Patents

Literature

182 results about "Titanium implant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The titanium dental implant is a screw-like pin partially imbedded in the jawbone to anchor the attachment of an artificial tooth. Titanium is one of the few materials which will bind tightly to the surrounding matrix of regenerating bone tissue. The implantation procedure requires invasive surgery.

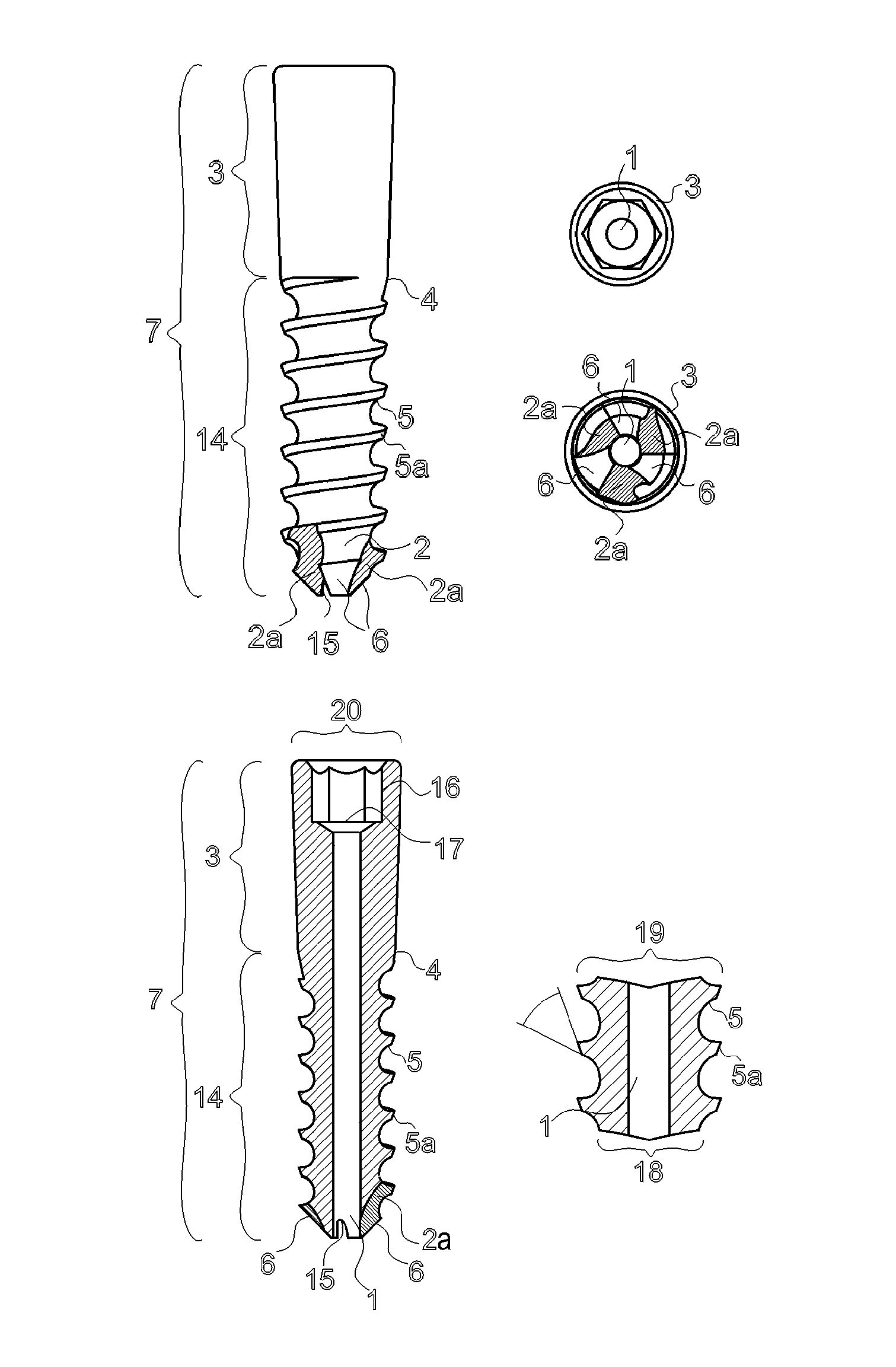

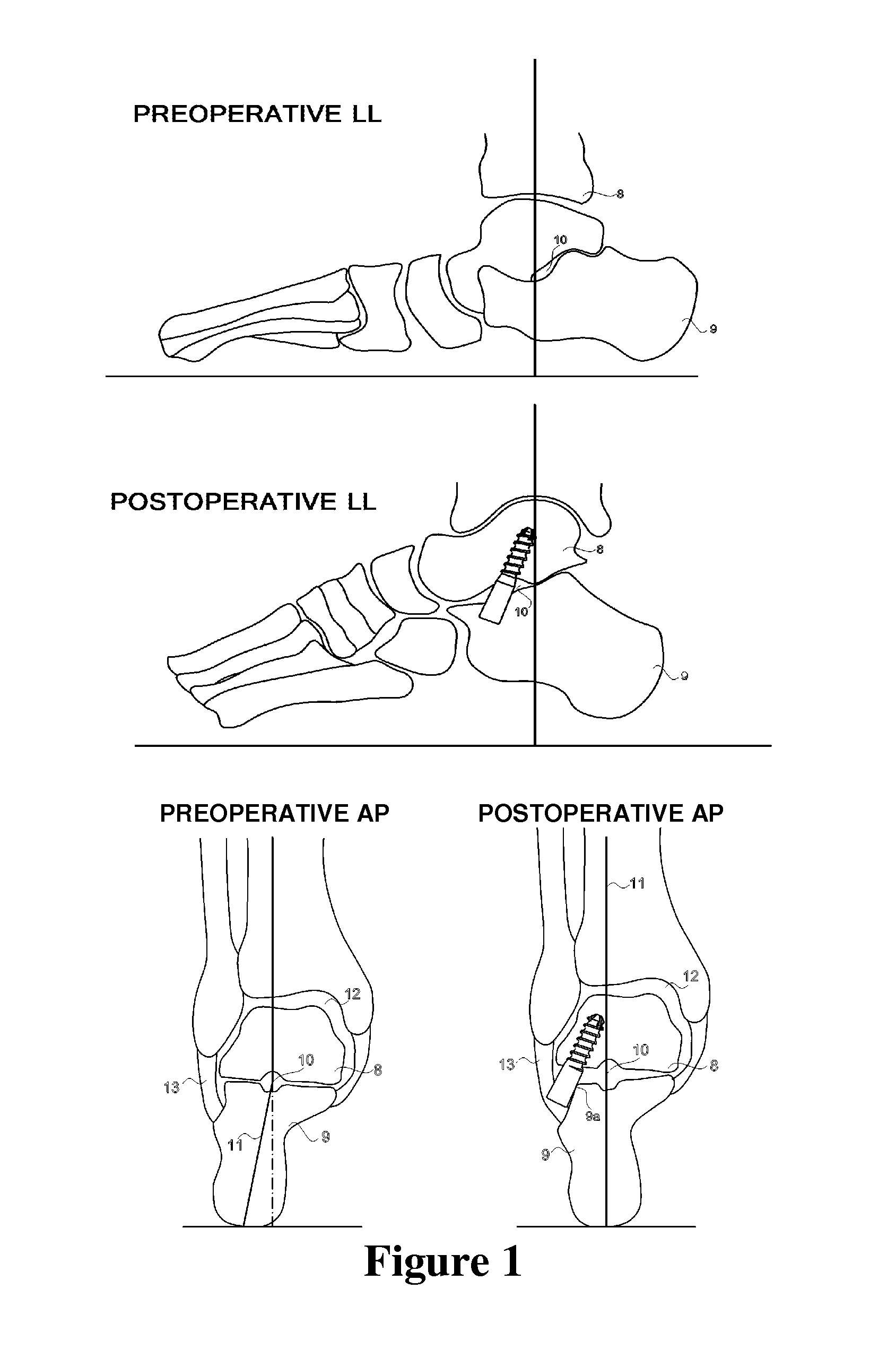

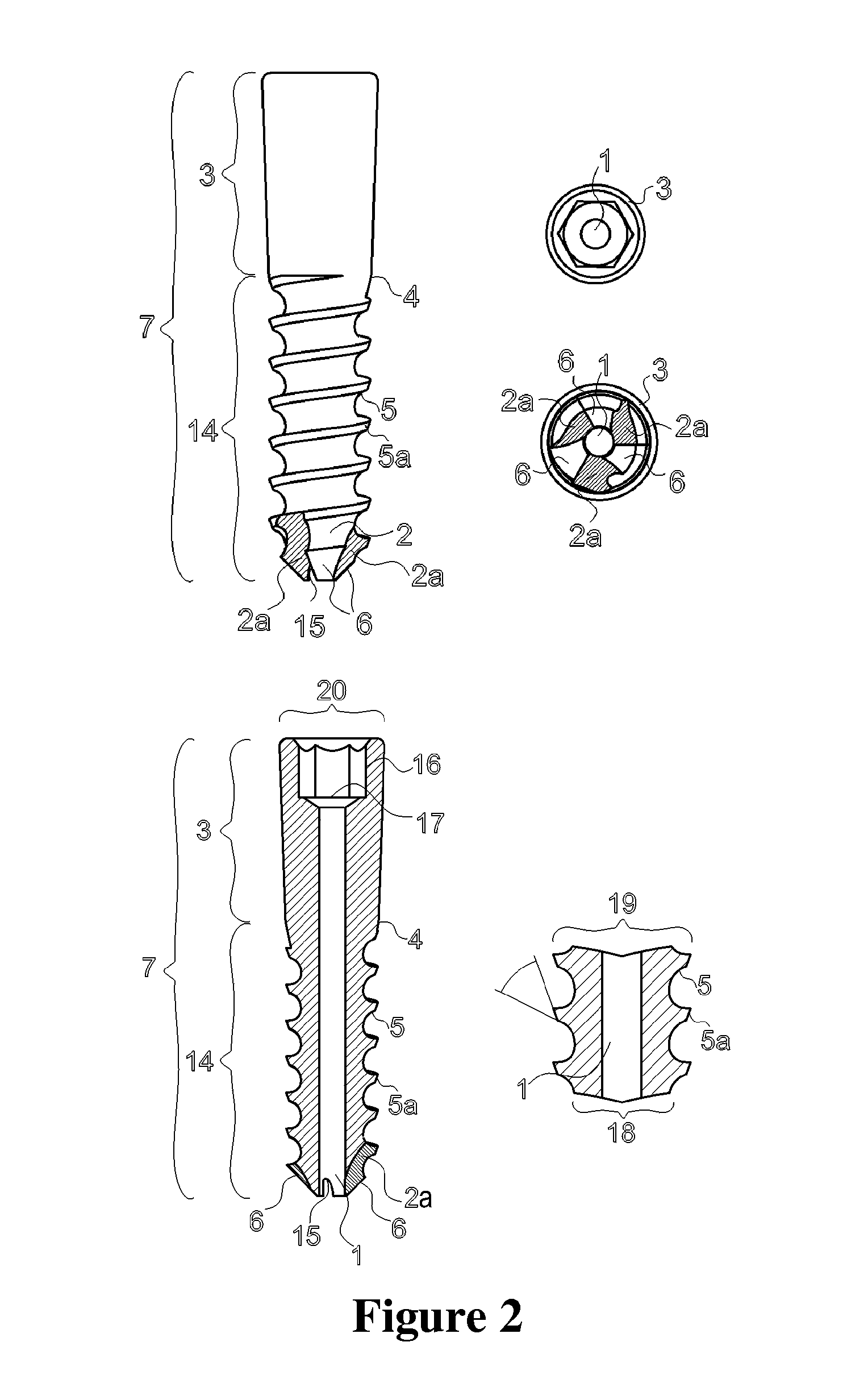

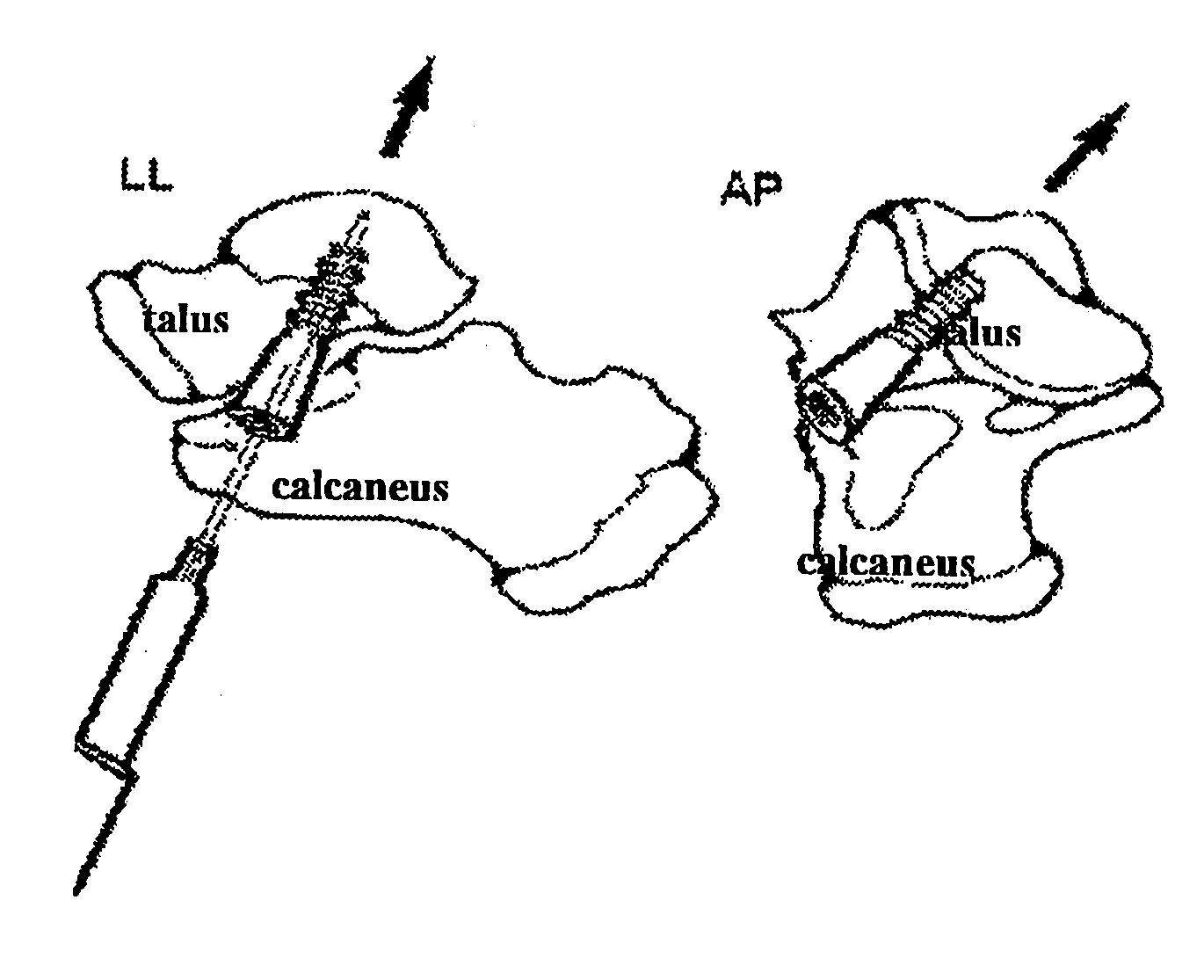

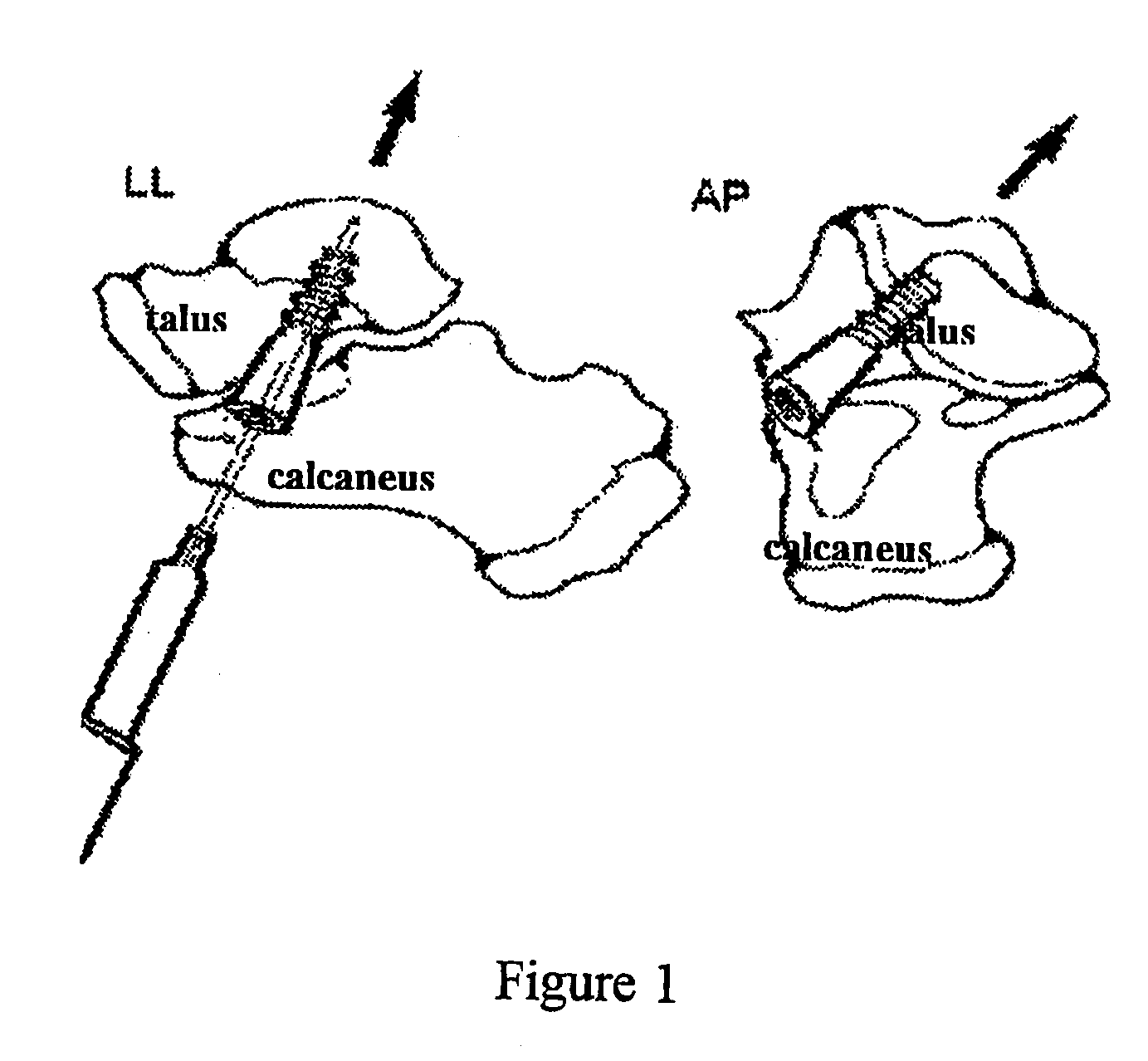

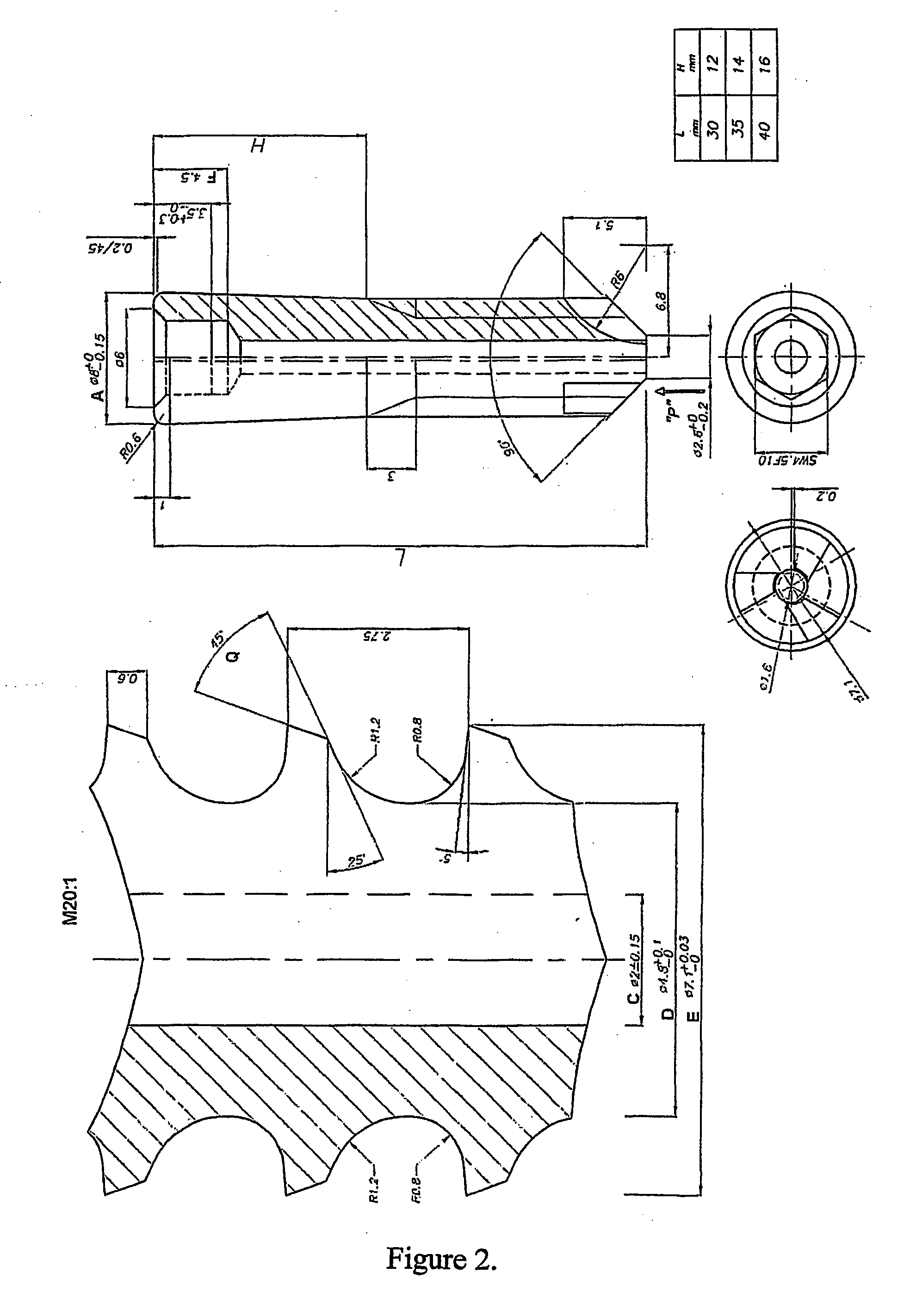

Canulated titanium implant for correcting flat feet in children

InactiveUS8267977B2Easier correctly placedHarming the surrounding tissueSuture equipmentsAnkle jointsMedicineTitanium

The cannulated titanium implant (screw) for correction of flat feet in children characterized by that: a) the diameter of the stem is D=4.8 mm±25%, recommended 4.8 mm±10%, and especially recommended 4.8 mm, b) it is cannulated, whose diameter is C=2 mm+25%, recommended 2 mm±10%, and especially recommended 2 mm, c) the screw-thread height is 1.15 mm±25%, recommended 1 / 15 mm±10%, and especially recommended 1.15 mm, d) on the point of the screw, which ends at the angle of 90°, on the apex thread are trisect cuts at the angle of 120°. The edges of the apex thread are cut at the angle of 55°. At the very top of the point of the screw, the trisect cuts of the apex thread go inward the tunnel in the length of the screw by 1.5 mm, e) this type of the point replaces the use of the drill and the tapping device.

