Two-phase calcium phosphate material, preparation method thereof, and two-phase calcium phosphate artificial bone ceramic

A calcium phosphate, artificial bone technology, applied in ceramic products, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of fast degradation and refractory degradation of β-TCP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

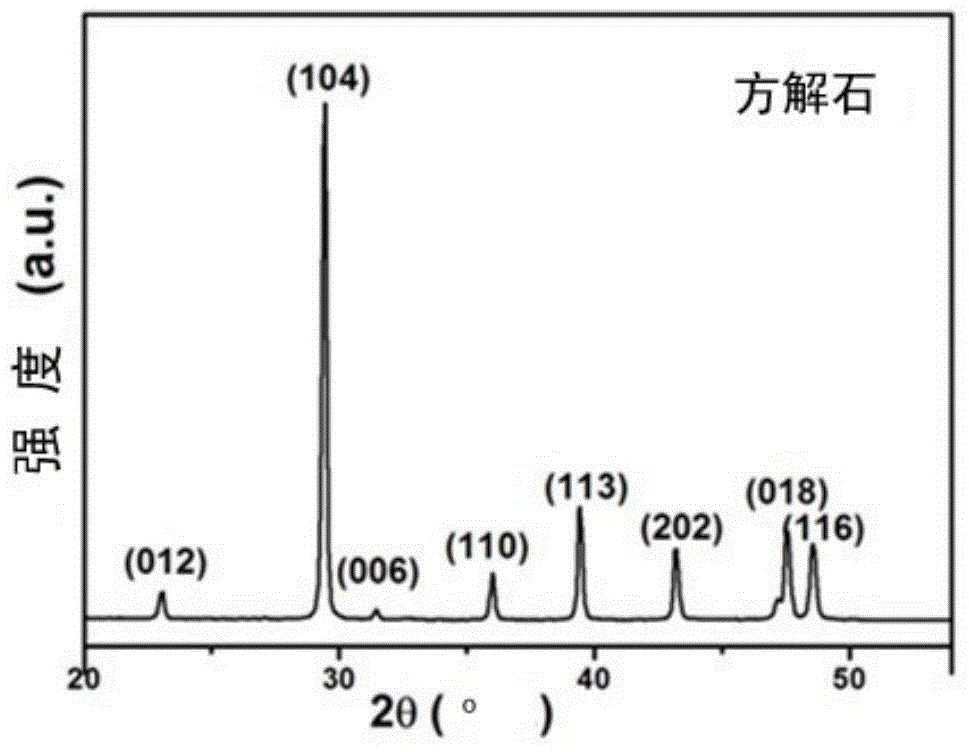

[0029] Raw materials and requirements: egg shells and diammonium hydrogen phosphate (analytical pure).

[0030] Removal of organic matter: After peeling and removing the egg membrane on the eggshell, immerse in boiling water and boil for 30 minutes, and ultrasonically vibrate in 10wt.% NaClO solution for 40 minutes to remove organic matter in the eggshell and impurities on the surface. After taking it out, wash it three times with deionized water and dry it in a vacuum oven at 100°C.

