Preparation method of beta-TCP/11A composite biological material

A technology of composite biomaterials and systems, applied in the field of preparation of β-TCP/HA composite biomaterials, can solve the problems of low strength, easy cracks, and low strength of porous ceramics, achieve good biocompatibility, and avoid sharp decline Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

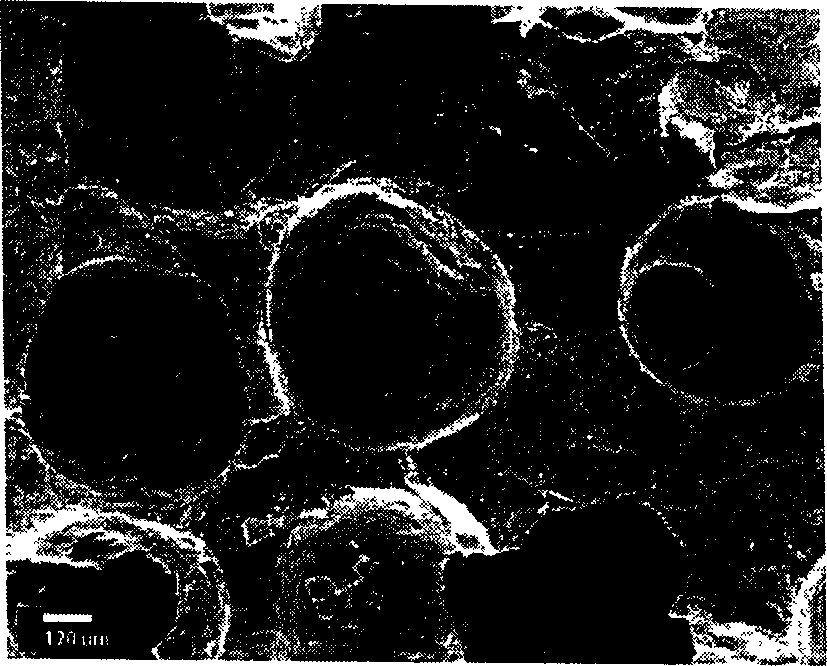

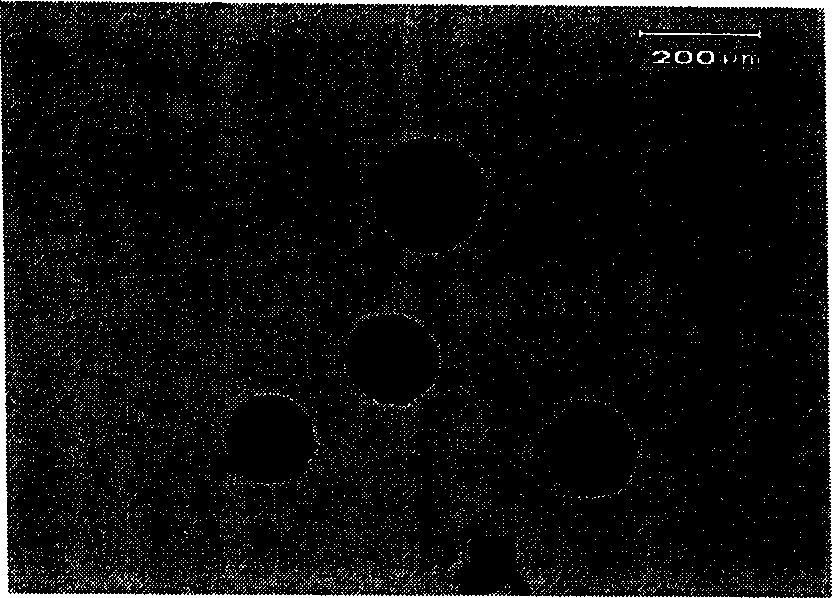

[0019] Embodiment 1: the (NH 4 ) 2 HPO 4 solution, Ca(NO 3 ) 2 4H 2 O with 3% mol Mg(NO 3 ) 2 mixed solution. Molar ratio (Ca+Mg) / P=1.5, (NH 4 ) 2 HPO 4 The solution was slowly added dropwise to the mixed solution. Stirring and constant use of NH 3 ·H 2 O adjusts the pH of the reaction solution to maintain it at 7-8. After the dropwise addition, continue to stir for 3 hours, then let stand for 4 hours, wash and filter the precipitate, dry at 75-80°C for 11 hours, calcinate the precipitated precursor at 800°C, and keep the temperature for 6 hours. The calcined powder was mixed with 2% NaHPO 4 Grind together. Pass through a 200-mesh sieve to obtain β-TCP powder. According to the bone glue / water ratio of 0.1g / ml and bone glue solution / β-TCP ratio of 2ml / g, put the β-TCP powder into the bone glue solution to make a slurry, then drop it into heat conduction oil at a temperature of 40°C to disperse into small The balls were cooled and filtered after two minutes, and...