Owner:ROTH SANDOR UMLAUT OVER

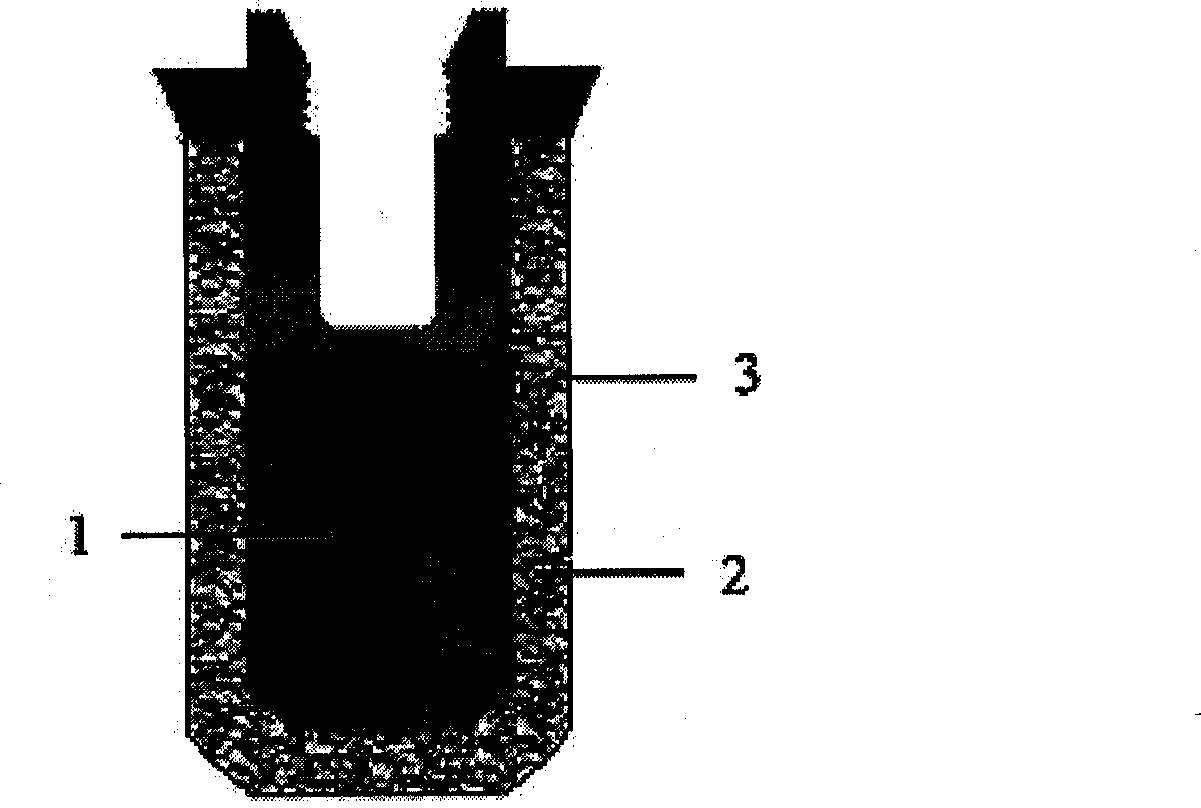

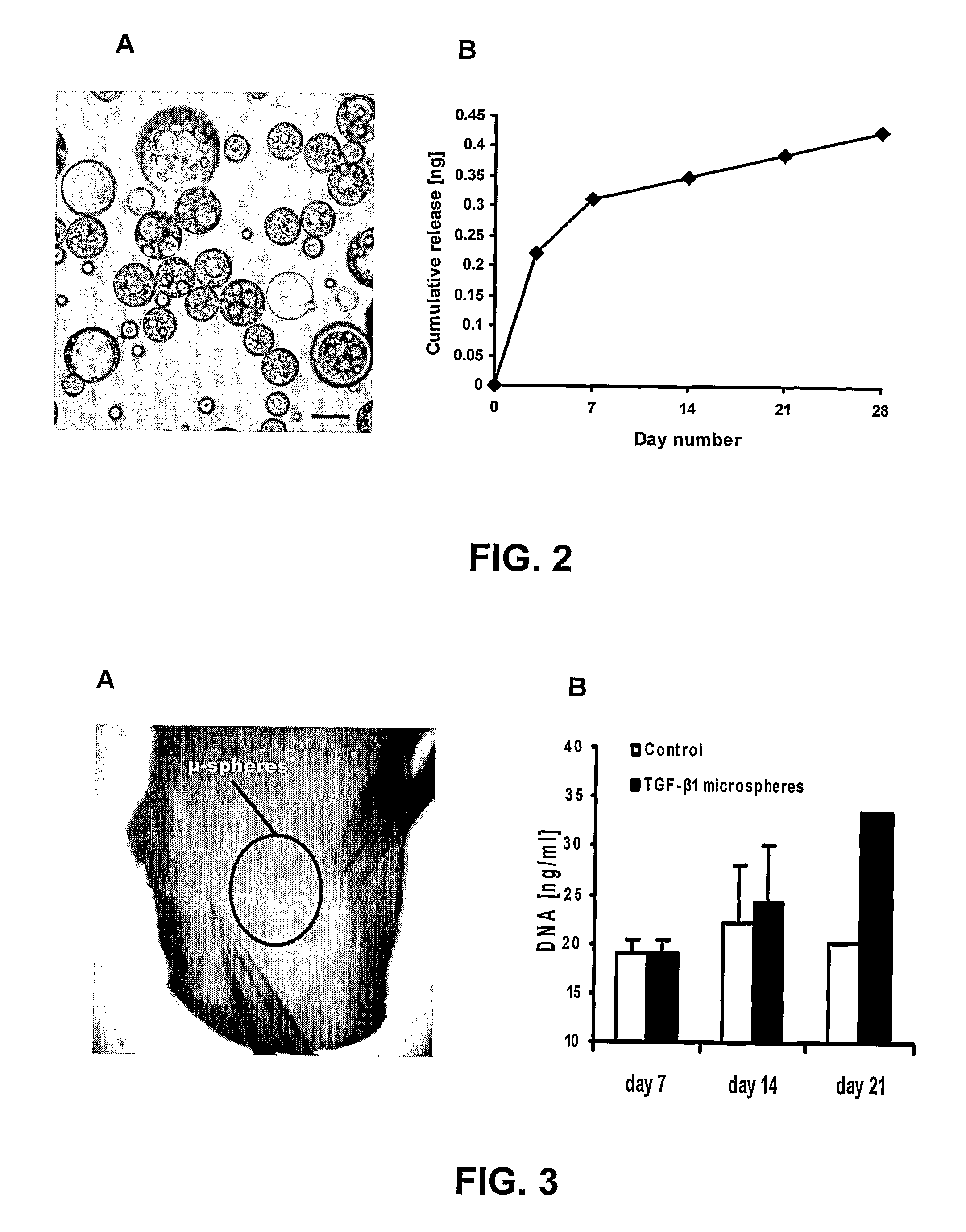

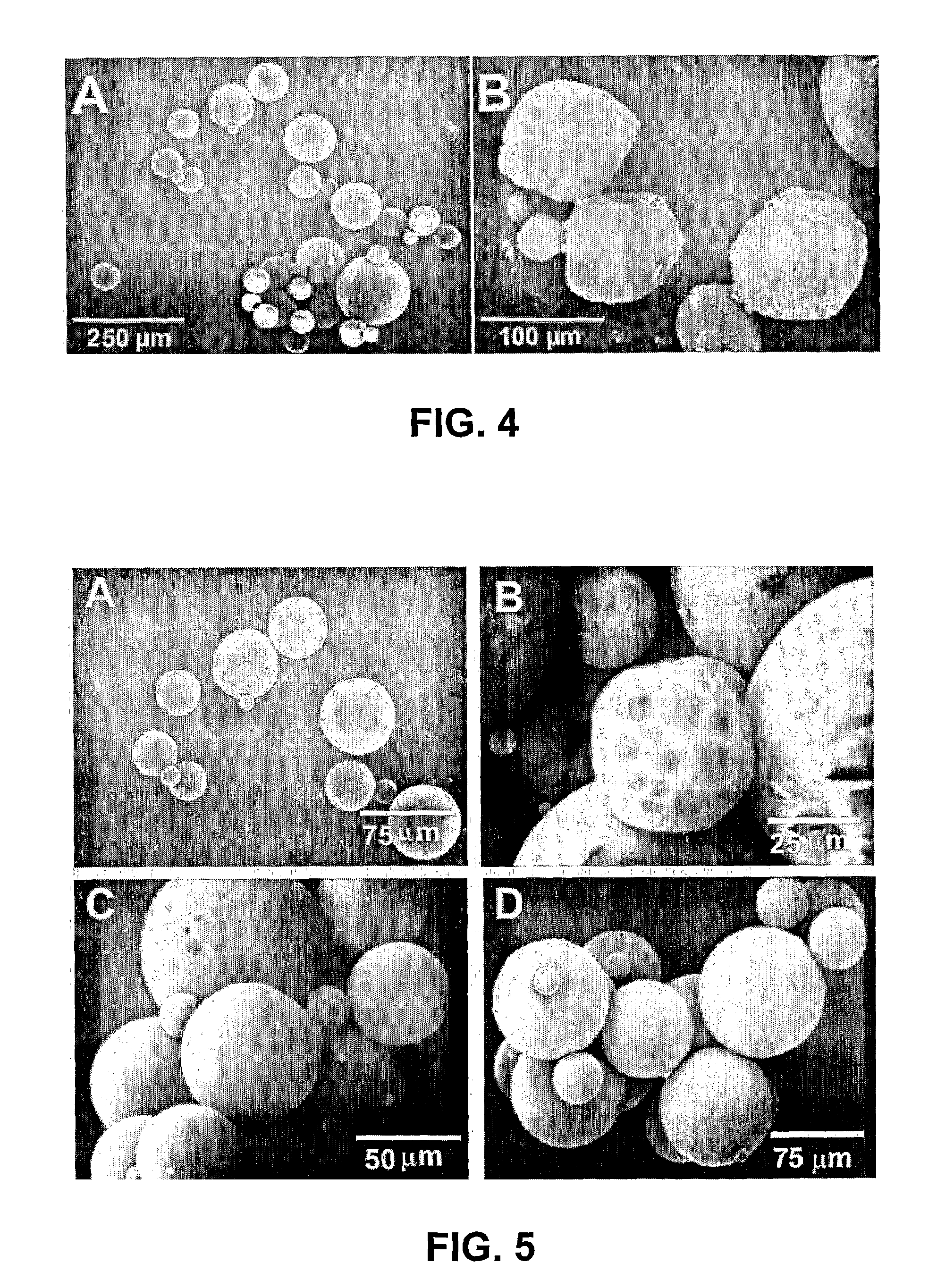

Medicinal porous titanium implant and method for preparing same

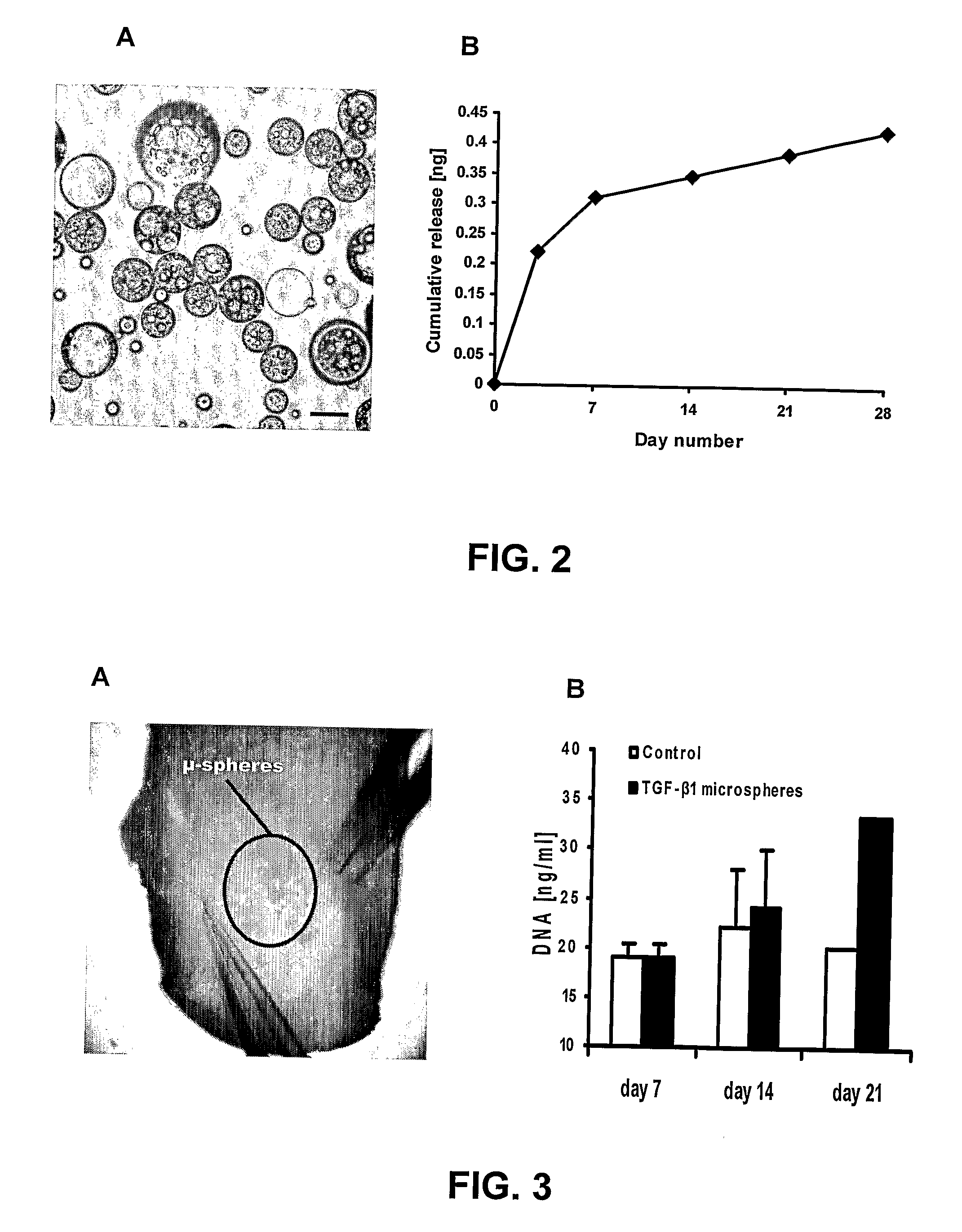

InactiveCN101518467AAchieve long-term stabilityIncrease initiativeDental implantsImpression capsStress concentrationMicrosphere

The invention discloses a medicinal porous titanium implant and a method for preparing the same. The porous titanium implant is prepared by a powder coinjection molding method; and a nano HA and TGF loaded sustained-release gelatin microsphere compound coating is deposited on the porous outer layer of the product. The outer layer of the implant has a communicated porous structure, the thickness of the porous layer is 0.4 to 1.1 millimeters, the porosity of the porous layer is 50 to 70 percent, and the aperture of the porous layer is 50 to 400 mum; the surface of the porous layer is deposited; and the binding strength of the outer layer and an inner core is 150 to 300MPa. Compared with the prior medicinal titanium implant material, the material of the medicinal porous titanium implant has higher mechanical strength, is in accordance with the mechanical performance of osseous tissue, avoids stress concentration and stress shielding, promotes stress transmission and growth of new bones, reduces time for osseointegration, and ensures the long-term stability of the implant. The method adopts once-for-all molding without post machining, thereby considerably reducing the cost.

