Patents

Literature

100results about How to "Enhanced osteogenic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

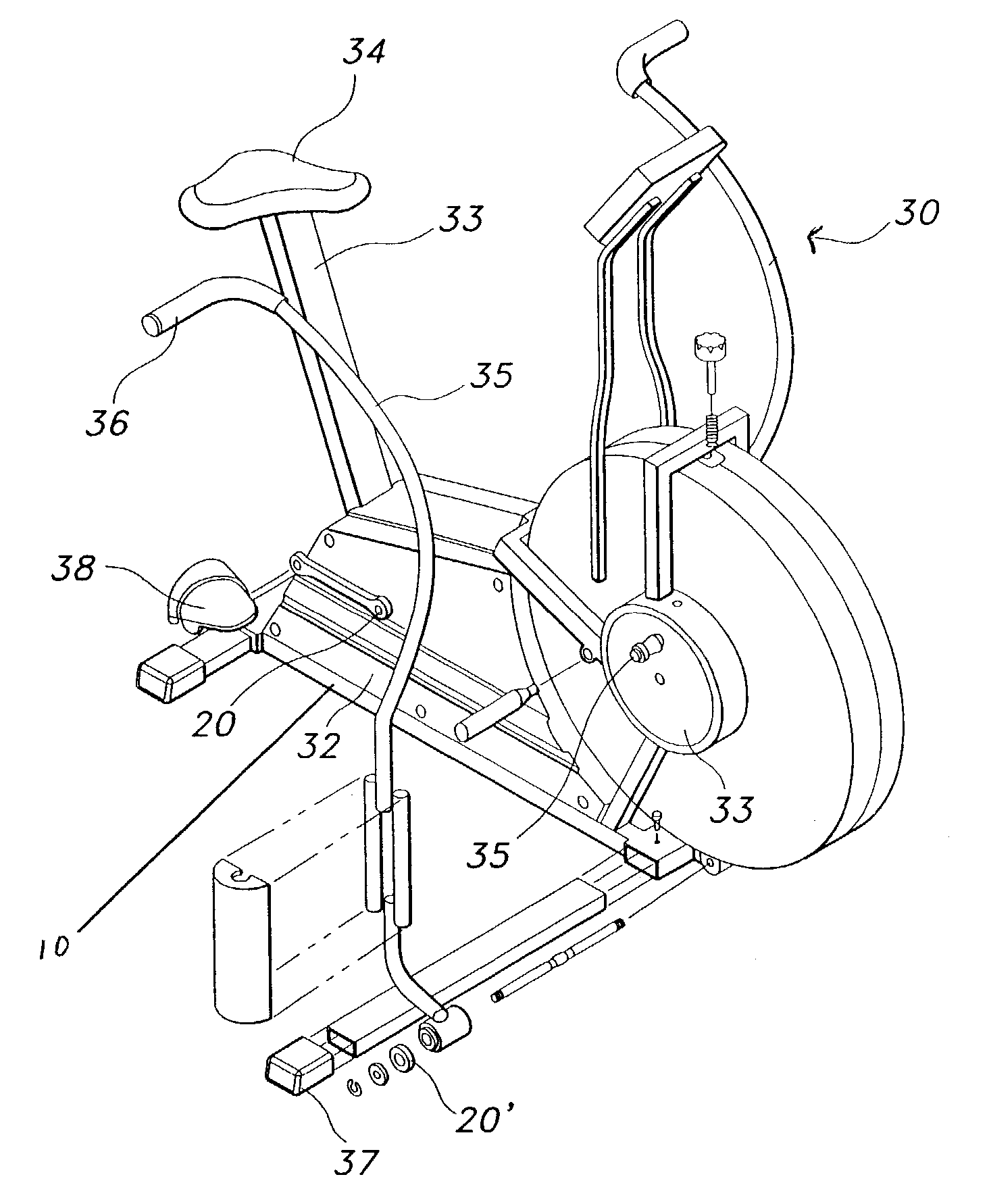

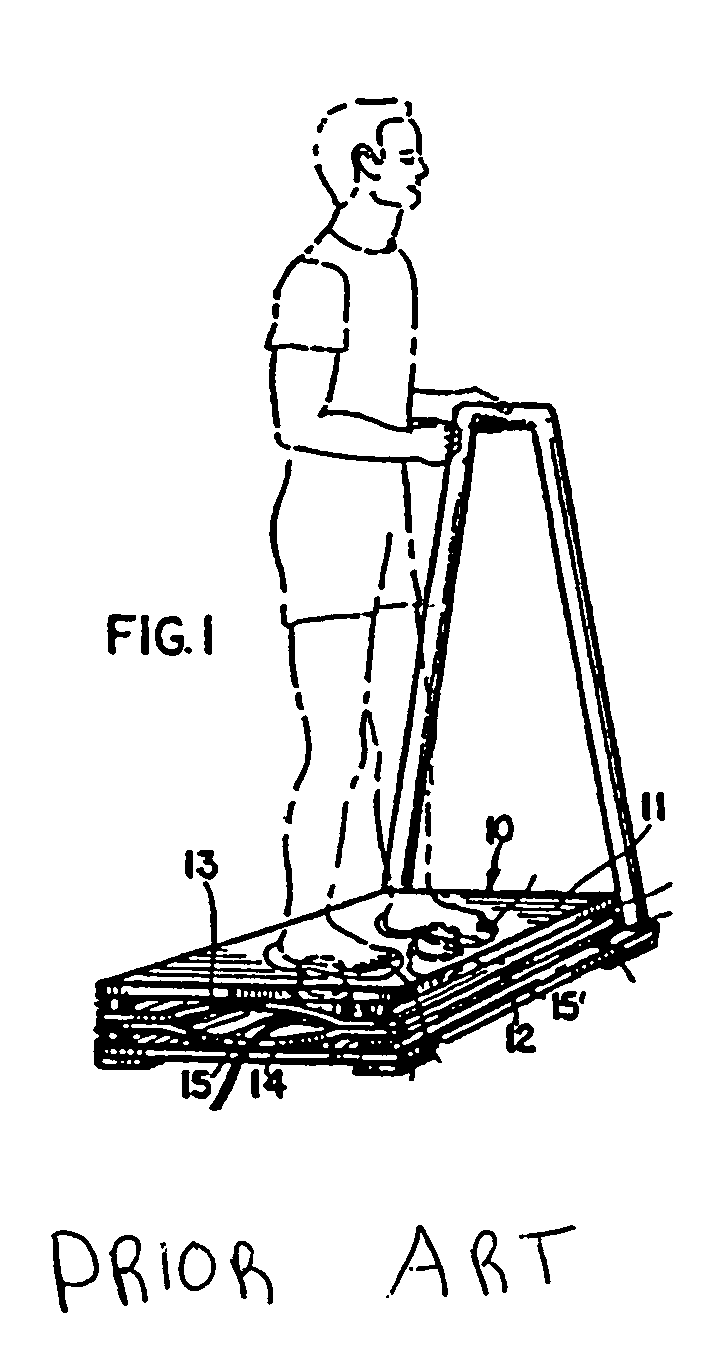

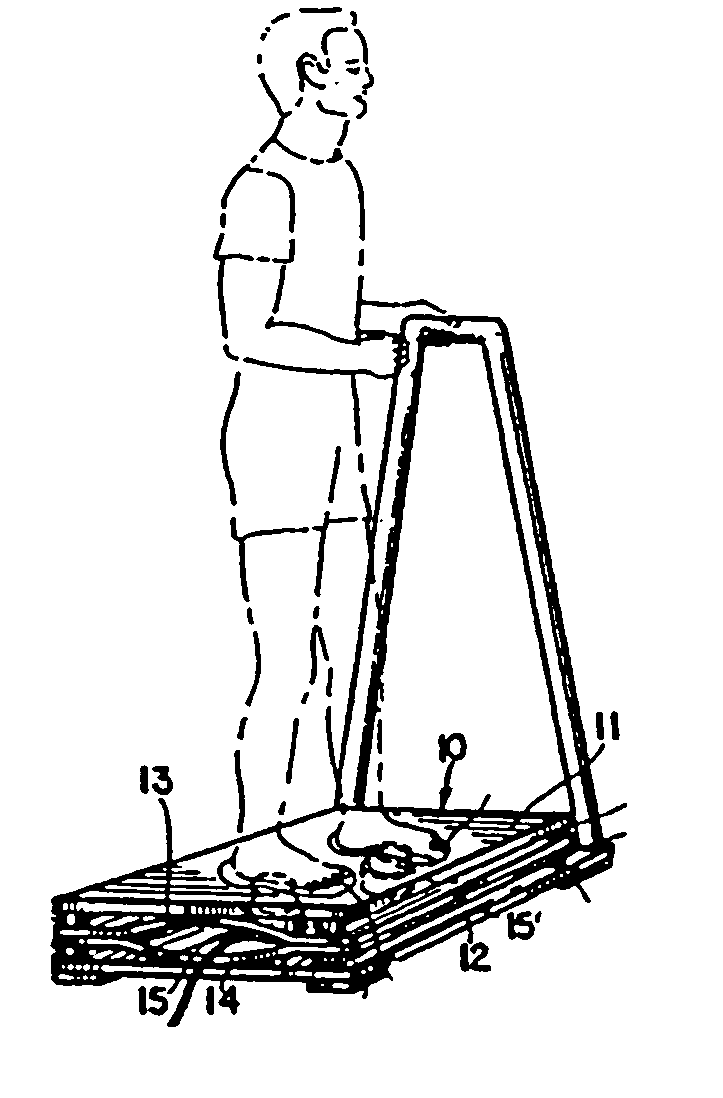

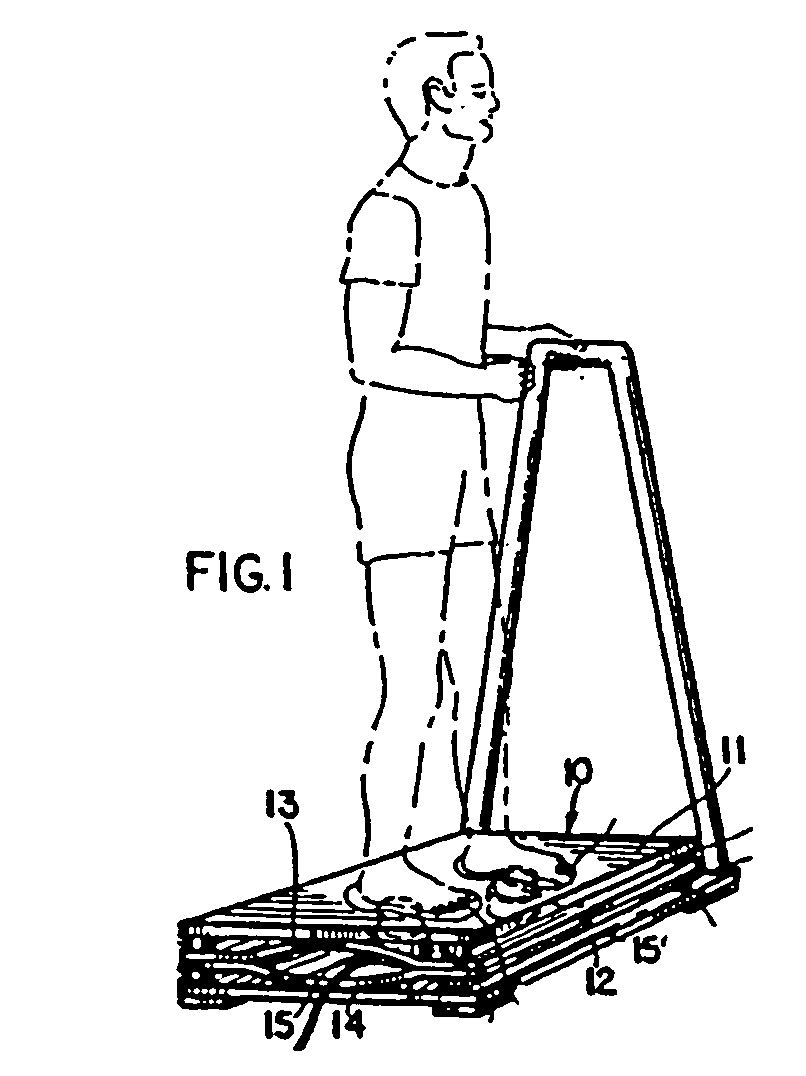

Exercise equipment utilizing mechanical vibrational apparatus

InactiveUS7166067B2Convenient timePatient compliance is goodChiropractic devicesVibration massageTherapeutic DevicesSports equipment

A therapeutic device, such as an exercise device, includes the principles of osteogenic repair by incorporating a vibrational loading mechanism into the exercise device. By doing so, the therapeutic device provides an increased osteogenic effect, thereby enhancing the benefits of the therapy. As an example, an exercise device includes a support surface for supporting all or part of the bodily tissue of an individual using the device. A linear or rotary vibrational loading mechanism associated with the frame or a rotational element of the exercise device drives the support surface at a selected load and frequency, thereby inducing mechanical loading of bodily tissue adjacent to the support surface sufficiently to facilitate the growth, development, strengthening, and / or healing of bone tissue. The vibrational loading mechanism may be incorporated into any exercise device, including standard exercise devices such as rowing machines, stair climbing machines, elliptical trainers, bicycles, cross-country ski trainers, treadmills, or weight trainers.

Owner:AMERICAN MEDICAL INNOVATIONS LLC

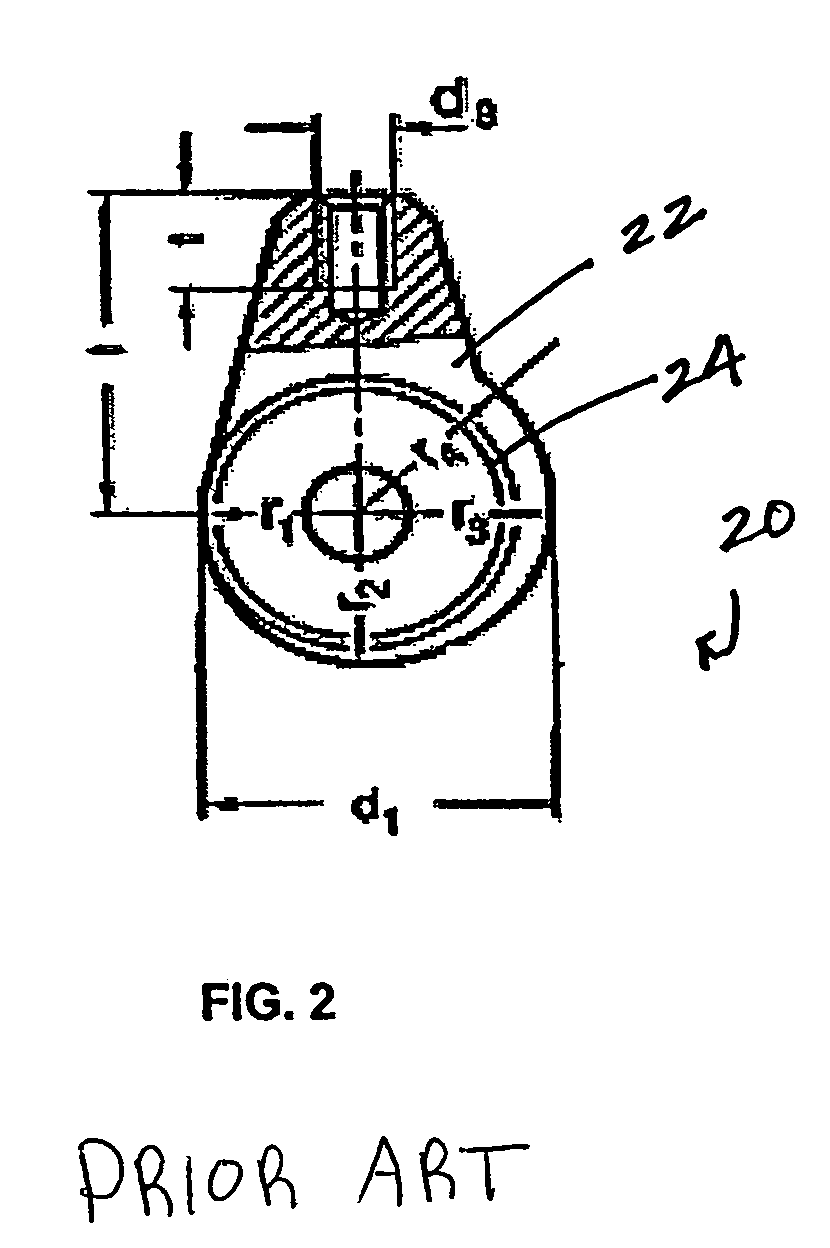

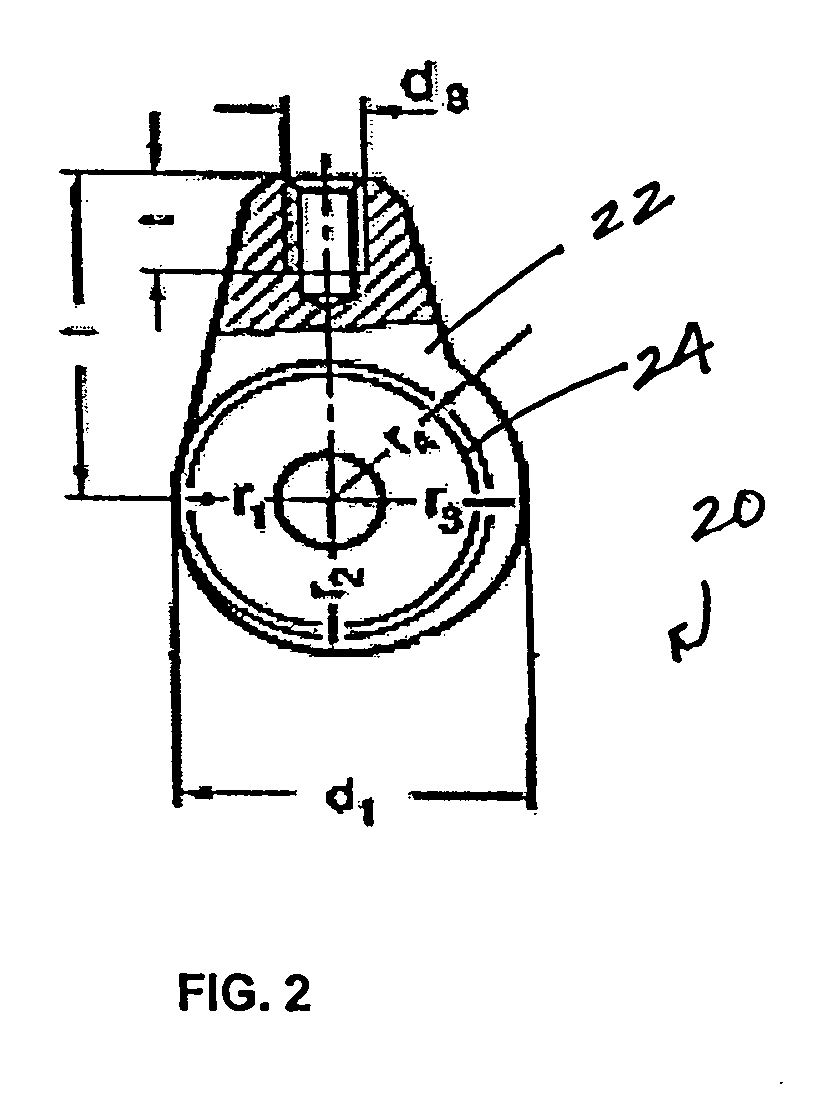

Vibrational loading apparatus for mounting to exercise equipment

InactiveUS20050165332A1Enhanced osteogenic propertiesConvenient timeChiropractic devicesVibration massageTherapeutic DevicesBone tissue

A therapeutic device, such as an exercise device, includes the principles of osteogenic repair by incorporating a loading mechanism into the exercise device. By doing so, the therapeutic device provides an increased osteogenic effect, thereby enhancing the benefits of the therapy. As an example, a exercise device includes a support surface for supporting all or part of the bodily tissue of an individual using the device. A linear or rotary loading mechanism associated with the frame or a rotational element of the exercise device drives the support surface at a selected load and frequency, thereby inducing mechanical loading of bodily tissue adjacent to the support surface sufficiently to facilitate the growth, development, strengthening, and / or healing of bone tissue. The loading mechanism may be incorporated into any exercise device, including standard exercise devices such as rowing machines, stair climbing machines, elliptical trainers, bicycles, cross-country ski trainers, treadmills, or weight trainers.

