Patents

Literature

59 results about "Beta tcp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product Code: 1216. Beta-TCP™ supports both healthy bile flow, and the normal bile acid to cholesterol conversion. It contains both digestive and antioxidant enzymes (vitamin C), along with Taurine and organic beet concentrate.

A gradient laminated composite supporting frame material based on bionic structures and its preparation method

The invention relates to a kind of laminated gradient composite scaffold material based on the bionic structure and its preparation method. The said material has three or more layers of porous structure, comprising of hyaluronic acid, PLGA, PLA, collagen II and nano-hydroxyapatite (nano-HA) , beta- tricalcium phosphate ( beta-TCP). The upper layer is made by collagen II / hyaluronic acid or PLGA and PLA imitating the cartilage layer. With the counterfeit the calcified cartilage layer in the middle, it is one layer or multi- sublayer, made by nano-HA or beta-TCP with collagen II / hyaluronic acid or PLGA and PLA; the bottom is made of nano-HA or beta-TCP with collagen II or PLGA and PLA. From top to bottom, the content of inorganic material increases in its layers, about 0 to 60 mass percent of layers. The aperture of the scaffold material is 50 to 450 micron, with 70 to 93 percent porosity. The scaffold material made by this invention has an adjustable degradation rate, good mechanical and biocompatible properties, can adapt to culture with cartilage bone cells and compound with growth factor and small molecular or peptides, it can be used to repair cartilage simultaneously.

Owner:HUAZHONG UNIV OF SCI & TECH

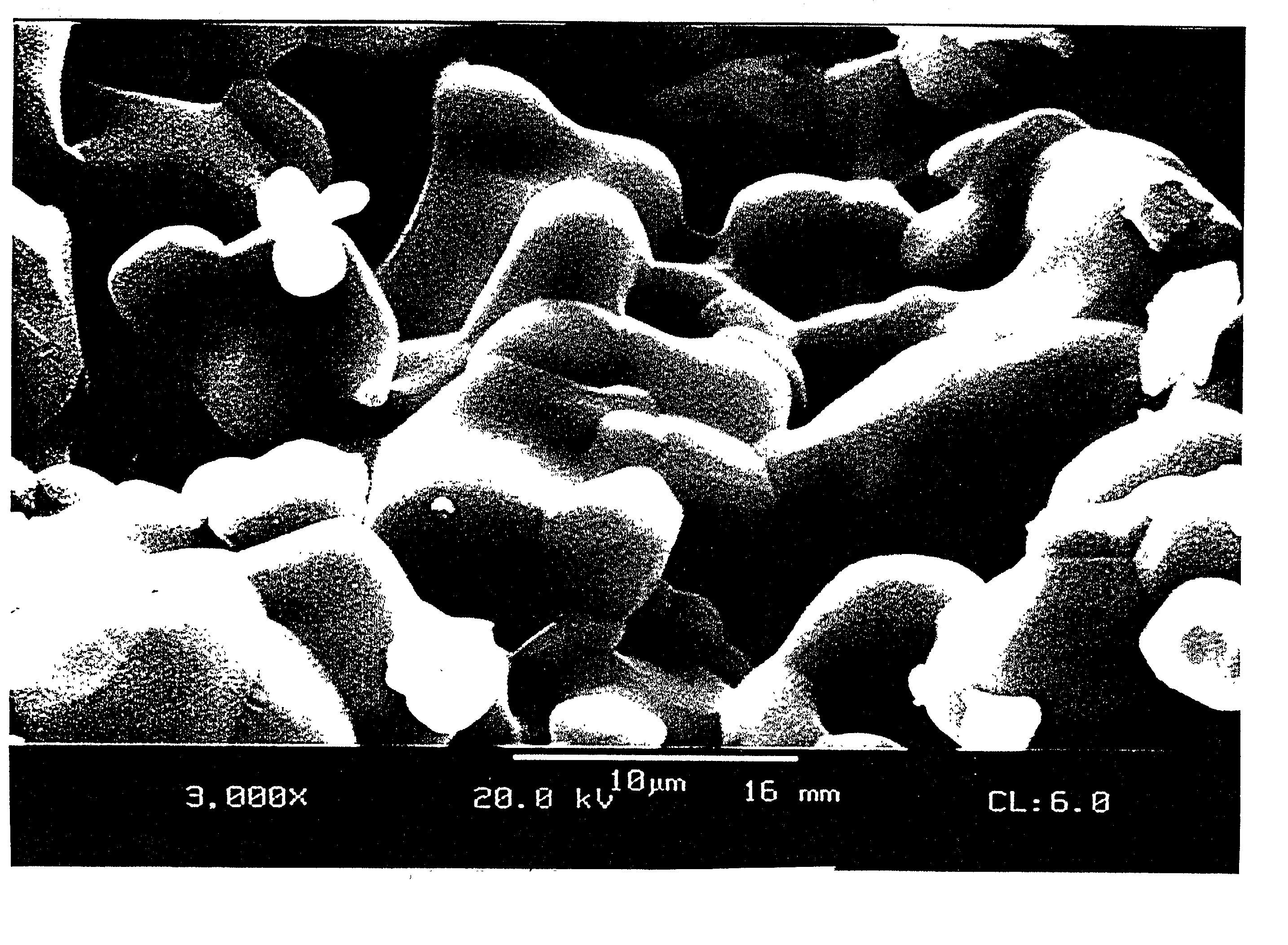

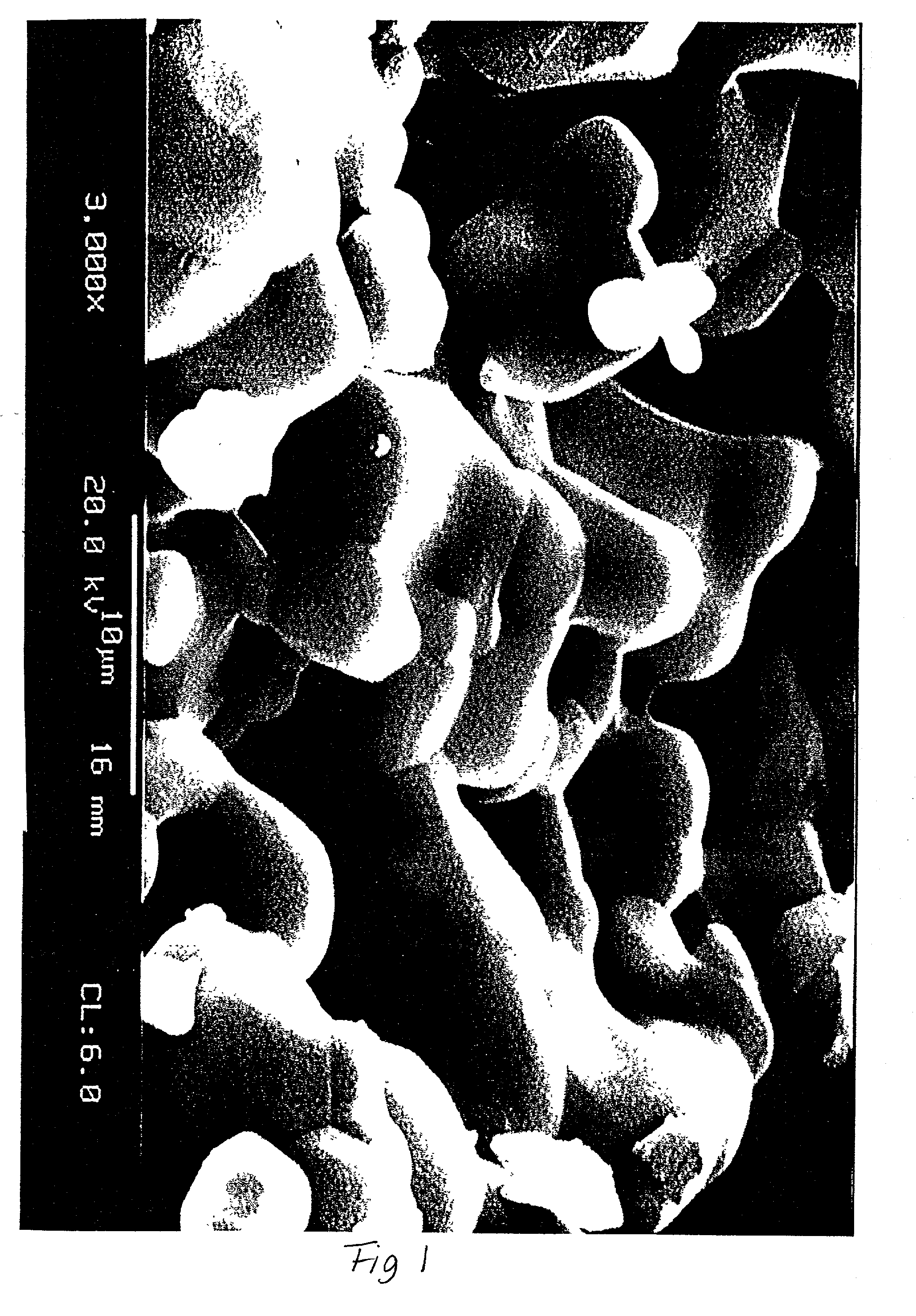

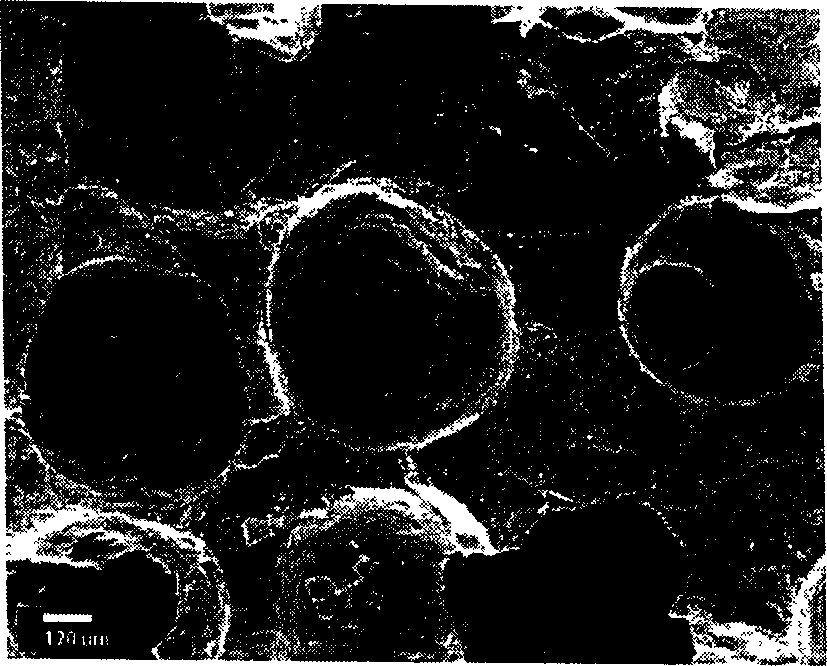

Resorbable bone replacement and bone formation material

The invention relates to a resorbable bone replacement and bone formation material (augmentation material) based on porous beta-tricalcium phosphate (beta-TCP).

Owner:CURASAN

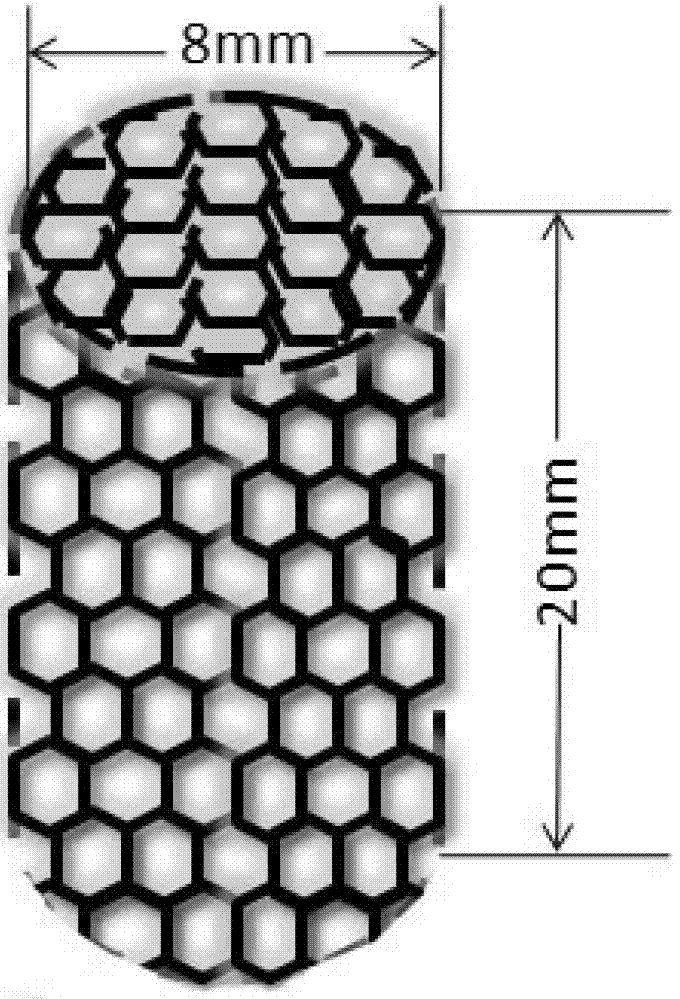

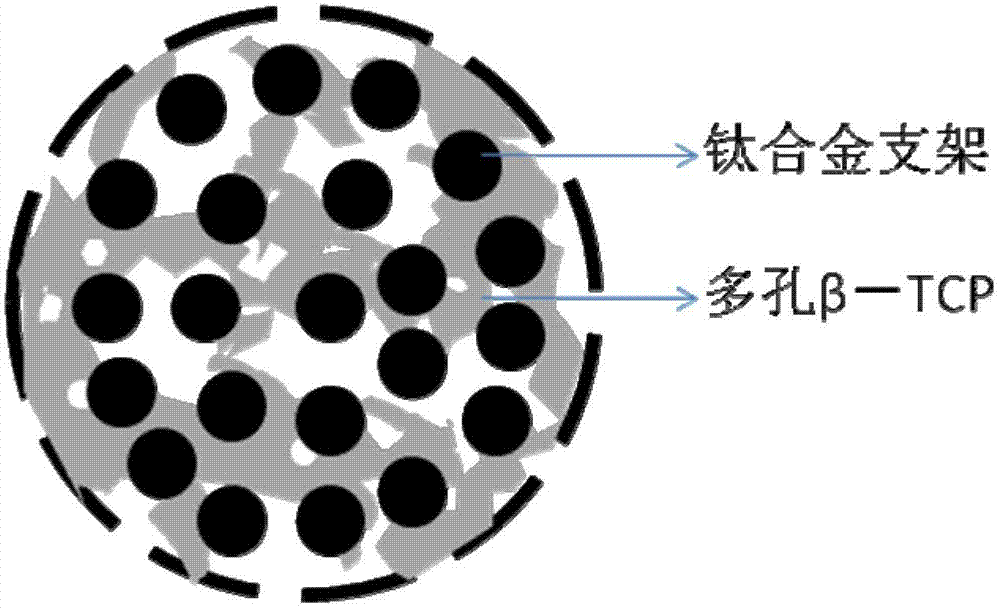

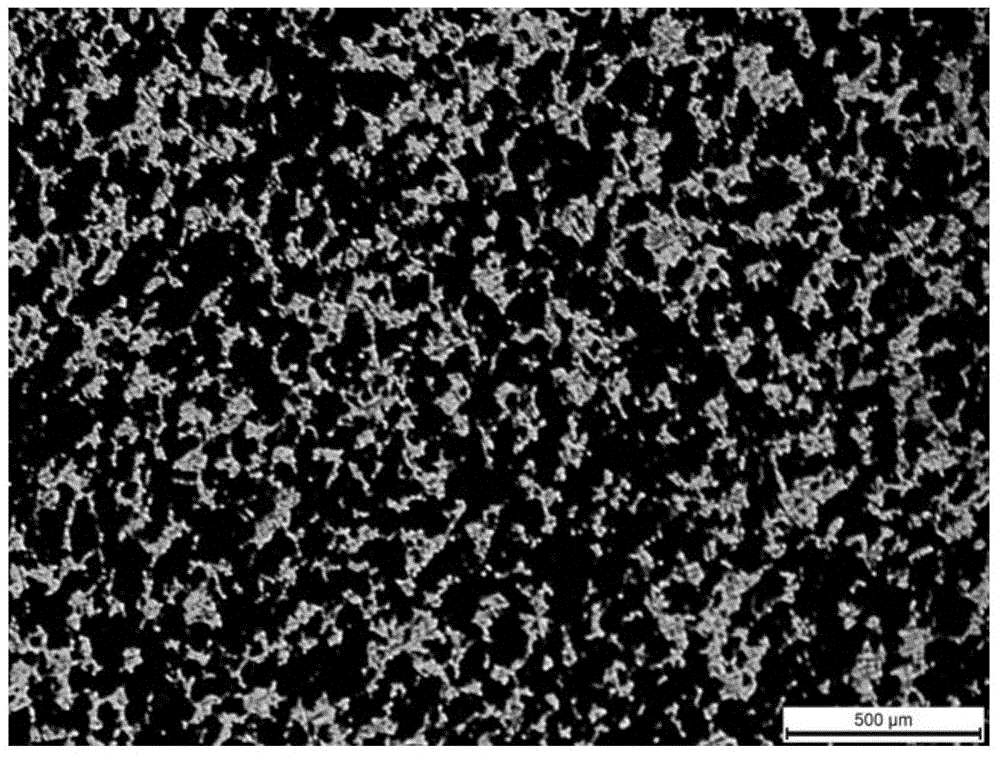

Compound porous beta-TCP (tertiary calcium phosphate) titanium alloy human astragal support bar and preparation method thereof

ActiveCN102764888AGood bone conductionAppropriate degradation rateAnkle jointsJoint implantsOsseointegrationPolyvinyl alcohol

The invention discloses a compound porous beta-TCP (tertiary calcium phosphate) titanium alloy human astragal support bar and a preparation method thereof. The preparation method includes the steps: firstly, inputting model data into an electronic beam melting device according to design requirements to prepare the needed porous titanium alloy human astragal support bar; and secondly, mixing powdery beta-TCP with hydrogen peroxide and polyvinyl alcohol solution into pasty slurry, pouring the pasty slurry into pores of a titanium alloy support after sufficiently and uniformly stirring the pasty slurry, removing excess water by an evaporation method, and performing rubber discharging and sintering to obtain the compound biological ceramic porous beta-TCP titanium alloy human astragal support bar. The porous titanium alloy human astragal support bar prepared by the preparation method has an elastic modulus similar to that of a human bone tissue, the compressive strength of the support bar is higher than that of a spongy bone and slightly lower than a cortical bone, the support bar can provide effective biomechanical support in an astragal after being implanted into the astragal by the aid of a regular pore structure and internally compounded porous beta-TCP components with fine osteoinductive activity, and the support bar has an excellent osseointegration capacity.

