Method for preparing multilevel-hole structure with titanium surface containing calcium and phosphorus

A pore structure, multi-layer technology, applied in surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve problems such as interface bonding limitations, improve force, promote osteoblast adhesion, and avoid severe discharge phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

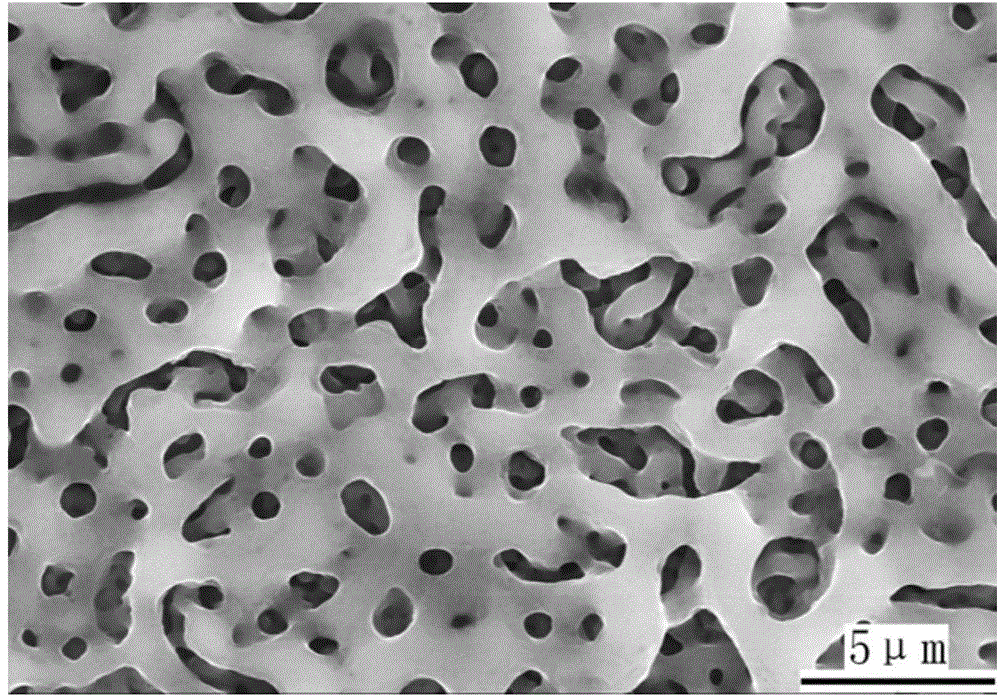

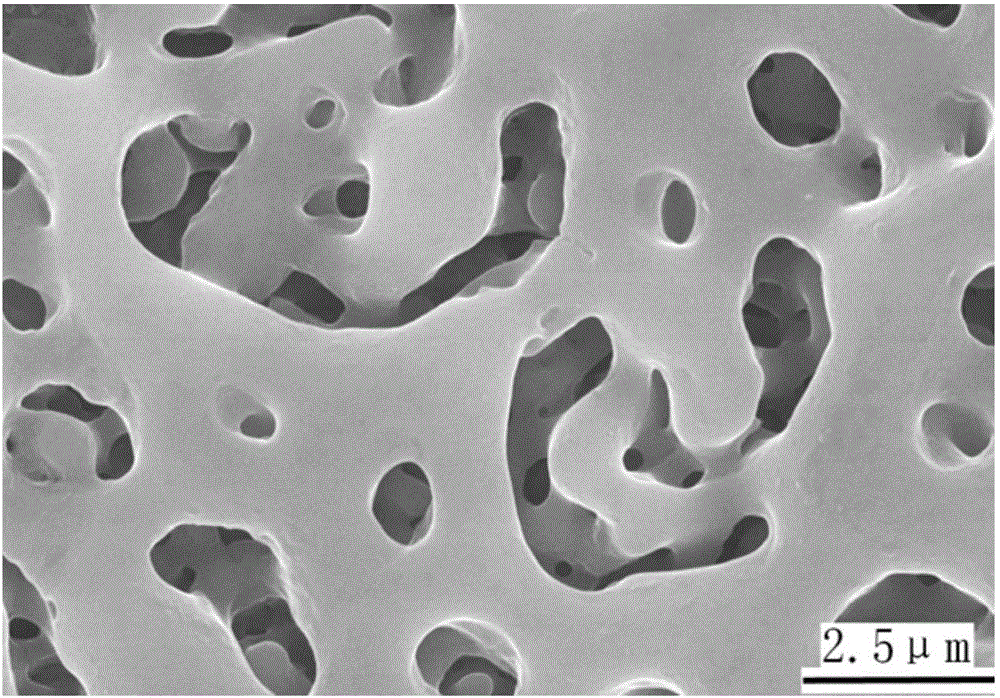

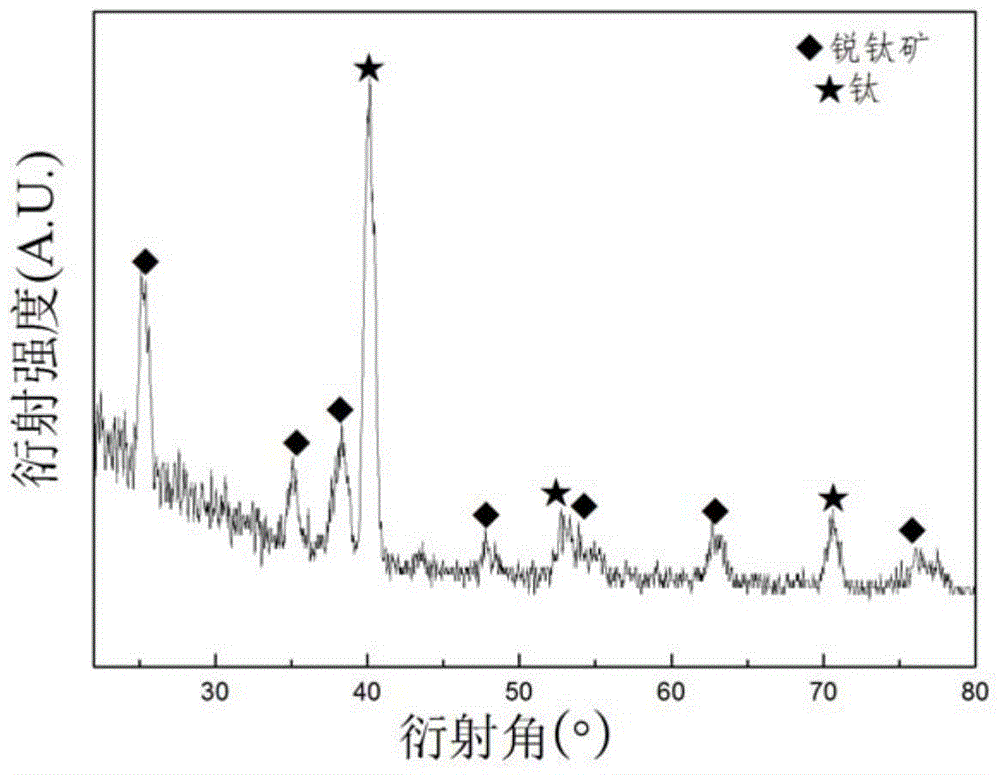

Image

Examples

Embodiment 1

[0029] (1) Weigh 0.05mol of NaH 2 PO 4 .2H 2 O powder, dissolved in 500ml of deionized water, stirred evenly by magnetic force to obtain NaH with a concentration of 0.1M 2 PO 4 .2H 2 O Electrolyte. Weigh again 0.1mol of (CH 3 COO) 2 Ca.H 2 The O powder was dissolved in 500ml of ionized water, and evenly stirred by magnetic force to obtain (CH 3 COO) 2 Ca.H 2 O Electrolyte.

[0030] (2) The medical pure titanium sheet (model: TA2, size: 10mm×10mm×1mm) is polished by sandpaper, then ultrasonically cleaned with ethanol and deionized water, and then placed as an anode in 0.1M NaH 2 PO 4 .2H 2 In the O electrolyte, the platinum electrode (its size is 30mm×30mm×1mm) is used as the cathode at this time, and the distance between the cathode and the anode is 30mm. The micro-arc oxidation treatment is carried out by a DC pulse power supply device, and its process parameters are voltage 300V, oxidation time 0.5h, frequency 100Hz, duty cycle 50%, and temperature 25°C. After...

Embodiment 2

[0036] (1) Weigh 0.1mol of NaH 2 PO 4 .2H 2 O powder, dissolved in 500ml of deionized water, stirred evenly by magnetic force to obtain NaH with a concentration of 0.2M 2 PO 4 .2H 2 O Electrolyte. Weigh again 0.15mol of (CH 3 COO) 2 Ca.H 2 O powder was dissolved in 500ml of ionized water, and the concentration of (CH 3 COO) 2 Ca.H 2 O Electrolyte.

