Preparation method of stable and high-performance implant surface

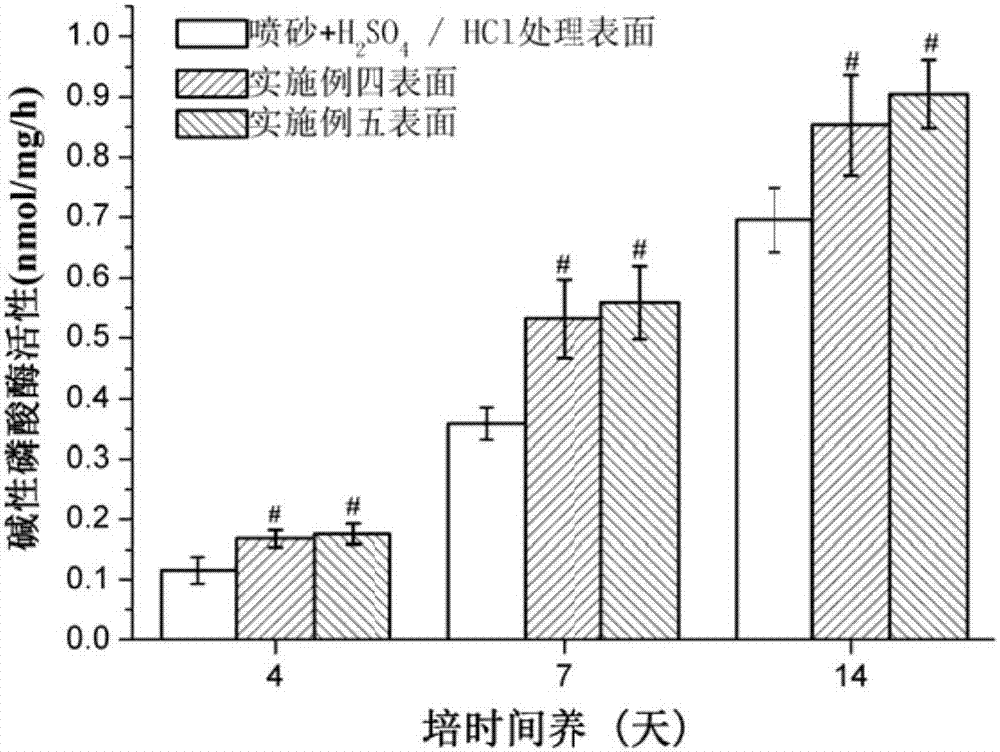

A high-performance implant technology, applied in prostheses, pharmaceutical formulations, coatings, etc., can solve the problems of decreased surface activity, poor osseointegration, unpredictable implant results, etc. Bone performance and success rate, the effect of excellent cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The titanium implant with a smooth surface is sprayed evenly with 40-60 mesh emery under 5 bar pressure for 60 seconds, and the sprayed implant is cleaned with acetone, ethanol and pure water under ultrasonic conditions for 15 minutes, and then washed with a large amount of pure water clean and blow dry with nitrogen.

[0028] Then directly put into a fully dissolved oxalic acid solution with a mass concentration of 37.5% in a boiling water bath for 60 minutes, rinse with a large amount of water, and blow dry with nitrogen.

[0029] The above-mentioned implants treated with oxalic acid were treated at 500° C. for 30 minutes, and then cooled naturally at room temperature.

Embodiment 2

[0031] The titanium implant with a smooth surface is sprayed evenly with 40-60 mesh emery under 5 bar pressure for 60 seconds, and the sprayed implant is cleaned with acetone, ethanol and pure water under ultrasonic conditions for 15 minutes, and then washed with a large amount of pure water clean and blow dry with nitrogen.

[0032] Then directly put into a fully dissolved oxalic acid solution with a mass concentration of 37.5% in a boiling water bath for 60 minutes, rinse with a large amount of water, and blow dry with nitrogen.

[0033] The above-mentioned oxalic acid-treated implants were treated at 500° C. for 60 minutes, and cooled naturally at room temperature.

Embodiment 3

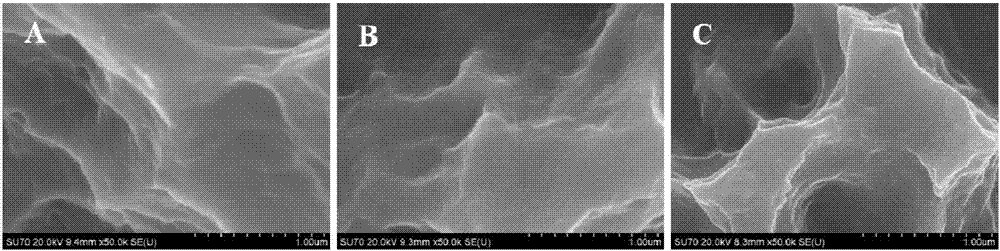

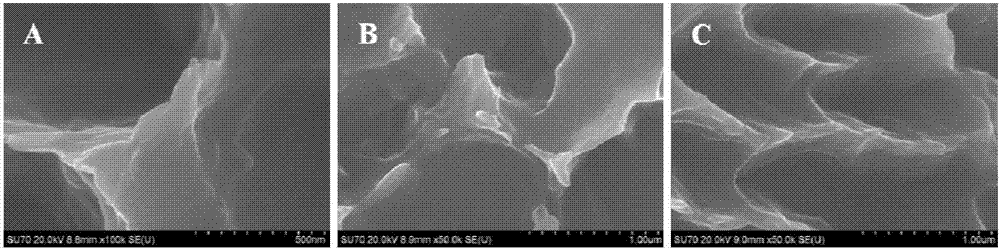

[0035] The surfaces prepared in Examples 1 and 2 were used for field emission scanning electron microscope morphology observation. figure 1 Showing its morphological characteristics, the temperature treatment process basically maintains the microstructure before the temperature treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com