Owner:AMERICAN MEDICAL INNOVATIONS LLC

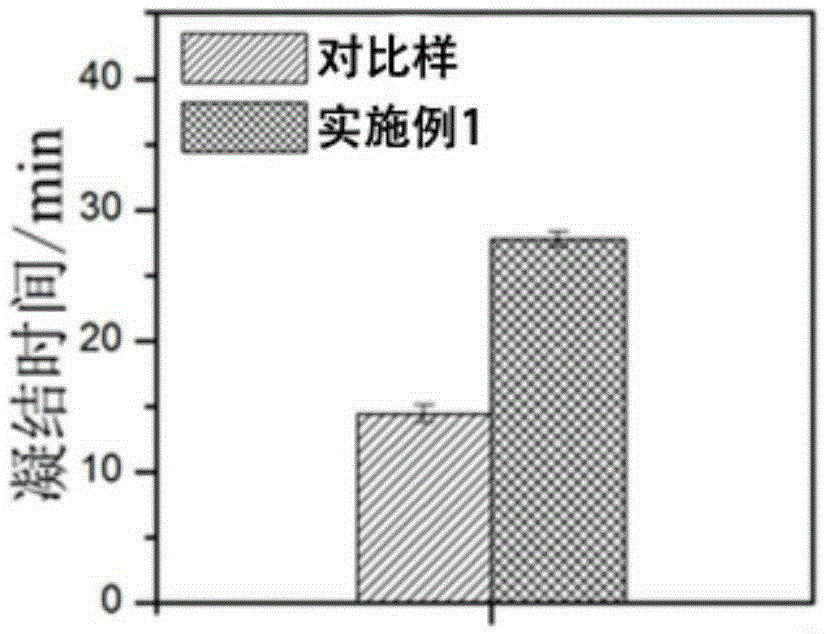

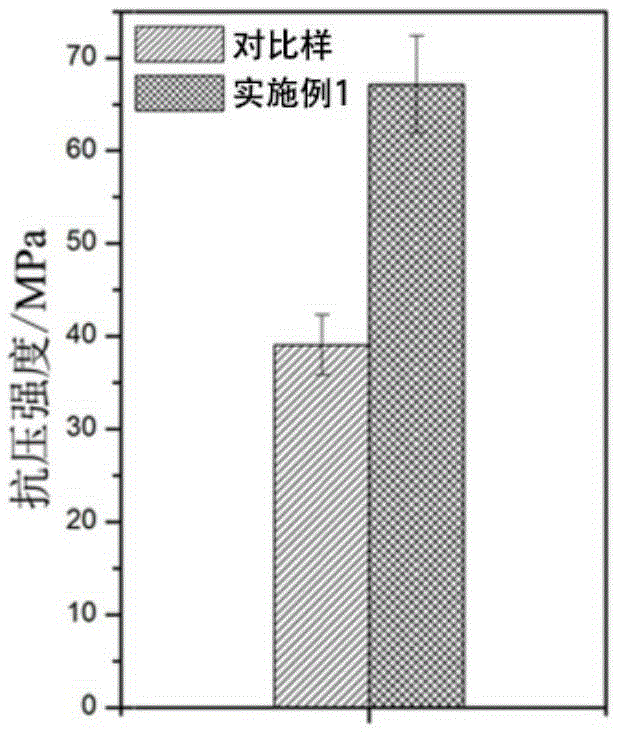

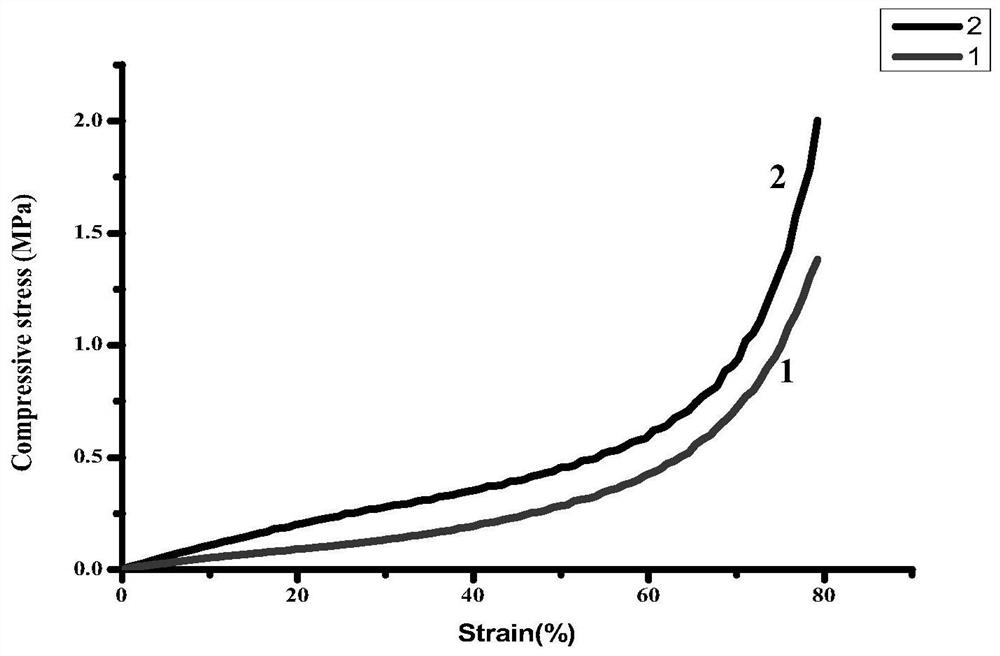

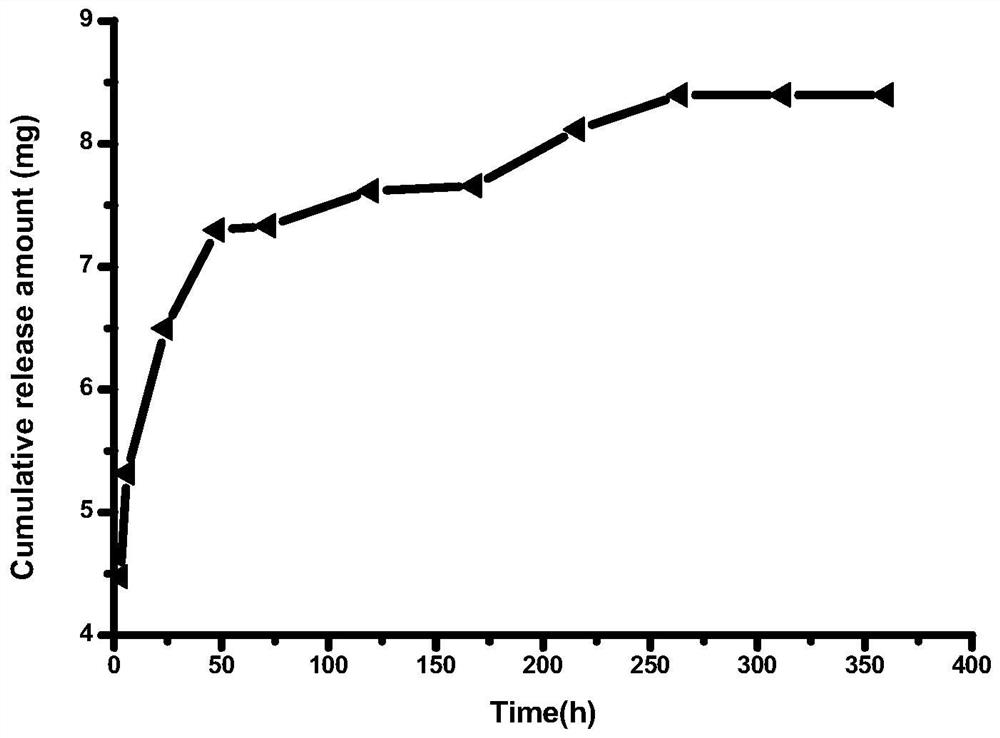

Preparation method of calcium phosphate bone cement simultaneously releasing zinc ions and silicate ions

ActiveCN105311680AEnhanced osteogenic propertiesGood osteogenic propertiesProsthesisCalcium biphosphateInorganic salts

The invention discloses a preparation method of calcium phosphate bone cement simultaneously releasing zinc ions and silicate ions. The preparation method comprises the following steps that (1) calcium phosphate bone cement powder, inorganic salt containing zinc ions and inorganic salt containing silicate ions are mixed evenly to obtain the calcium phosphate bone cement containing zinc and silicon elements, namely a solid phase; (2) the solid phase cement obtained through the step (1) and a liquid phase are blended, wherein the mass ratio of the liquid phase volume to the solid phase powder is 0.3-0.6 mL / g. The zinc ions and the silicate ions are simultaneously added into the calcium phosphate bone cement for the first time, the calcium phosphate bone cement has the advantages of having high mechanical strength and appropriate setting time and being capable of continuously releasing the zinc ions and silicate ions for a long time and controllable in release amount, and meanwhile the two different types of released functional ions can play roles of synergistically inhibiting bone absorption and promoting bone repair. Compared with traditional calcium phosphate bone cement, the calcium phosphate bone cement has more excellent bone defect repairing effect and wider clinical application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Chitin whisker/magnesium oxide whisker/biodegradable polyester composite material as well as preparation method and application thereof

ActiveCN105504715AImprove performanceGood toughening effectMagnesiaBiocompatibility TestingSynthetic Polymeric Macromolecules

The invention belongs to the field of composite materials and discloses a chitin whisker / magnesium oxide whisker / biodegradable polyester composite material as well as a preparation method and an application thereof. The composite material comprises the following components in percentage by weight: 0.1-20% of chitin whisker, 0.1%-20% of magnesium oxide whisker and 60-99.8% of biodegradable polyester, wherein the chitin whisker is a natural high polymer polysaccharide whisker, the magnesium oxide whisker is an inorganic whisker, and biodegradable polyester is a class of synthetic high polymers. The ternary composite material is skillfully integrated with the advantages of a natural high polymer material, a synthetic high polymer material and an inorganic material; by adjusting the mass ratio of the chitin whisker to the magnesium oxide whisker, the reinforcing and toughening effects which are superior to the reinforcing and toughening effects of single chitin whisker or magnesium oxide whisker to a biodegradable polyester matrix can be obtained; and furthermore, a poly-dopamine layer modified on the surface of the whisker has excellent biocompatibility and osteogenic activity and can endow the composite material with relatively ideal bone tissue healing promoting capacity.

Owner:JINAN UNIVERSITY

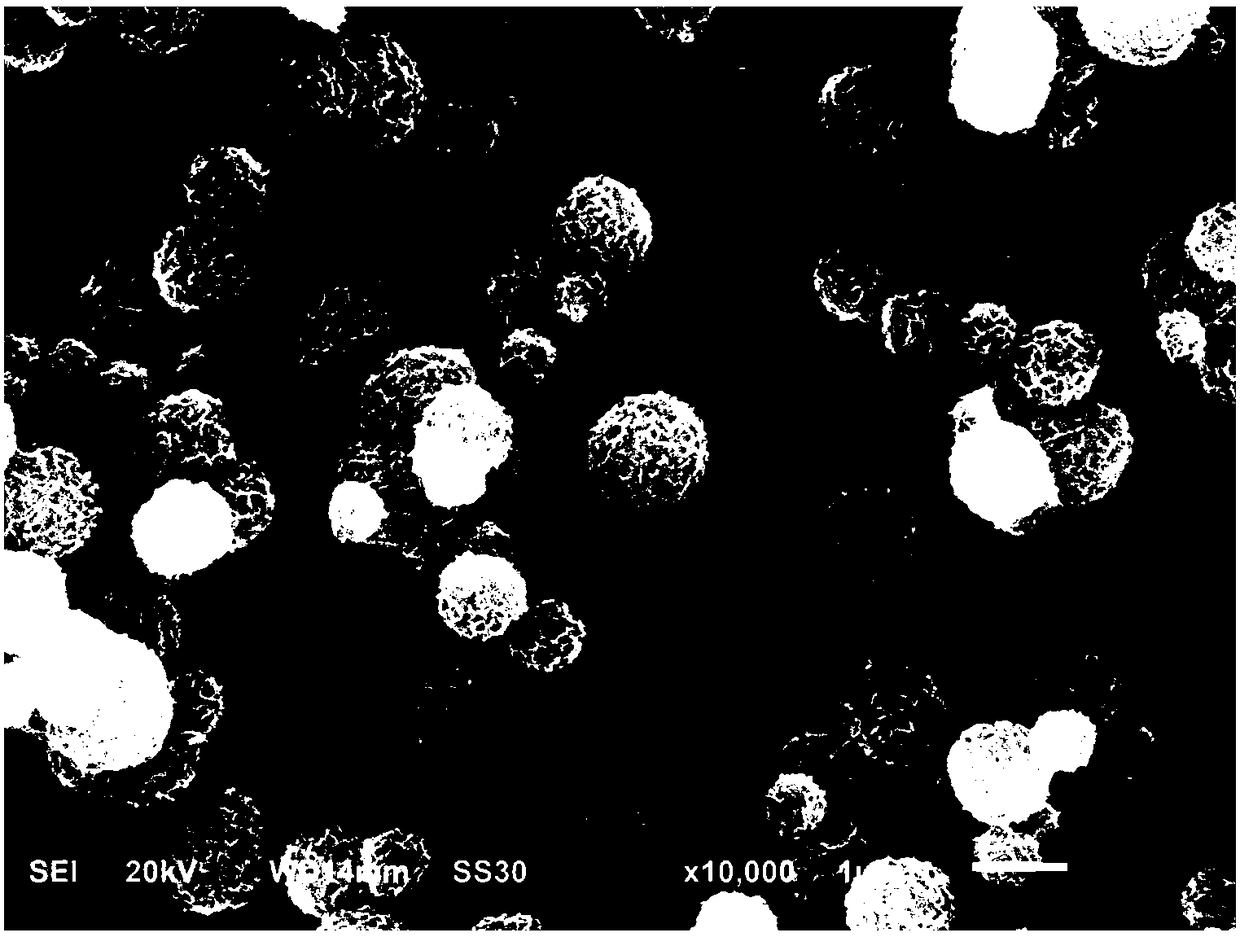

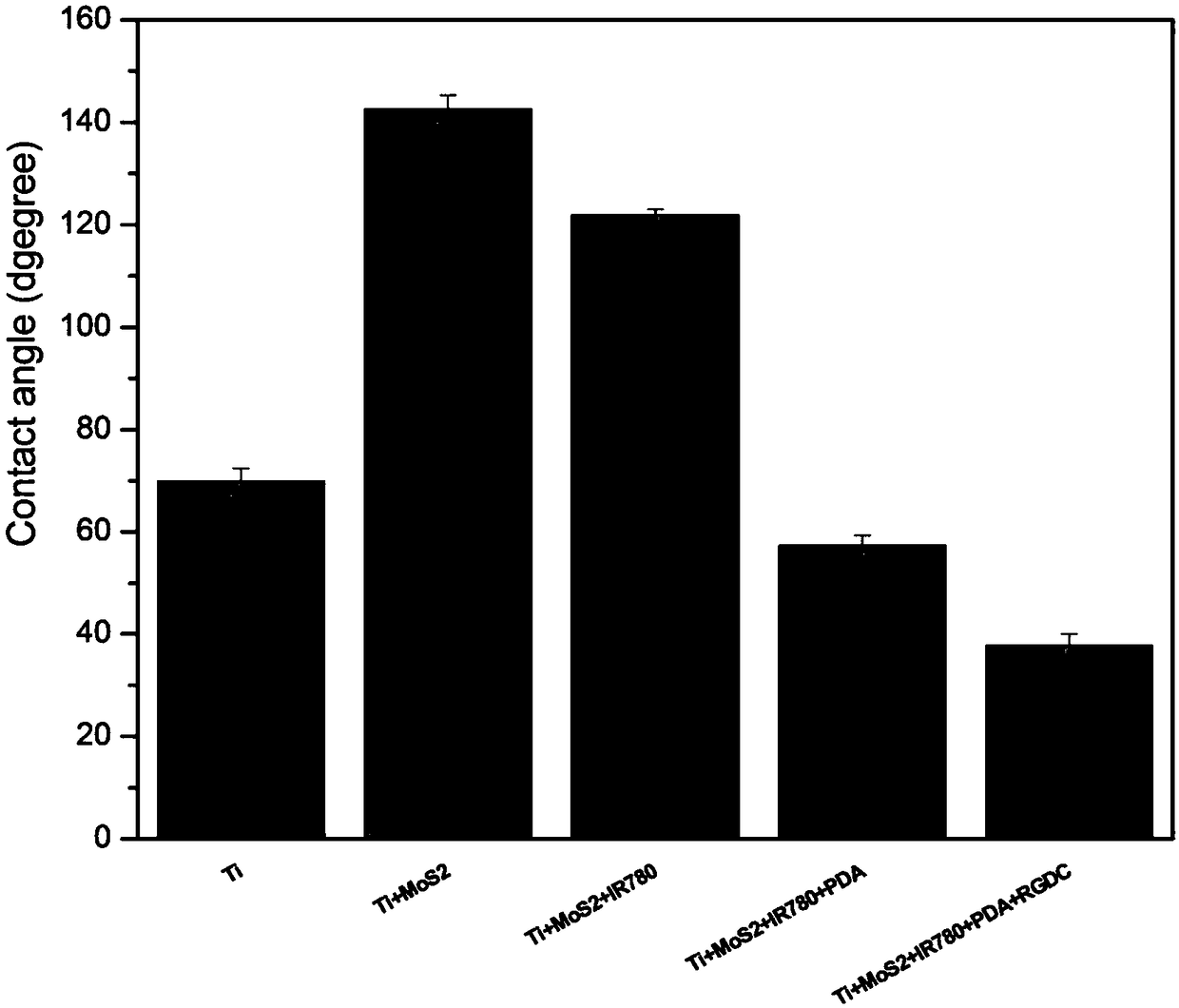

Preparation method of nano antibacterial coating based on molybdenum disulfide and photosensitizer near-infrared optical response

ActiveCN108392675ASimple processLow costPharmaceutical delivery mechanismLiquid/solution decomposition chemical coatingPhotosensitizerBiocompatibility Testing

The invention discloses a preparation method of a nano antibacterial coating based on molybdenum disulfide and photosensitizer near-infrared optical response. The preparation method specifically comprises the following steps: polishing a titanium sheet to remove dirt; preparing a molybdenum disulfide nano coating with near-infrared photo-thermal antibacterial performance by applying a photo-thermal method; dropwise adding a photosensitizer IR780 to enable the photosensitivity of the IR780 and the photo-thermal performance of molybdenum disulfide to generate a cooperative antibacterial effect;covering a titanium surface with the photosensitizer IR780 through a self-polymerized membrane by utilizing dopamine and grafting a polypeptide RGDC to obtain the coating. The coating has relatively good biocompatibility and osteogenesis; the method has a simple preparation process and low cost; the prepared coating can be used for extremely improving the antibacterial performance of implants in bodies, damages caused by secondary pollution can be reduced under the condition of short-time near-infrared light illumination and organisms are repaired; harms caused by the fact that antibiotics arerepeatedly used for resisting bacteria are reduced; the polypeptide RGDC is used so that the biocompatibility of the implants is better and the occurrence of infection is reduced.

Owner:HUBEI UNIV

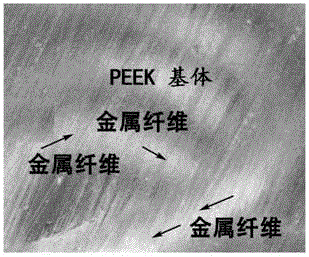

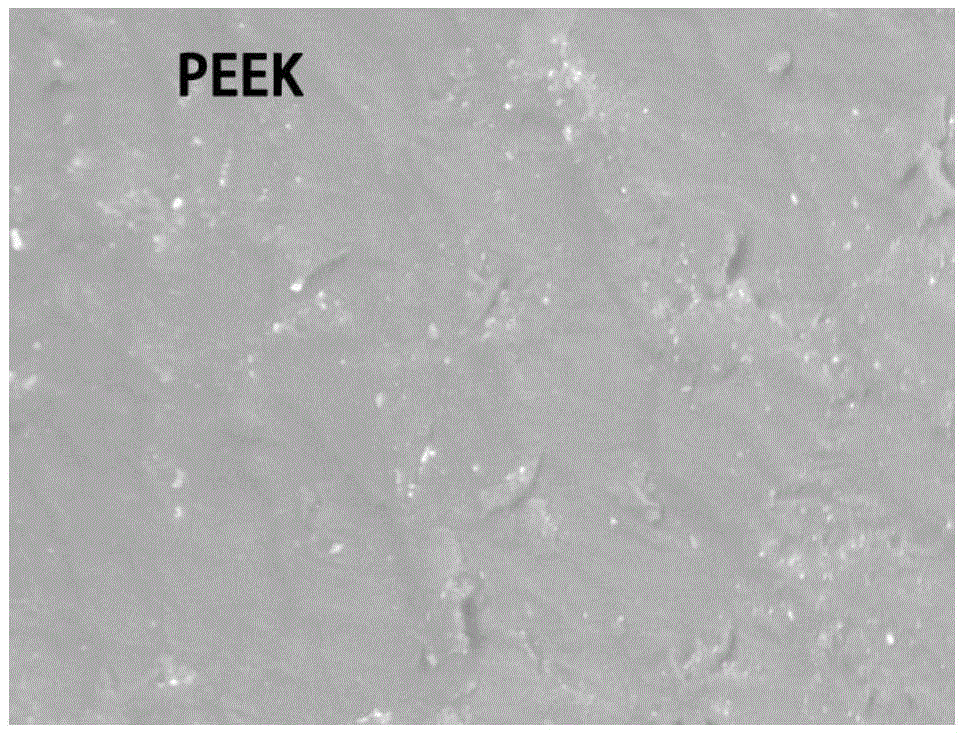

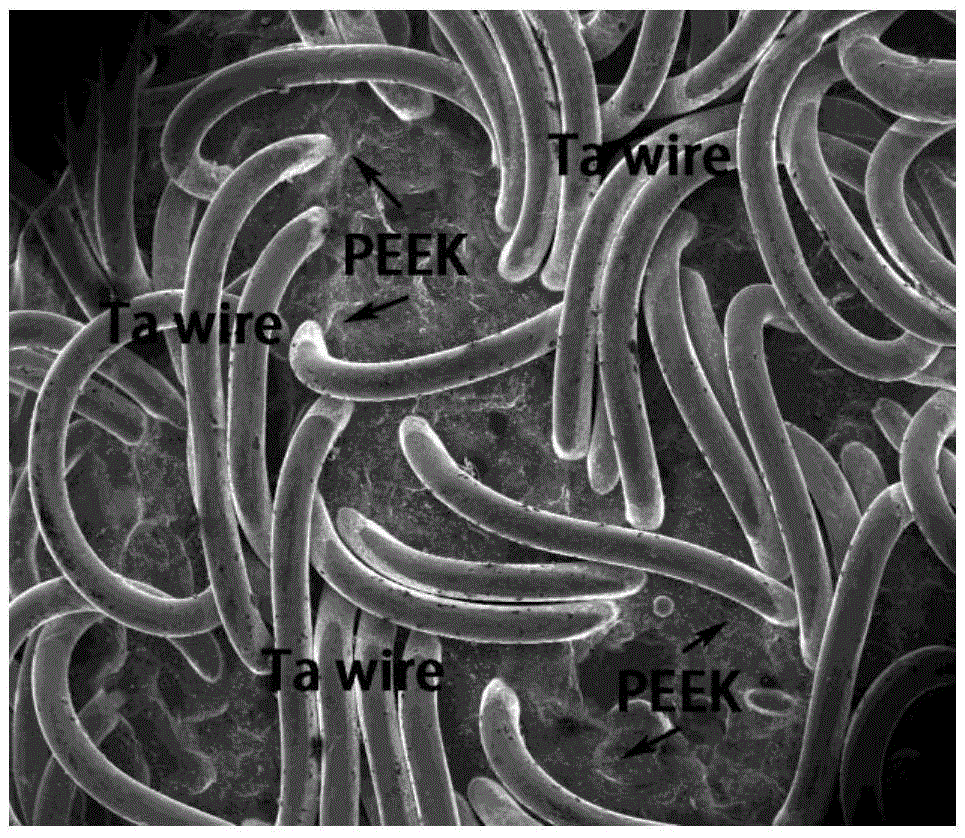

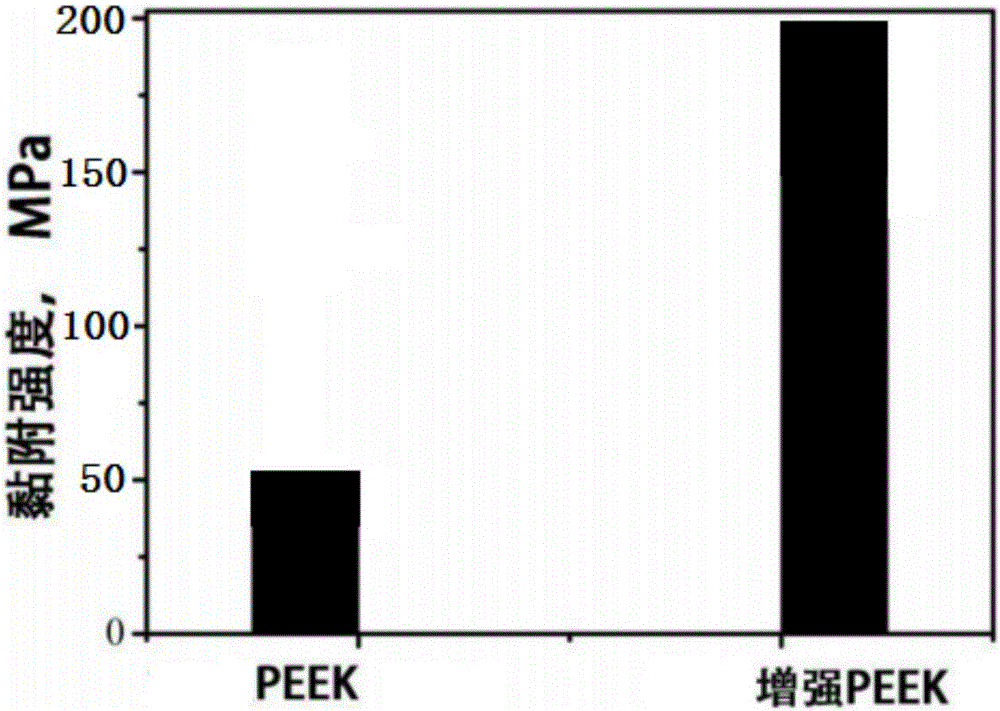

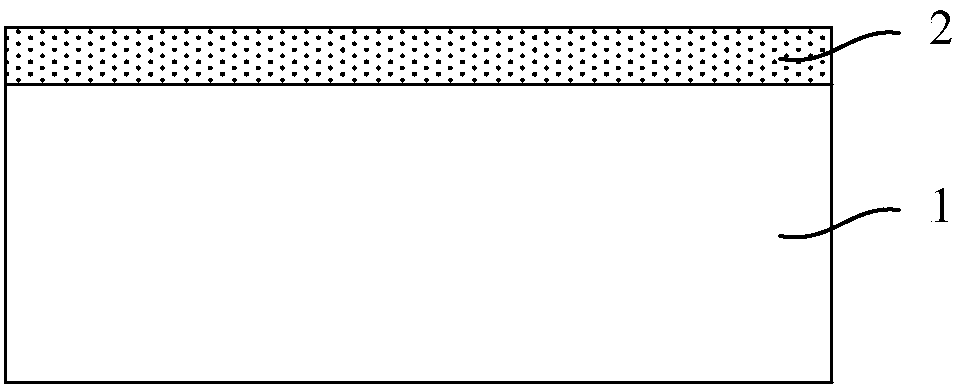

Method for improving surface bioactivity of polyether ether ketone

InactiveCN105536068AImprove biological activityEasy transferPharmaceutical delivery mechanismTissue regenerationDiseasePoly ether ether ketone