Embodiment 2

[0021] Embodiment 2: bone glue / water is 0.1g / ml, bone glue solution / β-TCP is 2ml / g, the β-TCP powder prepared in embodiment 1 is put into the bone glue solution to make slurry and then dripped at a temperature of Disperse into small balls in heat conduction oil at 50°C, cool and filter after two minutes, wash the small balls with acetone first, and then wash with absolute ethanol. The prepared pellets are sieved, and the particle size is between 125 μm and 700 μm.

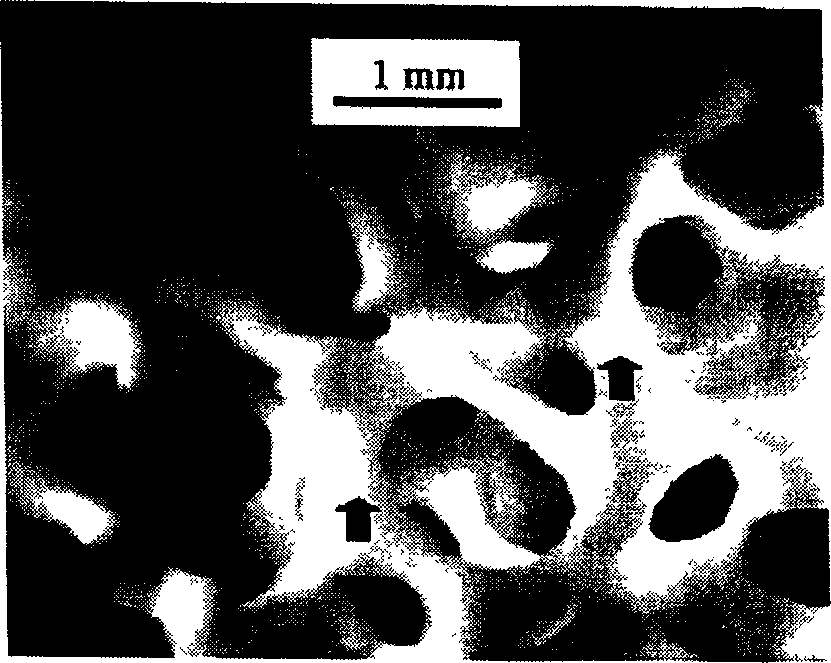

[0022] Press the β-TCP / bone glue pellets with a particle size range of 315-400 μm into a flake green body with a height of h=3mm and a diameter of Φ=10mm, and calcinate at 1000°C for 2 hours. The β-TCP sheet The body was first immersed in β-TCP sol twice, and then heat-treated at 600 °C. Then repeat 6 times in HA sol, heat treatment at 600°C after each dipping. Finally, it was sintered at 1000°C and kept for 2h.

Embodiment 3

[0023] Embodiment 3: bone glue / water is 0.1g / ml, bone glue solution / β-TCP is 2.5ml / g, puts the β-TCP powder prepared in embodiment 1 into the bone glue solution to make a slurry and then drops into temperature Disperse into small balls in heat conduction oil at 45°C, cool and filter after two minutes, wash the small balls with acetone first, and then with absolute ethanol. The prepared pellets are sieved, and the particle size is between 125 μm and 700 μm. Due to the increase in the proportion of bone glue, the elasticity of the ball is enhanced.

[0024] Press the β-TCP / bone glue pellets with a particle size range of 400-800 μm into a flake green body with a height of h=3mm and a diameter of Φ=10mm, calcinate at 1000°C, and keep warm for 2 hours. The β-TCP sheet The body was first immersed in β-TCP sol twice, and then heat-treated at 600 °C. Then repeat 6 times in HA sol, heat treatment at 600°C after each dipping. Finally, it was sintered at 1000°C and kept for 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com