Patents

Literature

108 results about "Microtubule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microtubules are polymers of tubulin that form part of the cytoskeleton and provide structure and shape to the cytoplasm of eukaryotic cells, some bacteria and some archaea (like Asgard). A microtubule can grow as long as 50 micrometres and are highly dynamic. The outer diameter of a microtubule is between 23 and 27 nm while the inner diameter is between 11 and 15 nm. They are formed by the polymerization of a dimer of two globular proteins, alpha and beta tubulin into protofilaments that can then associate laterally to form a hollow tube, the microtubule. The most common form of a microtubule consists of 13 protofilaments in the tubular arrangement.

Halloysite microtubule processes, structures, and compositions

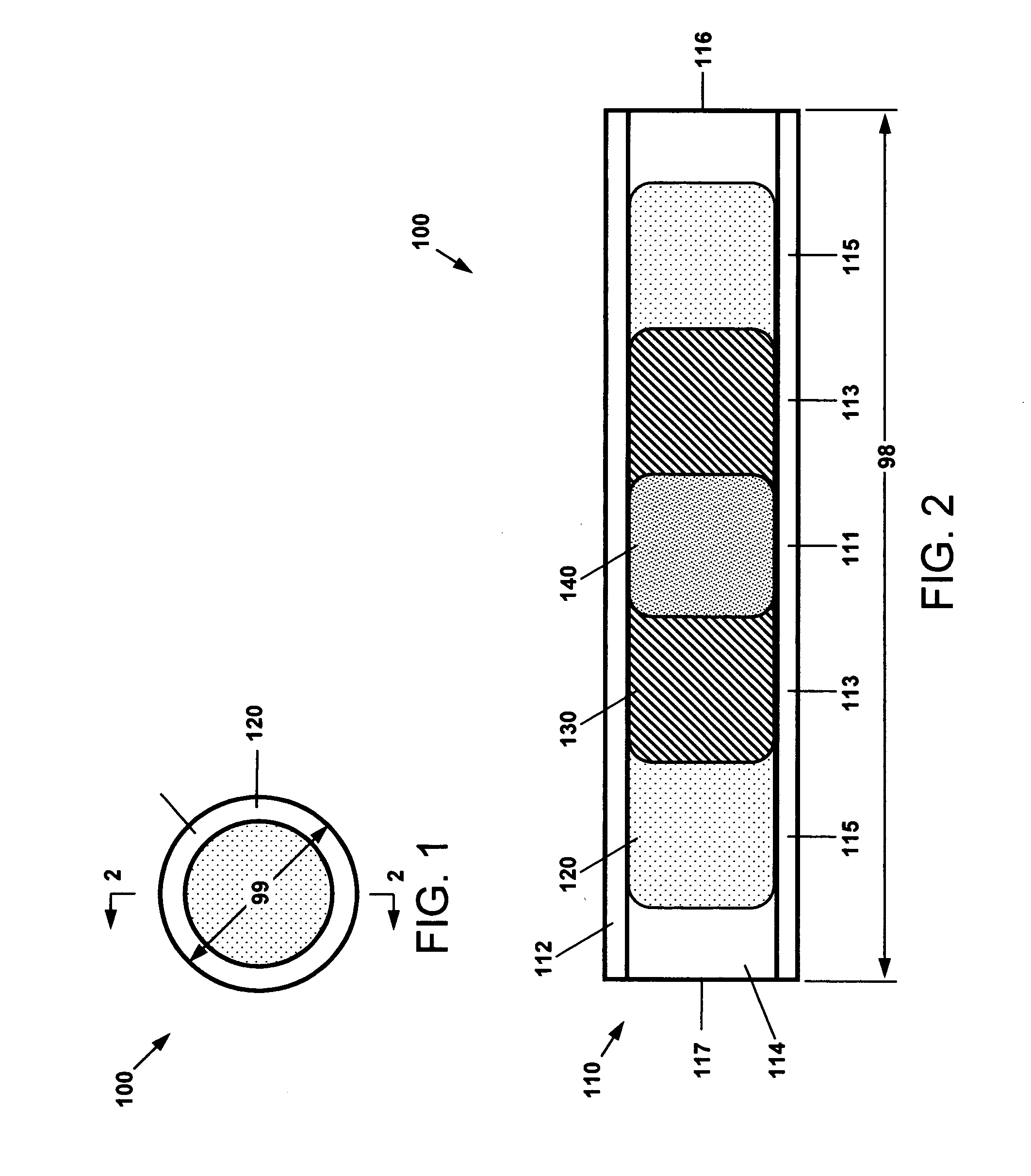

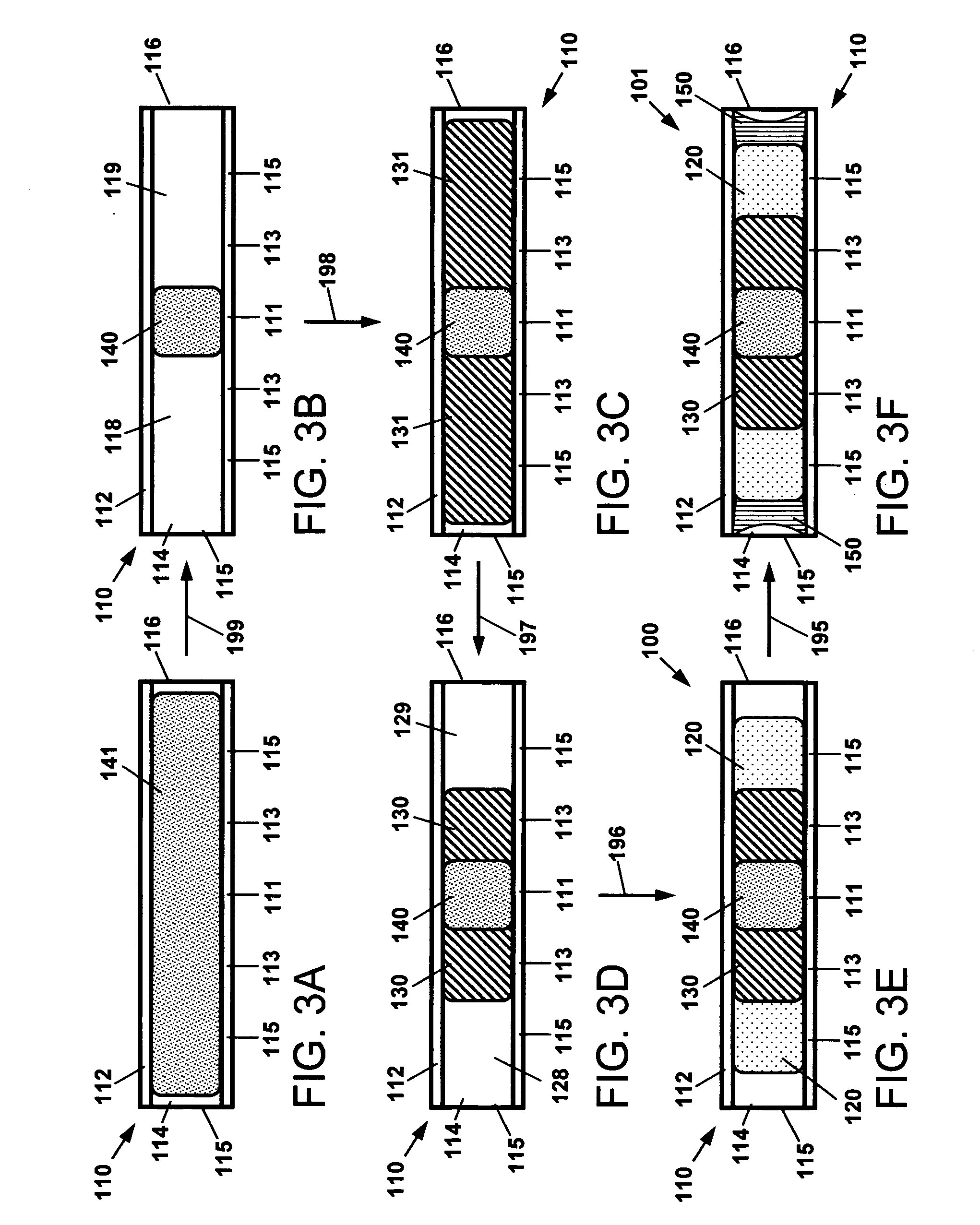

A composition for use in the delivery of a first active agent and a second active agent, the first active agent being sequentially deliverable after the second active agent, the composition comprising hollow mineral microtubules, each of the hollow mineral microtubules having a length, and opposing ends; and including a cylindrical wall, and a hollow lumen; and a central region, an intermediate region, and an outer region along the length; and within the microtubules, the first active agent disposed within the lumen in the central region of the microtubules, and the second active agent disposed within the lumen in the intermediate region of the microtubules. The composition may also be provided for the delivery of three or more active agents in sequence. There is further provided methods for making the compositions of the present invention.

Owner:NATURALNANO RES

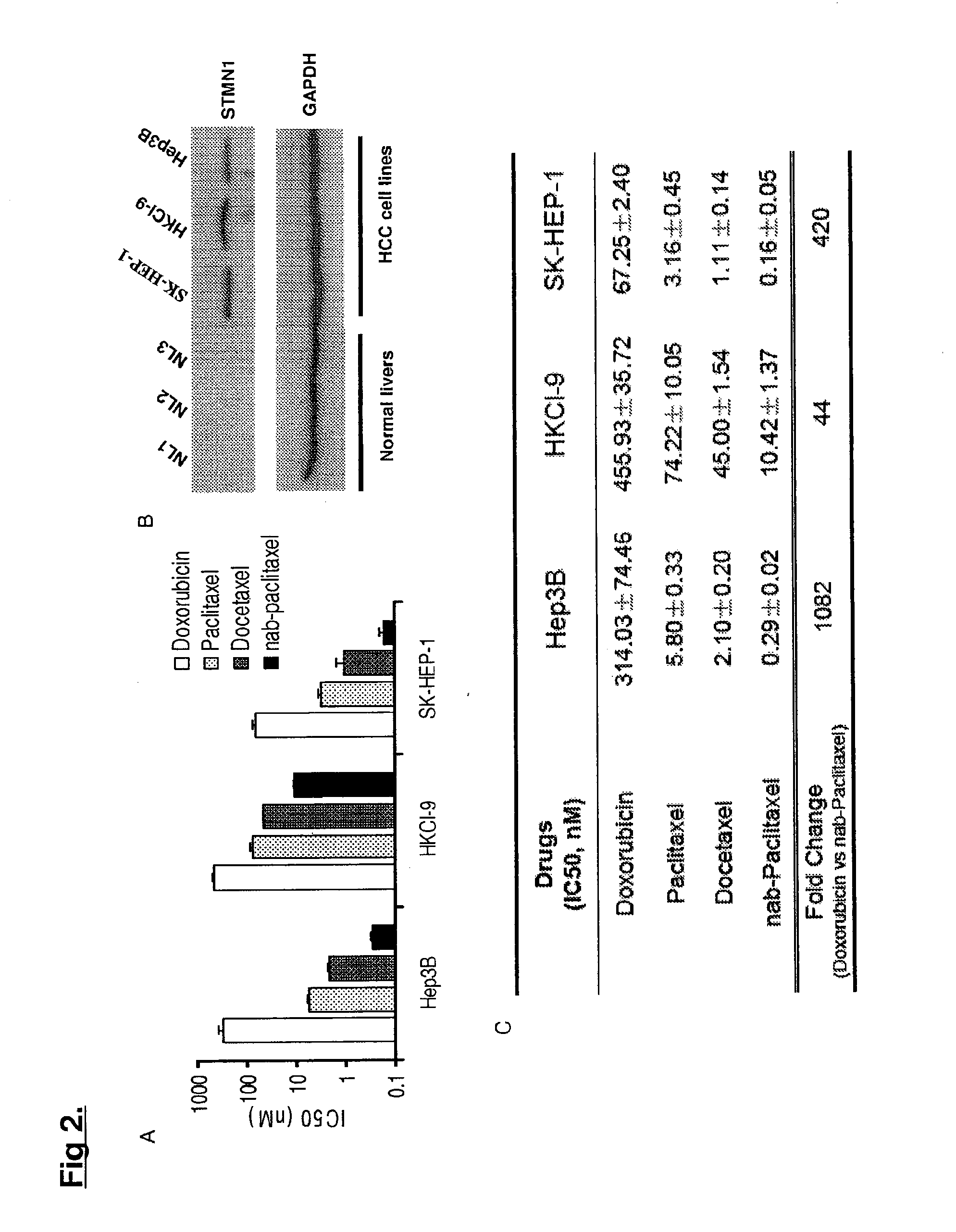

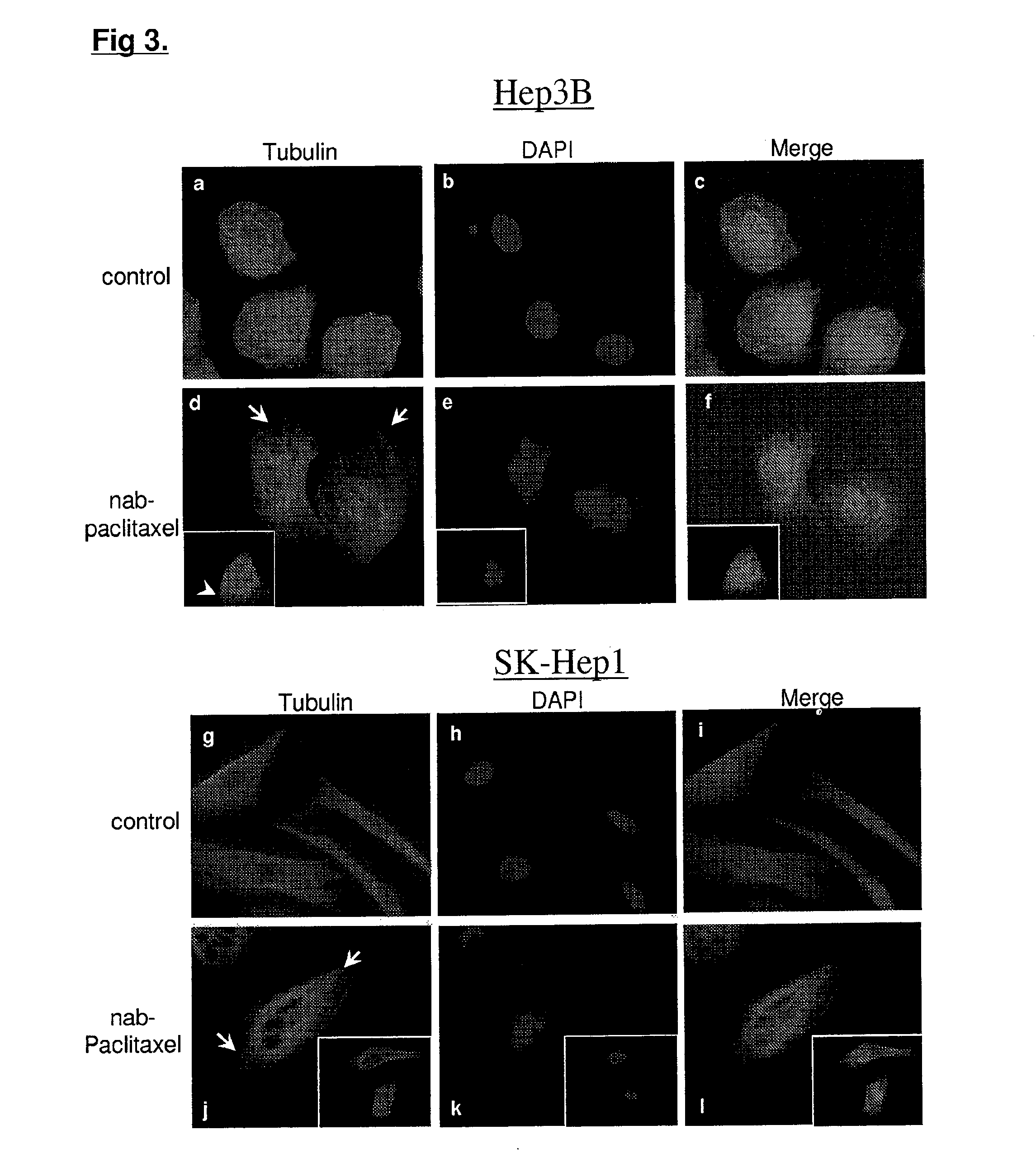

Methods for treating hepatocellular carcinoma

InactiveUS20140079787A1Many symptomShorten the progressPowder deliveryBiocideMicrotubuleNanoparticle

