Nano-grade beta-tricalcium phosphate and preparation method thereof

A tricalcium phosphate, nano-scale technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high site and production equipment requirements, easy mixing of other substances, complex processes, etc., to achieve simple steps, Guaranteed purity and safety, good bone conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 nanoscale β-tricalcium phosphate

[0047] 1) Prepare micron-sized β-TCP particles that meet the β-TCP standard for surgical implants as raw materials;

[0048] 2) Disperse micron-sized β-TCP particles in a diethylene glycol dispersion, use zirconia beads as the ball milling medium, and continuously ball mill at a speed of 1800r / min for 12 hours;

[0049] 3) Centrifuge to remove diethylene glycol dispersion;

[0050] 4) Rinse with dichloromethane, dry in vacuum, and store.

Embodiment 2

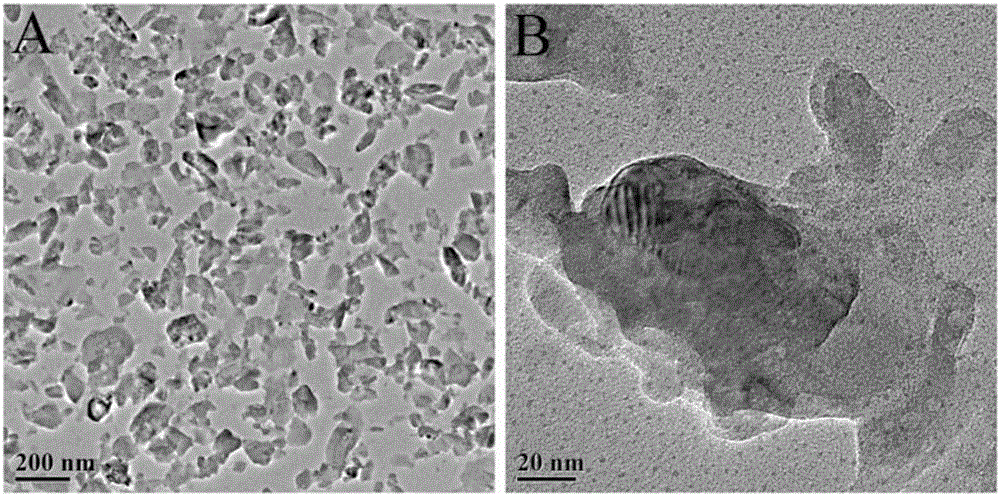

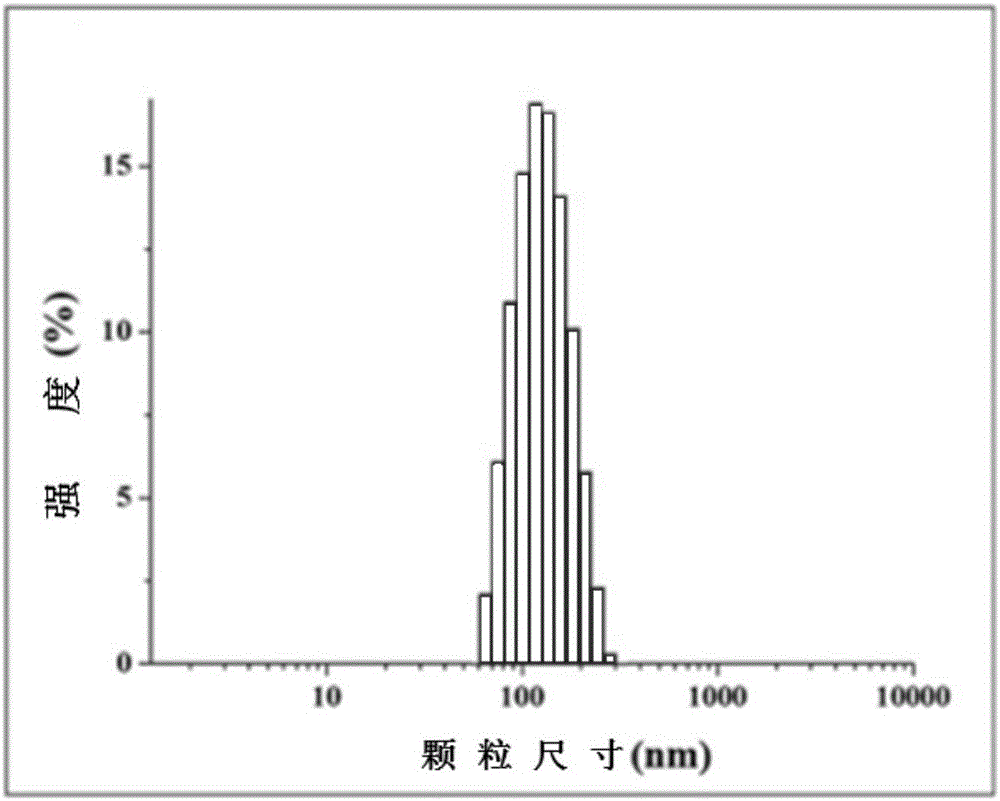

[0051] Embodiment 2 transmission electron microscopy and dynamic light scattering analysis verification

[0052]The particle size of the β-TCP particles prepared in Example 1 was observed by a H-7000 transmission electron microscope, and the acceleration voltage used was 75KV. The particle size of the prepared β-TCP particles was tested by dynamic light scattering. The Zetasizer Nano-ZS potential and particle size analyzer was used to determine the particle size and Zeta potential of polymer drugs. Particle size measurement parameters: He-Ne laser (wavelength 635nm), refractive index and viscosity are n=1.333 and η=0.933cp respectively, measurement temperature is 25°C. Potential measurement parameters: He-Ne laser (wavelength 635nm), scattering angle θ=14°, measurement temperature 25°C.

[0053] Observing the prepared nano-sized β-TCP particles by TEM, the particles are in irregular shape, and the particle size range is 20-160nm (such as figure 1 A, B). Observation by dyna...

Embodiment 3

[0054] The preparation of embodiment 3 polylactic acid / nanometer β-tricalcium phosphate composite material

[0055] 1) Weigh nano-sized β-TCP particles and PLA in proportion according to requirements, wherein the content of β-TCP is 10wt%, 30wt%, 50wt% respectively, prepare a composite solution with dichloromethane, stir and ultrasonically mix to obtain PLA / nano β-TCP complex solution, the solution is poured into a flat-bottomed glass dish, and vacuum-dried to obtain a PLA / nano β-TCP complex film;

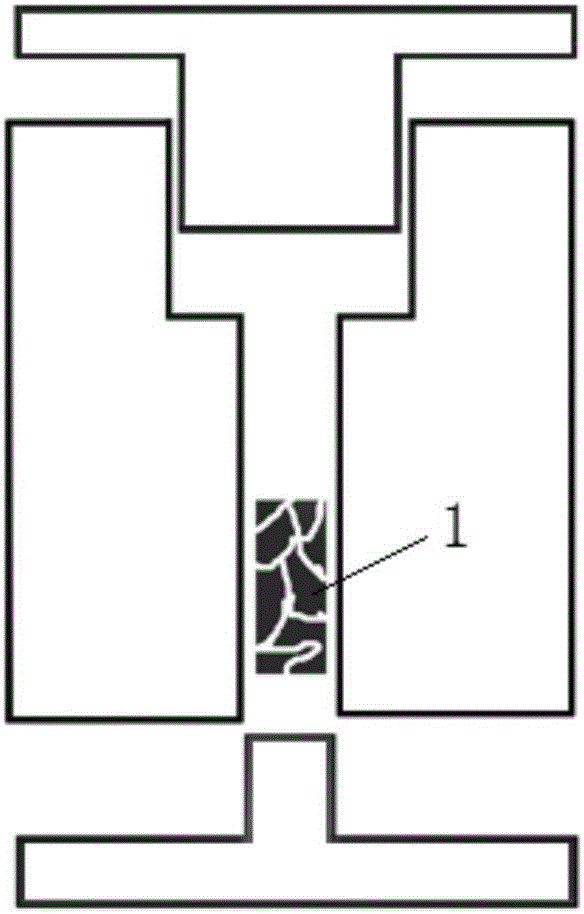

[0056] 2) Take the PLA / nano β-TCP composite film, melt and press it at 110°C and 260MPa to form a cylindrical parison of 10×20mm (diameter of the bottom surface×height), and hot press molding (the schematic diagram of hot pressing processing is shown in image 3 As shown, wherein 1 is a composite film, and the rest are processing molds), rapid cooling, and demoulding, the rods of high-strength PLA / nanometer β-TCP composite materials of different proportions can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com