Owner:CENT SOUTH UNIV

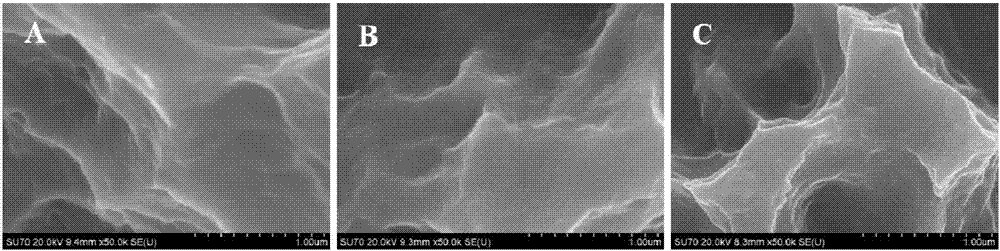

Surface processing technology for dental implant

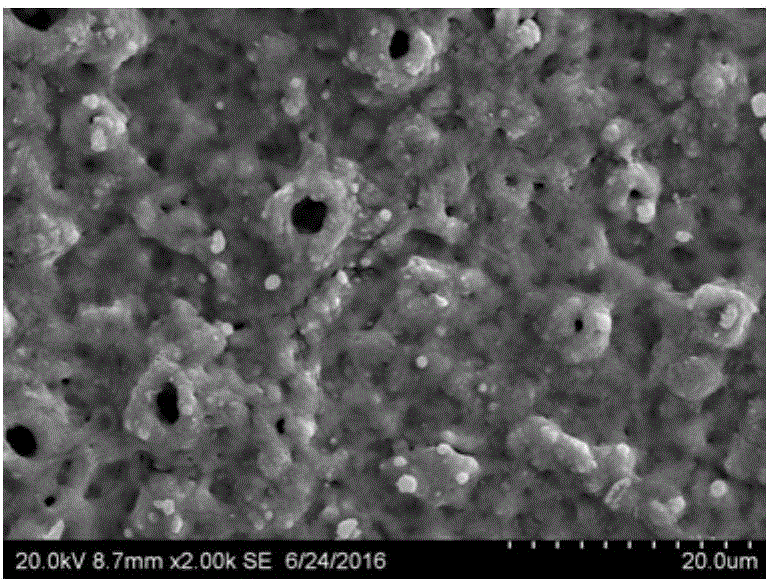

InactiveCN102232876AGood surface morphologyGood rough surfaceArtificial teethCleaning using liquidsAcid etchingTitanium

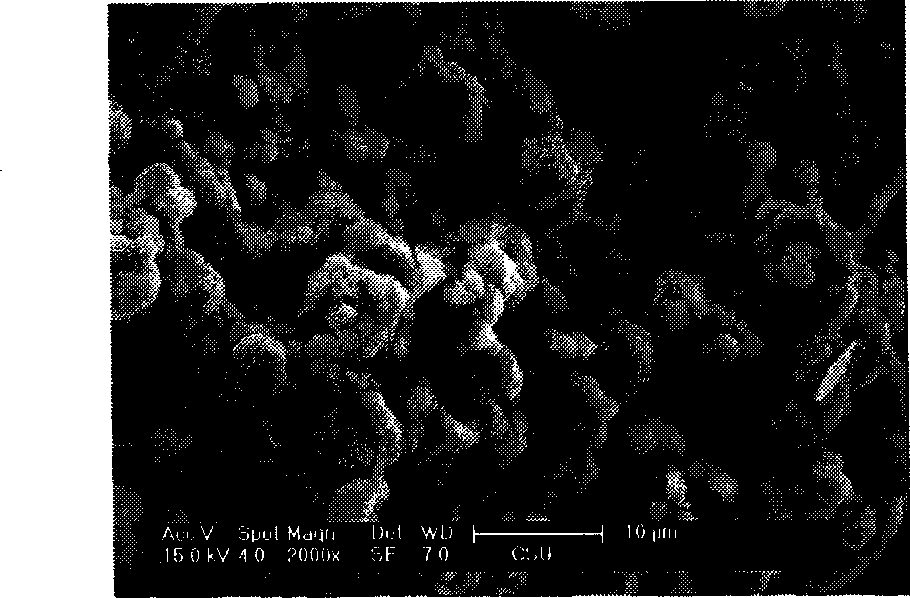

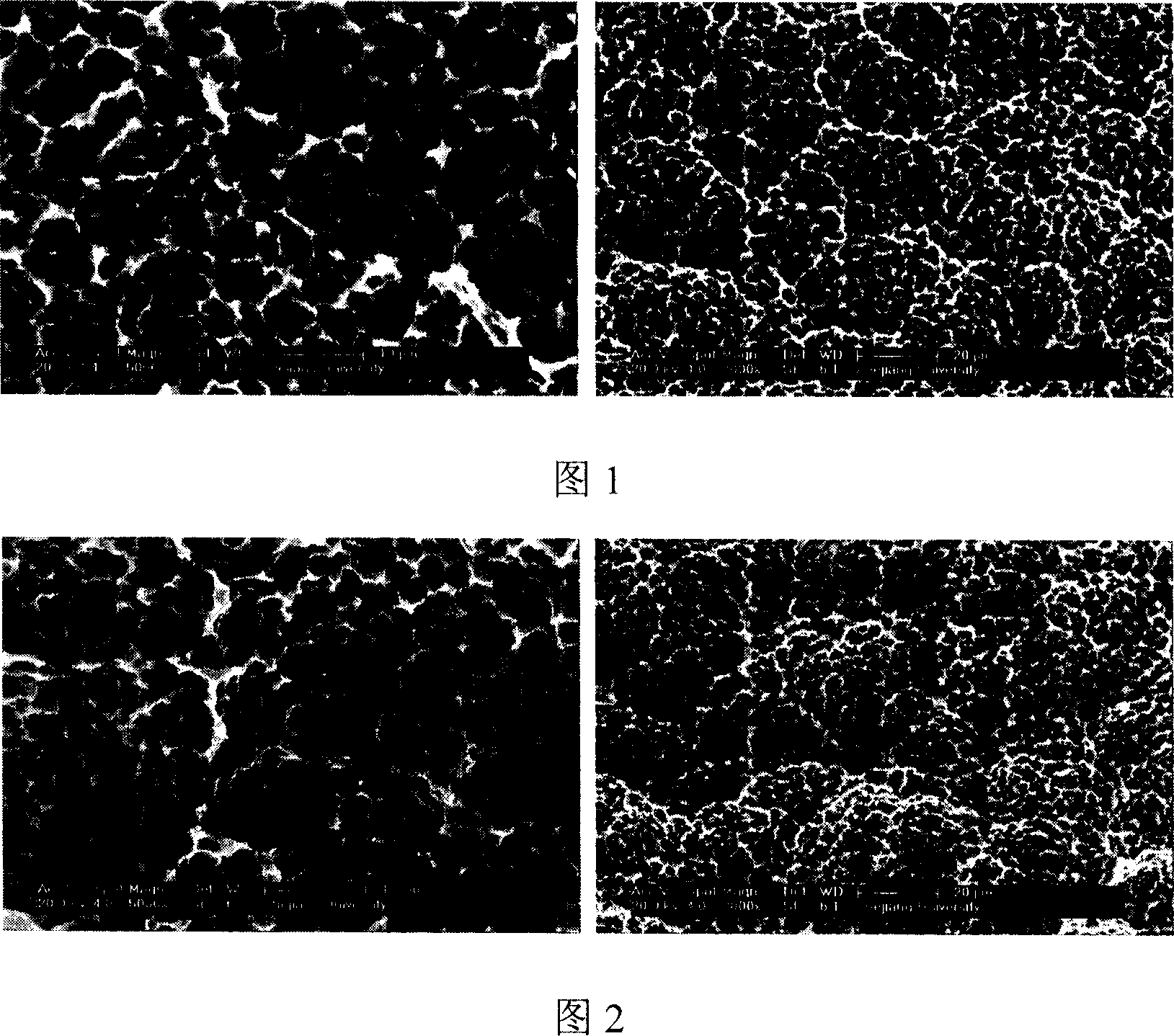

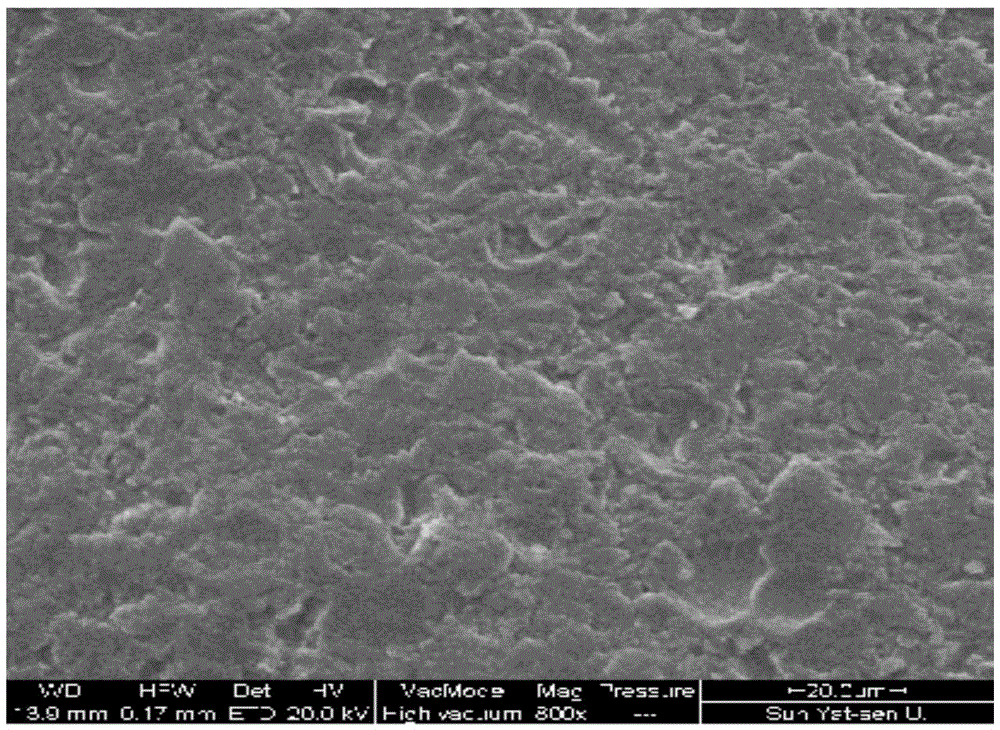

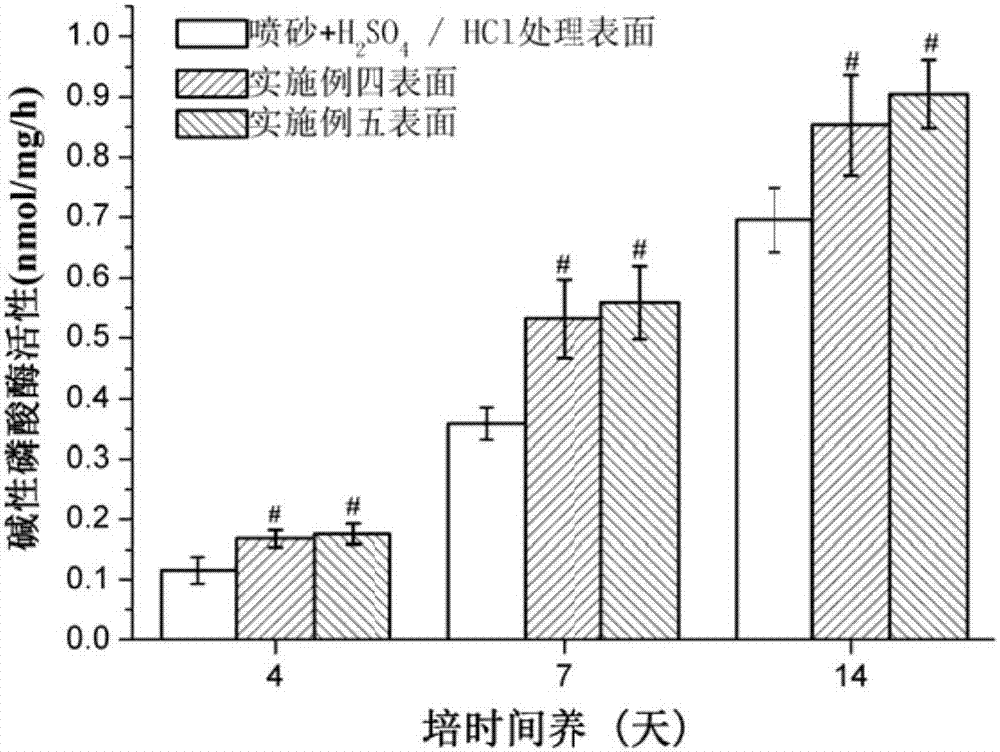

The invention discloses a surface processing technology for a pure-titanium dental implant. The technology comprises the following steps: A, removing oil from the dental implant by ultrasonic cleaning; B, sandblasting the dental implant by white corundum to make the surface of the implant to be uniform gray in color and allow a three-dimensional porous structure to be formed on the surface of the dental implant; C, carrying out acid etching on the surface of the sandblasted dental implant with a mixed liquid with a certain concentration and a certain ratio of sulfuric acid to hydrochloric acid to allow gradually decreased multilevel scallops to be formed on the surface of the dental implant; and D, flushing and neutralizing the acid etched dental implant, and removing oil. According to the surface processing technology for the dental implant designed by the invention, the multilevel porous structure with biological activity is formed on the surface of the pure-titanium implant, so the biological activity of the pure-titanium implant is improved, the stability of the implant is improved, the bone combination speed of the dental implant is accelerated, the bone interfacial combination strength of the implant is enhanced, thereby the technology has the advantages of simple and high efficient technology, and low cost.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

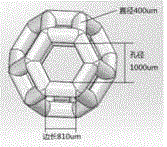

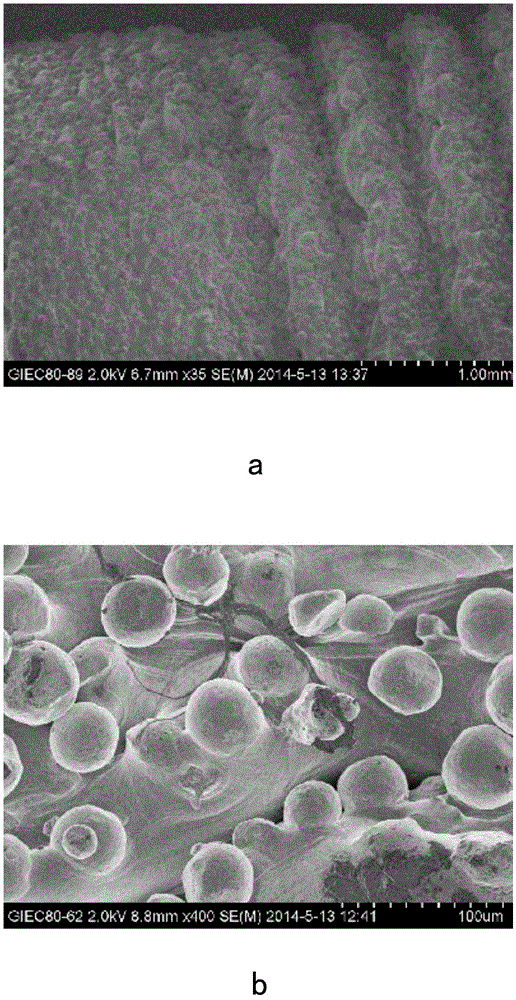

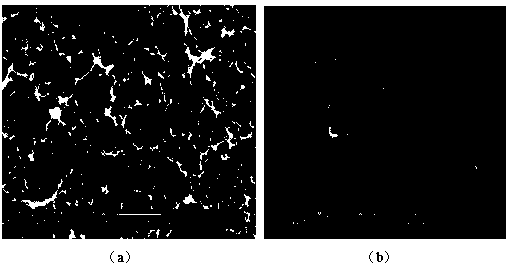

Biomedical porous pure-titanium implant material and preparation method thereof

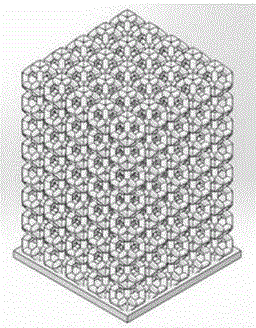

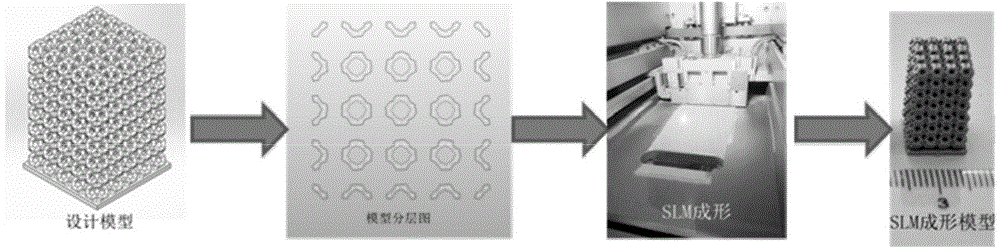

InactiveCN104646669AImprove compactnessImprove mechanical propertiesSelective laser meltingDot matrix

The invention discloses a preparation method of a biomedical porous pure-titanium implant material. The method comprises the steps of S1, constructing a three-dimensional model of the implant material through drawing software, slicing through layering software, conveying the obtained two-dimensional section information to a computer control system of an SLM former, and providing a laser scanning route; S2, paving a layer of titanium powder being 30 to 70 microns in thickness on a workbench of the SLM former through a powder paving layer; S3, performing selective laser meting for the titanium powder through a laser beam under the conditions that the power is 90 to 100W, the scanning spacing is 0.10 to 0.20mm, and the scanning speed is 275 to 540mm / s to obtain a layer of sections of the implant material, and synchronously lowering down the worktable in a distance equal to the height of a layer of powder; S4, repeating the steps 2 and 3 until the three-dimensional model of the implant material is formed; S5, automatically stopping working by the SLM former, cooling the three-dimensional model to reach room temperature, then performing sand blasting to obtain the porous pure-titanium implant material; the three-dimensional model is a porous structural mode using a tetrakaidecahedron unit as a dot matrix and formed by repeatedly accumulating the tetrakaidecahedron units.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Process of forming fluoric stepped hole structure on the surface of pure titanium dental implant

InactiveCN1985774AImprove long-term clinical successGood compatibilityDental implantsArtificial teethClinical successSurface modified

The process of forming fluoric stepped hole structure on the surface of pure titanium dental implant includes sand blasting the pure titanium implant, etching in mixed solution of sulfuric acid and hydrochloric acid, etching in mixed solution of hydrofluoric acid and nitric acid, soaking in sodium fluoride solution and other steps. The pure titanium dental implant with stepped hole surface structure has excellent bone tissue compatibility, capacity of raising the combination strength of the implant to the bone tissue and raised long term clinical success rate of dental implant.

