Heat conduction and storage composite, preparation method thereof and heat conduction, storage and dissipation device

A composite material and heat storage technology, applied in heat exchange materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of electronic products heat dissipation and cooling can not meet the heat dissipation requirements of high integration and high heat generation products, and reduce the temperature of electronic products. , to achieve the effects of excellent compressibility, reduced contact thermal resistance, and excellent heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

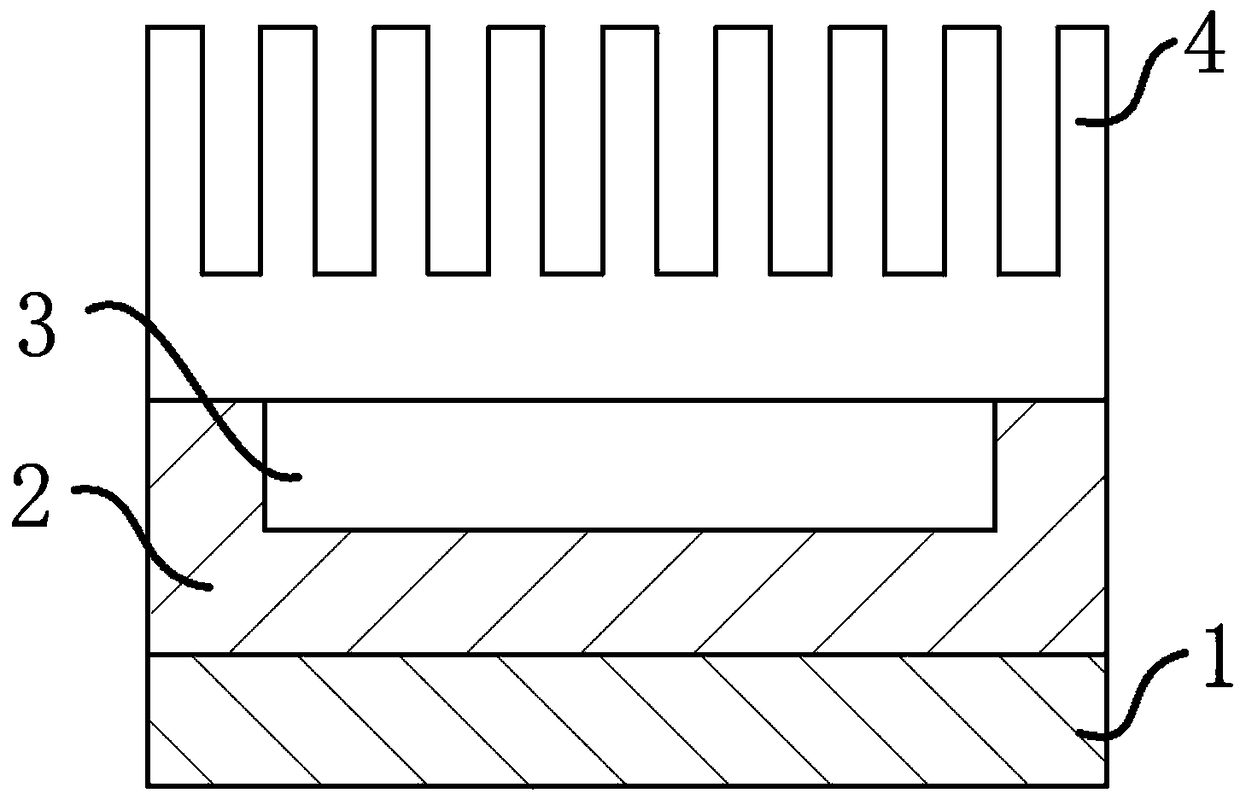

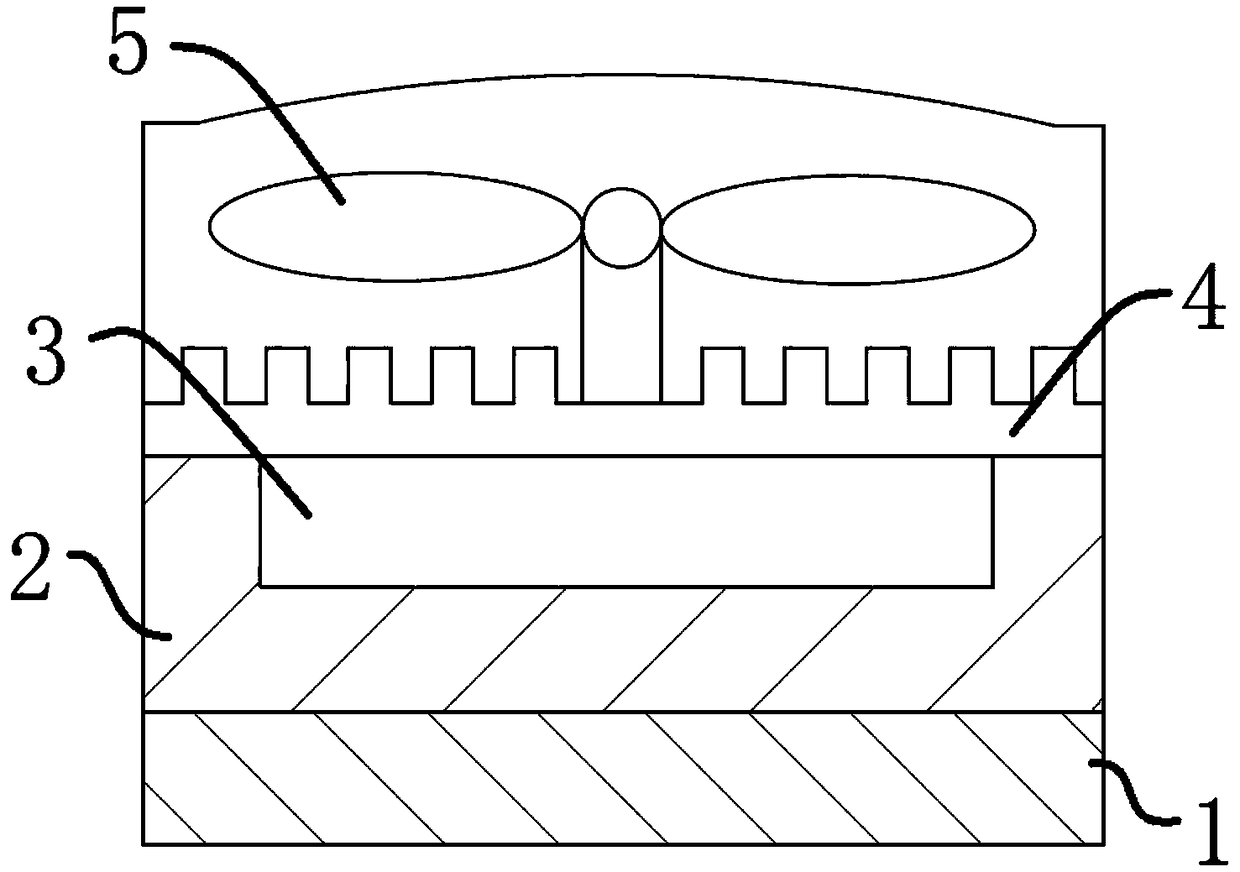

[0043] This embodiment provides a heat-conducting heat-storage composite material, which sequentially includes a heat-conducting silica gel layer, a metal layer and a phase-change material layer.

