Method for preparing beta-TCP//HAP/Ca2P2O7 multiphase porous bioceramic

A bioceramics, ca2p2o7 technology, applied in the direction of ceramic products, applications, medical science, etc., to achieve the effect of good pore connectivity, simple equipment, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

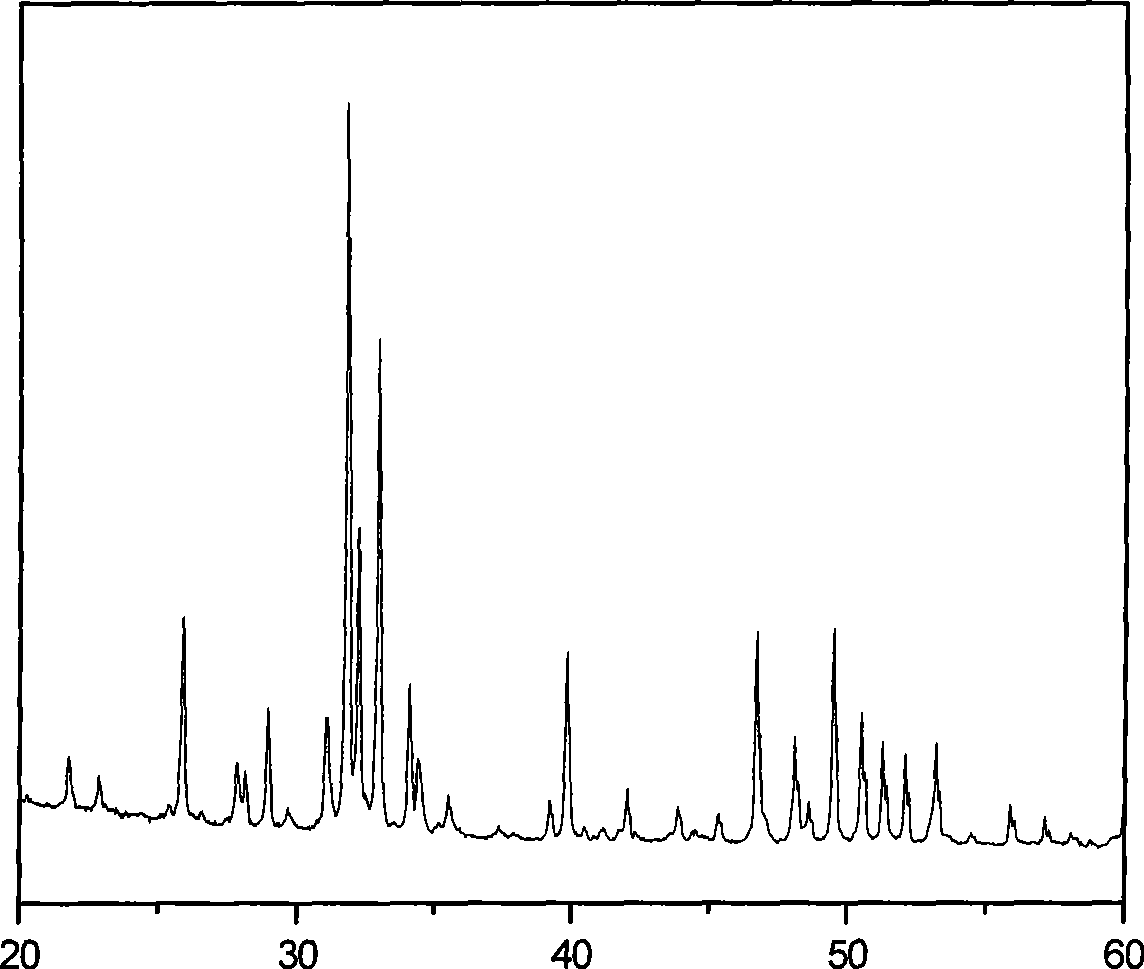

[0028] Take a healthy adult bovine femur, remove the surface soft tissue, and use a trepan drill with an inner diameter of 8mm to drill the femoral head and the cancellous bone of the distal femur. Boil in the solution for more than 10 hours; wash the boiled bovine cancellous bone with boiling hot water for more than 10 minutes, rinse with flowing normal temperature water for more than 10 minutes, rinse with deionized water for more than 10 minutes, and treat with serial alcohol for more than 10 minutes. Put the bovine spongy bone in a drying oven at 50°C-70°C to dry for more than 3 days, put the dried bovine spongy bone into a calciner for sintering, the heating rate is 5-10°C / min, and keep warm at 600°C-800°C for 3 hours Above, wait for it to cool down to room temperature naturally, take it out of the calciner. The use concentration is 0.04mol L -1 NH 4 h 2 PO 4 The bovine cancellous bone after degreasing and protein removal was treated with the solution, and at room tem...