The invention provides a method for improving surface bioactivity of polyether ether ketone (PEEK). The method is characterized in that in a PEEK preparation process or a PEEK re-formation process, a porous metal layer with excellent biocompatibility is embedded in the surface of PEEK, thereby obtaining a porous fiber / PEEK composite material; the structure of the composite material is that the surface is a bioactivity coating, and the base is a composite material of the metal porous layer and the PEEK. The method provided by the invention integrates PEEK surface modification and PEEK preparation; the method is simple and has low requirements on instruments. The prepared novel composite material has excellent performances, the bioactivity of the PEEK is improved, bone conduction and body fluid transmission are facilitated, the mechanical property and osteogenesis efficiency are improved, and the prepared composite material has stronger binding force between the porous metal layer and the PEEK so as to meet most application requirements, such as bone filling, bone repair, bone transplantation and bone fixation, and in particular the composite material can be applied to bone transplantation under loading conditions, such as interbody fusion cage, vertebral replacement, femoral head diseases, acetabular cup, fixing bolt and fixing plate.

Owner:SHANGHAI JIAO TONG UNIV

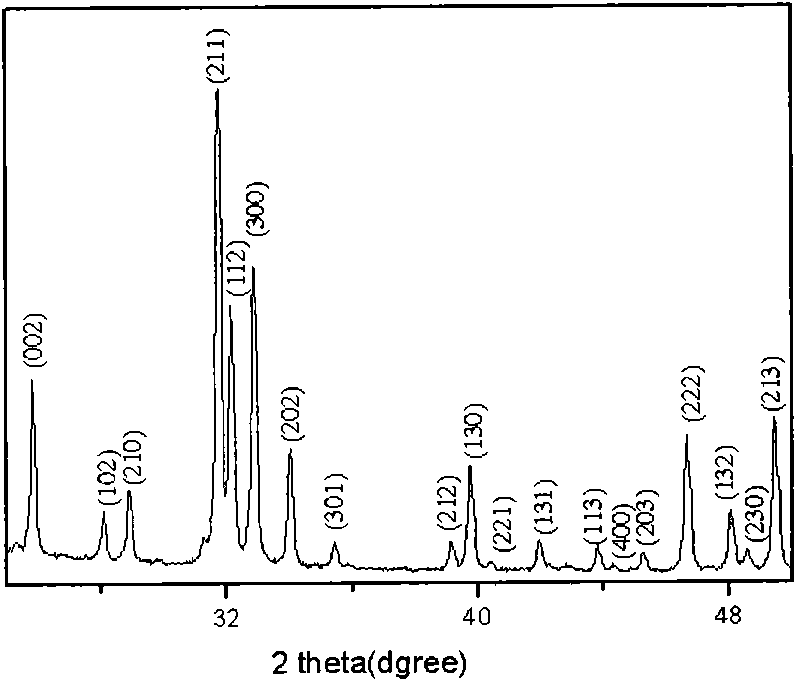

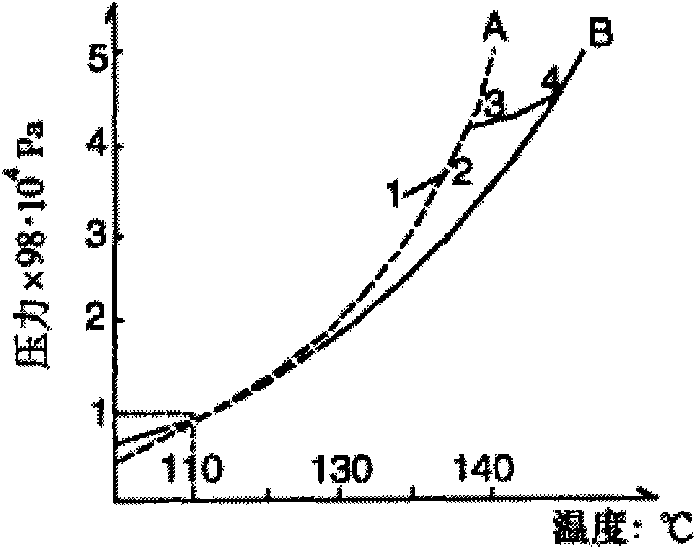

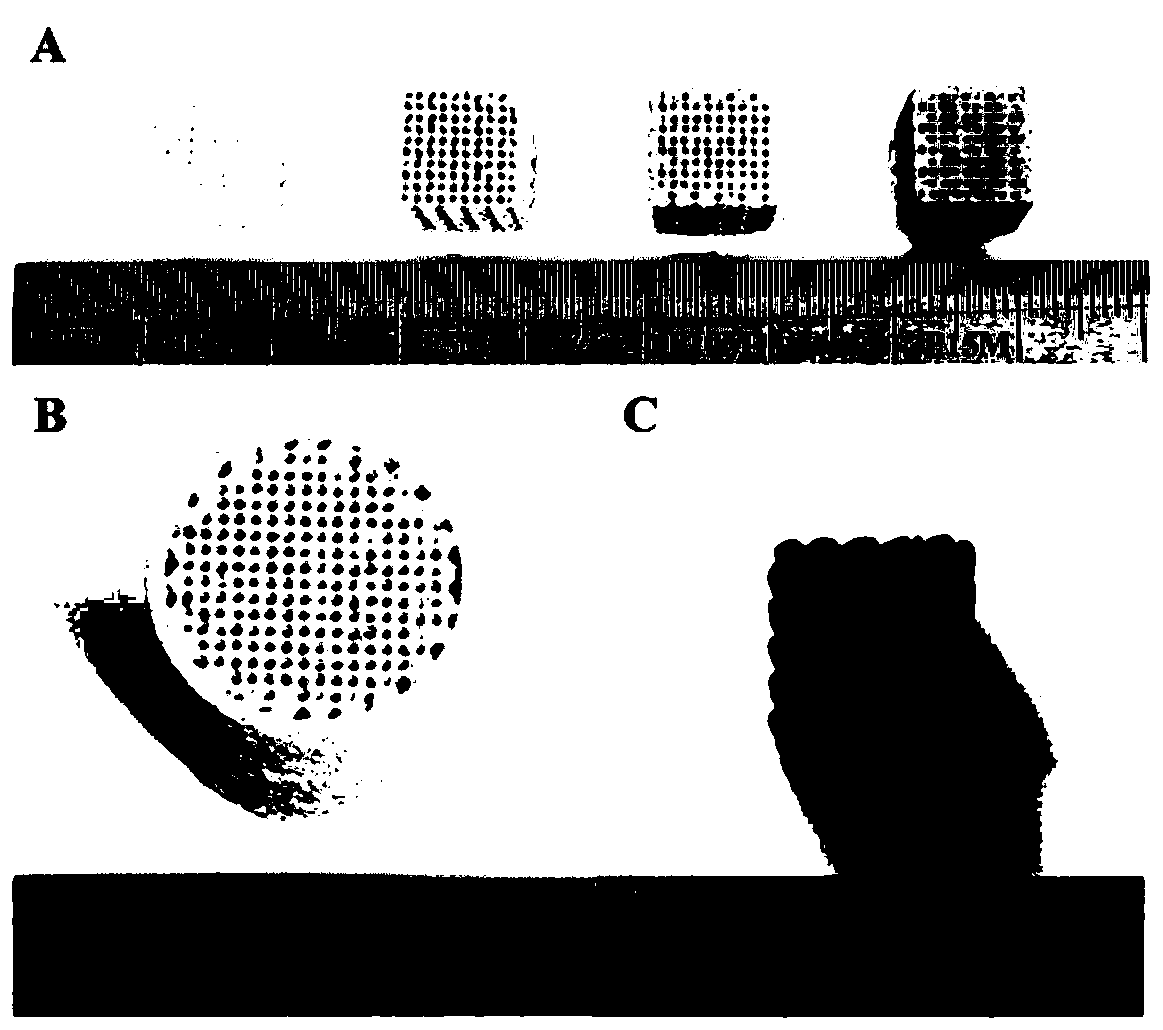

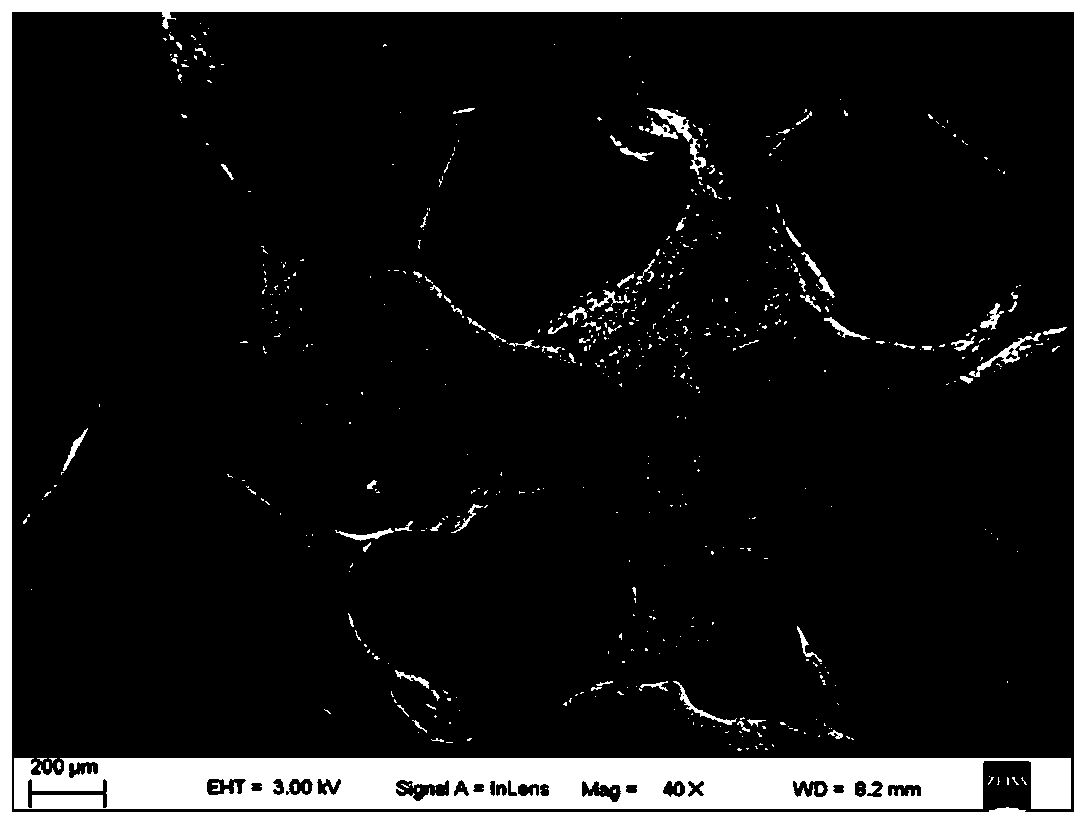

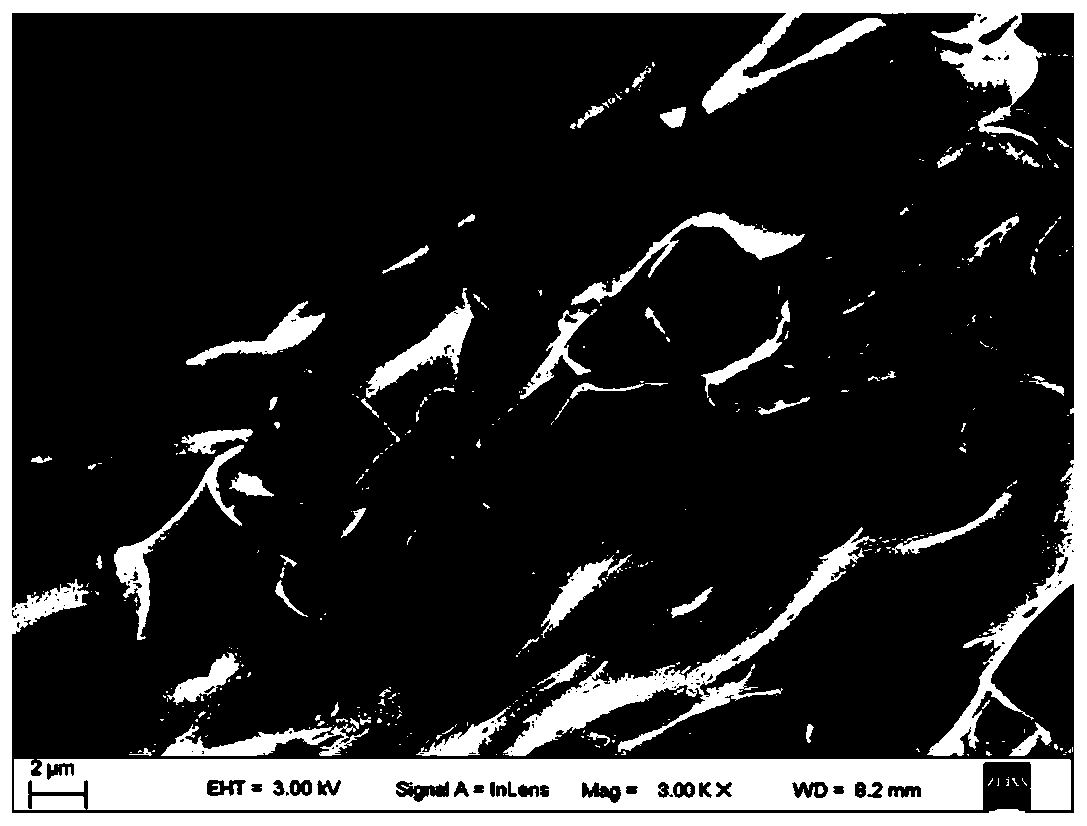

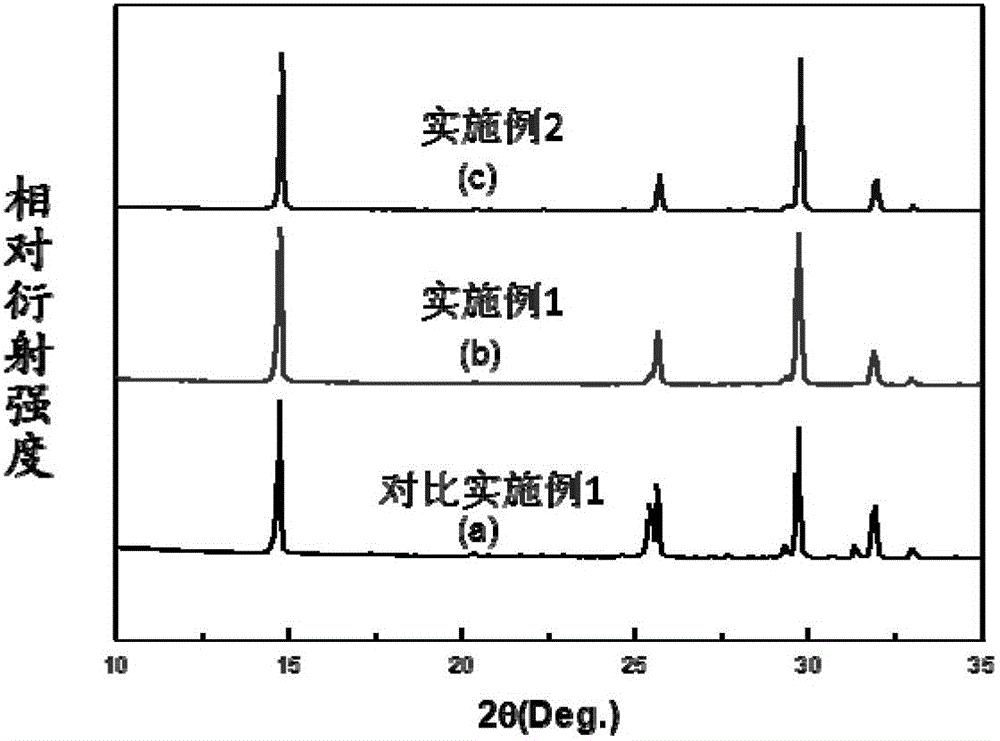

Alpha-calcium sulfate hemihydrates/beta-tertiary calcium phosphate porous granular-type composite artificial bones and preparation method thereof

The invention discloses a method for preparing alpha-calcium sulfate hemihydrates (alpha-CSH) / beta-tertiary calcium phosphate (beta-TCP) porous granular-type composite artificial bones, which is characterized in that the alpha-CSH is directly synthesized on the surface and / or in the pores of the beta-TCP granules synchronously by the hydrothermal synthesis process and finally the alpha-CSH / beta-TCP porous granular-type artificial bones is prepared. The invention has the advantages that the preparation process is simpler, the preparation period can be effectively reduced, and the preparation efficiency is improved; the proportion between alpha-CSH and beta-TCP phases of the granular-type composite artificial bones can be effectively controlled, thereby controlling the pore structure of the artificial bone granules; meanwhile, the invention guarantees the in-situ solidifying performance and degrading performance of the composite artificial bones, controls the evenness of the product and the porosity and pore diameter of the beta-TCP granules, improves the bone-formation performance and degrading performance of the composite artificial bones and further improves the quality of the product, thereby finally obtaining the composite artificial bones having self-solidifying performance and controllable degradation and having a certain biomechanical strength. The invention has good application and market prospect.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

Photothermal bone repair material for treating osteosarcoma and application of photothermal bone repair material

ActiveCN110302421AFacilitate depositionPromote proliferationEnergy modified materialsTissue regenerationMetal particleAluminum metal

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Preparation method and uses of biodegradable high mechanical strength organic/inorganic composite hydrogel

ActiveCN103087455AIncrease elasticityHigh breaking strengthElectrolytic coatingsPre irradiationPolyvinyl alcohol