Owner:维度(西安)生物医疗科技有限公司

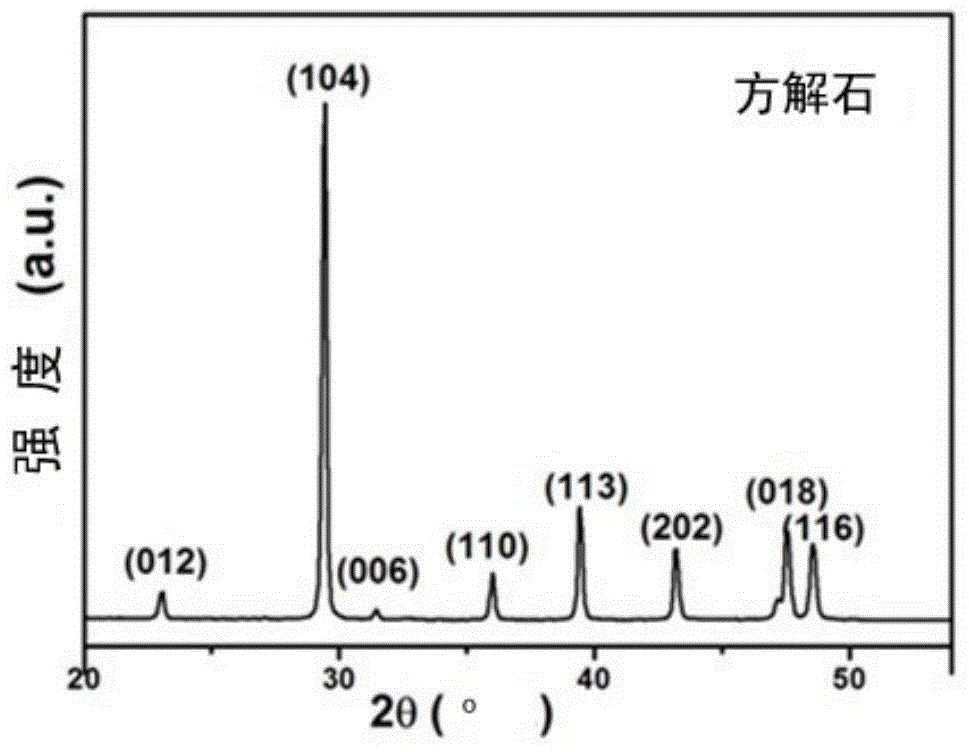

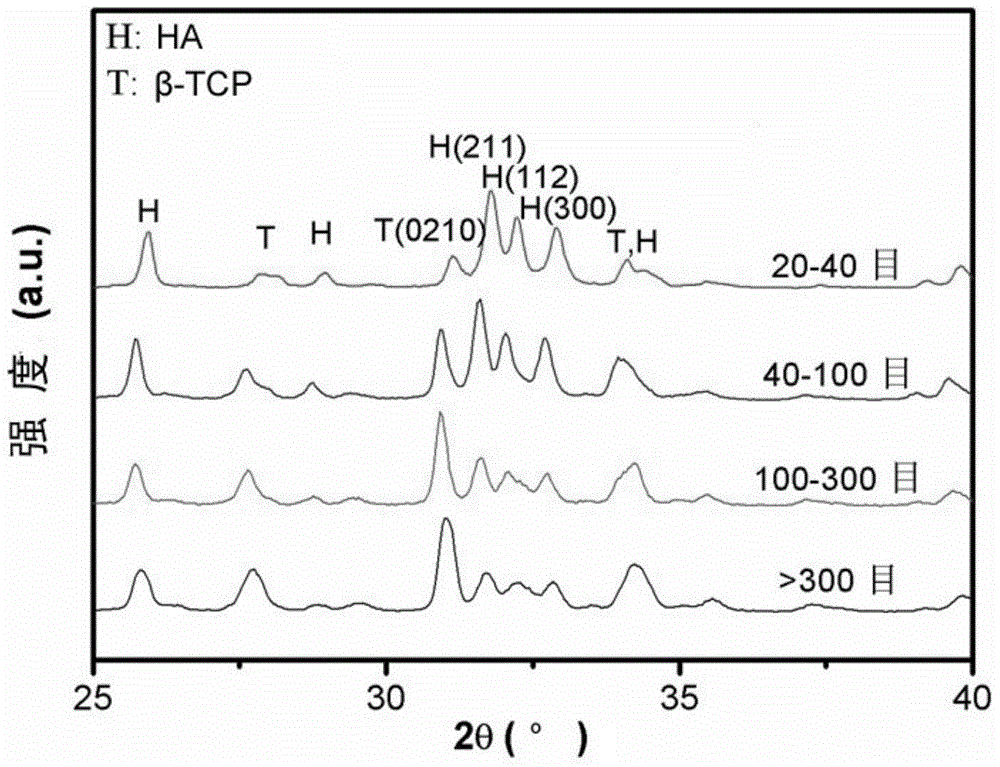

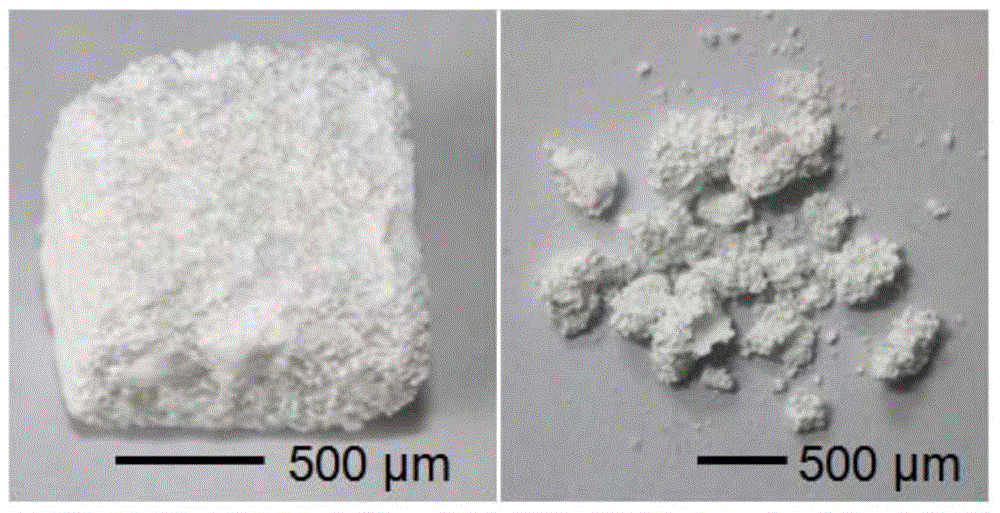

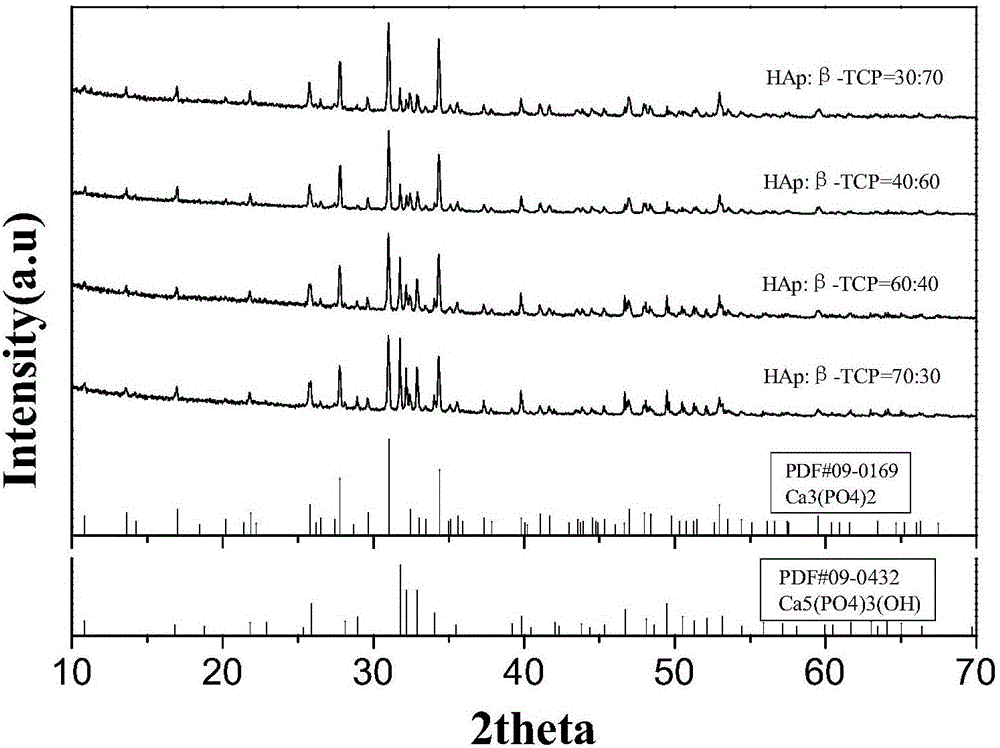

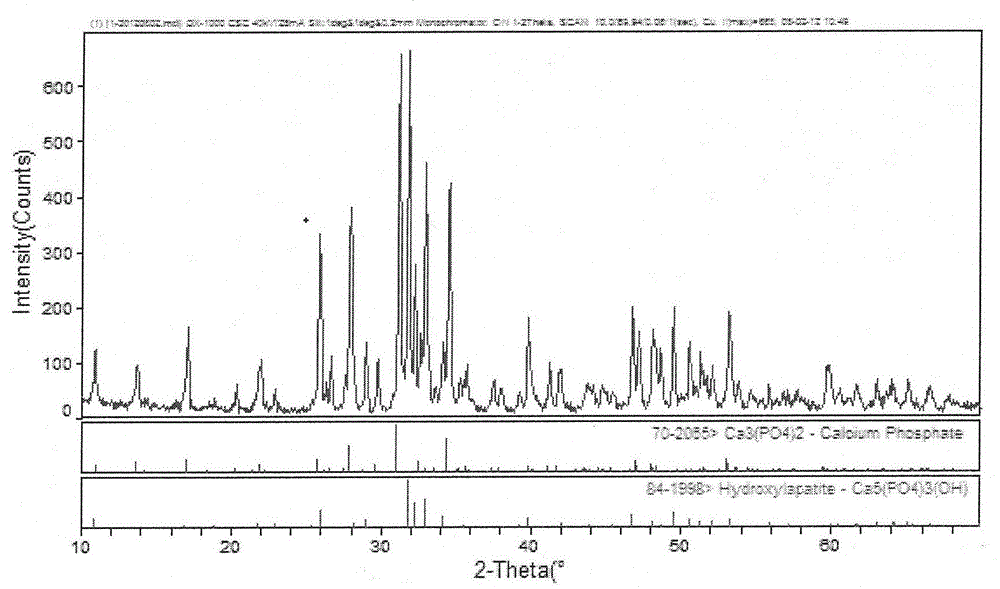

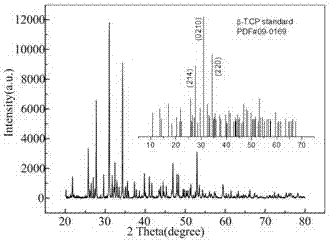

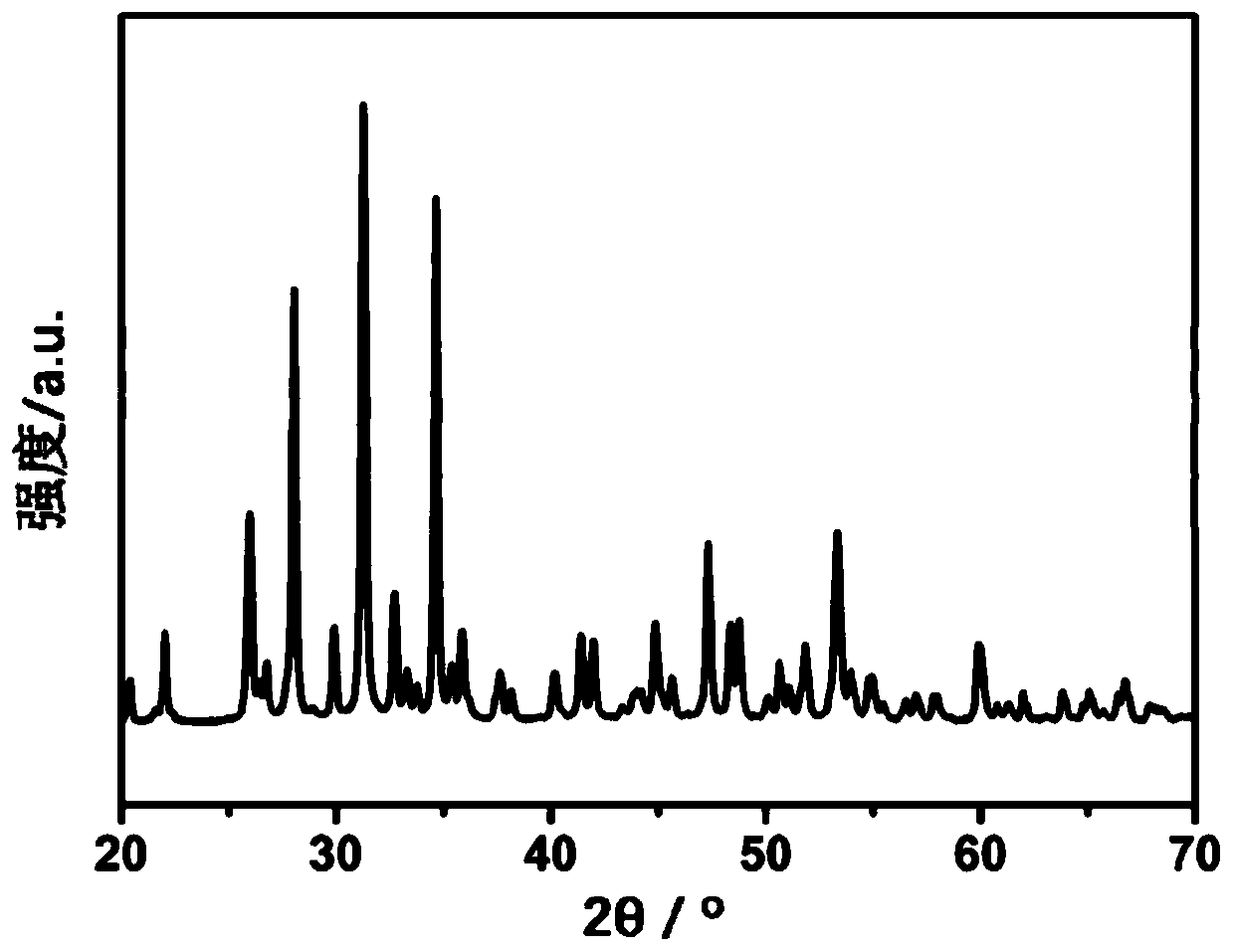

Two-phase calcium phosphate material, preparation method thereof, and two-phase calcium phosphate artificial bone ceramic

The invention discloses a two-phase calcium phosphate material, a preparation method thereof, and a two-phase calcium phosphate artificial bone ceramic, and belongs to the field of biological ceramic materials. The two-phase calcium phosphate artificial bone ceramic is prepared through preparing a beta phase tricalcium phosphate (beta-TCP) and hydroxy apatite (HA) mixture (the two-phase calcium phosphate material) from egg shells and carrying out a sintering process. The beta-TCP and the HA are prepared from the egg shells with abundant sources through a one-step chemical synthesis process, the mass proportions of the beta-TCP and the HA in the two-phase calcium phosphate are controlled through changing the particle dimensions of the egg shells in the hydrothermal synthesis process, and the preparation cost of the two-phase calcium phosphate material is low. The two-phase calcium phosphate ceramic is prepared through a template process under pressureless sintering conditions, and the two-phase calcium phosphate ceramic with different degradation speeds can be prepared through controlling the mass proportions of the beta-TCP and the HA, so different demands of bone defect patients on the degradation period of artificial bone scaffold materials due to individual difference are met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

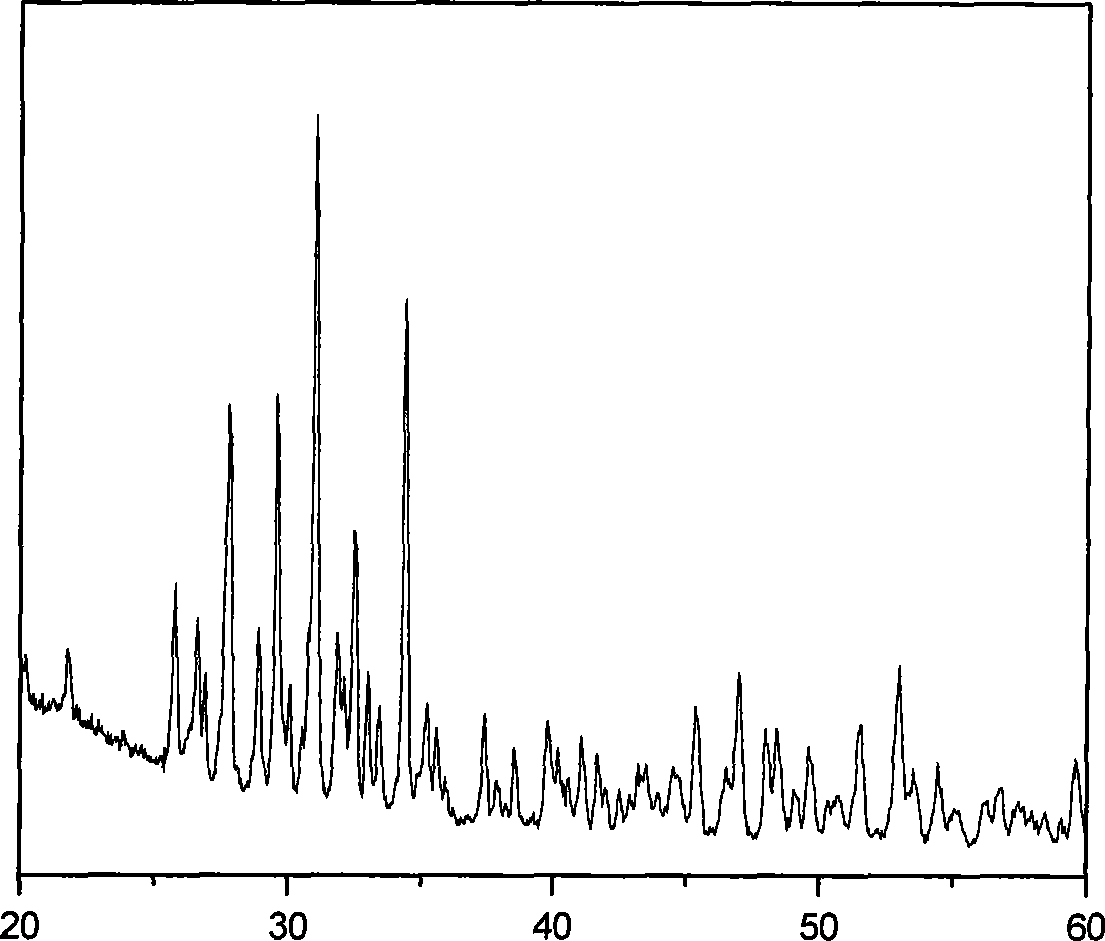

Alpha-calcium sulfate hemihydrates/beta-tertiary calcium phosphate porous granular-type composite artificial bones and preparation method thereof

The invention discloses a method for preparing alpha-calcium sulfate hemihydrates (alpha-CSH) / beta-tertiary calcium phosphate (beta-TCP) porous granular-type composite artificial bones, which is characterized in that the alpha-CSH is directly synthesized on the surface and / or in the pores of the beta-TCP granules synchronously by the hydrothermal synthesis process and finally the alpha-CSH / beta-TCP porous granular-type artificial bones is prepared. The invention has the advantages that the preparation process is simpler, the preparation period can be effectively reduced, and the preparation efficiency is improved; the proportion between alpha-CSH and beta-TCP phases of the granular-type composite artificial bones can be effectively controlled, thereby controlling the pore structure of the artificial bone granules; meanwhile, the invention guarantees the in-situ solidifying performance and degrading performance of the composite artificial bones, controls the evenness of the product and the porosity and pore diameter of the beta-TCP granules, improves the bone-formation performance and degrading performance of the composite artificial bones and further improves the quality of the product, thereby finally obtaining the composite artificial bones having self-solidifying performance and controllable degradation and having a certain biomechanical strength. The invention has good application and market prospect.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

Preparation method of wollastone/tricalcium phosphate composite bio-active material

