Alpha-calcium sulfate hemihydrates/beta-tertiary calcium phosphate porous granular-type composite artificial bones and preparation method thereof

A technology of tricalcium phosphate particles and calcium sulfate hemihydrate, which is applied in the field of medical materials, can solve the problem of difficulty in controlling the osteogenic performance and degradation performance of composite artificial bones, affecting product quality, inability to effectively control the spraying dosage of α-calcium sulfate hemihydrate, Spray uniformity β-tricalcium phosphate particle porosity and pore diameter to achieve the effect of ensuring in-situ curing performance and degradation performance, controllable degradation, and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Preparation of α-calcium sulfate hemihydrate / β-tricalcium phosphate porous granular composite artificial bone

[0050] (1) Take a healthy bovine femur and remove its surface soft tissue. Use a trephine with an inner diameter of 8mm to drill the femoral head and cancellous bone at the distal end of the femur. After soaking in sodium and hydrogen peroxide solution to remove cells and degrease, rinse with distilled water, boil in distilled water for 10 hours, rinse with running water for 3 hours, rinse with deionized water twice, dehydrate with 70%-100% gradient alcohol, and then dry at 50°C for 4 sky. The above-mentioned processed material was preliminarily calcined in a high-temperature calciner at a heating rate of 10°C / min, and calcined at 800°C for 3 hours. The calcined bone was taken out and soaked in 1M (NH 4 ) 2 HPO 4 In the solution for 24 hours, remove the excess liquid, take out the material and dry it again at 50°C for 4 days. The dried material ...

Embodiment 2

[0062] Embodiment 2: physical and chemical properties and index detection

[0063] Test the new product, provide test results and photos, and prove that the purpose of the invention has been achieved.