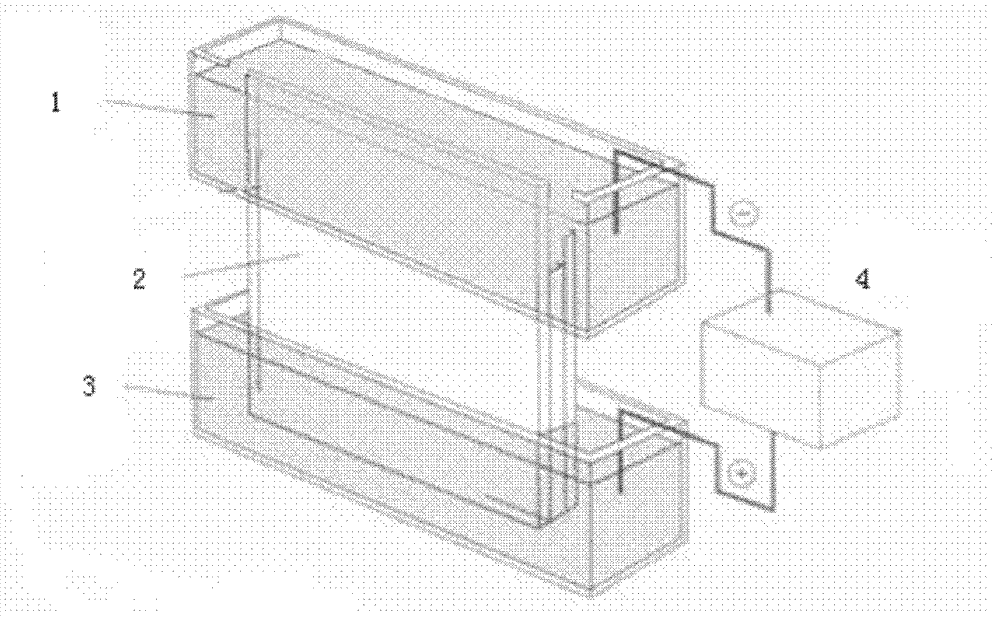

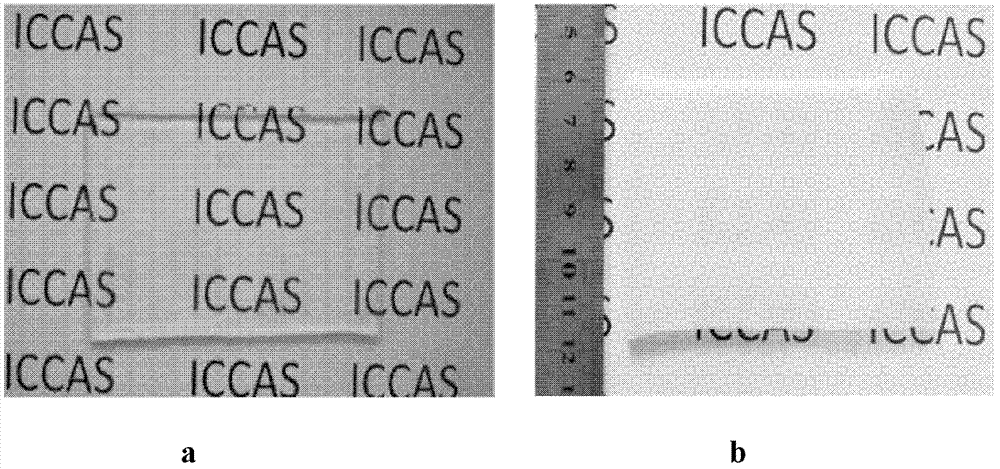

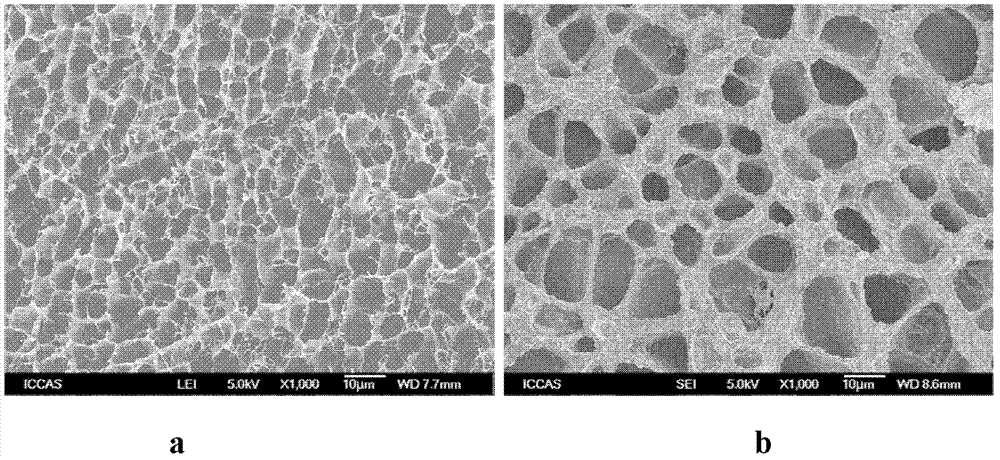

The present invention relates to a preparation method and uses of a composite hydrogel containing hydroxyapatite (HAP) nanoparticles, wherein an inorganic component in the composite hydrogel is HAP nanoparticles prepared in an in situ manner, an organic matrix in the composite hydrogel is an overoxidation micelle (pMIC) polyacrylamide gel prepared by using a pre-irradiation method, an overoxidation linear polymer chain polyacrylamide gel or a polyvinyl alcohol gel, and a mass ratio of the HAP to the polymer in the composite hydrogen is 1:5-1:3. According to the present invention, a freezing-defrosting circulation method is adopted to treat a gel, and an electrophoresis method is adopted to generate HAP nanoparticles inside the gel in an in situ manner, such that the HAP nanoparticles are uniformly dispersed in the gel, and HAP having a hollow sphere structure is obtained so as to enhance mechanical property and improve biological activity, such that potential application values in articular cartilage repair and tissue engineering materials are provided.

Owner:INST OF CHEM CHINESE ACAD OF SCI

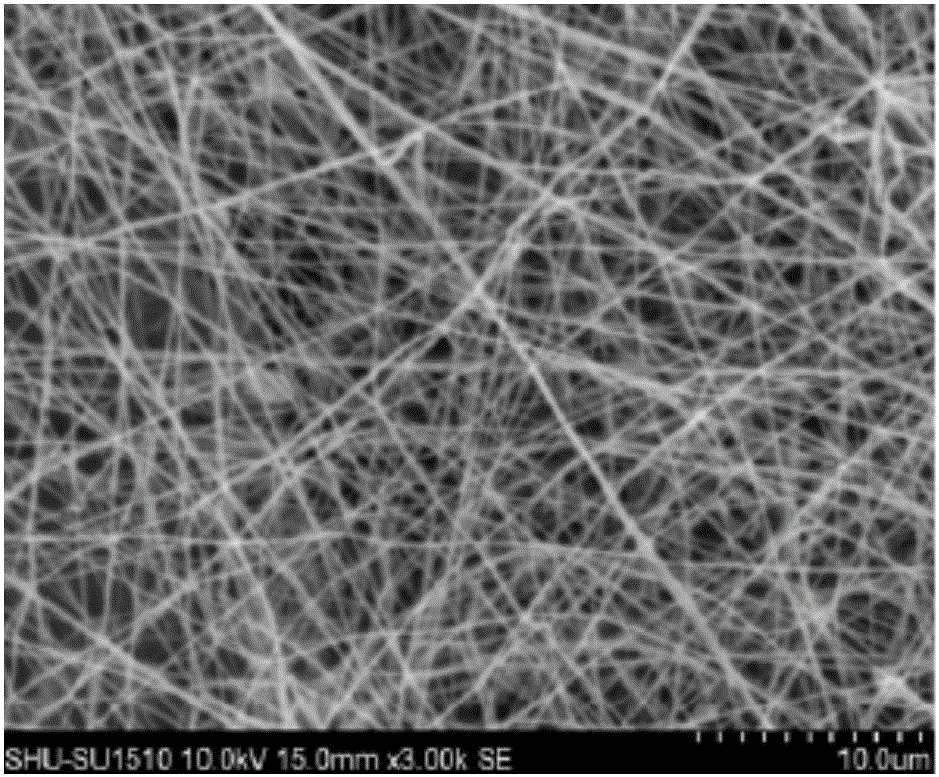

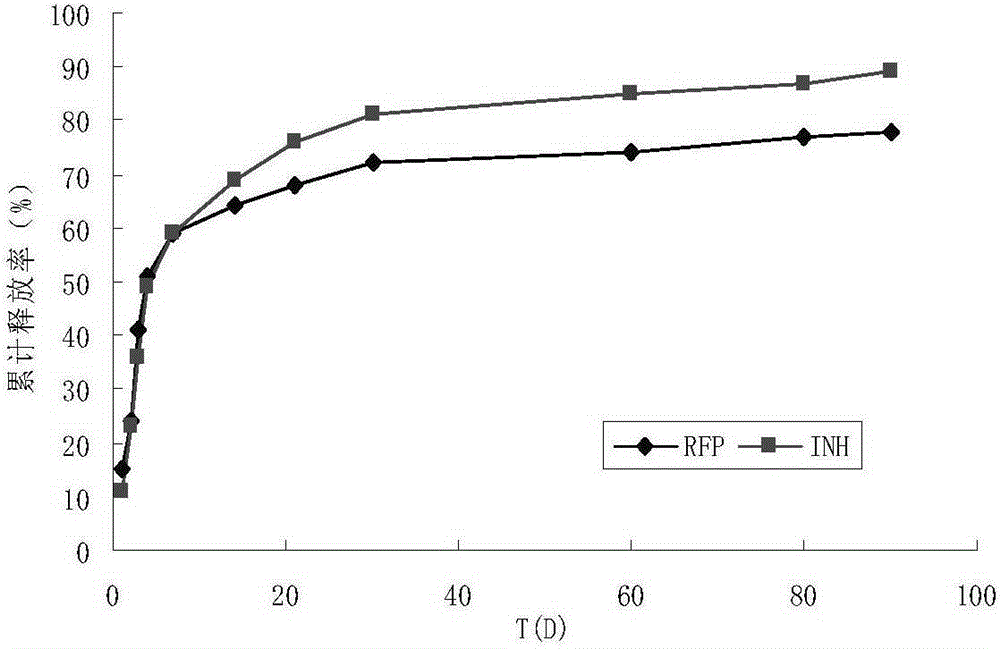

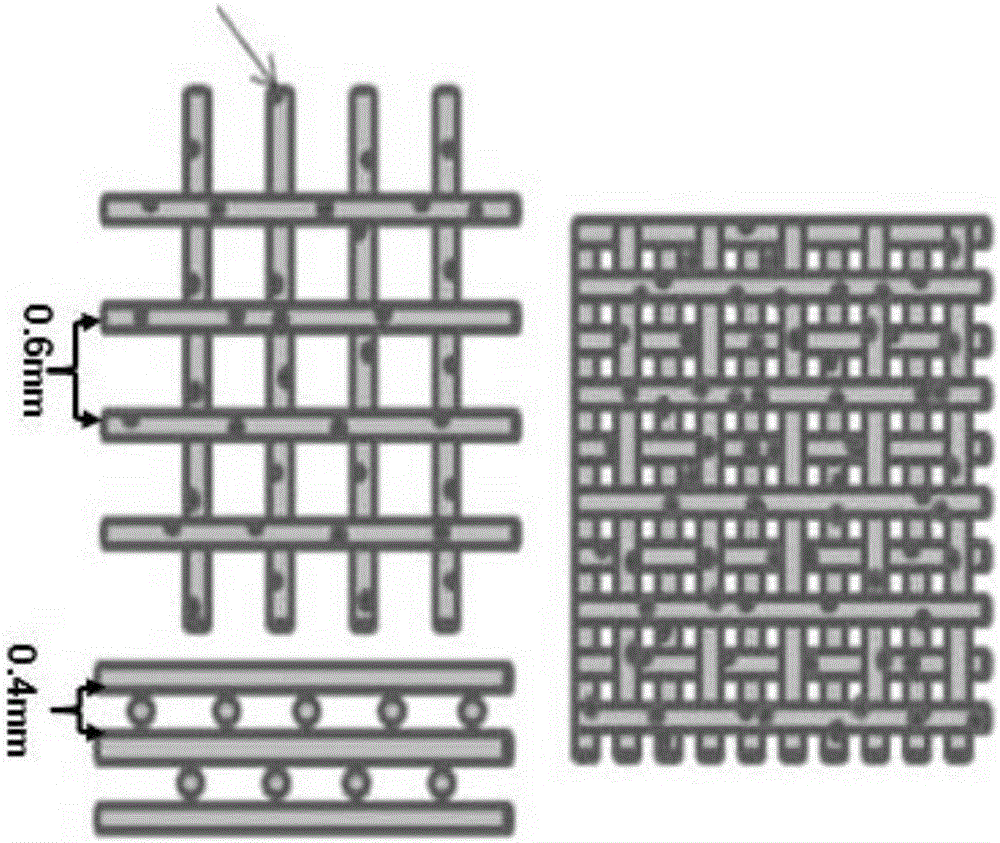

Bone tissue engineering stent and preparation method thereof

InactiveCN105268027AGood biocompatibilityEnhanced osteogenic propertiesAdditive manufacturing apparatusProsthesisAntituberculosis drugBone formation

The invention relates to a bone tissue engineering stent and a preparation method thereof. The bone tissue engineering stent is prepared from PLGA, isoniazide, rifampicin, allogeneic bone power and bone morphogenetic protein at the weight ratio of (87-51) to (1-6) to (1-6) to (10-30) to (1-7); according to the bone tissue engineering stent, polylactic acid-hydroxyacetic acid material, allogeneic bone power, antituberculosis drugs and bone morphogenetic protein are combined by adopting a 3D printing technology, a bioactive stent is manufactured by adopting the 3D printing technology, the physical, chemical and biological properties of the stent are detected, and the bone tissue engineering stent has the good biocompatibility and the good bone-formation promotion capacity and is biodegradable.

Owner:TIANJIN HAIHE HOSPITAL

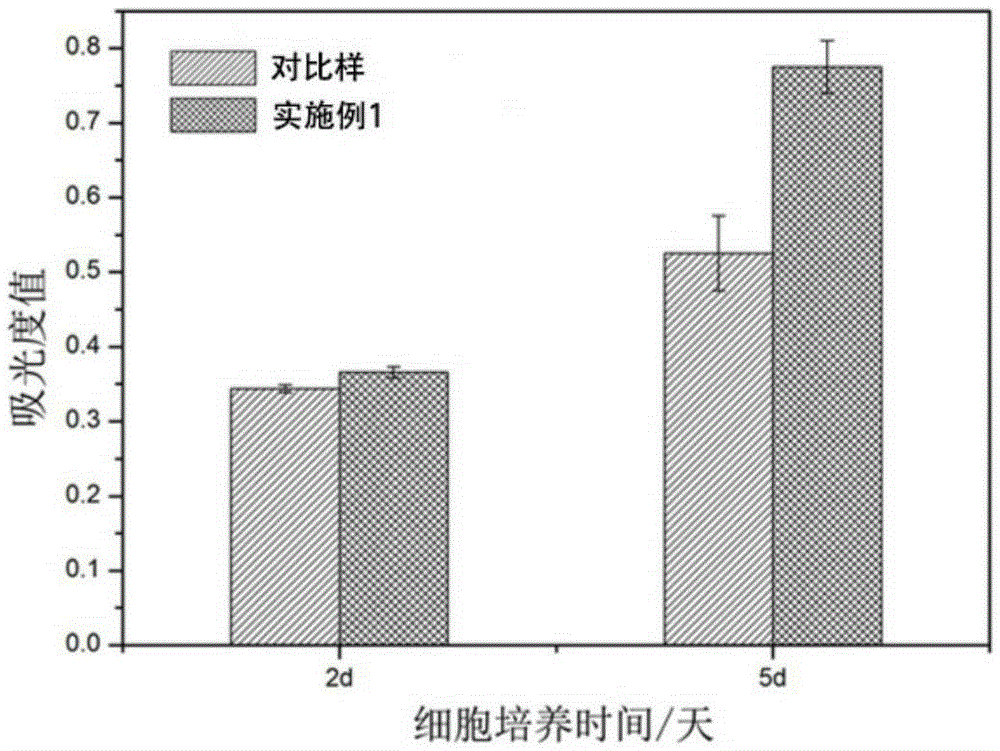

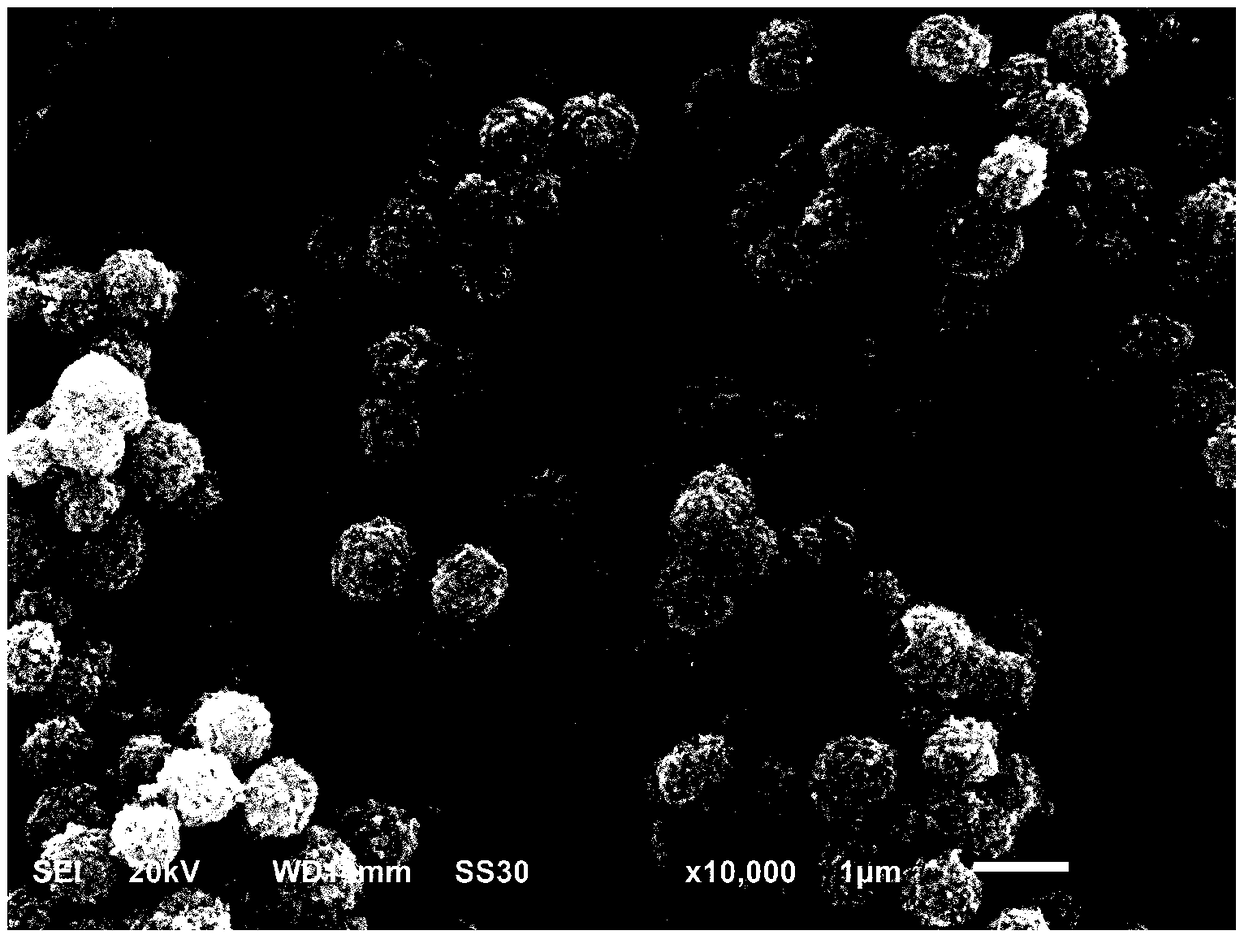

Preparation method of microcarrier used for cell three dimensional multiplication culture

InactiveCN107670113AGood biological propertiesHealthy growthPharmaceutical delivery mechanismTissue regenerationMicrosphereOsteoblast

The invention discloses a preparation method of a microcarrier used for cell three dimensional multiplication culture, and belongs to the field of tissue engineering material. According to the preparation method, Poly-L-lactic acid (PLLA) is taken as a matrix, gelatin is taken as a dispersant, and composite microspheres are prepared; the particle size of the composite microspheres is adjusted viacontrolling the concentration of a PLLA dichloromethane solution, the mass ratio of nano-hydroxyapatite (nHAp) to PLLA, and the using amount of gelatin; the PLLA is taken as the matrix to ensure the mechanical strength and biological degradability of a support; composite nHAp is capable of improving the osteo inductivity and the conductivity of the support, and at the same time, assisting PLLA toimprove cell osteogenic capability, and avoiding damage of cells under an overly acidic environment; the existing of nHAp is capable of forming a large amount of small pores on the surfaces of the PLLA microspheres, the existing of the small pores is capable of improving the mass transfer capability of the support, and providing cells with more abundant attachment sites. The microcarrier possessesexcellent biological performance on osteoblasts, and is suitable to be used in the field of bone tissue engineering.

Owner:DALIAN UNIV OF TECH

PEEK false tooth composite and preparation method thereof

The invention discloses a PEEK false tooth composite. The PEEK false tooth composite is prepared from, by weight, 110-150 parts of polyether-ether-ketone, 10-20 parts of nano calcium silicate, 8-12 parts of hydroxyl hydroxyapatites, 4-8 parts of barium glass short fibers, 15-22 parts of organic solvent, 8-18 parts of refined paraffin, 1-4 parts of co-binding agent, 8-12 parts of binder, 2-6 parts of antibacterial agent, 6-10 parts of carbide and / or 8-15 parts of oxide. The invention further discloses a preparation method of the PEEK false tooth composite. The preparation method includes the steps that firstly, the raw materials of nano calcium silicate, hydroxyl hydroxyapatites, carbide and / or oxide are mixed, the mixture is heated to 150-220 DEG C, the situation is kept for 10-30 min, cooling is carried out, the refined paraffin is added, mixing and stirring are carried out, and after the mixture is crushed ultrasonically, the organic solvent, polyether-ether-ketone, the co-binding agent, the binder and the antibacterial agent are added to be stirred till uniform paste is obtained; finally the barium glass short fibers are added, ball-milling and drying are carried out, and the finished composite powder is obtained.

