Preparation method of titanium implant with surface-controllable micro-nano composite structure biological membrane

A micro-nano composite structure and implant technology, which is applied in the direction of surface reaction electrolytic coating, prosthesis, drug delivery, etc., can solve the problems of uneven composition, irregular surface morphology of the film layer, and insufficient bonding strength, etc., to achieve Effects of long service life, promoting cell adhesion, strong meshing strength and self-locking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In general, the method for preparing a titanium implant with a surface-controllable micro-nano composite structure biofilm in the present invention comprises the following steps:

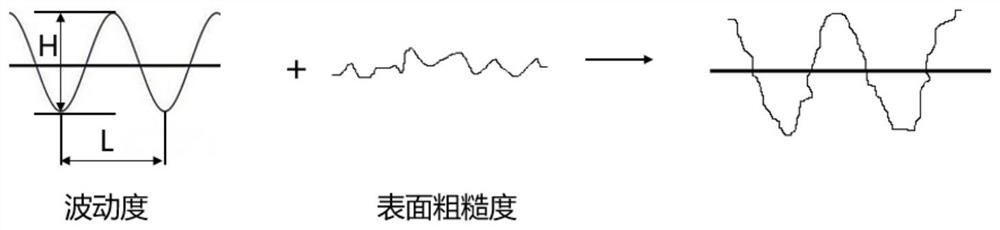

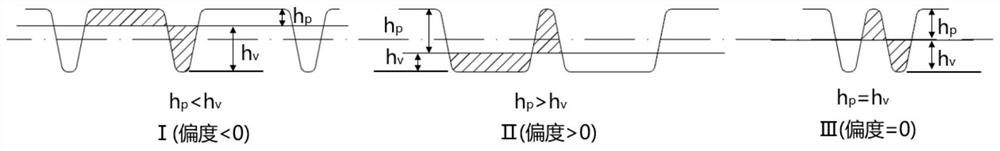

[0036] (1) Design titanium implant models (including pure titanium implants and titanium alloy implants) with specific topography (such as skewness, undulation, etc.) on the surface;

[0037] (2) The pre-set implant model is printed into shape by laser selective melting (SLM) technology in the additive manufacturing method;

[0038] (3) The plasma micro-arc oxidation (PEO) technology and hydrothermal post-treatment or electrophoretic deposition post-treatment are used to in-situ generate a hydroxyapatite film layer with nanopores on the surface of the titanium implant. Among them, the plasma micro-arc oxidation (PEO) technology was used to generate TiO in situ on the surface of the primary titanium implant. 2 / Ca 3 (PO 4 ) 2 Composite biofilm layer (that is, calcium-phosphorus biofilm lay...

Embodiment 1

[0042] A method for preparing a titanium implant with a surface controllable micro-nano composite structure biofilm, comprising the following steps:

[0043] (1) Design a titanium implant model with micron pores on the surface. The matrix material of the model is Ti-6Al-4V. The surface of the model is composed of a series of rounded frustum-shaped pits. 100μm, the depth is 100μm, and the pit pitch is 1mm.

[0044] (2) Using SLM technology to print the preset implant model. In the SLM process, the laser power is 150W, the spot diameter is 0.1mm, the scanning distance is 0.1mm, the powder coating thickness is 0.04mm, and the scanning speed is 1.2m / s.

[0045] (3) After polishing the implant matrix with 240#, 800#, 1200# sandpaper, wash it with acetone and deionized water.

[0046] (4) Electrolyte is configured, and the electrolyte is composed of calcium acetate of 0.05mol / L, sodium dihydrogen phosphate of 0.02mol / L, and EDTA-Na of 0.01mol / L.

[0047] (5) A micro-arc oxidation...

Embodiment 2

[0051] A method for preparing a titanium implant with a surface controllable micro-nano composite structure biofilm, comprising the following steps:

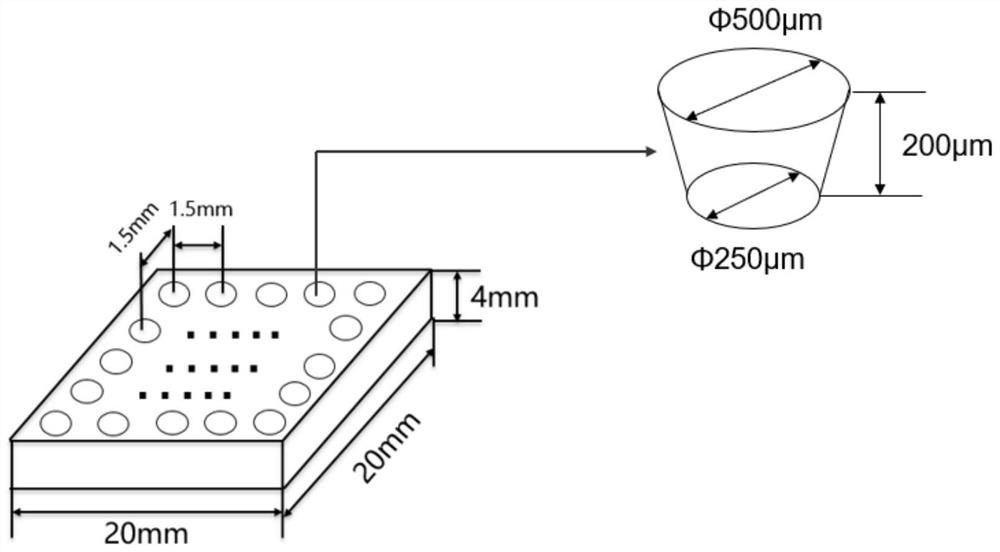

[0052] (1) Design a titanium implant model with micro-pores on the surface. The matrix material of the model is pure titanium. The surface of the model is composed of a series of rounded frustum-shaped pits. is 1000 μm, and the pit pitch is 1.5 mm.

[0053] (2) Using SLM technology to print the preset implant model. In the SLM process, the laser power is 200W, the spot diameter is 0.1mm, the scanning distance is 0.1mm, the powder coating thickness is 0.04mm, and the scanning speed is 1m / s.

[0054] (3) After polishing the implant matrix with 240#, 800#, 1200# sandpaper, wash it with acetone and deionized water.

[0055] (4) Electrolyte is configured, and the electrolyte is composed of 0.2mol / L calcium acetate, 0.1mol / L sodium dihydrogen phosphate, and 0.04mol / L EDTA-Na.

[0056] (5) A micro-arc oxidation device with an AC pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com