Owner:ABRAXIS BIOSCI LLC

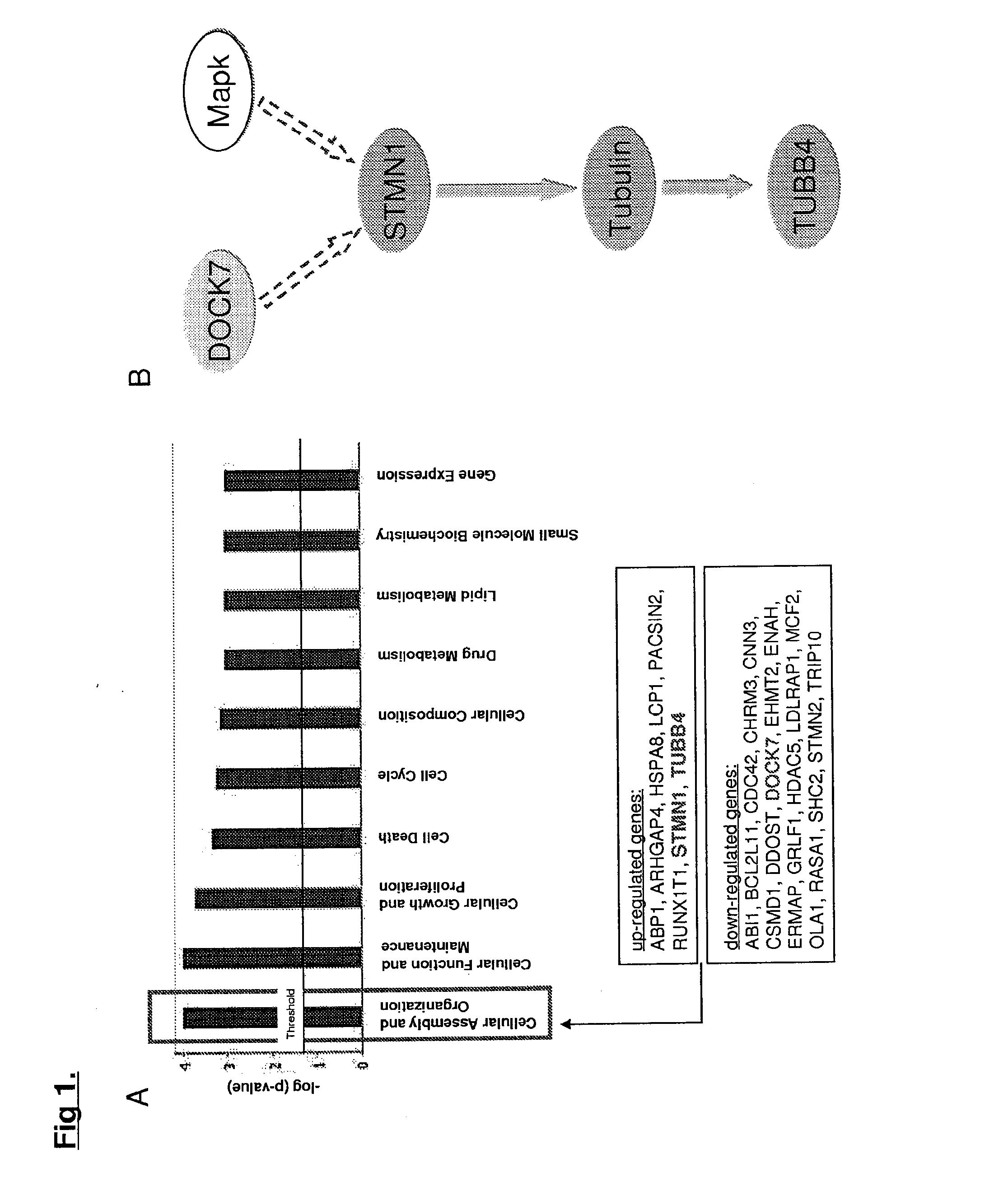

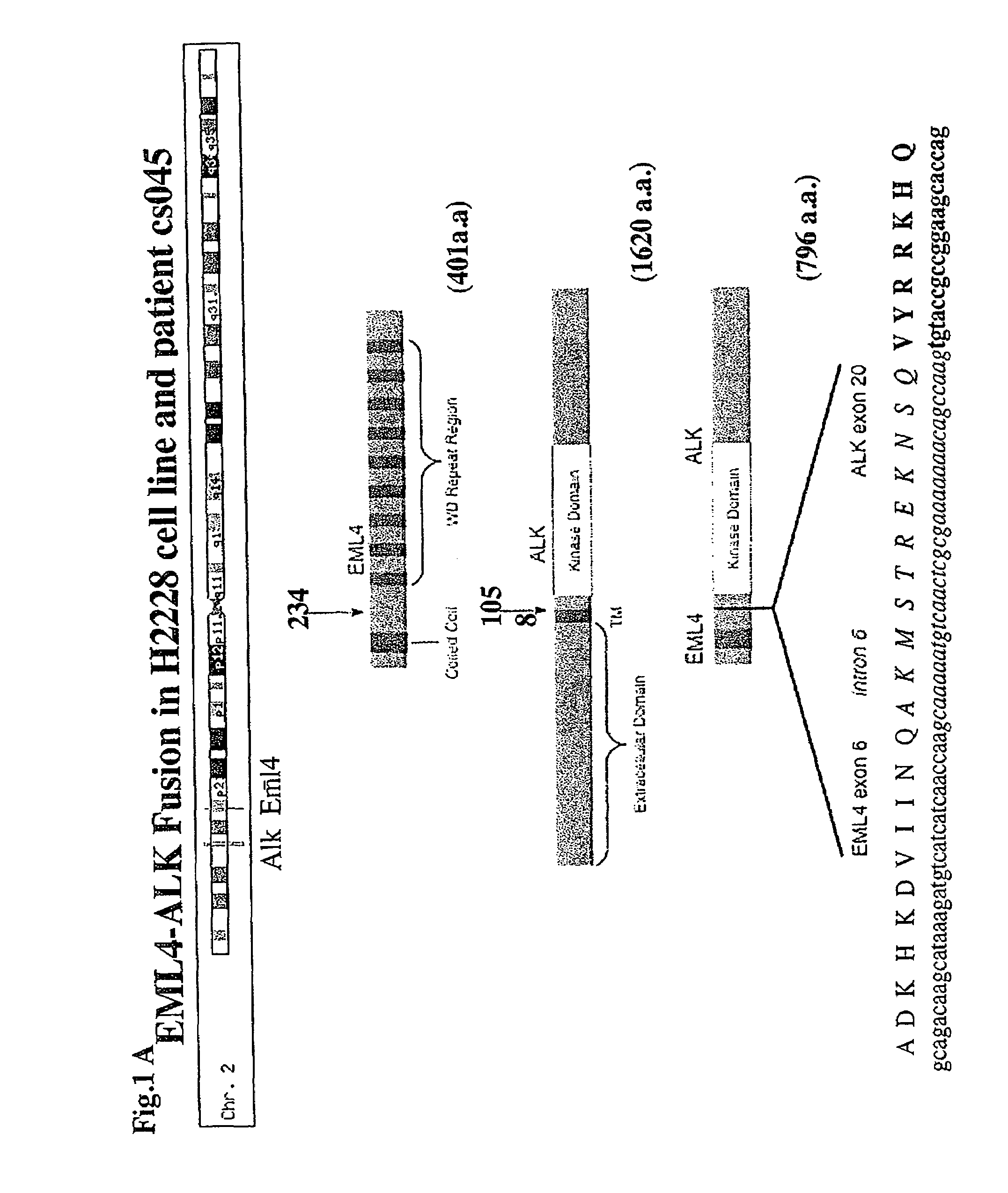

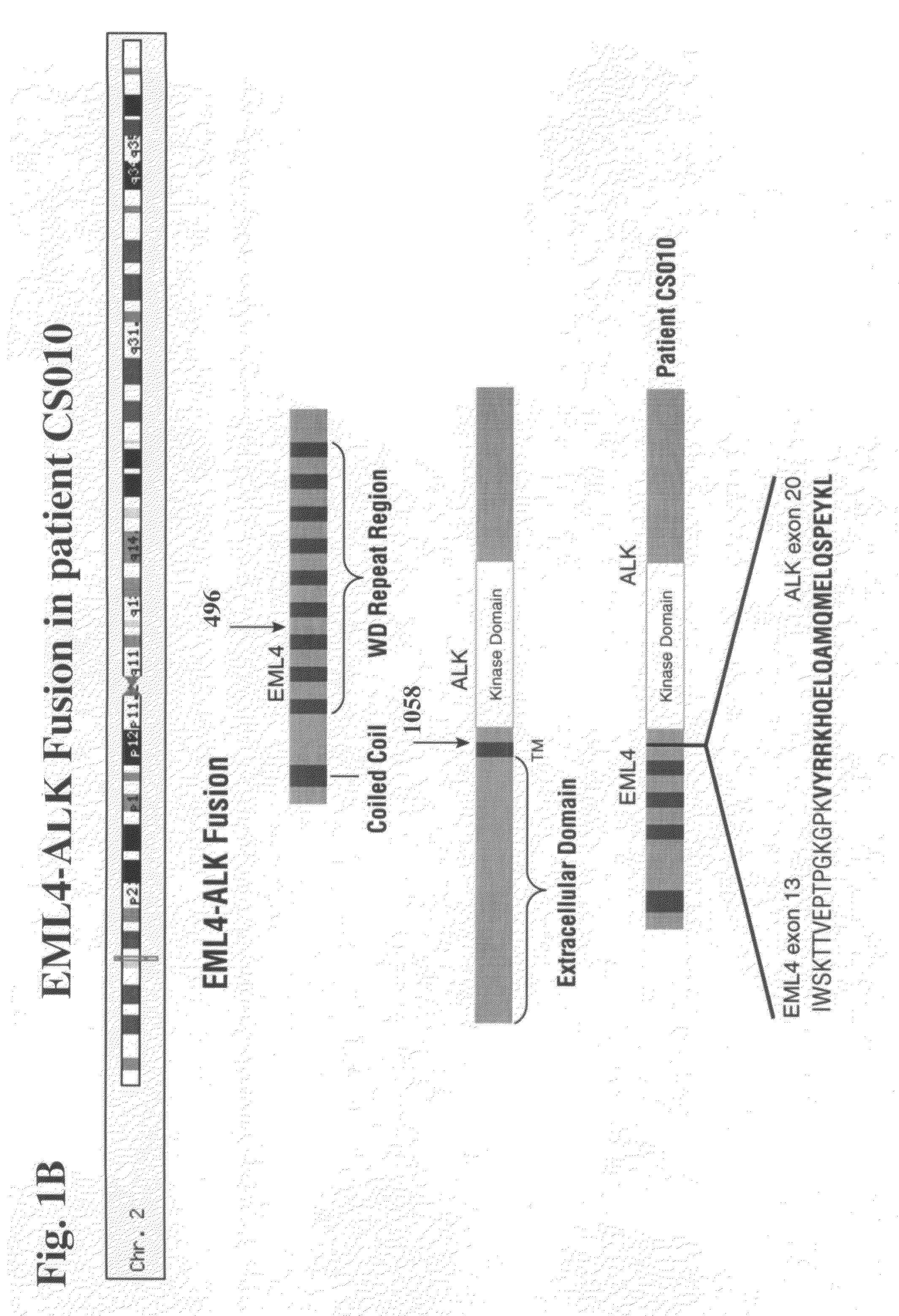

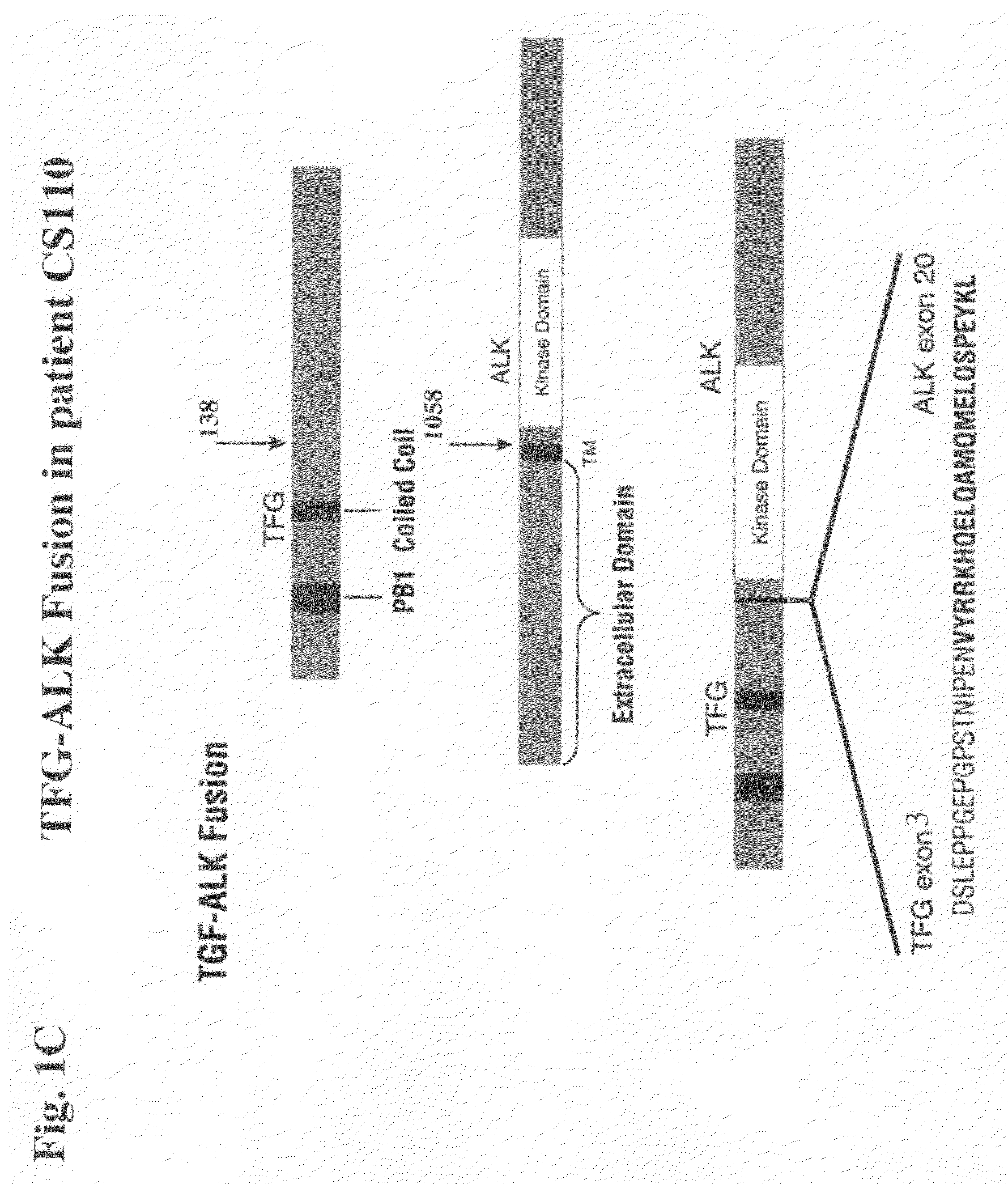

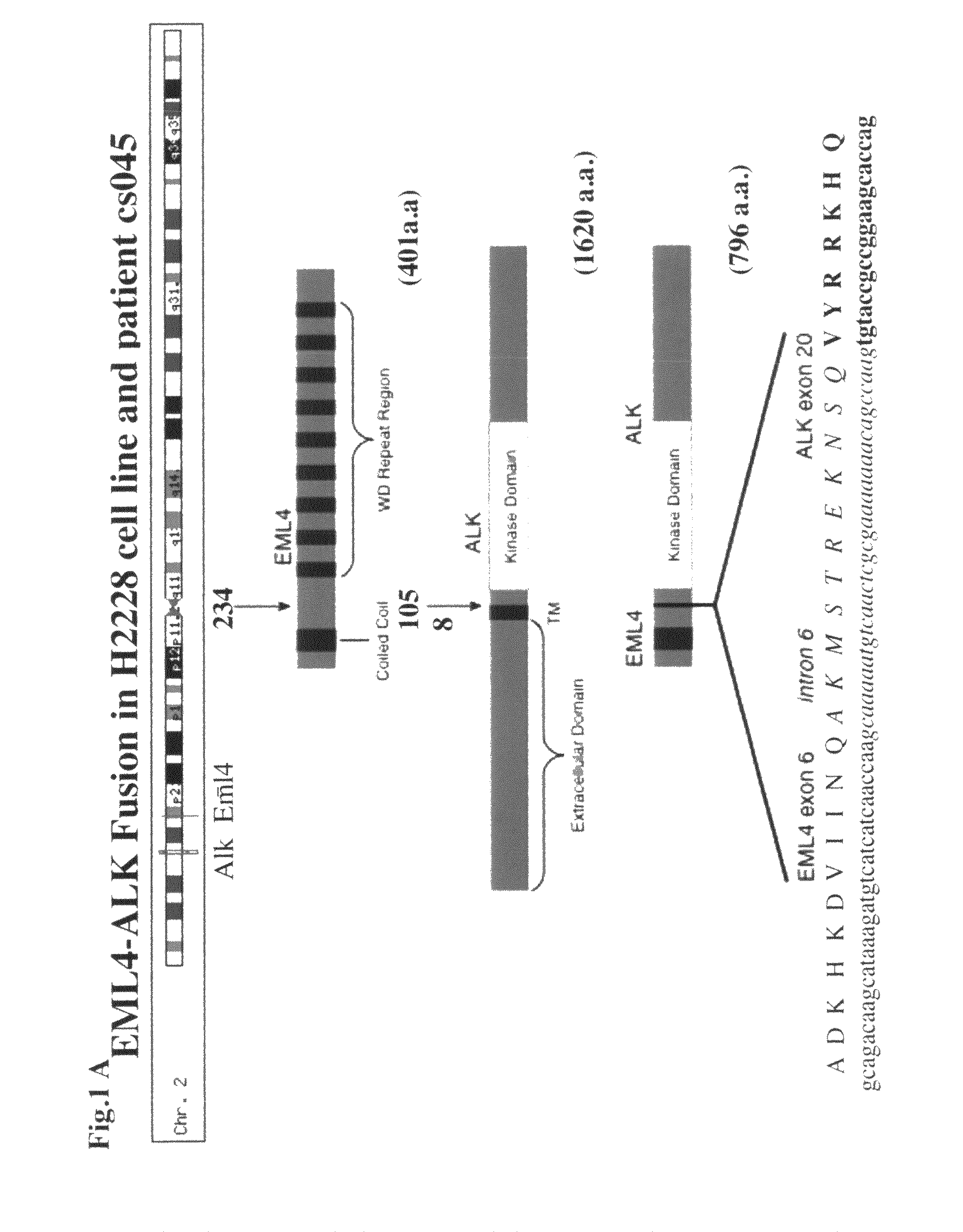

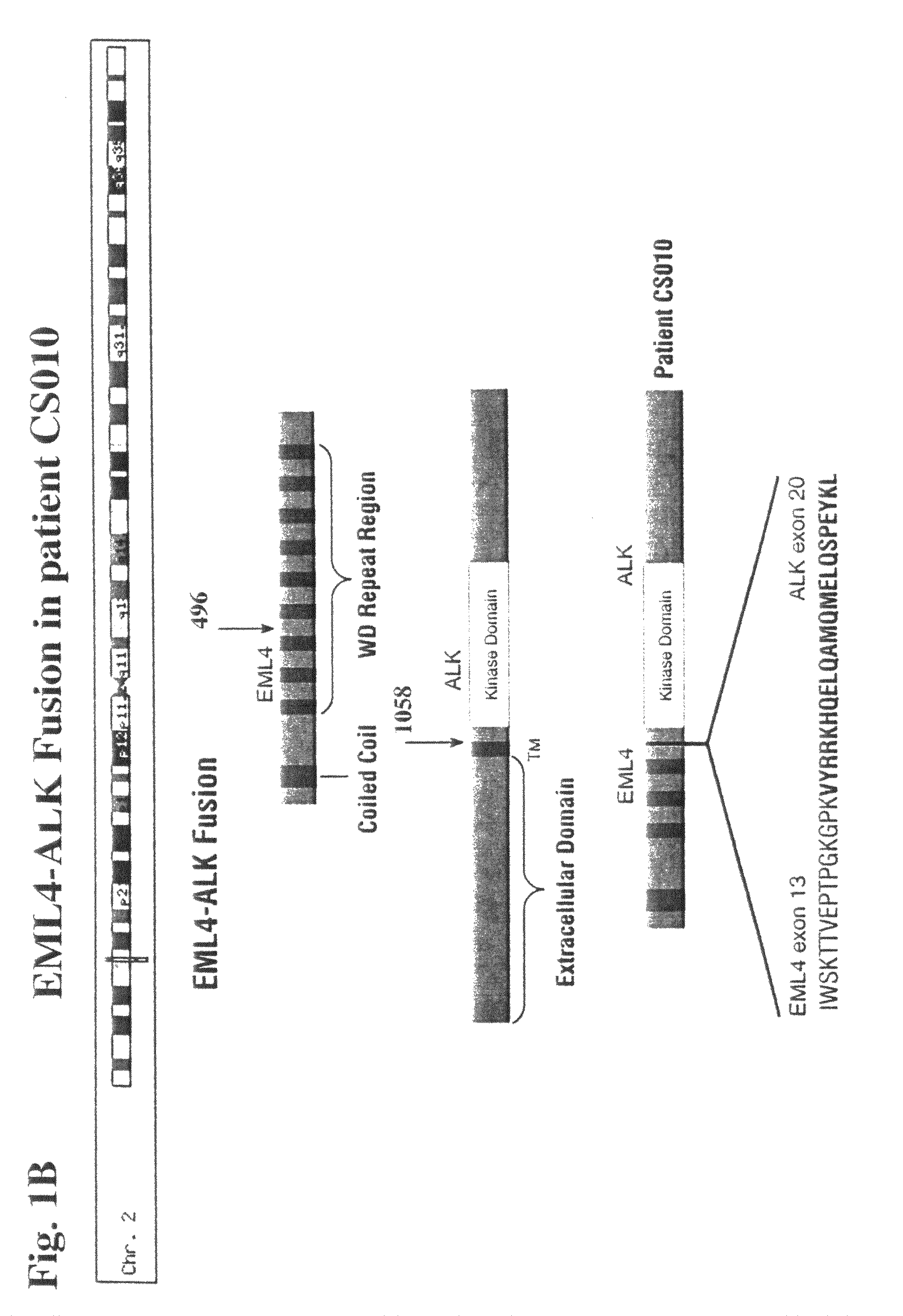

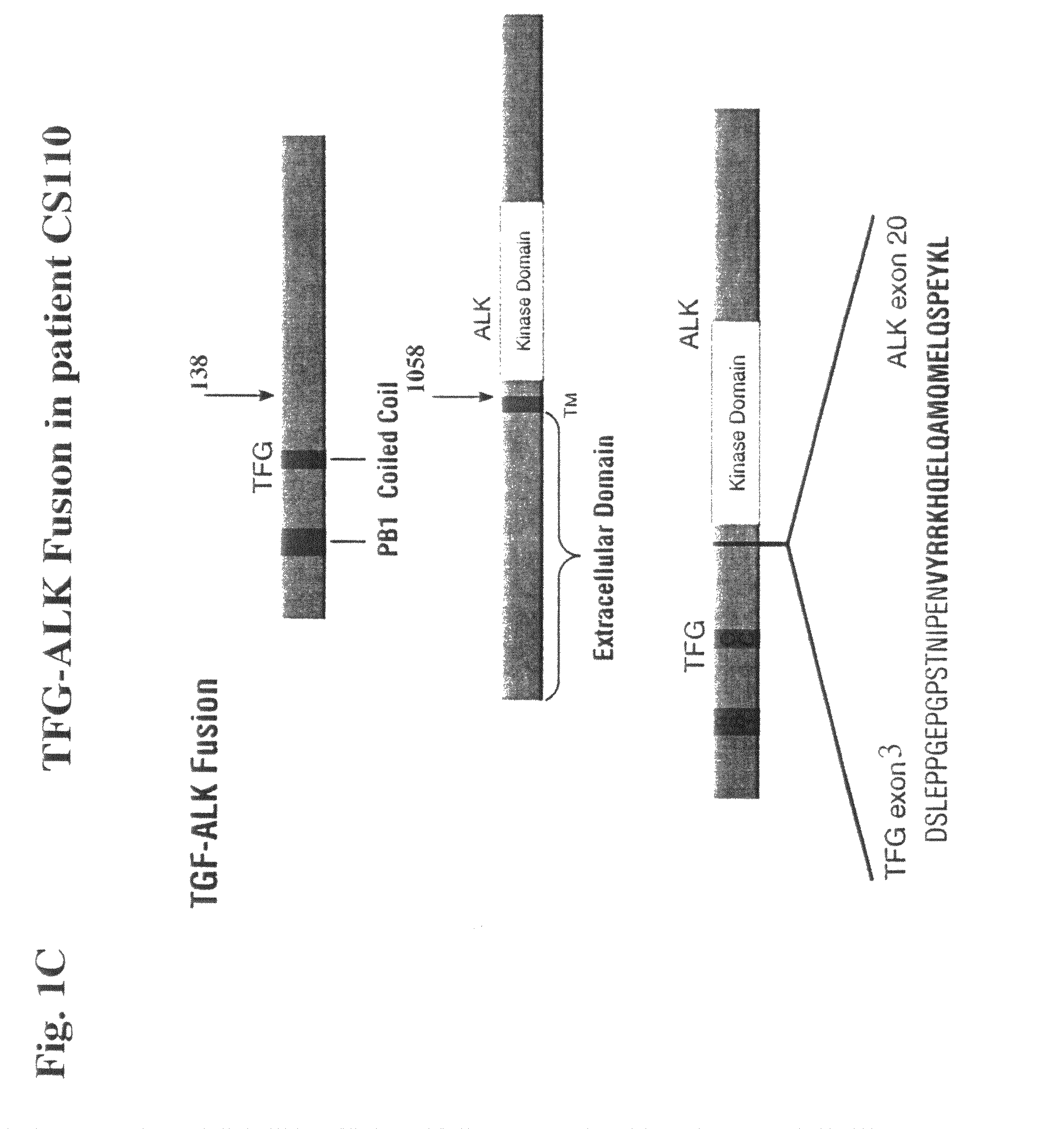

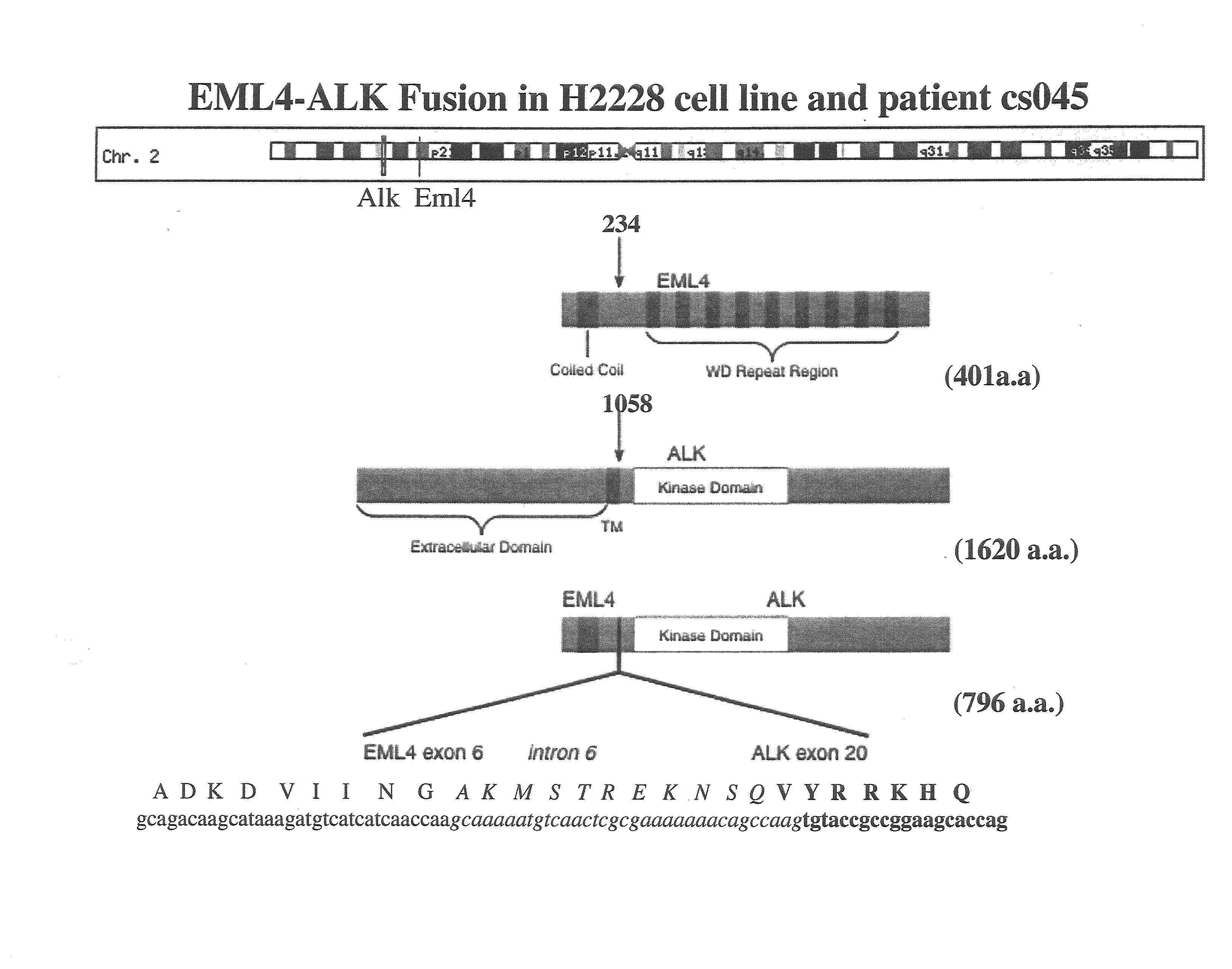

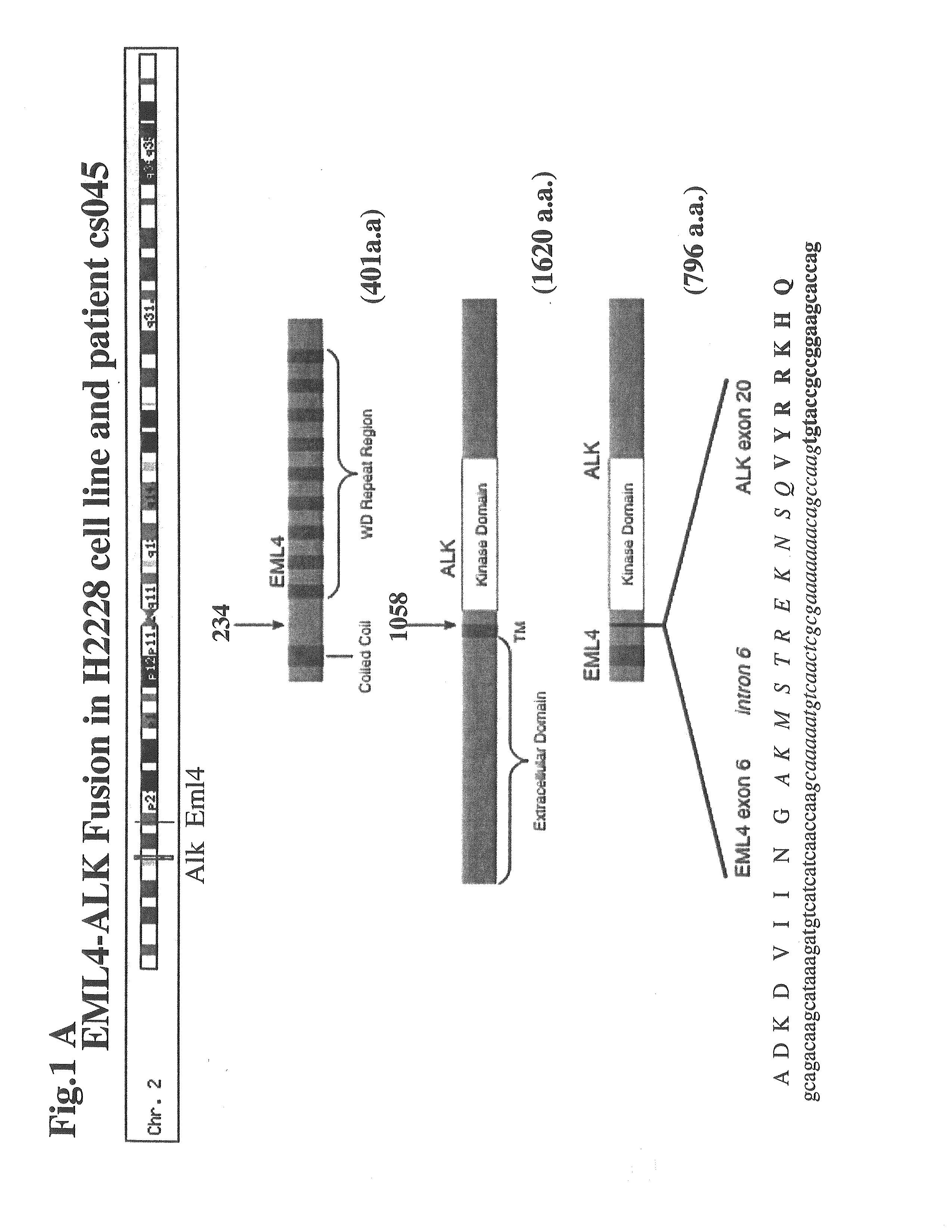

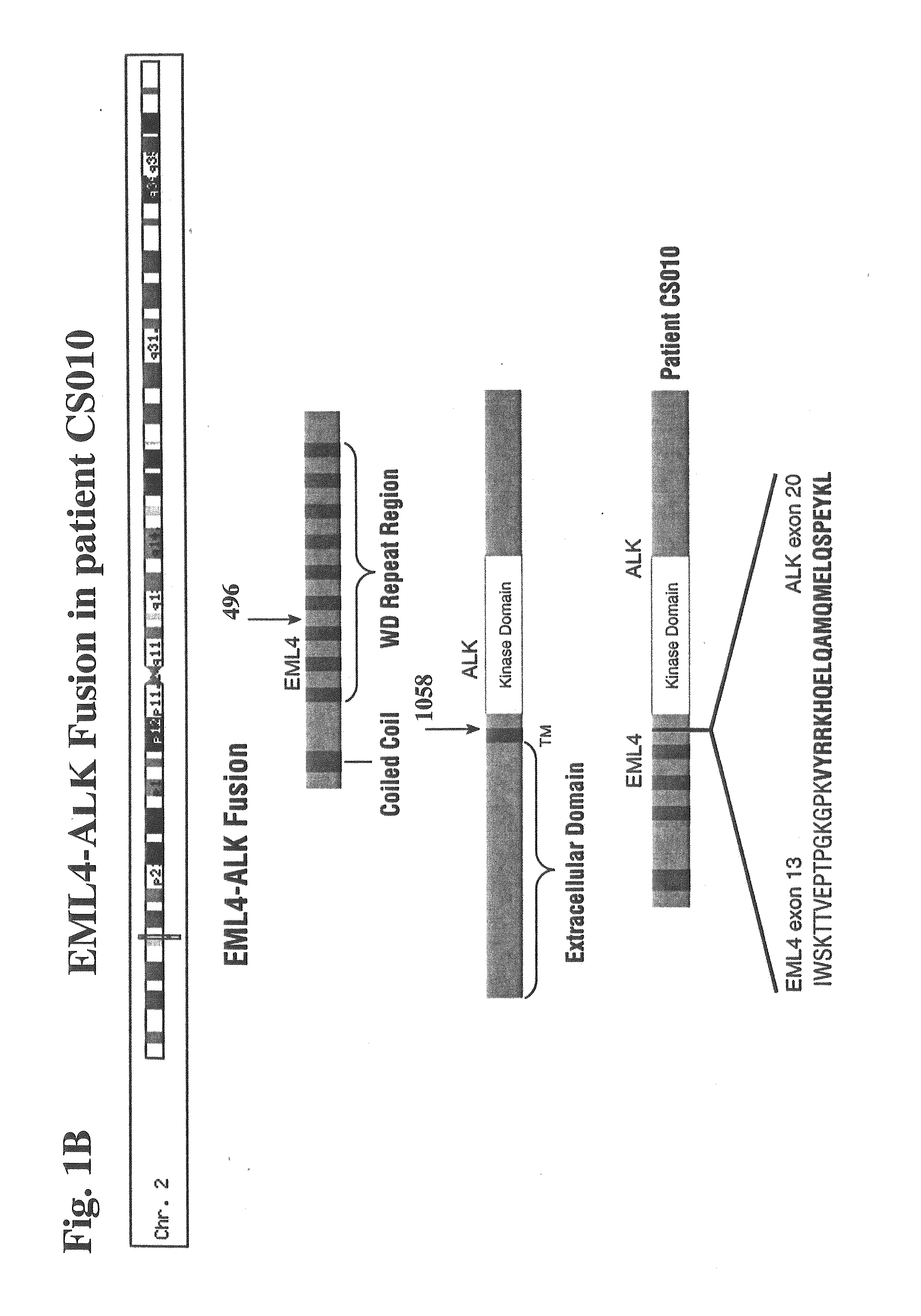

Gene defects and mutant ALK kinase in human solid tumors

In accordance with the invention, novel gene deletions and translocations involving chromosome 2 resulting in fusion proteins combining part of Anaplastic Lymphoma Kinase (ALK) kinase with part of a secondary protein have now been identified in human solid tumors, e.g. non-small cell lung carcinoma (NSCLC). Secondary proteins include Echinoderm Microtubule-Associated Protein-Like 4 (EML-4) and TRK-Fusion Gene (TFG). The EML4-ALK fusion protein, which retains ALK tyrosine kinase activity, was confirmed to drive the proliferation and survival of NSCLC characterized by this mutation. The invention therefore provides, in part, isolated polynucleotides and vectors encoding the disclosed mutant ALK kinase polypeptides, probes for detecting it, isolated mutant polypeptides, recombinant polypeptides, and reagents for detecting the fusion and truncated polypeptides. The disclosed identification of this new fusion protein enables new methods for determining the presence of these mutant ALK kinase polypeptides in a biological sample, methods for screening for compounds that inhibit the proteins, and methods for inhibiting the progression of a cancer characterized by the mutant polynucleotides or polypeptides, which are also provided by the invention.

Owner:CELL SIGNALING TECHNOLOGY

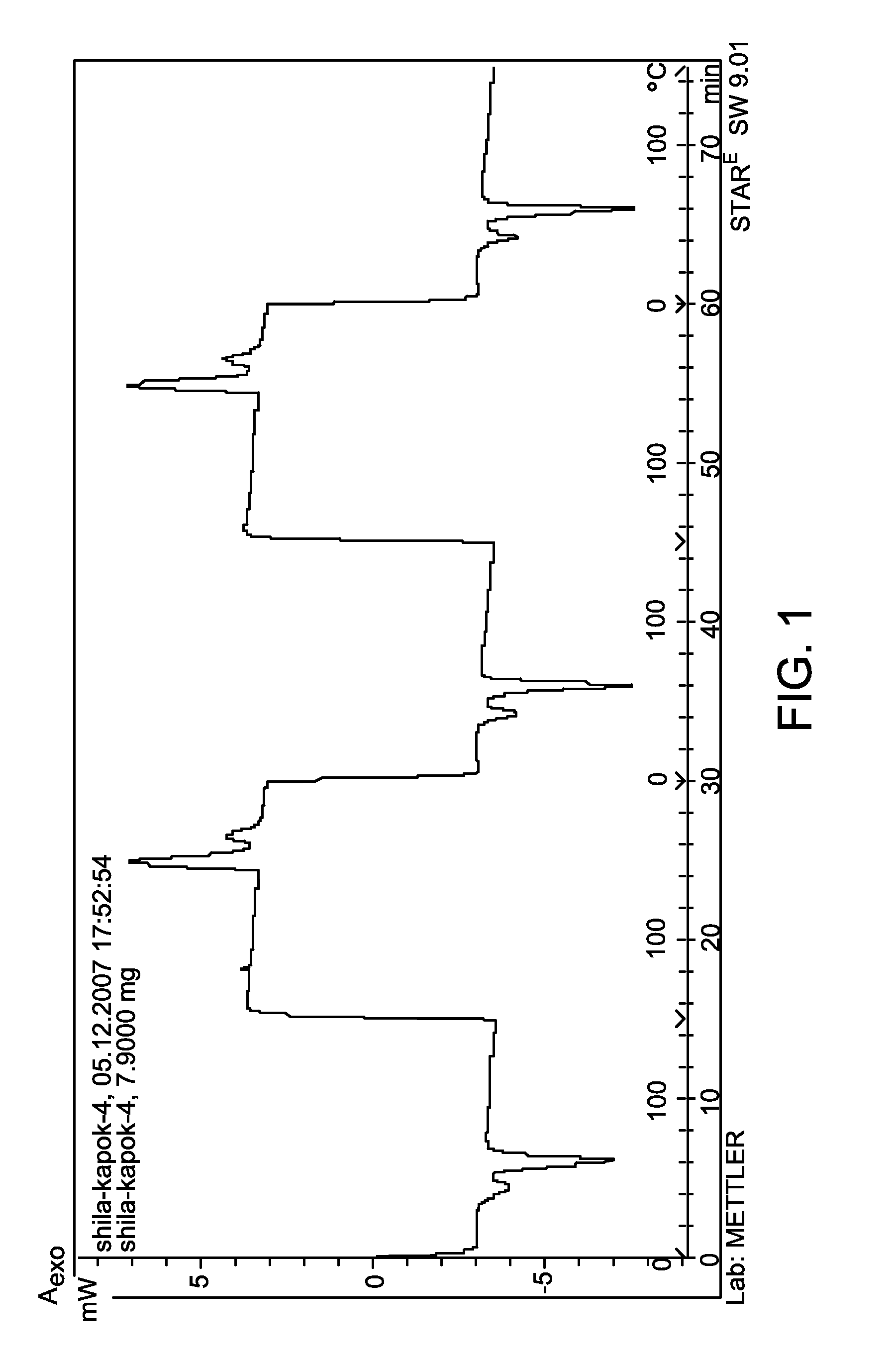

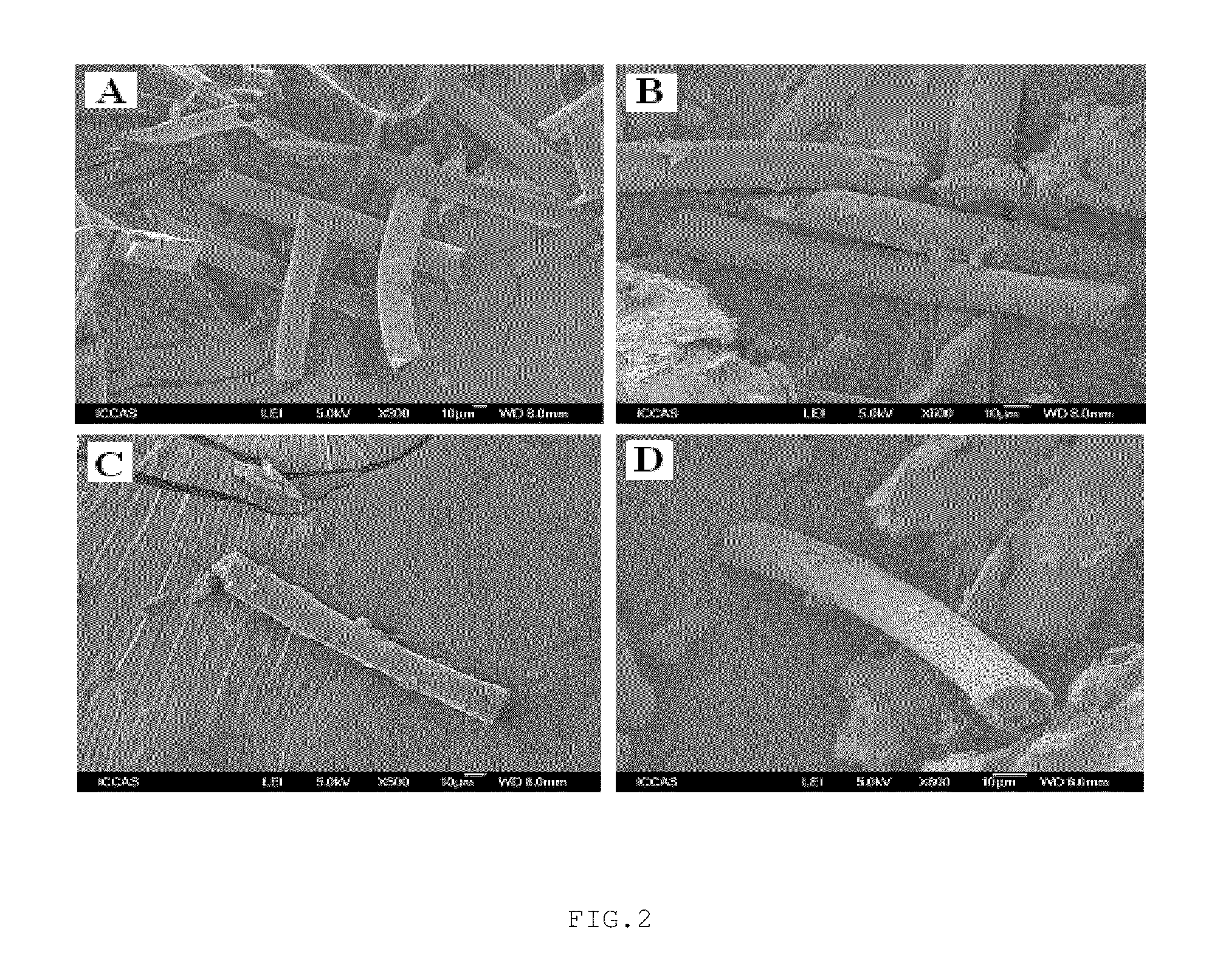

Natural microtubule encapsulated phase-change materials and preparation thereof

InactiveUS20100071882A1Cheap and easily available natural microfibersLarge specific surface areaHeat storage plantsMetal-working apparatusMicrotubulePolymer science

Microtubule encapsulated microcapsules of a phase-change material and preparation thereof are provided. The microcapsules of a phase-change material consist of a phase-change material, truncated microtubules, and a polymer. The truncated microtubules are formed by truncating hollow tubular natural fibers into fiber segments with a length of 0.1 mm-5 cm. The diameter of the hollow tubular natural fiber is 0.1-1000 μm. The phase-change material is encapsulated in the truncated microtubules and the truncated microtubules are covered with the polymer. The microtubules have high energy storage density due to high hollowness, and can transfer energy stably due to the closed structure, transfer heat rapidly due to the very fine micro-tubular structures, and may be used for a long term in view of the heat and chemical stability.

