Beta-TCP porous material and preparation method thereof

A porous material and slurry technology, applied in the field of β-TCP porous material and its preparation, can solve the problems of reducing the degradation performance of β-TCP material, bioglass cannot be completely degraded, and the strength will not be greatly improved, achieving superiority Degradability and mechanical properties, improvement of bone defect repair and reconstruction materials, the effect of improving mechanical properties and degradation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

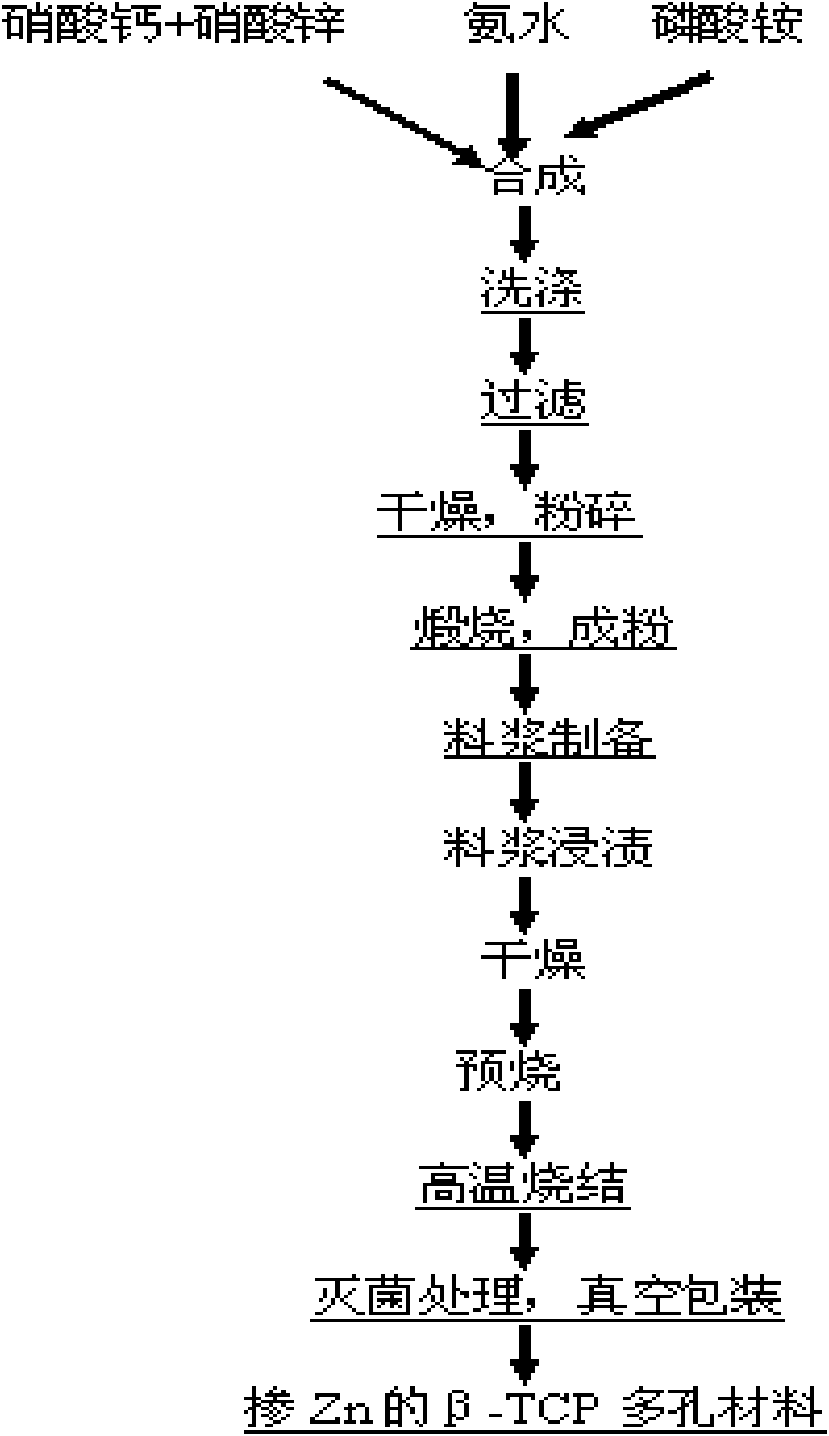

[0040] according tofigure 1 The wet chemical preparation of Zn-doped β-TCP porous material was carried out. Dissolve ammonium phosphate, zinc nitrate, and calcium nitrate in the dissolving tank completely and fully with deionized water respectively. The solution should be clear and transparent. The corresponding stoichiometric ingredients. Inject the ammonium phosphate solution into the reaction kettle, slowly drop the calcium nitrate and zinc nitrate solutions into the ammonium phosphate solution under room temperature and stirring conditions, at the same time, slowly drip ammonia water into the reaction kettle, and continue stirring for 4 hours after the reaction is complete. Aging for 24h. The aged sol was white, and the supernatant liquid was removed, and an equal amount of deionized water was added under stirring conditions, and after repeated washing for 3 times, it was filtered through a filter funnel with a filter cloth to obtain a Zn-doped β-TCP precursor. The Zn-do...

Embodiment 2

[0042] Dissolve ammonium phosphate, zinc nitrate, and calcium nitrate in the dissolving tank completely and fully with deionized water respectively. The solution should be clear and transparent. The corresponding stoichiometric ingredients. Inject the ammonium phosphate solution into the reaction kettle, slowly drop the calcium nitrate and zinc nitrate solutions into the ammonium phosphate solution under room temperature and stirring conditions, at the same time, slowly drip ammonia water into the reaction kettle, and continue stirring for 8 hours after the reaction is complete. Aging 48h. The aged sol was white, and the supernatant liquid was removed, and an equal amount of deionized water was added under the condition of stirring. After repeated washing for 4 times, the sol was filtered through a filter funnel and a filter cloth to obtain a Zn-doped β-TCP precursor. The Zn-doped β-TCP precursor was dried under vacuum at 90°C to remove moisture. The agglomerated powder is d...

Embodiment 3

[0044] Dissolve ammonium phosphate, zinc nitrate, and calcium nitrate in the dissolving tank completely and fully with deionized water respectively. The corresponding stoichiometric ingredients. Inject the ammonium phosphate solution into the reaction kettle, slowly drop the calcium nitrate and zinc nitrate solutions into the ammonium phosphate solution under room temperature and stirring conditions, at the same time, slowly drip ammonia water into the reaction kettle, and continue stirring for 10 hours after the reaction is complete. After aging for 36 hours, remove the supernatant, add an equal amount of deionized water, wash repeatedly for 5 times, and then filter through a filter bucket with a filter cloth to obtain a Zn-doped β-TCP precursor. The Zn-doped β-TCP precursor was dried under vacuum at 80°C to remove moisture. The agglomerated powder is dry-milled and crushed in the crusher, and then passed through a 100-mesh sieve, and the sieved material is returned to conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com