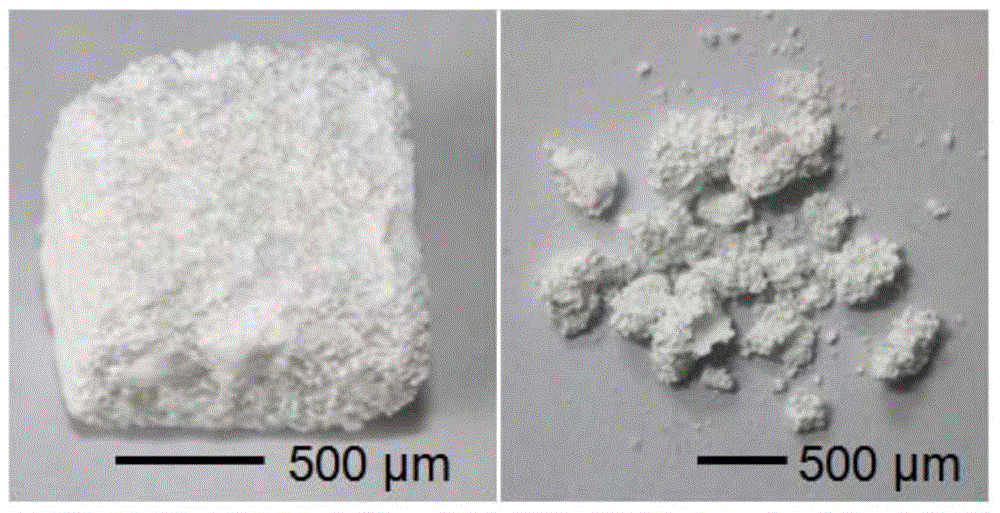

[0031] Grinding and sieving: Grind the eggshells after removing organic matter in a mortar and pass through 20 and 40 mesh sieves, and take 20-40 mesh eggshell particles (355-850 μm in size) for the next step of hydrothermal reaction.

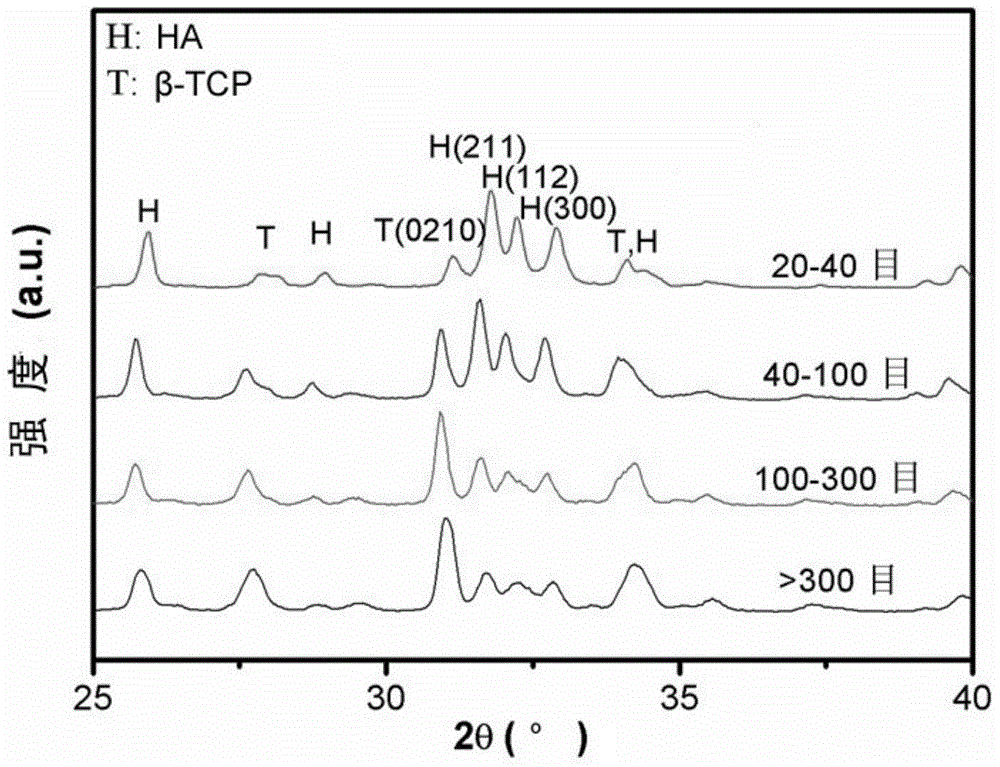

[0032] Hydrothermal reaction: mix 20-40 mesh eggshell particles with (NH 4 ) 2 HPO 4 The solution was mixed according to a weight ratio of 1:15 and placed in a hydrothermal reaction kettle, and the hydrothermal reaction was carried out at 200° C. for 24 hours ...

Embodiment 2

[0037] This example will select 40 and 100 mesh sieves to sieve to obtain eggshell particles (size 150-355 μm) as raw materials, and the mass percentage of β-TCP in the two-phase calcium phosphate material obtained by hydrothermal reaction is about 70% ( figure 2 ). All the other are with embodiment 1.

Embodiment 3

[0039] This example will select 100 and 300 mesh sieves to sieve to obtain eggshell particles (size 45-150 μm) as raw materials, and the mass percentage of β-TCP in the two-phase calcium phosphate material obtained by hydrothermal reaction is about 45% ( figure 2 ). All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com