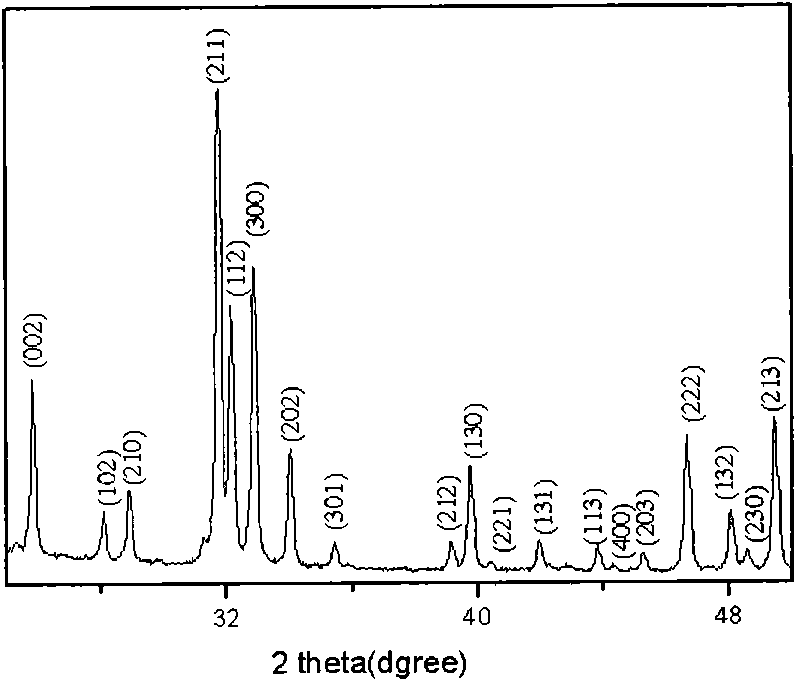

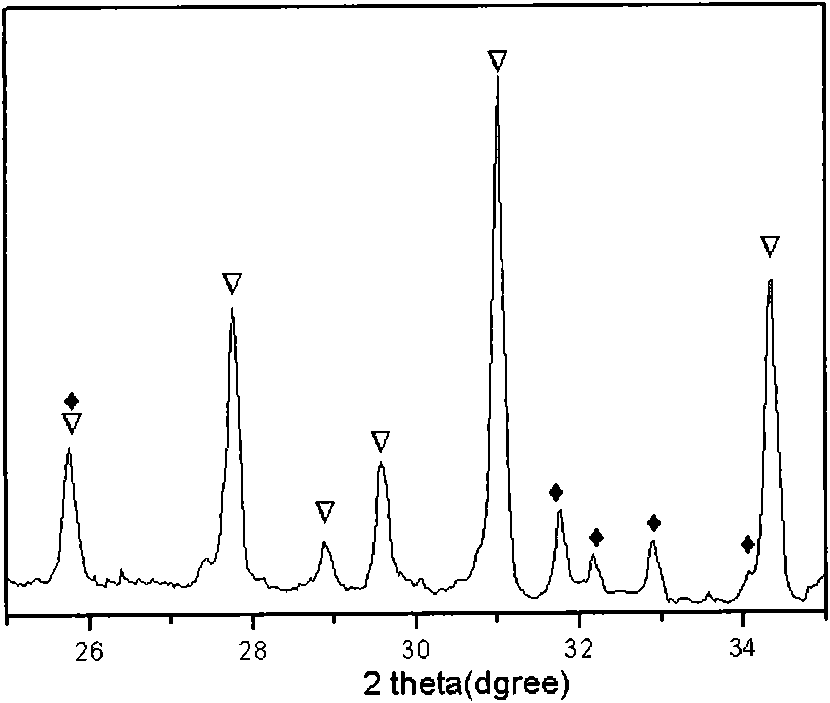

[0064] The single-phase β-TCP porous particles prepared in Example 1 were subjected to scanning electron microscopy, X-ray diffraction (XRD), porosity and biomechanical detection respectively. Scanning electron microscope at low magnification (×40) shows that the obtained material is a honeycomb porous structure, which retains the porous space structure of natural cancellous bone. The pore size and porosity are similar to that of cancellous bone, and the size of the macropores is between 50-600um. , under a high magnification lens (×3000), it can be seen that the walls of the macropores of the material are densely covered with microporous structures, the size of which is about 1um, and the connectivity between the pores is good, such as Figure 8 shown. Compared with the stan...

Embodiment 3

[0066] Embodiment 3: Degradation experiment in vitro and in vivo

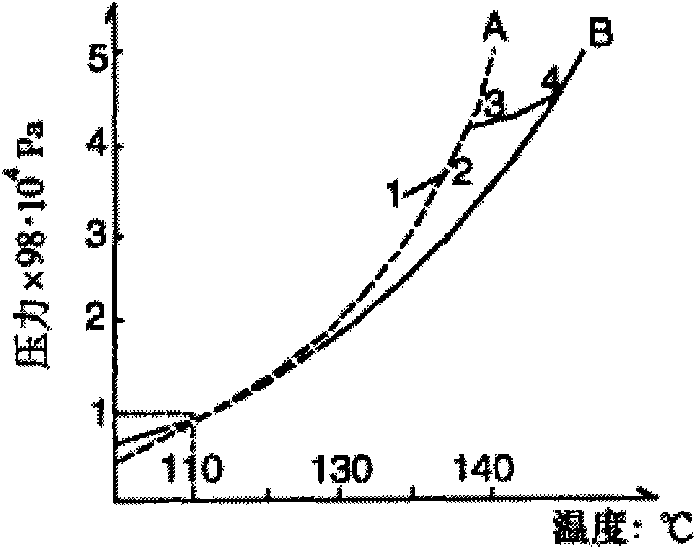

[0067] The α-CSH / β-TCP composite artificial bone prepared in Example 1 was prepared as a standard with a size of 12×8 mm, placed in a simulated body fluid with an initial pH value of 7.4, and kept at a constant temperature in a 37°C incubator without changing the fluid. Measure once a day in the first week, and then measure the pH value of the soaking solution with a pH meter every week until the pH value is constant and does not change. Then place the above test pieces in 50ml SBF solution with an initial pH value of 7.4, place them in an incubator at 37°C, store them at a constant temperature, change the solution every 2 days, and change the solution 30ml each time; at 4w, 8w, Measure the residual weight (Wr) of the specimen after drying to constant weight at 12w and 16 weeks, and calculate the in vitro degradation rate W% of the material = [100(Wo-Wr) / Wo].

[0068] During the degradation process of α-CSH / β-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com