Natural microtubule encapsulated phase-change materials and preparation thereof

a phase-change material and natural microtubule technology, which is applied in the field of natural microtubule encapsulated phase-change materials and the preparation thereof, can solve the problems of limited application of solid-liquid phase-change energy storage materials in practice, two materials are rarely used in practical applications, and the volume change of materials is great, etc., to achieve the effect of low cost, easy preparation, and high hollowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

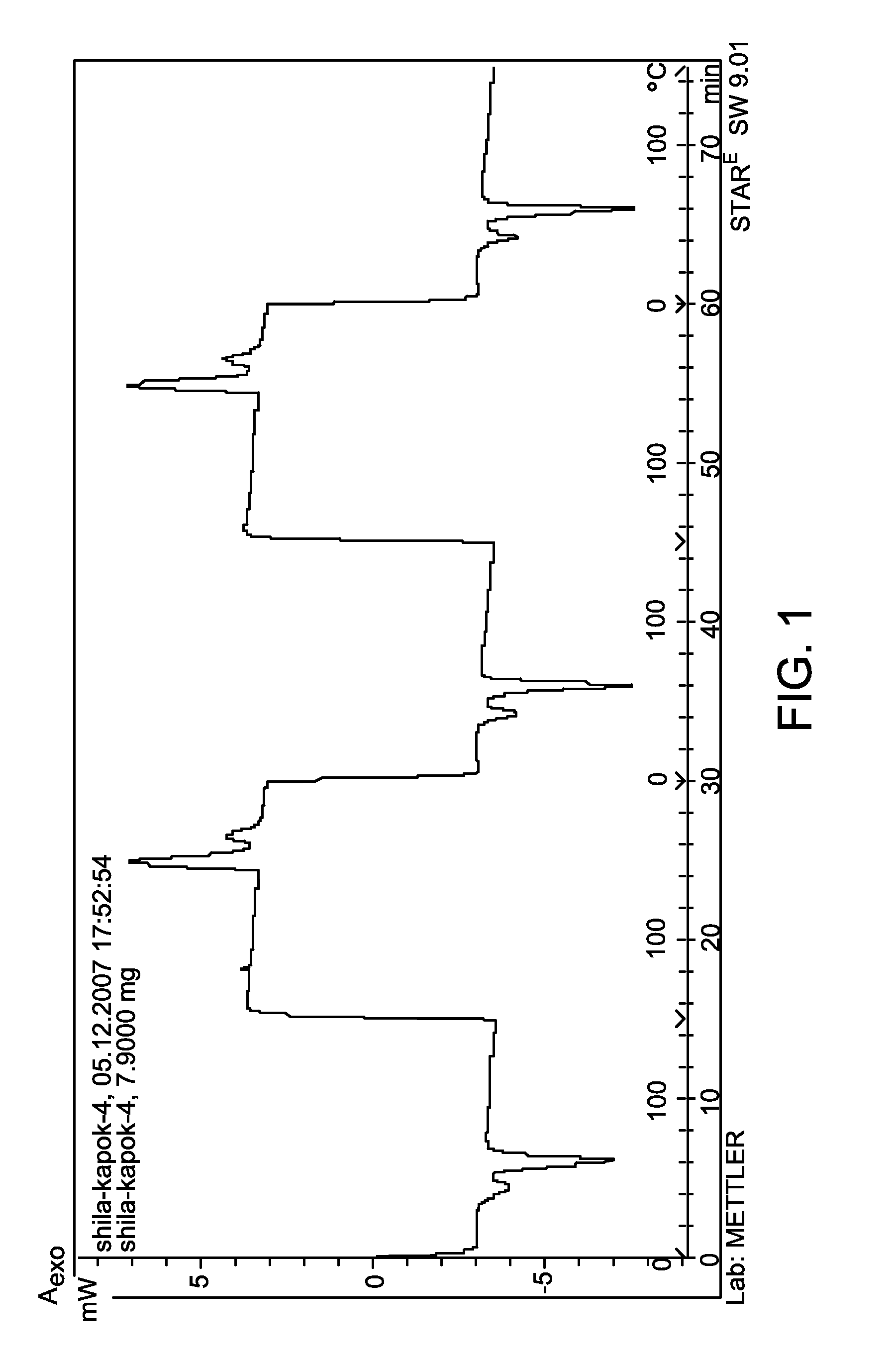

example 1

Preparation of Natural Kapok Fiber Encapsulated Paraffin and Urea-Formaldehyde Resin Encapsulated Microcapsules of a Phase-Change Material

[0032](1) Liquefaction of Phase-Change Material:

[0033]The organic phase-change material paraffin was heated to above the melting point of 60° C. to obtain a liquid paraffin phase-change material.

[0034](2) Filling Truncated Natural Microtubules with the Liquid Phase-Change Material:

[0035]1 g natural kapok fiber (truncated microtubules) having a length of 10-50 μm was dispersed into 10 mL liquid phase-change material obtained in Step (1), and immersed to make the capillary absorption reach a balance, such that the kapok fiber was fully filled with the liquid phase-change material.

[0036](3) Encapsulation of Microcapsulated Phase-Change Material:

[0037]2 g urea-formaldehyde prepolymer (obtained by adding 1 g urea into 2 ml 36% volume fraction aqueous formaldehyde solution and stirring until the mixture was fully dissolved, heating to 60° C., and mainta...

example 2

Preparation of Natural Milkweed Fiber Encapsulated Pentaerythritol and Cellulose Acetate Encapsulated Microcapsules of a Phase-Change Material

[0043](1) Liquefaction of Phase-Change Material:

[0044]Organic phase-change material pentaerythritol (PE) was dissolved in a small amount of ethanol, to obtain a liquid pentaerythritol (PE) solution phase-change material.