Owner:广西深雅医疗科技股份有限公司

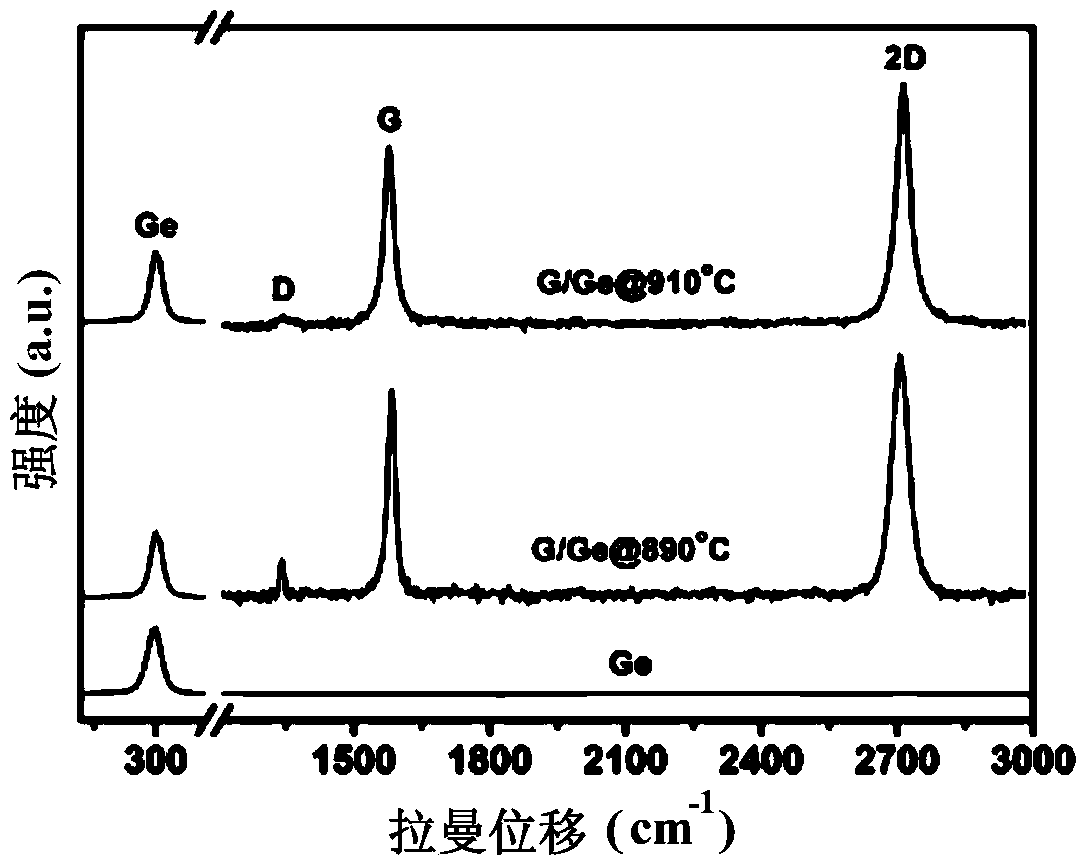

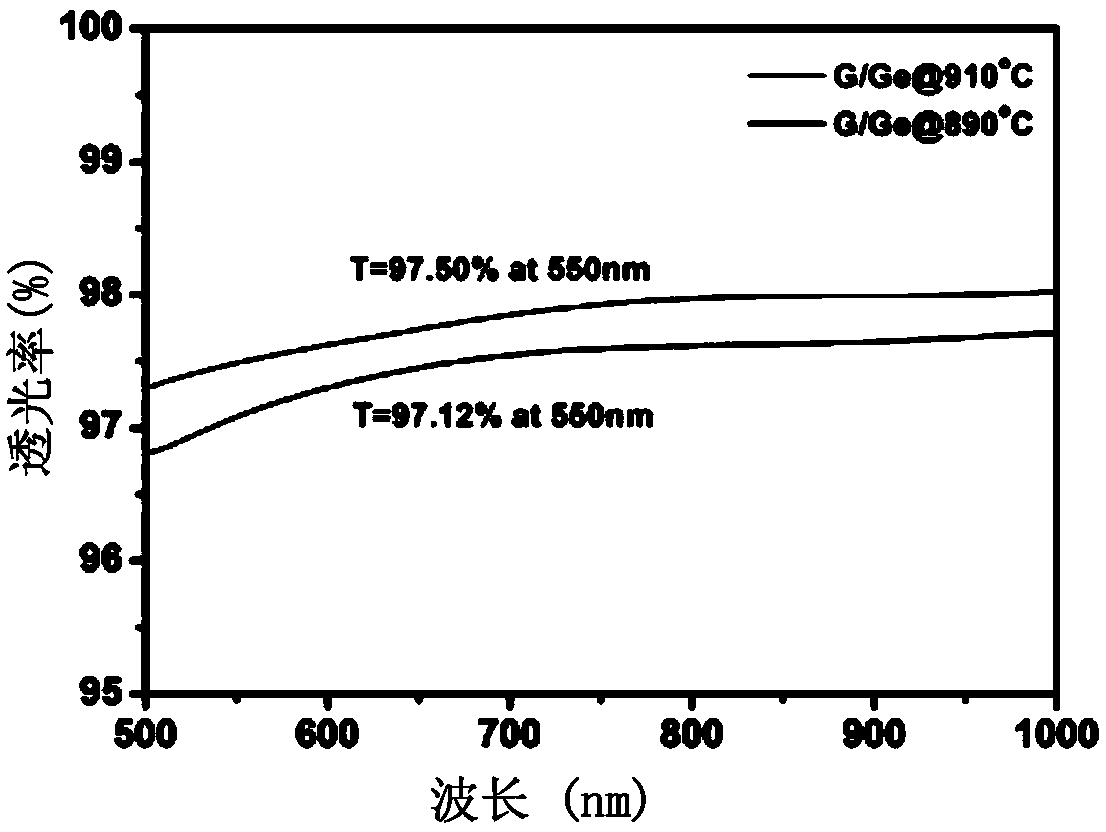

Application of germanium-based graphene in osteogenesis promotion

InactiveCN103820387APromote differentiationPromote osseointegrationCarbon active ingredientsSkeletal disorderHuman bodyOsseointegration

The invention provides application of germanium-based graphene in osteogenesis promotion. Germanium-based graphene can obviously promote the early alkaline phosphatase expression and late osteocalcin expression of bone narrow mesenchymal stem cells, and has the capability of obviously promoting the osteogenic differentiation of bone narrow mesenchymal stem cells; germanium-based graphene can be loaded on the surface of an implant with hard tissue, and then the implant can be implanted into a human body or animal body, so as to promote osteogenesis, improve the applying effect, promote osseointegration between the implant and bones, and promote the formation of new bones. Also, germanium-based graphene can be used as an osteogenesis promotion component to prepare drugs for treating bone defects or osteoporosis. In addition, germanium in germanium-based graphene has an anti-cancer anti-aging health-care function.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

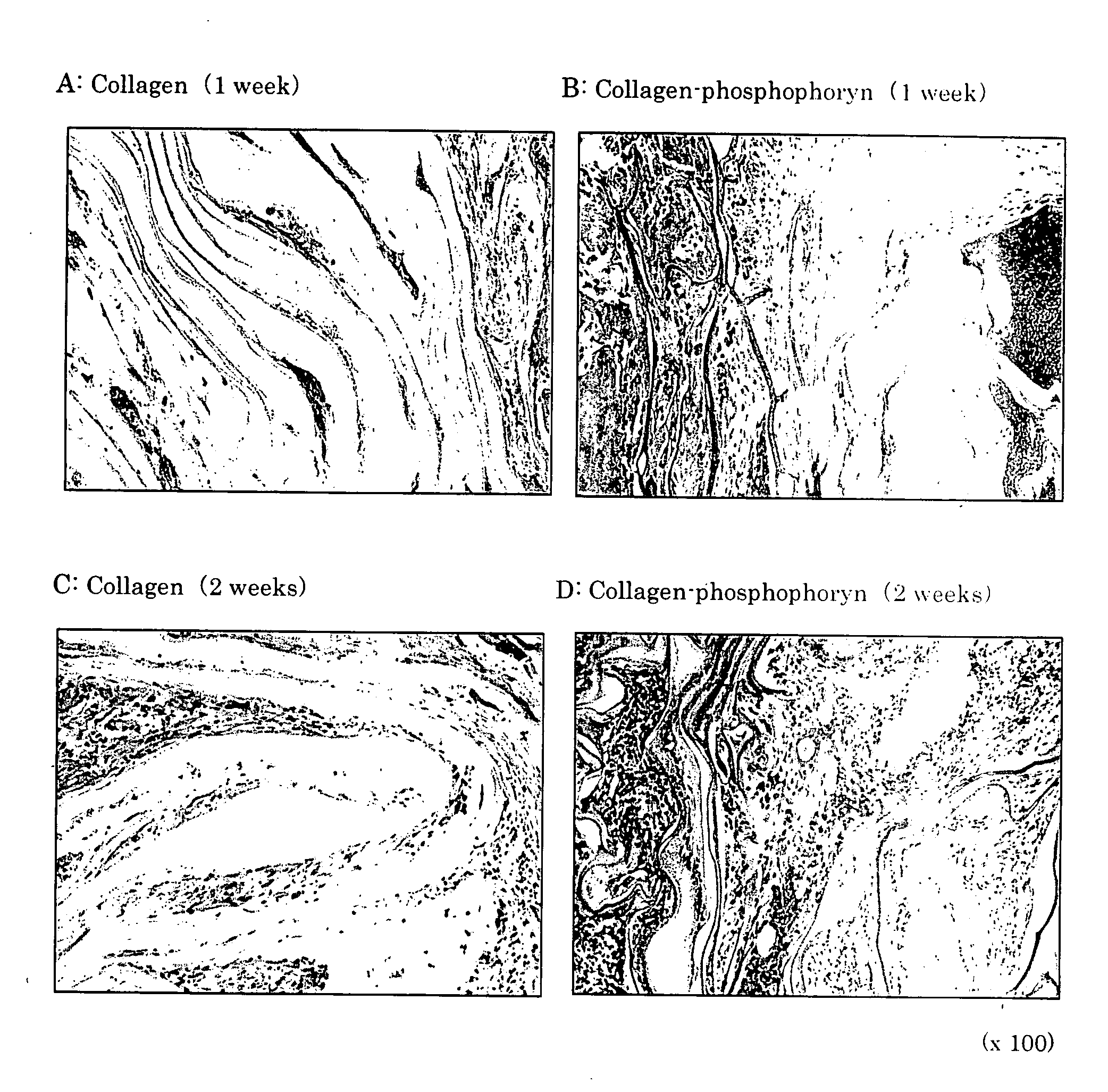

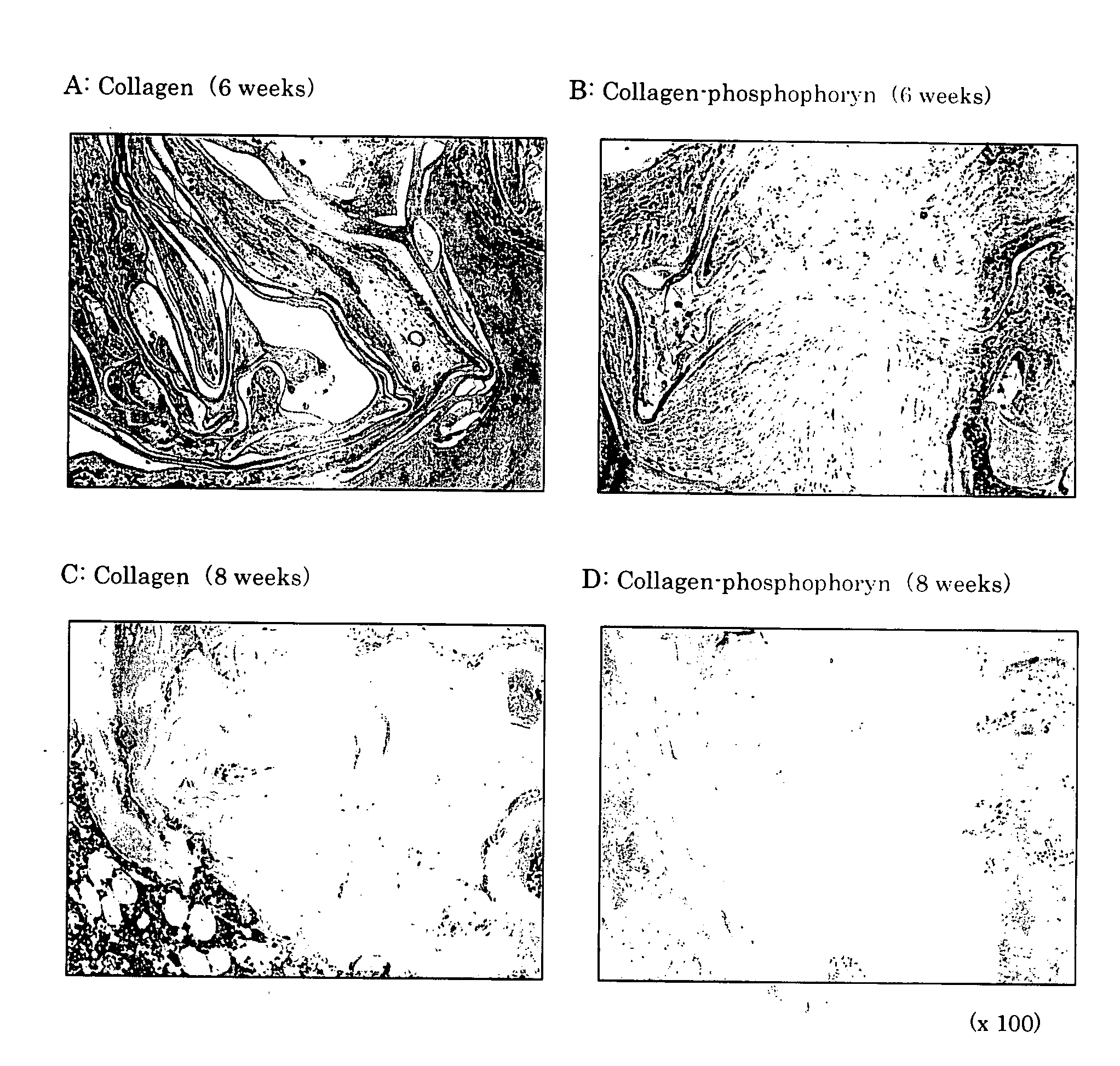

Composite biomaterial comprising phospholine

InactiveUS20050107286A1Enhanced osteogenic propertiesEasy to shapeBiocidePeptide/protein ingredientsBone Marrow-Derived CellArtificial bone

This invention relates to composite biomaterials having a sponge-like structure and comprising phosphophoryn and collagen, and to artificial bones obtained by culturing bone marrow-derived cells on the aforementioned composite biomaterials.

Owner:NAT INST OF ADVANCED IND SCI & TECH

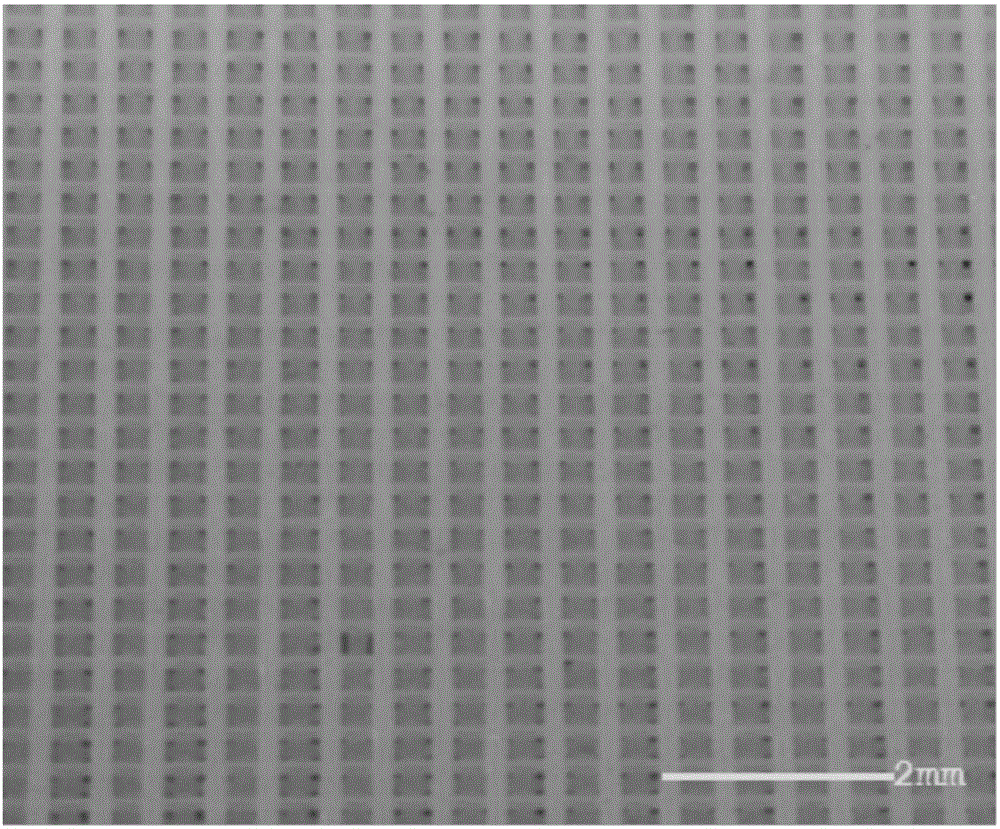

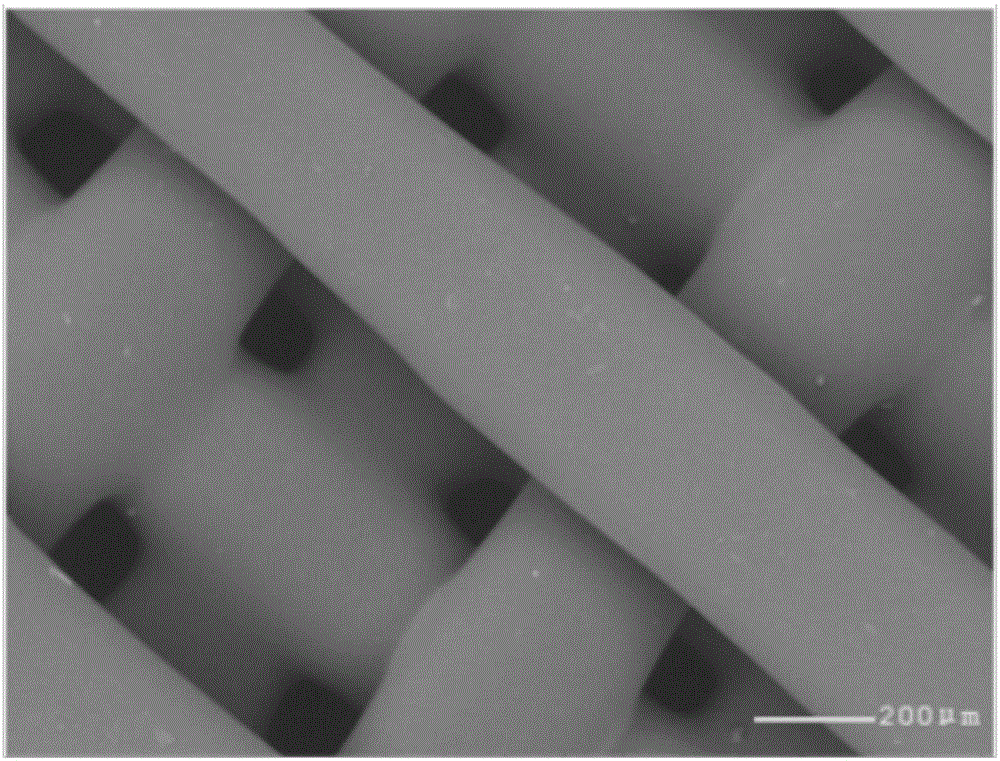

3D (three-dimensional) printing type polycaprolactone/oyster shell powder composite material, preparation method and application thereof and bone tissue engineering scaffold based on 3D printing type polycaprolactone/oyster shell powder composite material

The invention belongs to the technical field of tissue engineering and discloses a 3D (three-dimensional) printing type polycaprolactone / oyster shell powder composite material, a preparation method and application thereof and a bone tissue engineering scaffold based on the 3D printing type polycaprolactone / oyster shell powder composite material. The 3D printing type polycaprolactone / oyster shell powder composite material comprises polycaprolactone and oyster shell powder in a mass ratio of 95:5-80:20. The bone tissue engineering scaffold is excellent in mechanical performance and biocompatibility and has high porosity and a three-dimensional interconnected porous structure by taking the polycaprolactone as a host material and the / oyster shell powder with osteogenic activity as a reinforcing phase. The 3D printing type polycaprolactone / oyster shell powder composite material is applied to 3D printing and can be built into a three-dimensional scaffold model suitable for different patients, different bone defect parts and different bone tissue engineering requirements, excellent scaffold environments can be provided for bone tissue regeneration through controllable porous structures and individually designed shapes, and gold standards on bone defect repair are simulated maximally.

Owner:JINAN UNIVERSITY

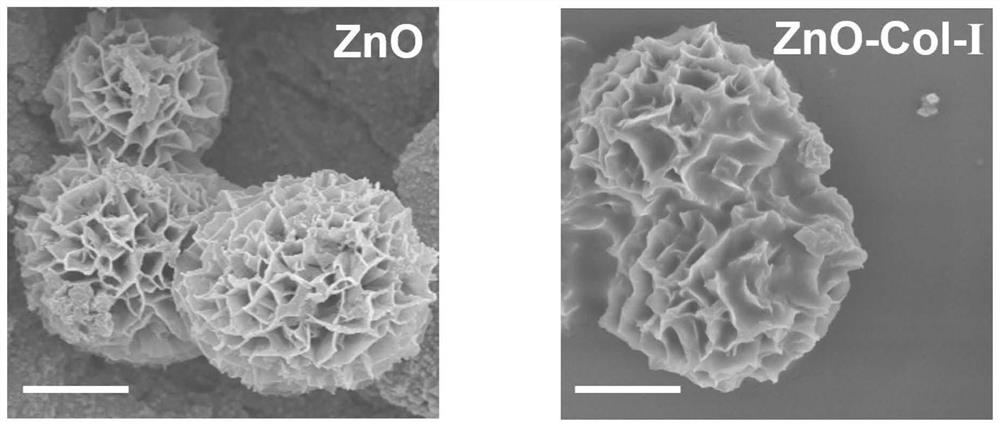

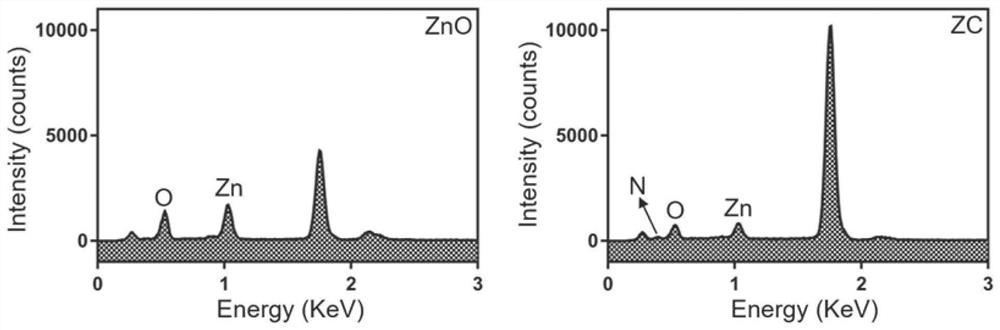

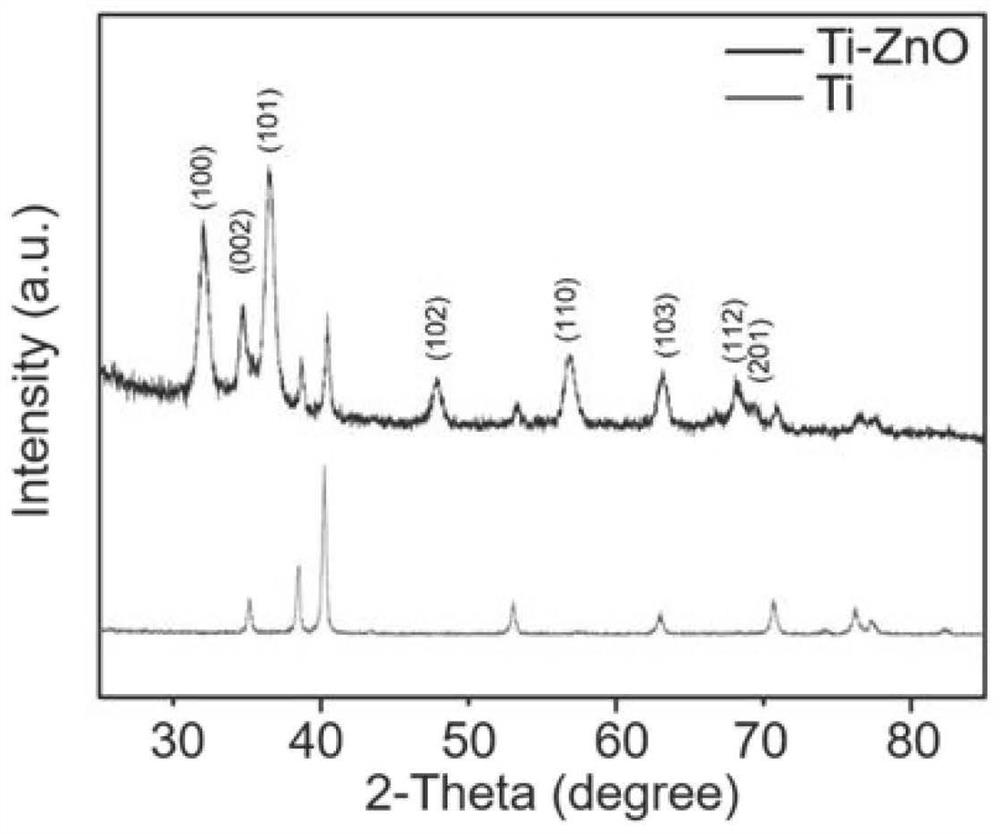

Double-photoresponse type zinc oxide, preparation method thereof and photosensitive coating with antibacterial osteogenesis

InactiveCN111646495AImprove adsorption capacityImprove antibacterial propertiesZinc oxides/hydroxidesTissue regenerationEngineeringSurgical implant

The invention relates to the technical field of surgical implants, and provides double-photoresponse type zinc oxide, a preparation method thereof, and a photosensitive coating with antibacterial osteogenesis. In the preparation process of zinc oxide, sodium citrate and hydroxypropyl methyl cellulose are added to control the morphology, a photothermal conversion material is added to enable zinc oxide to have photothermal conversion capacity, and lignin is added to reduce the energy band gap of zinc oxide; and the freeze-dried hydrothermal product is carbonized through microwave irradiation, and the energy band gap is further reduced, so that the material has response capability to yellow light. The zinc oxide prepared by the invention is of a tremella-shaped wrinkle structure, has dual response to yellow light and near-infrared light, has good adsorbability, antibacterial property and photo-thermal stability, and has photo-thermal conversion capability. The zinc oxide has antibacterialproperty and osteogenesis property, can effectively improve the antibacterial and osteogenesis capacity of the implant when being applied to the surface of the implant, and can realize the light-operated effect and on-demand effect of the antibacterial and osteogenesis functions of the implant due to the special photosensitivity of the coating.