[0037] (2) The medical pure titanium sheet (model: TA2, size: 10mm×10mm×1mm) is polished by sandpaper, then ultrasonically cleaned with ethanol and deionized water, and then placed as an anode in 0.2M NaH 2 PO 4 .2H 2 In the O electrolyte, the platinum electrode (its size is 30mm×30mm×1mm) is used as the cathode at this time, and the distance between the cathode and the anode is 30mm. The micro-arc oxidation treatment is carried out by a DC pulse power supply device, and its process parameters are voltage 270V, oxidation time 0.5h, frequency 100Hz, duty cycle 50%, and temperature 30°C. After the treatment, the titani...

Embodiment 3

[0040] (1) Weigh 0.075mol of NaH 2 PO 4 .2H 2 O powder, dissolved in 500ml of deionized water, stirred evenly by magnetic force to obtain NaH with a concentration of 0.15M 2 PO 4 .2H 2 O Electrolyte. Weigh again 0.1mol of (CH 3 COO) 2 Ca.H 2 The O powder was dissolved in 500ml of ionized water, and evenly stirred by magnetic force to obtain (CH 3 COO) 2 Ca.H 2 O Electrolyte.

[0041] (2) The medical pure titanium sheet (model: TA2, size 10mm×10mm×1mm) is polished by sandpaper, then cleaned with ethanol and deionized water ultrasonically, and then placed as an anode in 0.15M NaH 2 PO 4 .2H 2 In the O electrolyte, the platinum electrode (its size is 30mm×30mm×1mm) is used as the cathode at this time, and the distance between the cathode and the anode is 30mm. The micro-arc oxidation treatment is carried out by a DC pulse power supply device, and its process parameters are voltage 280V, oxidation time 1h, frequency 100Hz, duty cycle 50%, and temperature 20°C. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com