Dielectric nonlinear capacitor ceramic material and its making technique

A ceramic capacitor and ceramic technology, which is applied in the field of materials and components for electrical energy storage and release, can solve the problems of low electrical breakdown strength, wide electrical hysteresis, and difficulty in reaching capacitor materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

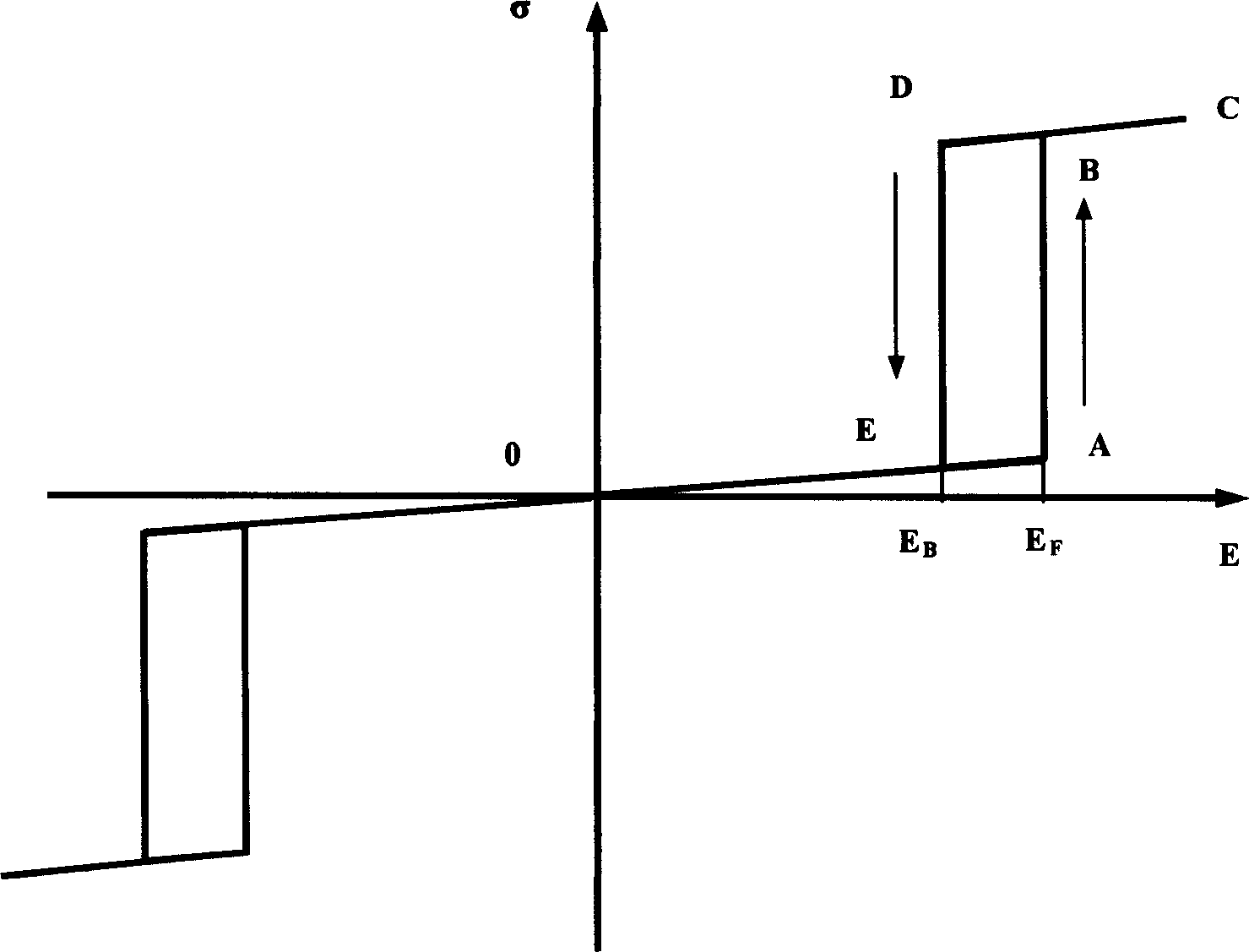

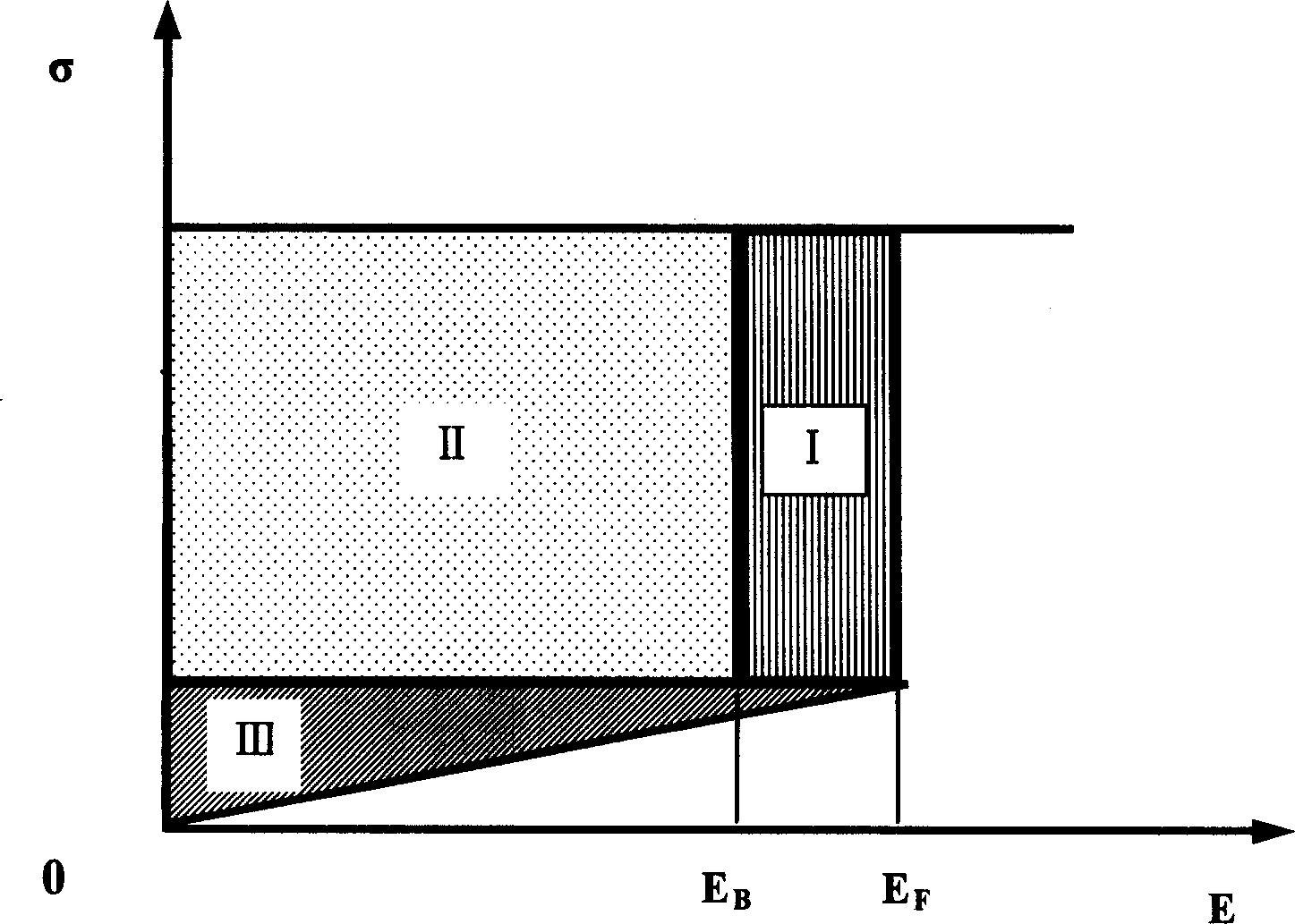

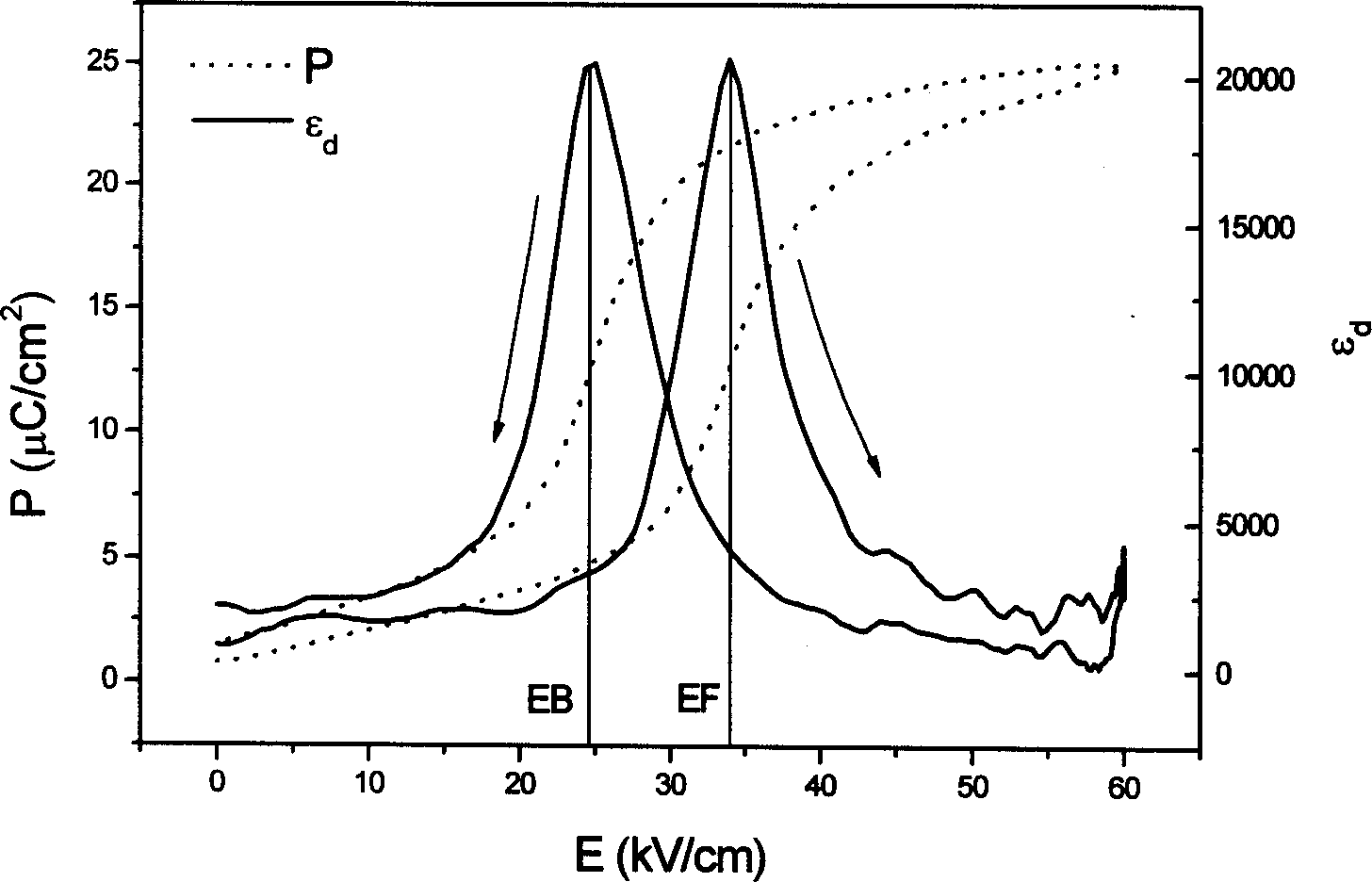

[0033] Embodiment 1: Nonlinear relationship of polarization intensity of antiferroelectric ceramics of the present invention as a function of applied voltage

[0034] Partially replace the positive divalent lead element in the lead zirconate titanate compound with positive trivalent lanthanum, and partially replace the positive tetravalent zirconium element in the lead zirconate titanate compound with positive tetravalent tin element to form lanthanum-modified zirconium tin lead titanate solid solution, the chemical composition