Owner:NANCHANG UNIV

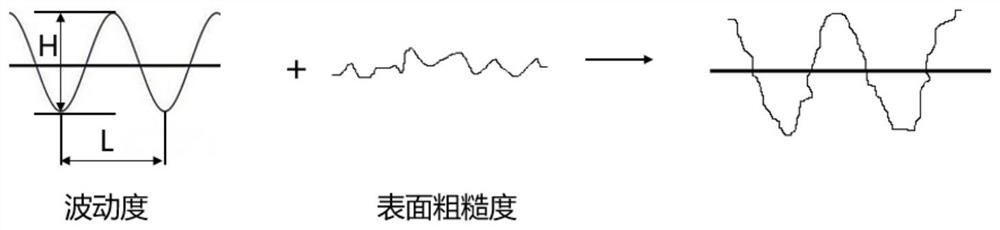

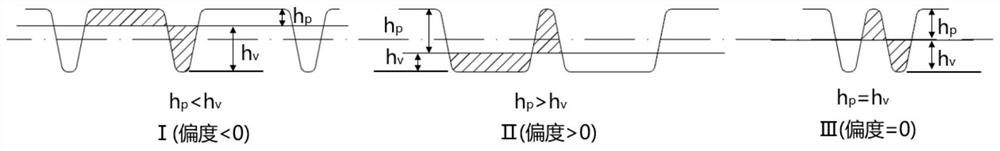

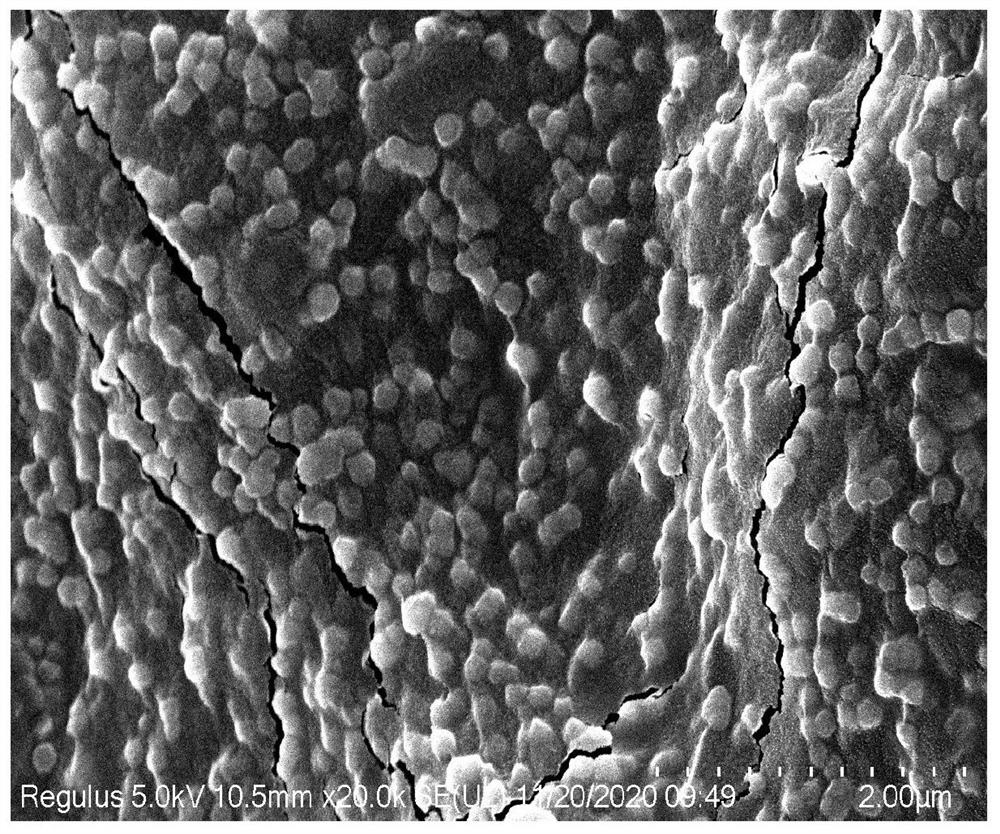

Preparation method of titanium implant with surface-controllable micro-nano composite structure biological membrane

ActiveCN112170841AHigh speedHigh strengthAdditive manufacturing apparatusSurface reaction electrolytic coatingSelective laser meltingElectrophoreses

The invention belongs to the field of biomedical materials, and discloses a preparation method of a titanium implant with a surface-controllable micro-nano composite structure biological membrane. Thepreparation method comprises the following steps of (1), designing a titanium implant model with micron pores on the surface; (2), printing and forming the titanium implant model by adopting a selective laser melting (SLM) technology in an additive manufacturing method to obtain a titanium implant primary product; and (3), generating a hydroxyapatite film layer with a micro-nano composite structure on the surface of the titanium implant primary product in situ by adopting a plasma micro-arc oxidation (PEO) technology in cooperation with hydrothermal method post-treatment or electrophoretic deposition method post-treatment, so as to obtain a titanium implant finished product. The detail structure design of the implant and the overall process flow design of the preparation method are improved for simulating the biological bone tissue structure, the micro-nano composite structure biological membrane layer with controllable surface morphology and components is obtained, and the bonding efficiency and bonding strength of the implant and surrounding tissues can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Composite material for processing micro-type bone retention pin and preparation method of composite material

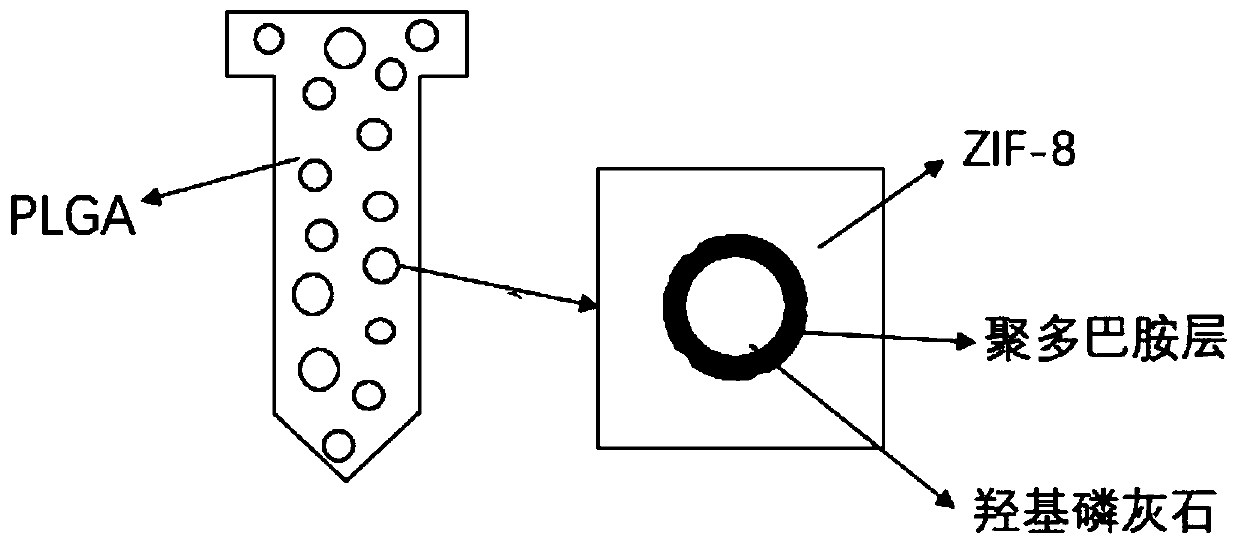

ActiveCN110639067ADelayed early degradationGood processing performanceSurgeryBio compatibilityStructural material

The invention discloses a composite material for processing a micro-type bone retention pin and a preparation method of the composite material. The composite material is obtained by the following steps: adding a biologically-active inorganic material and a zeolitic imidazolate structural material ZIF-8 into a solution of a binding material with biological activity, performing stirring at pH of 8-10 and room temperature to make the ZIF-8 coat the biologically-active inorganic material by the binding material with biological activity during polymerization, adding a bone scaffold substrate material, performing uniform dispersion in a high-speed mixing machine, and performing banburying mixing granulation to obtain the composite material. The composite material provided by the invention contains the bone scaffold substrate material, the biologically-active inorganic material and the zeolitic imidazolate structural material ZIF-8, so that the substrate of the bone scaffold substrate material can be strengthened, the early degradation of the material can be delayed, the osteogenesis ability of a body guided by the material and the biocompatibility can be improved, and the inducibility and antibacterial property are given to the bone scaffold substrate material; and the preparation method is simple, has low costs, and is convenient for promotion and application.

Owner:SICHUAN UNIV

Method for improving osteogenesis capacity of mesenchymal stem cells

PendingCN111849878AEnhanced osteogenic propertiesImprove mineralized nodulesCulture processSkeletal/connective tissue cellsOsseous DifferentiationMetforminum

The invention provides a method for improving the osteogenesis ability of mesenchymal stem cells, which comprises the following steps: inoculating the mesenchymal stem cells into an alpha-MEM culturemedium containing 10% of fetal calf serum, culturing, digesting and subculturing by 0.2% of pancreatin when the fusion degree of the mesenchymal stem cells is 80-85%, inoculating the obtained mesenchymal stem cells into an alpha-MEM culture medium containing 10% of fetal calf serum for culture, and adding osteogenesis induction liquid and a metformin aqueous solution for induction when the densityof the mesenchymal stem cells is greater than 90% for induction for 14-21 days. The metformin acts on the mesenchymal stem cells, alizarin red staining results show that the metformin can significantly improve the calcium mineralization nodule degree of the cells, and it is indicated that the metformin has a significant induction effect on mesenchymal stem cell osteogenic differentiation, the metformin can significantly improve the expression of the mesenchymal stem cell osteogenic differentiation related genes SIRT1, ALP, COL1A1, RUNX2 and BGLAP, and the improvement of the osteogenic differentiation capacity of the mesenchymal stem cells is of great significance to stem cell transplantation and bone biology research.

Owner:山东佰傲干细胞生物技术有限公司

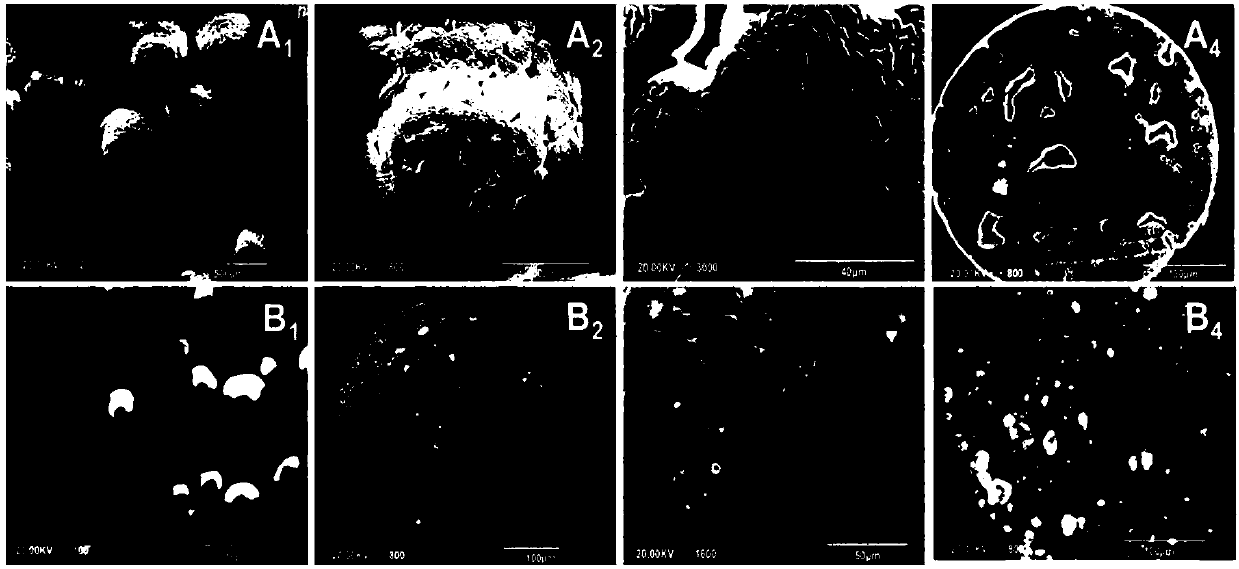

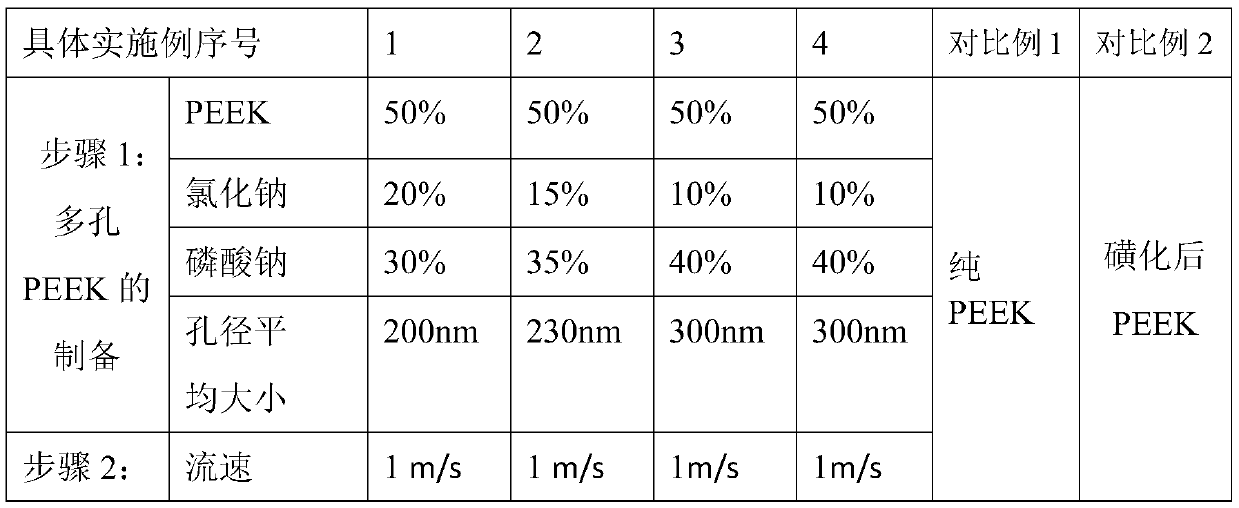

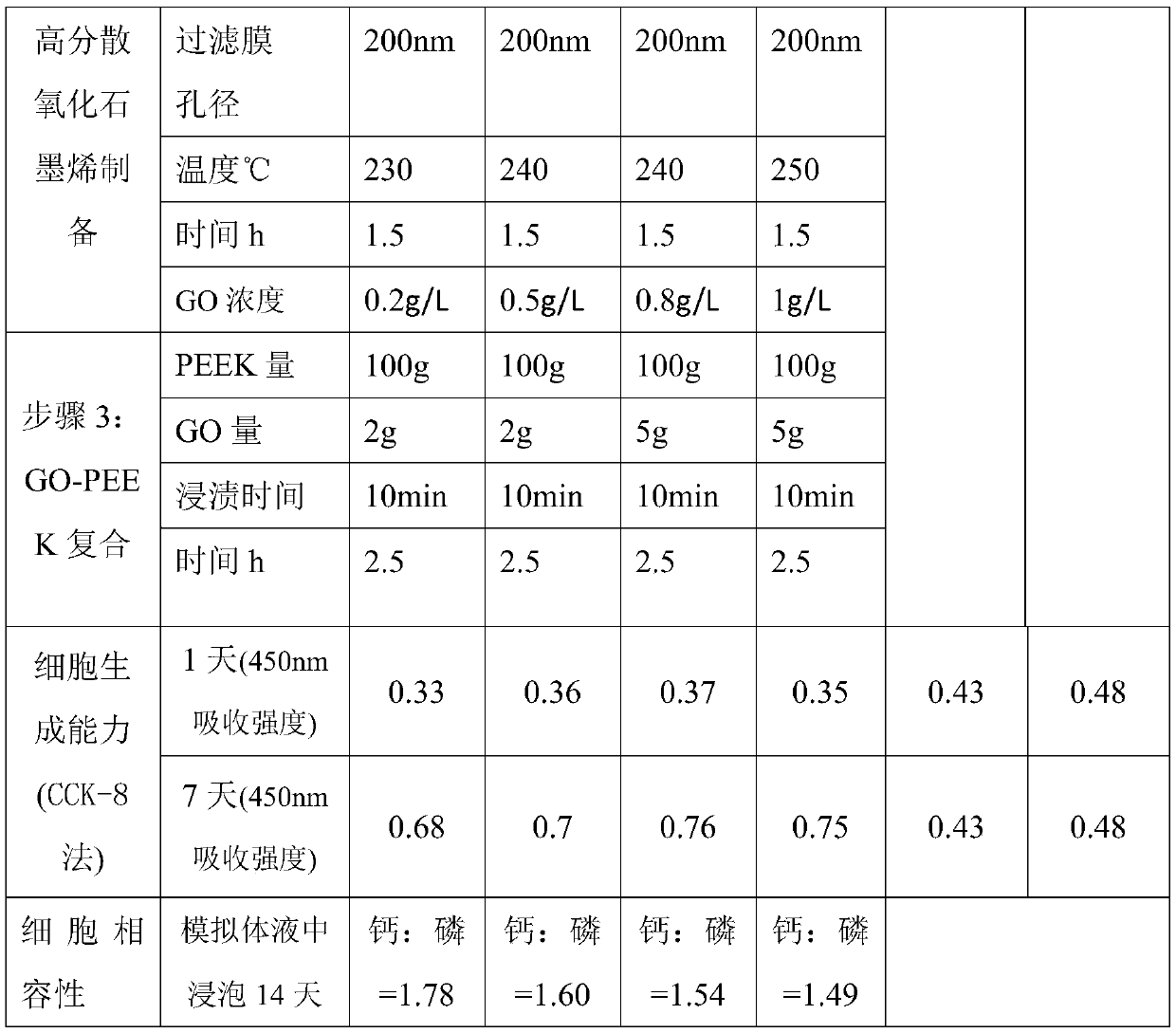

Functionalized graphene modified porous polyether-ether-ketone material and preparation method thereof

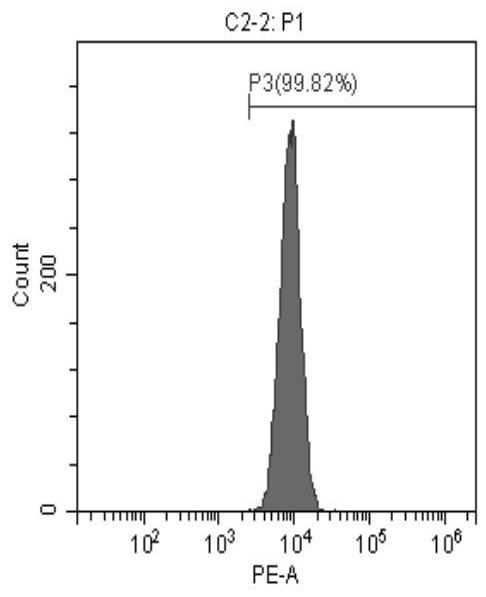

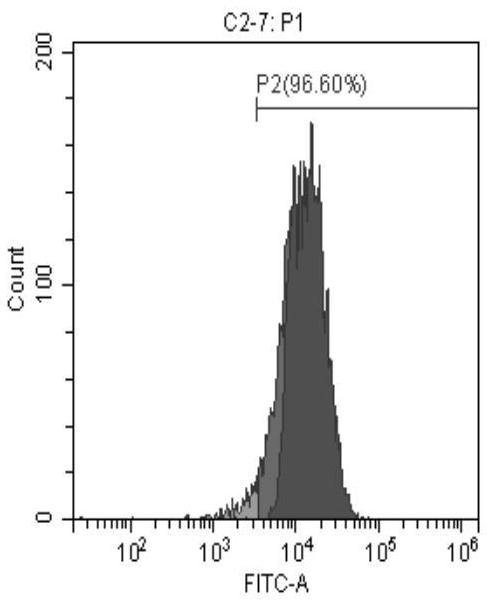

PendingCN110396217AEnhanced osteogenic differentiationHigh antibacterial activityProsthesisCvd grapheneSurface modification

The invention relates to functionalized graphene modified porous polyether-ether-ketone (PEEK) and a preparation method thereof. The porous PEEK is subjected to surface modification through the graphene oxide, so that the biological inertness of the PEEK is enhanced, and the bone conductivity and the antibacterial activity are improved. The method mainly comprises the following three steps: (1) preparing porous PEEK with soluble salt or soluble acid salt as filling particles; (2) preparing high-dispersion graphene oxide with controllable concentration throguh cross-flow membrane filtration; and (3) assembling the functionalized graphene on the porous PEEK. Through implantation of graphene oxide, a large number of active sites can be provided; the interaction with protein is improved through hydrophobic and electrostatic effects, so that the osteogenesis difference of cells is favorably enhanced.