Owner:ZHEJIANG UNIV

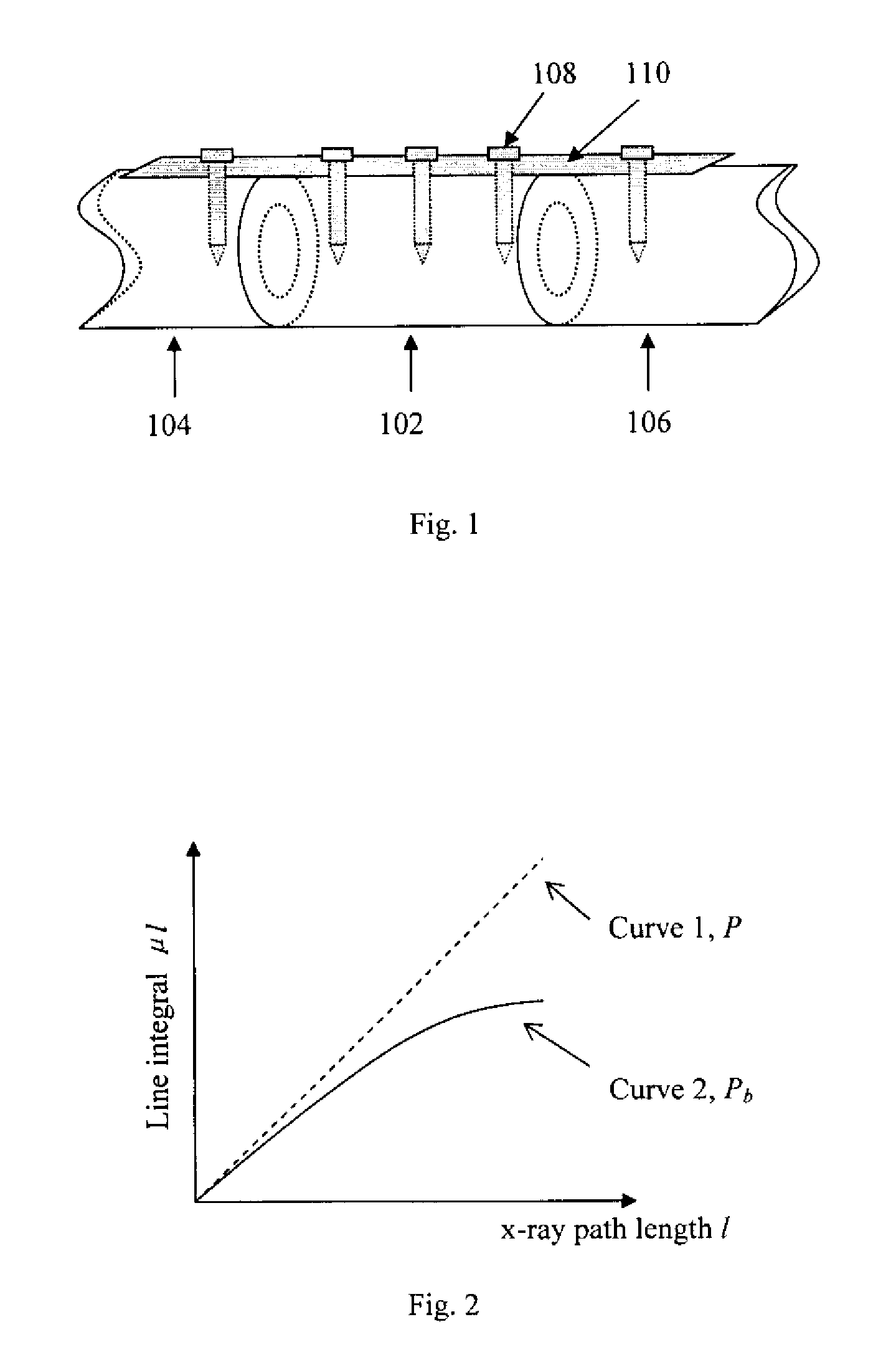

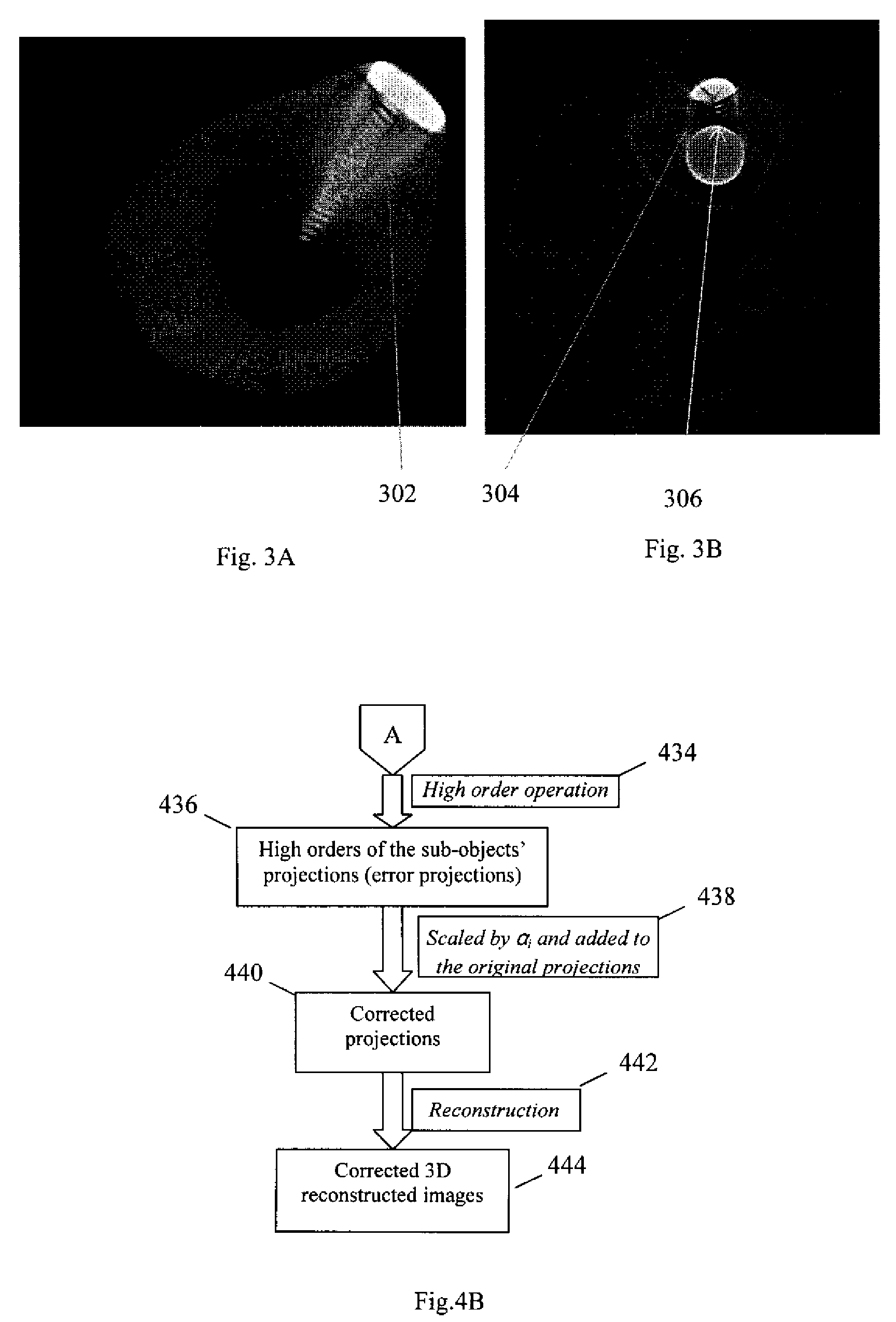

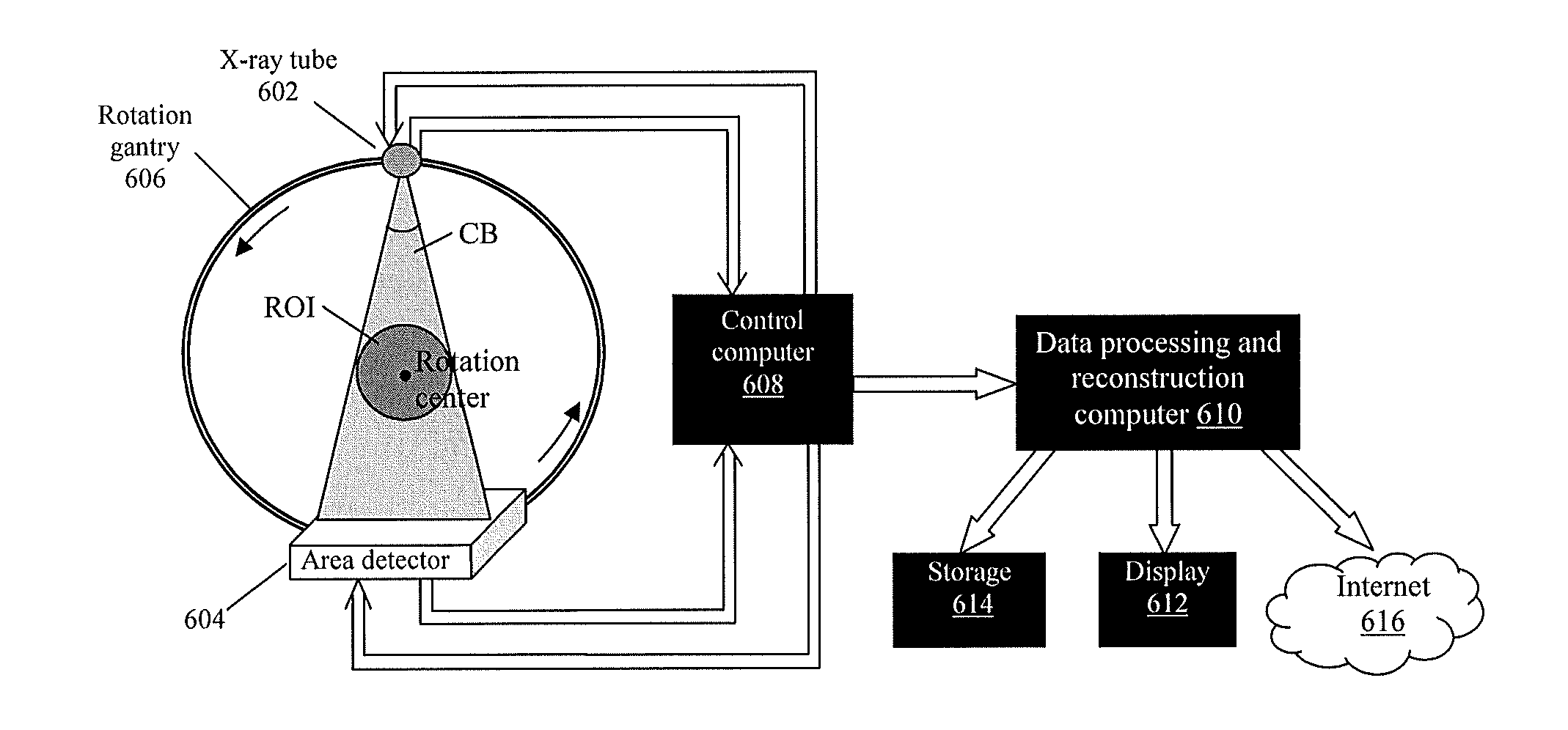

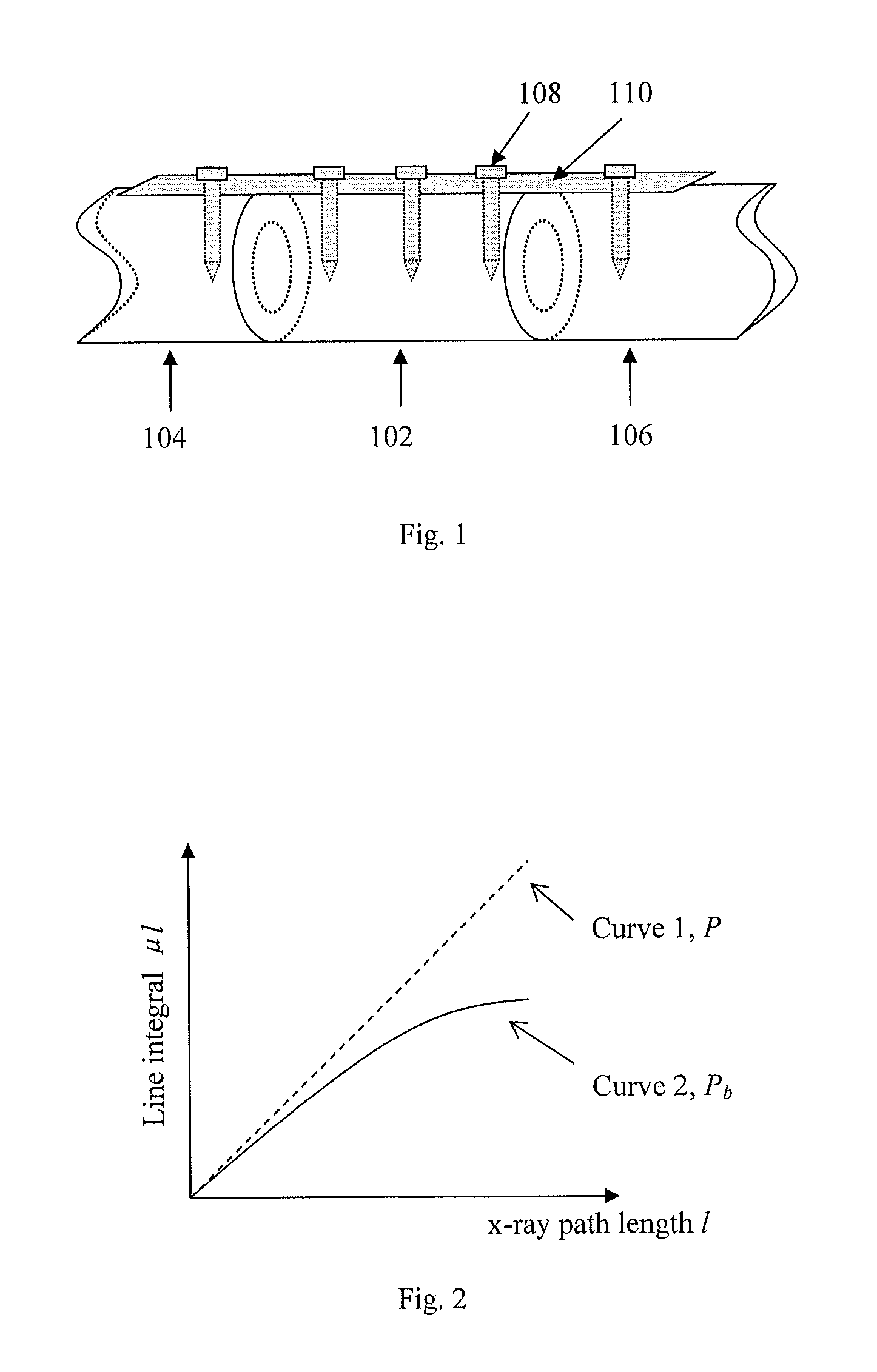

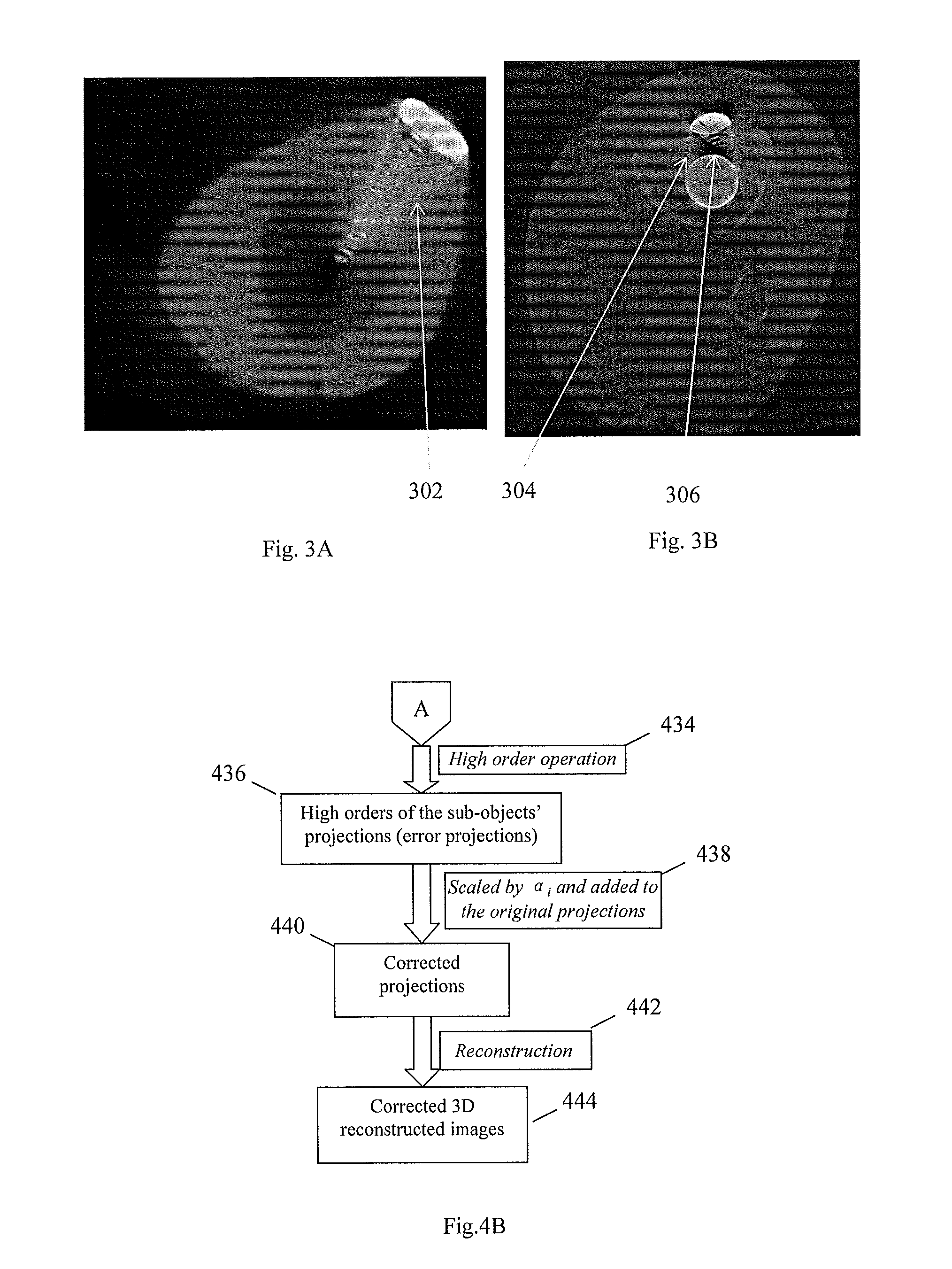

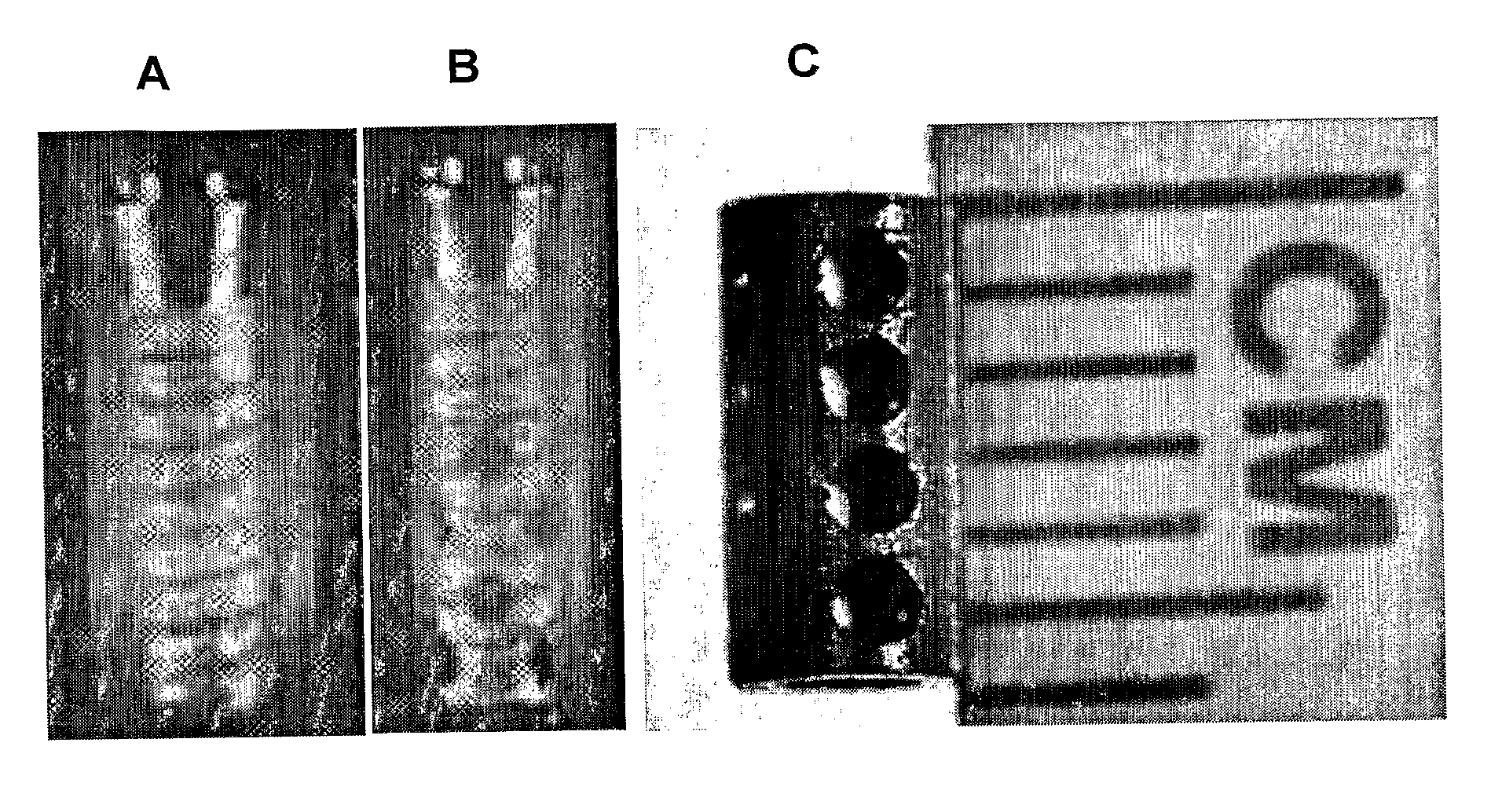

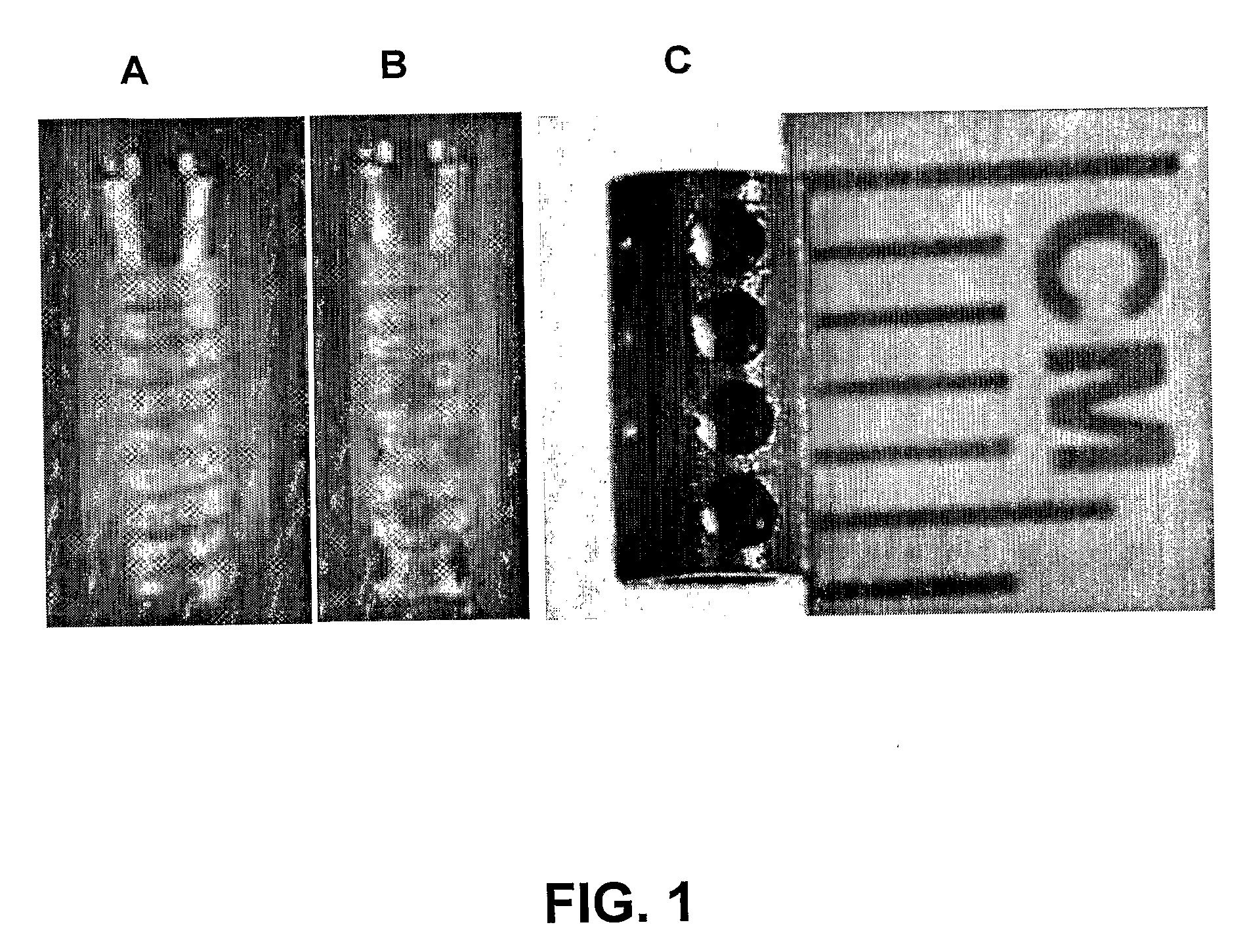

Method and apparatus for 3D metal and high-density artifact correction for cone-beam and fan-beam CT imaging

ActiveUS8023767B1Correction of artifactAccurate reconstruction imageImage enhancementReconstruction from projectionMetal ArtifactHigh density

A 3D metal artifacts correction technique corrects the streaking artifacts generated by titanium implants or other similar objects. A cone-beam computed tomography system is utilized to provide 3D images. A priori information (such as the shape information and the CT value) of high density sub-objects is acquired and used for later artifacts correction. An optimization process with iterations is applied to minimize the error and result in accurate reconstruction images of the object.