Owner:ETERNAL MATERIALS CO LTD

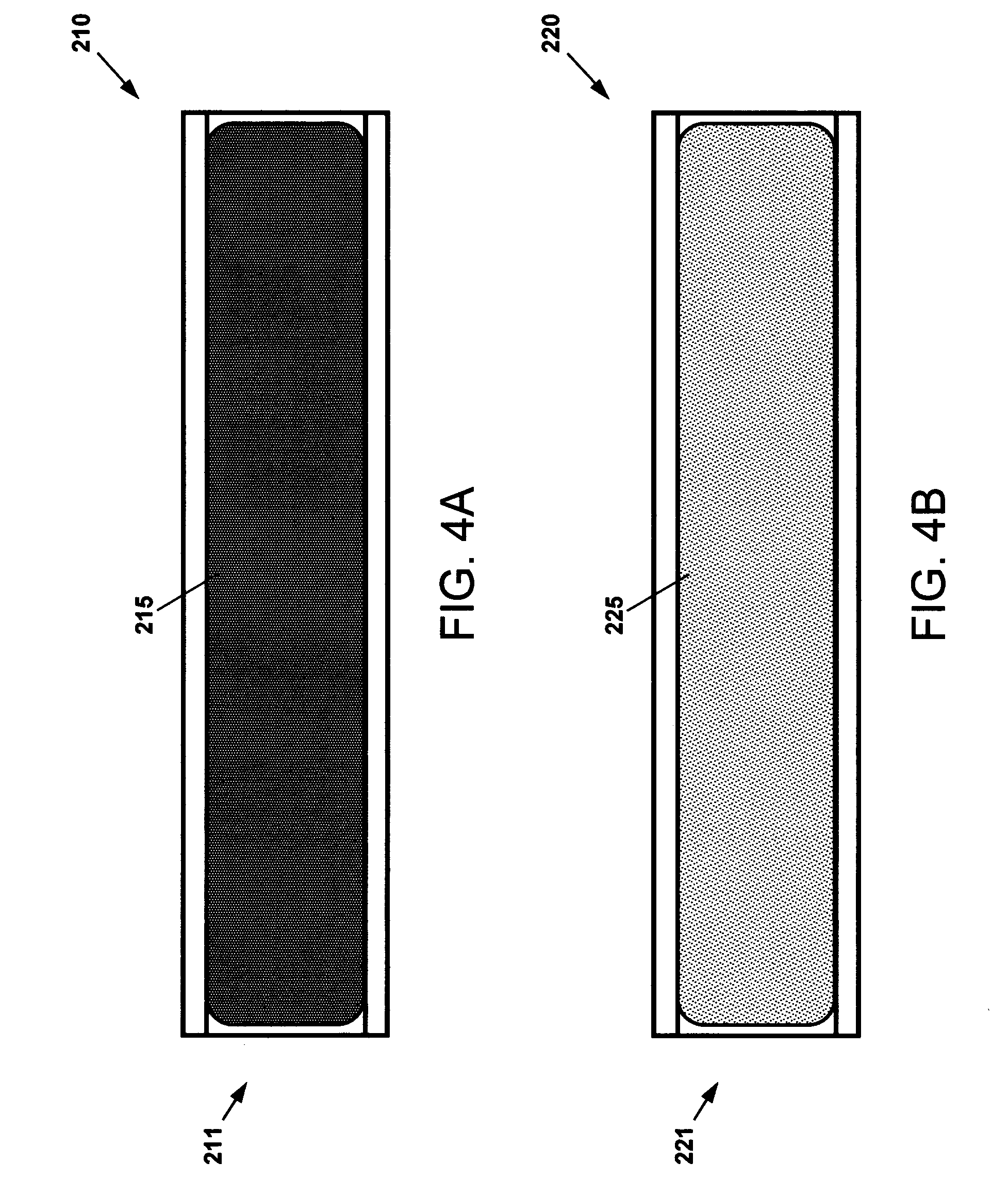

High performance energy storage and collection devices containing exfoliated microtubules and spatially controlled attached nanoscale particles and layers

ActiveUS20110151321A1High strengthIncreased durabilityAlkaline accumulatorsElectrolytic capacitorsMicrotubuleMelt extrusion

The present disclosure relates to energy storage or collection devices and methods for making such devices having electrode materials containing exfoliated nanotubes with attached electro- or photoactive nanoscale particles or layers.The exfoliated nanotubes and attached nanoscale particles or layers may be easily fabricated by methods such as coating, solution or casting or melt extrusion to form electrodes. Electrolytes may also be used for dispersing nanotubes and also in a polymeric form to allow melt fabrication methods.

Owner:BLACK DIAMOND STRUCTURES

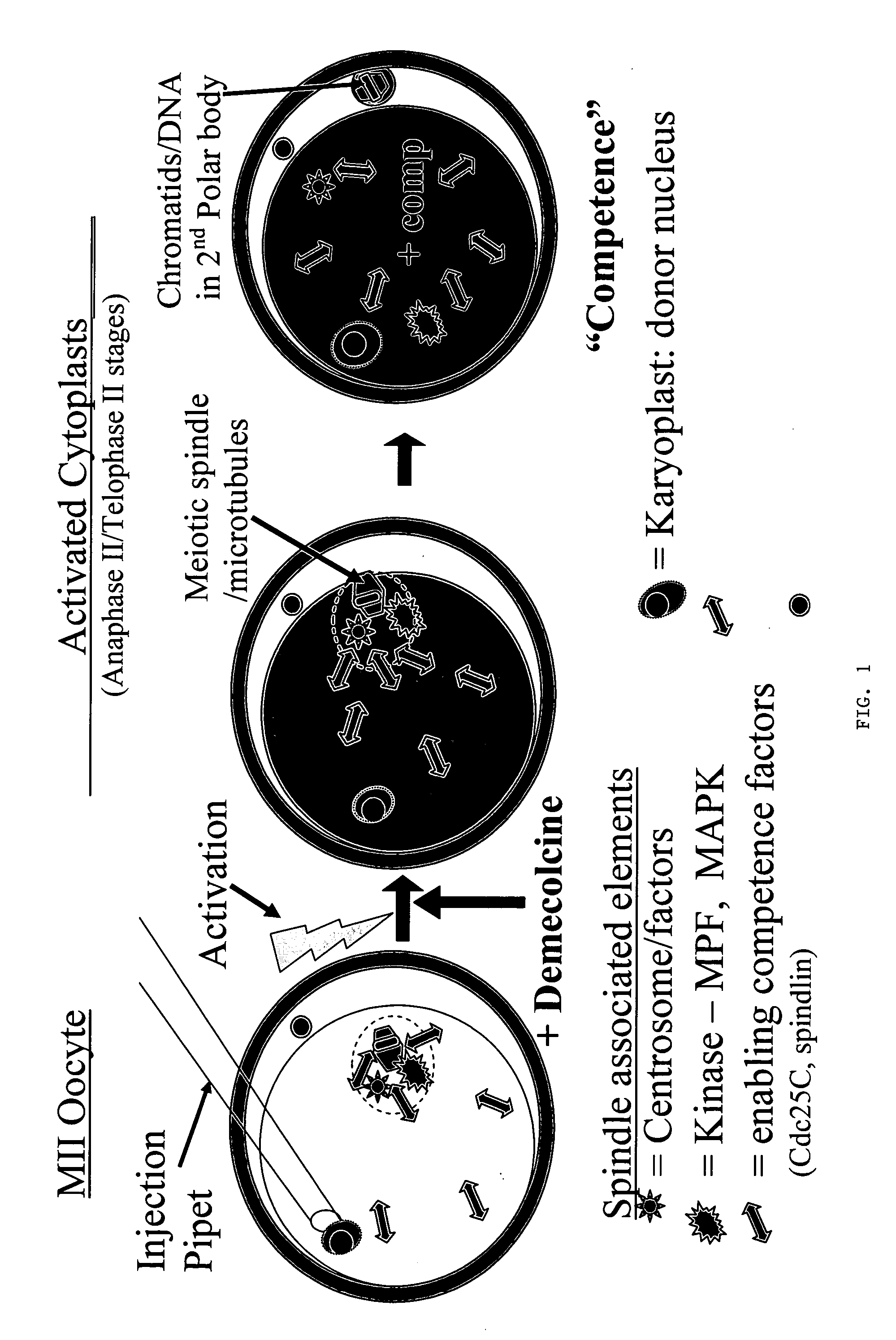

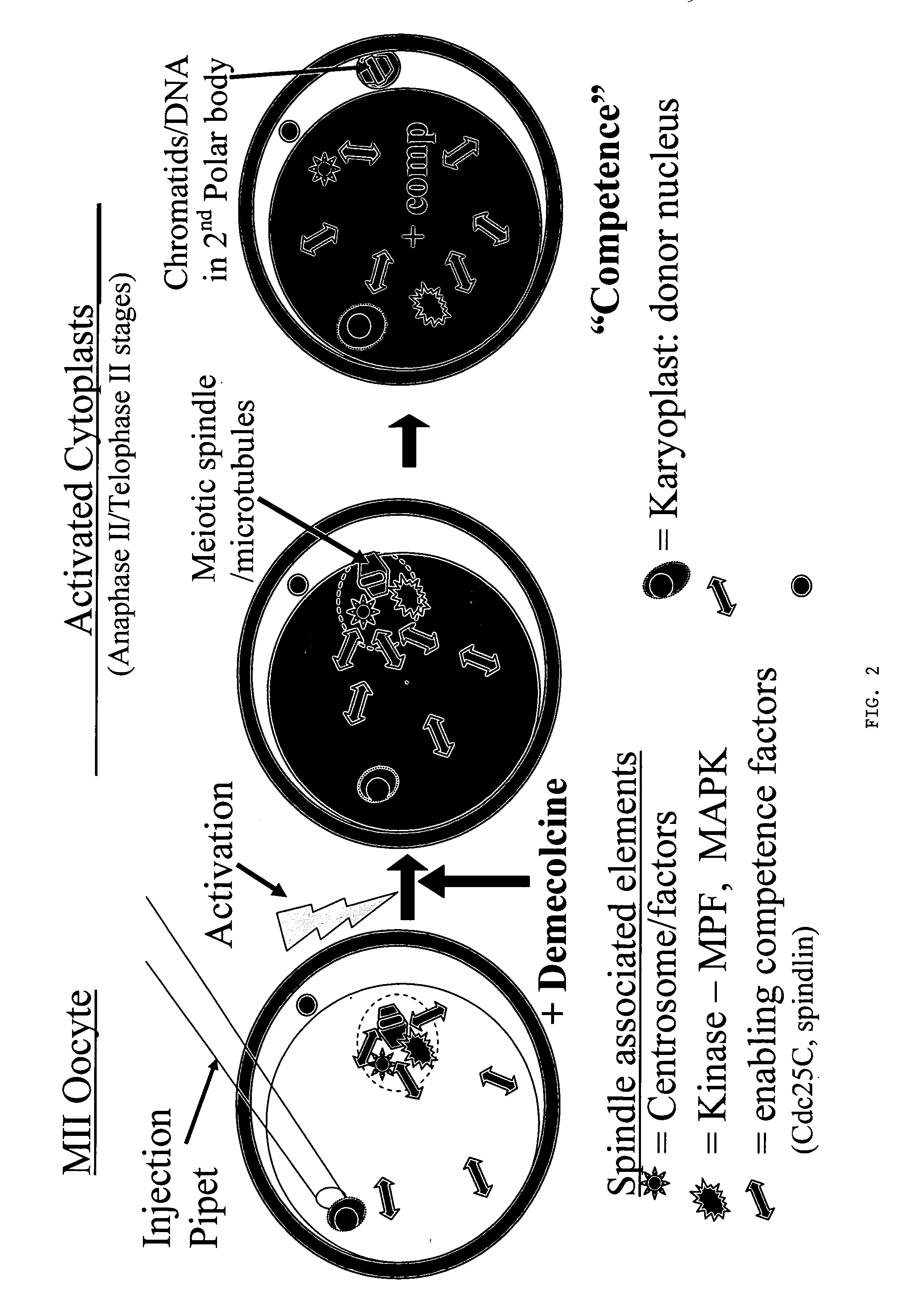

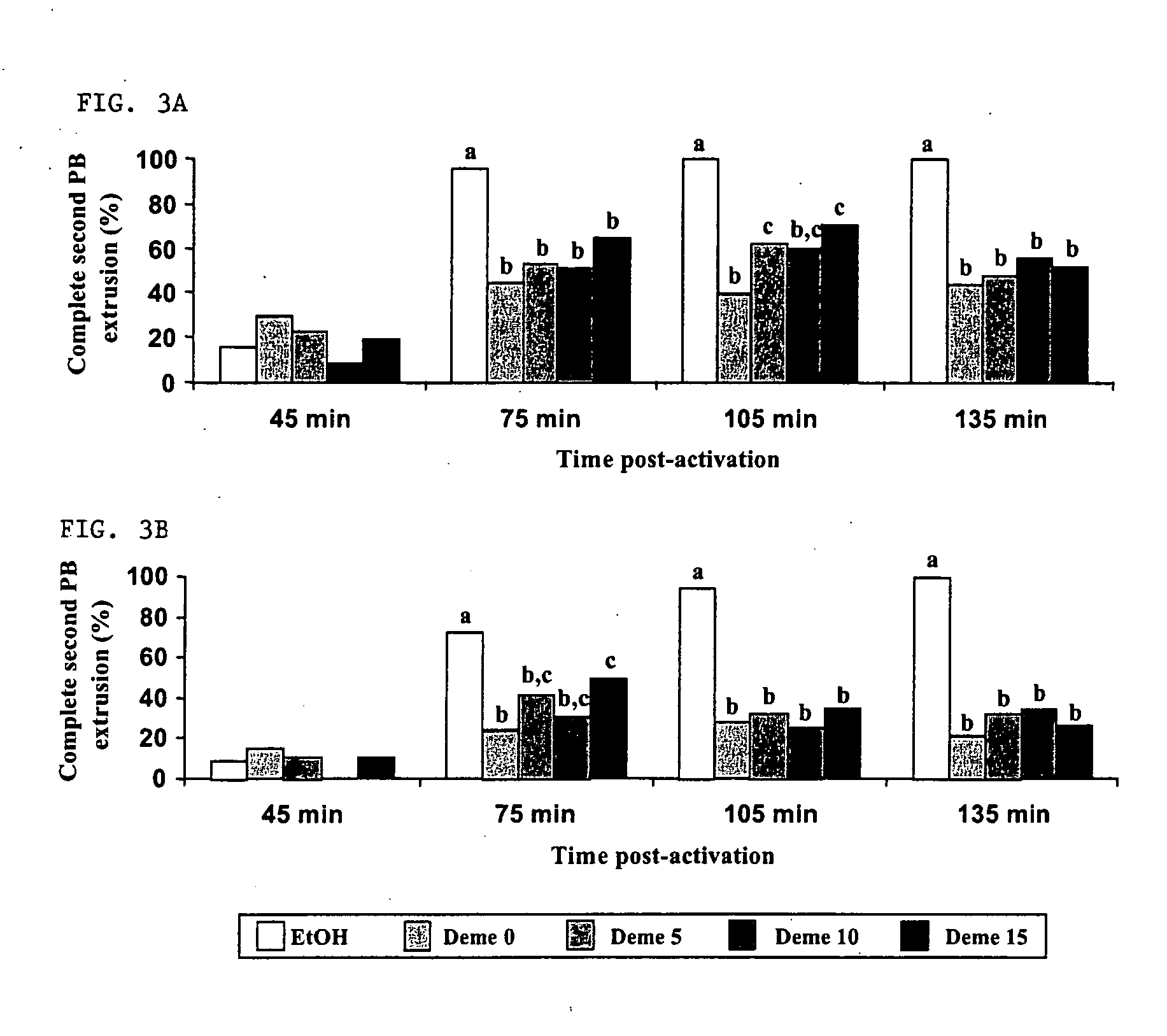

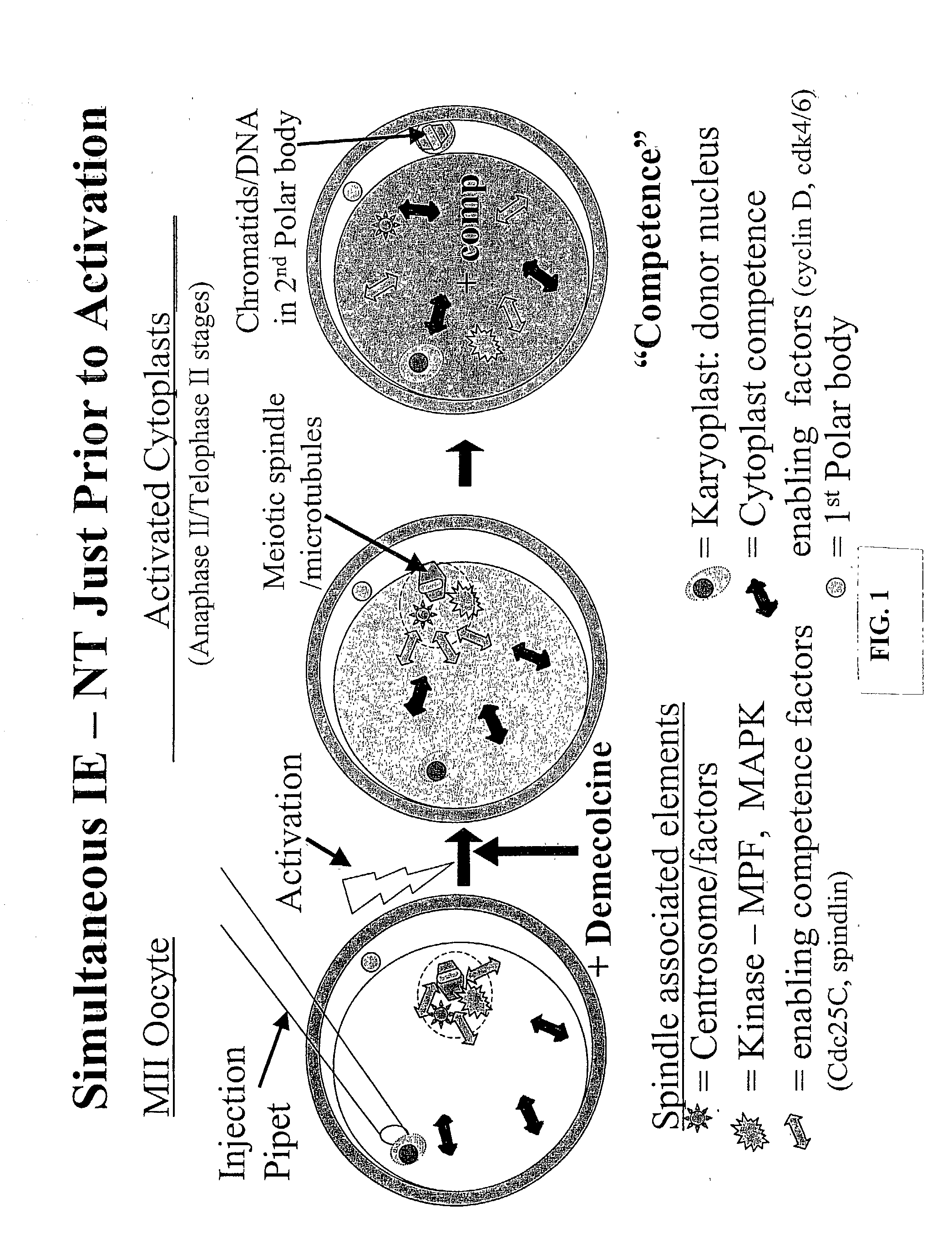

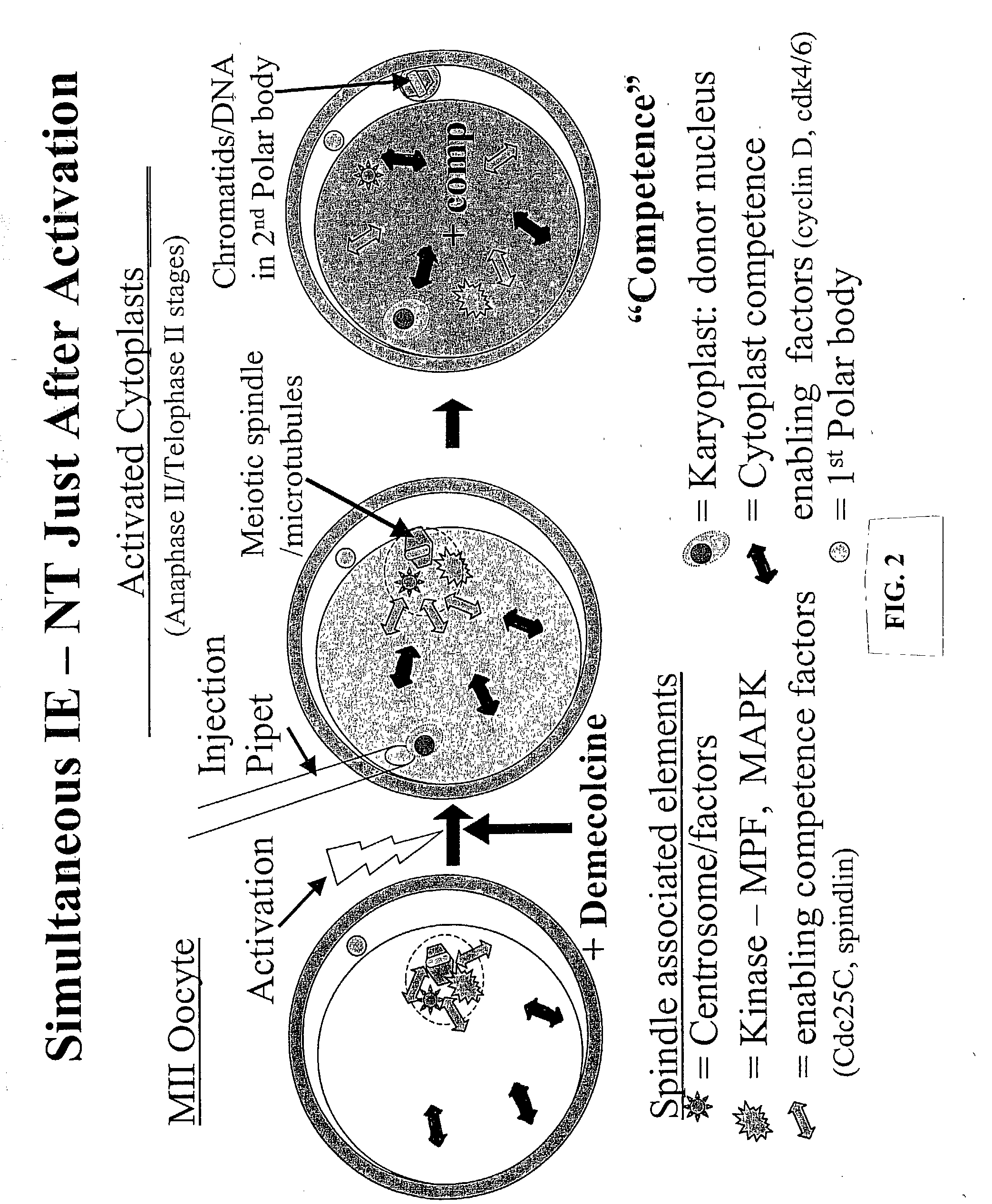

Nuclear transfer embryo formation method

A nuclear transfer embryo is formed by destabilizing microtubules of an oocyte, whereby essentially all endogenous chromatin collects at a second polar body during meiosis of an oocyte. The oocyte is fused with the nucleus of a donor somatic cell of the same species of said oocyte prior to cessation of extrusion of the second polar body from the oocyte, thereby forming the nuclear transfer embryo. In one embodiment, the nuclear transfer embryo is employed to impregnate an animal, such as a mammal. In another embodiment, the donor nucleus is transgenic.

Owner:TRUSTEES OF TUFTS COLLEGE

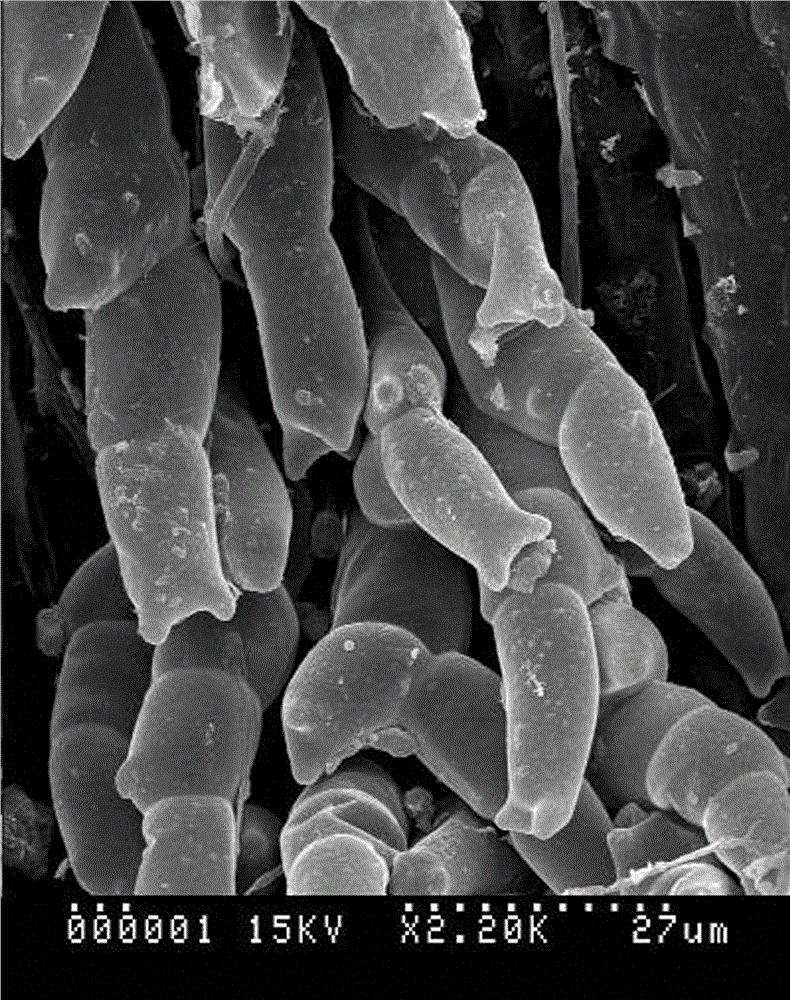

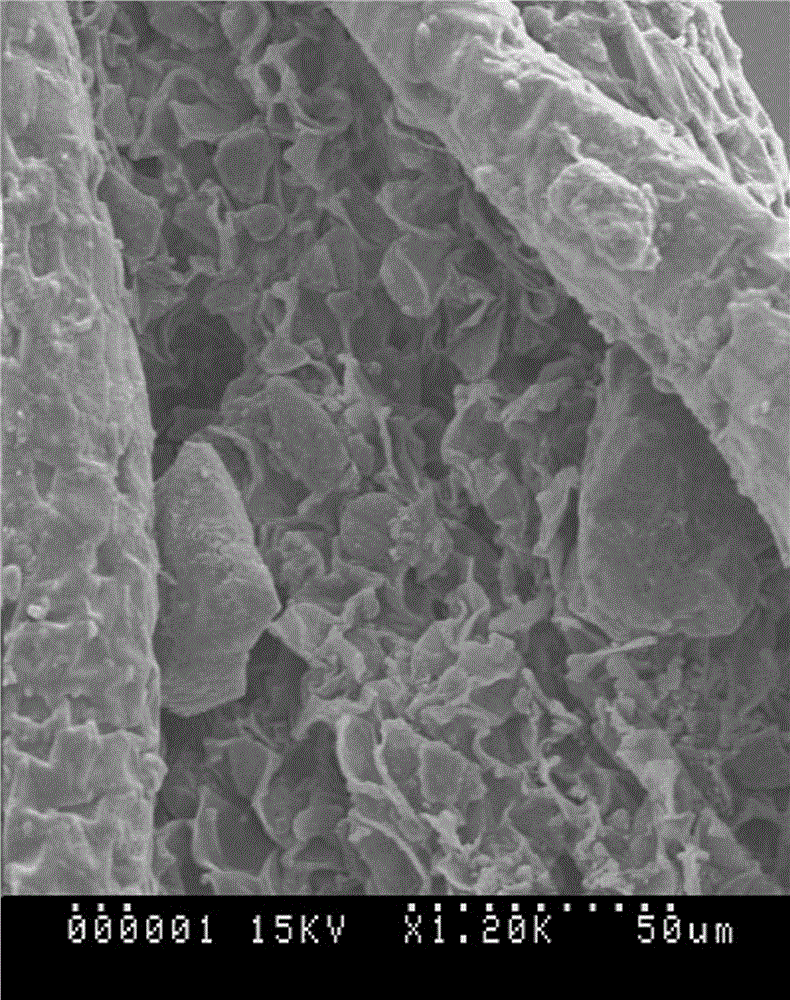

Moss scanning electron microscope observation material and preparation method thereof

InactiveCN104374626ASimple methodEasy to storePreparing sample for investigationMaterial analysis by measuring secondary emissionCritical point dryingHistiocyte

The invention relates to a preparation method of moss scanning electron microscope observation material. The method includes: sorting, to be more specific, sorting moss materials from biological crusts, and stripping leaves after cleaning; fixing, to be more specific, fixing the leaves in glutaraldehyde solution, and washing with buffer solution; dehydrating step by step with alcohol with gradient concentration; replacing, to be more specific, placing the leaves in ethanol-isoamyl acetate mixture for replacing, and placing the leaves in isoamyl acetate solution for replacing; critical point drying; loading onto a table. The method has the advantages that the method is simple and practical, and good in effect, the glutaraldehyde solution serving as the fixing solution is good in fixing effect on polysaccharide, glycoprotein, microtubule and the like, tissue cells do not become brittle after fixing, the influence of leaf cell surface tension can be avoided by the critical point drying, and the microstructures of samples are well preserved; reference is provided for the preparation of ideal moss samples, and the technical blank of related fields in China is filled.