Owner:王征

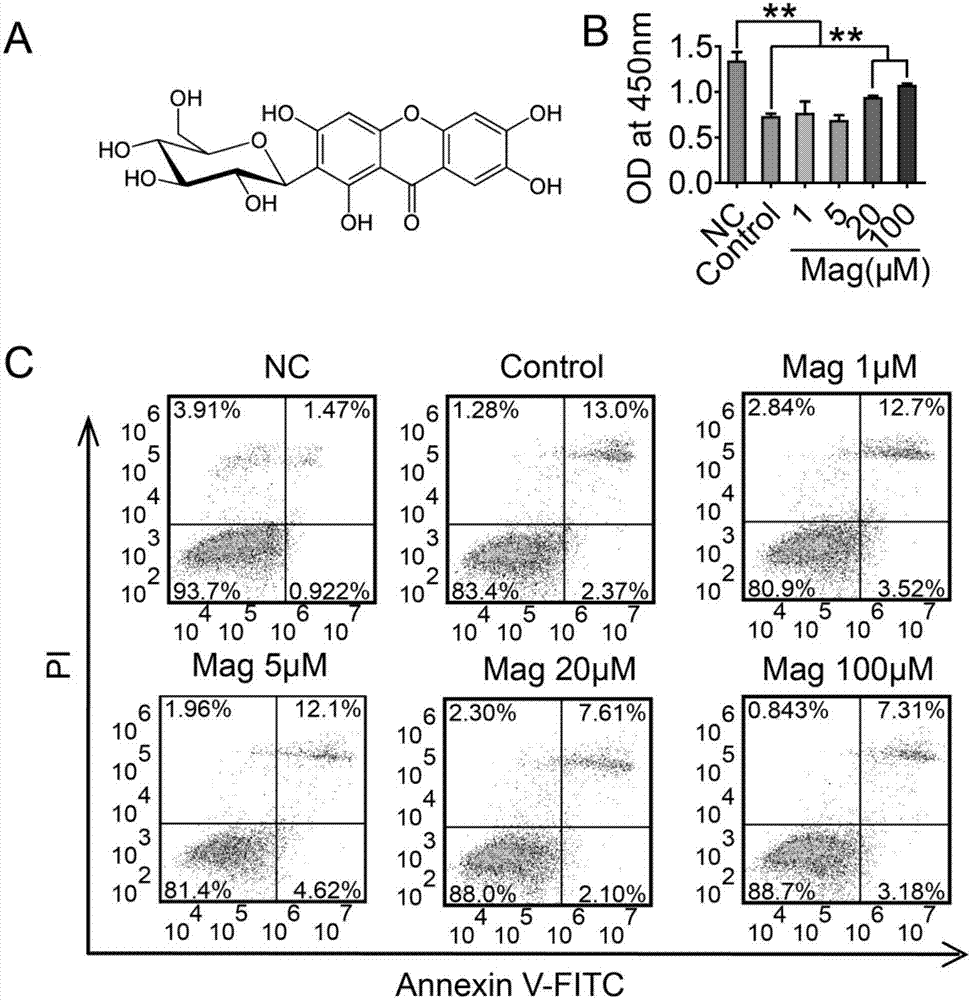

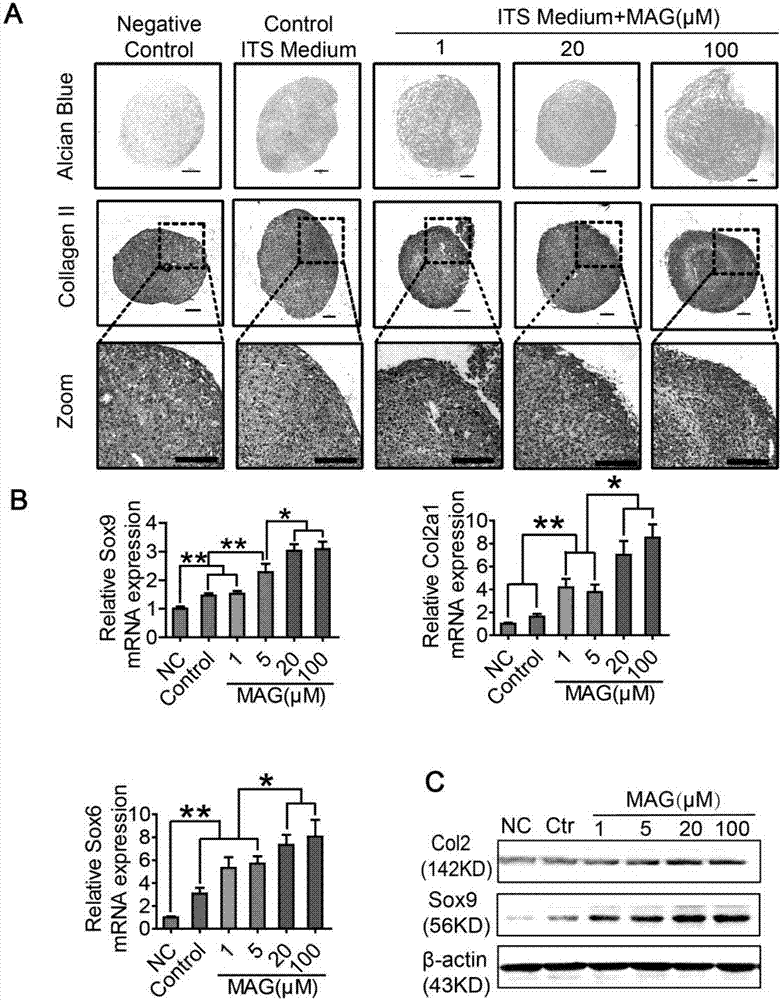

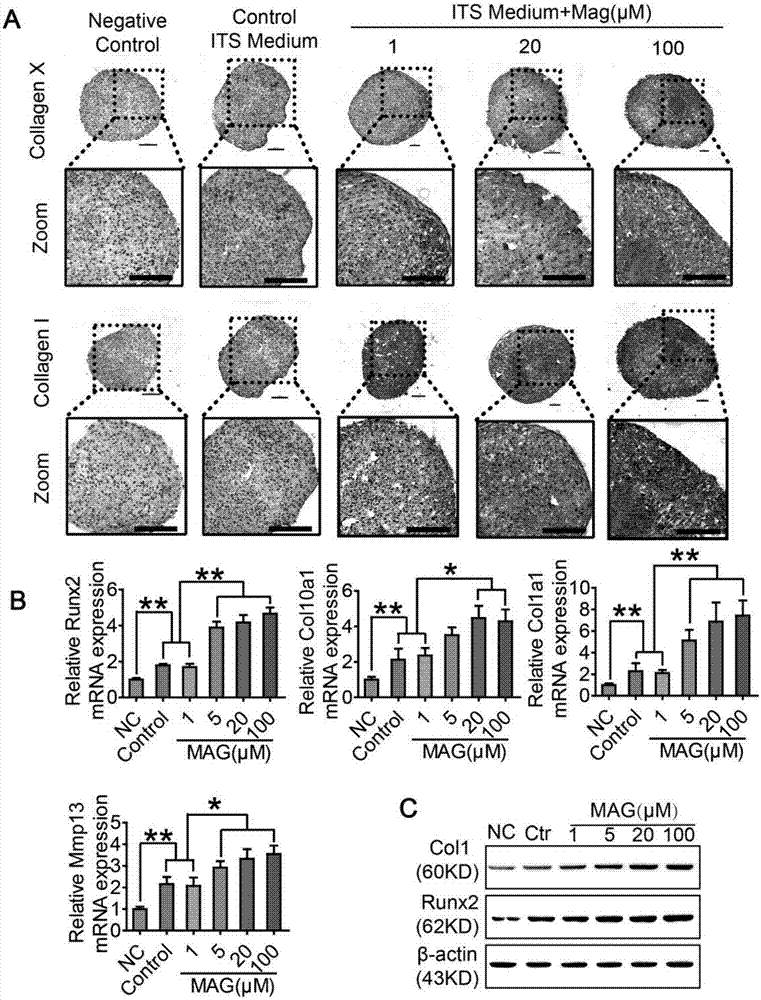

Application of mangiferin in preparing drug for promoting bone defect repair

InactiveCN107496413AImprove survivabilityEnhance bone formationOrganic active ingredientsSkeletal disorderAdemetionineEndochondral ossification

The invention relates to an application of mangiferin in preparing a drug for promoting bone defect repair and solves the problems that a host micro-environment in a conventional bone repair mode is short of blood supply, apoptosis of seed cells in an anaerobic environment is easily caused, the ossifying effect is poor and the like. By means of a policy of combining mangiferin with an endochondral ossification system for bone repair as the mangiferin not only plays a protecting role, but also promotes the osteogenic capability of seed cells, mesenchymal stem cells are planted on a porous bone scaffold material to construct a tissue engineering composite, then chondrogenic differentiation inductive culture is performed in vitro for two weeks, and the composite is implanted into a defect region to repair after hypertrophic chondrogenic differentiation inductive culture is performed for two weeks; the mangiferin can be loaded on the porous bone scaffold material and can be integrally systematically administrated; an in vivo research result shows that the repair method provided by the invention can repair bone defects successfully, and has a good application prospect in tissue engineering bone construction and bone defect repair.

Owner:ARMY MEDICAL UNIV

Bone repair material able to guide bone tissue regeneration

InactiveCN103157140AGood for guiding osteogenesisImprove stress resistanceProsthesisBiocompatibilityCompatibilization

The invention discloses a bone repair material able to guide bone tissue regeneration. The material is a composition of calcined bone powder with different particle sizes and a bioabsorbable high polymer material. The bone repair material is characterized in that: the particle sizes of the calcined bone powder range from 0.1-2mm; and the bioabsorbable high polymer material is one or more of collagen, chitin, chitosan, hyaluronic acid, chondroitin sulfate, calcium alginate, fibrous protein, and elastin. The bone repair material provided in the invention has an obvious bone healing guiding effect and good biocompatibility. Also with certain hardness and strength, the bone repair material is easy to shape and has rich sources, thus solving the making problems of artificial synthetic materials in the aspects of porosity, pore traffic and pore size, etc.

Owner:XIAN REJE BIOLOGICAL TECH

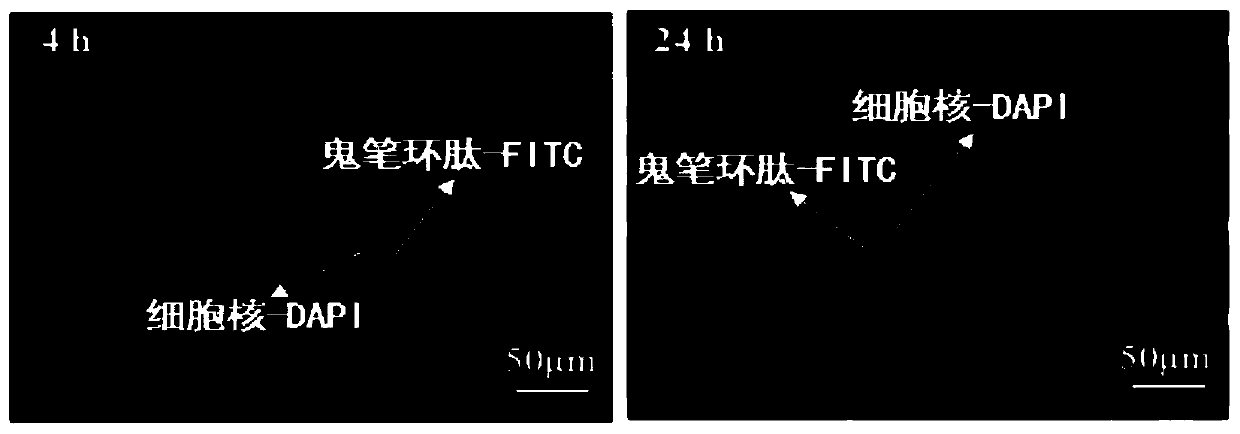

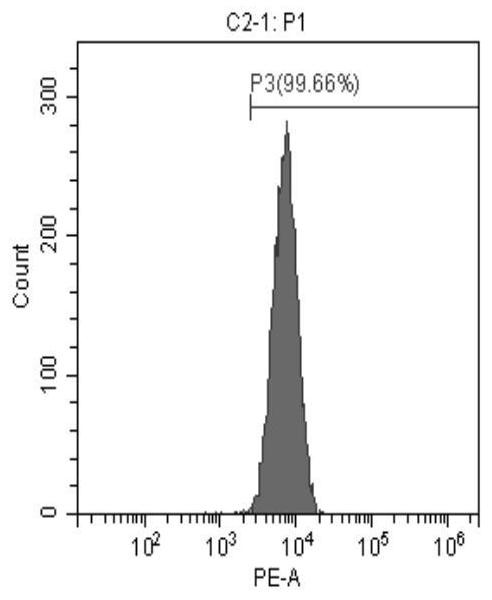

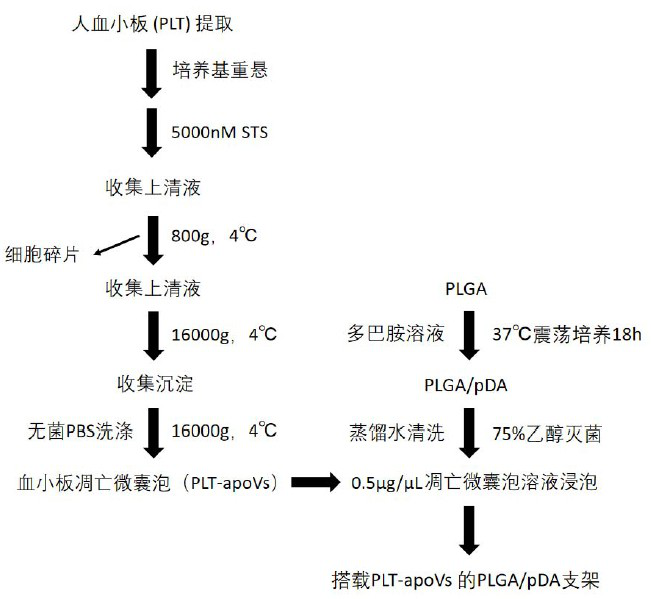

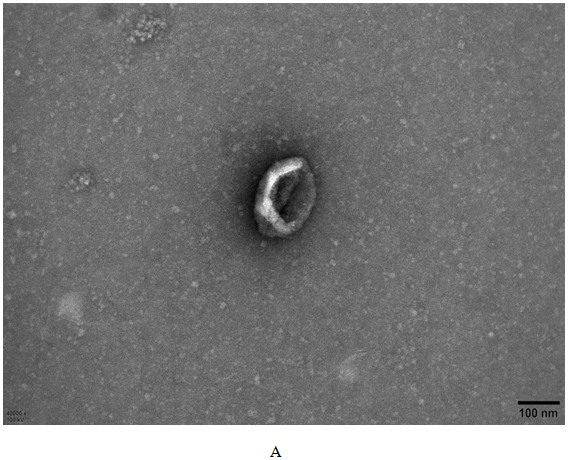

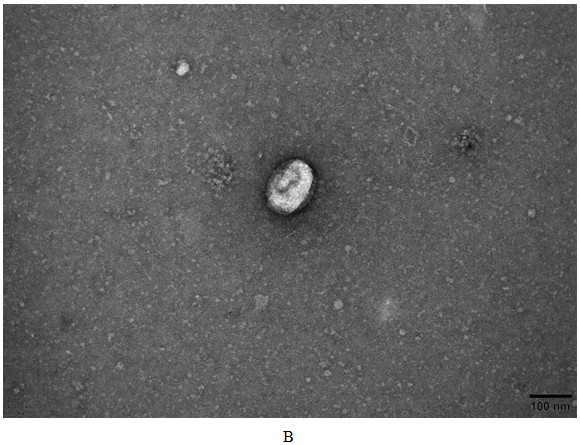

Application of human platelet apoptosis microvesicles

ActiveCN114306384AEasy to prepareLow costSkeletal disorderMammal material medical ingredientsHuman plateletGlycolic acid

The invention discloses application of human platelet apoptosis microvesicles in preparation of a preparation for promoting osteogenic differentiation of mesenchymal stem cells and provides a bone defect repair preparation which comprises a PLGA (poly (lactic-co-glycolic acid)) support material, and the human platelet apoptosis microvesicles are carried on the surface of the PLGA support material. The apoptosis microvesicles derived from human platelets provided by the invention can be extracted from blood of a patient, and ethical problems and immune problems are avoided. According to the bone defect repairing preparation constructed by the PLGA / pDA support carrying the human platelet apoptosis microvesicles, the defects that PLGA is hydrophobic and low in osteogenic activity are overcome, particularly, the human platelet apoptosis microvesicles are carried after a pDA film is loaded on the surface of the PLGA support, so that the human platelet apoptosis microvesicles can be slowly released in vivo, and the bone defect repairing preparation is used for repairing bone defects of the human platelet apoptosis microvesicles. The in-vivo osteogenesis capability of the mesenchymal stem cells is further improved.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