Owner:UNIVERSITY OF ROCHESTER

Three-dimensional printing technology based method for forming medical porous pure titanium implant

The invention relates to a three-dimensional printing technology based method for forming a medical porous pure titanium implant, comprising the following steps of: (1) mixing pure titanium powder with water-soluble binding materials, and grinding; (2) conveying the pure titanium powder to a platform, and inputting a designed titanium implant CAD file into matching software of three-dimensional printing equipment to direct the three-dimensional printing equipment to work; spraying binders to the titanium powder to form a two-dimensional plane by a printing head, , descending a work table to process a next layer after finishing processing one layer, and piling layer by layer for forming till a processed article is sprayed and formed completely; after the processed article is formed, standing the processed article, sweeping unbounded powder to obtain an initially forming article, and then sintering so as to obtain the medical porous pure titanium implant. The method is simple, has low cost and is suitable for industrialized production; the obtained medical porous pure titanium implant has high matching degree with a natural bone and can be better combined with a bone tissue due to a formed porous structure.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

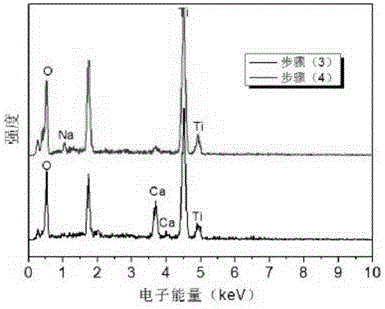

Surface treatment method for SLM molded titanium implant

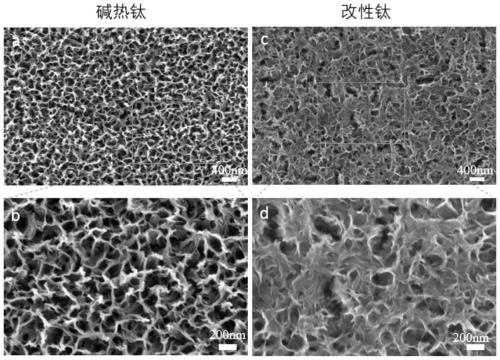

ActiveCN105537589AImprove microscopic morphologyImprove hydrophilicityAdditive manufacturingPharmaceutical delivery mechanismMicro nanoCalcification

The invention discloses a surface treatment method for an SLM molded titanium implant. The surface treatment method comprises the following steps: carrying out SLM molding on the titanium implant; carrying out sand blasting treatment: adopting corundum or titanium dioxide to carry out surface sand blasting treatment on the surface of the SLM molded titanium implant; picking to remove impurities: putting the SLM molded titanium implant subjected to the sand blasting treatment into a pickling solution to carry out pickling treatment; carrying out alkali thermal treatment: putting the SLM molded titanium implant subjected to the pickling treatment into an alkali solution to carry out hydro-thermal treatment; carrying out calcification treatment: taking a calcium salt solution as a cationic exchange fluid, putting the SLM molded titanium implant subjected to the alkali thermal treatment into the cationic exchange fluid at a temperature of 100-200 DEG C to carry out hydro-thermal treatment for 1-5 hours; and after teach step, sequentially putting the SLM molded titanium implant into acetone, 95% alcohol and deionized water to respectively ultrasonically clean and dry. The surface treatment method is simple in step, and is easy to operate; and the surface, with a micro-nano grading structure, of the SLM molded titanium implant is constructed, so that the roughness, the microstructure, the mineralization characteristics and the biological activity of the surface of the SLM molded titanium implant are effectively improved.

Owner:广东中科安齿生物科技有限公司

Application of femtosecond laser in pure titanium implantation material surface treatment

InactiveCN101264551AGood biocompatibilityReduce the impactTeeth fillingBone implantTitanium surfaceLaser processing

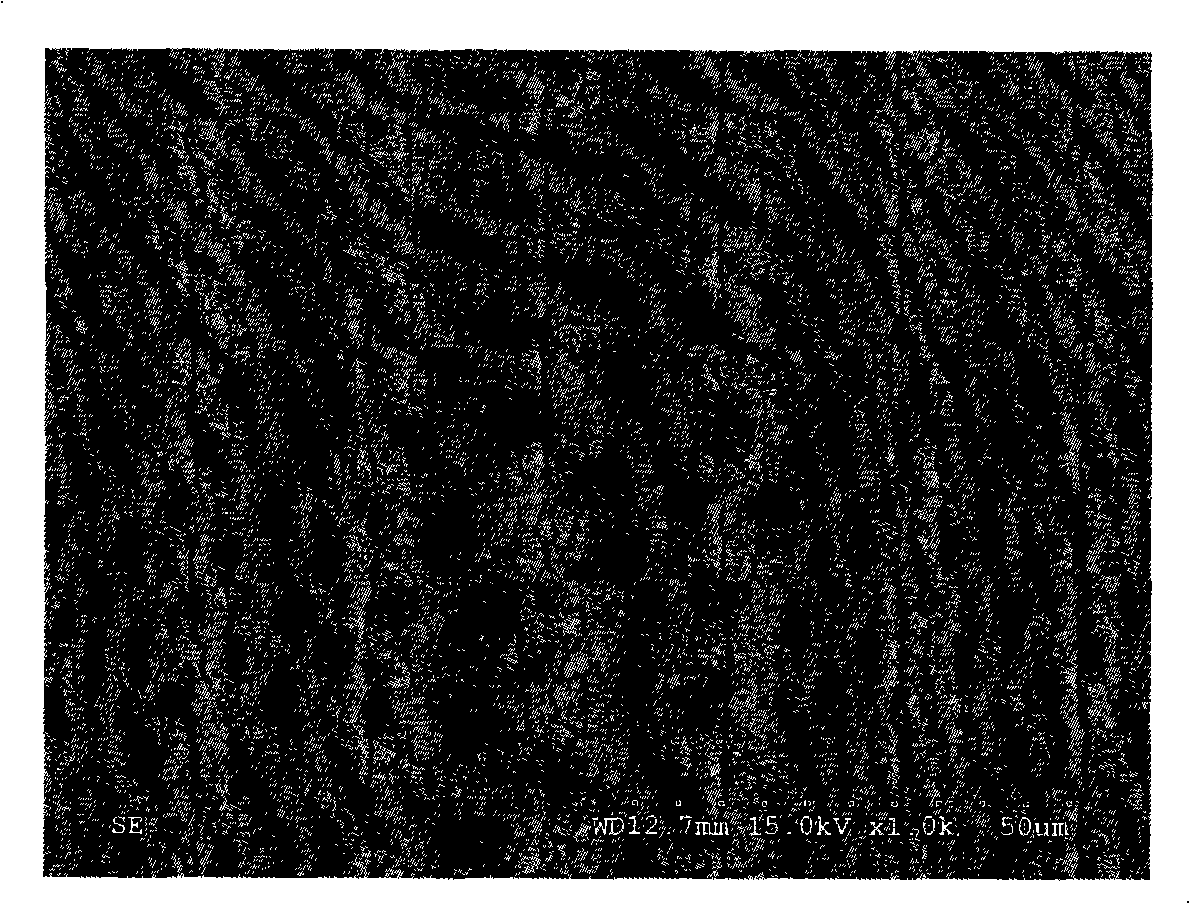

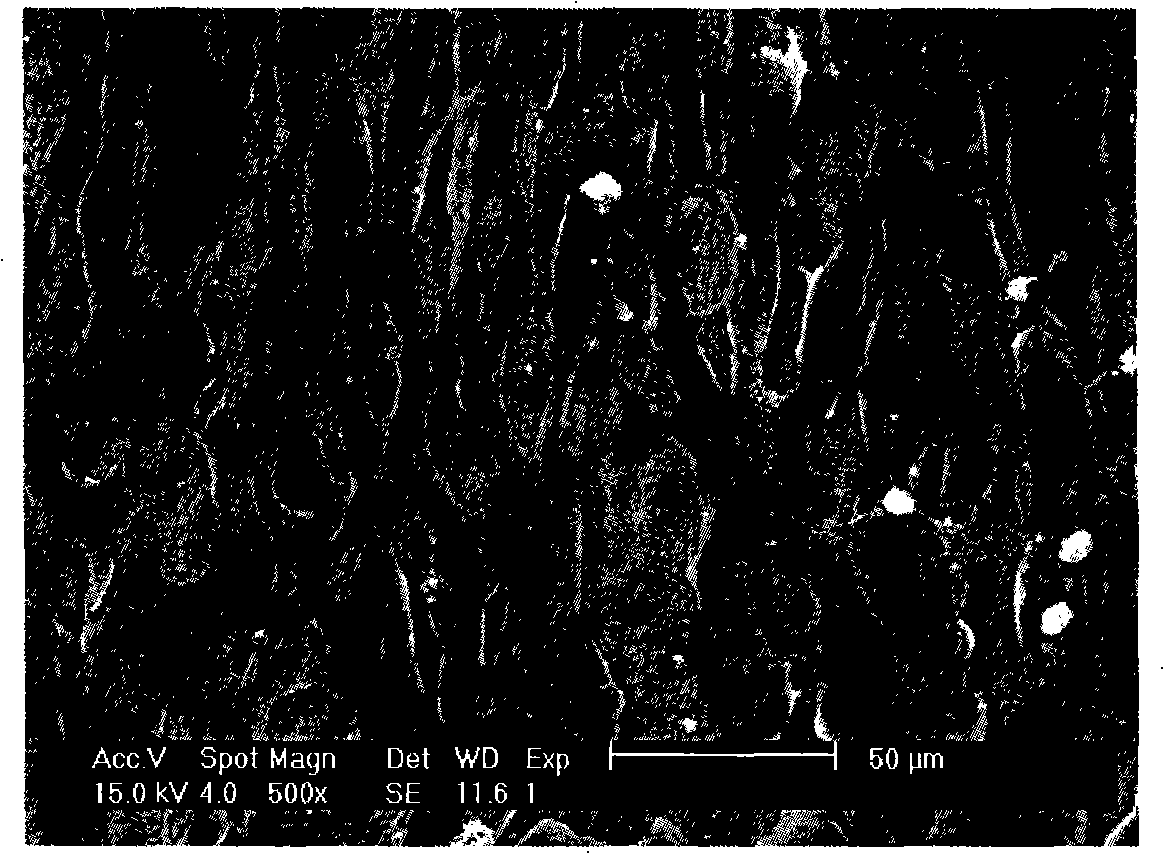

The invention relates to an application of femto-second laser in the surface treatment of the pure titanium implanting material, belonging to the technical field of application of laser in the material surface treatment. The application method comprises the following steps: in the air, the femto-laser impulse is in normal incidence and focused right on the top of the lump pure titanium implanting material which is ground and dried, a light spot with a radius of 5um is formed at the surface of the pure titanium implanting material, the femto-laser processing parameters are defined as follows: the impulse repeat frequency is 1 kHz, the single impulse power is from 5 to 200 micro joule, the impulse width is 50 femtosecond, the impulse center wavelength is 800 nanometer, the line interval of the laser processing is between 10 to 100 micron, the laser scanning speed is between 0.5 to 1.2 mm / sec, the laser polarization direction is regulated to be parallel to the laser scanning direction, the femto-laser scans the whole surface of the pure titanium implanting material, a titanium based biomedical material with an oxide layer generated on the titanium surface, even roughness, and a pattern of strips, holes, grooves or the combined pattern thereof formed on the pure titanium implanting material is made.

Owner:HEBEI UNIV OF TECH +2

Method for preparing antibacterial coating on surface of titanium implant

ActiveCN105688278AGood biocompatibilityImprove antibacterial propertiesPharmaceutical delivery mechanismLiquid/solution decomposition chemical coatingBiocompatibilityBiology

The invention provides a method for preparing an antibacterial coating on the surface of a titanium implant. A silver-loaded polyelectrolyte multilayer film is prepared on the titanium surface with a layer-layer self-assembly method, so that the titanium surface has good biocompatibility and antibacterial performance. The method is simple and particularly suitable for implants in complex shapes; the surface coating adopts natural polymers with good biocompatibility, so that the coating has bacterium killing and inhibiting properties and causes no toxic effect to cells.

Owner:WUHAN UNIV

Method and apparatus for 3d metal and high-density artifact correction for cone-beam and fan-beam ct imaging

ActiveUS20120008845A1Accurate reconstruction imageHigh artifactImage enhancementReconstruction from projectionMetal ArtifactHigh density

A 3D metal artifacts correction technique corrects the streaking artifacts generated by titanium implants or other similar objects. A cone-beam computed tomography system is utilized to provide 3D images. A priori information (such as the shape information and the CT value) of high density sub-objects is acquired and used for later artifacts correction. An optimization process with iterations is applied to minimize the error and result in accurate reconstruction images of the object.

Owner:UNIVERSITY OF ROCHESTER

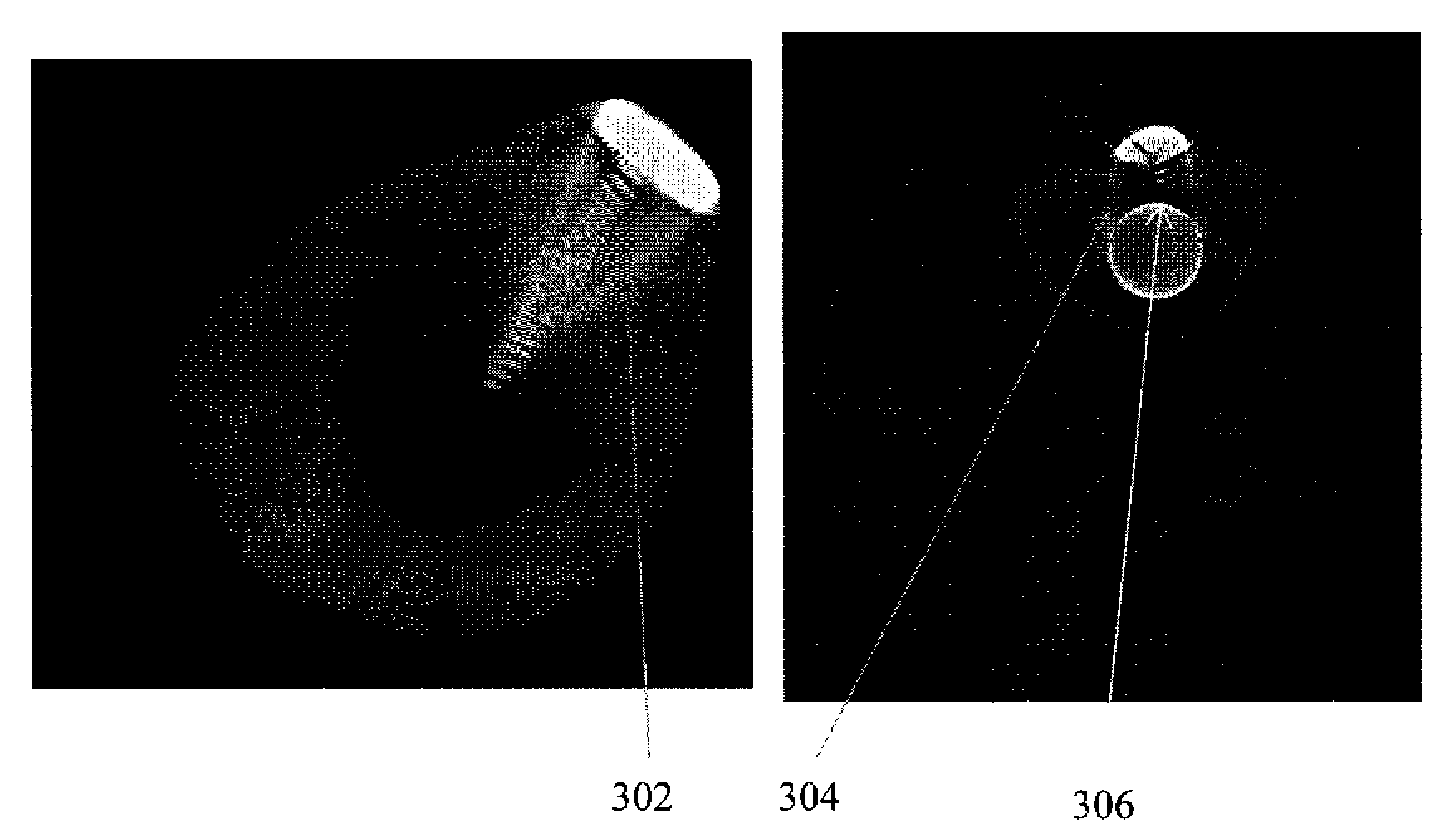

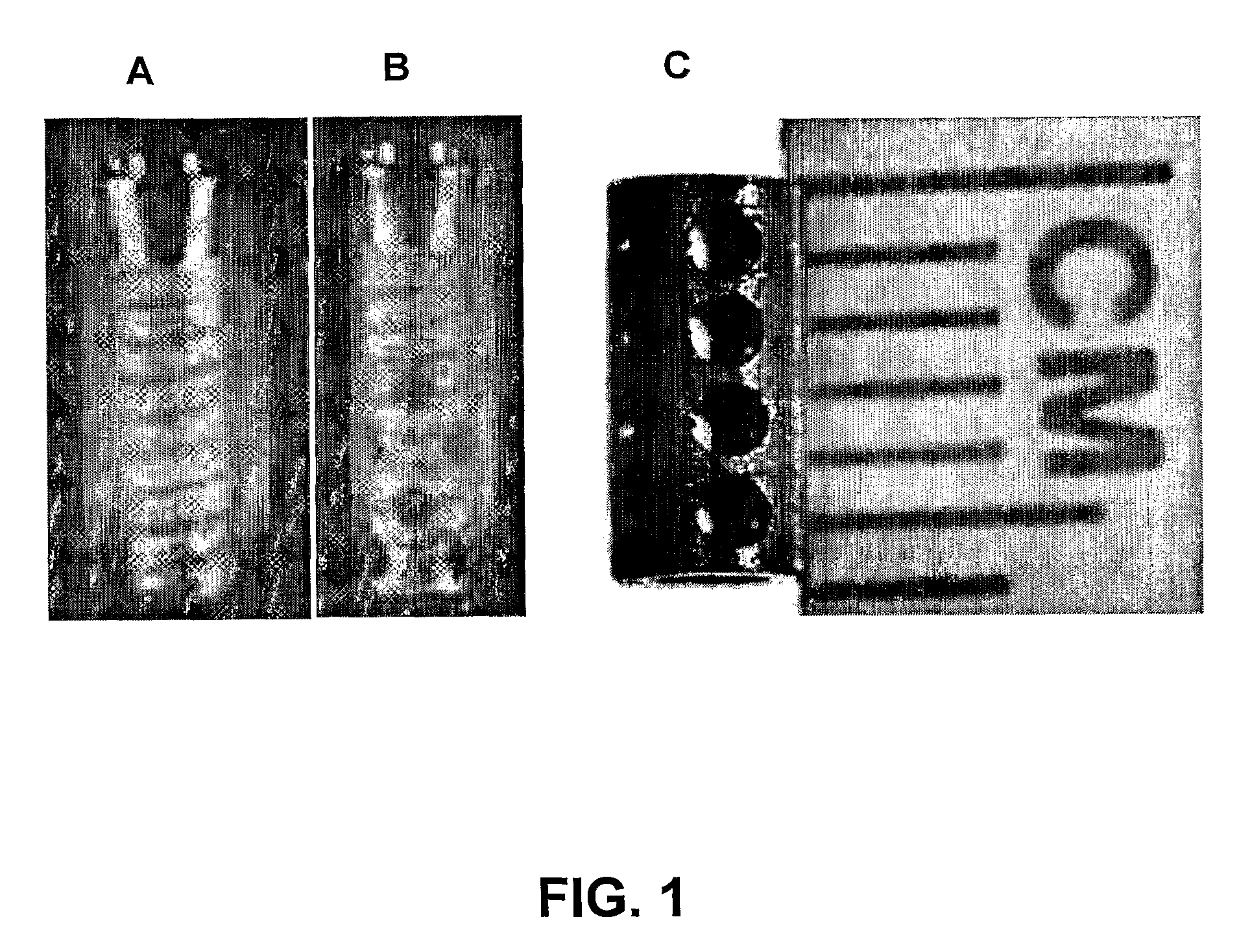

Hollow and Porous Orthopaedic or Dental Implant that Delivers a Biological Agent

InactiveUS20080095815A1Promote healingLow mechanical strengthOrganic active ingredientsDental implantsTitanium implantTitanium