Owner:刘永英

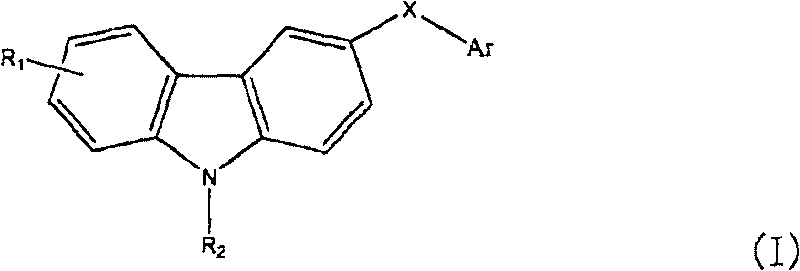

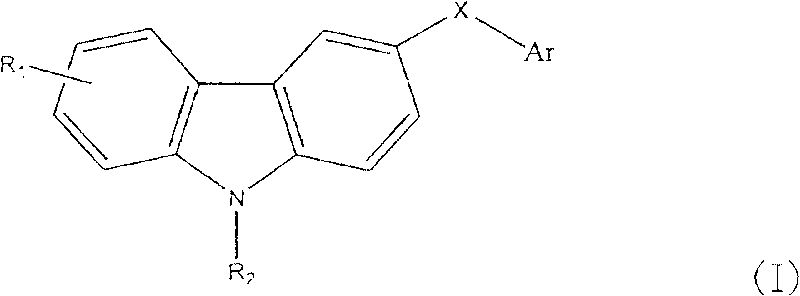

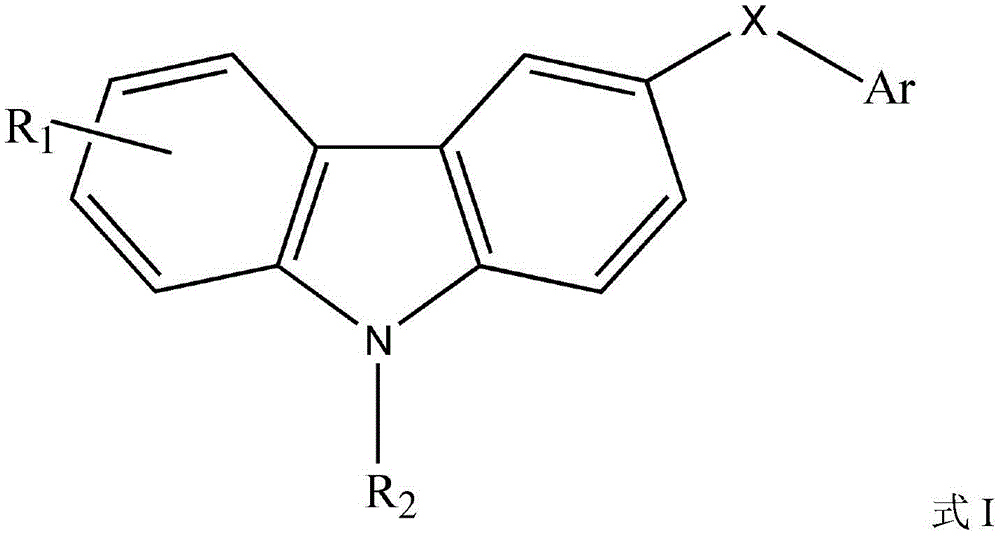

Carbazole sulfonamide derivative and its preparation method

The invention provides a new carbazole sulfonamide derivation and medicinal salt, comprising the general formula as follows (I). The compound can be small molecular microtubulin depressant which not only have the effect of antimicrocapillarity but also have the prominent antineoplastic activity, also the molecular weight is small, it is simple to synthesize and the toxic side effect is little. This invention also provides the medicinal compounds which contain the carbazole sulfonamide derivation as active constituent.

Owner:SHANXI PUDE PHARMA CO LTD

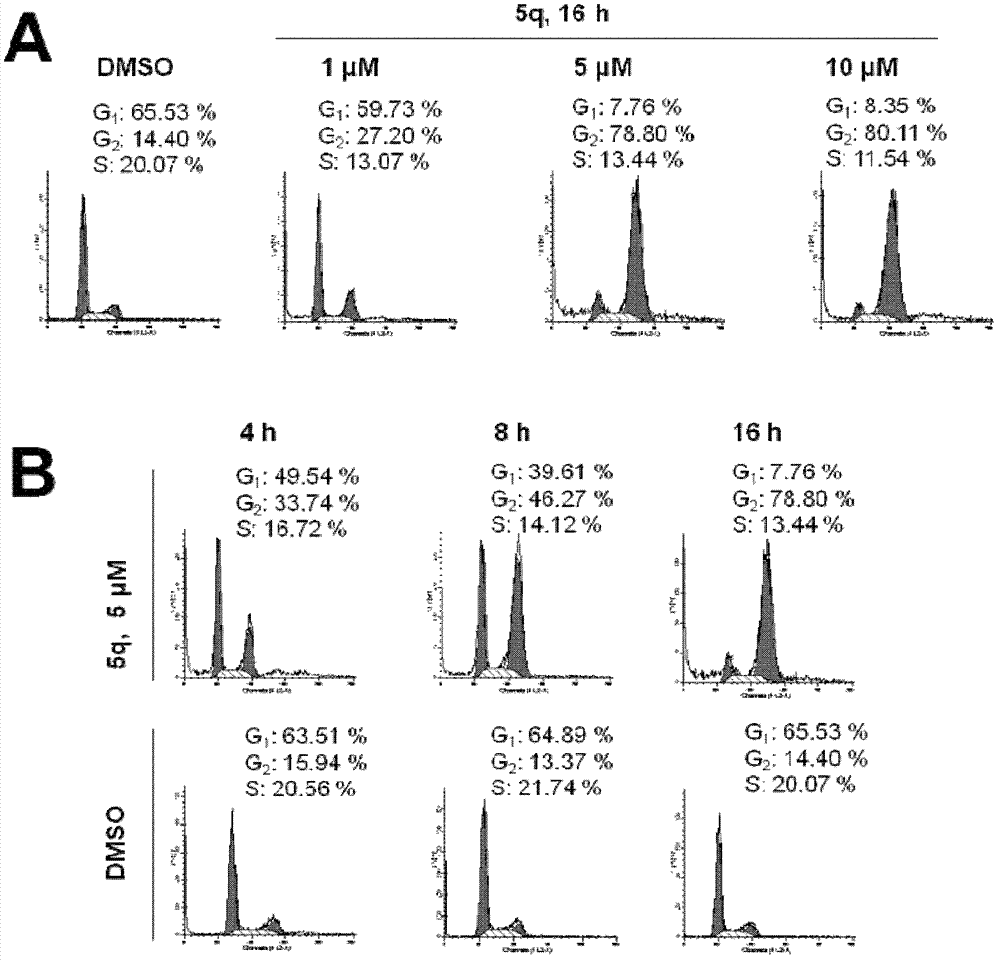

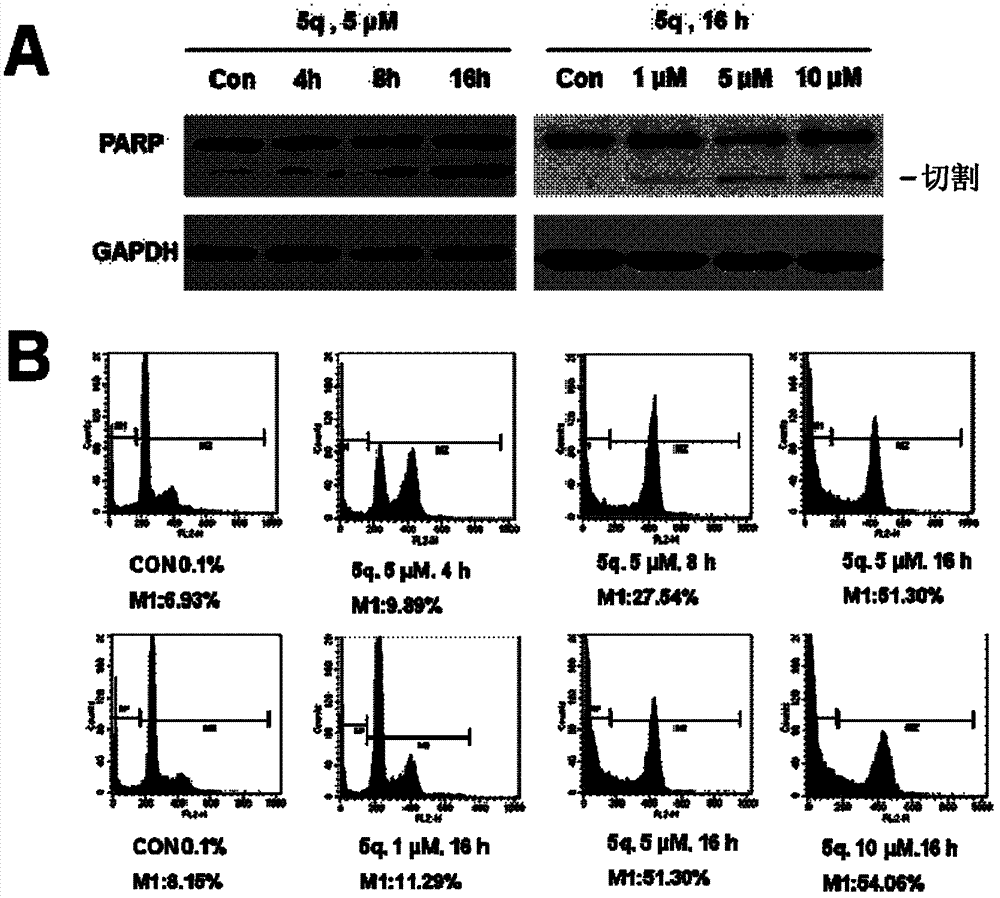

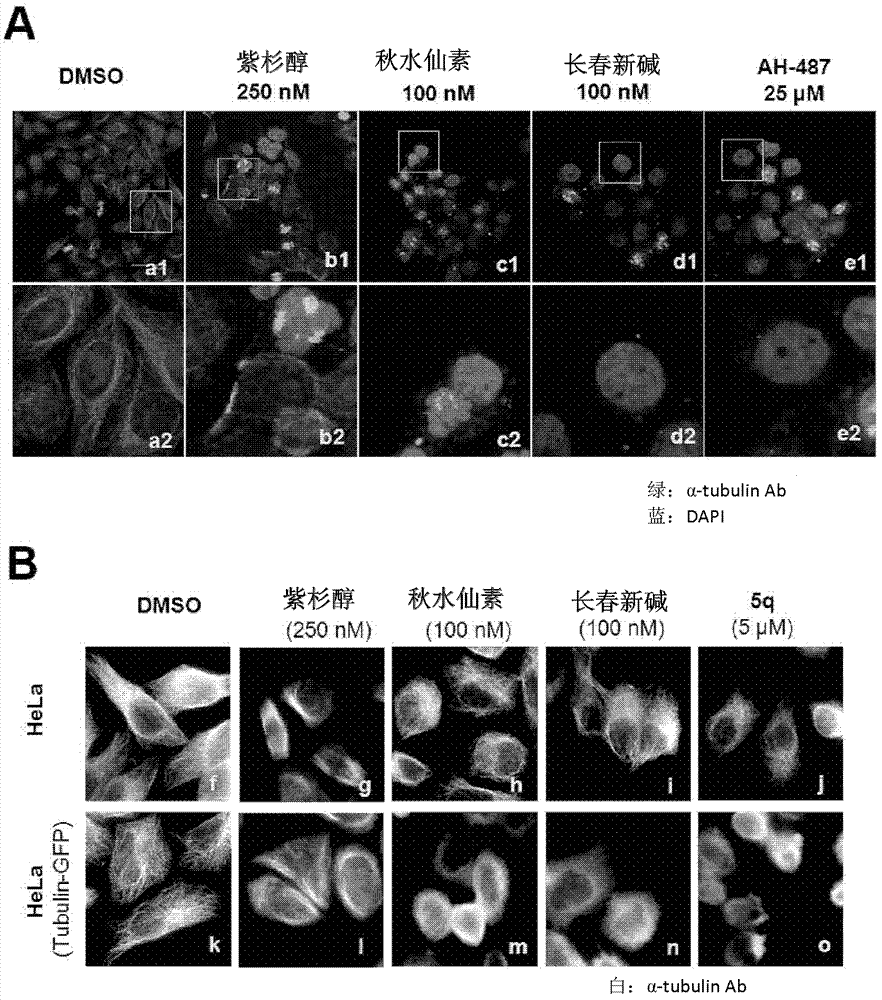

Sulfonamide compound and medicinal compositions thereof, and preparation methods and applications thereof

ActiveCN103193691AInhibition of polymerizationGrowth inhibitionSulfonic acid amide preparationAmide active ingredientsSide effectApoptosis

The invention discloses a sulfonamide compound and medicinal compositions thereof, and preparation methods and applications thereof. The sulfonamide compound can be used as a micro-molecular tubulin inhibitor, has an anti-microtubule effect in vitro, can induce the apoptosis of tumor cells in vitro, has an obvious inhibition effect on multidrug resistance cells in vitro, and has a substantial in-vivo oral antitumor activity. Additionally, the compound has the advantages of small molecular weight, simple synthesis, and small toxic side effects. The invention also provides medicinal compositions containing the sulfonamide compound and pharmaceutically acceptable salts thereof as an active component.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

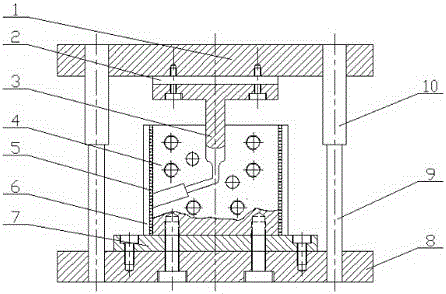

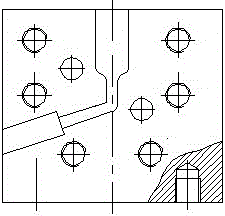

Preparation method of magnesium alloy microtubule and special-purpose die

Owner:常州市申鑫新材料科技有限公司

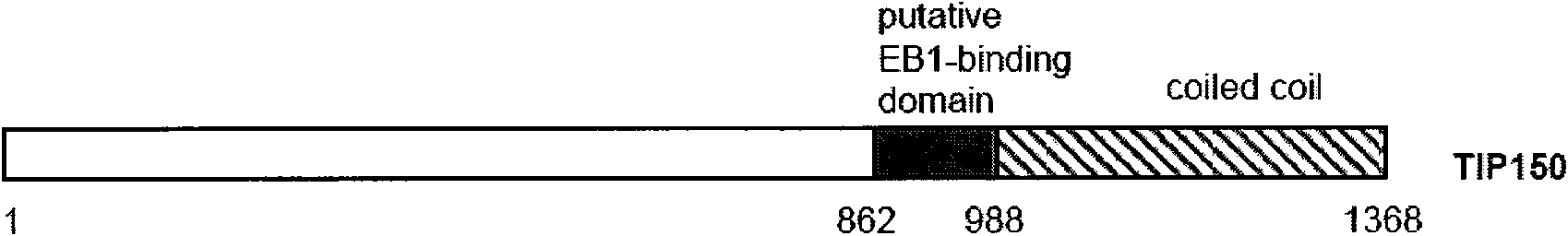

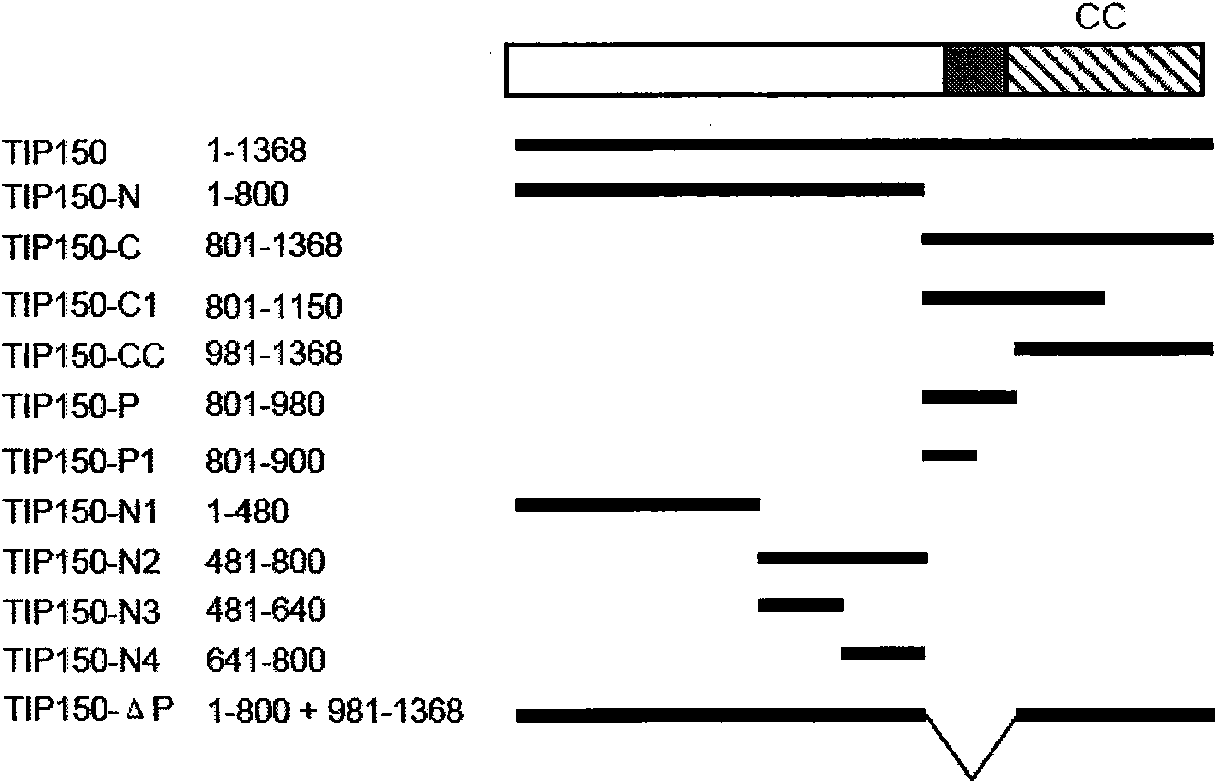

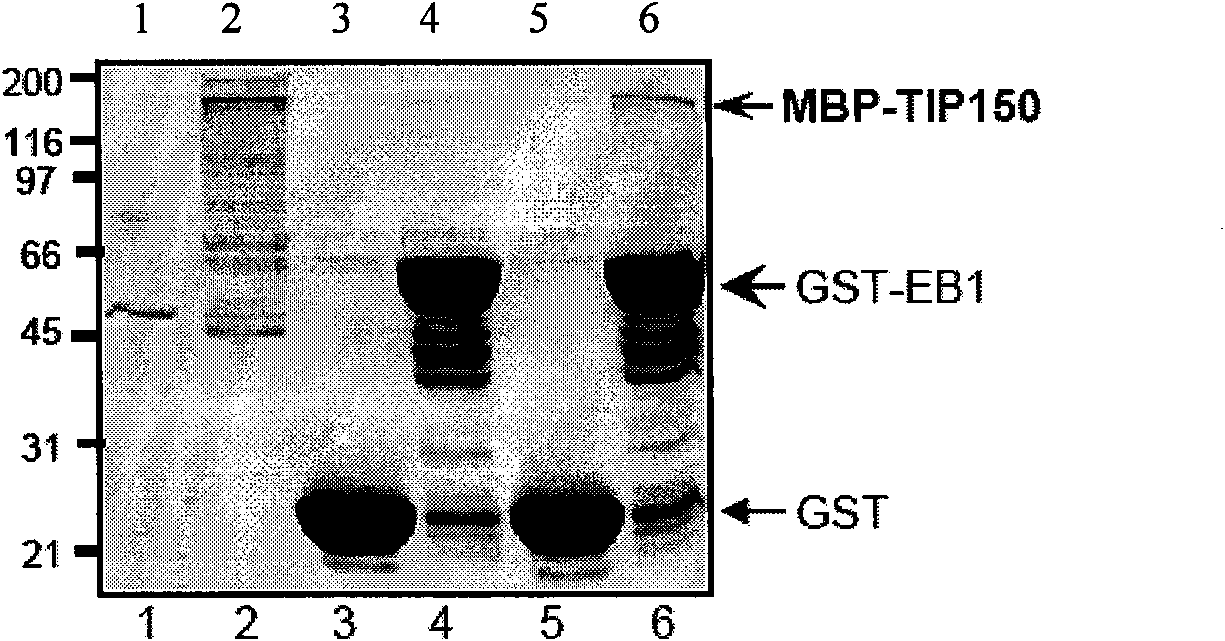

Microtubule-associated protein and coding genes and application thereof

InactiveCN101812127APositioning does not affectReduce positioningPeptide/protein ingredientsMicroorganismsWAS PROTEINMicrotubule Depolymerization

The invention discloses a microtubule-associated protein and coding genes and application thereof. The microtubule-associated protein is protein of (a) or (b): (a) protein formed by an amino acid sequence as shown by a sequence one in a sequence table; and (b) protein derived by the sequence one, related to the inhibition of the microtubule de-polymerization activity of MCAK protein and formed ina way the amino acid sequence of the sequence one is substituted and / or deleted and / or added by one to ten amino acid residues. The protein of the invention participates in the regulation and the control of the forward end dynamics of microtubules through the mutual effect with EB1 and MCAK and stabilizes the microtubules through inhibiting the microtubule de-polymerization activity of the MCAK protein. After the coding genes of the low-interference RNA of microtubule-associated protein genes are introduced into a host, the microtubule positioning of the MCAK is seriously affected. The protein and the coding genes thereof play a great role in the medical field and the pharmaceutical field and thereby the application prospect is wide.