Embodiment 2

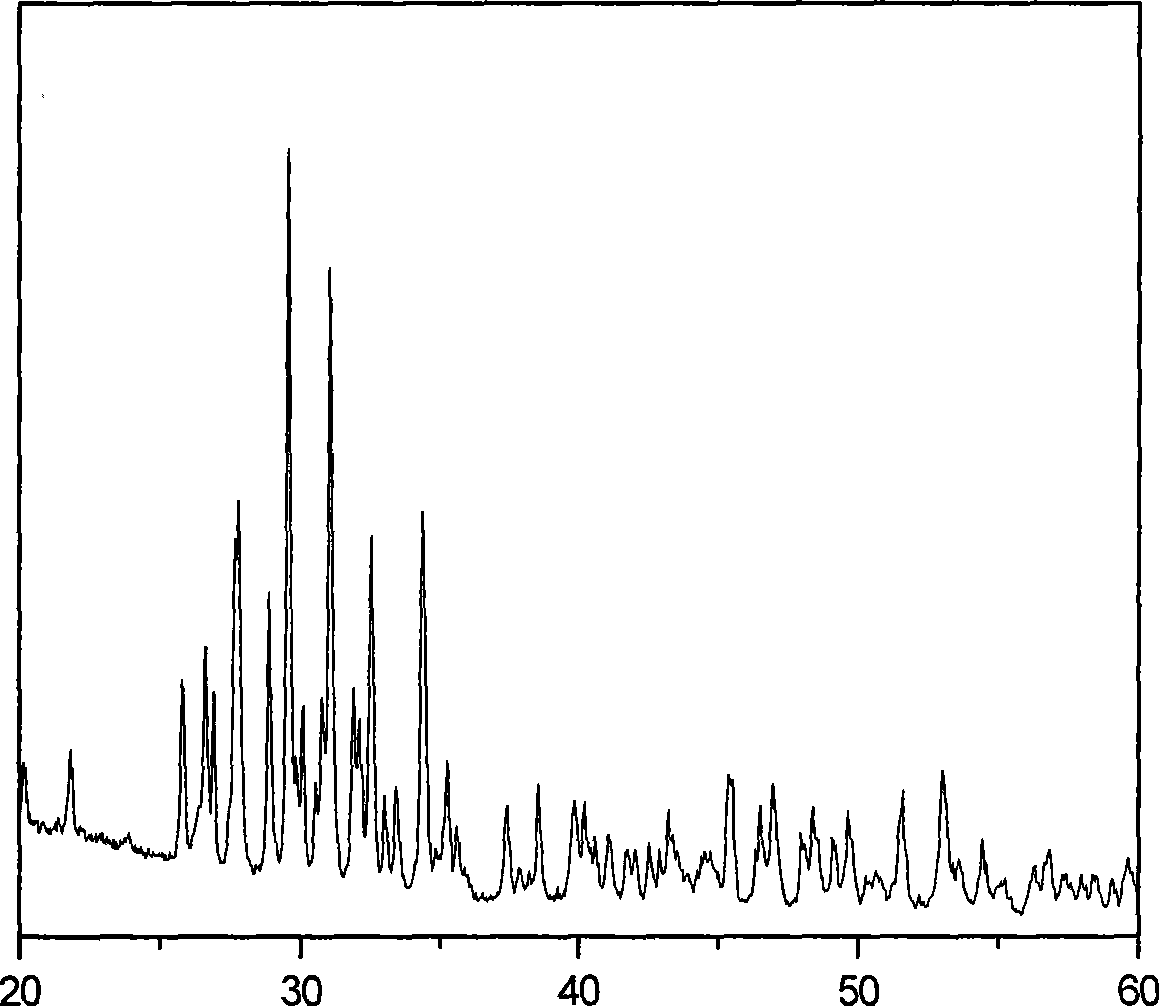

[0030]Take a healthy adult bovine femur, remove the surface soft tissue, and use a trepan drill with an inner diameter of 8mm to drill the femoral head and the cancellous bone of the distal femur. Boil in the solution for more than 10 hours; wash the boiled bovine cancellous bone with boiling hot water for more than 10 minutes, rinse with flowing normal temperature water for more than 10 minutes, rinse with deionized water for more than 10 minutes, and treat with serial alcohol for more than 10 minutes. Put the bovine spongy bone in a drying oven at 50°C-70°C to dry for more than 3 days, put the dried bovine spongy bone into a calciner for sintering, the heating rate is 5-10°C / min, and keep warm at 600°C-800°C for 3 hours Above, wait for it to cool down to room temperature naturally, take it out of the calciner. The use concentration is 1.00mol·L -1 NH 4 h 2 PO 4 The bovine cancellous bone after degreasing and protein removal was treated with the solution, and at room temp...