This invention relates to the synthesis of new tooth or bone from an encapsulated biological agent such as a growth factor or stem cells contained within a hollow and porous biocompatible vehicle such as a titanium implant placed (implanted) within the body of a host animal such as a human.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

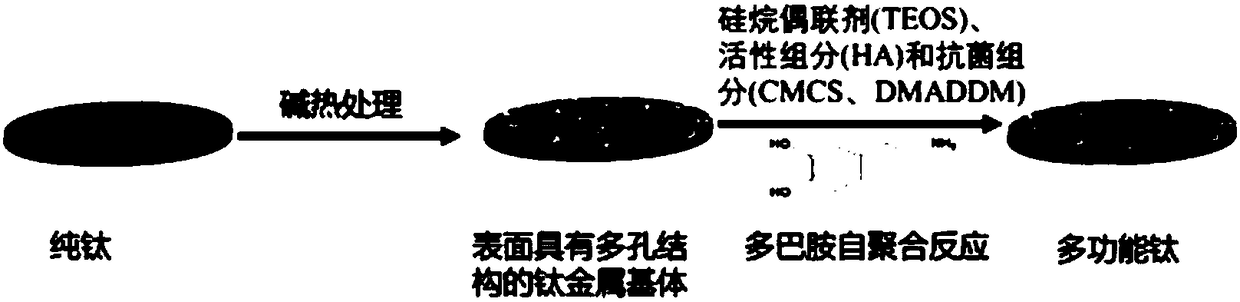

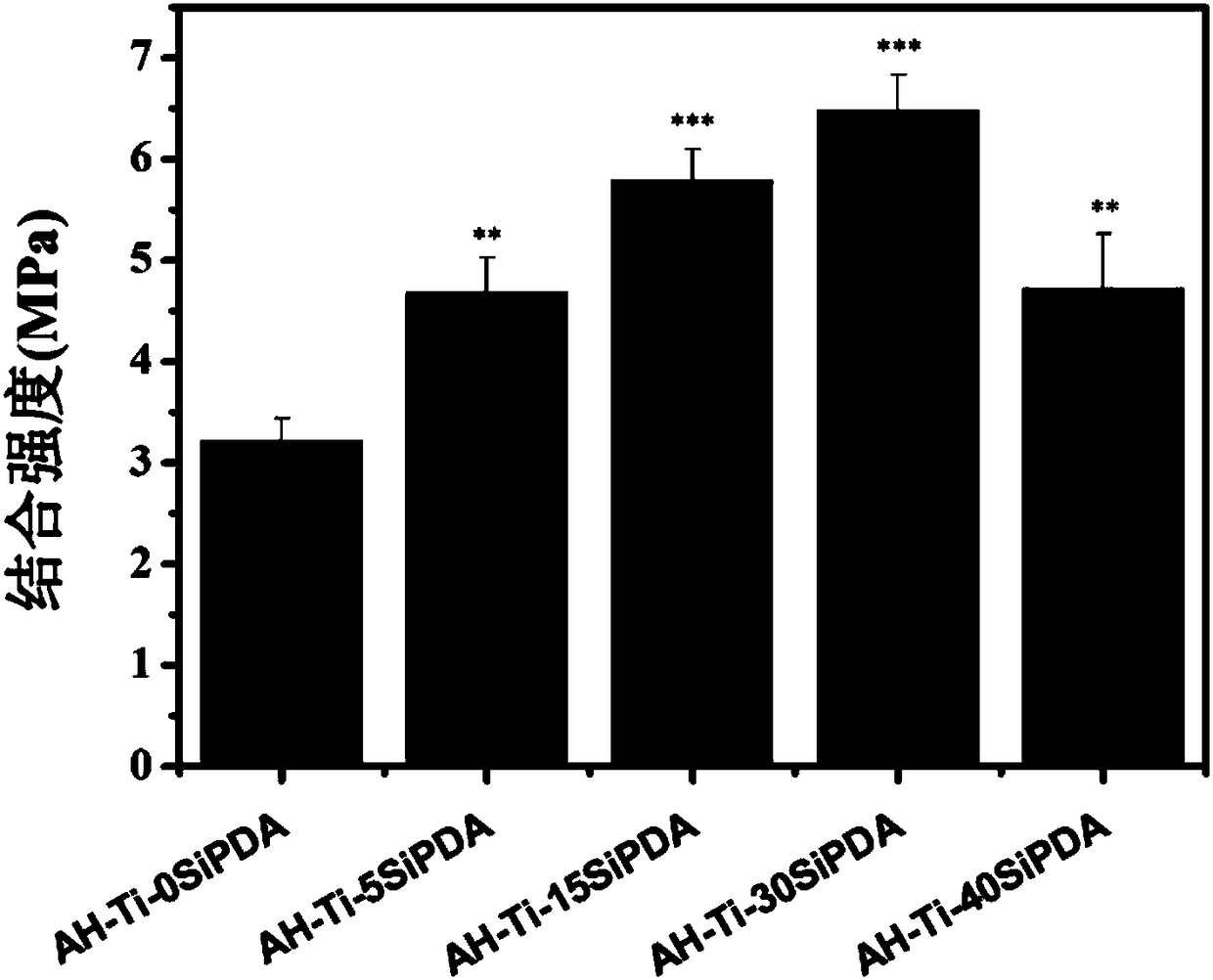

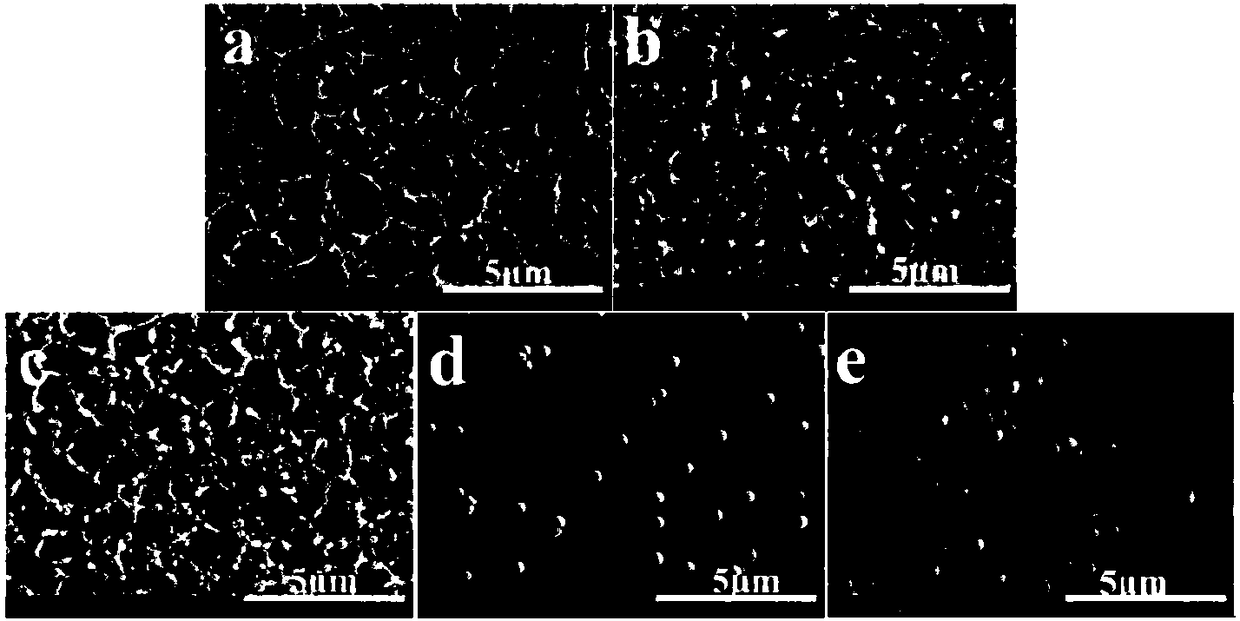

Multifunctional titanium implant based on polydopamine modification and preparation method of multifunctional titanium implant

InactiveCN108187135AImprove antibacterial propertiesHigh bonding strengthPharmaceutical delivery mechanismTissue regenerationTitanium metalBiocompatibility Testing

The invention provides a multifunctional titanium implant based on polydopamine modification and a preparation method of the multifunctional titanium implant. The multifunctional titanium implant is prepared as follows: a silane coupling agent is added to the surface of pre-activated titanium metal and subjected to an auto-polymerization reaction with polydopamine, functional groups are grafted onthe surface of a polydopamine coating obtained through the auto-polymerization reaction, and finally, the multifunctional titanium implant is obtained, wherein the bonding strength between the polydopamine coating and the surface of the titanium metal is 4.5-6.5 MPa. The multifunctional titanium implant adopts a porous surface structure, has good cell biocompatibility, has an efficient antibacterial effect on peri-implantitis specific bacteria and particularly has a significant synergistic antibacterial effect on multiple strains. The preparation method of the multifunctional titanium implanthas the characteristics of being simple in process and suitable for promotion.

Owner:SICHUAN UNIV

Surface treatment process of bioactive metallic titanium implant having multistage micro-pit structure

InactiveCN103451602ANot easy to fall offInhibit sheddingVacuum evaporation coatingSputtering coatingAcid etchingDrug biological activity

The invention relates to a surface treatment process of a bioactive metallic titanium implant having a multistage micro-pit structure, and the surface treatment process comprises the following steps: pretreatment, sandblasting treatment, acid etching treatment, sputtering treatment and glow discharge treatment; according to the surface treatment process, a multistage micro-pit three-dimensional structure having a bioactive tantalum coating is formed on the surface of the metallic titanium implant, so that the binding strength between the tantalum coating and the metallic titanium implant is very good, the tantalum coating is not easy to shed, shedding of the tantalum coating during or after an implantation process is avoided, the biological activity of the metal titanium implant can be improved, bone deposition of the surface of the metal titanium implant is accelerated, the tissue healing time is shortened, and through the formation of synostosis between the metal titanium implant and a surrounding bone tissue, the effect of improvement of the stability of the metal titanium implant can be achieved.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

Surface mount method of mineralized collagen gradient coating for medical titanium implant

InactiveCN101984144AEvenly distributedGood biocompatibilityElectrolytic inorganic material coatingBiocompatibility TestingStrong binding

The invention relates to a surface mount method of mineralized collagen gradient coating for medical titanium implant. Based on the effect of voltage and electrolyte composition on in-situ biomineralization self-assembly of collagen in electrolyte, permineralized calcium phosphate layer, mineralized collagen layer and unmineralized pure collagen layer are assembled from the titanium substrate upward in profile by electrochemical codeposition technology. The components and structure of the above product are similar to those of natural bones. The product of good biocompatibility and biological responsiveness can accelerate the osteointegration of implanted area and shorten the period of treatment. The strong binding force between the coating and the titanium substrate prevents the occurrence of coating shedding due to friction stress during the process of implantation. The coating provided by the invention is applicable to clinical applications.

Owner:ZHEJIANG UNIV

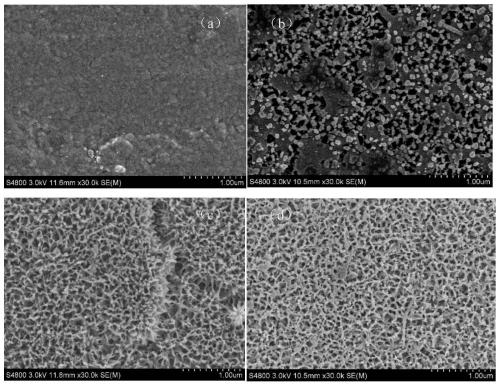

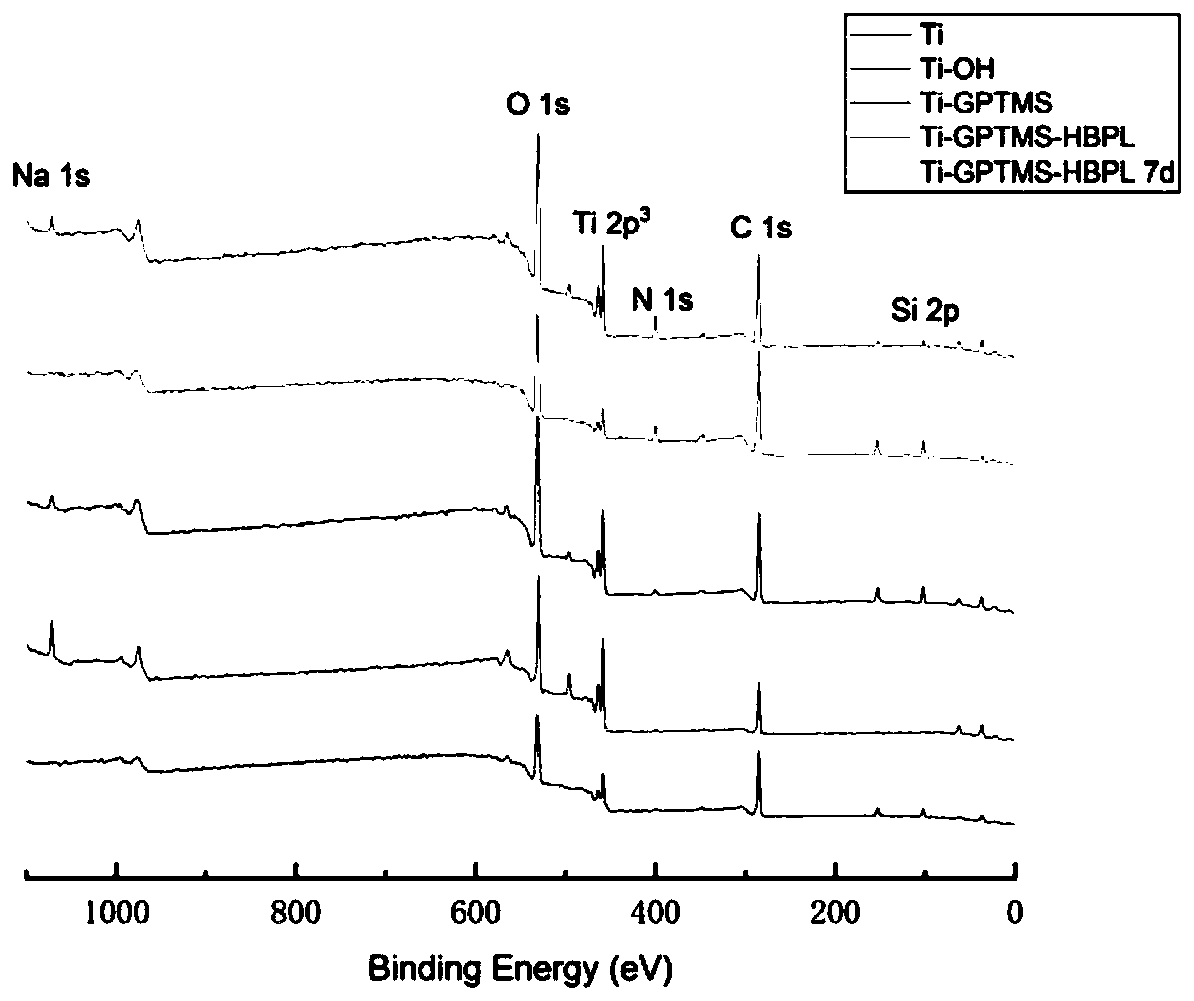

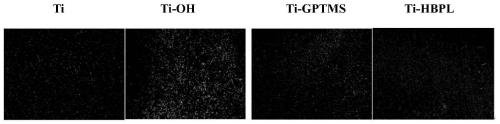

Titanium implant material with anti-infection and osseointegration promoting functions, and preparation method thereof

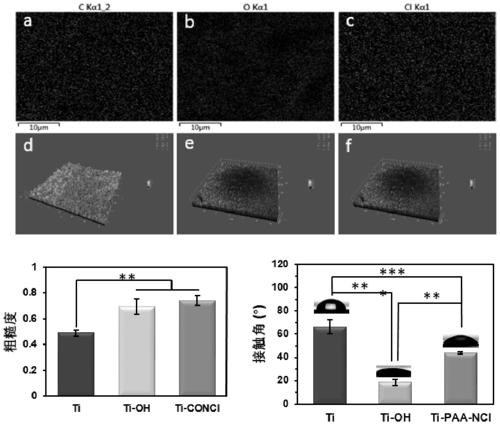

ActiveCN111035803AHigh reactivityMild reaction conditionsTissue regenerationProsthesisOsteoblastStaphyloccocus aureus

The invention relates to a titanium implant material with anti-infection and osseointegration promoting functions, and a preparation method thereof. According to the method, hyperbranched polylysine (HBPL) is prepared through a thermal initiation one-pot method; HBPL is covalently grafted to a titanium sheet by using a silane coupling agent gamma-(2,3-epoxypropoxy)propyltrimethoxysilane (GPTMS); the hyperbranched polylysine fixed on the surface of the titanium sheet has good sterilization effects on gram-positive staphylococcus aureus and gram-negative escherichia coli; and compared with puretitanium, the material can promote the adhesion, the proliferation and the differentiation of osteoblasts, and does not have cytotoxicity. According to the invention, the titanium implant material issimple in technological process and low in production cost, has the functions of infection resistance and osseointegration promoting on the basis of good safety, innovatively applies hyperbranched polylysine to the field of implants, has important significance in modification of titanium implants, and has good application prospect.

Owner:ZHEJIANG UNIV

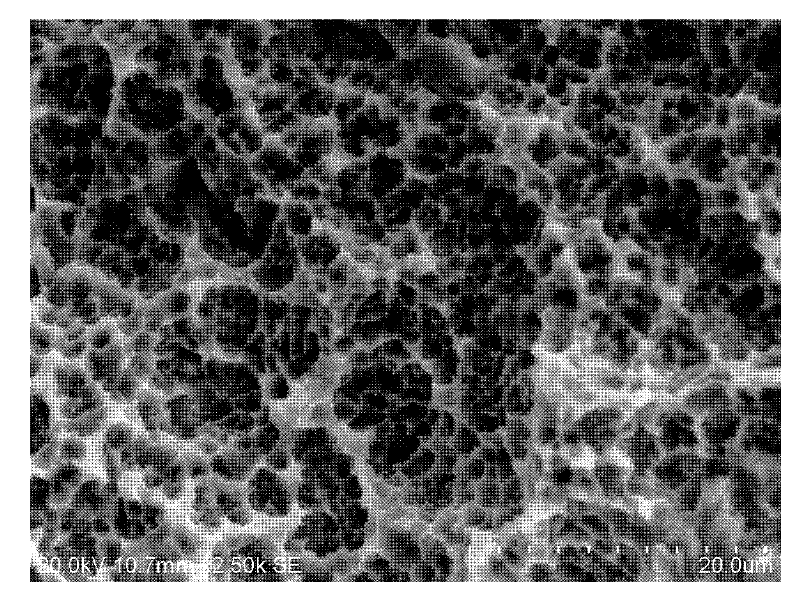

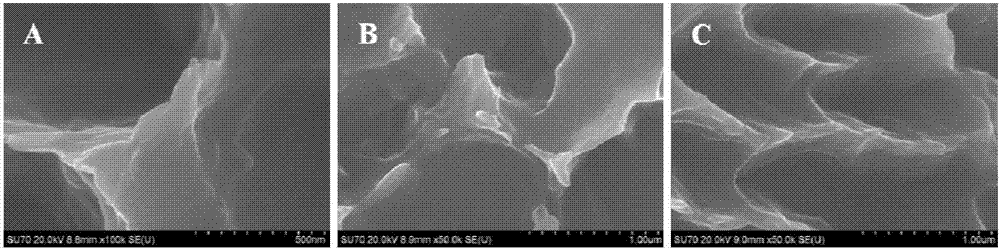

Method for preparing implant surface with multi-scale complex porous structure

ActiveCN104233318AEnhance osteogenic activityGood antibacterial effectProsthesisAcid etchingSand blasting

The invention provides a method for preparing an implant surface with a multi-scale complex porous structure and for preparing a titanium-based implant surface with antibacterial and osteogenic functions. The method adopts a three-step reduction method of sand blasting, oxalic-acid acid etching and alkali treatment and simulates a morphology environment for new bone formation in vivo under the physiological condition. The osseointegration of the implant surface can be accelerated, the surface is beneficial to the long-term stability of the implant, has a significant antibacterial performance, can inhibit infection of early planting, and can further improve the success rate of planting. With adoption of the method, a micro-nano composite pure titanium implant surface with the osteogenic and antibacterial performances, namely a three-dimensional implant surface with the multi-scale complex structure is prepared. The surface has an osteogenic activity higher than that of SLA most widely used in clinic and good antibacterial performance and has a wide application prospect. The surface has the extremely vital significance on expanding oral planting indications, shortening the implant restoration course, reducing infections relative to planting and increasing the success rate of planting.