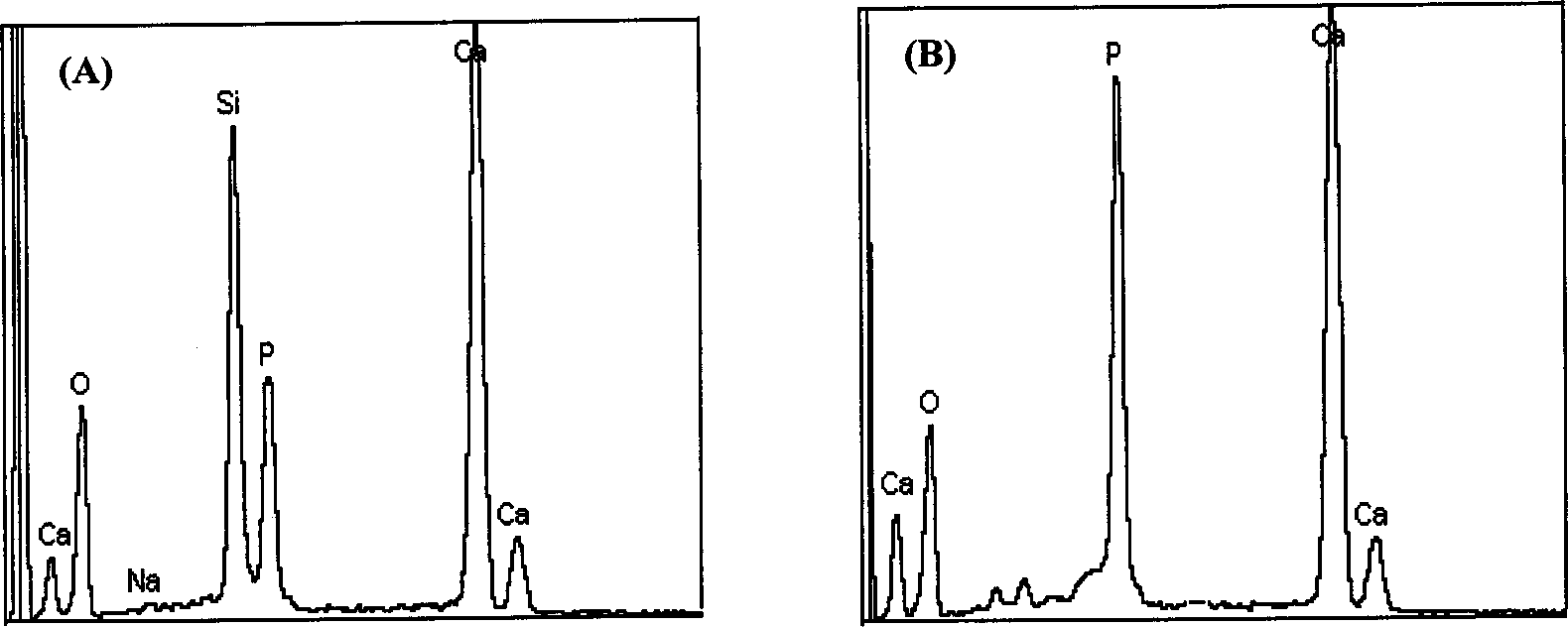

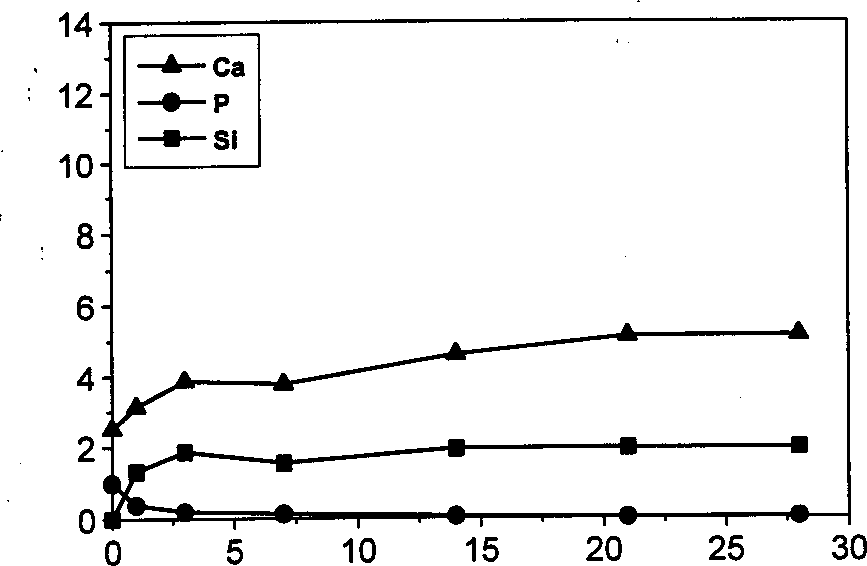

The preparation method of wollastonite / tricalcium phospate composite biological material includes the following steps: using Na2SiO3 or silicon sol as silicon source and using Ca(Na3)2 or CaCl2 and Ca(OH)2 as calcium source, respectively preparing their solutions with a certain concentration and pH value, adding proper quantity of beta-tricalcium phosphate (beta-TCP) to calcium contained solution, uniformly dispersing, then utilizing chemical coprecipitation process to prepare calcium silicate hydrate and beta-TCP powder uniformly-mixed precipitate, washing and drying, roasting at 800-900 deg.c to obtain wollastonite and beta-TCP composite powder, granulating, dry-pressing and forming, sintering for 2-5 hr. at 1300-1400 deg.C to obtain the invented wollastonite / tricalcium phosphate composite biological ceramics. According to the different requirements, the above-mentioned composition can be resulated, specially the formation of in-situ porous structure is favourable for growing of tissue and blood vessel, etc.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

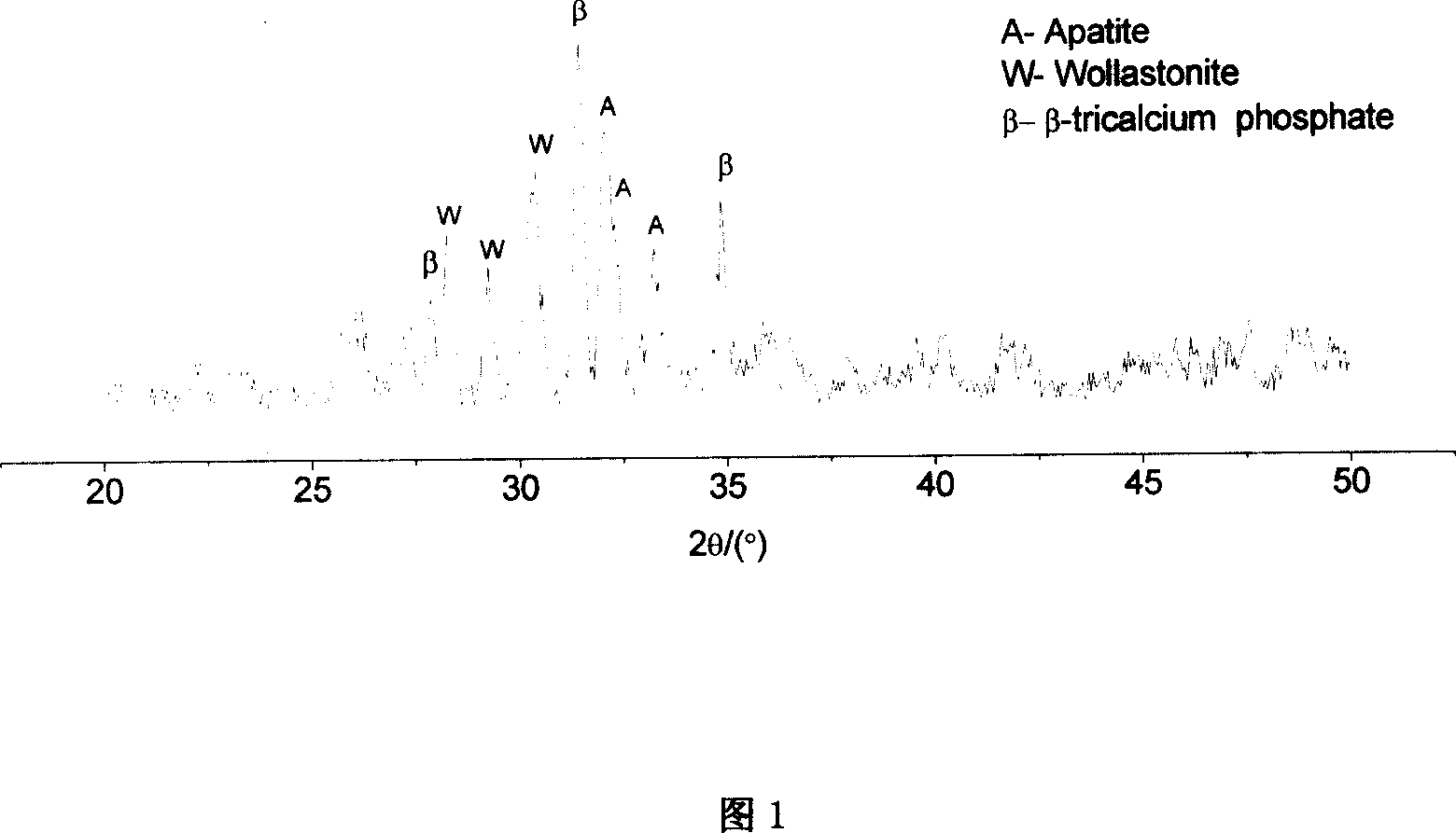

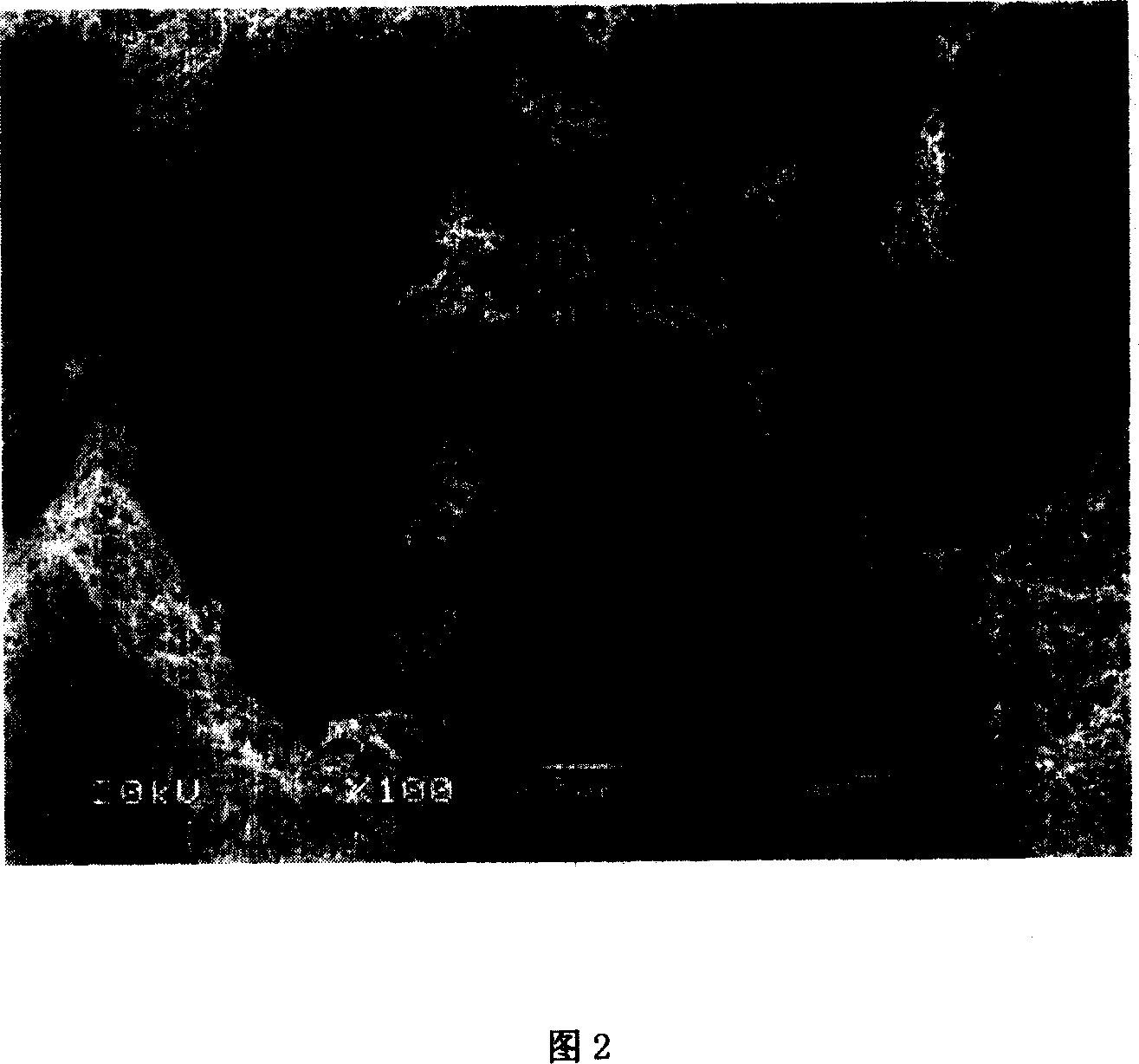

Composite organism ceramic material composed of apatite-wollastonite/beta-tricalcium phosphate

InactiveCN1923752AImprove biological activityFast adhesionCeramicwarePorosityAlpha-tricalcium phosphate

The invention discloses a composite biological active ceramic material of Apatite-Wollastonite / beta-tricalcium phosphate (AW / beta-TCP), which comprises the following steps: adopting sol-gel process to prepare AW former powder; preparing TCP former powder through chemical sediment method; sieving TCP former powder through 60-order standard sieve; putting AW former powder and TCP former particle in the material mixing machine according to different proportion; adding certain rate corresponding to powder weight geoceric acid or naphthalene particle with grain size at 20-30 order; making 5wt% polyvinyl alcohol solution as adhesive; blending completely; moulding; drying; sintering to obtain porous product.

Owner:SICHUAN UNIV

Preparation method of beta-TCP/11A composite biological material

A composite beta-TCP / HA biomaterial with high biocompatibility and mechanical strength and regulatable porosity is prepared through preparing beta-TCP powder from (NH4)2HPO4 solution, Ca(NO3)2 solution and filler (Mg or Sr), preparing the beta-TCP / bone glue microspheres from beta-TCP powder and bone glue in heat-conducting oil, die pressing, sintering to obtain beta-TCP ceramic, immersing it in HA sol and beta-TCP sol, and heat treating.

Owner:TIANJIN UNIV

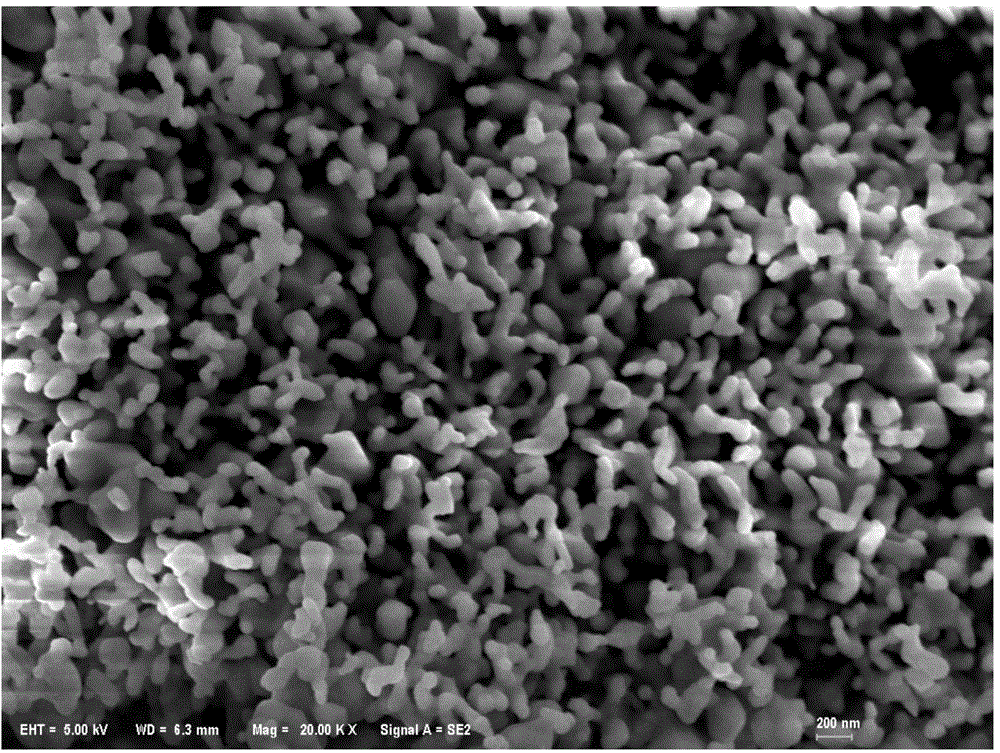

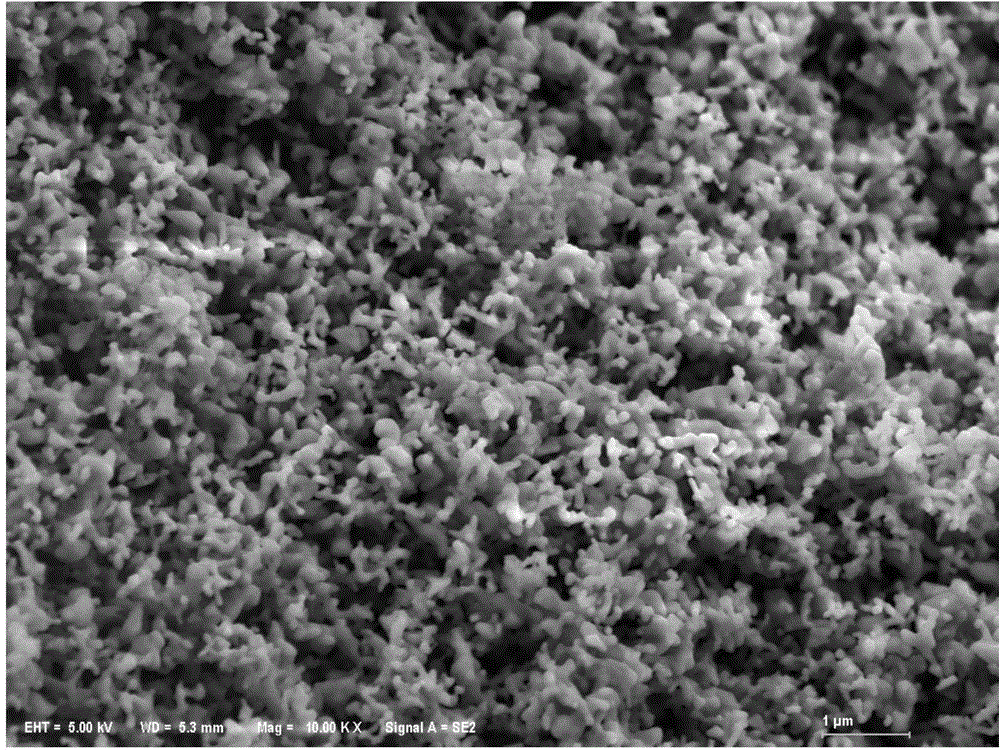

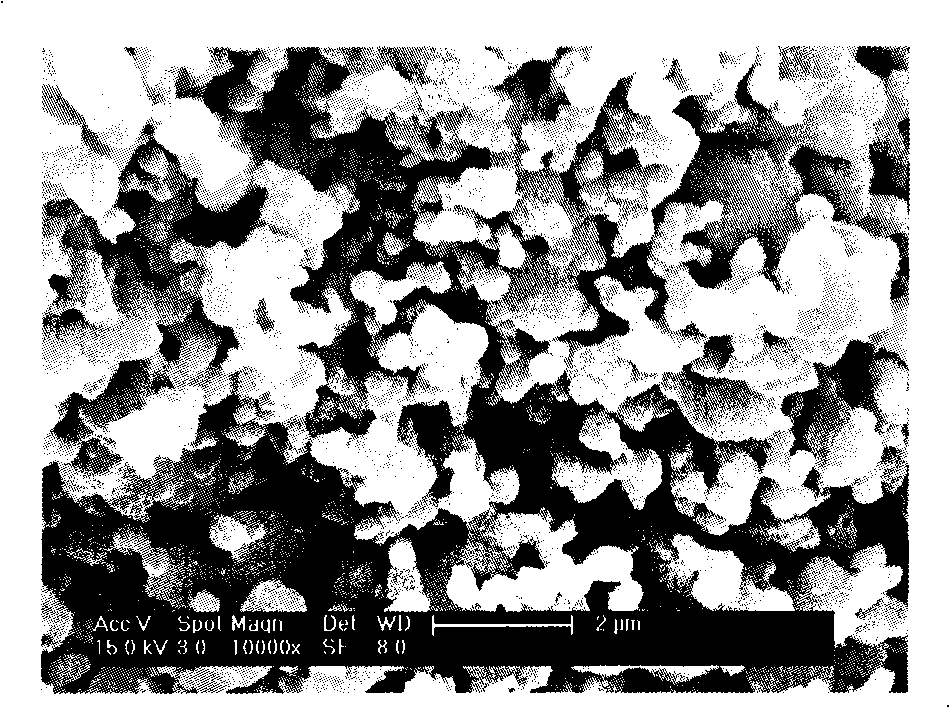

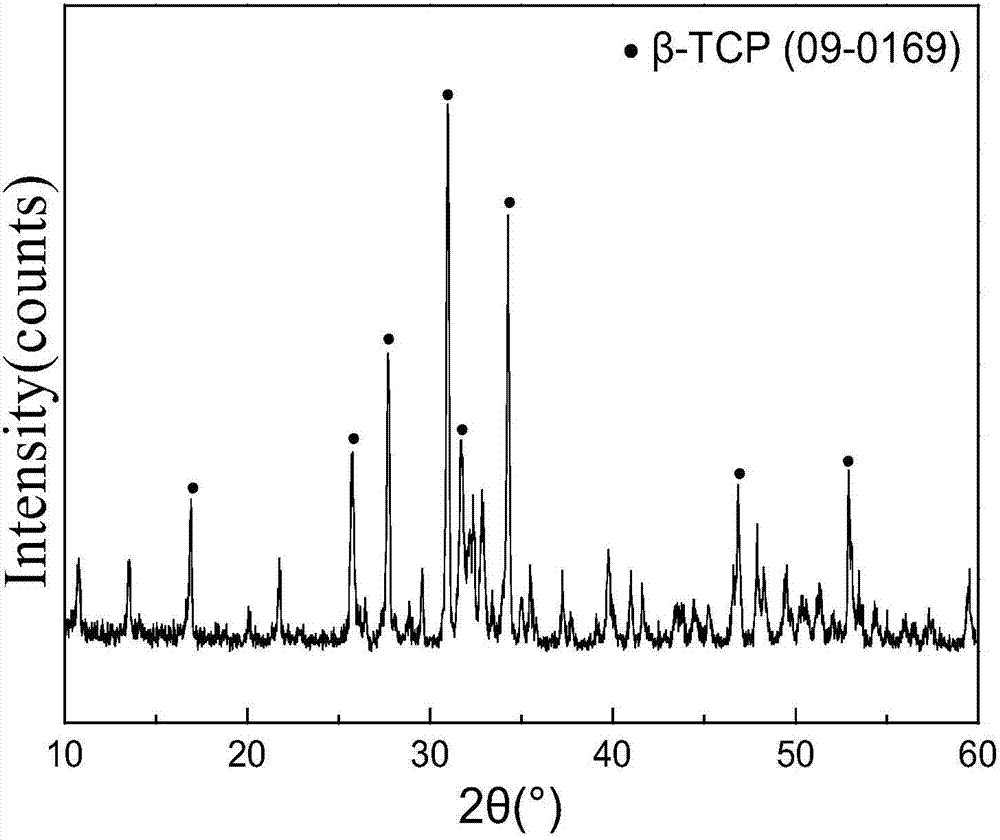

Preparation method of mesoporous beta-TCP (tricalcium phosphate) powder

ActiveCN104445130ASmall apertureIncrease the aperturePhosphorus compoundsTri calcium phosphateBeta tcp