Owner:UNIV OF SCI & TECH OF CHINA

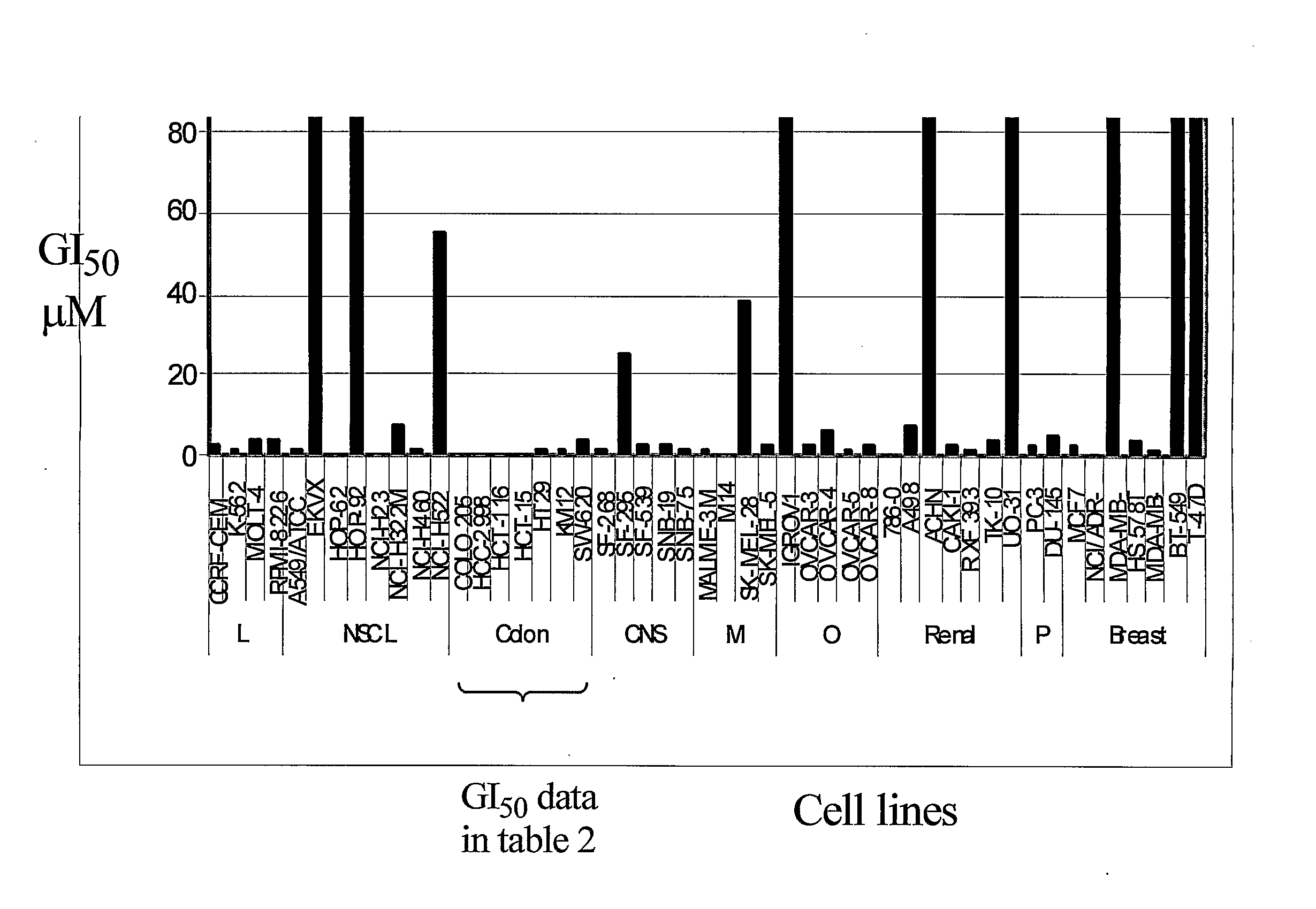

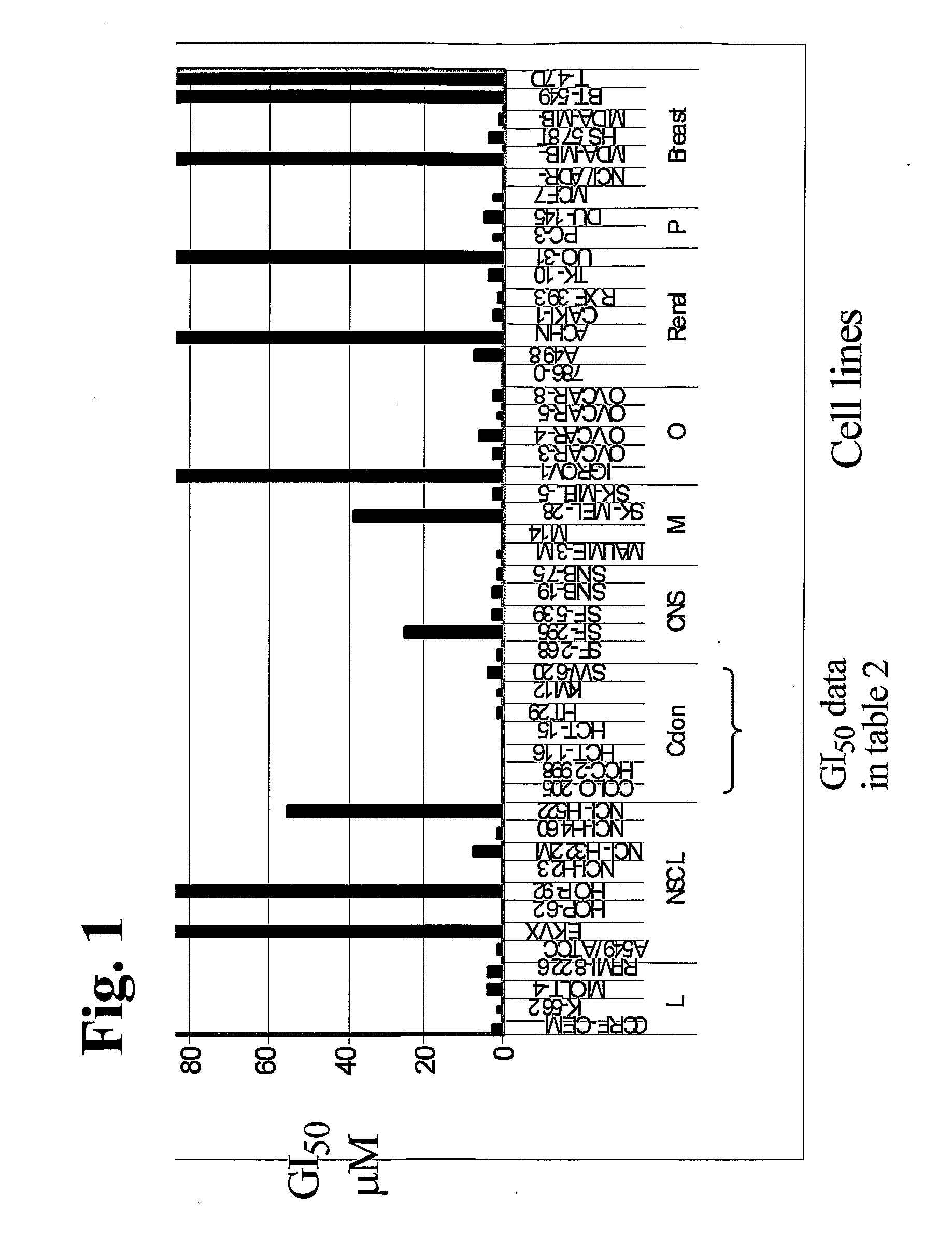

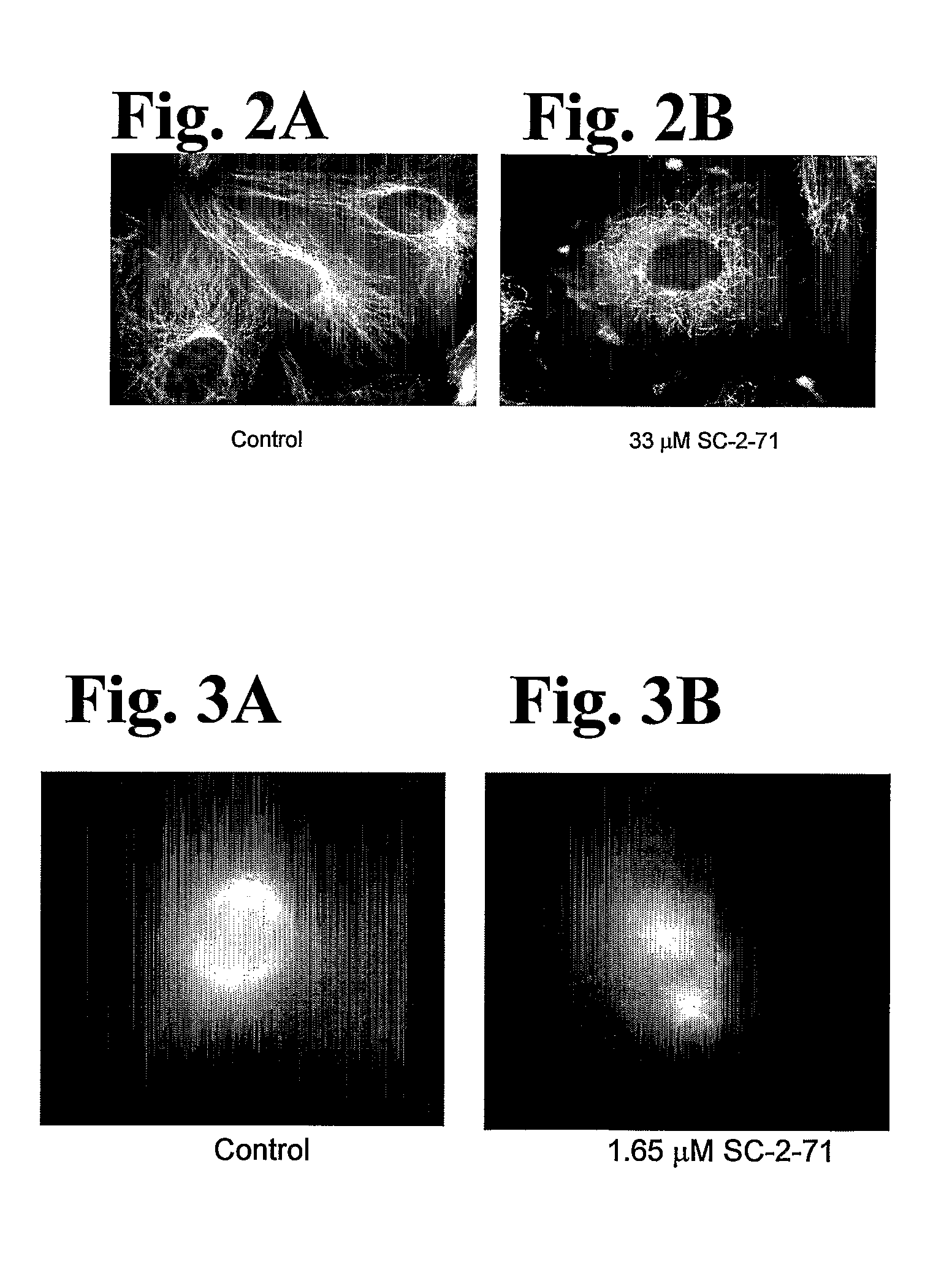

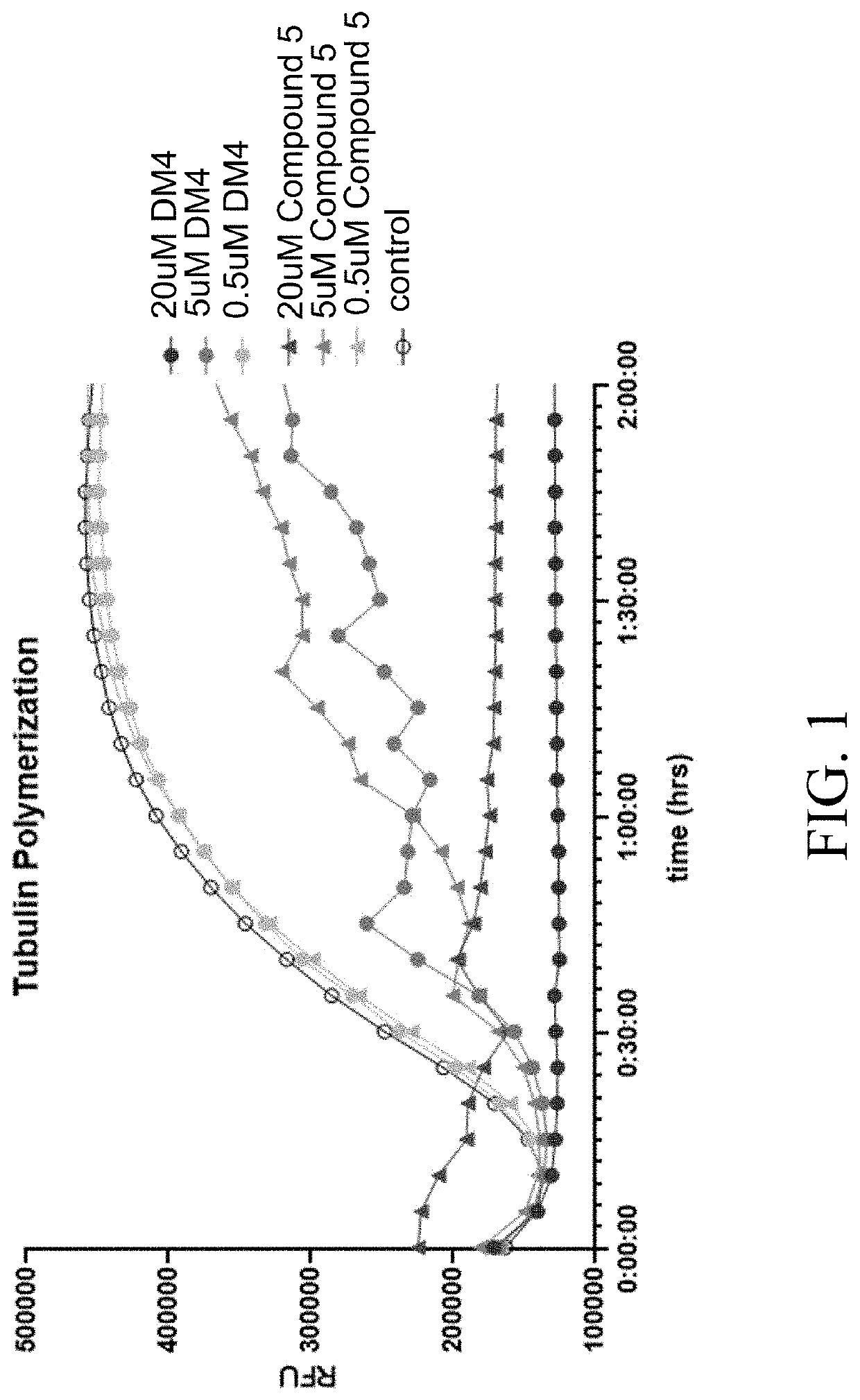

Dual Small Molecule Inhibitors of Cancer and Angiogenesis

The present invention provides analogs and derivatives of thalidomide which inhibit cancer and angiogenesis. The present invention further provides compounds which disrupt microtubule polymerization. The present further provides methods of treating cancers comprising mutant p53.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

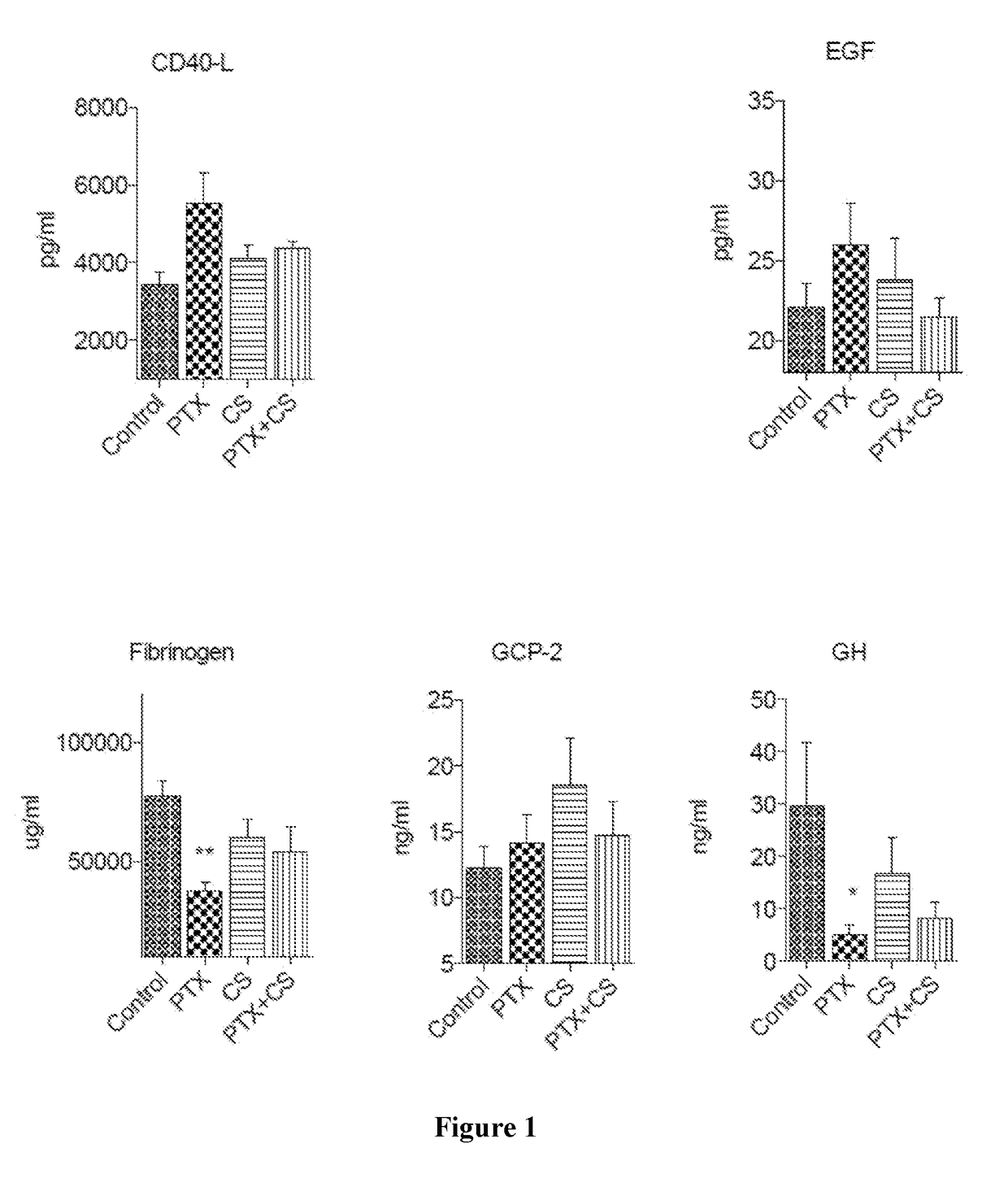

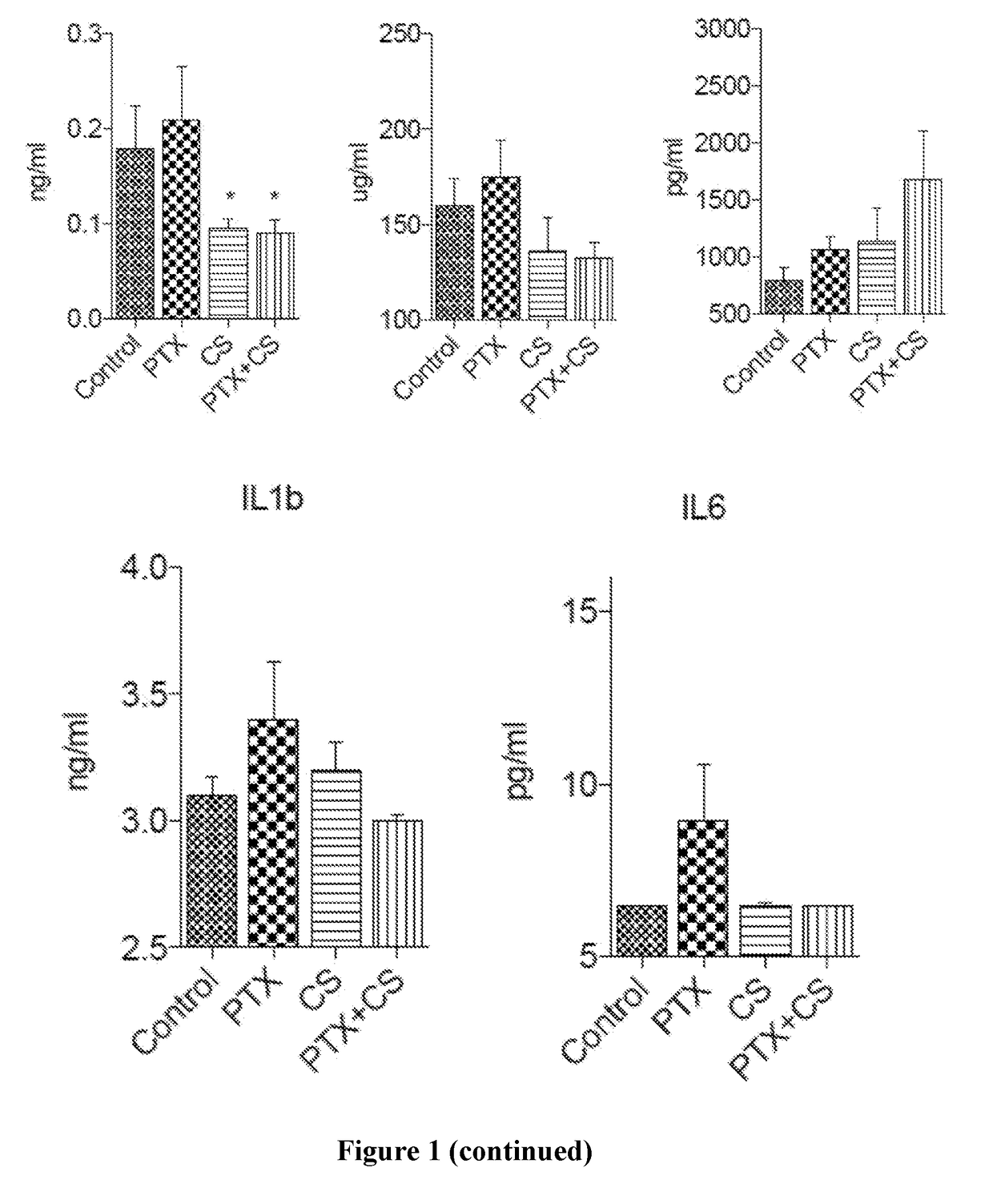

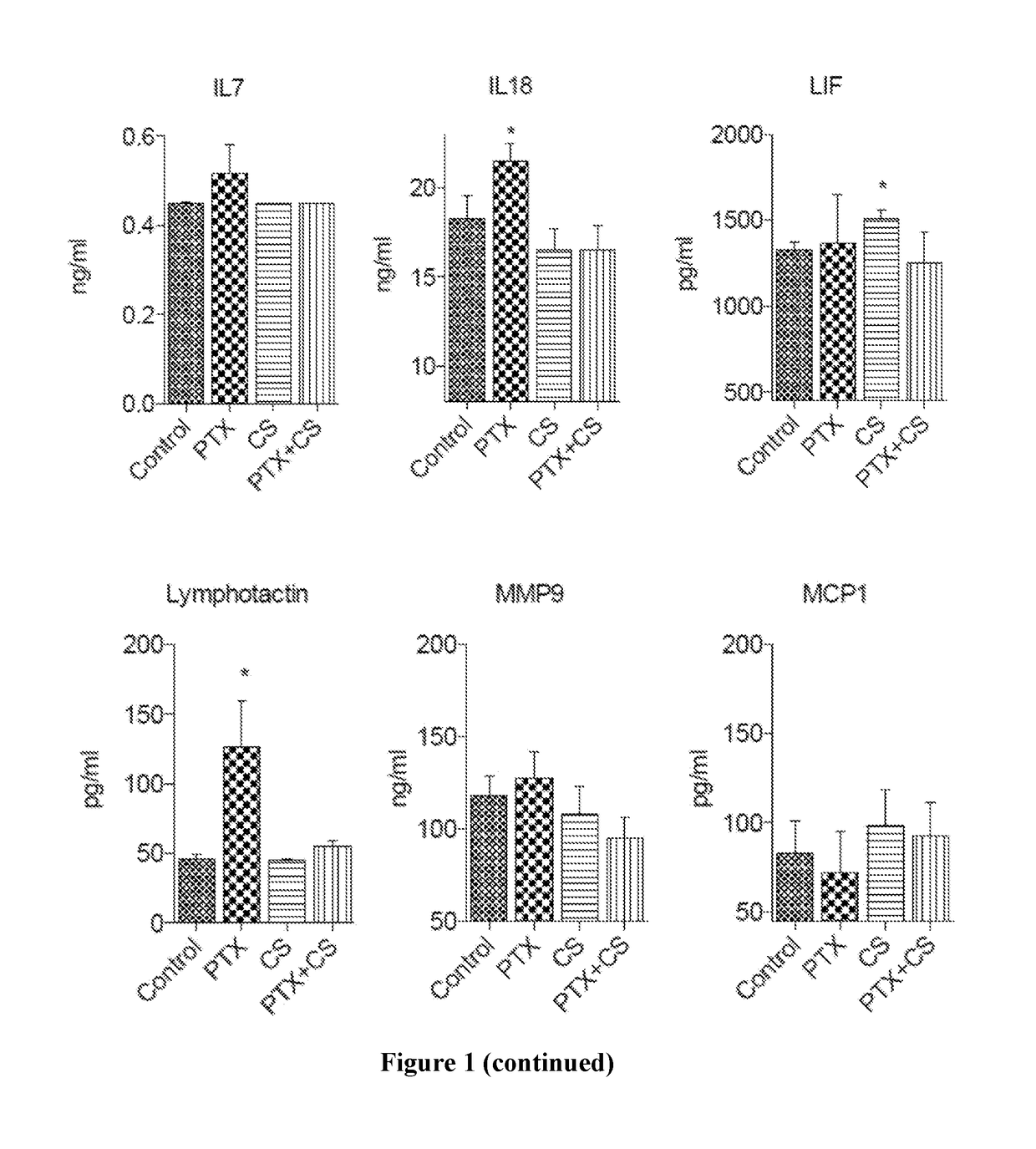

Method of treating inflammation using natural compounds and/or diet

The current invention is directed to a treatment of an inflammatory disease comprising administering to a subject in need of such treatment a composition comprising epigallocatechin-3-gallate (EGCG), curcumin, glucosinolates and / or derivatives thereof and medium chain triglycerides and, optionally, providing a ketogenic diet or a modified ketogenic diet to the subject. In an embodiment, the inflammatory disease is increased inflammation in the subject caused by the administration of a microtubule stabilizing drug such as paclitaxel.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

