track beams, re-measure the center distances of the middle part, the blocking part, and the gantry crane track beams, fix the track beams and install the first and second tracks, and re-measure the first and second tracks. After the center distance of the two tracks, the first track and the second track are fixed, the gantry crane is installed on the second track, and the driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com