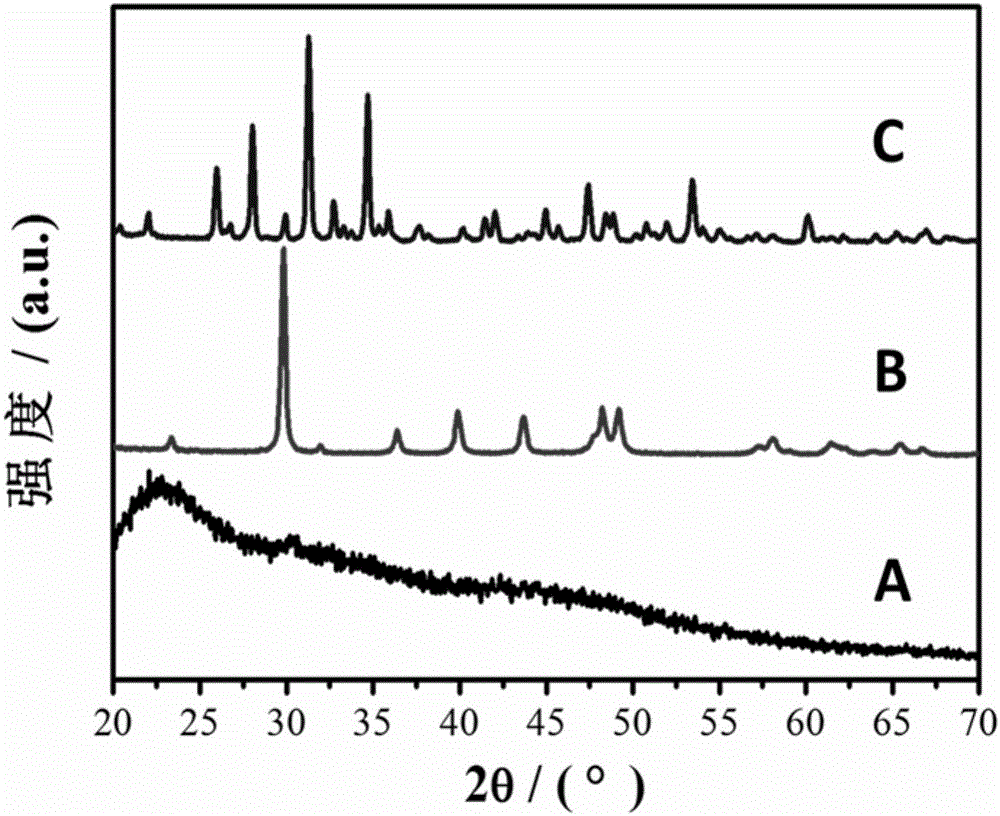

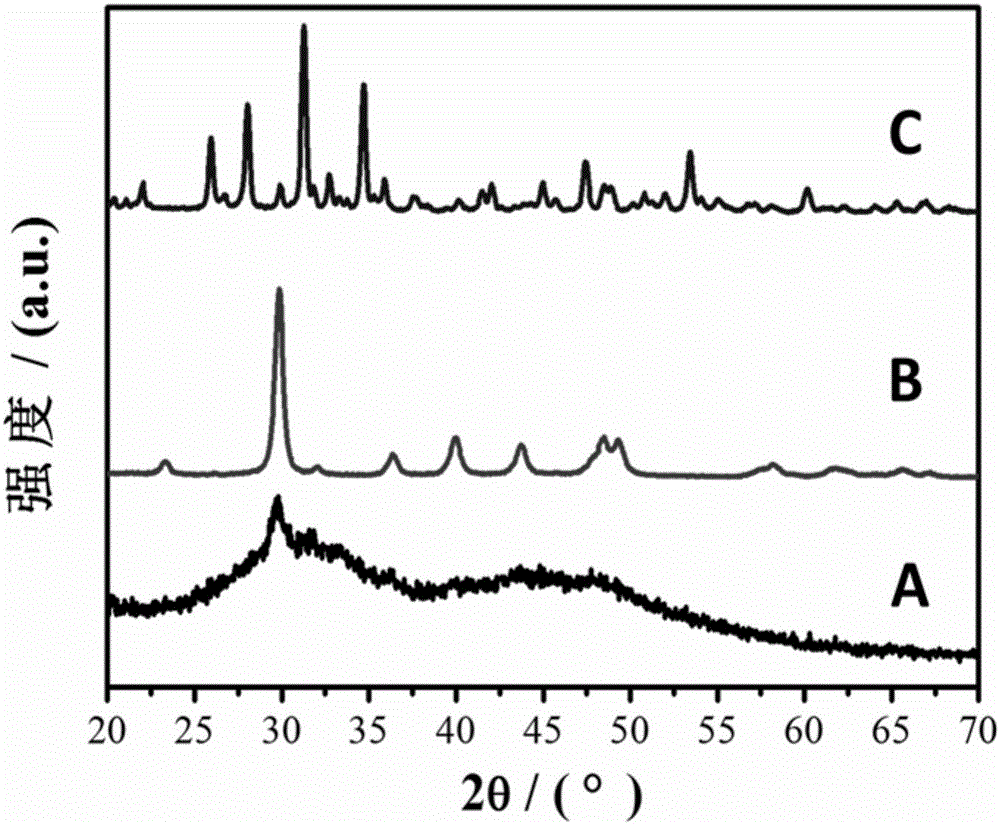

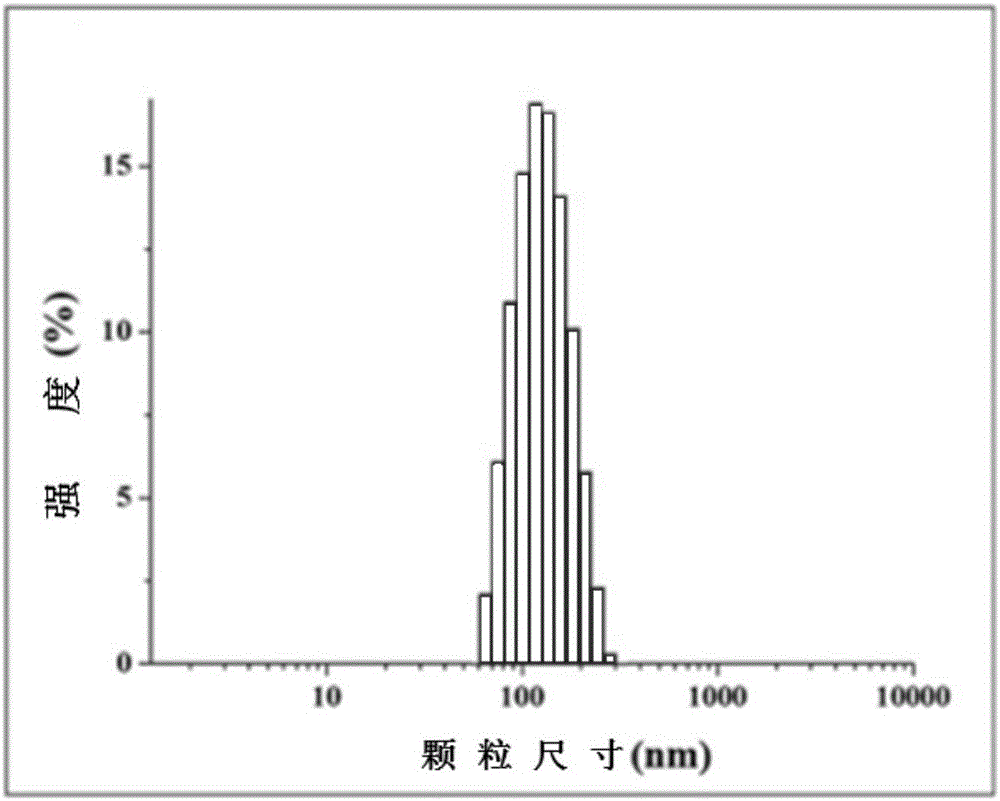

The invention relates to a preparation method of mesoporous beta-TCP (tricalcium phosphate) powder. The preparation method comprises steps as follows: 1), two parts of transparent solutions containing surfactants, cosurfactants and water are prepared; 2), a calcium-containing inorganic salt solution and a phosphorus-containing inorganic salt solution are added to the transparent solutions respectively and stirred, a phosphorus-containing inorganic salt mixed solution is added to a calcium-containing inorganic salt mixed solution, the pH value is adjusted, and the mixture is stirred to obtain an emulsion; and 3), the mixture is left to stand, subjected to ageing, centrifugation, washing and drying, placed in a high-temperature furnace, heated and subjected to heat preservation, and mesoporous beta-TCP powder is obtained. The preparation method has the benefits as follows: 1, the operation is simple, energy consumption is low, the cost is low, the reaction condition is mild, and harmful substances are not generated in the preparation process; and 2, the obtained mesoporous beta-TCP powder has smaller pore diameter and has a three-dimensional pore structure, the average pore diameter of the mesoporous beta-TCP powder is 8.80-21.36 nm, and the specific surface area is 10.11-153.43 m<2> / g.