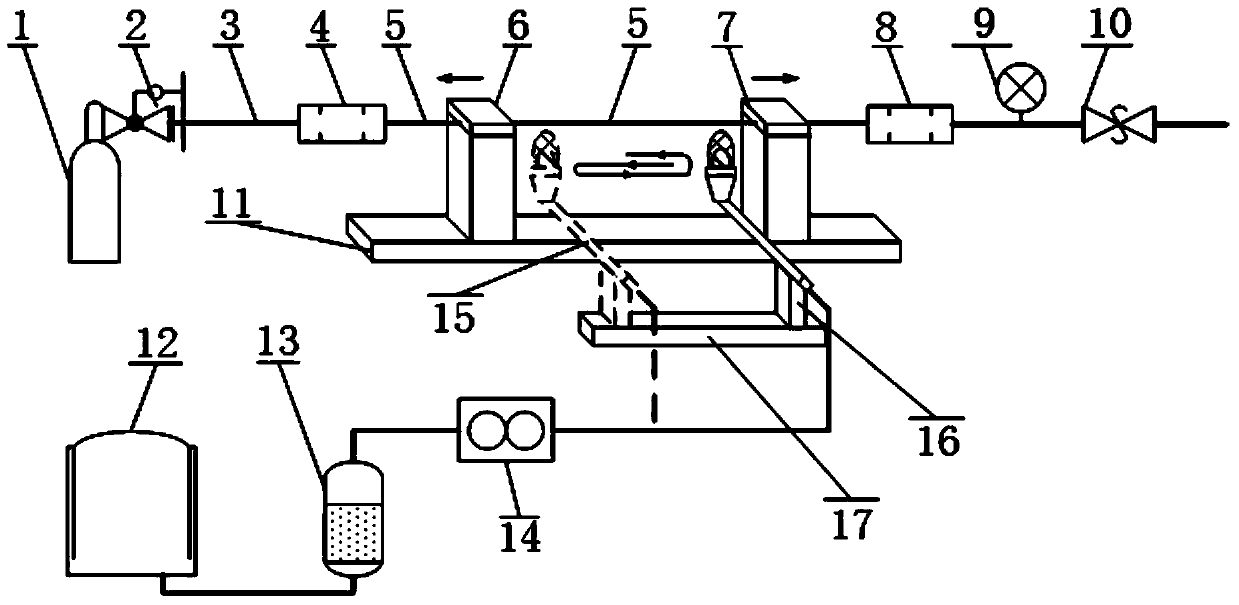

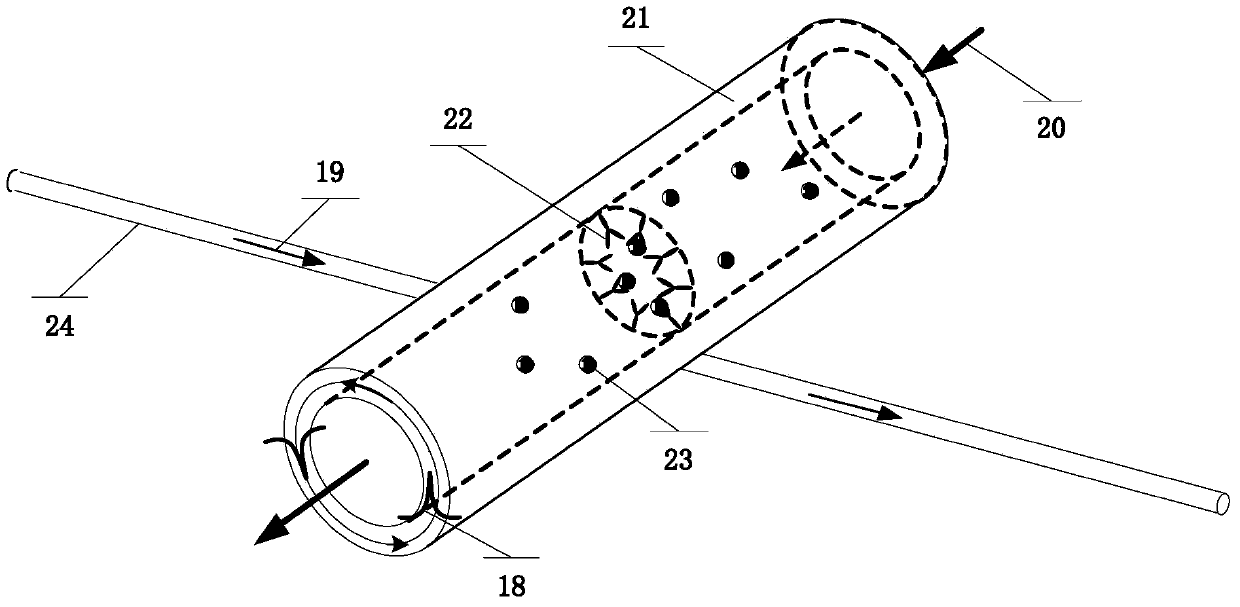

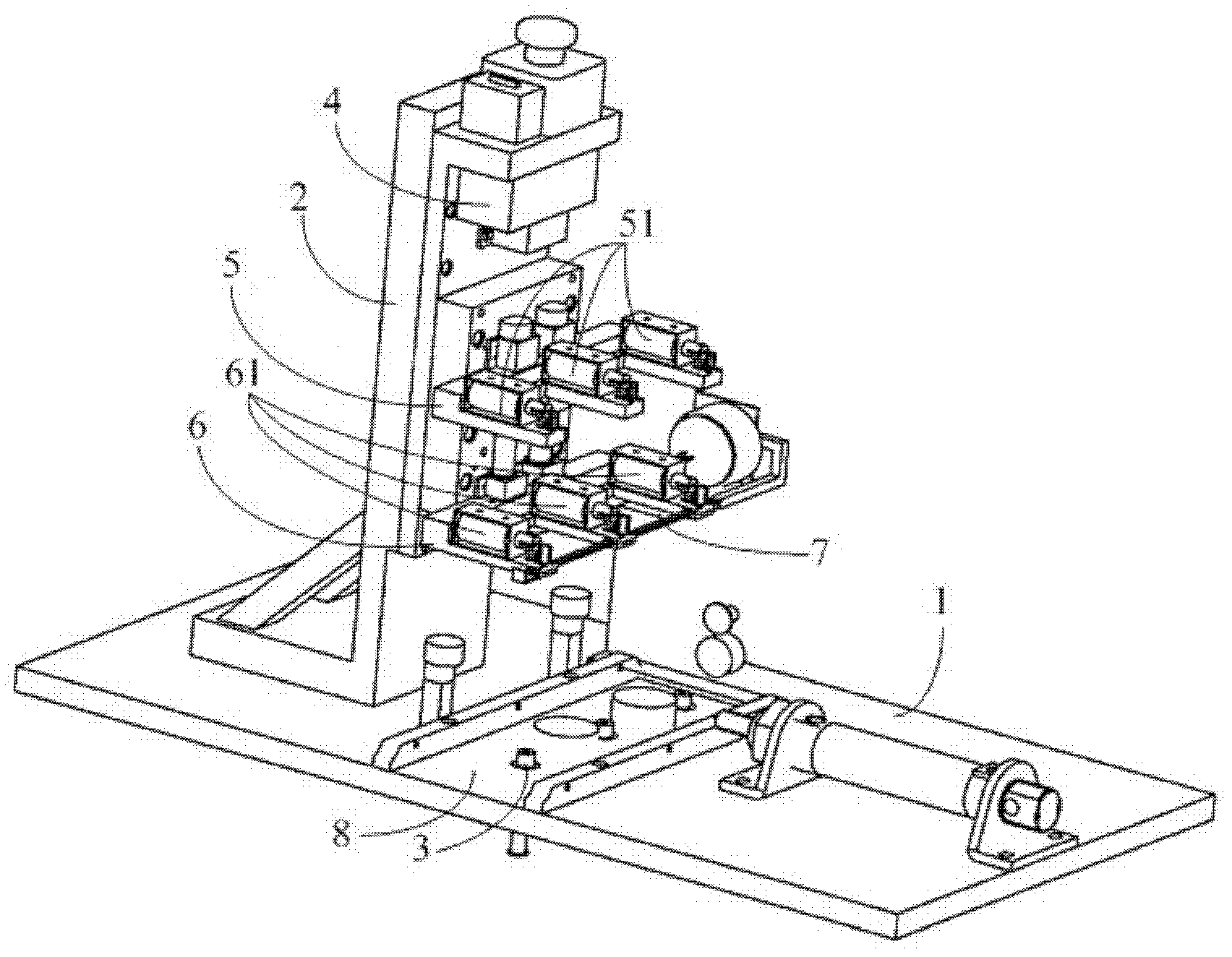

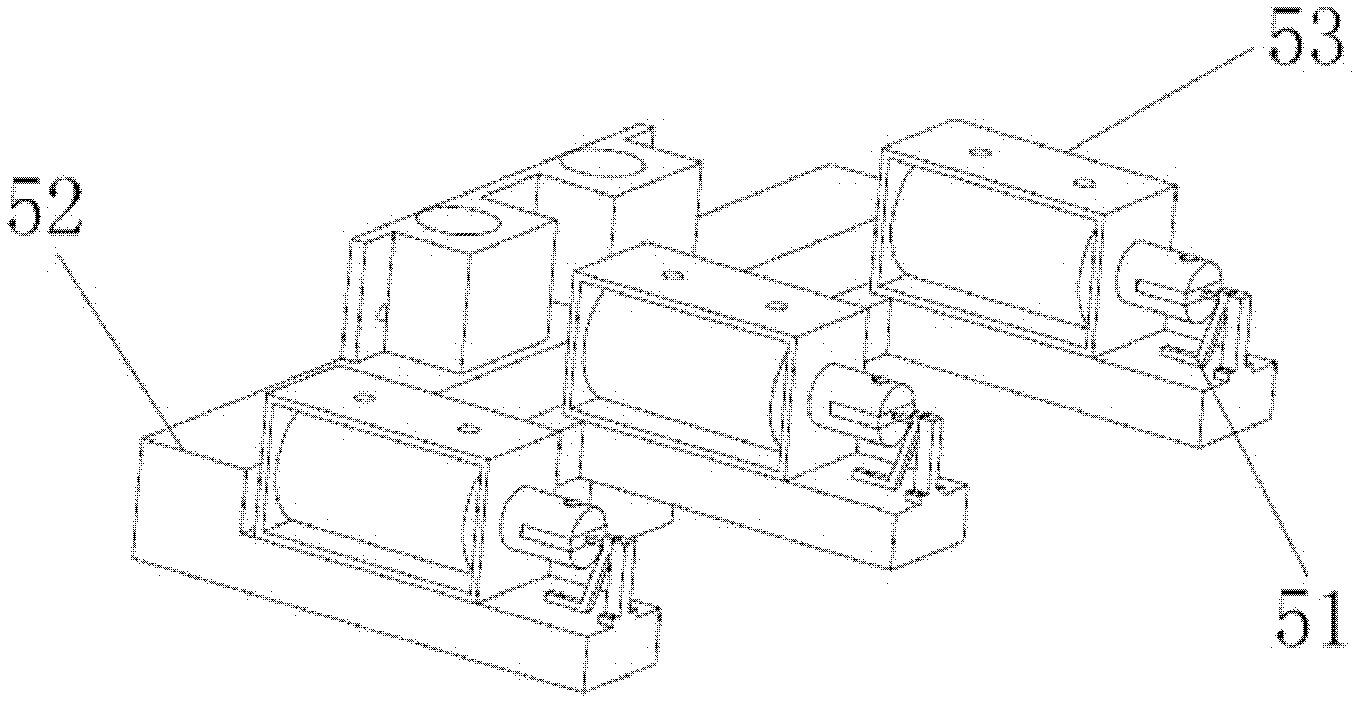

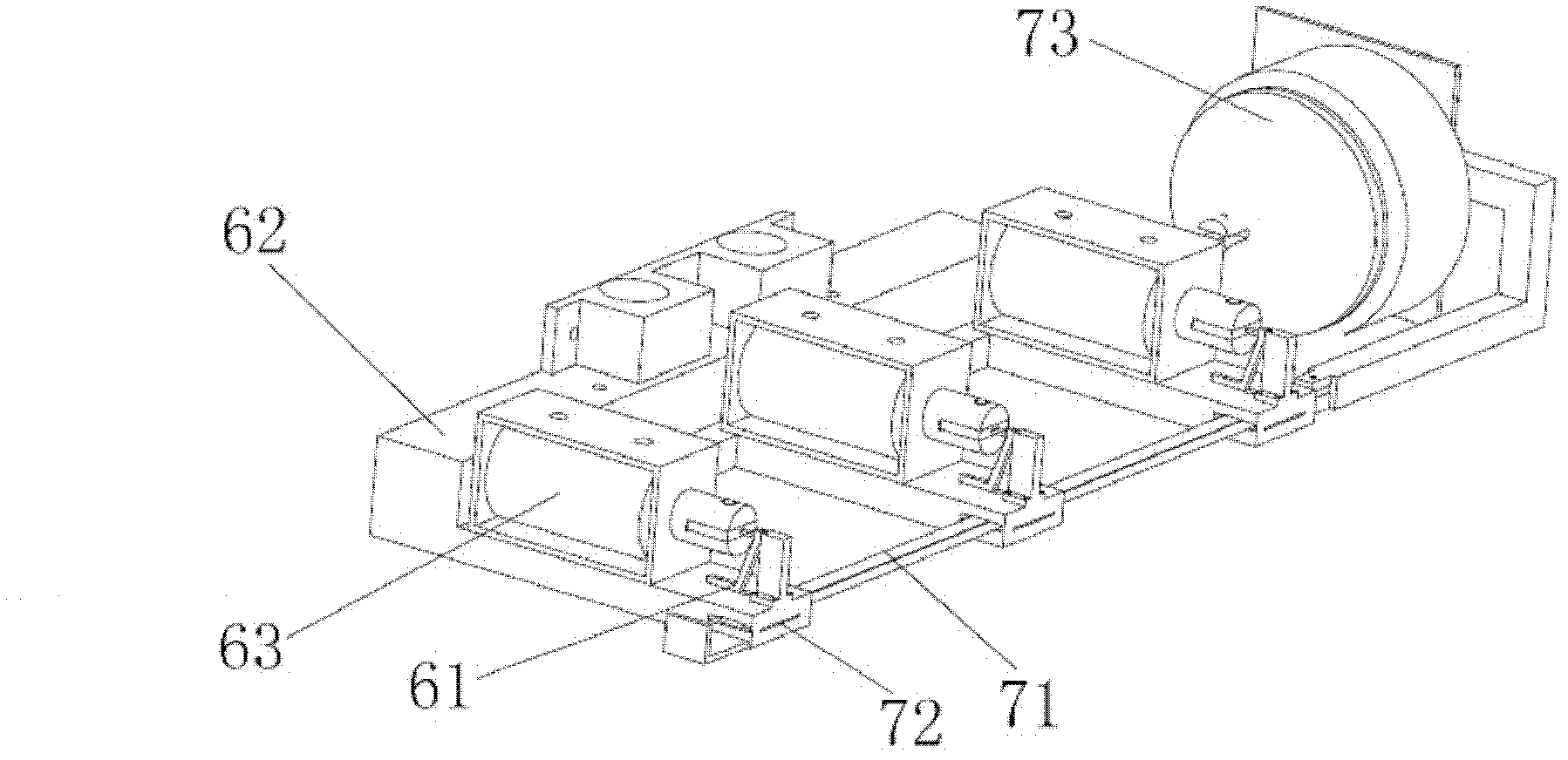

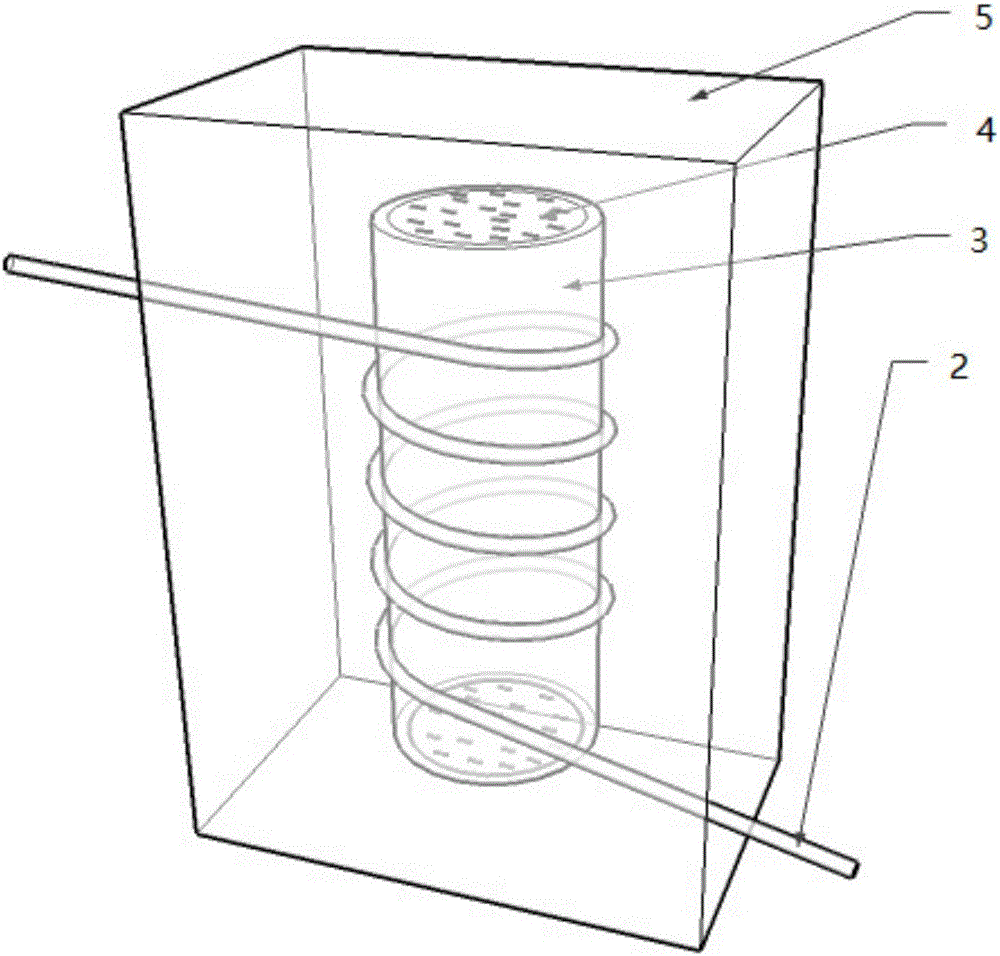

Ultrathin-wall microtubule production device and production method thereof

ActiveCN103424359AHeating evenlyShorten the timePhase-affecting property measurementsEngineeringThick wall

The invention discloses an ultrathin-wall microtubule production device and a production method thereof. The ultrathin-wall microtubule production device comprises a nitrogen gas cylinder, a pressure reducing valve, a PU (poly urethane) tube, a caliber conversion device, a thick-wall microtubule, a left microtubule gripper, a right microtubule gripper, another caliber conversion device, a high-precision barometer, a back pressure valve, a long-stroke and high-precision micro displacement platform, a hydrogen-oxygen producing machine, a gas dryer, a gas flow controller, a flame gun, a flame-gun clamping device and a short-stroke and high-precision micro displacement platform. The production method includes that nitrogen with precisely-controlled barometric pressure enters an inner cavity of the microtubule, from the caliber conversion device, to apply outward pressure upon a tubule wall of the microtubule; oxyhydrogen with precisely-controlled flow rate forms oxyhydrogen flame, at a position of a nozzle of the flame gun, to evenly heat the thick-wall microtubule; the microtubule grippers with precisely-controlled speed and distance evenly stretch the microtubule to obtain the ultrathin-wall microtubule finally. The ultrathin-wall microtubule produced by the method is smooth in the tubule wall, a resonant cavity is constructed to ensure a good field evanescent function and a high Q value, and the time for producing one ultrathin-wall microtubule is less than 30 minutes.

Owner:TIANJIN UNIV

Carbazole sulfonamide derivative eutectic and preparation method thereof

ActiveCN105418487AAnti-microtubuleGood antitumor activityOrganic active ingredientsOrganic chemistrySolubilityMicrotubule

The present application discloses a novel carbazole sulfonamide derivative eutectic and a preparation method thereof. The carbazole sulfonamide derivative eutectic is formed by oxalic acid, maleic acid, malonic acid or glutaric acid, and a carbazole sulfonamide derivative, has an antimicrotubular effect, and significant tumor resistance, and has the advantages of simple synthesis, small side effects, and high dissolution rate and solubility.

Owner:SHANXI PUDE PHARMA CO LTD

Wire-threading machine for threading metal wire into microtubule

InactiveCN102489997ASimple structureImprove wire threading efficiencyMetal working apparatusMicrotubuleEngineering

The invention discloses a wire-threading machine for threading a metal wire into a microtubule. The wire-threading machine comprises a vertical frame, an upper chuck subassembly, a lower chuck subassembly, a driving device, a microtubule mounting clamp and a scissors subassembly, wherein the vertical frame is arranged on a base; the upper chuck subassembly is arranged on the vertical frame and is provided with an upper chuck for clamping the metal wire; the lower chuck subassembly is arranged below the upper chuck subassembly, is connected with the upper chuck subassembly through a guide rod and corresponds to the upper chuck subassembly; the lower chuck subassembly is provided with a lower chuck for clamping the metal wire which stretches out of the upper chuck subassembly; the driving device is arranged on the vertical frame and can be used for driving the upper chuck subassembly and the lower chuck subassembly to slide along the vertical frame; the microtubule mounting clamp is arranged on the base and is provided with a plurality of microtubule mounting positions corresponding to the upper chuck and the lower chuck of the upper chuck subassembly and the lower chuck subassembly; the scissors subassembly is arranged below the lower chuck subassembly and is arranged on a same bracket of the lower chuck subassembly; and a cutting opening of the scissors subassembly corresponds to the position on the lower chuck of the lower chuck subassembly, at which the metal wire stretches out. According to the wire-threading machine provided by the invention, the metal wire coated with a radioactive material can conveniently threaded into the microtubule, so that damages to operators are avoided.

Owner:BEIJING ZHIBO BIO MEDICAL TECH

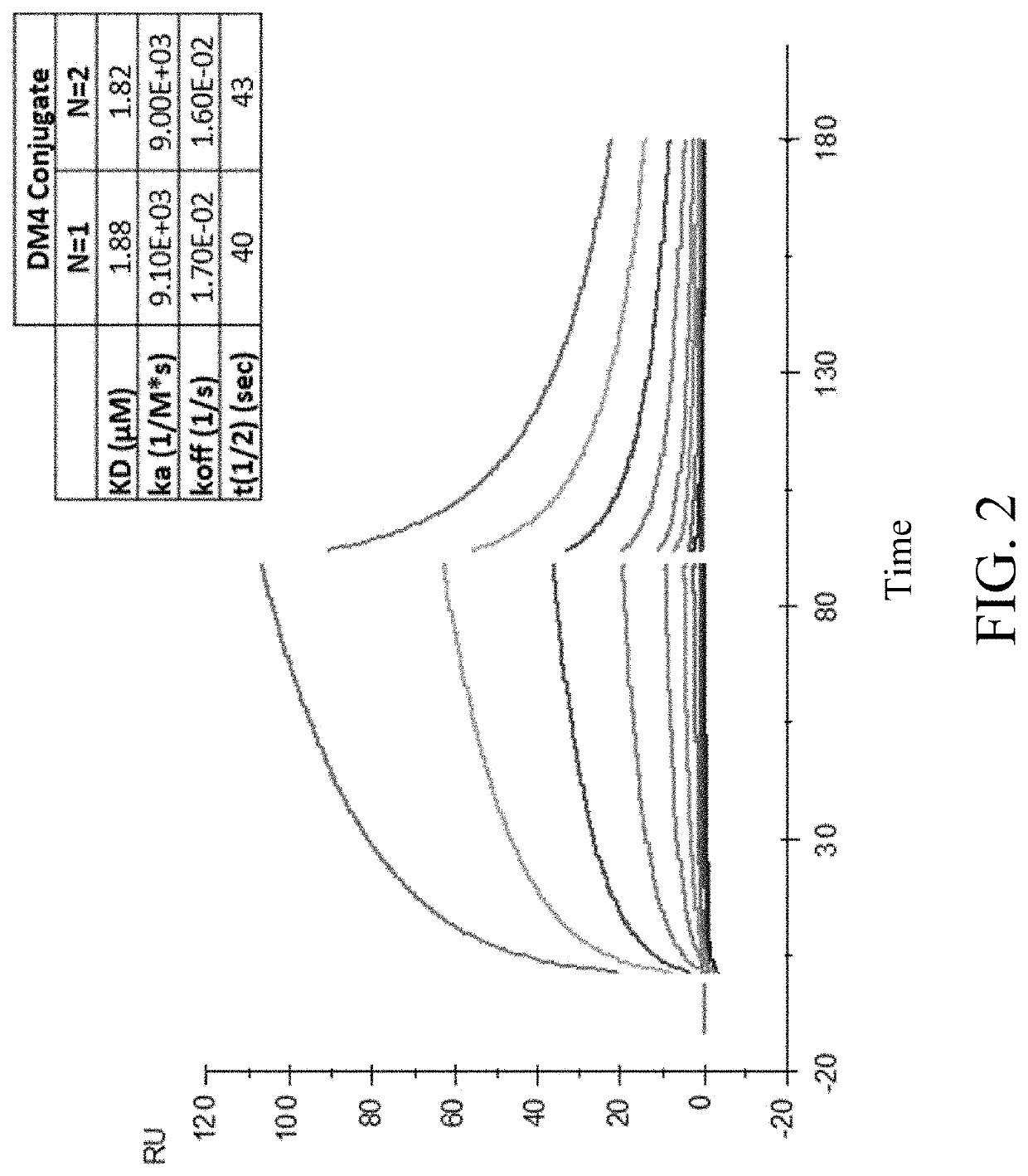

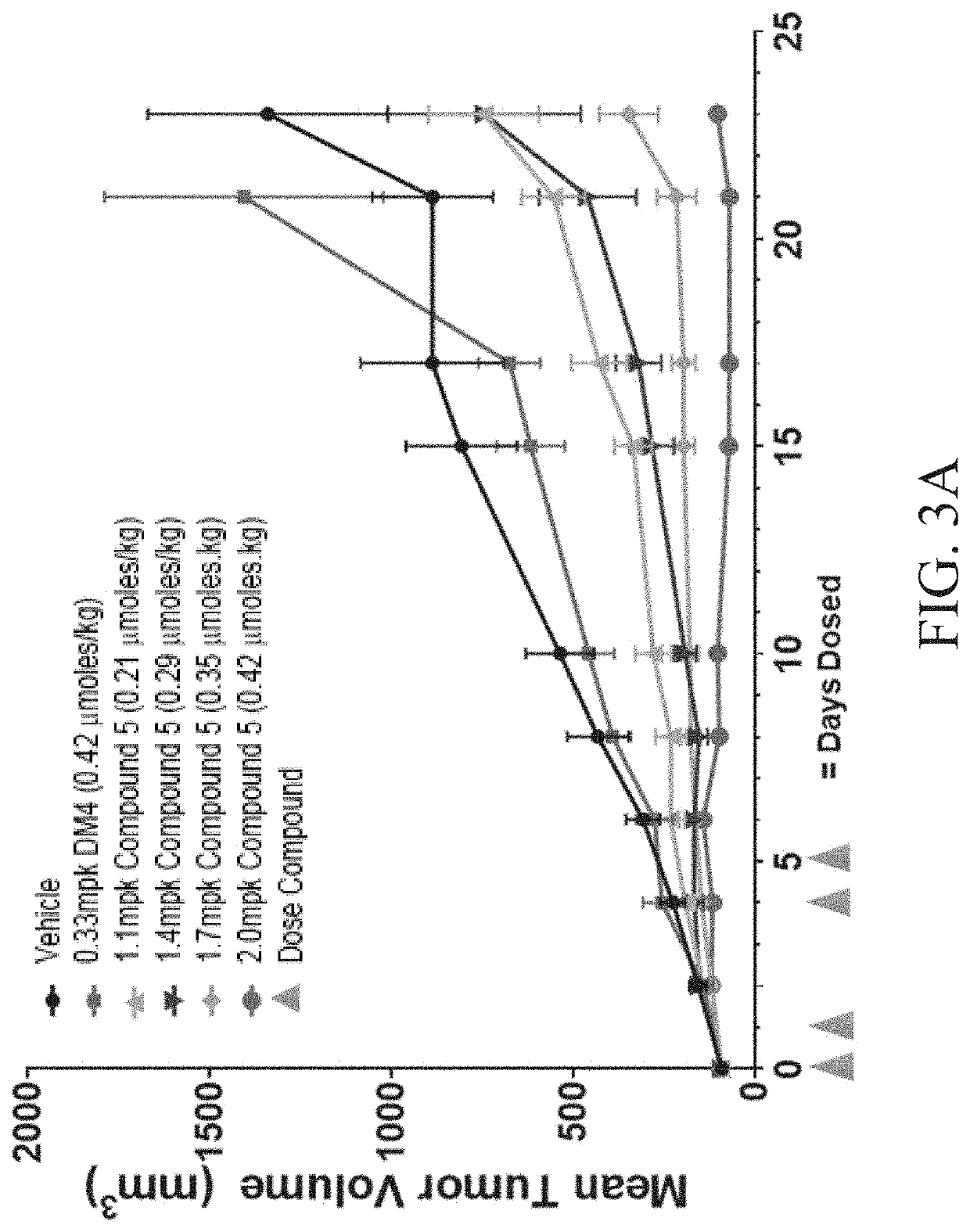

Peptide conjugates of microtubule-targeting agents as therapeutics

The present invention relates to peptide conjugates of microtubule-targeting agents such as maytansinoid derivatives which are useful for the treatment of diseases such as cancer.

Owner:CYBREXA 3 INC

Gene defects and mutant ALK kinase in human solid tumors

Novel gene deletions and translocations involving chromosome 2 resulting in fusion proteins combining part of Anaplastic Lymphoma Kinase (ALK) kinase with part of a secondary protein have now been identified in human solid tumors, e.g. non-small cell lung carcinoma (NSCLC). Secondary proteins include Echinoderm Microtubule-Associated Protein-Like 4 (EML-4) and TRK-Fusion Gene (TFG). The EML4-ALK fusion protein, which retains ALK tyrosine kinase activity, was confirmed to drive the proliferation and survival of NSCLC characterized by this mutation. The invention therefore provides, in part, isolated polynucleotides and vectors encoding the disclosed mutant polypeptides, probes for detecting it, isolated mutant polypeptides, and reagents for detecting the fusion and truncated polypeptides. The invention also provides methods for determining the presence of these mutant polypeptides in a biological sample, methods for screening for compounds that inhibit the proteins, and methods for inhibiting the progression of a cancer characterized by the mutant polynucleotides or polypeptides.

Owner:CELL SIGNALING TECHNOLOGY

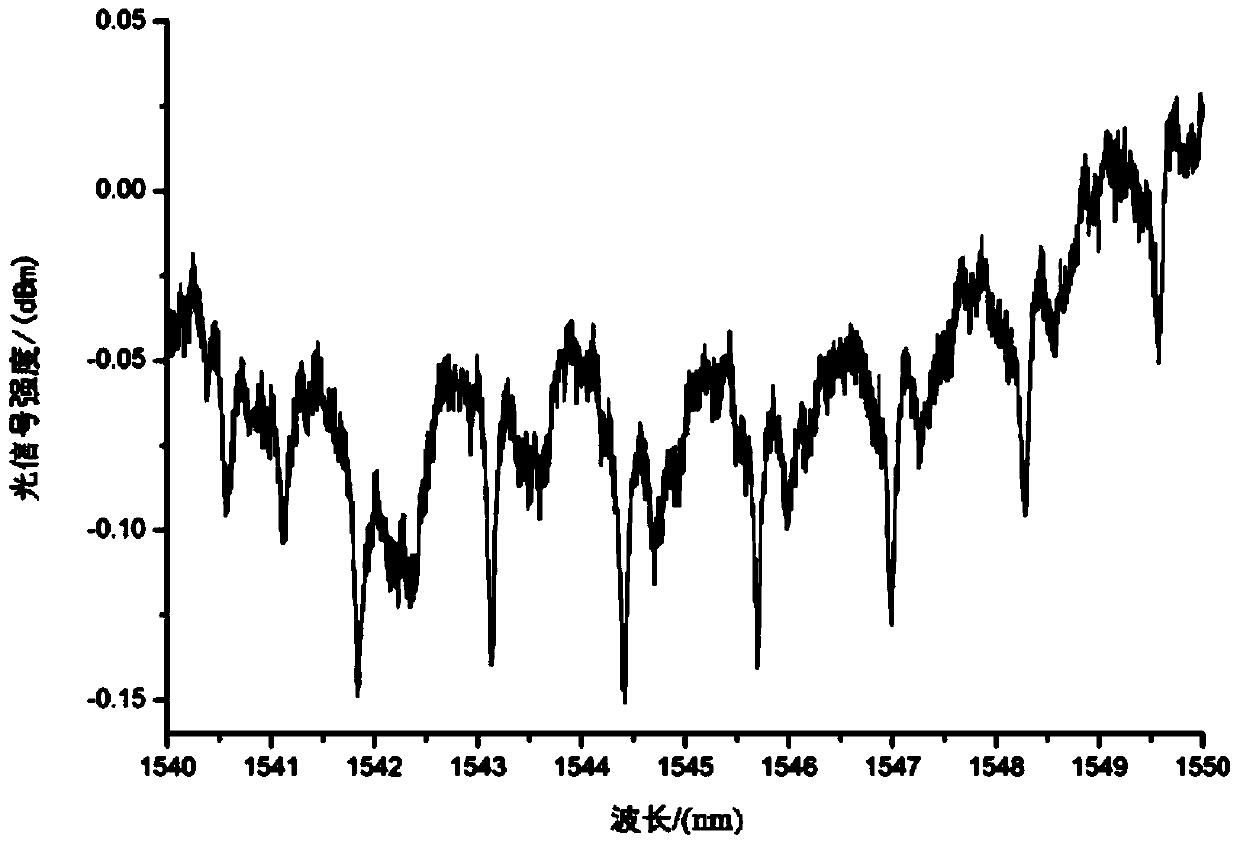

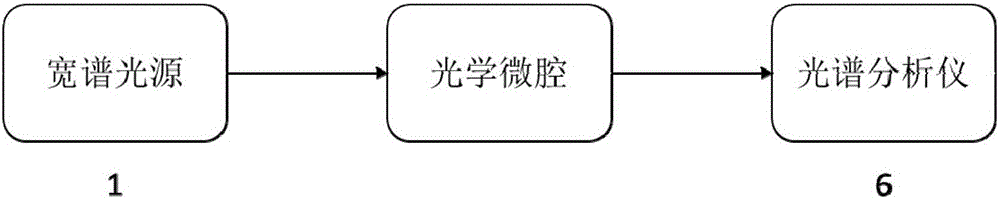

Extra-high sensitive magnetic field sensor based on multiple-mode interference optical microcavity

InactiveCN105842637AHigh quality factorHigh sensitivityMagnetic field measurement using magneto-optic devicesSpectrum analyzerOptical microcavity

The present invention discloses an extra-high sensitive magnetic field sensor based on multiple-mode interference optical microcavity. Microfiber, a microtubule and a magnetofluid are fixedly sealed to form an optical microcavity; the microfiber is wound around the microtubules in a spiral mode; the microtubule is hollow and internally packaged with the magnetofluid; the input end and the output of the microfiber are respectively connected with a broadband optical source and a spectrum analyzer; the part of the microfiber winding the outer wall of the microtubule is taken as a fiber wrapping region, and the electromagnetic wave is able to generate multiple-mode interference wherein; the electromagnetic wave is emitted by the broadband optical source and is transmitted to the fiber wrapping region through the microfiber; and the evanescent wave part of the electromagnetic wave in the fiber wrapping region is able to pass through the microtubule wall into the magnetofluid, pass through the electromagnetic wave of the optical microcavity and then pass through the microfiber to output to a spectrum analyzer. The extra-high sensitive magnetic field sensor based on a multiple-mode interference optical microcavity is provided with a structure winding the microfiber onto the microtubule so as to greatly increase the contact of the electromagnetic wave and the magnetofluid, and therefore the sensitivity is higher.

Owner:ZHEJIANG UNIV

High performance energy storage and collection devices containing exfoliated microtubules and spatially controlled attached nanoscale particles and layers

ActiveUS8475961B2Enhanced strength and ruggednessElectrolytic capacitorsFinal product manufactureMicrotubuleMelt extrusion

The present disclosure relates to energy storage or collection devices and methods for making such devices having electrode materials containing exfoliated nanotubes with attached electro- or photoactive nanoscale particles or layers.The exfoliated nanotubes and attached nanoscale particles or layers may be easily fabricated by methods such as coating, solution or casting or melt extrusion to form electrodes. Electrolytes may also be used for dispersing nanotubes and also in a polymeric form to allow melt fabrication methods.

