Mixed liquid gasification burner and nozzle-free water cooling gasification furnace end comprising same

A burner and gasifier technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of clogging of gas nozzles with kitchen waste, insufficient combustion of mixed gas, weakening of mixed fuel flow, etc., to achieve increased gasification Time, improve energy efficiency, reduce the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

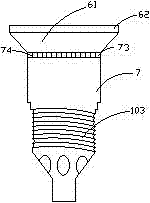

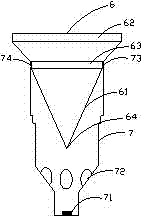

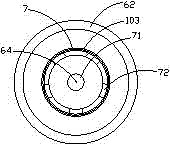

[0038] Such as Figure 1~4 As shown, this embodiment provides a mixed liquid gasification burner, including a protection component and a flow guide component 6, the protection component is used to connect the nozzle, the flow guide component 6 is used to divert the gas fuel, and cooperate with the protection component to prevent the nozzle from clogging ;

[0039] The protection part comprises a hollow pipe fitting 7, and the hollow pipe fitting 7 is provided with a nozzle interface 71, a hollow pipe fitting 7 successively from bottom to top.

[0040] Gas inlet 72, gas fuel outlet 73, the gas fuel outlet 73 is located at the joint of the conical part 61 and the hollow pipe 7, the gas fuel outlet 73 includes a plurality of welding pieces 74, the welding pieces 74 are arranged at intervals, and welded on the conical part The gas fuel outlet 73 is formed at the connection with the hollow pipe. In this embodiment, one end of the welding sheet 74 is welded on the second plane 63 ,...

Embodiment 2

[0047] This embodiment provides a nozzleless water-cooled gasification furnace head provided with Embodiment 1, including a water-cooled gasification furnace head and a mixed liquid gasification burner;

[0048] Such as Figure 5 ~ Figure 6 As shown, the water-cooled gasification furnace head includes a shell 1 and a water-cooled tube 5. The shell 11 is provided with a gasification tube 2, a combustion chamber 4, and a gas nozzle 41 in sequence from the outside to the inside. The gas nozzle 41 is arranged outside the combustion chamber 4. , and only one nozzle is provided, the gasification tube 2 is disc-shaped and arranged on the periphery of the combustion chamber 4, according to the volume of the combustion chamber 4, the gasification tube 2 can be coiled for multiple turns, and one end 21 of the gasification tube 2 is connected to the combustion chamber 4 The gas nozzle 41 is connected with the other end 22 of the liquid fuel source, and the pump is used to transport the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com