Owner:WUHAN UNIV OF TECH

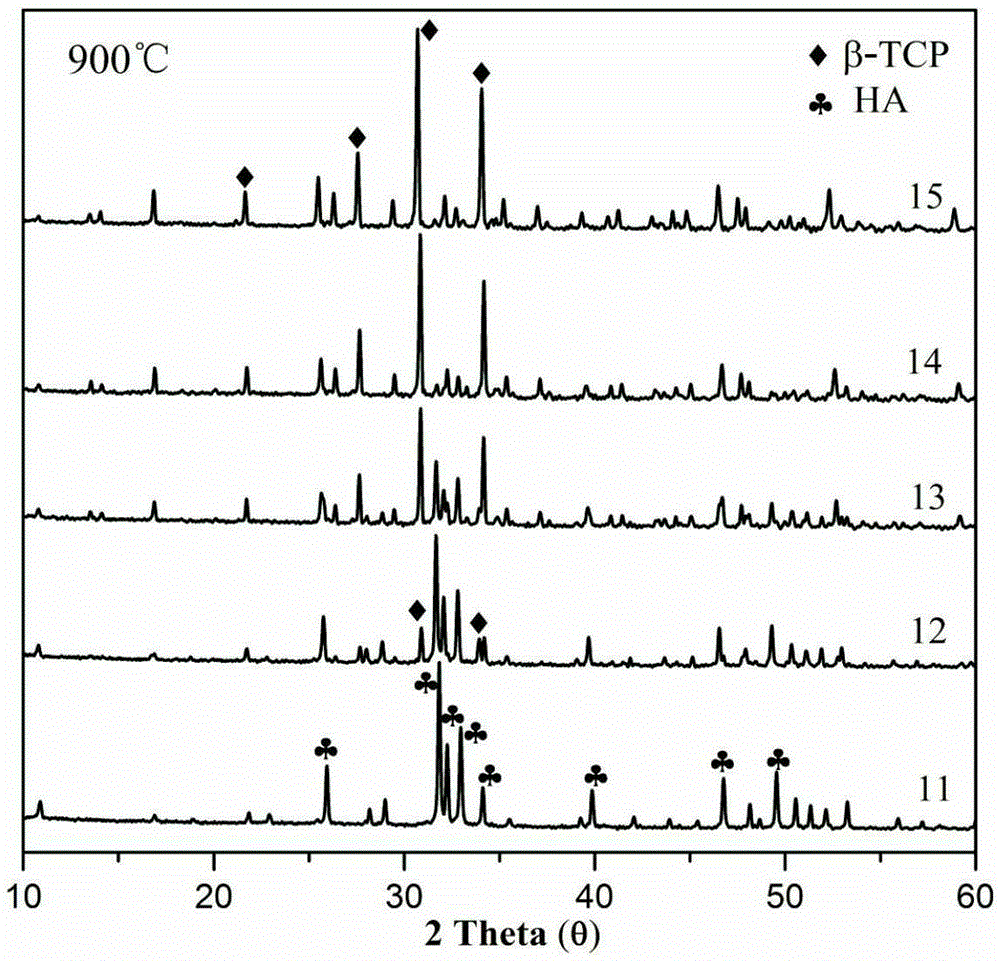

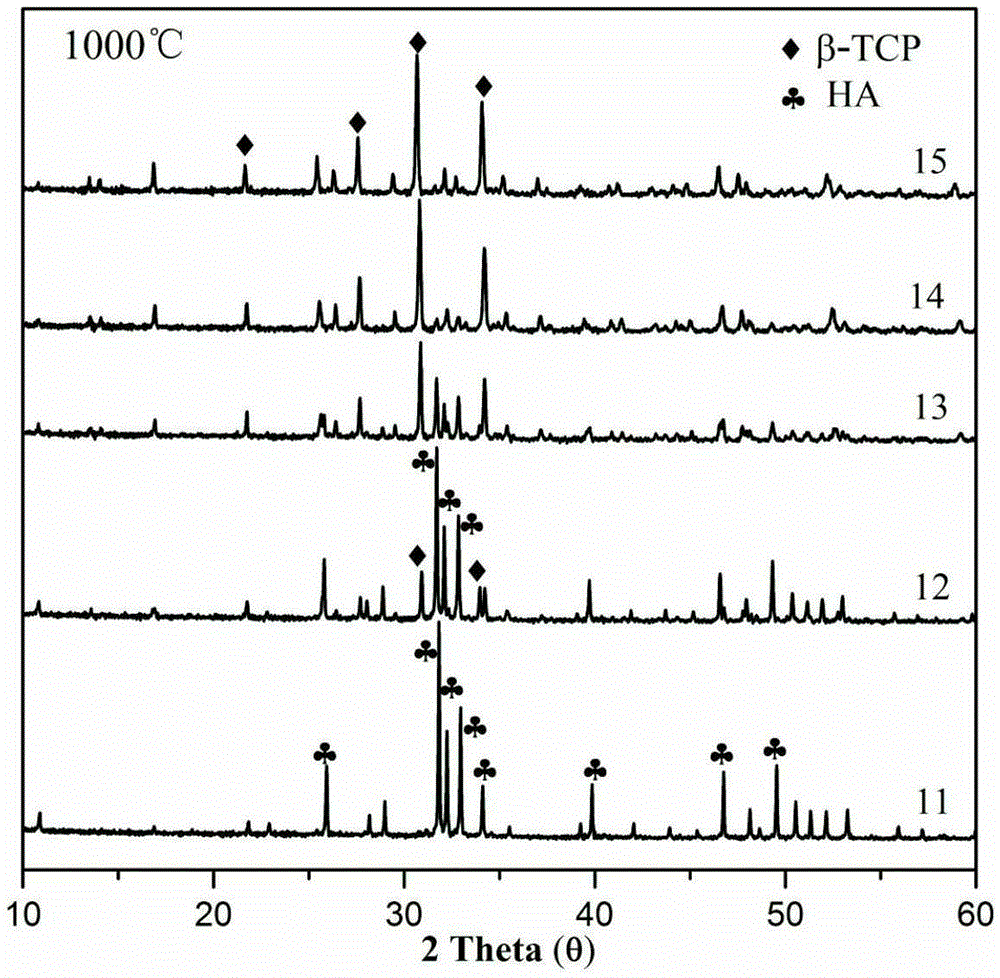

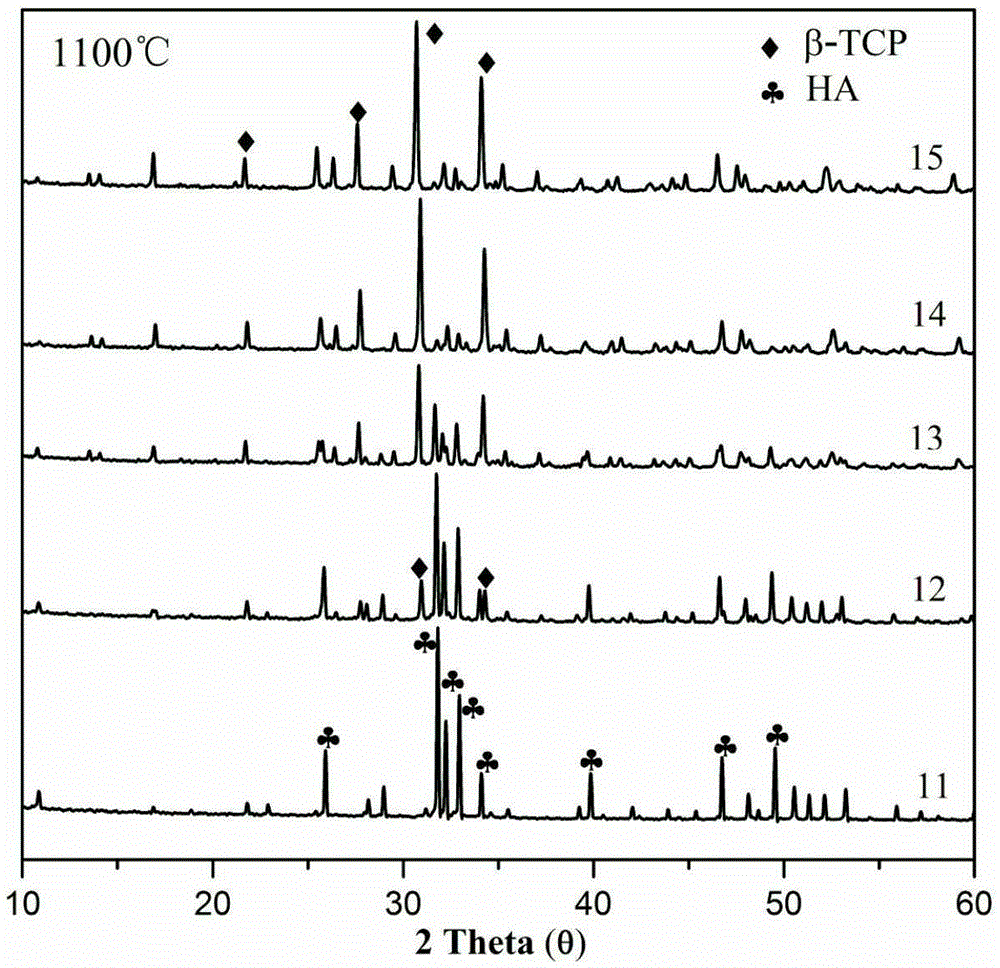

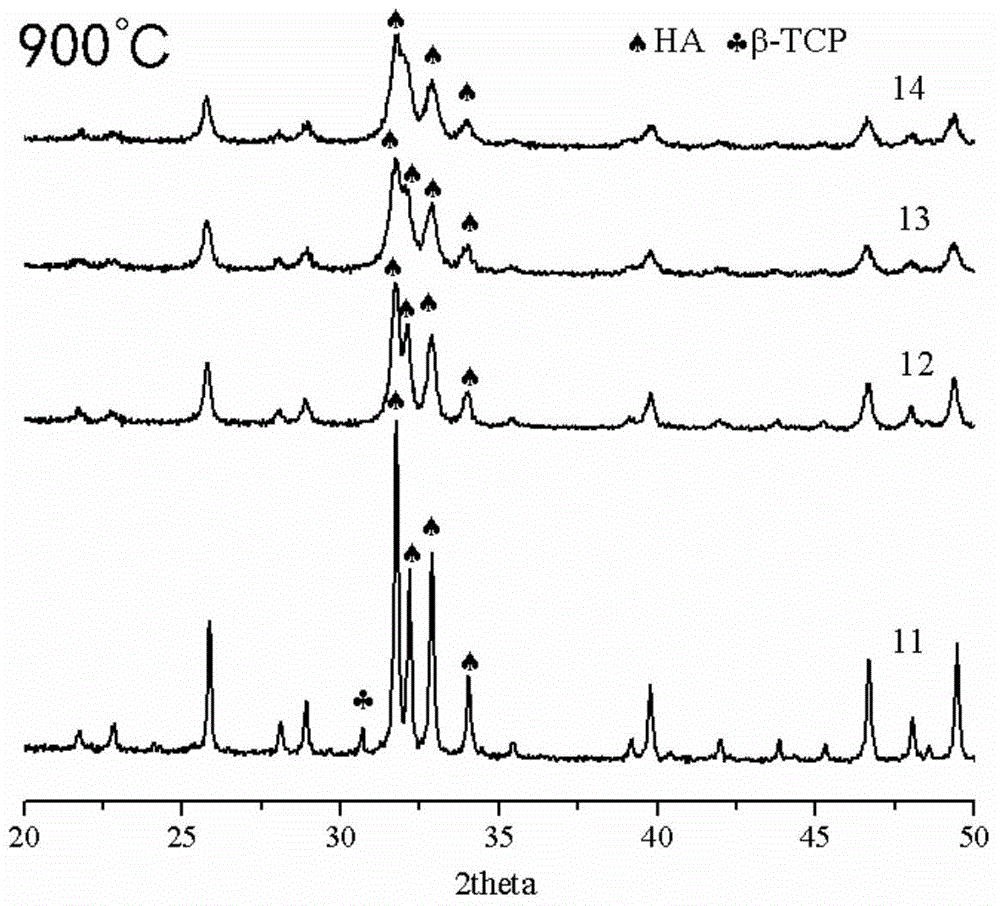

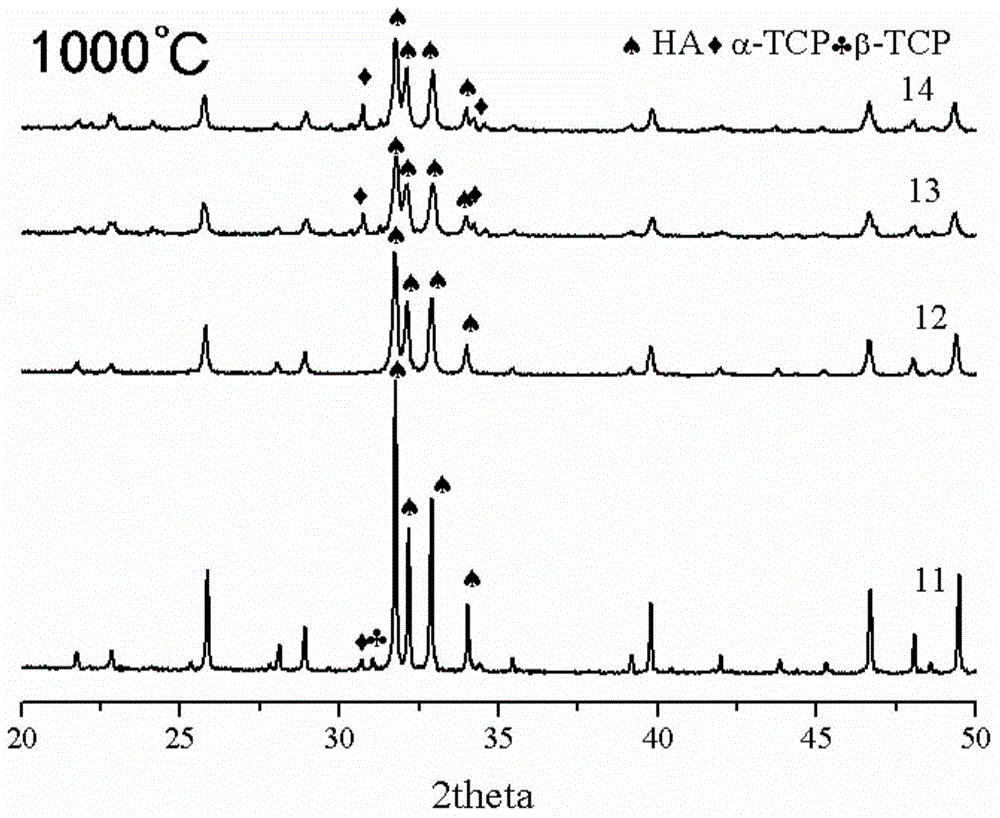

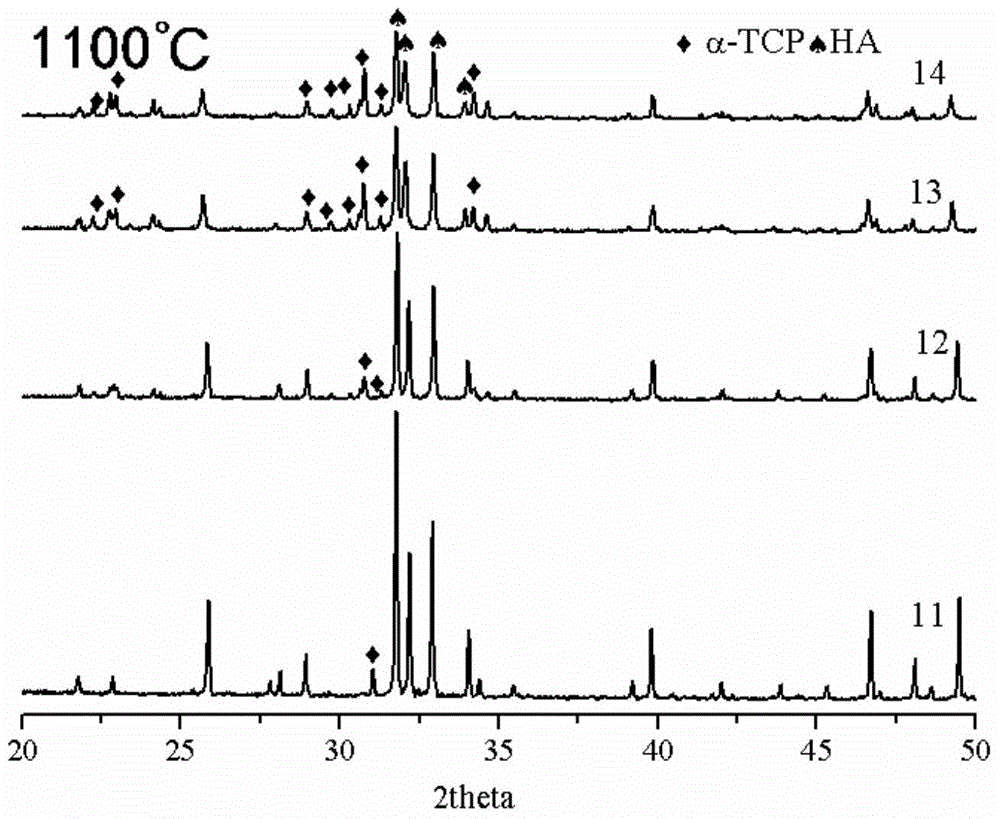

Controllable-phase strontium-doped calcium phosphate powder and preparing method thereof

ActiveCN105327390AImproves bone bondingImprove biological activityProsthesisCalcium biphosphateStrontium

The invention belongs to the technical field of biomedical materials and discloses controllable-phase strontium-doped calcium phosphate powder and a preparing method thereof. The preparing method comprises the steps of adding a (NH4)3PO4.3H2O solution to a Ca(NO3)2.4H2O and (NH4)3PO4.3H2O mixing solution dropwise for reaction according to the molar ratio of (Ca+Sr) / P=1.67, conducting centrifugal washing and drying on the reaction product, and conducting grinding to obtain strontium-doped calcium phosphate precursor powder; conducting heat preservation sintering on the strontium-doped calcium phosphate precursor powder at 900-1200 DEG C, and obtaining the controllable-phase strontium-doped calcium phosphate powder after cooling. Strontium-doped calcium phosphate biphase powder with different HA and beta-TCP proportions can be prepared in a controllable mode by adjusting the strontium doping amount, and higher biological activity and broader application prospects are realized compared with traditional calcium phosphate powder.

Owner:SOUTH CHINA UNIV OF TECH

Biphase calcium phosphate (BCP) composite powder synthesized by high-temperature solid phase reaction and preparation method thereof

The invention discloses biphase calcium phosphate (BCP) composite powder synthesized by a high-temperature solid phase reaction. BCP powder is biphase composite powder prepared from hydroxyapatite (HA) and beta-tricalcium phosphate (beta-TCP), in which the molar ratio Ca / P of calcium to phosphorus is 1.5 to 1.67, wherein the value ranges of the relative mass percent of HA and beta-TCP two phases are each 1 to 99 percent; the sizes of crystalline grains of the HA and beta-TCP two phases are 20nm to 300 microns; the crystallinity is 50 to 100 percent. The invention also discloses a preparation method of the BCP composite powder synthesized by the high-temperature solid phase reaction. The BCP composite powder is prepared through the high-temperature solid phase reaction of a calcium-containing solid compound and a calcium-phosphorus solid containing compound. The BCP composite powder has the advantages that a reaction period is short; the costs of raw materials are low; the equipment investment is low; no waste gas and waste water are discharged; further, the proportion of the HA and beta-TCP two phase in the BCP powder is easily regulated and controlled at the same time; the two phases are distributed uniformly; the sizes of the crystal grains and the crystallinity are controllable; finally; the production requirement that the compression strength of BCP biphase composite ceramic is improved or a degradation speed is regulated and controlled is met.

Owner:SUZHOU DINGAN ELECTRONICS TECH

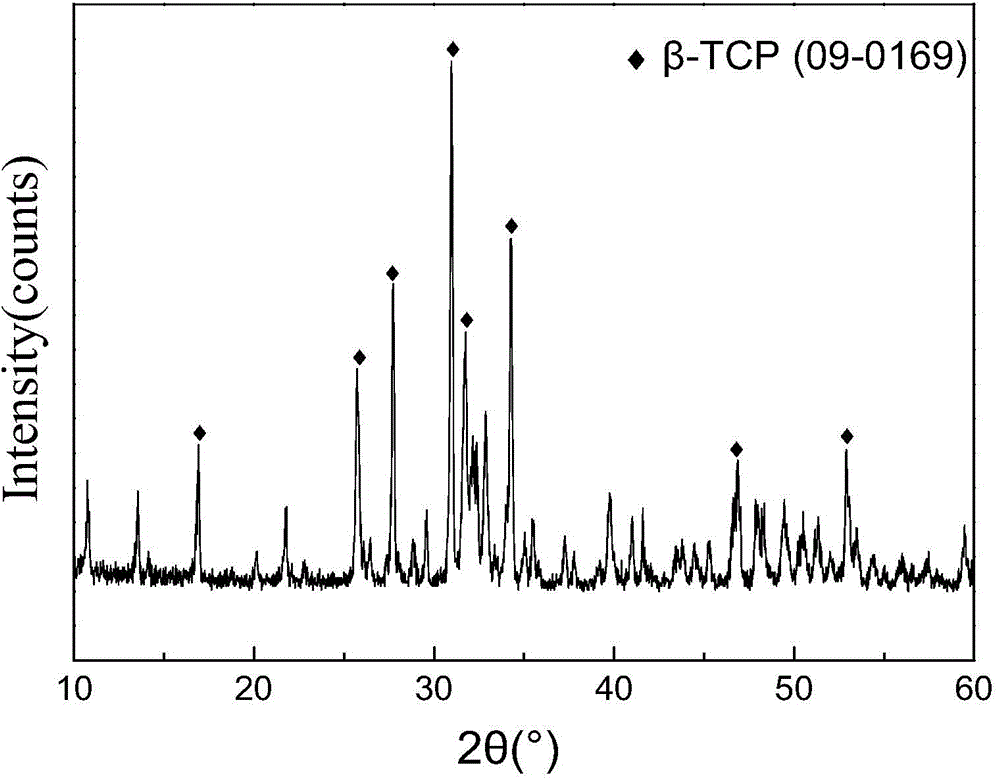

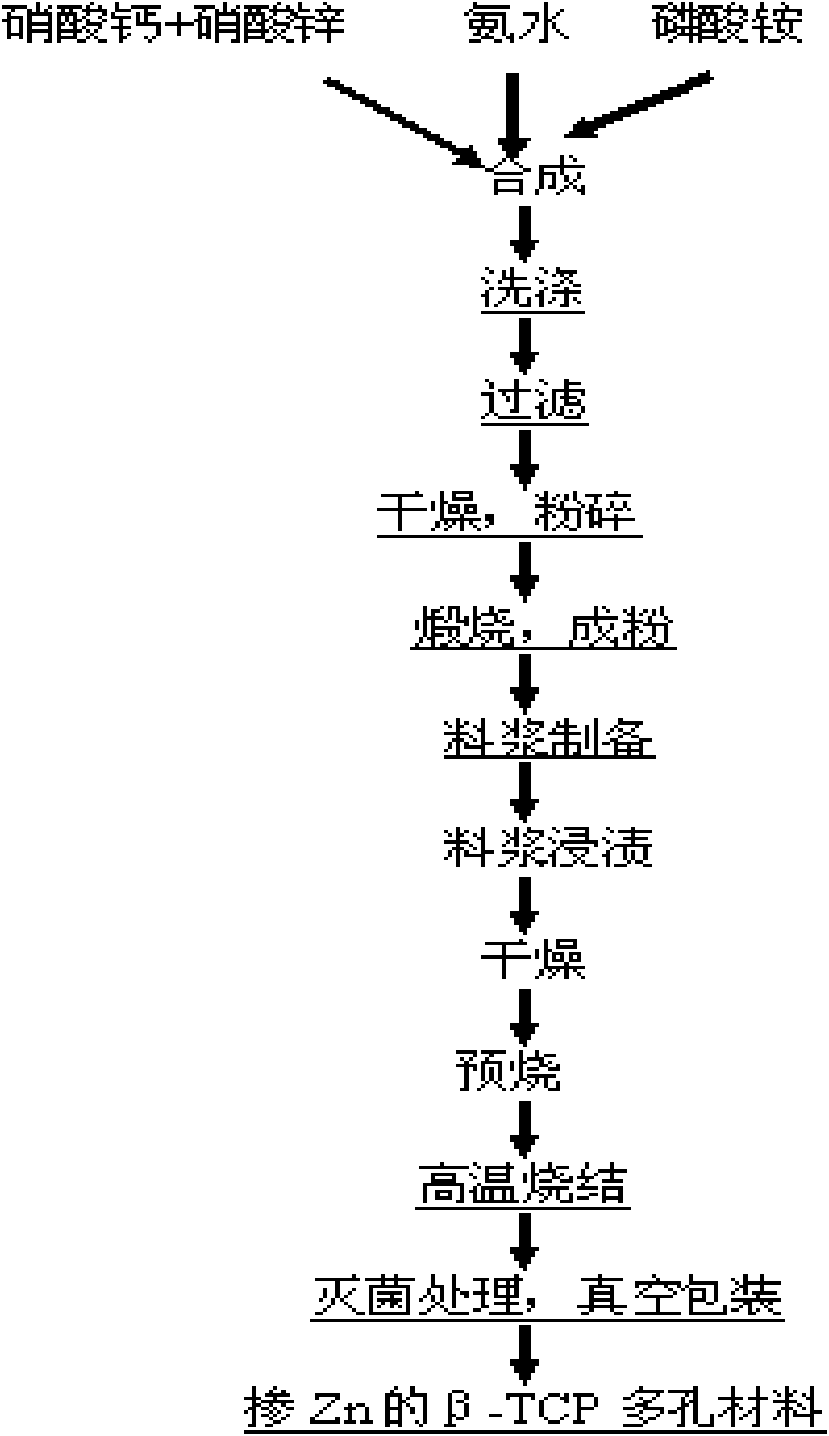

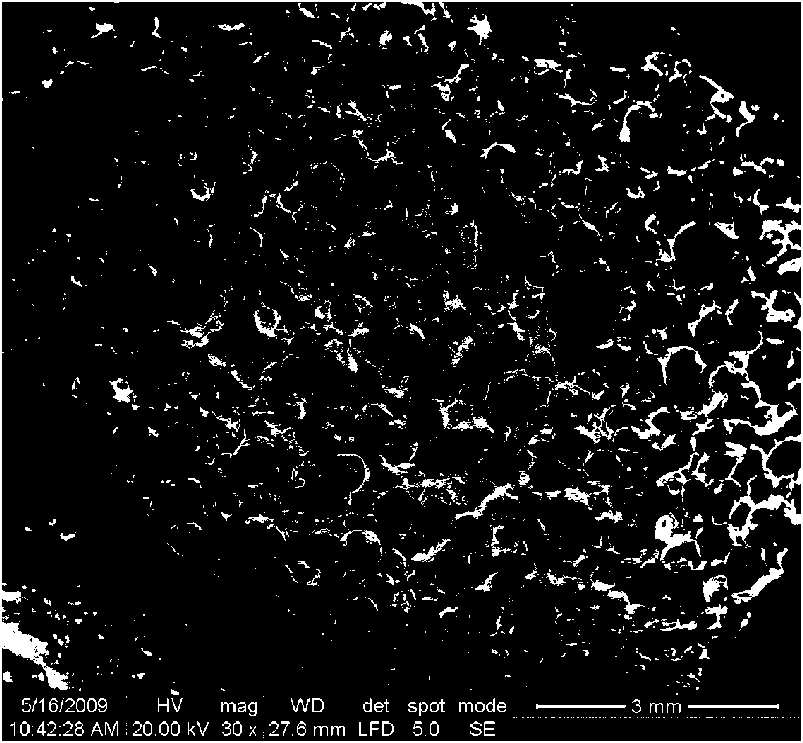

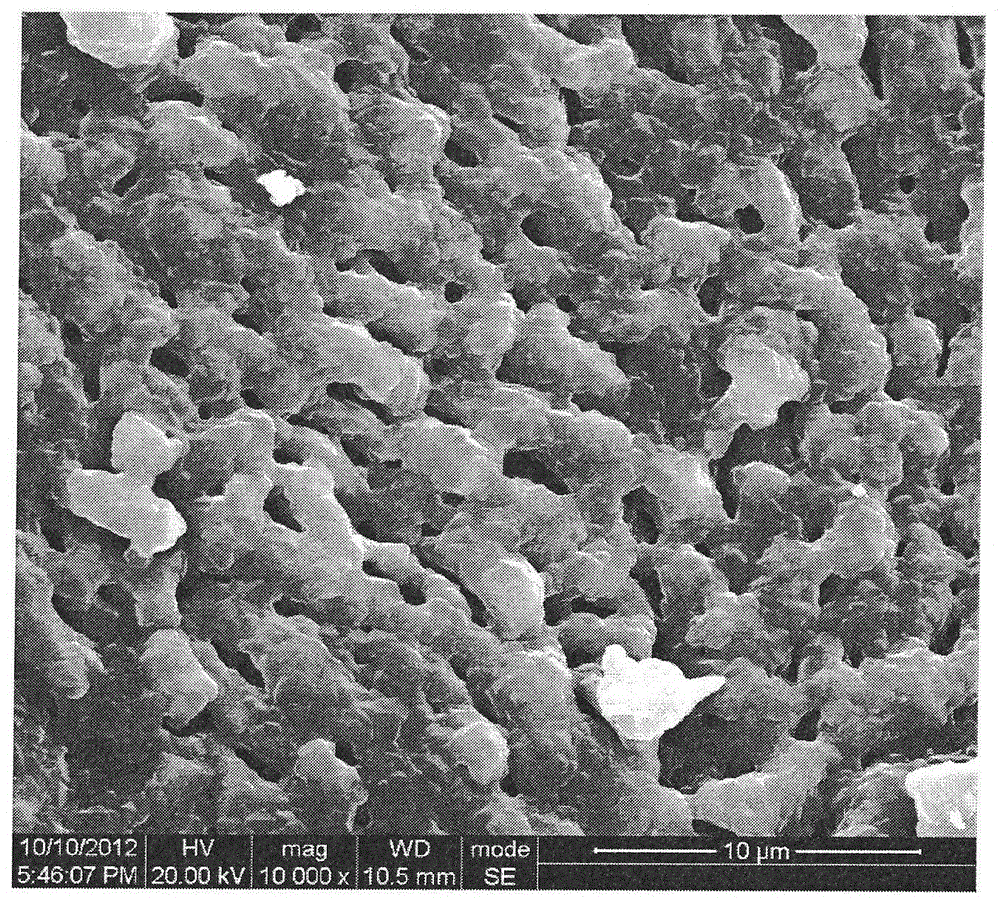

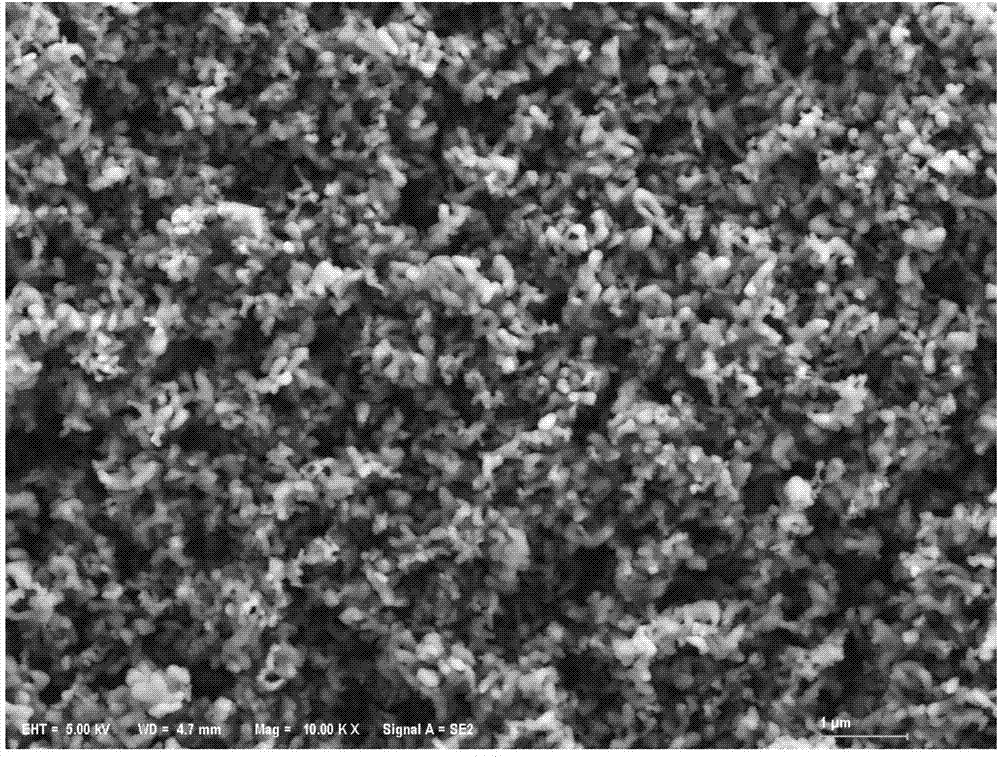

Beta-TCP porous material and preparation method thereof

The invention relates to a Beta-TCP porous material and a preparation method thereof. Natural plant fiber or polyurethane sponge is used as a pore creating material. A three-dimensional-net-shaped skeleton green body is prepared by immersing the pore creating material into a slurry made from Beta-TCP which is doped with a trace element Zn. The Beta-TCP porous material is obtained by drying and sintering the three-dimensional-net-shaped skeleton green body. The Beta-TCP material which is doped with the Zn better satisfies the need for material degradation and osseous tissue creeping growth. In the invention, the addition of the trace element Zn into the Beta-TCP porous material improves the ALP activity and promotes the degrading of the Beta-TCP porous material in the case of low porosity, thereby greatly improving the pressive strength and the degrading capability of the Beta-TCP porous material and solving the problem that the mechanical property and the biodegradation property of a Beta-TCP porous biological ceramics embedded material are not matched. The Beta-TCP porous material has good degradation property and good mechanical property, is expectable to improve the defects of bone defect repairing and rebuilding materials, and can be widely and clinically used.

