Ultrathin-wall microtubule production device and production method thereof

A technology for manufacturing devices and manufacturing methods, which is applied in the field of biosensors, and can solve problems such as rough tube walls, affecting the sensitivity of biodetectors, and inability to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

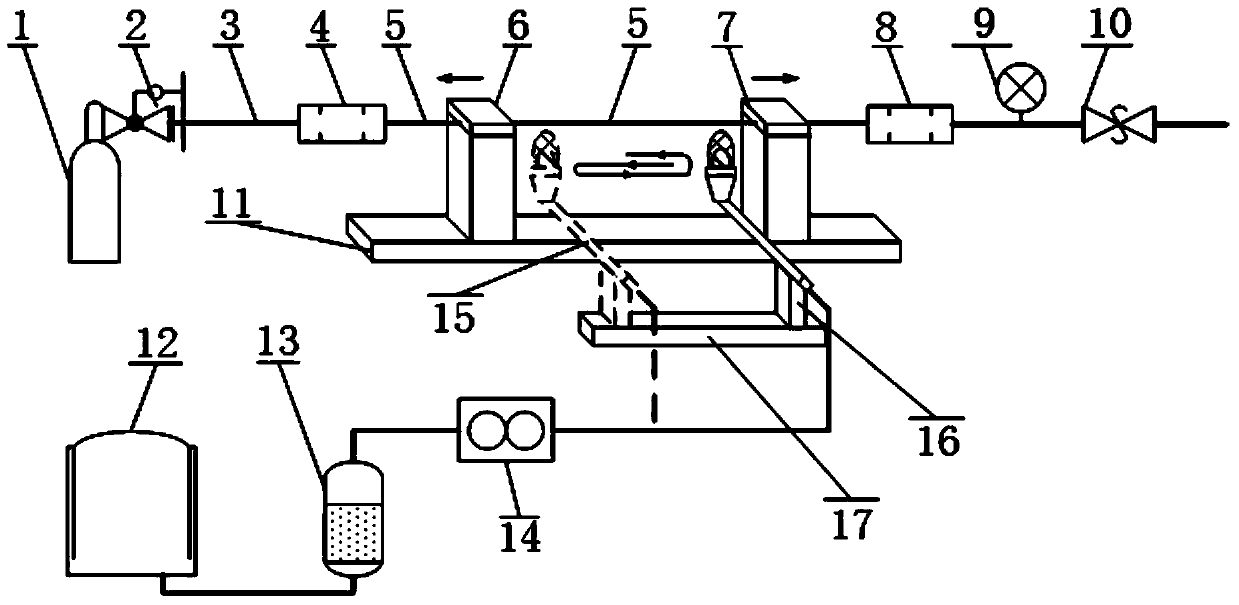

[0028] Example 1: Ultra-thin-walled microtube manufacturing device

[0029] Such as figure 1 As shown, the production device includes a nitrogen gas cylinder 1, a pressure reducing valve 2, a PU tube 3, a caliber conversion device 4, a thick-walled microtube 5 and a left microtube holder 6, a right microtube holder 7, and a caliber conversion Device 8, high-precision barometer 9, back pressure valve 10, long-stroke high-precision micro-displacement stage 11, hydrogen and oxygen generator 12, gas dryer 13, gas flow controller 14, flame spray gun 15 and flame spray gun holding device 16 , Short-stroke high-precision micro-displacement stage 17.

[0030] among them:

[0031] Nitrogen gas cylinder: Standard nitrogen gas cylinder is used for the nitrogen gas (0.1MPa~1.0MPa) in the pressurized gas path inside the microtube.

[0032] Pressure reducing valve: installed at the outlet of the nitrogen gas cylinder to control the inlet pressure of the gas path behind it to prevent the pressure i...