Owner:BLACK DIAMOND STRUCTURES

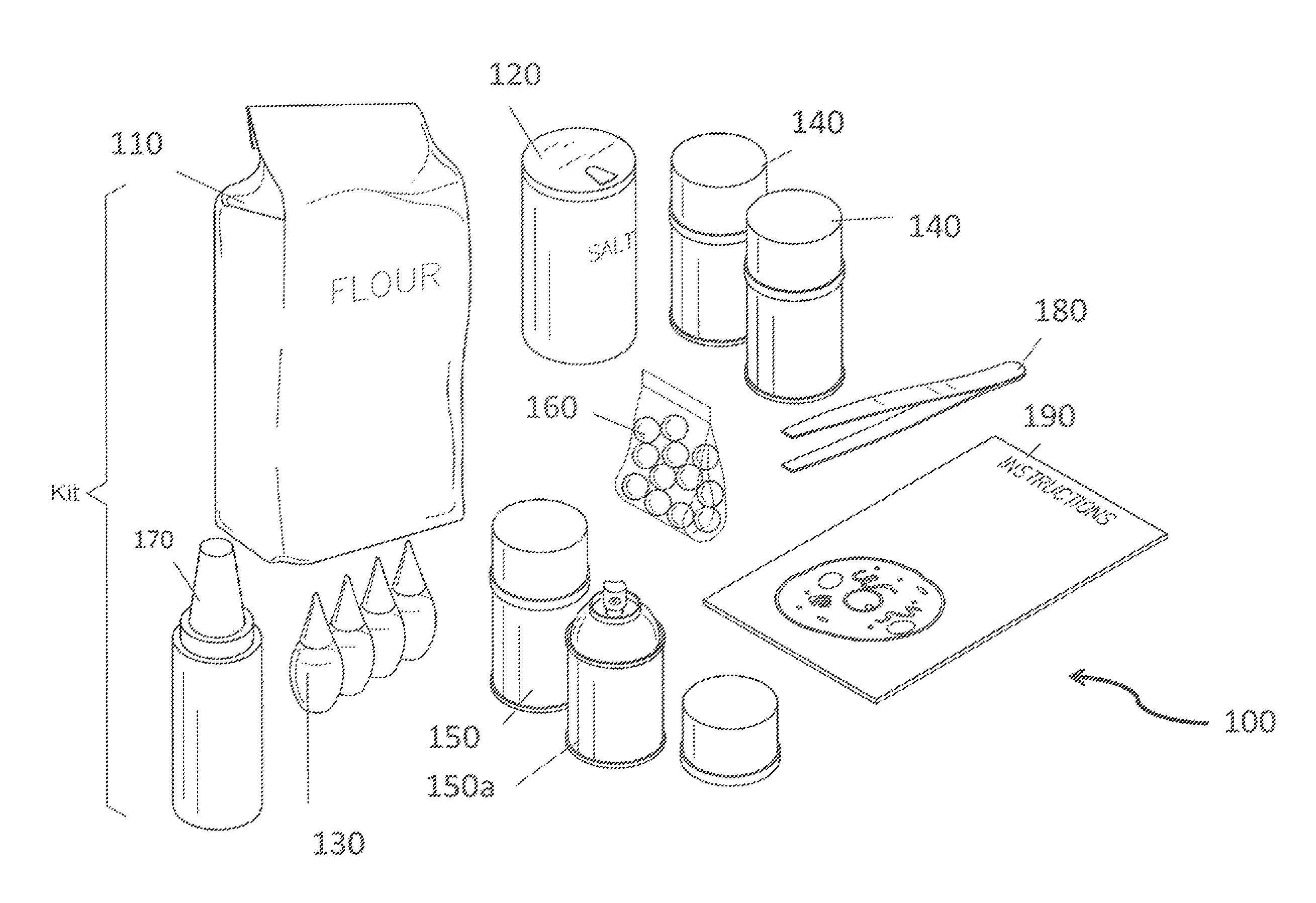

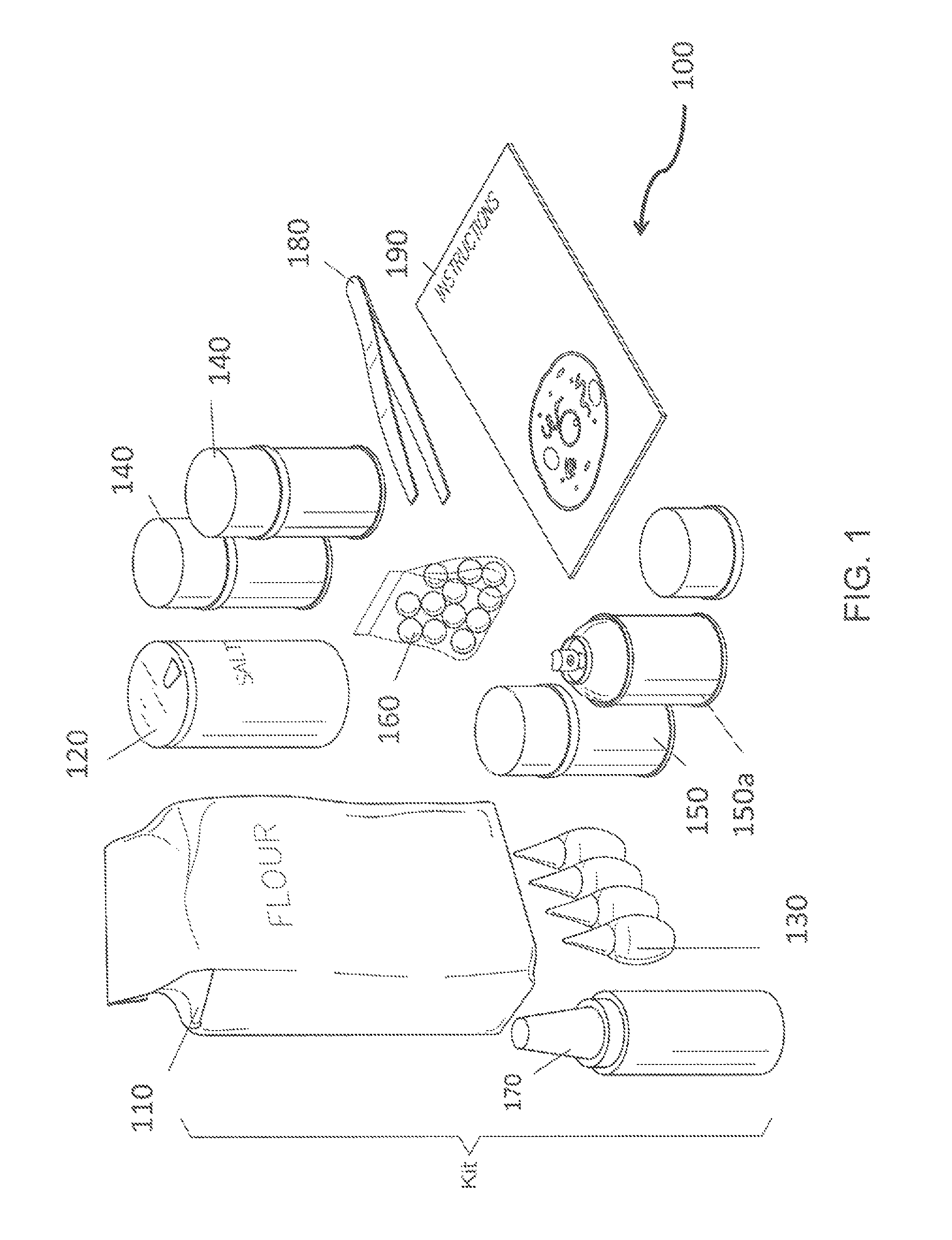

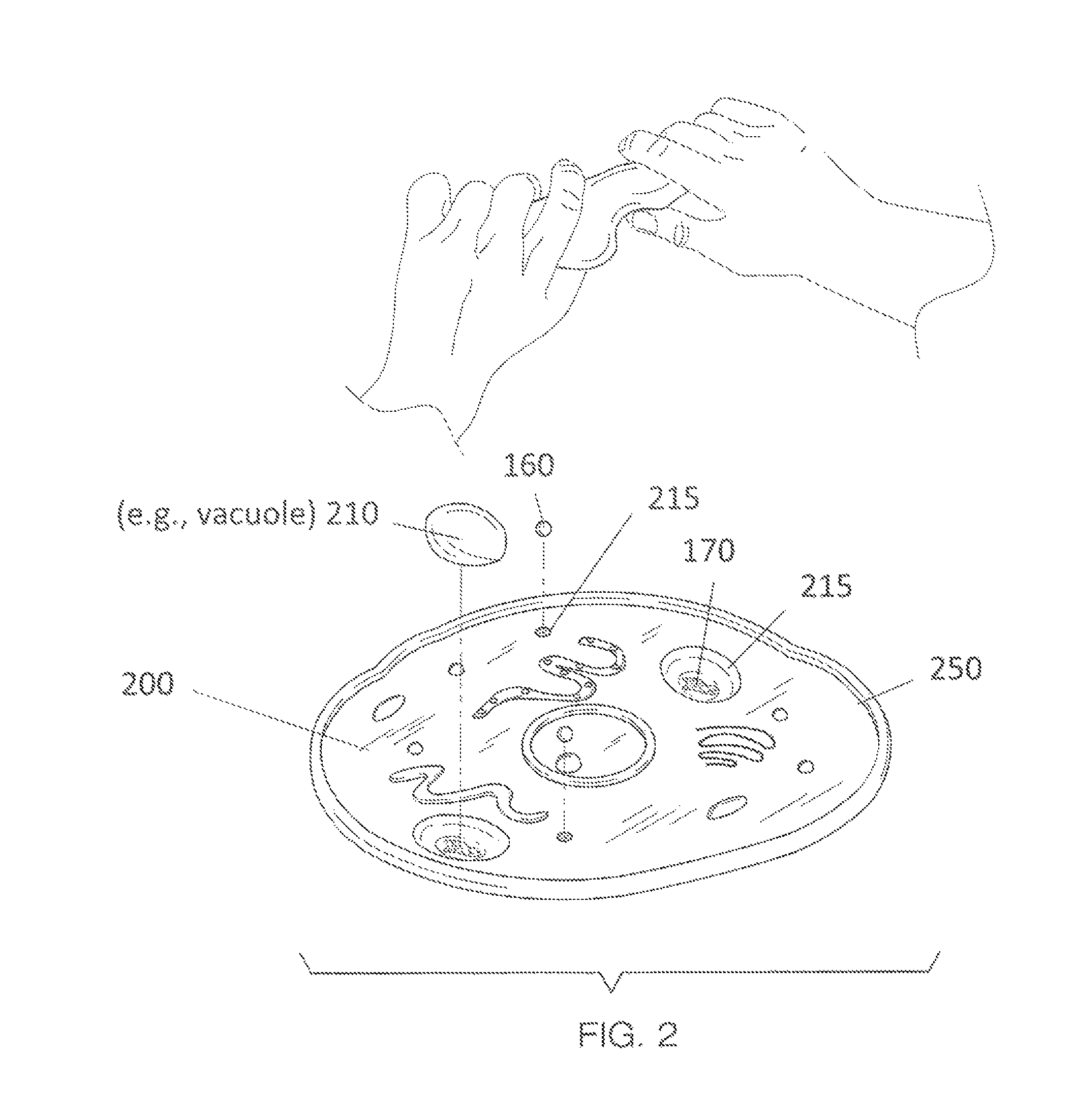

Kit for building a model of a cell

A method of creating a model of a biological cell. The method features providing a circular base with indentations disposed therein, forming a cell membrane and at least one organelle from a mixture formed by mixing all-purpose flour and water. Organelles may include a nuclear membrane, a cell wall, mitochondria, a smooth endoplasmic reticulum (ER), a rough ER, a vacuole, a golgi apparatus, a nucleolus, a nucleoplasm, chromatin, a ribosome, DNA, RNA, transcription machinery, a histone, and a microtubule. The outside edge of the base is lined with the cell membrane. The organelles are inserted into indentations or atop the base. The organelles can be secured with glue.

Owner:POMPEY AUDREY SIOUX

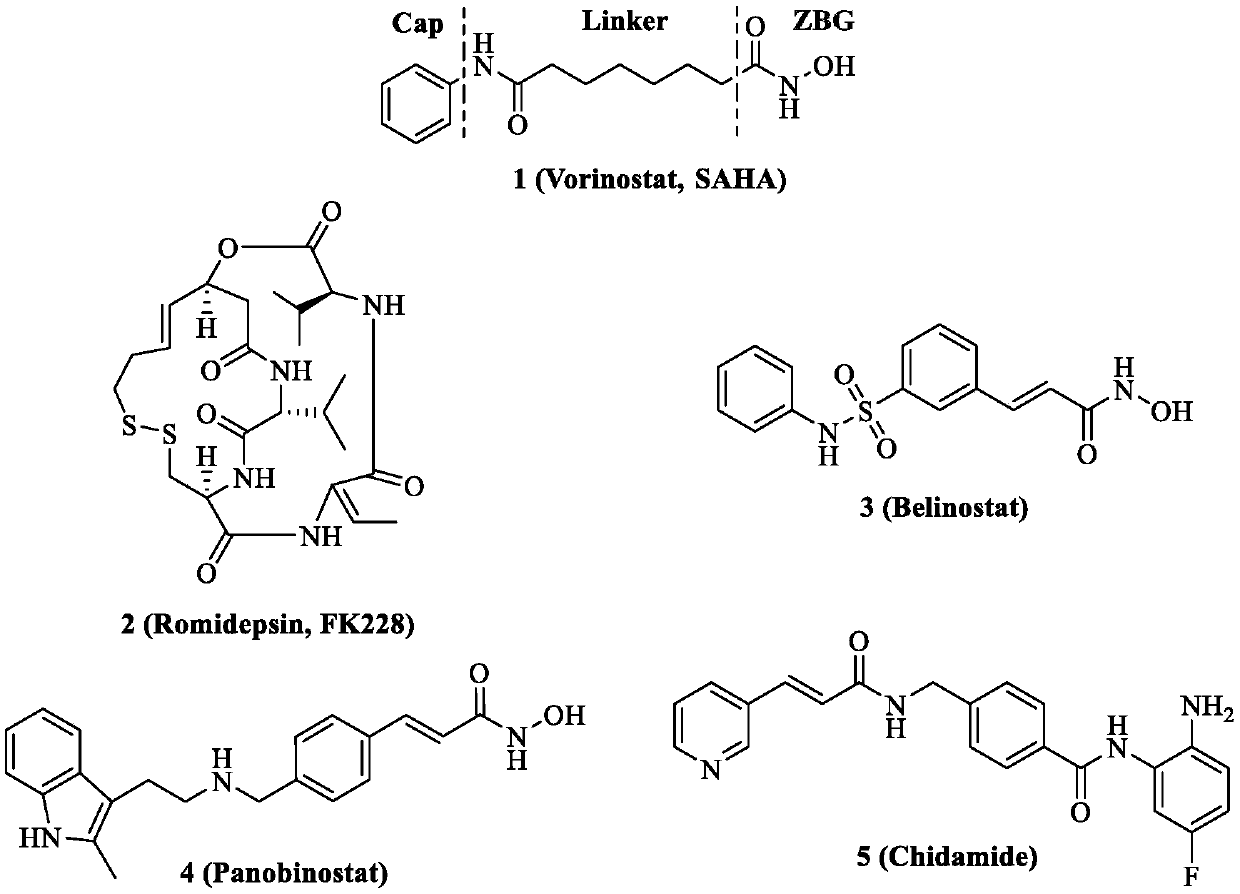

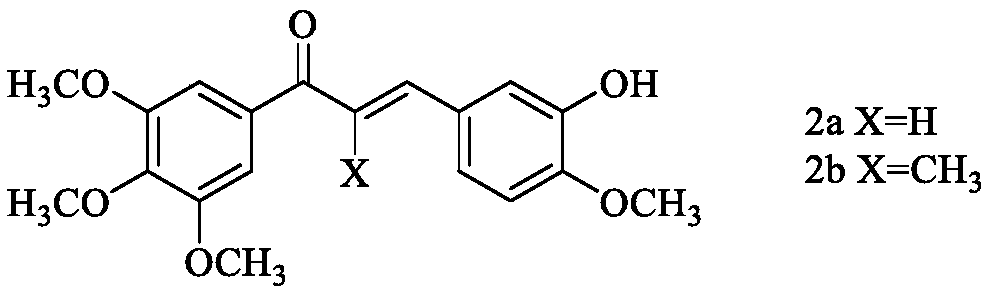

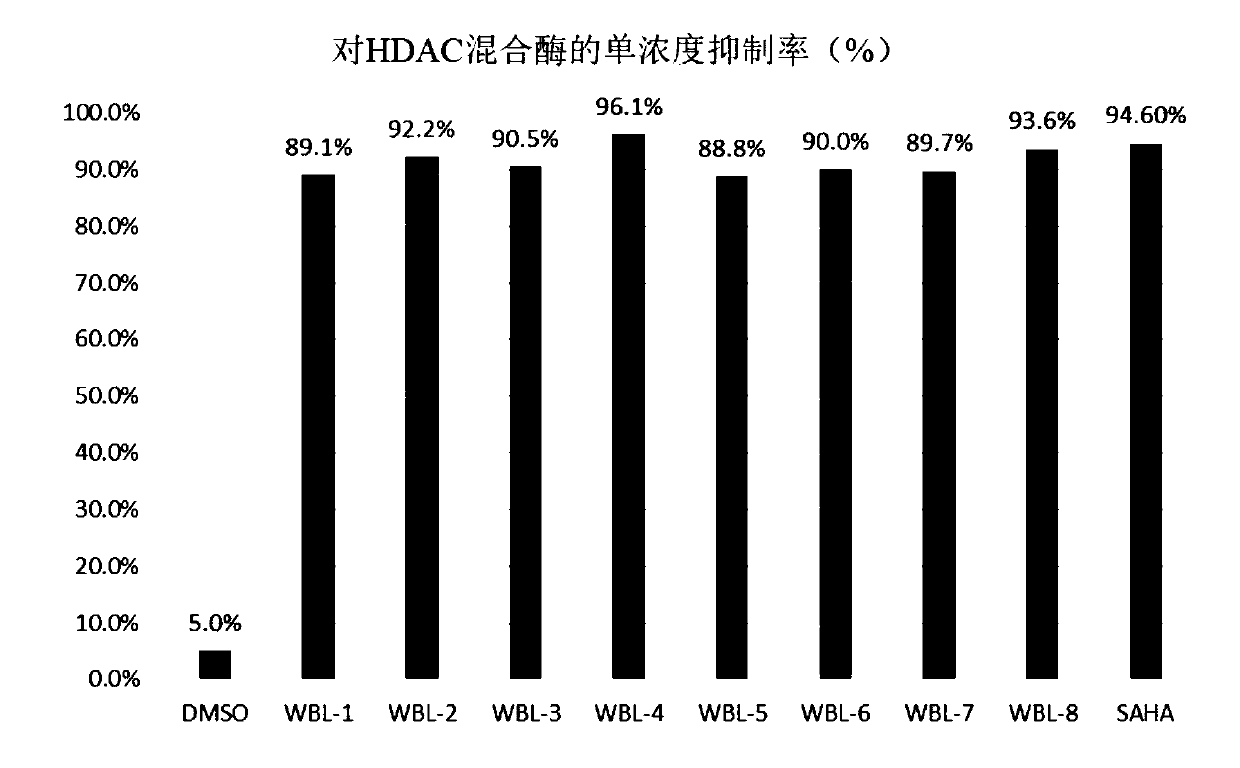

Histone deacetylase and microtubule dual target inhibitor and preparation method thereof

ActiveCN109651199AHas microtubule polymerization inhibitory activityEnhanced inhibitory effectOrganic chemistryAntineoplastic agentsHistone deacetylaseStereochemistry

The invention discloses a histone deacetylase and microtubule dual target inhibitor and a preparation method thereof. The inhibitor is as shown in I) or II) in description, and the inhibitor has the dual inhibitory activity of microtubules and histone deacetylase simultaneously.

Owner:QINGDAO UNIV

Nuclear transfer embryo formation method

InactiveUS20040019924A1Confirm comparative in vitro development potentialIncrease chanceTissue cultureFermentationAnimal scienceMeiosis

A nuclear transfer embryo is formed by destabilizing microtubules of an oocyte, whereby essentially all endogenous chromatin collects at a second polar body during meiosis of an oocyte. The oocyte is fused with the nucleus of a donor somatic cell of the same species of said oocyte prior to cessation of extrusion of the second polar body from the oocyte, thereby forming the nuclear transfer embryo. In one embodiment, the nuclear transfer embryo is employed to impregnate an animal, such as a mammal. In another embodiment, the donor nucleus is transgenic.

Owner:TRUSTEES OF TUFTS COLLEGE

Synergistic tumor inhibition composition and application thereof

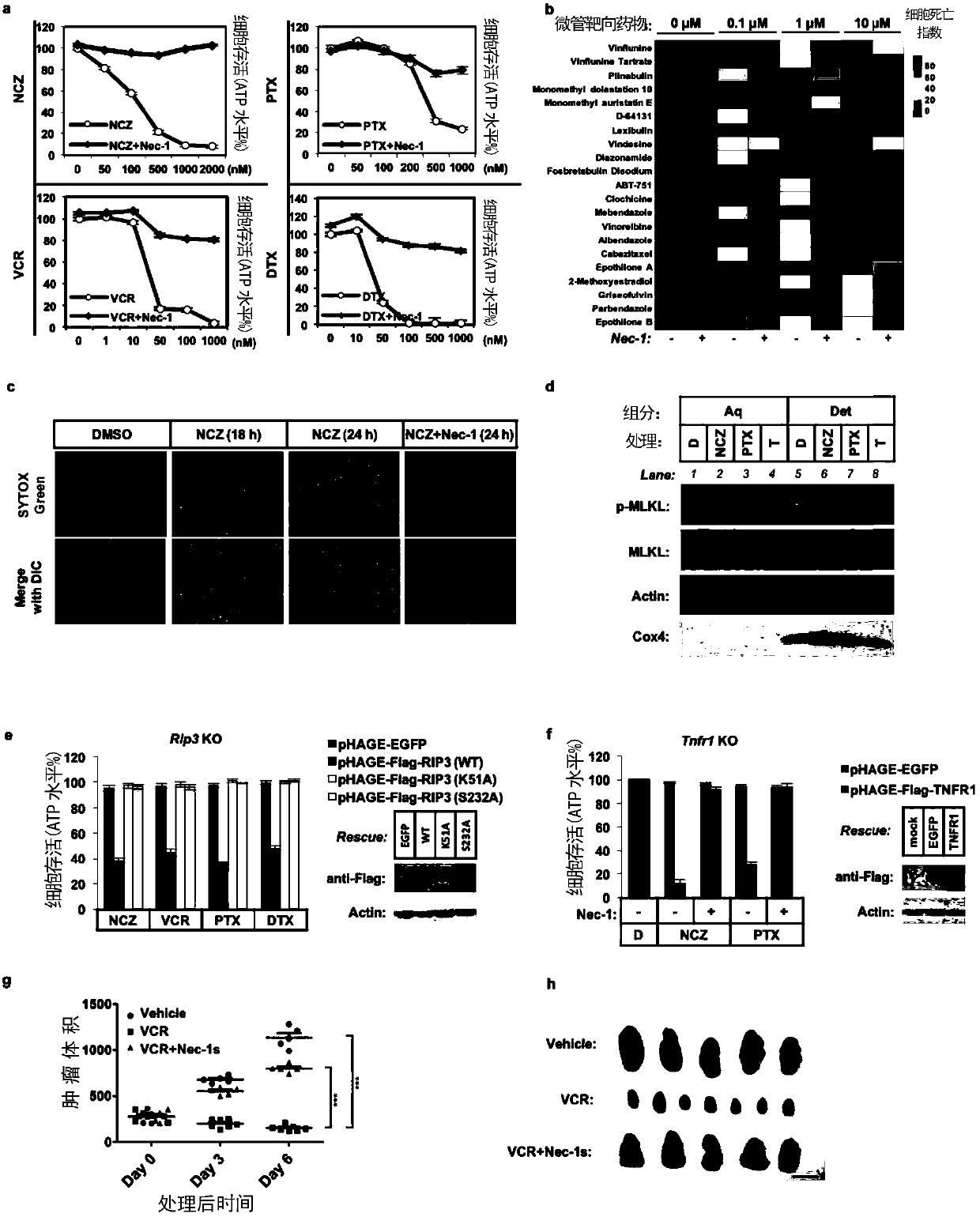

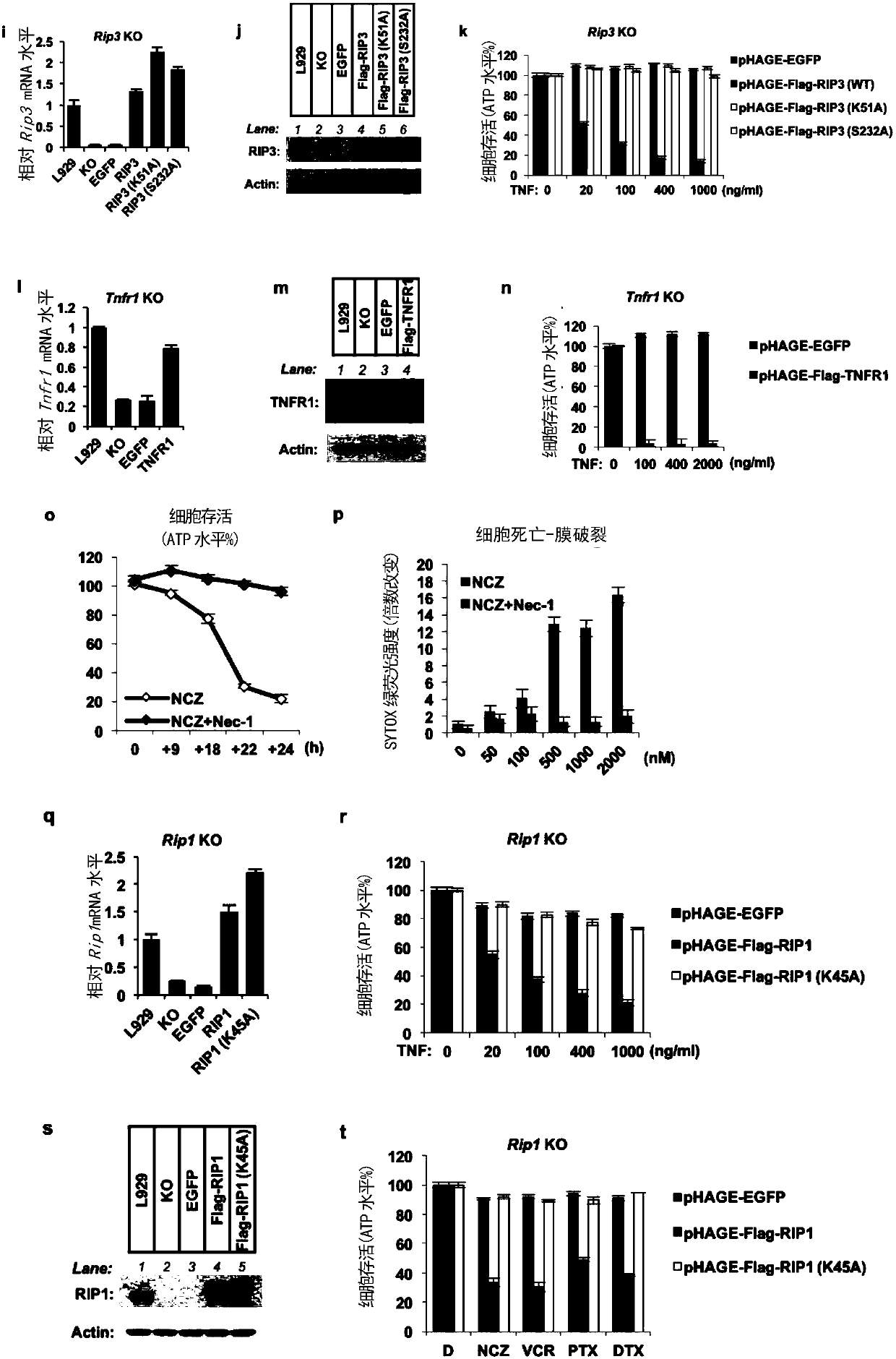

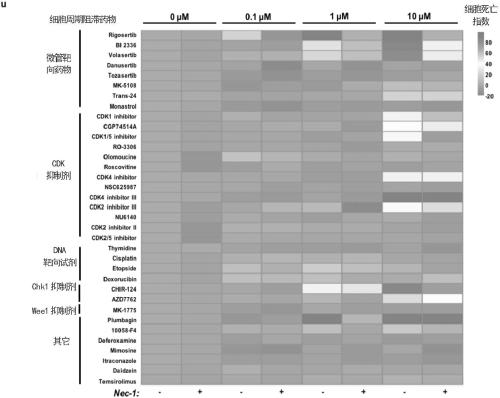

The invention relates to a synergistic tumor inhibition composition and application thereof. A molecular mechanism of microtubule-targeting agents (MTAs) in a process of triggering programmed cell death of tumor cells is provided for the first time, a JNK-cJun pathway is utilized to excite a membrane to locate the transcription of TNF (membrane-bound TNF, mTNF), the membrane localization TNF further activates apoptosis or necrosis of a death receptor TNFR1 and an initial cell, and the molecular mechanism can be used as an anti-tumor targeting drug taking the membrane- localization TNF as a target and can be used for developing a drug for promoting the efficacy of MTAs drugs. The invention also discloses a novel pharmaceutical composition scheme, namely combining MTAs drugs and IAP inhibitors (such as Smac mimics (SM), i.e., Smac analogues), tumor cell apoptosis induced by MTAs drugs and caused by membrane localization TNF up-regulation can be greatly promoted, and the effective dose and the medication time of the MTAs drugs are reduced so that the toxic and side effects of the chemotherapeutic drugs are reduced.

Owner:CENT FOR EXCELLENCE IN MOLECULAR CELL SCI CHINESE ACAD OF SCI

Gene Defects and Mutant ALK Kinase in Human Solid Tumors

In accordance with the invention, novel gene deletions and translocations involving chromosome 2 resulting in fusion proteins combining part of Anaplastic Lymphoma Kinase (ALK) kinase with part of a secondary protein have now been identified in human solid tumors, e.g. non-small cell lung carcinoma (NSCLC). Secondary proteins include Echinoderm Microtubule-Associated Protein-Like 4 (EML-4) and TRK-Fusion Gene (TFG). The EML4-ALK fusion protein, which retains ALK tyrosine kinase activity, was confirmed to drive the proliferation and survival of NSCLC characterized by this mutation. The invention therefore provides, in part, isolated polynucleotides and vectors encoding the disclosed mutant ALK kinase polypeptides, probes for detecting it, isolated mutant polypeptides, recombinant polypeptides, and reagents for detecting the fusion and truncated polypeptides. The disclosed identification of this new fusion protein enables new methods for determining the presence of these mutant ALK kinase polypeptides in a biological sample, methods for screening for compounds that inhibit the proteins, and methods for inhibiting the progression of a cancer characterized by the mutant polynucleotides or polypeptides, which are also provided by the invention.