Owner:CENT SOUTH UNIV

Hemostatic clip made from absorbable magnesium-based composite material and preparation method of hemostatic clip

InactiveCN103480035APromote degradationImprove mechanical propertiesSuture equipmentsWound clampsAbdominal cavityMagnesium matrix composite

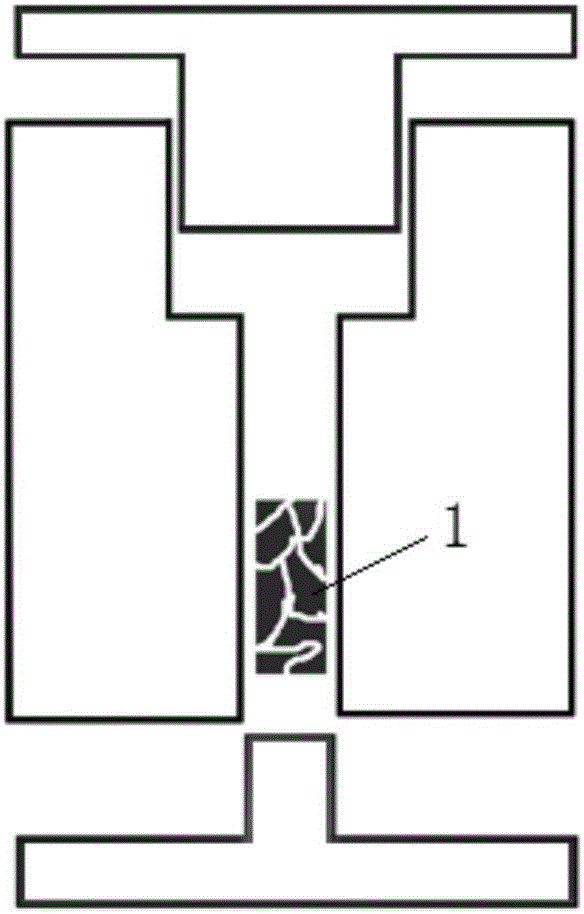

The invention relates to a hemostatic clip made from an absorbable magnesium-based composite material. The absorbable magnesium-based composite material is adopted to prepare a hemostatic clip body which is in a V shape, the top included angle and an included angle formed by adjacent edges of two folding edges are both obtuse angles less than 180 degrees, the cross section of the hemostatic clip is a rectangular shape with 0.9-1.1mm in length and 0.65-0.75 in width, and cross grains with width of 0.2mm and distance of 1.7mm are formed at the inner side of the hemostatic clip. The preparation method of the hemostatic clip comprises the steps of drawing an absorbable magnesium-based composite material rod used as a preparation material, cutting cross grains, forming, performing annealing treatment and washing. The hemostatic clip has the advantages that the hemostatic clip made from the absorbable magnesium-based composite material has excellent biological degradability and physical and mechanical properties, can be shaped easily and has low preparation cost, the toughness of magnesium alloy can be effectively improved and the fracture phenomenon can be greatly reduced due to the addition of HA (Hydroxyapatite) or beta-TCP (Tertiary Calcium Phosphate), and the hemostatic clip has good effect in minimally invasive surgery of abdominal cavity in department of surgery.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Bone repair material

The invention relates to a bone repair material which is prepared by the following steps: 1, cutting the cancellous bone parts of mammal chines and thighbones into small blocks and then poaching and drying; 2, soaking the cancellous bones by phosphoric acid; 3, putting the cancellous bones in a pressure cooker to cook, rinsing by deionized water and drying; 4, modifying the cancellous bones; and 5, putting the cancellous bones in a high-temperature furnace to calcine. In the bone repair materials, the proportion of hydroxyapatite (HA) to beta-tertiary calcium phosphate (TCP) is between 1: 4 and 4: 1, so that the defects that the HA is too stable and the beta-TCP is degraded too quickly are overcome, the degrading speed of the material can be adjusted through the proportion of the HA to the beta-TCP to ensure that the degrading speed of the material is matched with the growth speed of the surrounding bone tissues and then the function of remarkably promoting bone healing is provided; and the bone repair material has certain hardness and strength, is easy to plasticize and rich in source, and can be used for solving the manufacturing difficulties of artificial synthetic materials in the aspects of porosity, pore traffic and pore size.

Owner:BEIJING AKEC MEDICAL

Composite bioactivity functional coating

ActiveCN103041449AHigh modulus of elasticityGood biomechanical propertiesCoatingsMetal coatingPhosphate

The invention discloses a composite bioactivity functional coating, in particular a composite bioactivity functional coating positioned on a metal base body. The composite bioactivity functional coating comprises a first titanium metal coating positioned on the metal base body, a tantalum metal coating positioned on the first titanium metal coating and a hydroxyapatite or beta-TCP (tricalcium phosphate) bioactivity coating positioned on the tantalum metal coating.

Owner:苏州宸泰医疗器械有限公司

Three-dimensional bone-like structure artificial bone with high bioactivity and high strength and preparation method thereof

The invention discloses a three-dimensional bone-like structure artificial bone with high bioactivity and high strength and a preparation method thereof. The preparation method comprises the following steps of: (1) performing mineralization treatment on a three-dimensional structure natural bone; (2) sintering the three-dimensional structure natural bone subjected to mineralization treatment to obtain a hydroxyapatite (HA) three-dimensional structure scaffold or a beta-tricalcium phosphate (TCP) three-dimensional structure scaffold; and (3) soaking the HA three-dimensional structure scaffold or the beta-TCP three-dimensional structure scaffold in biomimic bone solution, and performing vacuum pumping to obtain the artificial bone. In the preparation method, the three-dimensional structure natural bone is subjected to mineralization treatment and sintering, and then is compounded with simulated body fluid which has high bioactivity and contains collagen to form the three-dimensional structure HA or beta-TCP scaffold with high bioactivity and high strength; and the compression strength of the artificial bone is 5MPa, the porosity is between 70 and 75 percent, and the aperture is between 100 and 600mu m. The three-dimensional bone-like structure artificial bone with high bioactivity and high strength can repair various bone defects and induce osteogenesis.

Owner:山东宇宁医疗器械有限公司

Preparation method of silicon-doped alpha-tricalcium phosphate ceramic

ActiveCN104557015AEasy to synthesizeOvercome the gross disadvantageNano siliconAlpha-tricalcium phosphate

The invention discloses a preparation method of silicon-doped alpha-tricalcium phosphate ceramic. The preparation method comprises the following steps: (1) mixing Ca(NO3)2.4H2O, (NH4)3PO4.3H2O and Si(OCH2CH3)4 of different amounts at a certain temperature according to a molar ratio Ca / (P+Si)=1.67 to obtain precursor nano silicon-doped hydroxyapatite powder; and (2) sintering the precursor nano silicon-doped hydroxyapatite powder in a muffle at 900-1,200 DEG C according to a heating rate of 5-10 DEG C / min, preserving heat for 3-10h, and cooling to normal temperature at a cooling rate of 5-10 DEG C / min to obtain ceramic powder. Compared with the prior art, the method disclosed by the invention can be used for preparing Si-alpha-TCP ceramic powder without beta-TCP at a relatively low temperature, and the content of Si-alpha-TCP can be controlled by controlling the silicon doping amount and the precursor synthesis temperature.

Owner:SOUTH CHINA UNIV OF TECH

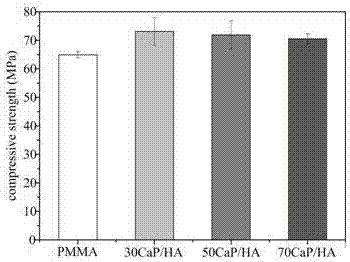

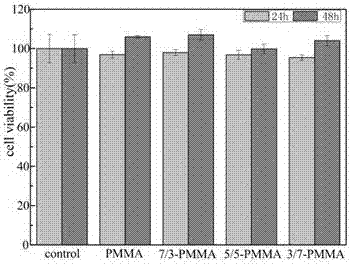

Compound bone cement with high inorganic components as well as preparation method and application of compound bone cement

ActiveCN107041970AMechanical properties are not affectedGood biocompatibilityProsthesisBenzoyl peroxideApatite

The invention discloses compound bone cement with high inorganic components. The compound bone cement contains a solid-phase component and a liquid-phase component, wherein the solid-phase component contains P(MMA-co-MPS) surface-modified hydroxyapatite, polymethyl methacrylate, beta-tricalcium phosphate and benzoyl peroxide, and the liquid-phase component contains methyl methacrylate and dimethyl terephthalate; the mass volume ratio of the solid-phase component to the liquid-phase component of the compound bone cement is 1 to (2.5-3.5); and the sum of P(MMA-co-MPS) surface-modified hydroxyapatite and methyl methacrylate is 35%-40% of weight of the solid-phase component. According to the compound bone cement, tricalcium phosphate (beta-TCP) and P(MMA-co-MPS) surface-modified hydroxyapatite are compounded, and meanwhile, the proper modification degree of p(MMA-co-MPS) to hydroxyapatite is adjusted, so that the mechanical performance of the raw materials is guaranteed, meanwhile, the biological activity of the material is increased, and the degradation speed of the material is proper; and therefore, the compound bone cement has excellent mechanical properties and biological properties.

Owner:SUN YAT SEN UNIV

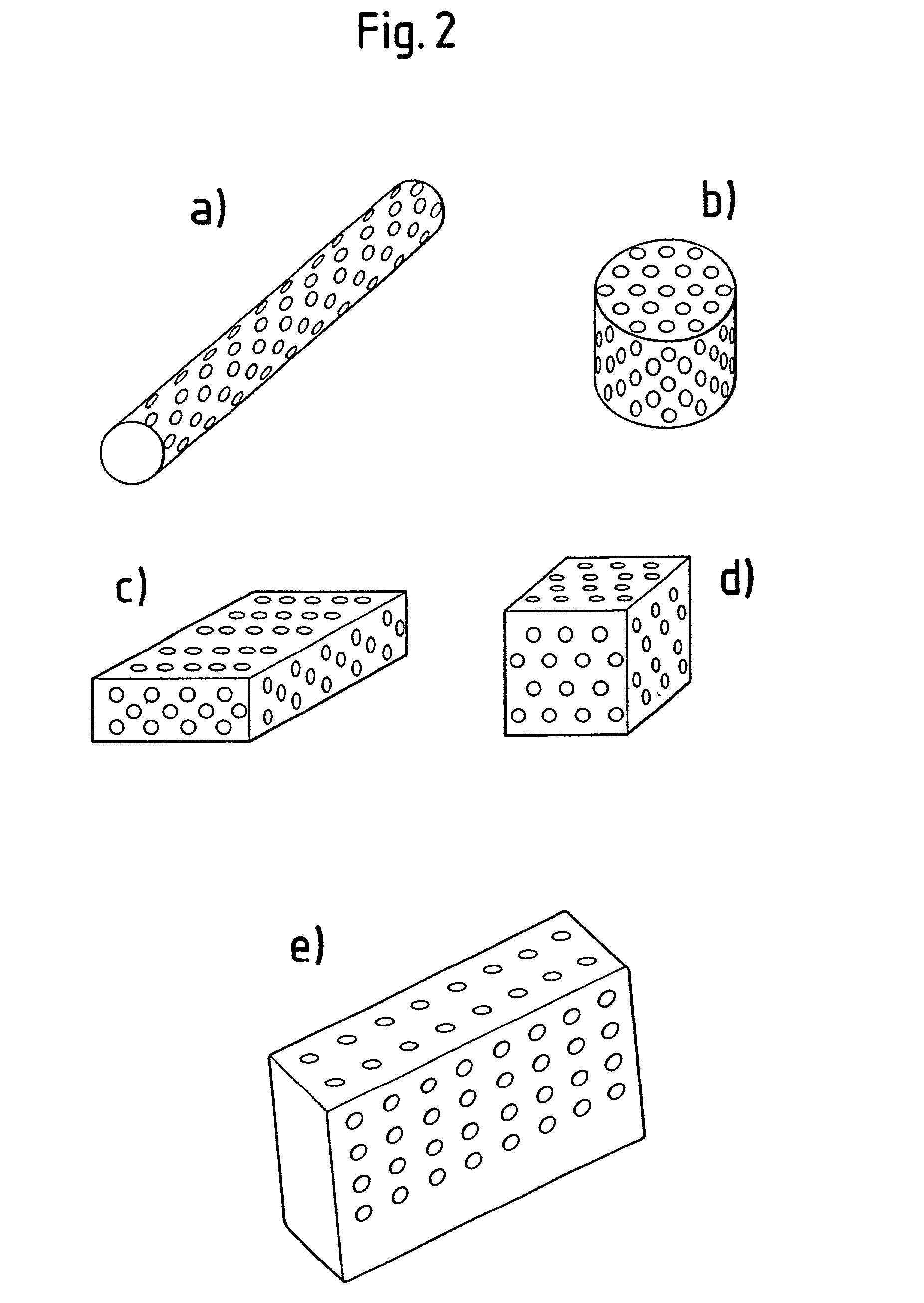

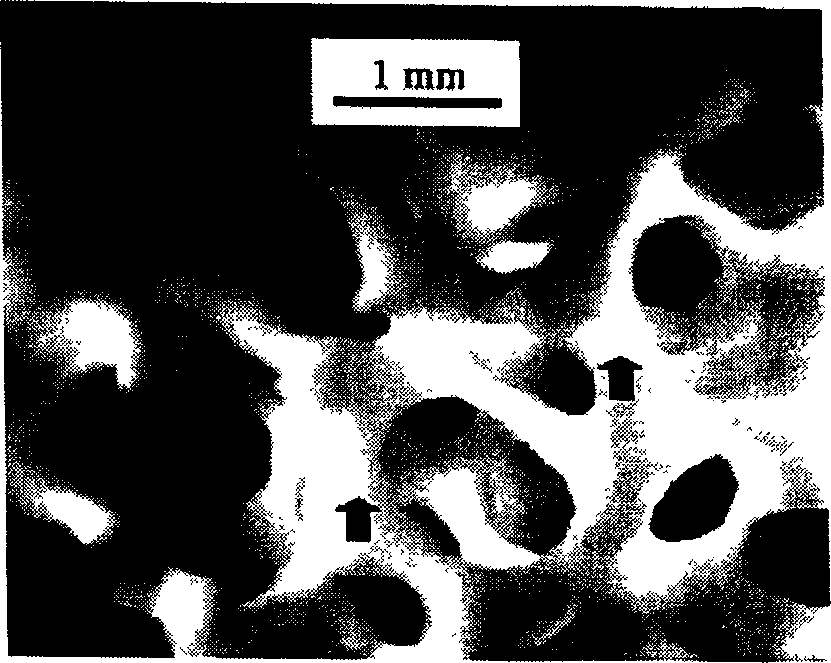

Bone grafting material of gradient porous beta-TCP with bioactivity and anti-infection effect, preparation method and application thereof

InactiveCN101884811APhysical and chemical properties are not affectedHigh activityAntibacterial agentsOrganic active ingredientsActive proteinAntibiotic Y

The invention relates to a bone grafting material of gradient porous beta-TCP with bioactivity and an anti-infection effect. The bone grafting material consists of anti-infection medicaments, BMP-2 and beta-TCP. The invention also provides a method for preparing the bone grafting material of the gradient porous beta-TCP with the bioactivity and the anti-infection effect. The method comprises the following steps of: constructing the gradient porous beta-TCP; and compounding the gradient porous beta-TCP with the anti-infection medicaments and the BMP-2. The invention also provides the application of the bone grafting material. The grafting material has the advantages that: different structures are manufactured in the same ceramic by a manufacturing process of constructing a gradient porous bioceramic with the bioactivity and the anti-infection effect; the BMP-2 and antibiotics are compounded in the same material separately; and the physical and chemical properties of the material are ensured to be free from influence and the co-existence of two active substances are ensured, so that a good osteogenic active protein and a medicament sustained-release effect are achieved.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Method for preparing beta-TCP//HAP/Ca2P2O7 multiphase porous bioceramic

InactiveCN101456754ALow priceExperimental preparation process safetyCeramicwareProsthesisHuman bodyBiocompatibility Testing

The invention relates to a bone issue repair material, in particular to a method for preparing beta-TCP / HAP / Ca2P2O7 multiphase porous bioceramic, which belongs to the biomedicine field. The method comprises the following steps: firstly, performing the degreasing and deproteinization treatment on bovine cancellous bone; secondly, using NH4H2PO4 solutions with different concentrations to treat the degreased and deproteinized bovine cancellous bone; and finally drying and sintering the bovine cancellous bone at high temperature to be prepared into the bioceramic. The prepared material can keep a three-dimensional porous structure of natural bone, has better pore connectivity, can induce the growth of new bone, and has the characteristics of good biological degradability, biocompatibility and good mechanical property. The NH4H2PO4 solutions used to treat the bovine cancellous bone is steadier and can not release ammonia gas which is harmful to human bodies at normal temperature, and the experimental preparation process is safer and healthier.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