expression that obtains the antiferroelectric ceramic capacitor of the present invention is (Pb 0.925 La 0.05 )[(Zr 0.70 sn 0.30 ) 0.85 Ti 0.15 ]O 3 . Using oxides PbO and ZrO containing the above elements 2 , SnO 2 、TiO 2 , La 2 o 3 After weighing and mixing according to the molar ratio of the elements, the bulk antiferroelectric ceramics are produced through ball milling, pre-sintering, secondary ball milling, granulation, compacting, plast...

Embodiment 2

[0036] Embodiment 2: the embodiment of antiferroelectric ceramics of the present invention as discharge capacitor

[0037] Use positive trivalent lanthanum and positive divalent strontium to partially replace the positive divalent lead element in the lead zirconate titanate compound, and use positive tetravalent tin elements to partially replace the positive tetravalent zirconium element in the positive zirconate lead titanate compound to form a common combination of lanthanum and strontium. Doping modified lead zirconium tin titanate solid solution to obtain the chemical composition expression of the antiferroelectric ceramic capacitor of the present invention is (Pb 0.91 La 0.02 Sr 0.06 )(Zr 0.54 sn 0.30 Ti 0.16 )O 3 . The antiferroelectric ceramics and capacitors were obtained under conditions similar to those of the ceramics and capacitors in Example 1. The antiferroelectric ceramics were discs with a thickness of 0.060 cm and an area of 7.80 cm. After applying a ...

Embodiment 3

[0038] Embodiment 3: the embodiment of antiferroelectric ceramics of the present invention as discharge capacitor

[0039] The difference between this example and Example 2 is that the positive divalent lead element in the lead zirconate titanate compound is partially replaced with the positive divalent barium to form a co-doped and modified zirconium tin lead titanate solid solution with lanthanum and barium. The chemical composition expression of antiferroelectric ceramic capacitor of the present invention is (Pb 0.92 La 0.04 Ba 0.02 )(Zr 0.56 sn 0.40 Ti 0.12 )O 3 , all the other are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com