Owner:CELL SIGNALING TECHNOLOGY

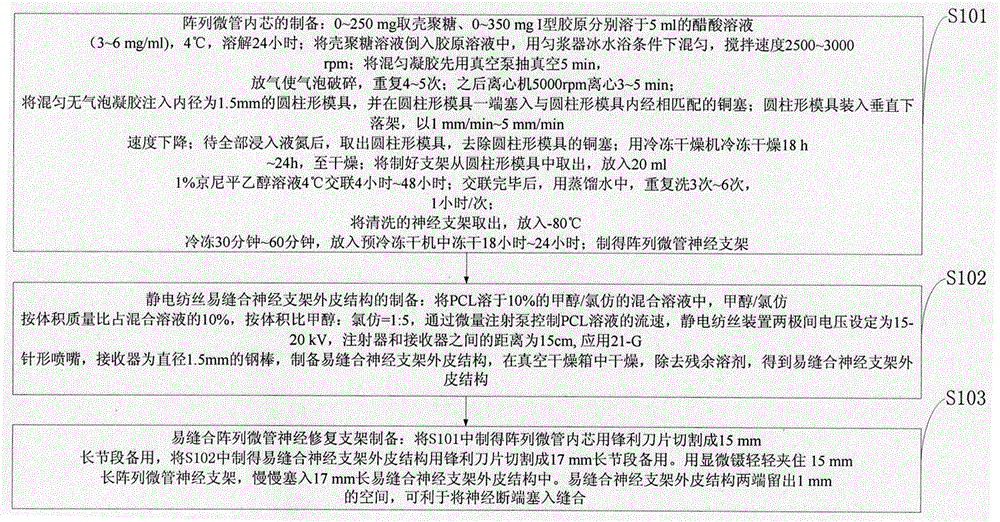

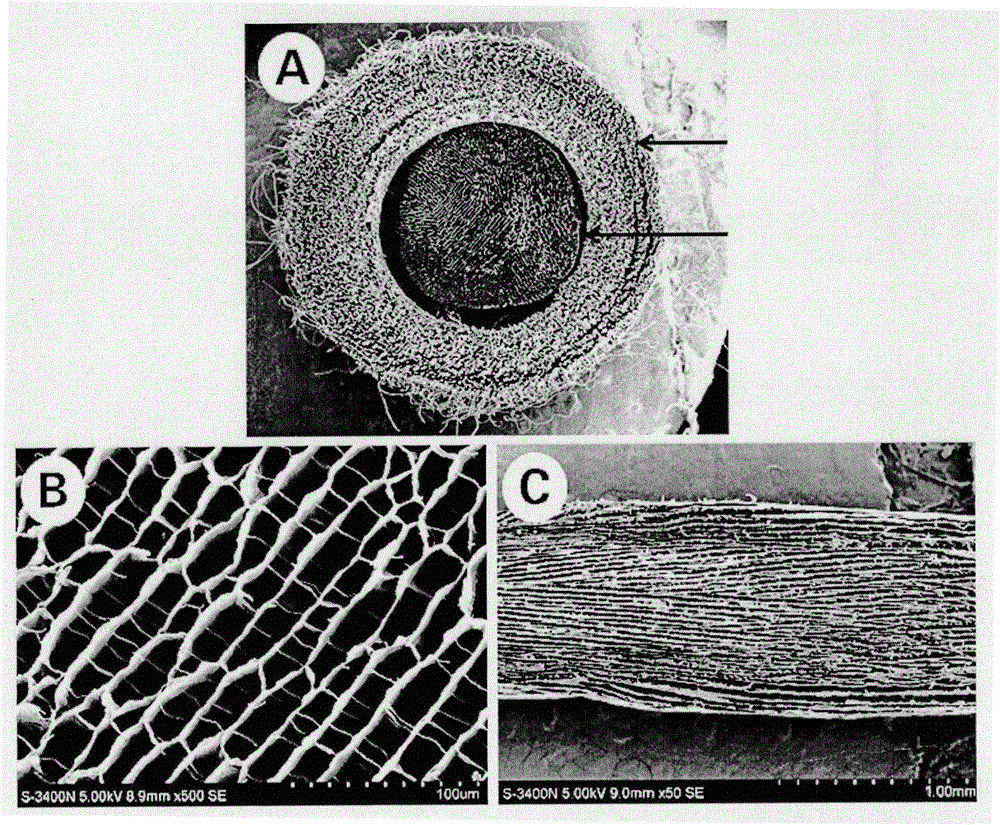

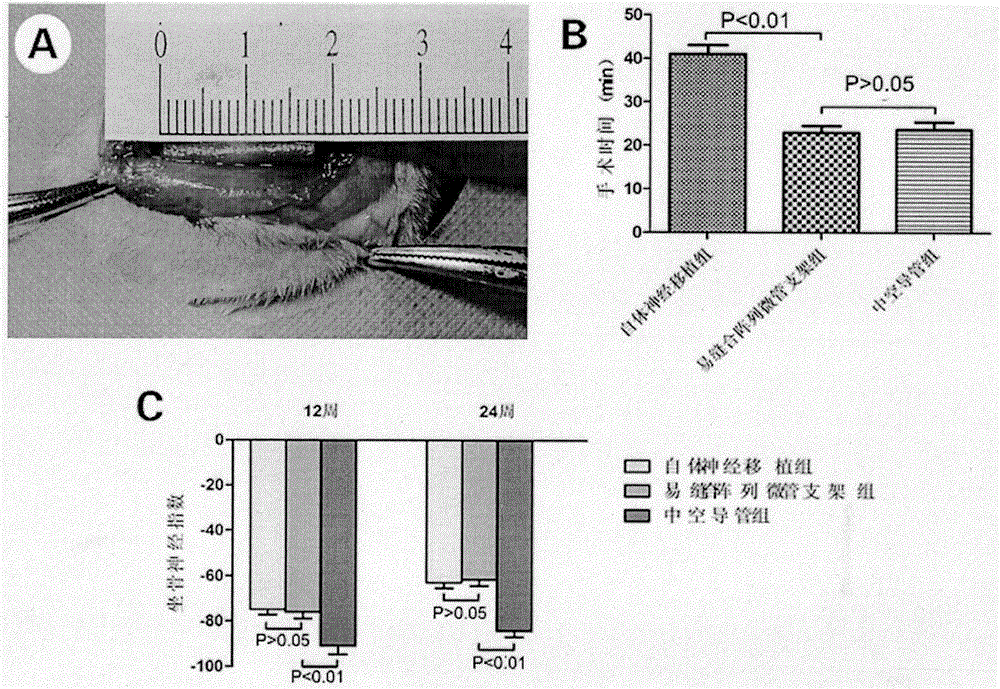

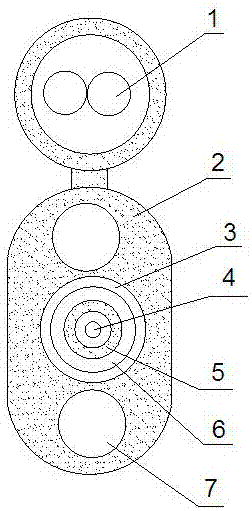

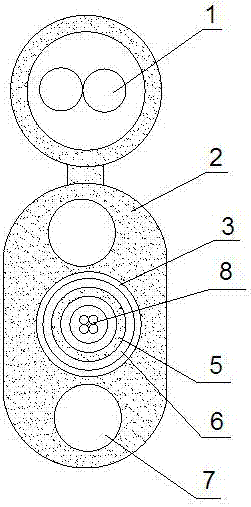

Preparation method and application of easy-to-suture array microtubular nerve regeneration stent

ActiveCN106806941AGood for tucking in suturesOptimize the appearance structureElectro-spinningTissue regenerationMicrotubuleElectrospinning

The invention discloses a preparation method and application of an easy-to-suture array microtubular nerve regeneration stent. The preparation method comprises the following steps: preparation of an array microtubular inner core, preparation of an electrostatic spinning easy-to-suture nerve stent skin structure, and preparation of the easy-to-suture array microtubular nerve regeneration stent. A regeneration method comprises the following steps that an array microtubular nerve stent physically guides nerve regeneration by use of longitudinally and parallelly arranged array mocrotubular structures; and the easy-to-suture nerve stent skin structure wraps the array microtubular nerve stent to achieve nerve stuffing and is used for suturing of nerve stumps and a bridging stent. Through changes of matching between an array microtubular inner core die and an electrostatic spinning receiving steel bar, the easy-to-suture array microtubular nerve regeneration stent with the length of 10-100 mm and the internal diameter of 1-8 mm can be prepared, and spaces reserved at two ends of the easy-to-suture nerve stent skin structure are 1-5 mm, and stuffing suture of the nerve stumps is facilitated.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Photoelectric composite cable for high-definition multimedia transmission and manufacturing method thereof

PendingCN107329218AImprove bending resistanceEasy to separateCommunication cablesFibre mechanical structuresMicrotubuleElectricity

The present invention discloses a photoelectric composite cable for high-definition multimedia transmission. The cable comprises electrical units, an optical unit, reinforcers and over sheaths. The reinforcers are arranged at the upper side and the lower side of the optical unit, the upper portions of the reinforcers are provided with the electrical units, the electrical units, the reinforcers and the optical unit are coated with the over sheaths, the electrical units are insulation electron beams or twisted wires, the optical unit comprises a tight tube optical fiber or an optical fiber microtubule located at the center, a reinforcement layer is coated with the tight tube optical fiber or the optical fiber microtubule, the reinforcement layer performs external plastic extruding of an inner sheath, and the inner sheath is coated with a waterproof layer. The photoelectric composite cable has good stretching resistance and flattening resistance performances, the optical unit portion has water-blocking and flame retardation performances and good bending resistance performance and can be used in the outdoor hostile environment, the optical fiber is employed to perform data transmission to effectively perform interference resisting, the transmission distance is long, the transmission capacity is large, and the optical unit and the electrical units are easy to be separated so as to facilitate processing the composite cable into a connector module in later period.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

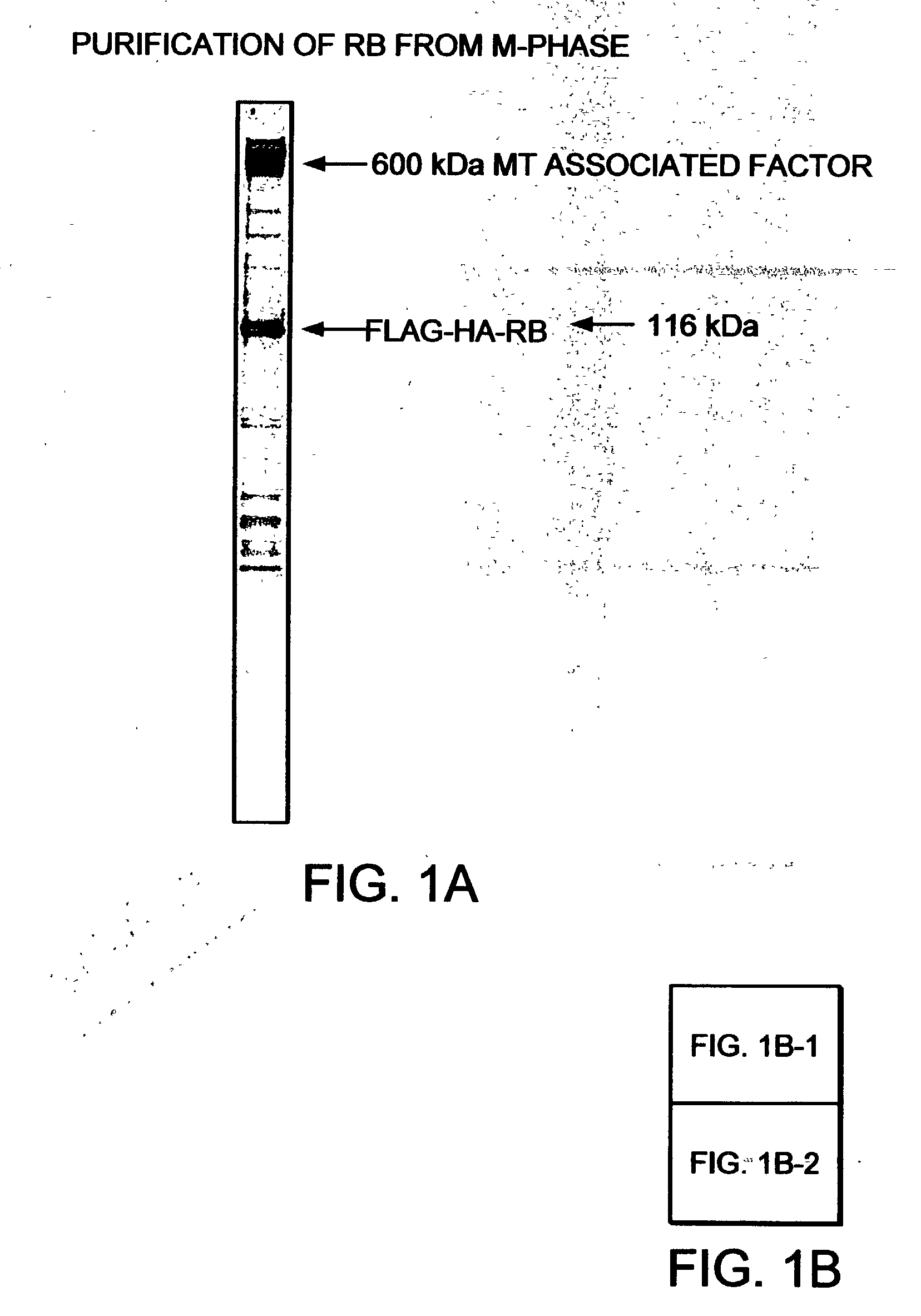

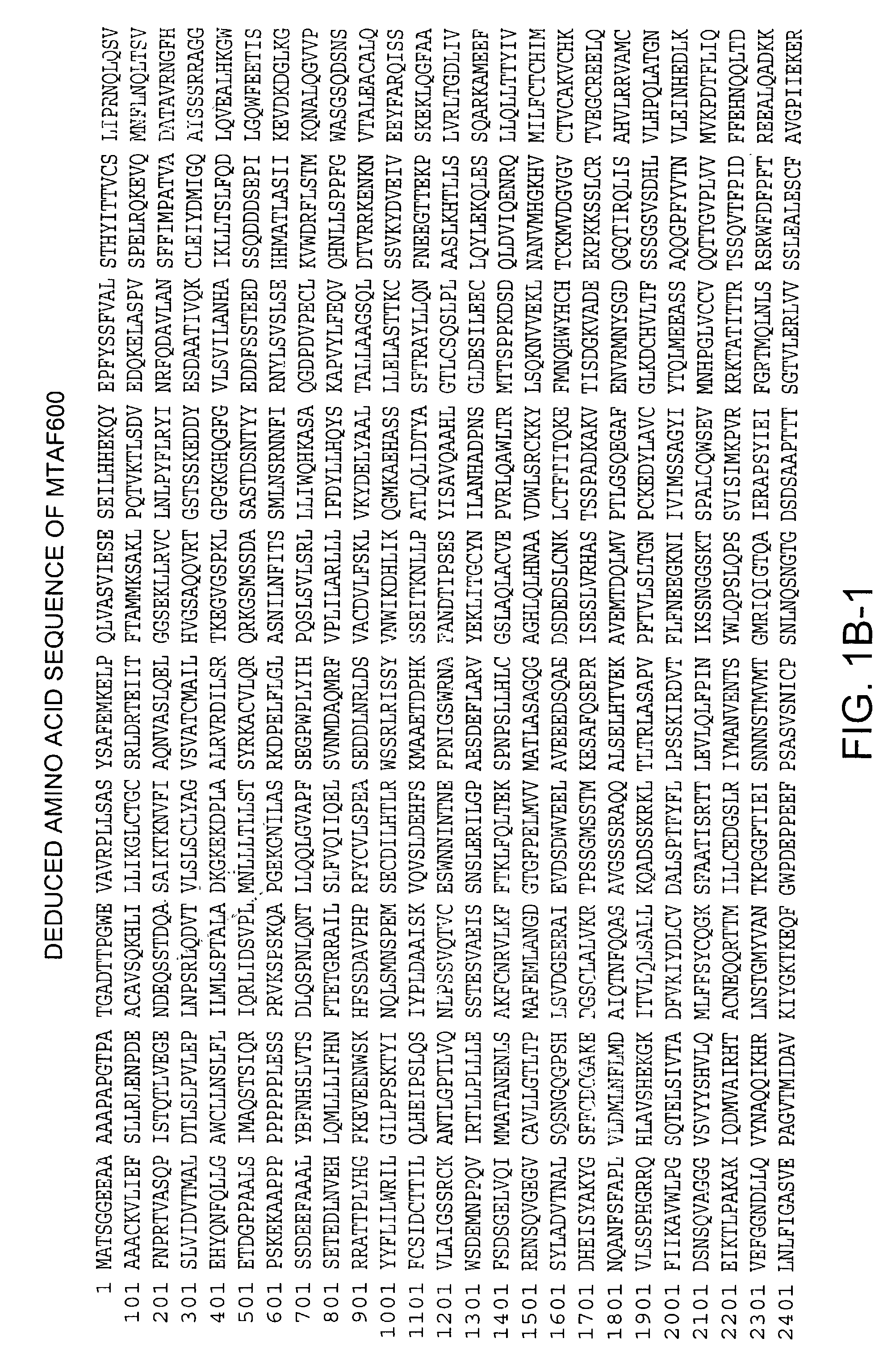

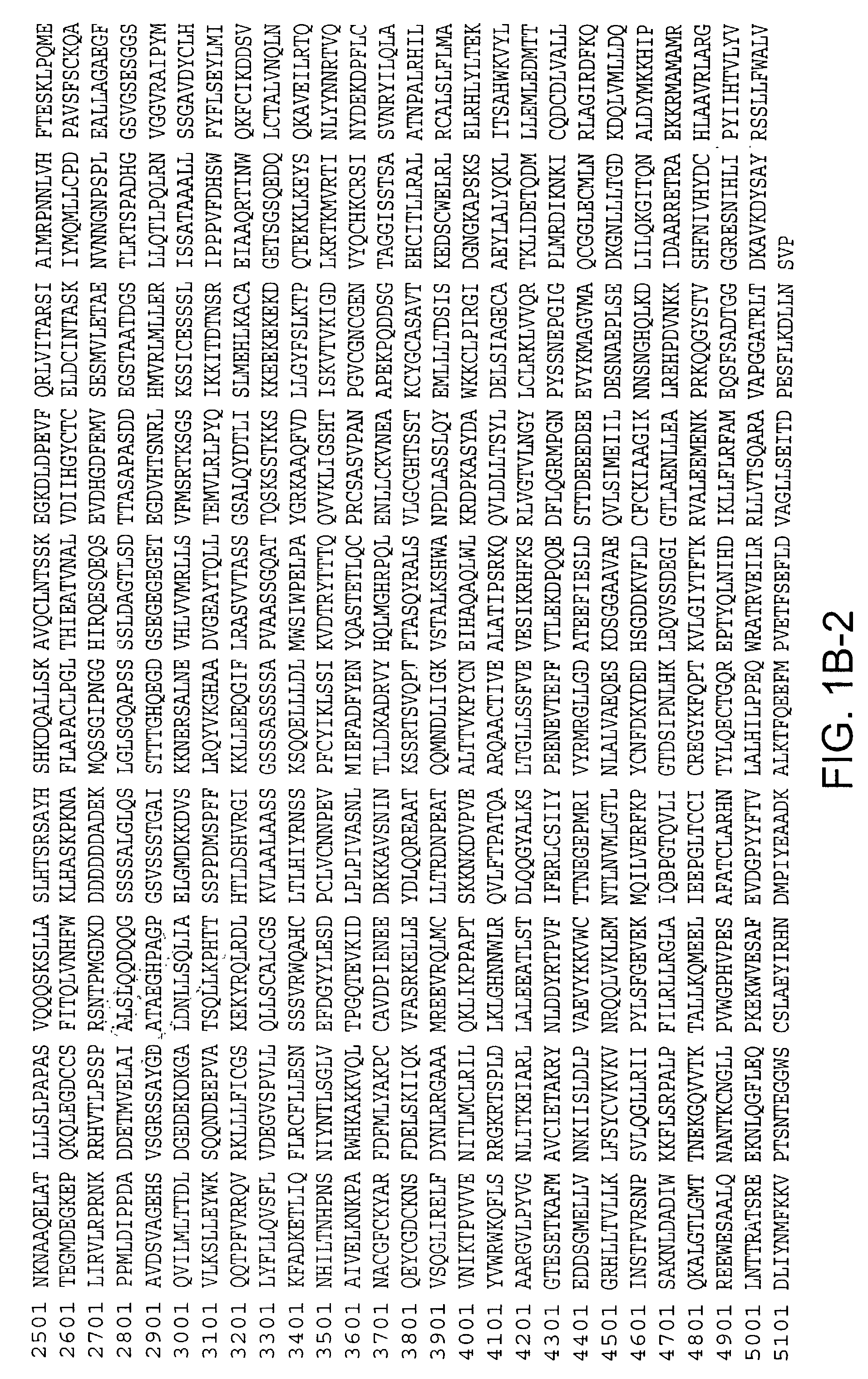

Methods and compositions for modulating tumor suppression

The purification of native RB (retinoblastoma) as a complex, including P107, P130, and a 600 kDa subunit, termed MTAF600 (microtubule associated factor 600) is described. MTAF600 binds to RB regardless of the phosphorylation status of RB, and binds to RB without disrupting the interaction between RB and E2F. It is further shown that E2F and DP proteins co-purified with MTAF600 and RB, such that hypophosphorylated RB may gain access to E2F as a complex with MTAF600. In addition, MTAF600 binds to microtubules and plays a role in active repression of E2F-responsive genes, cell cycle arrest, and genomic stability. The sequence of MTAF600 is described herein, along with its binding properties to proteins such as RB and microtubules, and its sequence homology. Further, methods and reagents for assaying the presence of MTAF600 or mutants thereof, pharmaceutical formulations, and methods for treating disease are also described.

Owner:DANA FARBER CANCER INST INC

Method for acquiring anti-sheath blight gene associated resistance gene analogs and molecular markers thereof

InactiveCN103146690AIncrease resistanceHarm reductionDNA preparationDNA/RNA fragmentationEarly generationAgricultural science

The invention discloses a method for acquiring anti-sheath blight gene associated resistance gene analogs of rice and molecular markers thereof. The method comprises: designing RGA (resistance gene analog) primers for complete genome resistance analogs to obtain genotypes of rice germplasms, acquiring anti-sheath blight phenotypes of 178 core germplasms through a sheath blight pathogen microtubule identification technology, combining the RGA genotypes and the anti-sheath blight phenotypes to carry out molecular character association analysis and performing clone sequencing on a PCR product, thus obtaining the anti-sheath blight associated resistance gene analogs and molecular markers thereof. In the invention, by means of genetic transformation and hybridization, the anti-sheath blight gene associated resistance gene analogs can be introduced into common cultivated rice to improve the resistance of rice to sheath blight. The anti-sheath blight gene associated molecular markers obtained in the invention can be used for detecting the existence of anti-sheath blight genes, realizes indirect selection of disease-resistant plants, and can exempt identification of inoculated sheath blight pathogens from the influence of climate, geographical positions and other uncertain factors, thus being able to be used for early generation selection, anti-sheath blight variety breeding period shortening, and breeding efficiency improvement.

Owner:CROP INST SICHUAN PROVINCE ACAD OF AGRI SCI

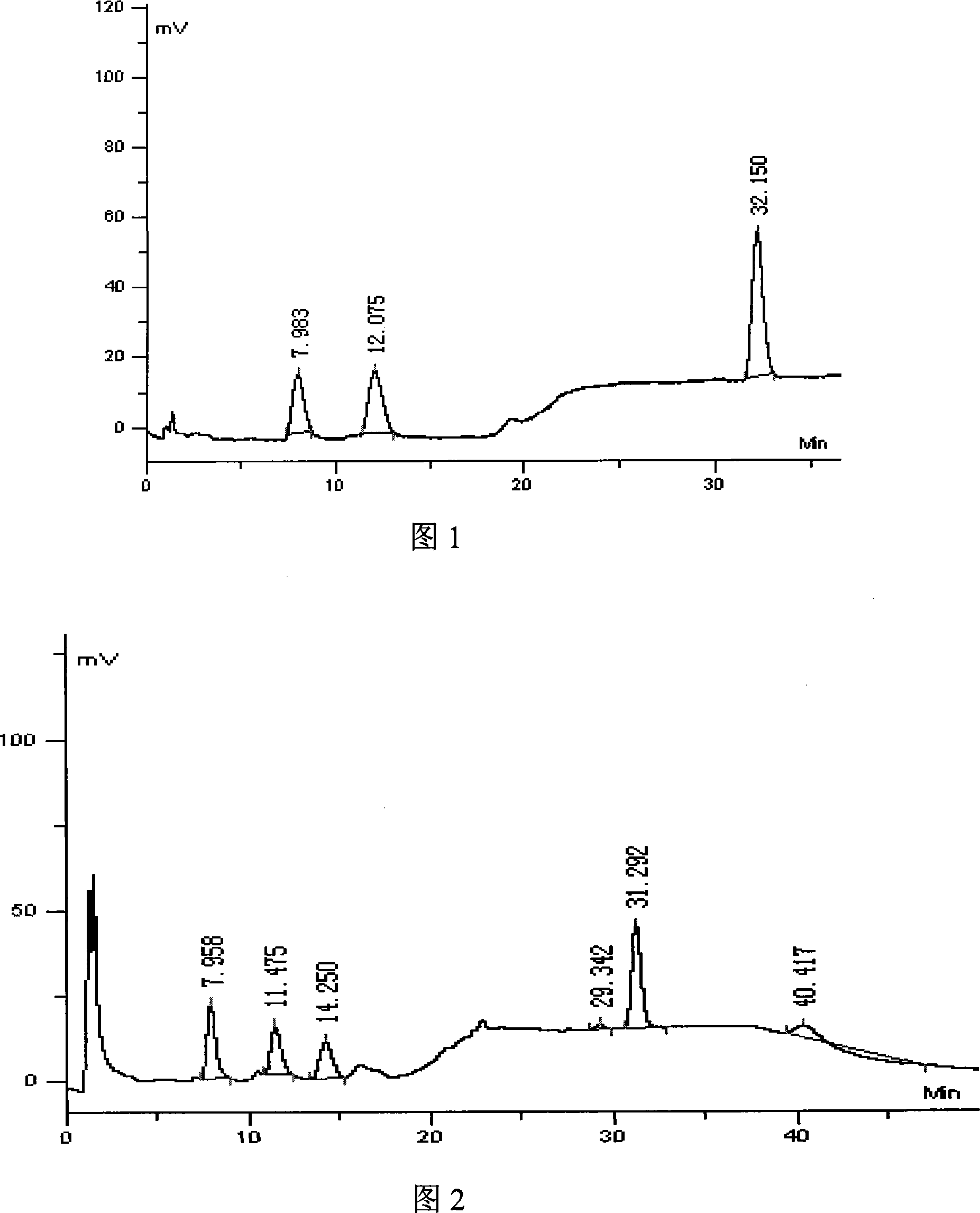

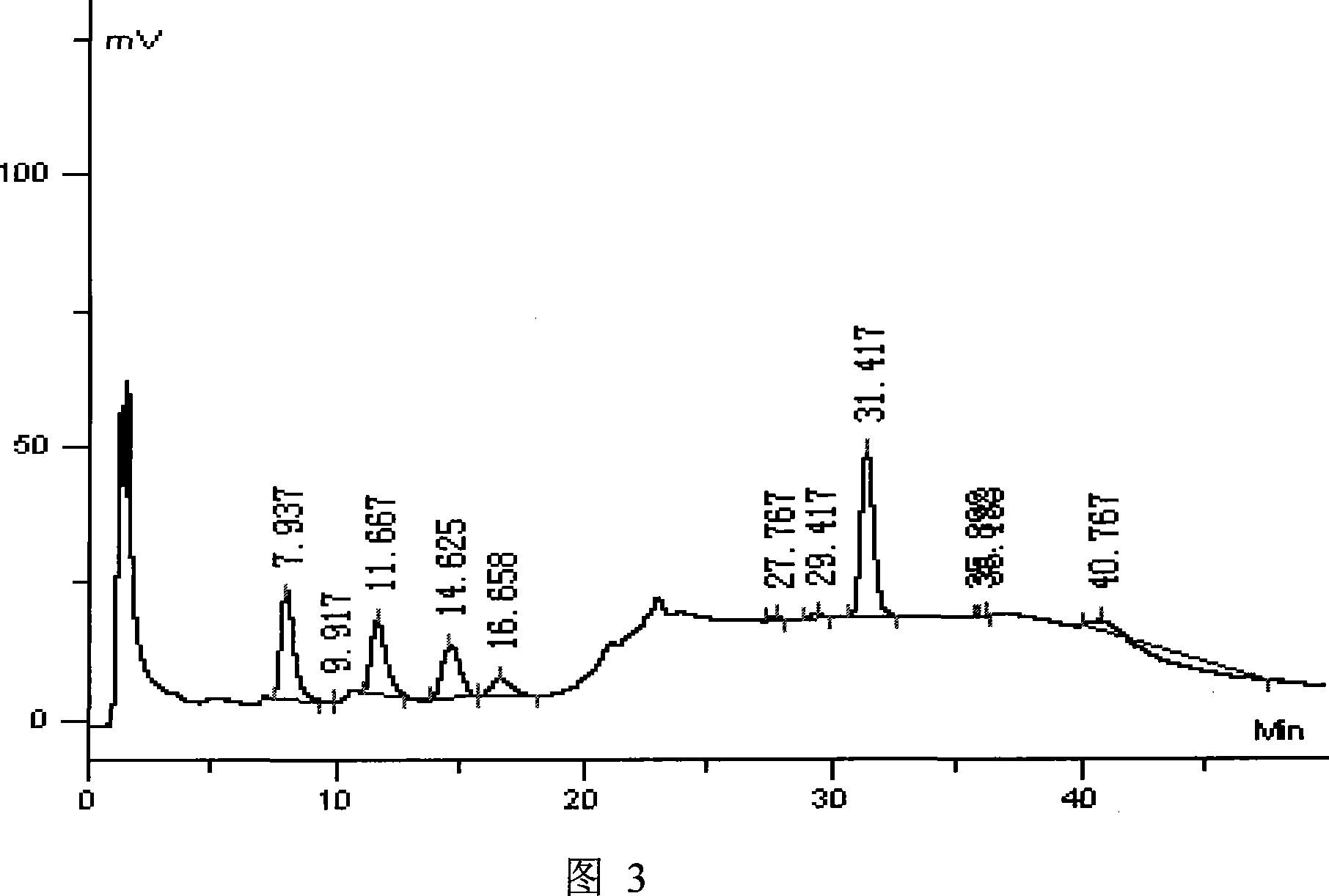

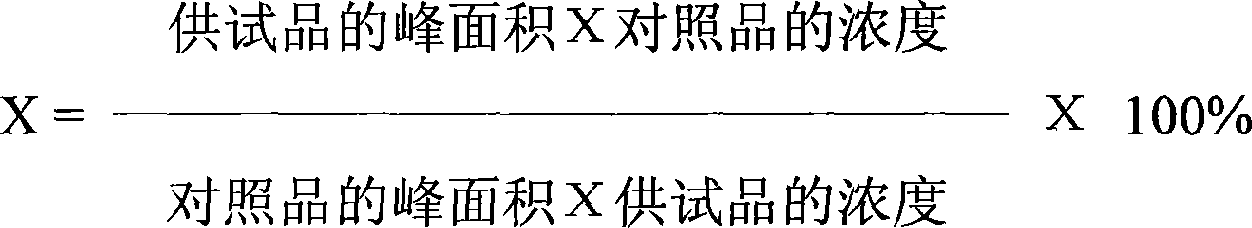

Method for disposable measuring bighead atractylodes rhizome inner ester and atractylone with HPLC microtubule method disposable

InactiveCN101113975AEasy to operateReduce mistakesComponent separationSpecial data processing applicationsAtractylenolide IIIMicrotubule

The invention discloses a method of single time measurement of atractylenolide and atractylon. The procedure includes preparing mobile phase resolution A and B made of chromatographic pure methanol, acetonitrile and redistilled water, preparing the mixed control solution made of atractylenolide I, atractylenolide III and atractylon, preparing sample solution, testing the three absorption peaks of control solution and samples at three different time respectively by chromatograph of liquid according to the setting gradient of mobile phase A and B and the time, and calculating the content of atractylenolide I, atractylenolide III and atractylon according to the formula X=(peak area of sample is multiplied by density of control then is divided by peak area of control and is multiplied by density of sample) is multiplied by 100 percent. The invention can determine the content of atractylenolide I, atractylenolide III and atractylon in atractylodes macrocephala by only one sample injection. Thus the operation is simplified, the error of multiple sample injection is reduced and analysis of the constituent ration of the three ingredients is convenient. The invention is of important academic value and meaningful in practical application.

Owner:ZHEJIANG ACAD OF TRADITIONAL CHINESE MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com