Owner:ZHEJIANG UNIV

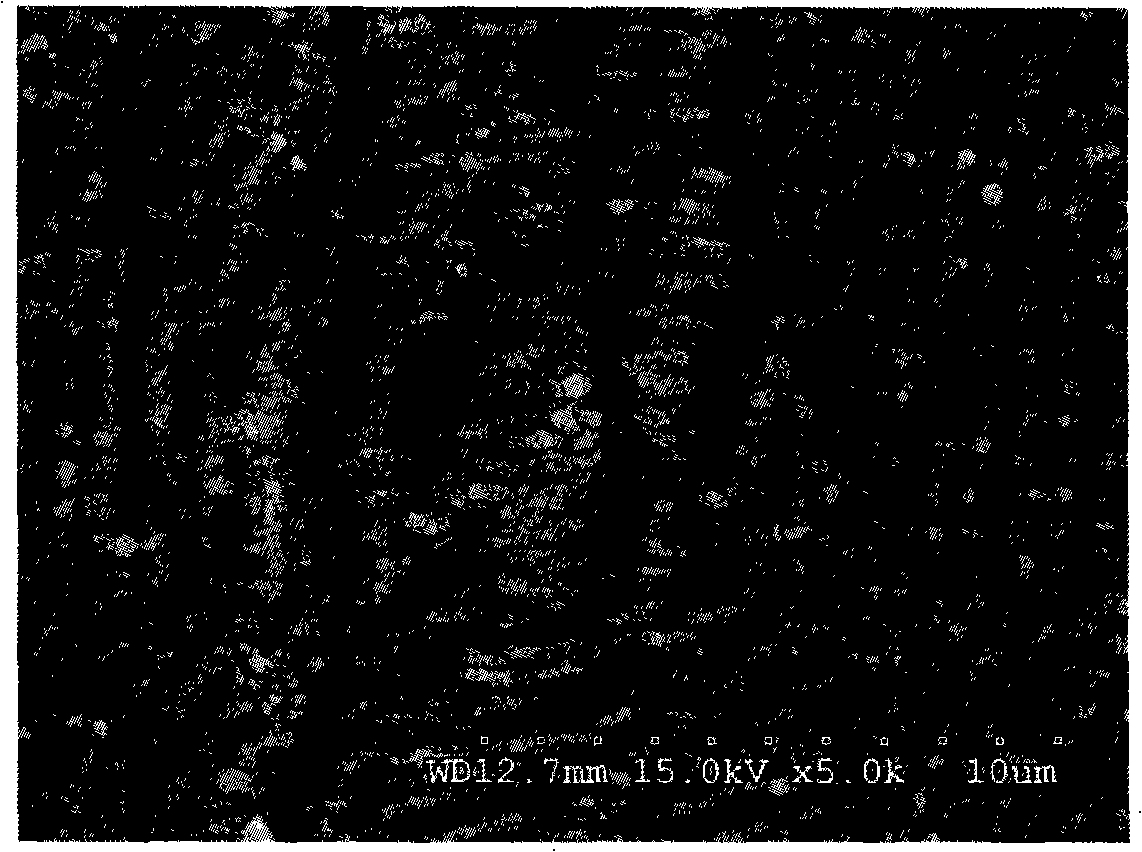

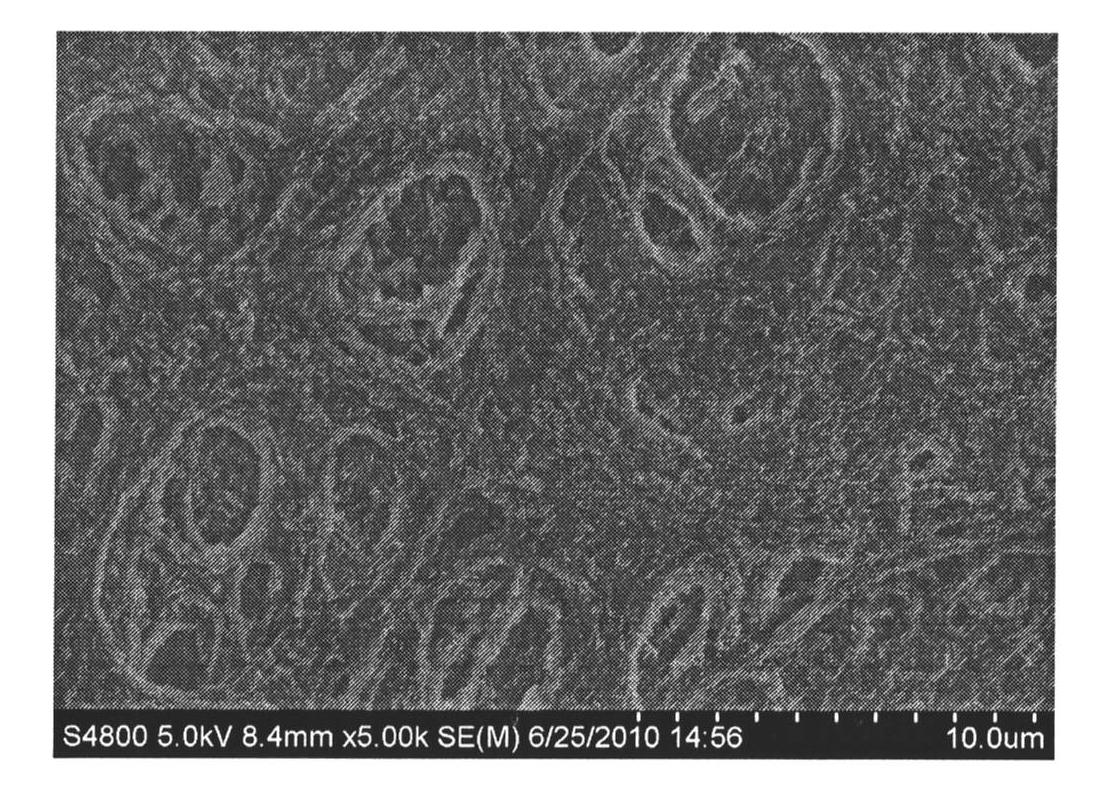

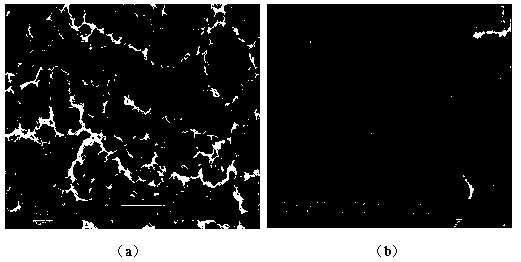

Preparation method of multilevel cellular structure for medical pure titanium implant surface

The invention provides a preparation method of a multilevel cellular structure for a medical pure titanium implant surface. The preparation method comprises the step of pretreatment of surface: placing a pure titanium implant into the mixed liquid, and ultrasonically cleaning, then drying; the step of sand blasting, wherein the surface subjected to the sand blasting is changed from metallic luster of silver to lead, concave pits with different depth are formed, and the aperture is ranged from 10 to 40 microns; and the step of acid etching: placing the test sample subjected to the sand blasting into the mixed solution for acid etching, wherein the surface subjected to magnetic stirring has color darker than that before sand blasting, cellular pores are formed based on the concave pits formed in sand blasting, and the aperture is ranged from 0.5 to 3 microns. According to the preparation method, white emery sand higher in purity is adopted and used as the main material for sand-blasting abrasive, so that nearly no pollution is brought to the surface, and the implant surface is prevented from deep damaging; and the titanium dioxide is beneficially used for preventing the sharp from occurring on the surface to result in damage. The multilevel cellular structure is prepared on the implant surface, no particles produced in stand blasting are residual, the benefit is provided for the combination respect to the bone tissue, and the healing time is reduced.

Owner:大连理工(营口)新材料工程中心有限公司

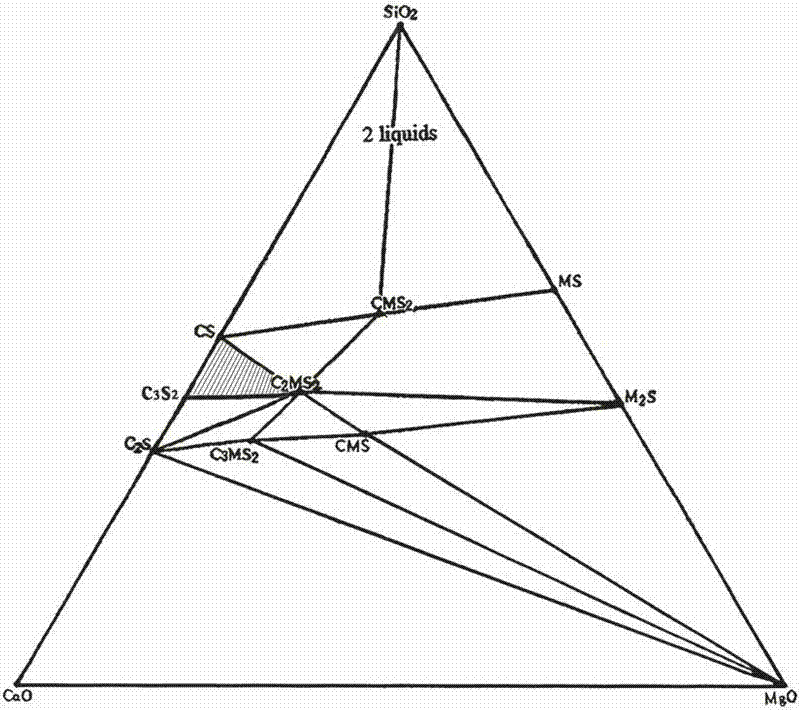

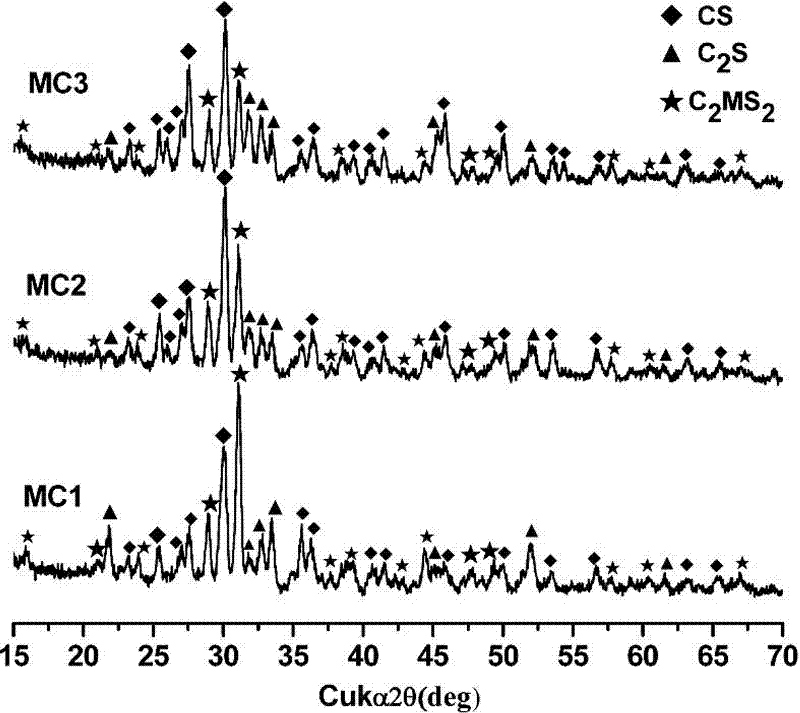

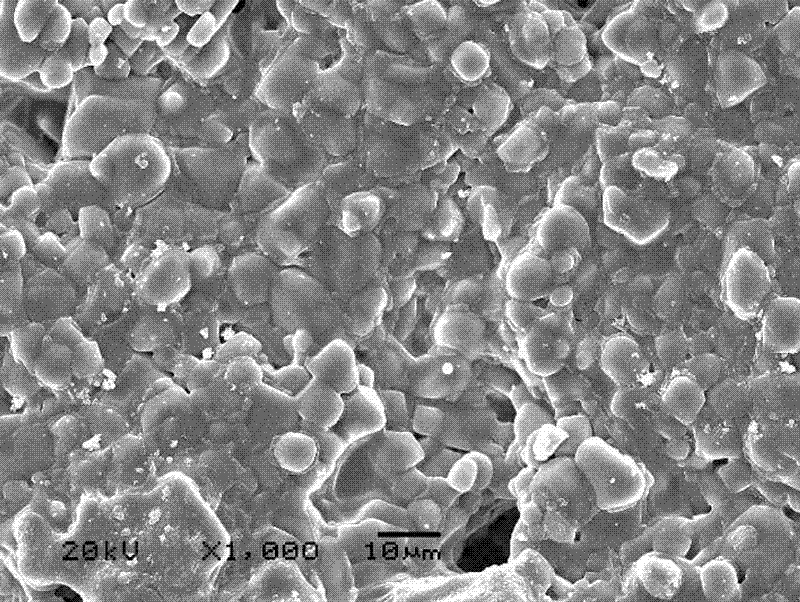

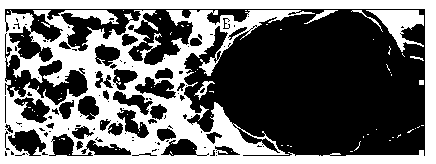

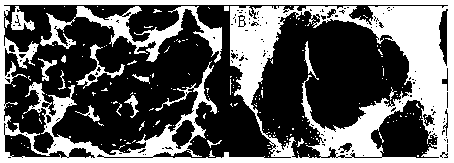

Design and preparation method for novel calcium-magnesium-silicon multiphase bioactive ceramic, and use thereof

InactiveCN102357260AHigh bonding strengthMeet the design requirementsCoatingsProsthesisOsteoblastTitanium alloy

The present invention relates to a design and preparation method for a novel calcium-magnesium-silicon multiphase bioactive ceramic, and a use thereof. According to the present invention, chemical compositions of three novel calcium-magnesium-silicon multiphase bioactive ceramics are firstly designed based on preliminary experimental results and theoretical analysis of phase diagrams; then tetraethoxysilane, water, magnesium nitrate hexahydrate and calcium nitrate tetrahydrate are adopted as raw materials, a sol-gel method is adopted for synthesis of three novel calcium-magnesium-silicon multiphase bioactive ceramic powders; the powders are subjected to dry-pressing and forming to obtain a material bisque; the bisque is subjected to sintering for 2 hours at a temperature of 1300-1350 DEG C to obtain a compact ceramic block body. According to the present invention, the multiphase ceramic MC2 is prepared by the method provided by the present invention, wherein the thermal expansion coefficient of the multiphase ceramic MC2 matches with titanium alloy TC4; because the intrinsic stress between the metal and the ceramic is reduced, the metal-ceramic bonding strength can be improved when the multiphase ceramic MC2 is adopted as the titanium-based bioactive coating; the ceramic has good mechanical property, good biological activity and good osteoblast compatibility; the novel calcium-magnesium-silicon multiphase ceramic MC2 is a potential bioactive ceramic material, and can be used in the surface modification fields of titanium implants in orthopedics, dentistry or plastic surgery, and human body hard tissue repairing and implanting materials; the method provided by the present invention has characteristics of simple process, easily-controlled components and conditions, and is easy to popularize.

Owner:SICHUAN UNIV

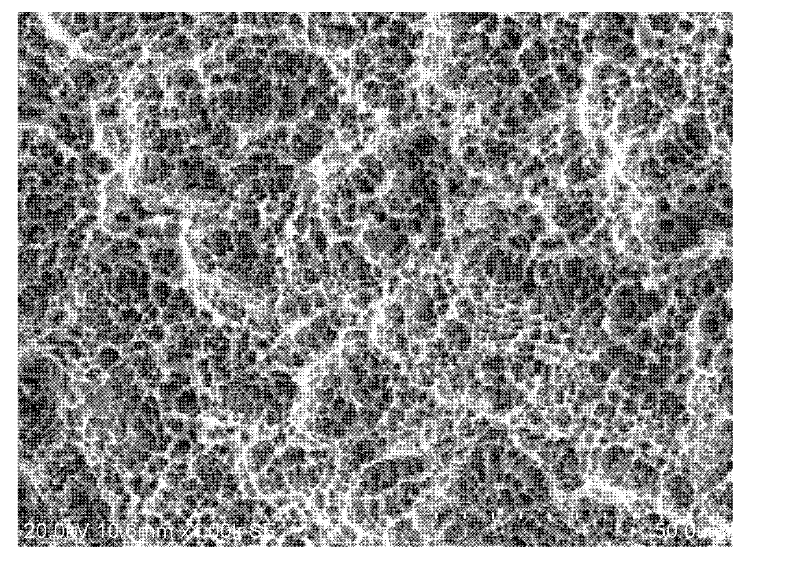

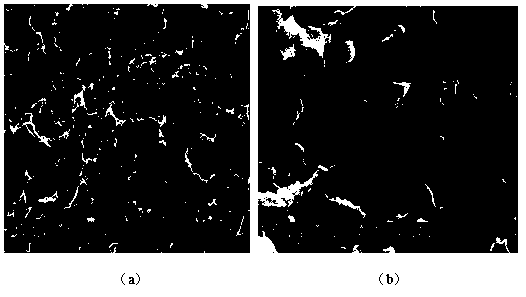

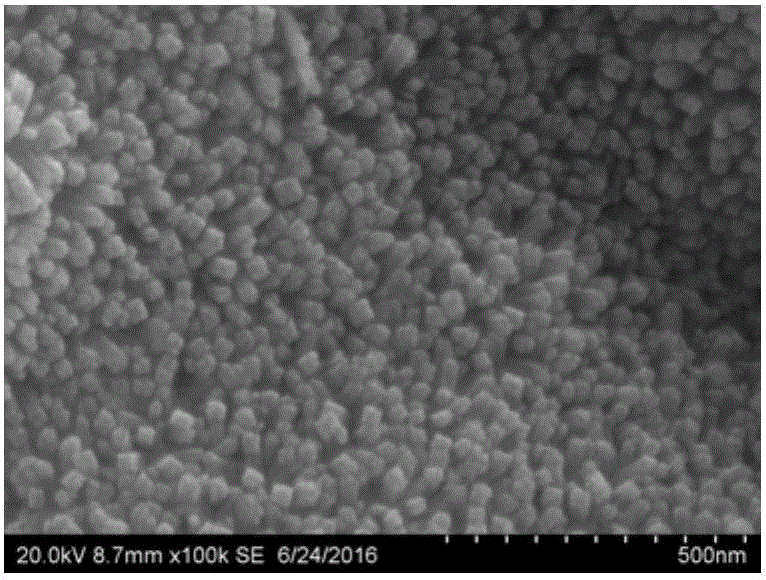

Preparation method of titanium implant surface with micro-nano composite structure

The invention provides a preparation method of a titanium implant surface with a micro-nano composite structure. The preparation method comprises the following steps: (1) performing blast sanding and ultrasonic processing on a smooth implant surface, then washing with water, and drying; (2) processing the implant surface in an oxalic acid solution for 30-240 min, then washing with water, and drying, wherein the concentration of the oxalic acid solution is 30% to saturation; and (3) taking a mixed acid solution of H2SO4 with the concentration of 98% and H2O2 with the concentration of 30% for processing, and then washing with water to obtain the titanium implant surface with the micro-nano composite structure. According to the preparation method of the titanium implant surface with the micro-nano composite structure, disclosed by the invention, the implant surface with the micro-nano composite structure is obtained by performing a secondary etching on a micron-structure surface processed by sand blast and oxalic acid, and compared to the micron-structure surface, titanium implant surface is provided with a microstructure with more levels, which is capable of providing more comprehensive environment signals for cell growth and tissue regeneration; and the titanium implant surface with the micro-nano composite structure has super-hydrophilicity and the protein adsorption capability is remarkably enhanced, which are of a great significance to further improving the surface biological activity of implants.

Owner:ZHEJIANG UNIV

Method for preparing titanium implant and obtained titanium implant

ActiveCN103736148APromote osseointegrationIncrease success rateSurface reaction electrolytic coatingProsthesisMicro nanoTio2 nanotube

The invention discloses a method for preparing a biomimetic titanium implant with a micro-nano composite structure on a surface and the obtained titanium implant. The method comprises the following steps: A) processing pure titanium or a titanium alloy into an implant substrate, performing surface polishing, performing ultrasonic washing by using acetone, absolute ethanol and deionized water in sequence, and drying; B) processing the surface of the substrate into a micro-nano structure by adopting a mixed acid ultrasonic treatment mode or a mechanical sandblasting treatment mode; C) oxidizing the surface of the micro-nano structure into a titanium oxide nanotube film in situ by adopting a constant-voltage direct-current anodic oxidation technology, so that the biomimetic titanium implant with the micro-nano composite structure on the surface is obtained. The biomimetic titanium implant disclosed by the invention can effectively increase the compatibility and the bonding capacity with bones, and is also favorable to the adhesion, the proliferation, the differentiation and the functional expression of cells, so that the osseointegration capacity and the operation success rate of the implant are improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method of preparing TiSrO3 coating on surface of titanium implant

ActiveCN104032291AImprove bindingLarge specific surface areaMetallic material coating processesHeat treatedMaterials science

The invention discloses a method of preparing TiSrO3 coating on the surface of a titanium implant. The method comprises the following steps: after carrying out sand blasting and double acid treatment on a pure titanium implant, putting the titanium implant in a hydrothermal solution containing strontium ions for hydrothermal treatment and surface modification; and forming a nanoscale protruding structure with multiple holes on the surface of the implant, wherein the protruding layer on the surface is a strontium titanate crystal structure and an anatase crystal structure and has the effects of promoting osteoblast and osteogenic differentiation of stem cells. Meanwhile, the coating has good wettability and has a wide application value.