[0045](2) Filling Truncated Natural Microtubules with the Liquid Phase-Change Material:

[0046]1 g natural milkweed fiber having a length of 0.5-10 μm was dispersed into 10 mL liquid phase-change material obtained in Step (1), and immersed to make the capillary absorption reach a balance, such that the milkweed fiber was fully filled with the liquid phase-change material.

[0047](3) Encapsulation of Microcapsulated Phase-Change Material:

[0048]The ethanol in the phase-change material microcapsule containing ethanol solvent obtained in Step (2) was vaporized, the phase-change material pentaerythritol (PE) solution was concentrated an...

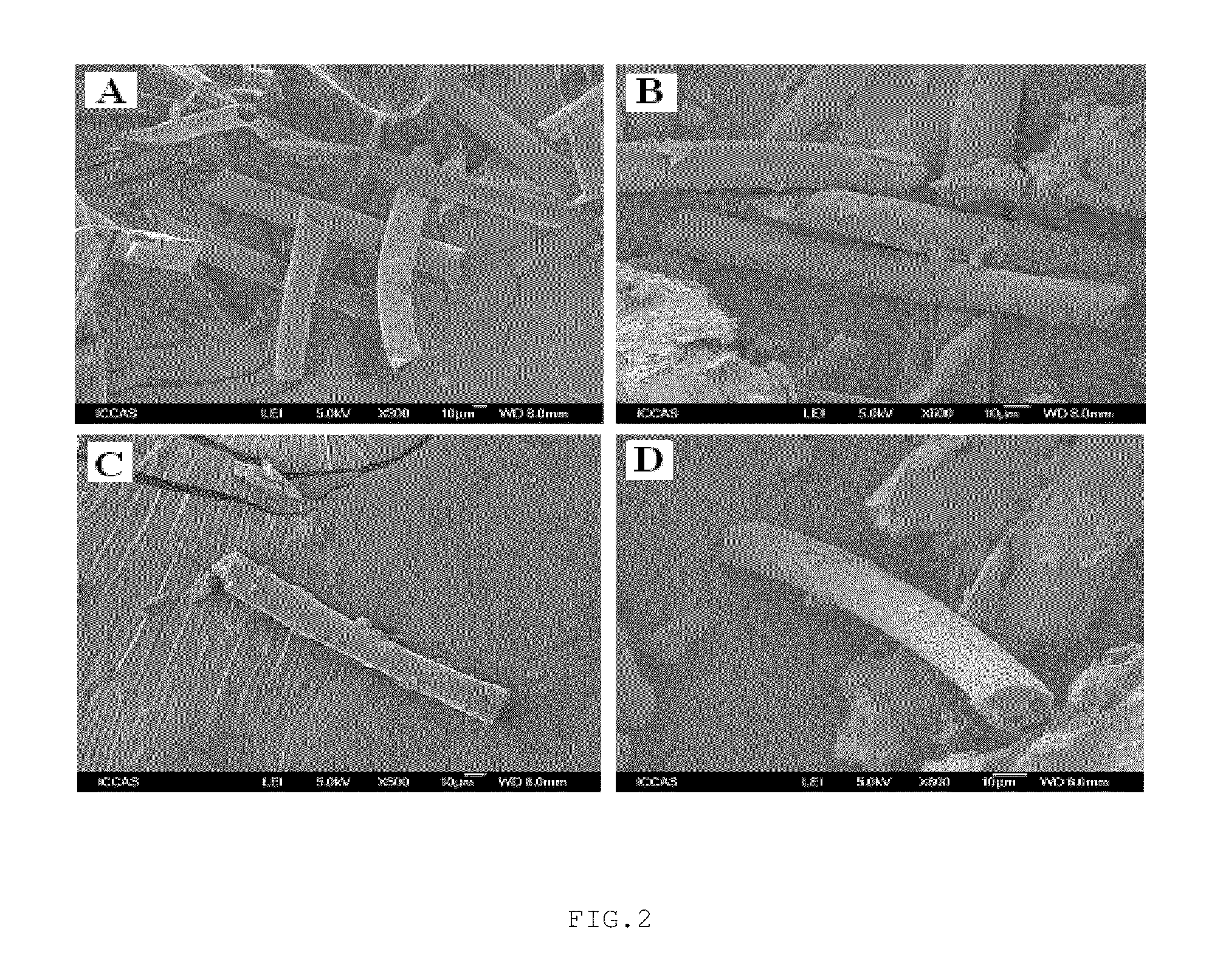

example 3

Preparation of Natural Bamboo Fiber Encapsulated CaCl2.6H2O and Cellulose Acetate Encapsulated Microcapsules of Phase-Change a Material

[0052](1) Liquefaction of Phase-Change Material:

[0053]1 g inorganic phase-change material CaCl2.6H2O was dissolved in 10 mL deionized water, to obtain a liquid CaCl2.6H2O solution phase-change material.

[0054](2) Filling Truncated Natural Microtubules with the Liquid Phase-Change Material:

[0055]1 g natural bamboo fiber having a length of 500-1000 μm was dispersed in 10 mL liquid phase-change material obtained in Step (1), and immersed to make the capillary absorption reach a balance, such that the bamboo fiber was fully filled with the liquid phase-change material.

[0056](3) Encapsulation of Microcapsulated Phase-Change Material:

[0057]The deionized water in the phase-change material microcapsules containing deionized water obtained in Step (2) was vaporized, the phase-change material CaCl2.6H2O solution was concentrated and solidified, and then immerse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com