Embodiment 3

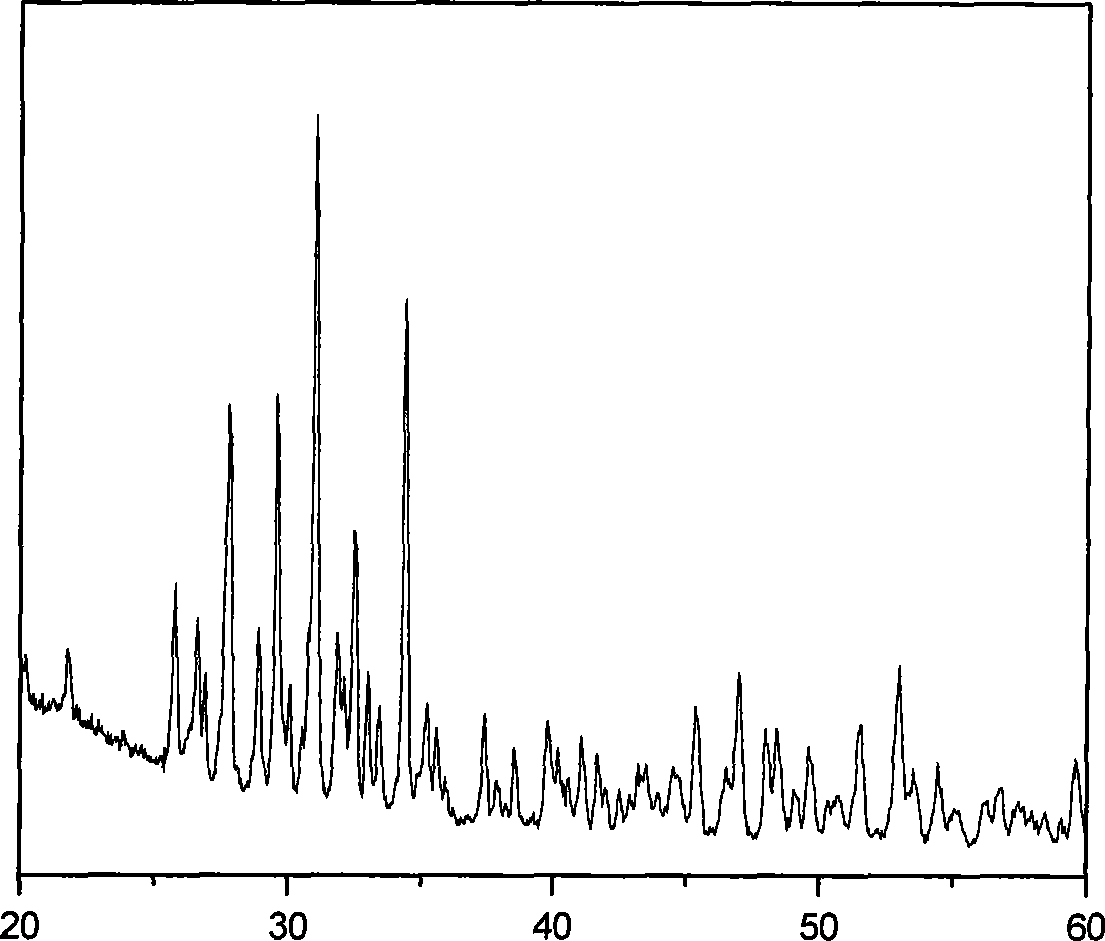

[0032] Take a healthy adult bovine femur, remove the surface soft tissue, and use a trepan drill with an inner diameter of 8mm to drill the femoral head and the cancellous bone of the distal femur. Boil in the solution for more than 10 hours; wash the boiled bovine cancellous bone with boiling hot water for more than 10 minutes, rinse with flowing normal temperature water for more than 10 minutes, rinse with deionized water for more than 10 minutes, and treat with serial alcohol for more than 10 minutes. Put the bovine spongy bone in a drying oven at 50°C-70°C to dry for more than 3 days, put the dried bovine spongy bone into a calciner for sintering, the heating rate is 5-10°C / min, and keep warm at 600°C-800°C for 3 hours Above, wait for it to cool down to room temperature naturally, take it out of the calciner. The use concentration is 0.60mol·L -1 NH 4 h 2 PO 4 The bovine cancellous bone after degreasing and protein removal was treated with the solution, and at room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com