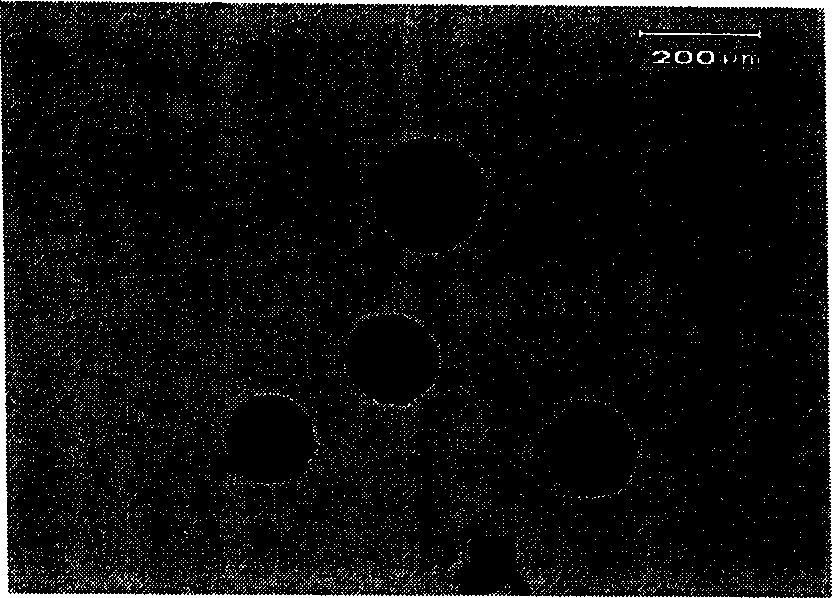

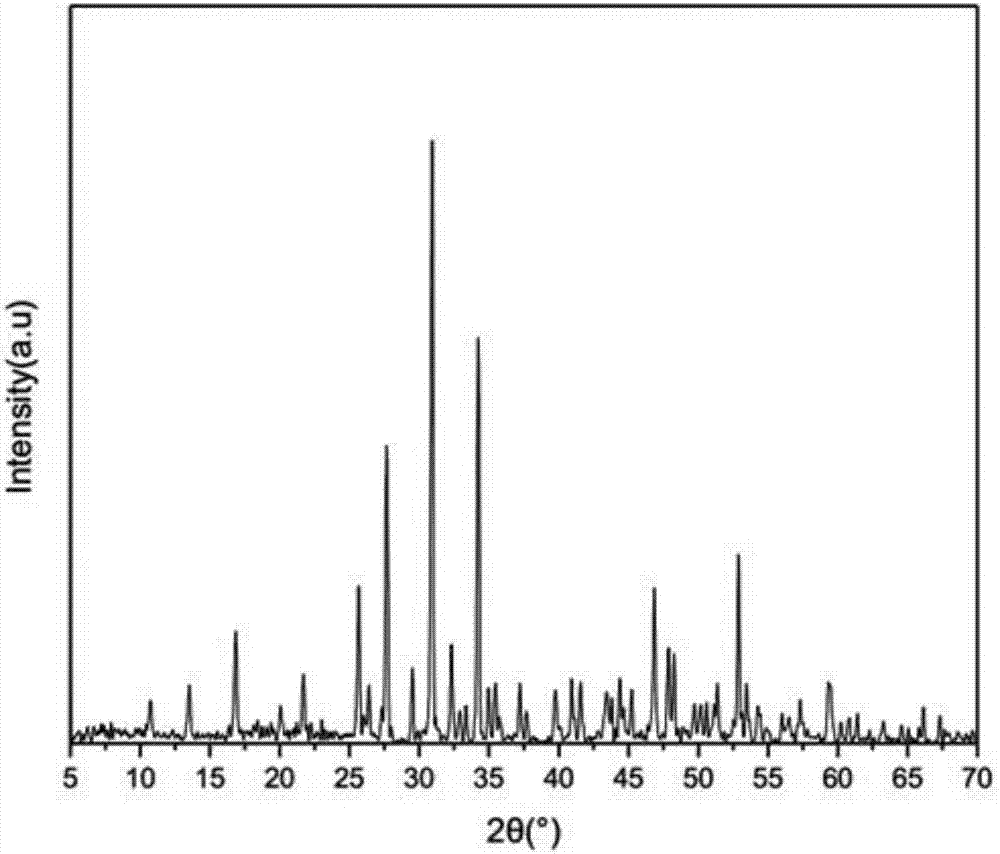

Method for preparing different particle sizes of porous beta-TCP microspheres by oil-in-water type solid emulsification

InactiveCN106890606ALarge specific surface areaGood biocompatibilityPharmaceutical delivery mechanismTissue regenerationMicrospherePolyvinyl alcohol

The invention discloses a method for preparing different particle sizes of porous beta-TCP microspheres by oil-in-water type solid emulsification. The method includes the steps of subjecting a calcium nitrate solution and a hydrogen phosphate solution to mixed reaction to obtain a hydroxyapatite precursor, dispersing the hydroxyapatite precursor into a polyvinyl butyral-dichloromethane solution to obtain a mixed solution, subjecting the mixed solution and a polyvinyl alcohol solution to mixed reaction to obtain precursor microspheres, and sintering to obtain a target product, namely the porous beta-TCP microspheres. The method has the advantages that the particle size of the microspheres is controlled through oil-phase concentration and a rotation speed, and the prepared beta-TCP microspheres are porous, controllable in size and excellent in biocompatibility and can be applied to the field of biological materials such as bone tissue engineering.

Owner:WUHAN UNIV OF TECH

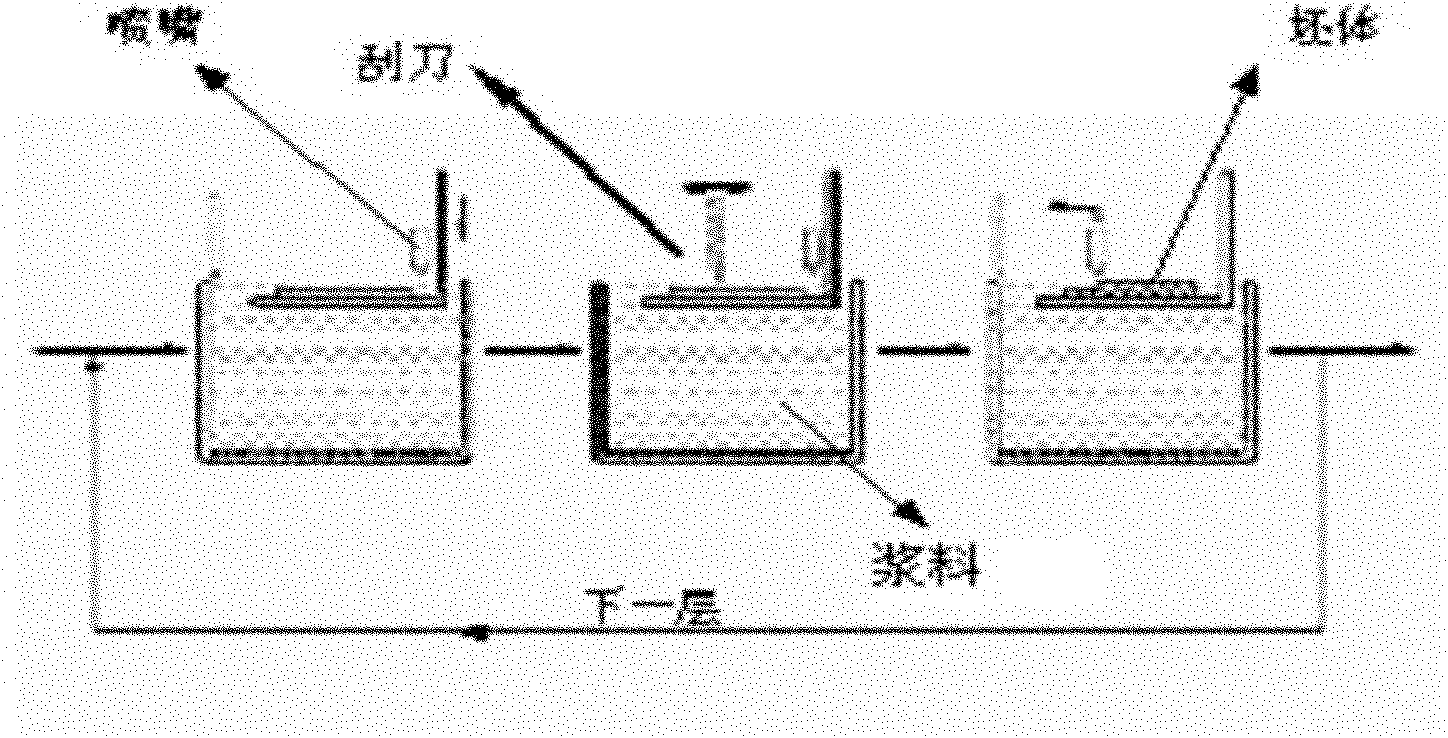

Porous beta-TCP and its preparation method

InactiveCN1765821ARaw materials are easy to getSimple technologyBone implantCeramicwareFilling materialsSlurry

The invention relates to the field of biological material, more specifically a porous beta-TCP and its preparing process, wherein organic sponge is used as the stencil during the preparing process, which comprises (1) slurry preparation, (2) organic sponge treatment, (3) grout-filling, (4) drying, (5) sintering, (6) secondary grout-filling, (7) drying, (8) secondary sintering.

Owner:丁连珍

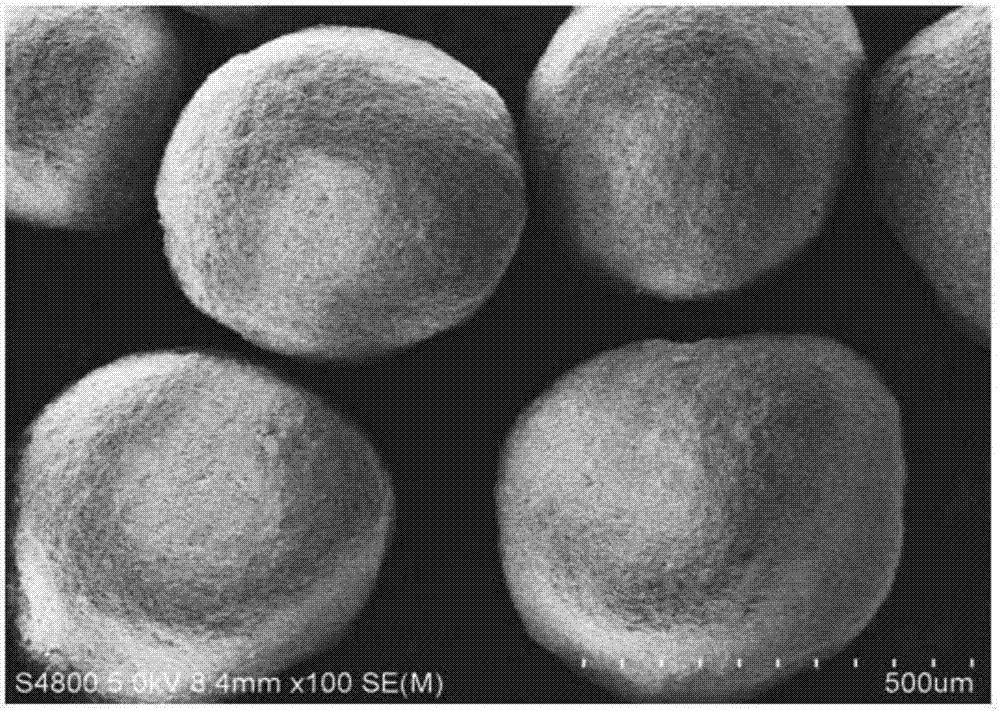

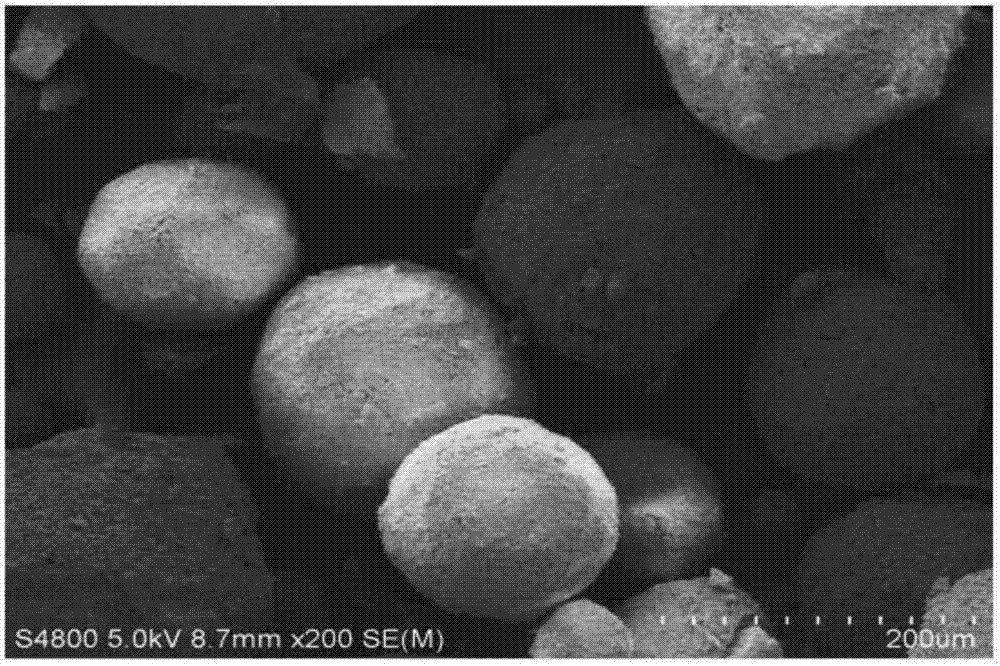

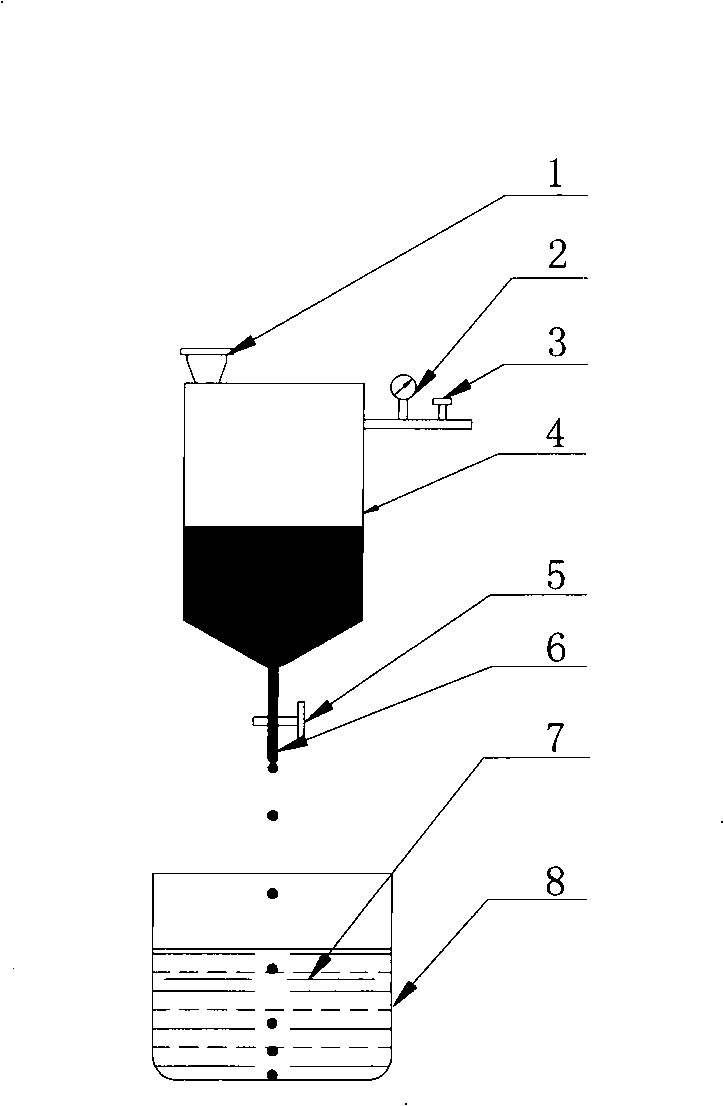

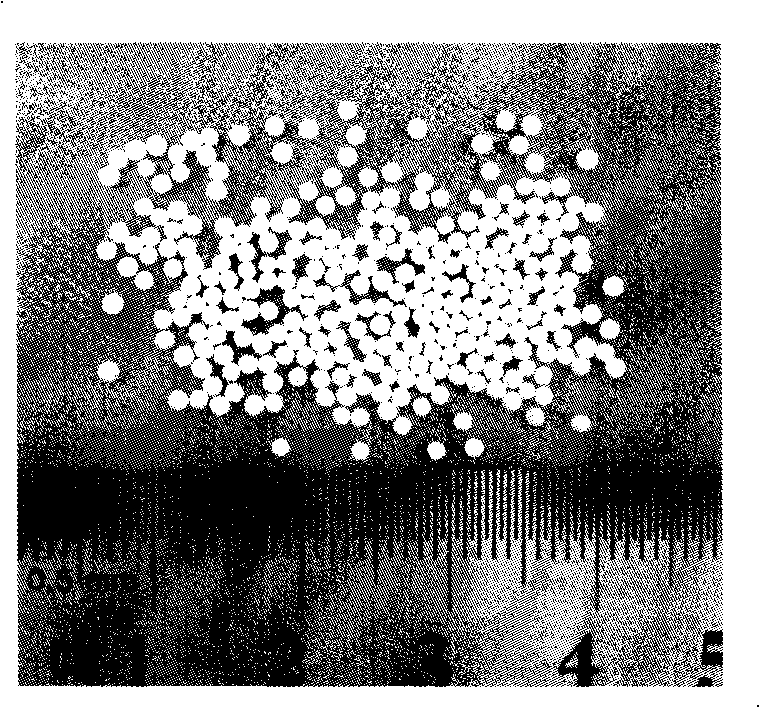

Phosphate biological ceramic microsphere, preparation method and apparatus thereof

InactiveCN101401953ALarge specific surface areaUniform particle size distributionImpression capsDentistry preparationsCross-linkPorosity

The invention relates to a phosphate bioceramic microsphere, a method and a device for preparing the same. The particle diameter of the phosphate bioceramic microsphere is between phi 0.8 and 4 millimeters; the interior of a particle body is micropores of which the aperture is less than 150 micrometers; the micropores are communicated with each other; the porosity of the micropores is between 65 and 90 percent; and the particle body consists of phosphates of calcium, magnesium and sodium. The method for preparing the phosphate bioceramic microsphere comprises the following steps: step one, weighing HA powder and beta-TCP powder, and mixing the powders evenly; step two, taking (NaPO3)6 and Mg(H2PO4)2 of which the mass is between 5 and 15 percent of the mixed powders of the HA and the beta-TCP to prepare a caking agent solution, and taking a suspending agent of which the mass is between 0.5 and 5 percent of the mixed powders of the HA and the beta-TCP to prepare a suspending agent solution; and step three, evenly mixing the caking agent solution prepared in the step two with the suspending agent solution, then adding the powders prepared in the step one into the obtained solution, and evenly mixing to obtain a ceramic slurry; step four, dripping the ceramic slurry prepared in the step three into a thermal insulation container for condensation to form spherical particles; and step five, cross-linking and sintering the spherical particles after the condensation to obtain the phosphate bioceramic microspheres.

Owner:SOUTHEAST UNIV

Preparation method of bionic nanofiber scaffold with electrical stimulation effects

InactiveCN105664240APromote regenerationEasy to manufactureFilament/thread formingPharmaceutical delivery mechanismFiberNeurotrophic factors

The invention discloses a preparation method of a composite bionic nanofiber scaffold with electrical stimulation effects. Beta-tricalcium phosphate is polarized for 0.5-3 hours in air with the effects of a 2-8KV / cm-1 direct-current electric field at 200-600 DEG C, and polarized beta-TCP is obtained; polylactic acid is dissolved in an organic solvent, the polarized beta-TCP powder is added, and PLA / beta-TCP pre-electrospinning liquid 1 is prepared; a medicament with biological activity is added in an aqueous solution of chitosan-acetic acid with uniformly stirring for dispersion, and CS / medicament with biological activity pre-electrospinning liquid 2 is prepared; PLA / CS / beta-TCP is prepared by coaxial electrospinning. The nanofiber scaffold with electrical stimulation effects has a double layer internal structure and a large surface area, in order to realize timely and proper controlled release of neurotrophic factors and various medicaments; the nanofiber scaffold has the advantages of good biological compatibility, stable performance, preservation convenience, and good application prospects in peripheral nerve repair and other biomedical fields.

Owner:WUHAN UNIV OF TECH

Synthesis method of mesoporous beta-tricalcium phosphate microemulsion

ActiveCN104495773ASmall apertureGood biocompatibilityPhosphorus compoundsInorganic saltsSynthesis methods

The invention relates to a synthesis method of a mesoporous beta-tricalcium phosphate microemulsion. The method comprises the following steps: 1) adding a surfactant, an oil phase and a co-surfactant to water, and stirring evenly, so as to obtain a microemulsion; 2) adding a calcium inorganic salt solution to the microemulsion, fully stirring, adding a phosphorous inorganic salt solution, adjusting the pH value of the emulsion, keeping the temperature invariable, and stirring to obtain the emulsion; and 3) standing, ageing, separating out sediments by using a centrifuging method, washing, drying, then putting into a high-temperature furnace, heating, and carrying out heat preservation, so as to obtain mesoporous beta-TCP powder. The synthesis method has the beneficial effects that 1, the synthesis method disclosed by the invention is simple, easy to operate, good in repeatability and low in energy consumption; and 2, the mesoporous beta-TCP powder obtained by the synthesis method disclosed by the invention is relatively small in aperture, and has a three-dimensional pore structure; the mean pore size is 7.11-20.25nm; and the specific surface area is 12.85-156.38m<2> / g.

