Power battery module temperature control system for new energy coach

A temperature control system, power battery technology, applied in batteries, secondary batteries, circuits, etc., can solve the problem that the consistency of heating and heat dissipation of the monomer cannot be well guaranteed, the temperature of the battery module is difficult to control, and the leakage of electricity and water. and other problems, to achieve the effect of improving service life, simple and compact design, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with the accompanying drawings:

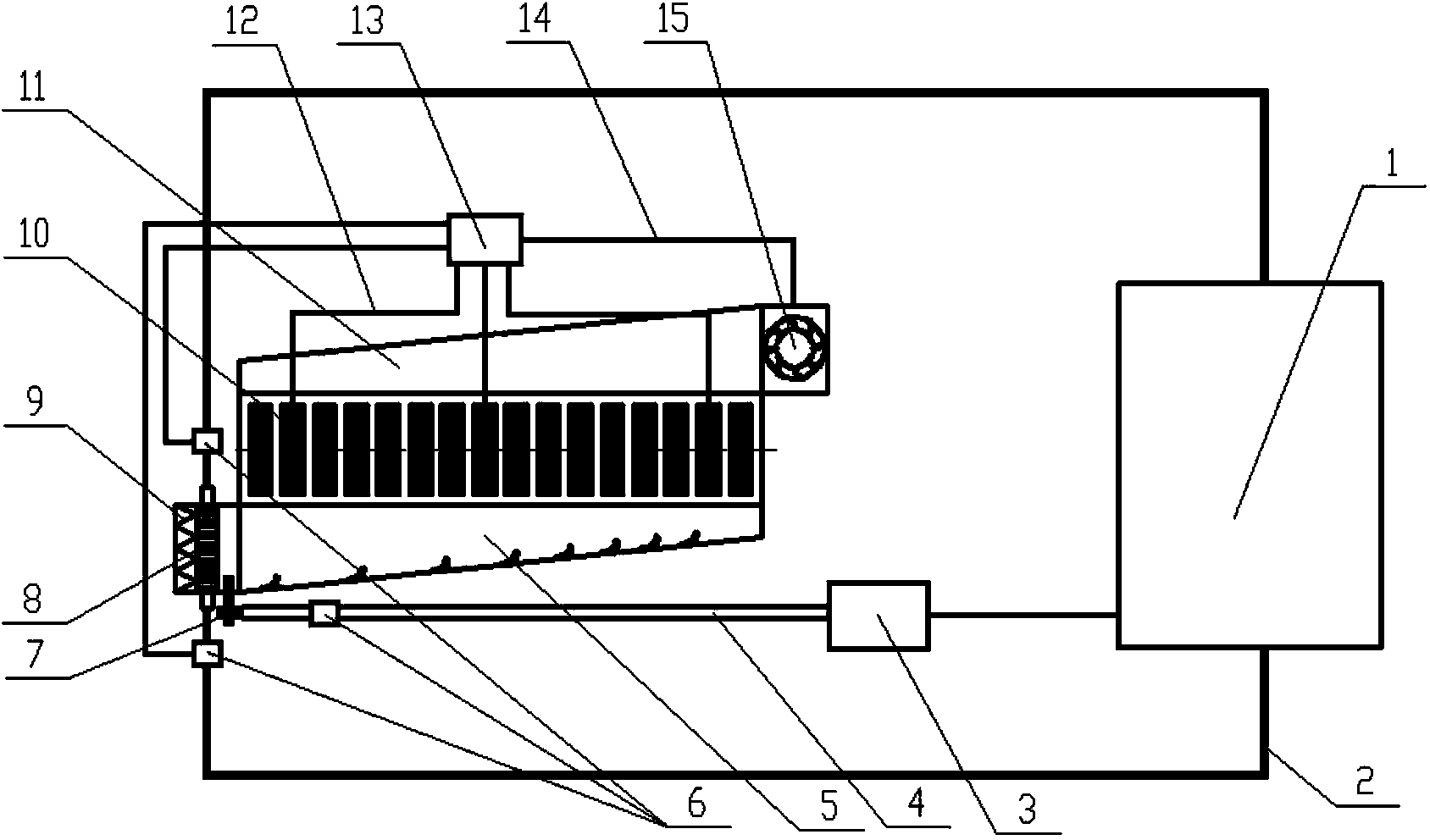

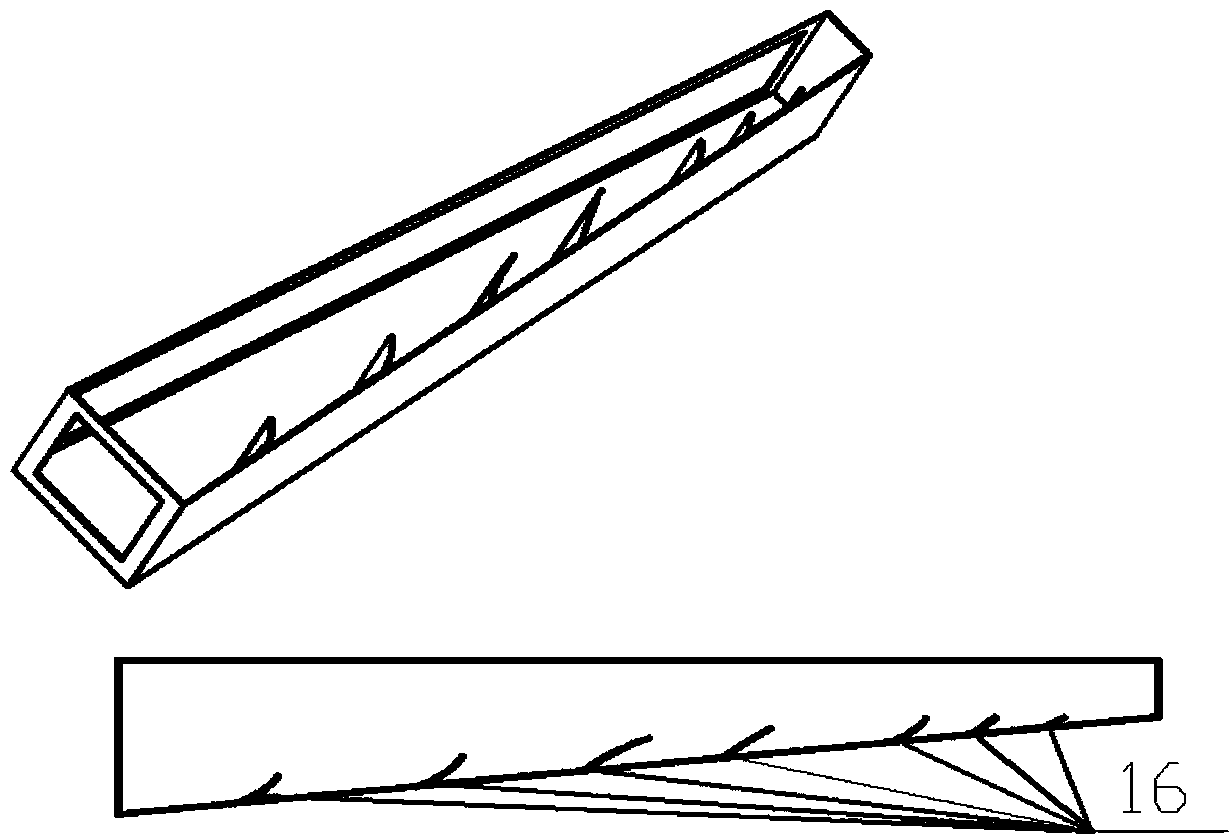

[0029] like Figure 1-2 As shown in the figure, the temperature control system and device for the power battery module for a new energy bus includes the following 4 parts: the battery module 10, the battery management system, the battery heating and cooling device, and the energy supply system;

[0030] The battery management system includes a temperature collection line 12, a CAN communication harness 14, a battery management controller 13, and a solenoid valve 6; the battery heating and cooling device includes a perforated heat sink 8, a vortex tube 7, a battery air inlet shroud 5, and a battery outlet air guide The flow hood 11 , the fan 15 ; the energy supply system includes the engine cooling water pipeline 2 and the air pipeline 4 .

[0031] The cells in the battery module 10 are arranged and fixed in parallel. There is a certain gap between the cells and the cells...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com