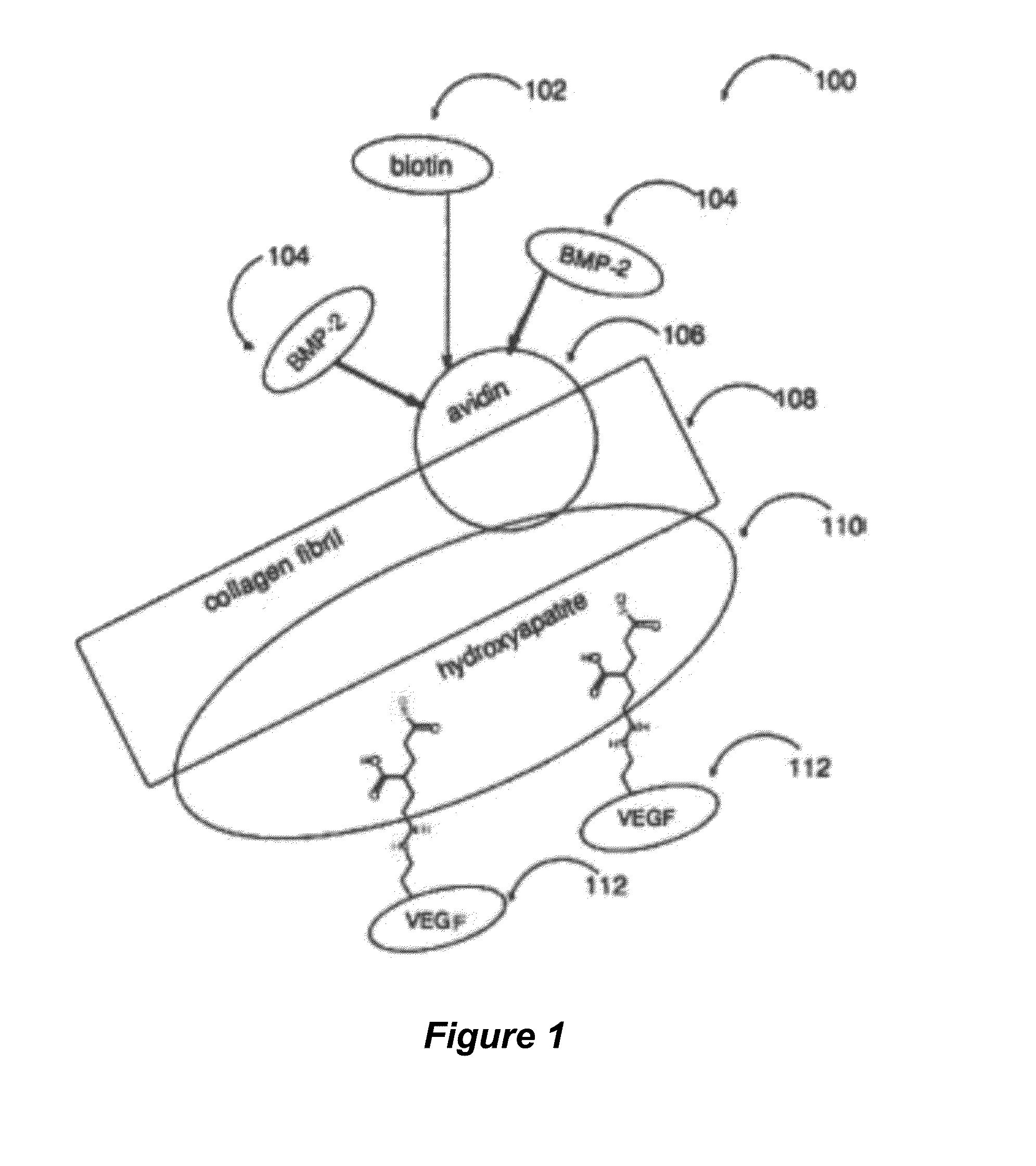

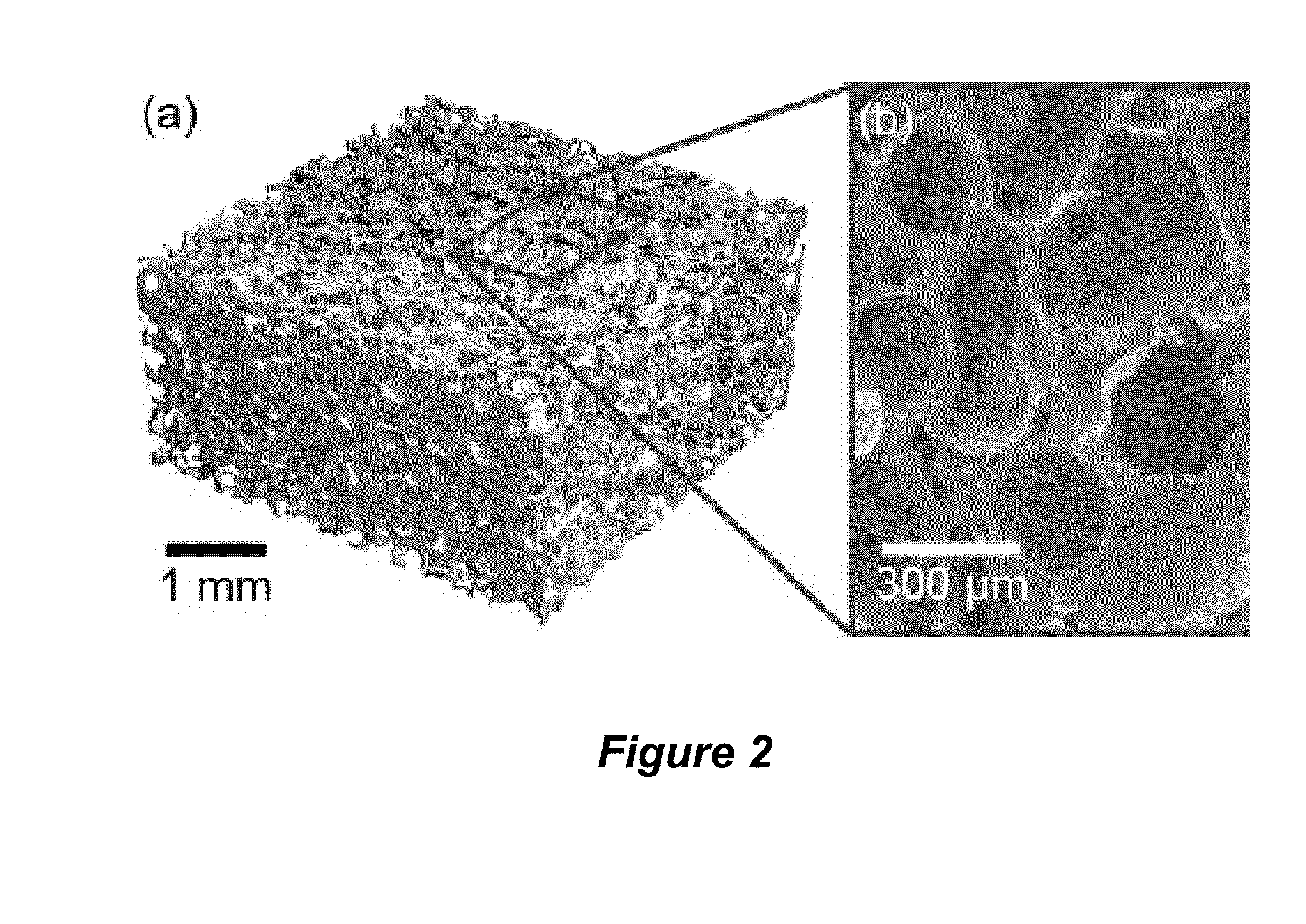

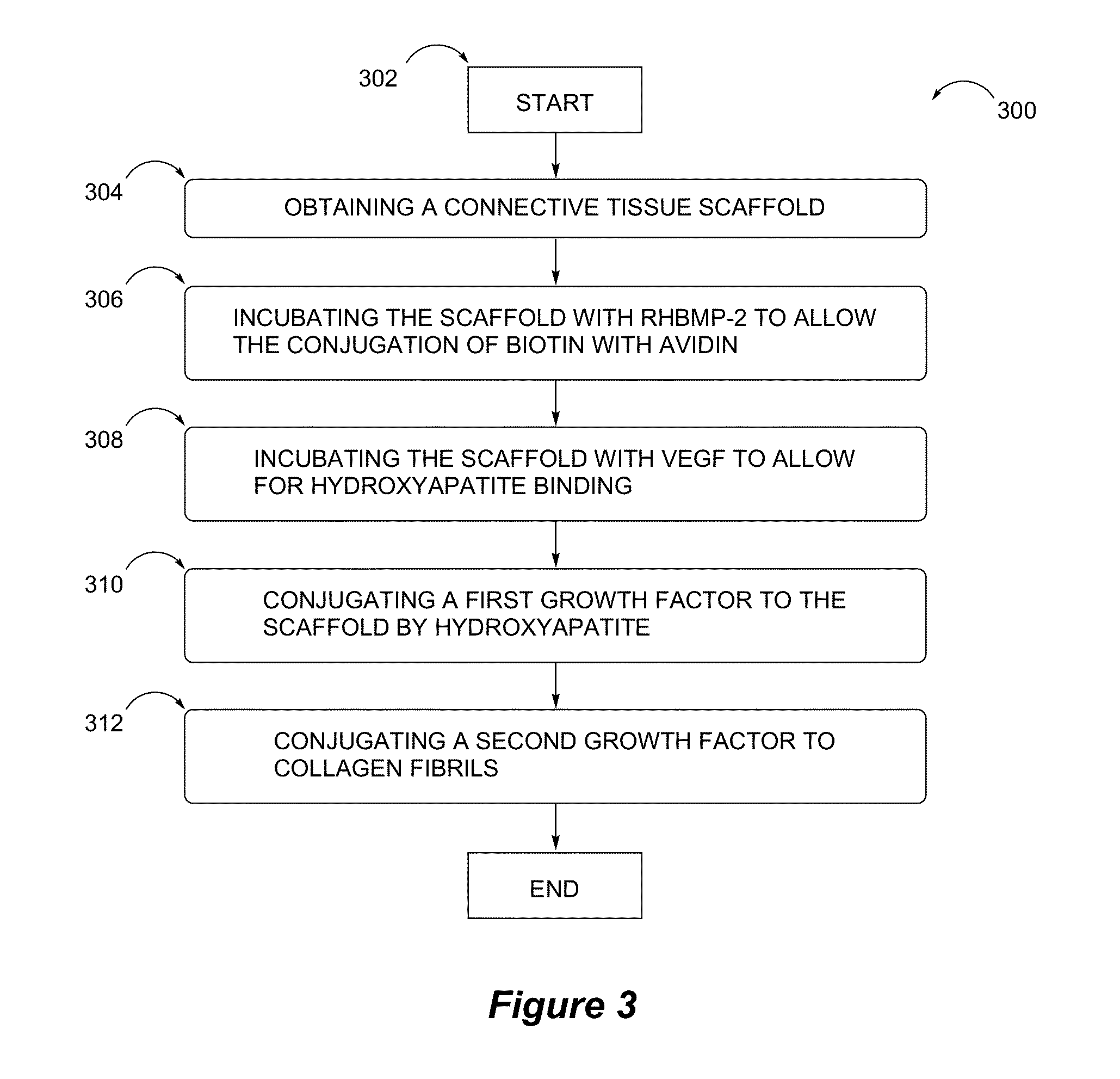

Tissue scaffolds having bone growth factors

ActiveUS20150132354A1High mechanical strengthEnhanced osteogenic propertiesPeptide/protein ingredientsSkeletal disorderCalcium biphosphateCollagen scaffold

The invention provides a novel composite bone graft system utilizing a porous collagen scaffold having a matrix impregnated with calcium phosphate particles and more than one bioactive agent, one of which is conjugated to the matrix. The graft system exhibits increased mechanical strength and osteogenic properties by providing sites for tissue attachment and propagation. The bioactive agents are delivered to the scaffold via different mechanisms to enable sequential and sustained release of the bioactive agents over time.

Owner:UNIV OF NOTRE DAME DU LAC

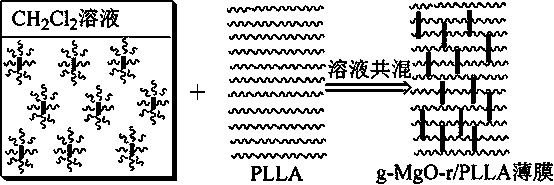

Preparation method of L-polylactide-modified MgO nano-rod composite material

The invention discloses a preparation method of an L-polylactide-modified MgO nano-rod composite material. The preparation method comprises the following steps: 1) preparing an MgO nano-rod; 2) performing surface modification on the MgO nano-rod; 3) preparing the L-polylactide-modified MgO nano-rod composite material. The invention has the advantages that the preparation method is simple in technology and easy to implement; the prepared composite material can be used for preparing fracture inner fixing products including bone nails, bone lamellae, and cancellous bone screws; the osteogenic capability when the material is planted into an animal body is obviously better than that of PLLA; the preparation method adopts the MgO nano-rod as a reinforced bone frame, so that the improvement on composite material mechanic performance is more effective than that of MgO-NPs grains since crystal whisker distributed in the polymer matrix can improve the strength and plasticity of the composite material through four manners, namely load transmission, crack bridging, crack deflection, and extraction effect.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for modifying nano-decalcification bone matrix particle coating layer by virtue of polycaprolactone-tricalcium phosphate bone tissue engineering scaffold

ActiveCN109172863AAvoid destructionGood biocompatibilityPharmaceutical delivery mechanismTissue regenerationFreeze-dryingSlurry

The invention discloses a method for modifying a nano-decalcification bone matrix particle coating layer by virtue of a polycaprolactone-tricalcium phosphate bone tissue engineering scaffold. The method comprises the following steps: mixing an allogeneic decalcification bone matrix material with 75% ethanol, soaking the polycaprolactone-tricalcium phosphate bone tissue engineering scaffold into diluted nano-decalcification bone matrix slurry, putting the polycaprolactone-tricalcium phosphate bone tissue engineering scaffold into liquid nitrogen, so as to finish primary freezing; putting the obtained frozen scaffold into a vacuum freeze-drying machine, carrying out freeze-drying for at least 48 hours to finish the modification of a surface coating layer, so as to obtain the polycaprolactone-tricalcium phosphate bone tissue engineering scaffold modified with the nano-decalcification bone matrix particle coating layer. By utilizing a low-temperature freezing method, the activity of a nano-DBM biological material is effectively guaranteed; and the osteogenic capability of the scaffold is improved based on original scaffold holes. According to the method, a certain theoretical basis isprovided for the research and development of bone transplantation substitutions and bone defect repairing materials.

Owner:SECOND AFFILIATED HOSPITAL SECOND MILITARY MEDICAL UNIV

Reamed product passing through negative pressure catheter collecting device

A reaming product taking device through a negative pressure extractor pipeline adopts the negative pressure extractor pipeline. The front end of the negative pressure extractor pipeline is a sucker, and the tail is communicated with a negative pressure drainage bottle. The device is characterized in that the negative extractor pipeline is provided with a reaming product cut-off device in series. The invention can realize the recovery of the reaming product passing through the negative pressure extractor pipeline, and the reaming product can be used effectively in the internal fixation with nail in marrow, thus healing the fracture.

Owner:田晓华

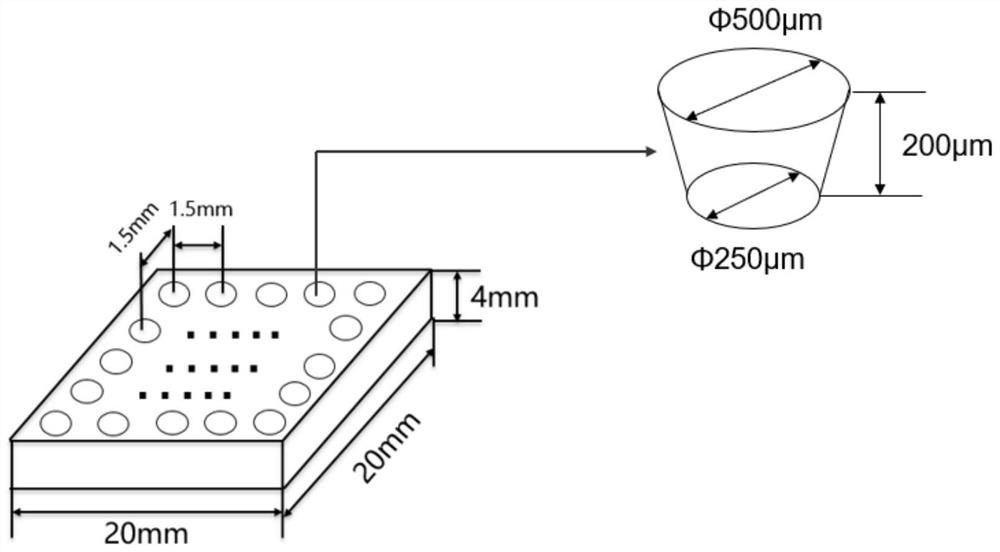

Design and manufacturing method of surface structure of parodontium-simulated dental implant

ActiveCN111227965AEnhanced osteogenic propertiesReduce peripheral inflammationDental implantsAdditive manufacturing apparatusBone TrabeculaeComputer printing

The present invention relates to a design and manufacturing method of a surface structure of a parodontium-simulated dental implant. The design and manufacturing method comprises the following steps:1) a dental implant is divided into 2 layers and printing files are generated by using a 3D printing software; 2) an inner layer is a solid structure and an outer layer is a gradient hollow structurewith gradually increased porosity from inside to outside; 3) the porosity of an innermost layer of the hollow structure is 0 and the porosity of an outermost layer is 50-80%; 4) pores and interstitialtrabecula are trabecula-like structures; 5) printing and forming are conducted by using a laser cladding 3D printer; 6) the used material can be pure titanium, titanium alloy, zirconia or titanium-zirconium-based amorphous metal glass; and 8) the dental implant can be used as a dental implant product after being sterilized. The method can effectively improve osteogenesis performance of a surfaceof the dental implant, simulates a mechanical buffering effect of parodontium to a certain extent, reduces local stress concentration in a chewing functional state, obviously reduces occurrence and progress of inflammation around the dental implant through the complex bone interface structure of the dental implant, and improves long-term success rate of dental implant restoration.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Method for preparing multifunctional sodium alginate stent embedded with drug-loaded microspheres by using 3D printing technology based on in-situ emulsification

ActiveCN113368304AStable drug loadingGood compatibilityAdditive manufacturing apparatusTissue regenerationMicrosphereAntiinflammatory drug

The invention discloses a method for preparing a multifunctional sodium alginate stent embedded with drug-loaded microspheres by using a 3D printing technology based on in-situ emulsification, and aims to provide a preparation method of a multifunctional bone defect repair stent material. The method is characterized by comprising the following steps: by taking a bioactive substance lecithin as an emulsifier, dispersing an amination modified polylactic acid solution dissolved with an antibacterial or anti-inflammatory drug into a sodium alginate solution to form a stable emulsion, then constructing the sodium alginate stent embedded with the drug-loaded microspheres in situ by utilizing a low-temperature 3D printing technology, and using divalent strontium ions (Sr<2+>) as a cross-linking agent to improve the mechanical properties and osteogenic activity of the stent. The method has the characteristics that the prepared tent can be individually designed according to the characteristics of the bone defect part of a patient, and the prepared stent has multiple functions of good biological activity, osteogenic ability, mechanical property, antisepsis, anti-inflammation and the like, and has potential application prospects in the field of bone tissue engineering.

Owner:FUJIAN NORMAL UNIV

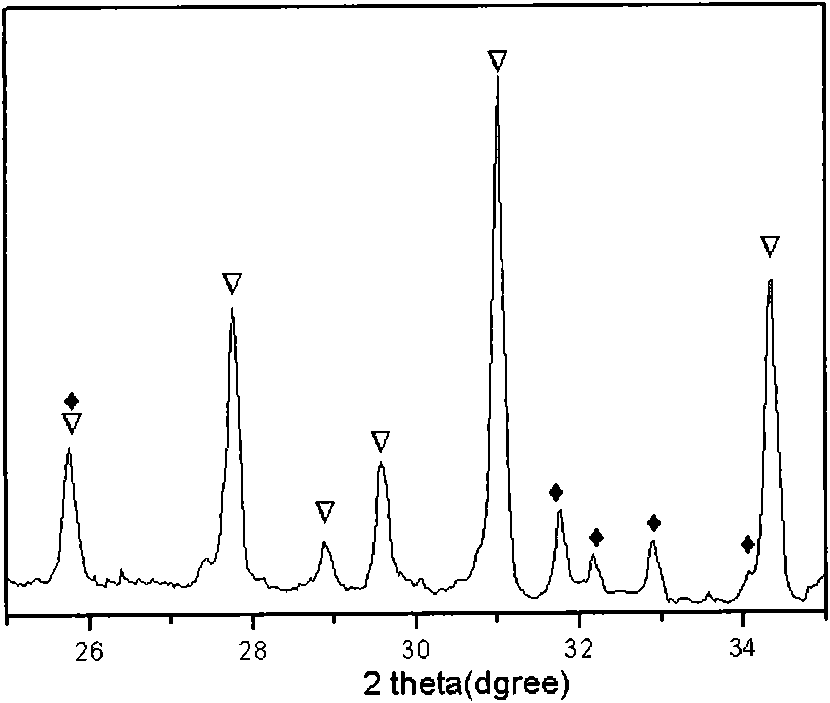

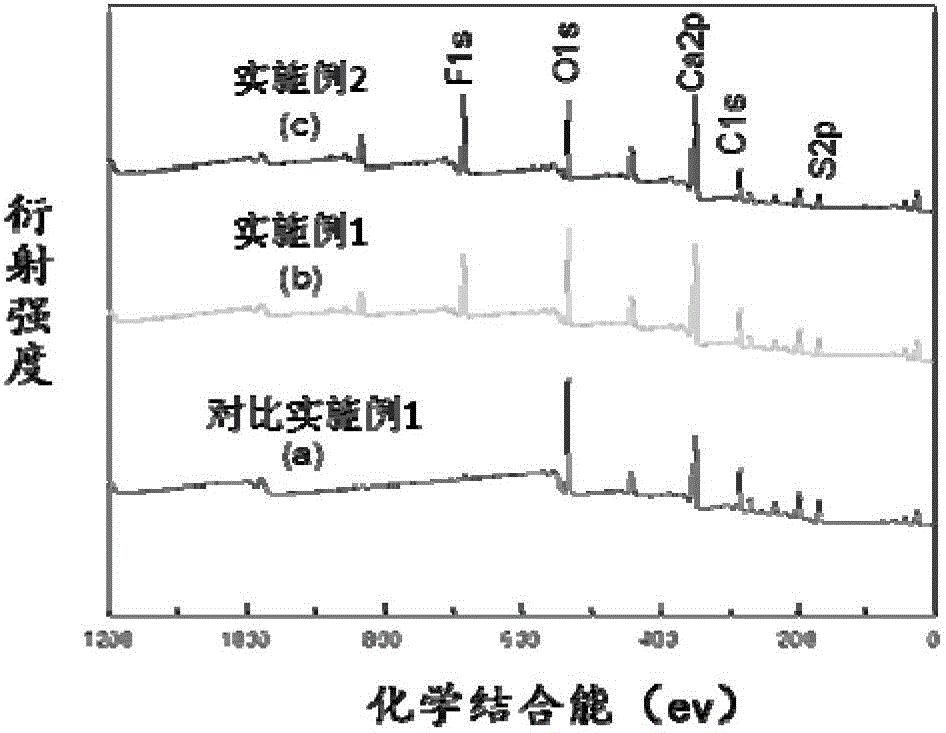

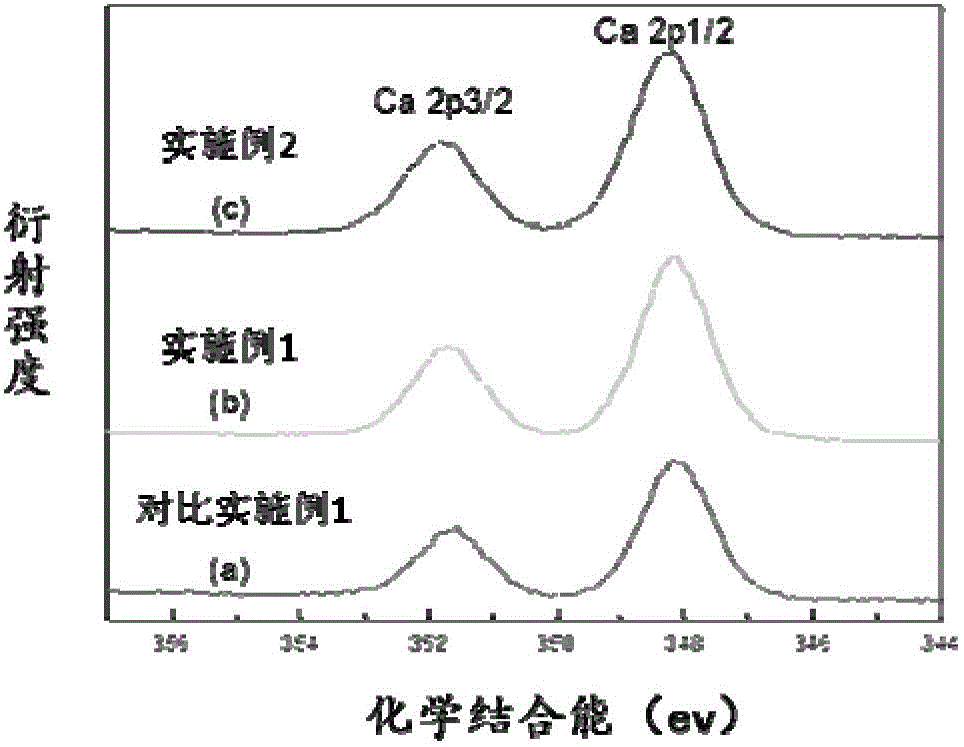

Preparation methods for fluorine-containing alpha-calcium sulfate hemihydrate powder and fluorine-containing calcium sulfate artificial bone material

ActiveCN104016397AUniform sizeAffects crystal morphologyImpression capsCalcium/strontium/barium sulfatesArtificial boneBiocompatibility

The invention discloses preparation methods for fluorine-containing alpha-calcium sulfate hemihydrate powder and a fluorine-containing calcium sulfate artificial bone material, and belongs to the field of medical biological materials. The preparation method for the fluorine-containing alpha-calcium sulfate hemihydrate powder is as follows: adding a fluorinating agent in a process of adding calcium sulfate dihydrate into mixed reaction liquor of calcium chloride aqueous liquor and absolute ethyl alcohol for partly removing crystalline water to prepare alpha-calcium sulfate hemihydrate, so that fluoride ions partly substitute ions in calcium sulfate hemihydrate to prepare the fluorine-containing alpha-calcium sulfate hemihydrate powder. The fluoride ions change crystal structure of calcium sulfate hemihydrate, so that the crystalline grain feature of the fluorine-containing alpha-calcium sulfate hemihydrate powder is obviously changed to an equiaxial hexagonal prism shape from a slender prism shape. The material has good degradation property and biocompatibility, and therefore, the prepared fluorine-containing alpha-calcium sulfate hemihydrate artificial bone material can be applied to the medical repair field, for example, can be used as dental materials such as a dental cementation material, dental filler, a pit and fissure sealant, and the like, and can be used as a root canal product, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com