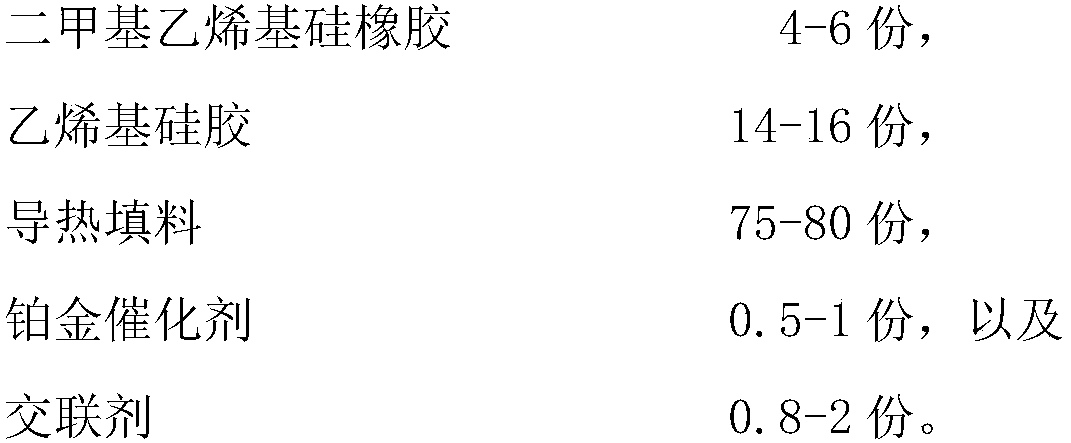

[0044] The thermally conductive silica gel layer is prepared from the following raw materials in parts by weight:

[0045]

[0046]

[0047] A further embodiment is that the thickness of the heat-conducting silica gel layer is 0.12 mm.

[0048] A further embodiment is that the crosslinking agent (methyl hydrogen silicone oil) has a viscosity of 780-800 mPa·s at 25°C.

[0049] The metal layer is copper foil with a thickness of 0.06mm.

[0050] The phase change material layer is prepared from the following raw materials in parts by weight:

[0051]

[0052] The viscosity range of the high-viscosity polyisobutylene is 600-1200 mPa·s.

[0053] A further embodiment is that the phase change wax is selected from a mixture of micron granular paraffin wax and microcrystalline wax, ...

Embodiment 2

[0062] This embodiment provides a heat-conducting heat-storage composite material, which sequentially includes a heat-conducting silica gel layer, a metal layer and a phase-change material layer.

[0063] The thermally conductive silica gel layer is prepared from the following raw materials in parts by weight:

[0064]

[0065]

[0066] A further embodiment is that the thickness of the heat-conducting silica gel layer is 0.15 mm.

[0067] A further embodiment is that the crosslinking agent (methyl hydrogen silicone oil) has a viscosity of 820-850 mPa·s at 25°C.

[0068] The metal layer is gold foil with a thickness of 0.05 mm.

[0069] The phase change material layer is prepared from the following raw materials in parts by weight:

[0070]

[0071] The viscosity range of the high-viscosity polyisobutylene is 800-1400 mPa·s.

[0072] A further embodiment is that the phase change wax is selected from a mixture of micron granular paraffin wax and microcrystalline wax,...

Embodiment 3

[0080] This embodiment provides a heat-conducting heat-storage composite material, which sequentially includes a heat-conducting silica gel layer, a metal layer and a phase-change material layer.

[0081] The thermally conductive silica gel layer is prepared from the following raw materials in parts by weight:

[0082]

[0083] A further embodiment is that the thickness of the thermally conductive silica gel layer is 0.1mm.

[0084] A further embodiment is that the crosslinking agent (methyl hydrogen silicone oil) has a viscosity of 750-800 mPa·s at 25°C.

[0085] The metal layer is silver foil with a thickness of 0.07mm.

[0086] The phase change material layer is prepared from the following raw materials in parts by weight:

[0087]

[0088] The viscosity range of the high-viscosity polyisobutylene is 900-1200 mPa·s.

[0089] A further embodiment is that the phase-change wax is selected from a mixture of micron-sized granular microcrystalline wax, palm wax, and whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com