Embodiment 2

[0048] Example 2: Manufacturing method of ultra-thin-walled microtubes

[0049] The manufacturing process of the above-mentioned ultra-thin-walled microtube manufacturing device is as follows:

[0050] 1. Install raw materials. Take a thick-walled quartz microtube 5 with a length of l (10mm~20mm), an outer diameter of D1 (100μm~700μm), and a wall thickness of d1 (30μm~60μm), and connect the left and right ends to the left and right diameter conversion devices respectively 4, 8, to make the overall gas path connected; after that, fix both ends of the thick-walled quartz microtube 5 on the left and right microtube holders 6, 7 respectively, and adjust the left and right microtube holders The devices 6, 7 make the microtube parallel to the axis of the guide rail of the long-stroke high-precision micro-translation stage 11;

[0051] 2. Nitrogen pressurization. Turn on the switch of the nitrogen cylinder 1 and adjust the size of the pressure reducing valve 2 so that the downstream gas ...

Embodiment 3

[0059] Embodiment 3: Application examples

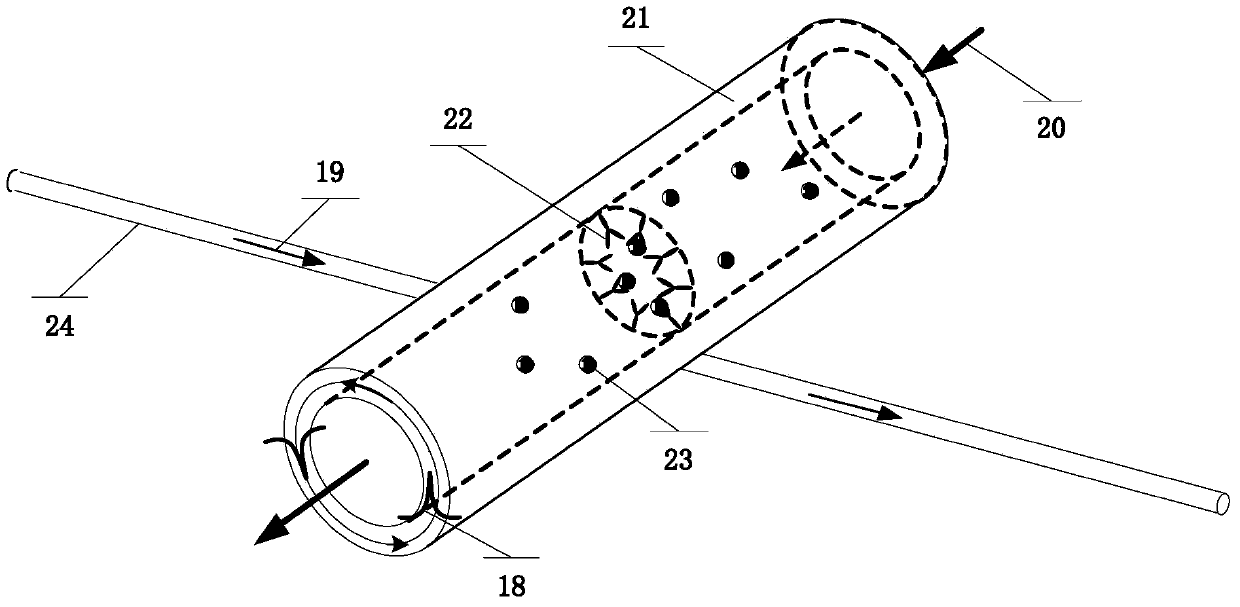

[0060] The ultra-thin-wall micro-tube resonant cavity manufactured by the ultra-thin-wall micro-tube manufacturing device and method of the present invention can be applied to WGM-based optical microfluidic biosensing.

[0061] Its local sensor structure is like figure 2 As shown, the biological detection reagent 22 is solidified on the inner wall of the ultra-thin-walled microtube resonant cavity 21, and the microfluidic test sample 20 is transported from the ultra-thin-walled microtube resonant cavity 21. The ultra-thin-walled microtube resonant cavity 21 forms a micro-resonant cavity perpendicular to the axial direction in the tube wall, and the light waves propagating in the cavity penetrate into the microfluidic detection sample 20 in the ultra-thin-walled microtube resonant cavity 21 through the evanescent wave field for detection .

[0062] When the microfluid 20 transporting the biomolecule to be detected passes through the ultra-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com