Owner:ZHEJIANG UNIV

Method of preparing titanium implant having bioelectricity activity by carrying out water-vapor treatment on tin-bearing microarc oxidation coating

ActiveCN106400087ACompact structureNot affected by porous structure morphologySurface reaction electrolytic coatingSolid state diffusion coatingTin dioxideNano structuring

The invention discloses a method of preparing a titanium implant having bioelectricity activity by carrying out water-vapor treatment on a tin-bearing microarc oxidation coating. A titanium sample is placed in a stainless steel tank filled with an electrolytic solution for microarc oxidation; then the titanium sample is placed in a reaction kettle for the water-vapor treatment, tin dioxide in a nano structure grows on the surface of the titanium sample, an electroactivity biological microarc oxidation coating which is in a microscope porous structure is obtained, and tin dioxide grows on the surface of the electroactivity biological microarc oxidation coating. No discontinuous interface exists between the coating and a substrate, bone-like apatite can be formed through rapid induction in a simulated body fluid environment, and the titanium implant has good bioactivity.

Owner:XI AN JIAOTONG UNIV

Canulated titanium implant for correcting flat feet in children

InactiveUS20090082818A1Easier correctly placedReduce harmSuture equipmentsAnkle jointsCalcaneusEngineering

It is possible to satisfy all the requirements of minimal invasiveness with maximal permanent result by placing the invented implants (screw). The shape of the screw solves all mentioned technical problems that occurred thus far, i.e. it can be directed through a small gap in the skin by Kirschner's guide-wire (because the screw is hollow-canulated). The screw is larger in body, so a much greater force is needed for it to break. If it does break, it can be removed easier with less lesions to the surrounding bone tissue. At the point of the screw are trisect cuts (on the apex thread) which also make the lesion of the bone lesser as is as it is inserted in its position. Since the head of the screw is bigger and conical, without a narrow part leading to the screw-thread, the screw self-tightens into the bone, which makes the loosening rarer. The loosening is also rarer because of the shape of the screw-thread. The screw has the equal effect throughout the whole time it is implanted in the body. The osteolysis of the heel bone in which the screw stems against is also reduced. The conical shape of the head of the screw, without a narrow part (neck) between the head and the screw-thread, it does not allow ingrowing of the bone tissue, so it can be easily removed when the necessary time of correction is finished. The time necessary for the surgical procedure is significantly shorter, taking up 15 minutes, thus reducing the possibility of a infection, which is also helped by a small operative area. After the placement of the screw, the patient can walk two days after the surgery and he / she does not need any plaster immobilization or physical therapy. The screw is made out of titanium alloy, which gives it a certain toughness; the patient can undergo magnetic examinations, if there is need for such, while the screw is implanted.

Owner:ROTH SANDOR UMLAUT OVER

Hollow and porous orthopaedic or dental implant that delivers a biological agent

InactiveUS8337873B2Promote healingLow mechanical strengthOrganic active ingredientsDental implantsTitanium implantTitanium

This invention relates to the synthesis of new tooth or bone from an encapsulated biological agent such as a growth factor or stem cells contained within a hollow and porous biocompatible vehicle such as a titanium implant placed (implanted) within the body of a host animal such as a human.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

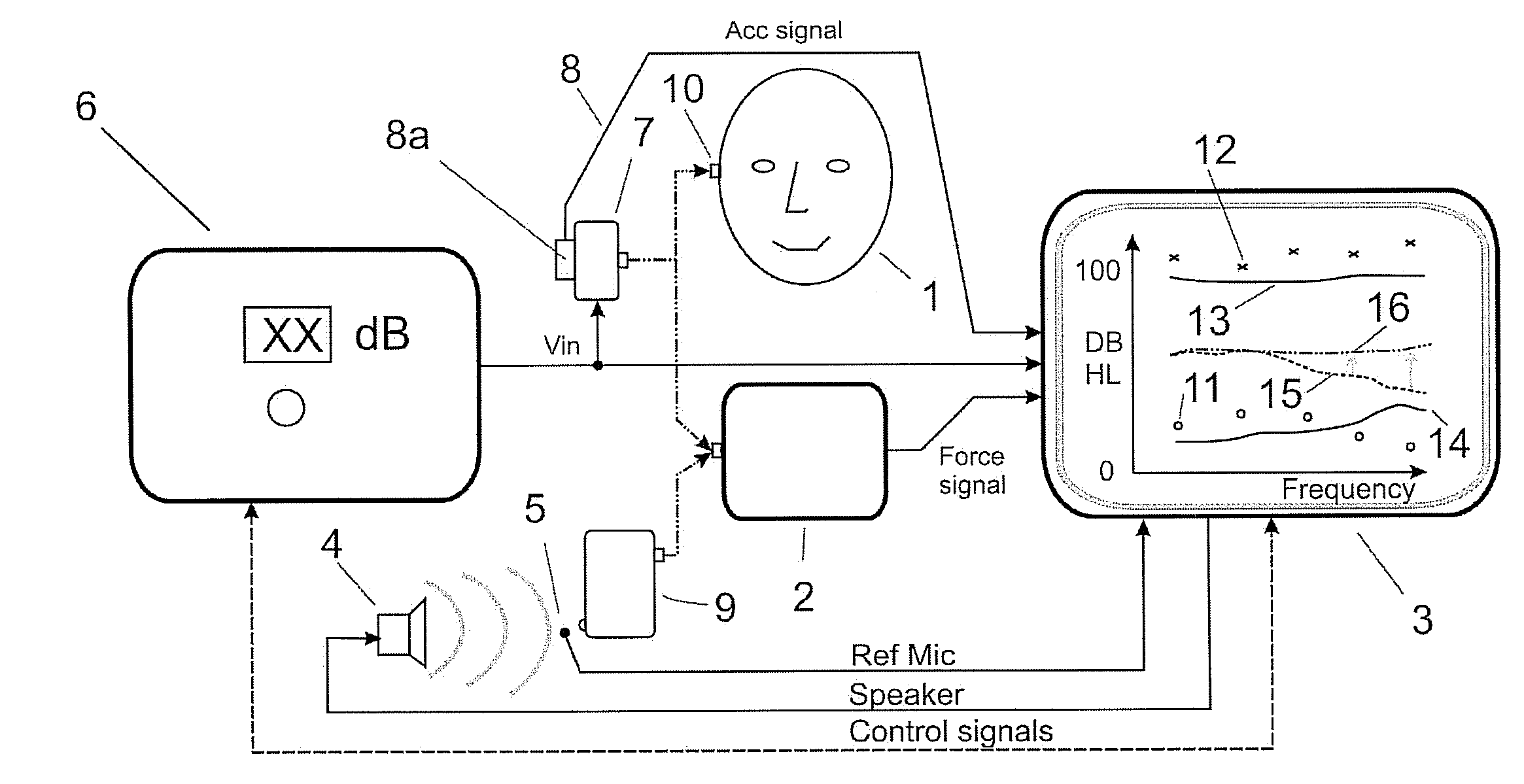

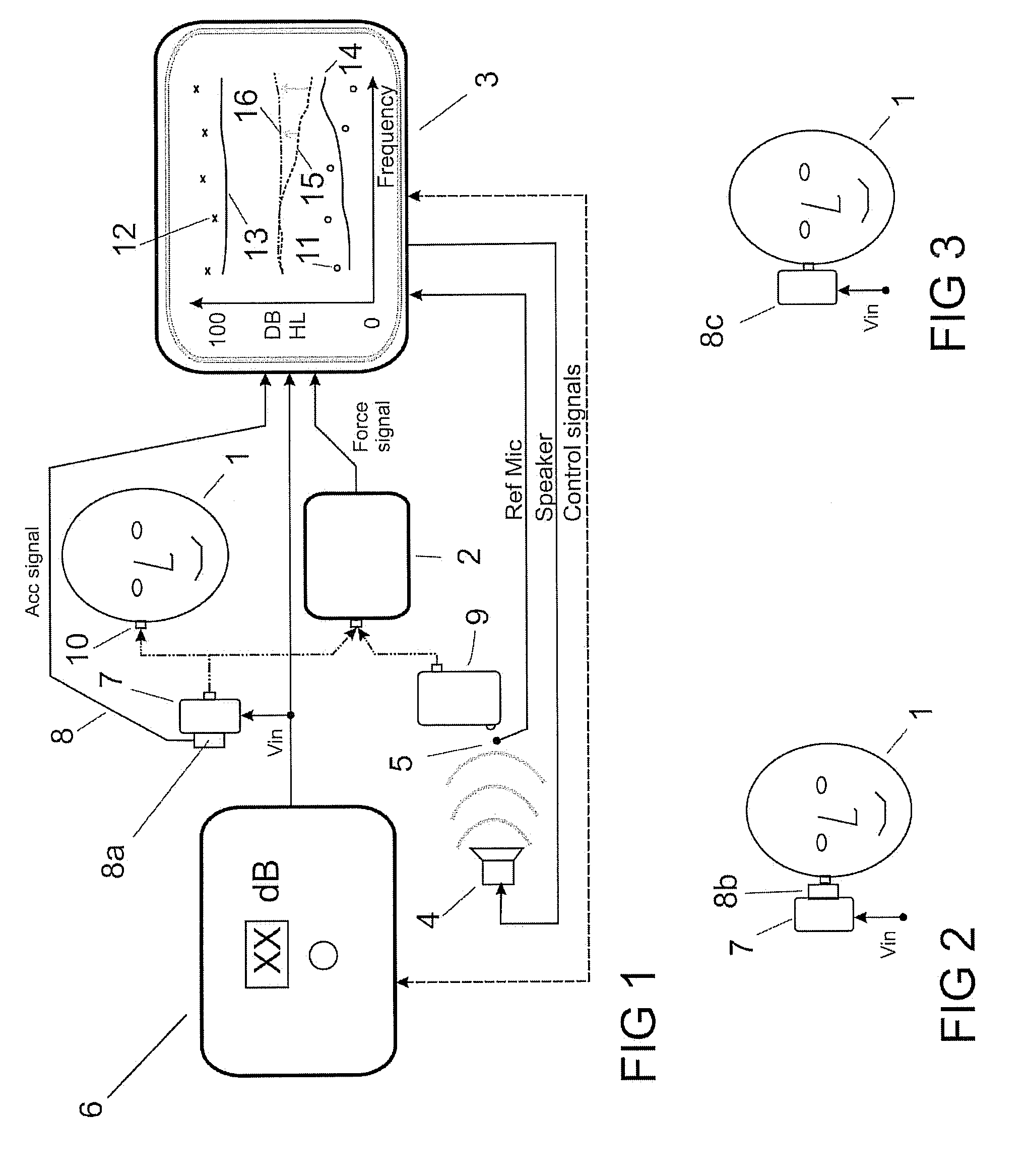

Fitting and verification procedure for direct bone conduction hearing devices

InactiveUS20090136050A1Improve hearing rehabilitationBone conduction transducer hearing devicesInertial sensorsBone conduction hearing deviceTitanium implant

The present invention relates to a method for fitting and verification of direct bone conduction hearing devices to a patient, whereina. in a first step the hearing threshold and loudness discomfort levels are measured directly on a titanium implant of a patient,b. in a second step these hearing threshold and loudness discomfort levels are converted to equivalent force thresholds (FHT) and loudness discomfort levels (FLDL) on an artificial skull force measuring device,c. in a final step the output force levels of the direct bone conduction hearing device is measured in a free sound field with the device attached to the said artificial skull force measuring device and compared to the FHT and the FLDL as the base for final adjustments of the device.

Owner:OSSEOFON

Surface activation method of dental implant

InactiveCN101773412AEvenly distributedPromote ingrowthDental implantsArtificial teethActivation methodTitanium alloy

A surface activation method of a dental implant comprises: putting a titanium implant in 1-3M of H2SO4 liquid, using the titanium or titanium alloy of the titanium implant as an anode and using a Pt material as a cathode to carry out anode oxidation by using an anode oxidation method, preparing an oxidation film with a three-dimensional spherical pore microstructure on a surface, and existing round pits in different sizes and with apertures of 100-200nm in local areas; and putting the titanium implant with the oxidized anode in 3-5M of NaOH alkali solution for processing and forming a titanium gel on the surface, wherein the enriched Ti-OH groups induce the generation of calcium phosphate crystal nucleuses to form a bone-like apatite layer. The invention uses the combination of the anode oxidation method and an alkali process method for preparing an active TiO2 coating layer on the surface of the titanium alloy, the implant processed by the anode oxidation method has good compatibility with bone, and bonding strength and bone sediment yield are both obviously higher than that of the unprocessed titanium, thereby greatly improving the clinic success ratio of the dental implant.

Owner:沈阳天贺新材料开发有限公司

Preparation method of stable and high-performance implant surface

ActiveCN106890357AEnhanced osteogenic propertiesIncrease success ratePharmaceutical delivery mechanismSolid state diffusion coatingMicron scaleAcid etching

The invention provides a preparation method of a stable and high-performance titanium implant surface. The preparation method comprises three key steps of sand blasting, acid etching and temperature processing or four key steps of sand blasting, acid etching, secondary acid etching / alkali treatment and temperature processing, wherein sand blasting is carried out by virtue of titanium or titanium alloy, acid etching is carried out for a certain time by virtue of an oxalic acid system or an H2SO4 / HCl system or an HF / HNO3 system at a certain temperature, and finally, a micron-scale structural surface is directly subjected to temperature processing or is subjected to acid etching or alkali treatment before temperature processing. According to the preparation method, a large-scale fluctuation structure is obtained through sand blasting, a micron-scale structure / micron-nanometer composite structure is obtained through acid etching, an implant surface with a titanium oxide crystal form and a micron-nanometer composite structure is obtained through temperature processing, and crystalline titanium oxide is obtained by the surface when an original micron-nanometer structure is maintained, so that the surface has good bone integrating capacity, is very stable under a natural storage condition and has good ageing resistance and excellent broad-spectrum antimicrobial ability in a window phase.

Owner:ZHEJIANG UNIV

Long-acting renewable antibacterial coating on surface of titanium implant

ActiveCN111118484AImprove antibacterial propertiesLong antibacterial effectMetallic material coating processesProsthesisPolymer sciencePolymer chemistry

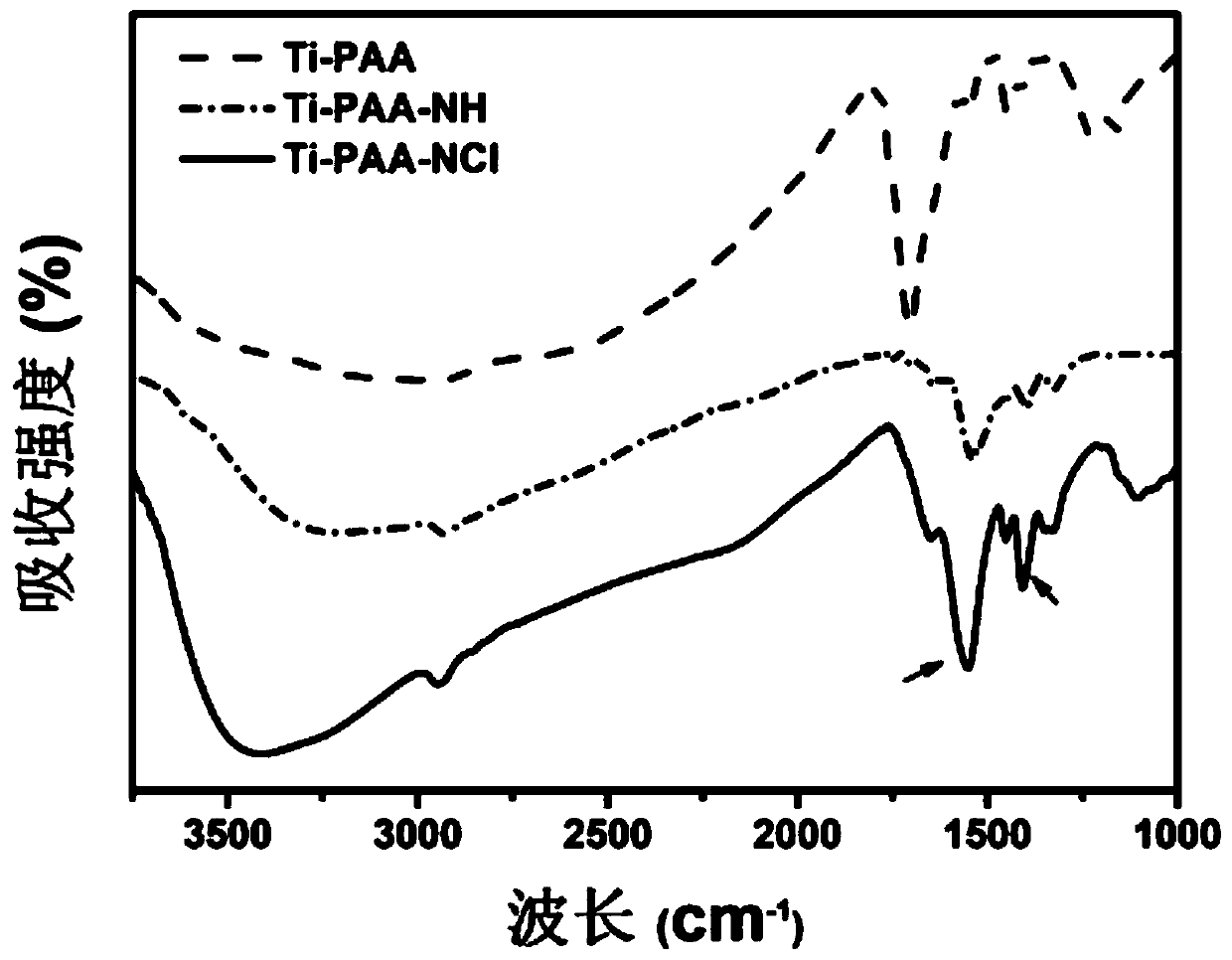

The invention relates to a long-acting renewable antibacterial coating on the surface of a titanium implant, and belongs to the field of oral biomedical materials. The invention provides a method forpreparing the renewable antibacterial coating on the surface of the titanium implant. The method comprises the following steps that a titanium sheet is taken and polished with SiC abrasive paper, andthe titanium sheet is cleaned with a solvent and aired; then alkali heat treatment is carried out, and the titanium sheet is treated with a silane coupling agent KH570; and then the titanium sheet acts with ethylene diamine after carrying out free radical polymerization reaction with acrylic acid monomer, then the titanium sheet is soaked in a sodium hypochlorite solution, and the renewable antibacterial coating on the surface of the titanium implant is prepared. According to the long-acting renewable antibacterial coating on the surface of the titanium implant, a firm and stable macromolecular antibacterial layer is constructed on the surface of the titanium sheet by adopting a covalent bonding method and a polymer grafting method, so that the effect of lasting antibacterial is achieved;and according to the long-acting renewable antibacterial coating on the surface of the titanium implant, halamine polymer is applied to the surface modification of the titanium implant for the first time, the antibacterial coating capable of being recycled is constructed, the antibacterial layer is firm and stable, the antibacterial time is long, and the antibacterial layer can be recycled.

Owner:HOSPITAL OF STOMATOLOGY SUN YAT SEN UNIV +1

Method for obtaining a composite coating on titanium implants for tissue engineering

ActiveUS20170088969A1Improve adhesionPromote proliferationElectrolytic inorganic material coatingSurgeryCALCIUM CATIONSingle layer graphene

A composite coating and method for preparing the composite coating on titanium implants for tissue culture and tissue engineering is provided. The implants are characterized in that the titanium component to be coated is placed in a aqueous solution containing calcium cations, phosphate anions, and dispersed carbon nanoparticles (such as single layer graphene oxide or graphene oxide) in an amount of about 0.05%-1.50% by weight relative to the total weight of aqueous solution. The dimensions of the dispersed graphene oxide should be around, but not limited to, 300-800 nm (X-Y), while their thickness is about 0.7-1.2 nm. The aqueous solution with carbon nanoparticles is prepared by mixing for at least 72 h in temperature in range 20-35° C. and sonicated before electrodeposition process. In the prepared solution is further placed titanium which acts as cathode element (may be the implant), and anode which can be, for example, a platinum rod. Between the cathode and anode is set a potential from −1.3V to −1.7V which results in coating formation by electrodeposition. The titanium implant before the electrodeposition process is treated in sodium hydroxide of HF to improve coating formation and thickness.

Owner:JACKSON STATE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com