Owner:WUHAN UNIV OF TECH

Injectable and degradable artificial bone material and preparation method thereof

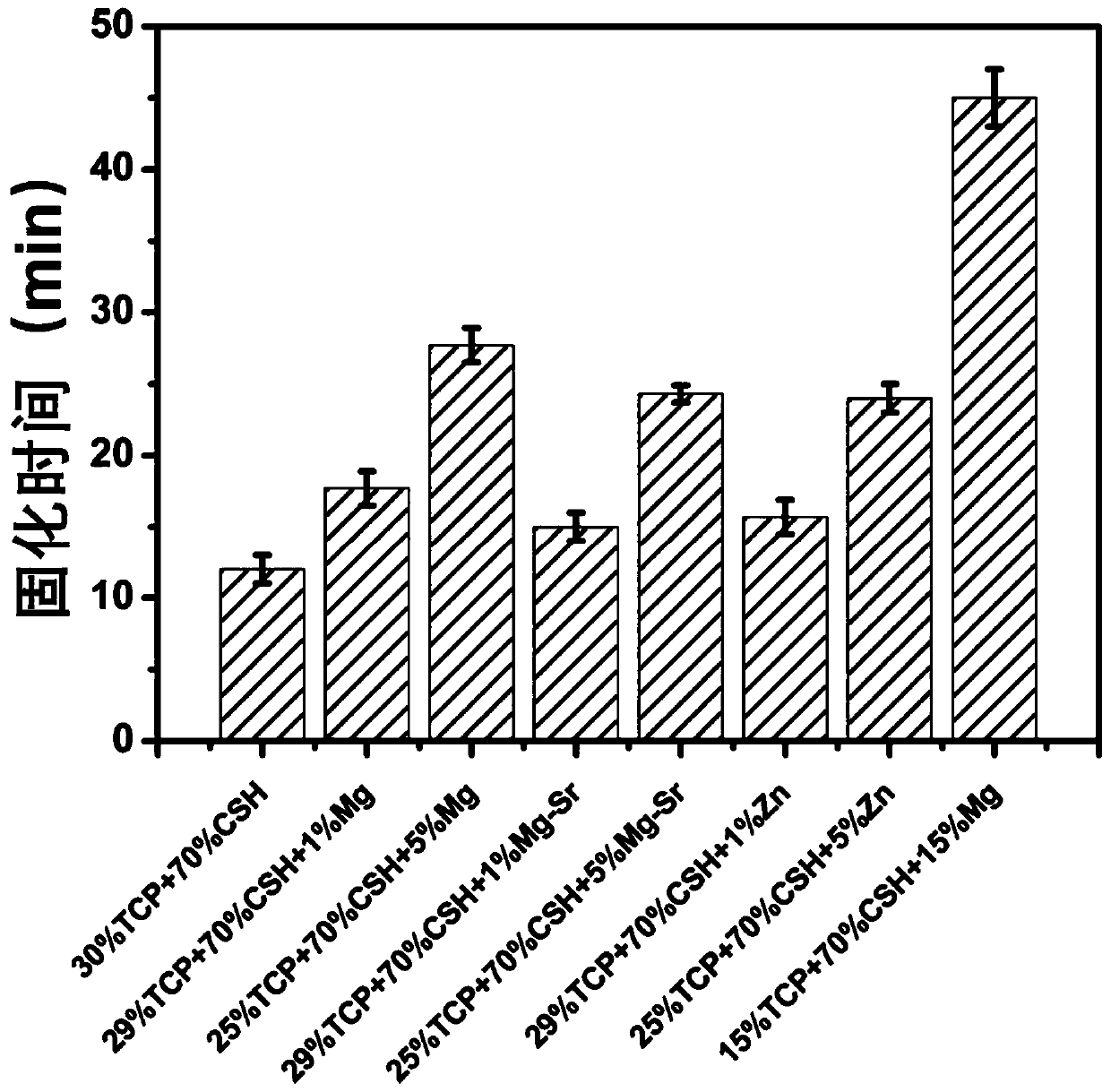

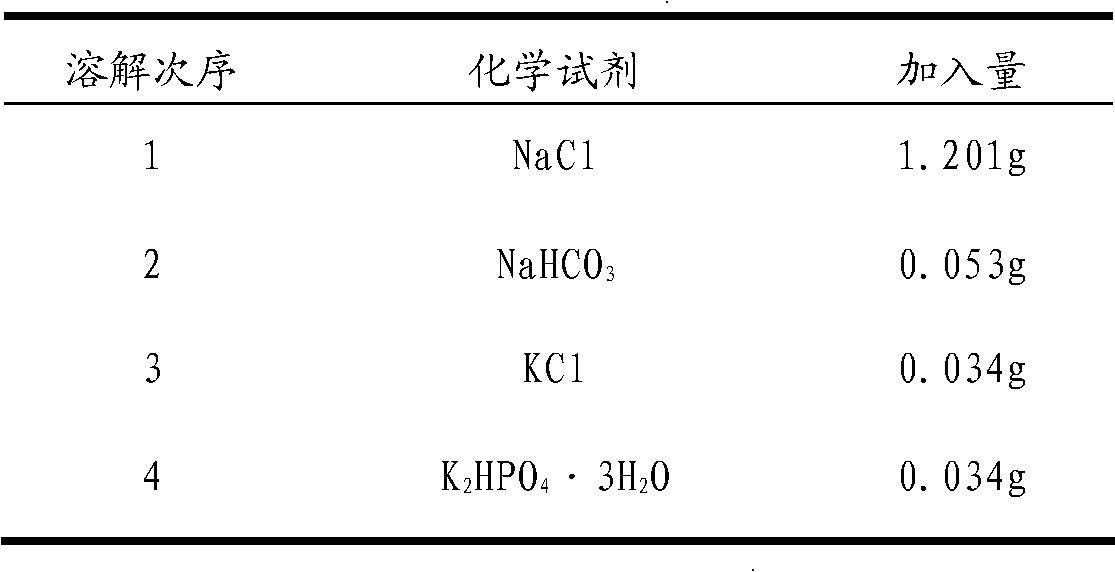

ActiveCN109701072AGood regulationRegulatory remodelingProsthesisPolyvinyl alcoholTri calcium phosphate

The invention relates to the technical field of biomedical materials, in particular to an injectable and degradable artificial bone material and a preparation method thereof. The material consists ofa solid phase and a liquid phase. The solid phase host material is a nano beta phase tricalcium phosphate and calcium sulfate hemihydrate powder material, and the solid phase auxiliary functional material is metal magnesium, magnesium strontium alloy or a metal zinc powder material. The liquid phase is a 5% by weight polyvinyl alcohol aqueous solution or normal saline. The solid phase and the liquid phase are uniformly mixed for use, the curing time range is 5-60min, and the curing strength range is 2-10 MPa, so that the artificial bone material is formed. Compared with existing artificial bone materials, on the one hand, a nano beta-TCP material in the bone material improves the biological activity of the artificial bone material after implantation; and on the other hand, the metal or alloy powder can rapidly degrade in the body, and forms a pore canal structure inside the artificial bone material so as to realize a self pore forming process, to facilitate the transportation of nutrients and to promote the growth of cells and capillaries.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

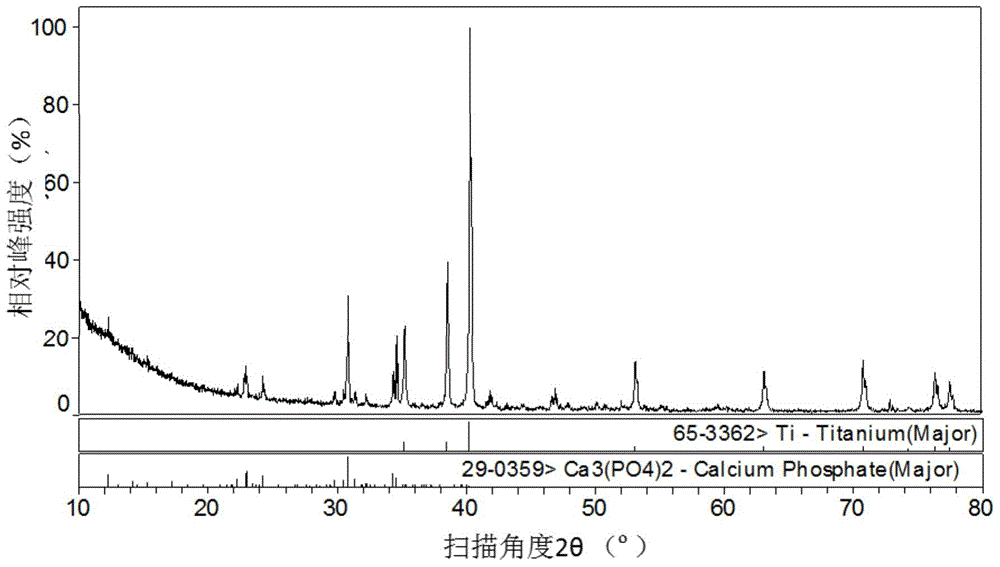

Titanium/tricalcium phosphate composite applied to bone implanting material and preparation method of titanium/tricalcium phosphate composite

InactiveCN104941003AGood mechanical propertiesReduce intensityProsthesisMass ratioTri calcium phosphate

The invention discloses a titanium / tricalcium phosphate composite applied to a bone implanting material. The titanium / tricalcium phosphate composite adopts a continuous network structure, tricalcium phosphate in the composite accounts for 10-50 wt% of the mass of the composite and is alpha-TCP or a mixture of alpha-TCP and beta-TCP, and the mass ratio of alpha-TCP to beta-TCP is (1-9): 1. A preparation method of the titanium / tricalcium phosphate composite comprises the following steps: (1) preparing a solution; (2) preparing tricalcium phosphate; (3) mixing and ball-milling titanium and tricalcium phosphate, and then preparing the titanium / tricalcium phosphate composite by the spark plasma sintering method. The titanium / tricalcium phosphate composite adopts a metal and ceramic continuous network structure, and has not only a favorable mechanical property, strength and an elastic modulus, which are close to human bones, but also excellent bioactivity and degradability.

Owner:CENT SOUTH UNIV

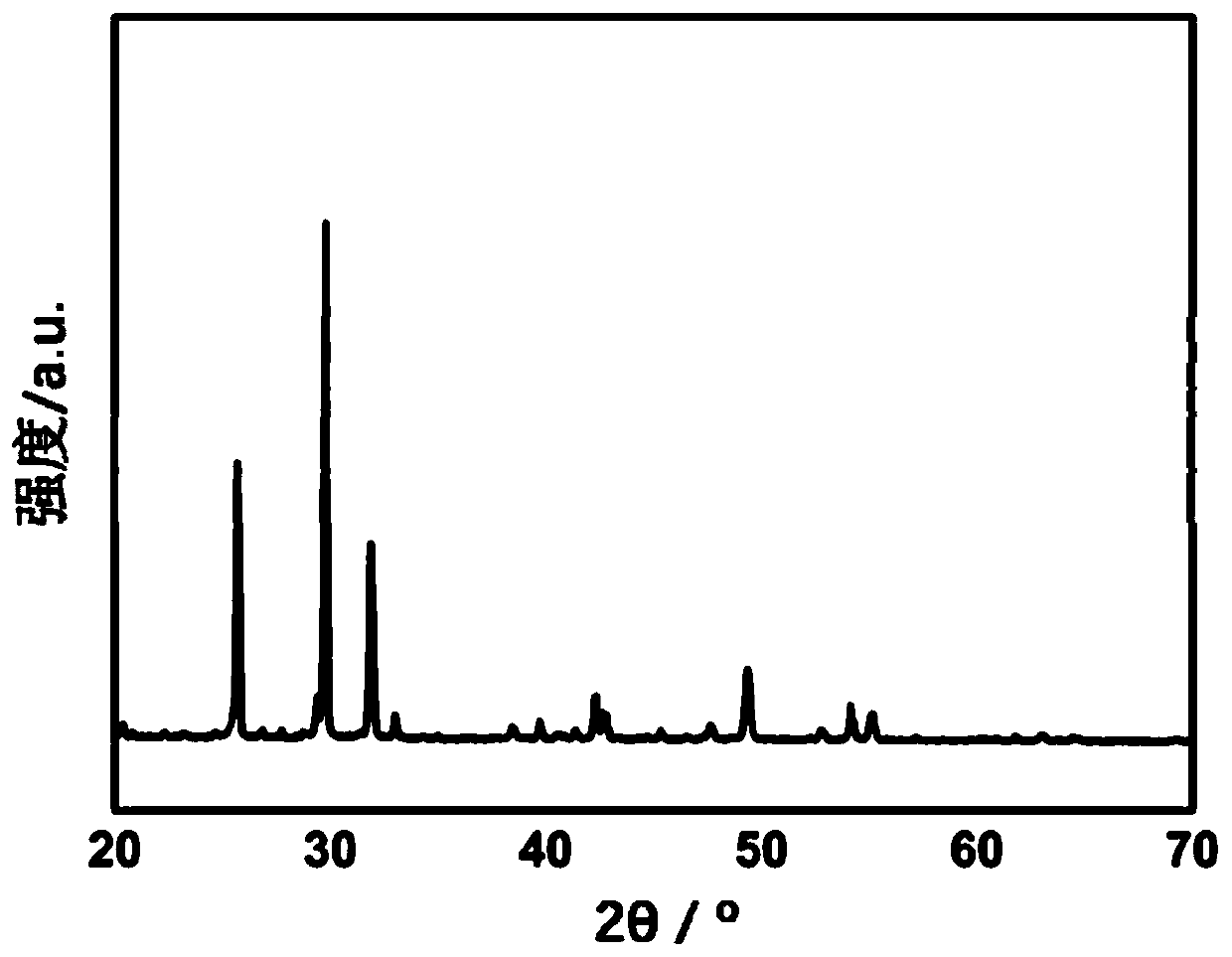

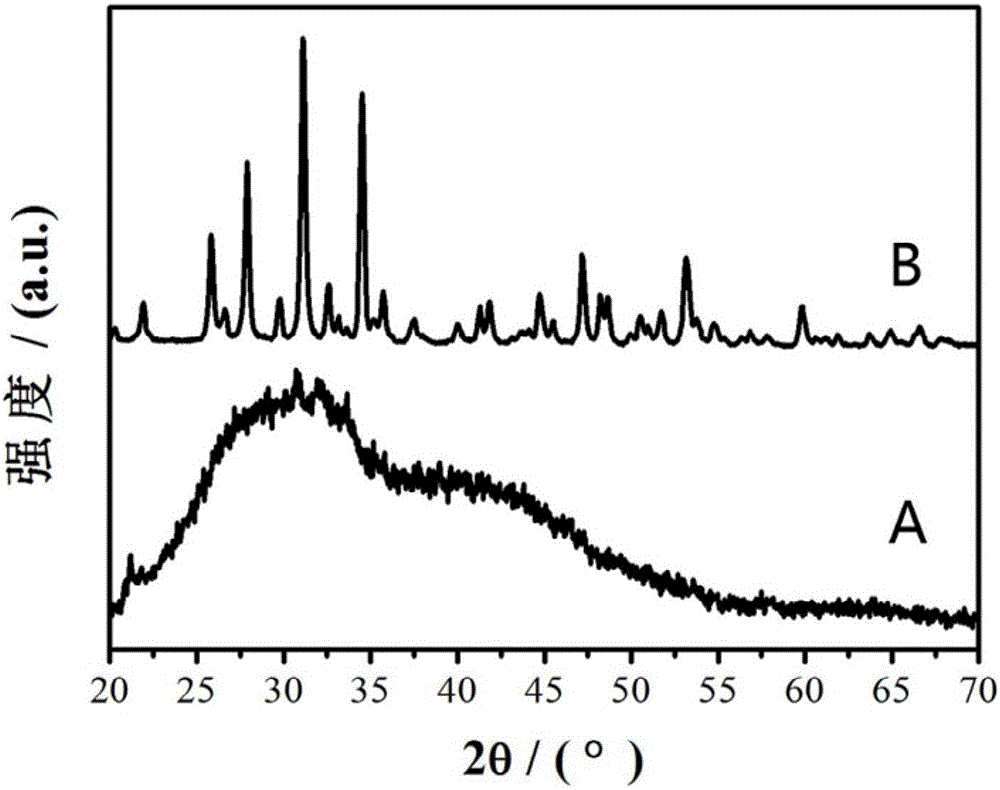

Method for preparing beta-tricalcium phosphate crystal material under low temperature condition

ActiveCN105948012ASolve the problem that it is difficult to prepare β-TCP nanomaterialsLow reaction temperatureTissue regenerationPhosphorus compoundsSr elementApatite

The invention discloses a method for preparing a beta-tricalcium phosphate crystal material under a low temperature condition, and belongs to the technical field of biomaterials. The method comprises the following steps: preparing amorphous calcium carbonate doped with different contents of Mg and amorphous apatite doped with different contents of Mg and Sr through a rapid precipitation technology, and converting the Mg-containing calcite and the amorphous apatite containing Mg and Sr into Mg-doped or Mg and Sr codoped beta-TCP crystal material through using a hydrothermal synthesis technology. Compared with present high temperature calcining or solid phase reaction methods for preparing the beta-TCP crystal material, the method disclosed in the invention has the advantages of low reaction temperature, production cost reduction, and solving of the problem of preparation of beta-TCP crystal nanomaterial through a high temperature reaction. Mg and Sr element doping also can improve the bioactivity of the beta-TCP material, is in favor of promoting bone restoration, and has great values in the fields of bone restoration and bone transplantation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

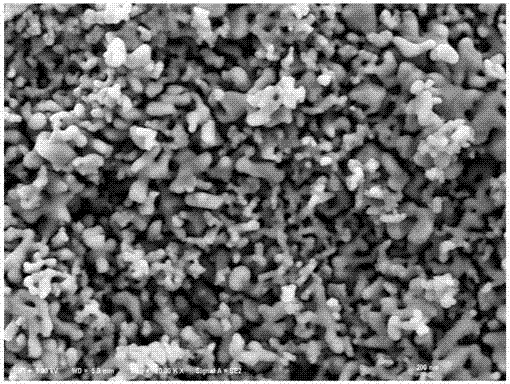

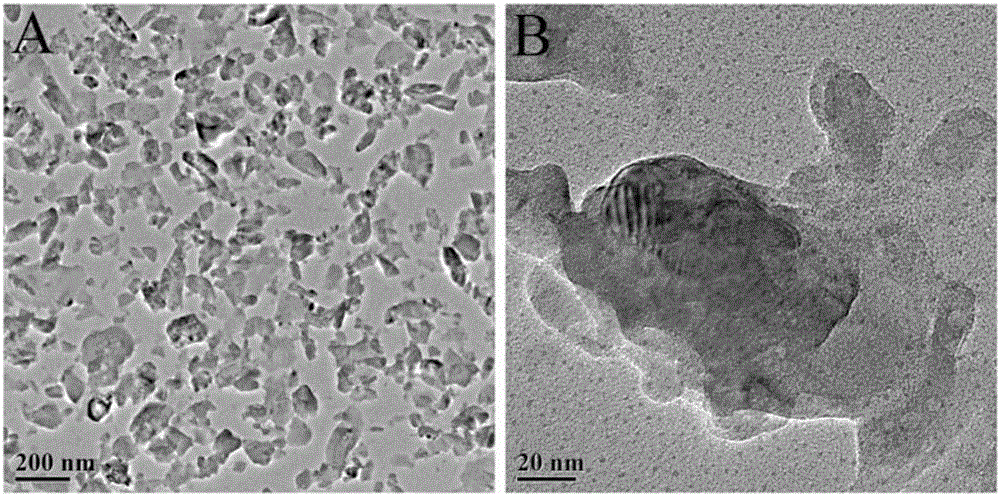

Nano-grade beta-tricalcium phosphate and preparation method thereof

InactiveCN106276835ADegradableGood osteoinductivityTissue regenerationPhosphorus compoundsDiethylene glycolTri calcium phosphate

The invention discloses nano-grade beta-tricalcium phosphate and a preparation method thereof. A zirconium oxide bead is used as a ball milling medium, and beta-TCP particles are continuously subjected to ball milling for 8 to 16 hours in a diethylene glycol dispersion solution; under the action of high-speed rotation and intensive impacting and milling effect of a ball mill, micron-grade beta-TCP crystal particles are refined into nano-grade crystal particles. According to the preparation method provided by the invention, other chemical substances are not liable to mix; the particle diameter of machined particles is changed, while chemical and crystallization properties are not changed, so that the purity and the safety of the beta-TCP are guaranteed; the nano-grade beta-tricalcium phosphate can be used as a biodegradable material of a surgical implant.

Owner:花沐医疗科技(上海)有限公司

Method for preparing artificial bone with three-dimensional bone-like structure and product prepared by method

The invention discloses a method for preparing an artificial bone with a three-dimensional bone-like structure and a product prepared by the method. The method comprises the following steps of: preparing a green body with a three-dimensional bone-like structure by a three-dimensional laminated assembly molding process; drying and sintering the green body to obtain a high-strength hydroxyapatite (HA) scaffold with a three-dimensional structure or a high-strength beta-tricalcium phosphate (TCP) scaffold with a three-dimensional structure; and then compounding the high-strength HA scaffold or the high-strength beta-TCP scaffold with imitation bone solution with high bioactivity to obtain a HA or beta-TCP scaffold with a three-dimensional structure which has high bioactivity and high strength, wherein the HA or beta-TCP scaffold has high bioactivity, the compressive strength is more than 5Mpa, the porosity is 70 to 75 percent, and the aperture is 100 to 600mu m. The artificial bone with the three-dimensional bone-like structure which has high bioactivity and high strength can repair various bone defects and induce the bone defects into bones.

Owner:北京惠方医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com