Method for preparing artificial bone with three-dimensional bone-like structure and product prepared by method

A three-dimensional structure and three-dimensional technology, applied in the field of artificial bone, can solve problems such as low biological activity, lack of support, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

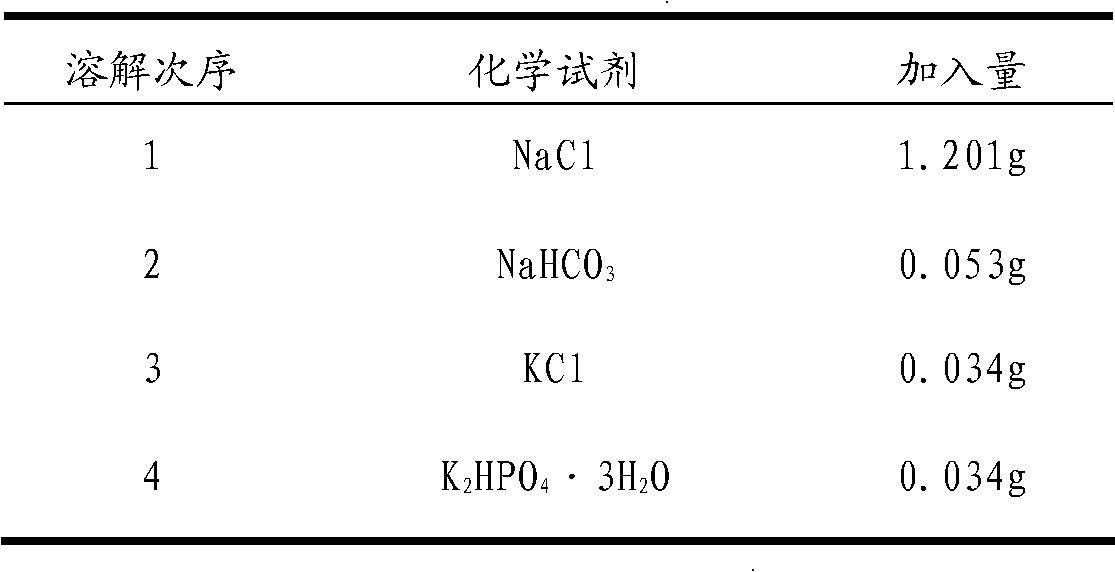

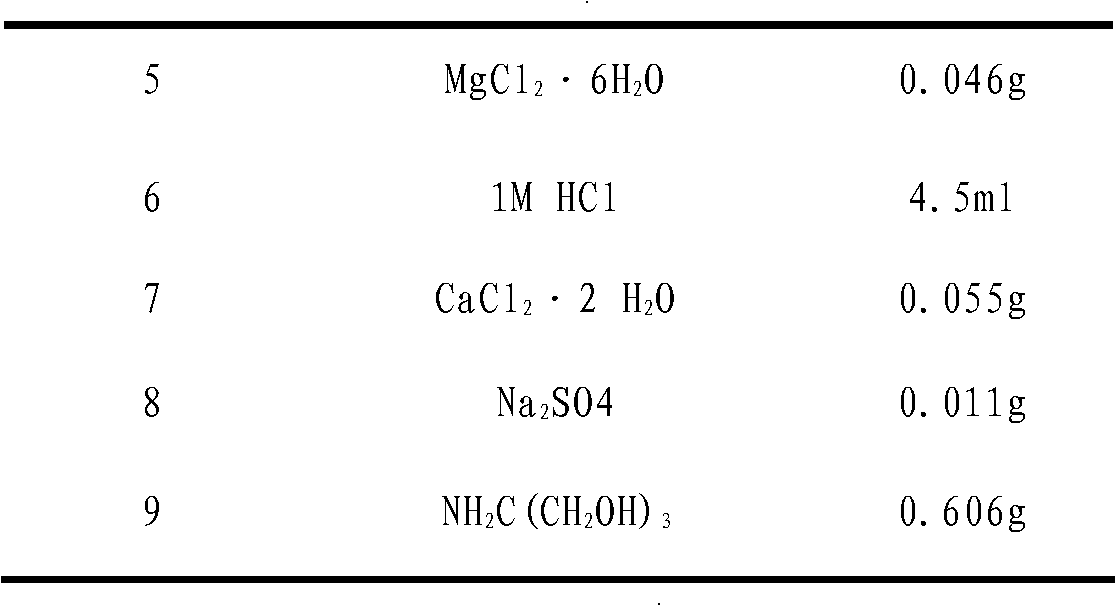

[0023] (1) Add 30vol% HA hydroxyapatite, 0.3 gram of sodium lauryl sulfate and 0.3 gram of lauryl alcohol per 100 ml of deionized water, and stir evenly to obtain a ceramic mixed slurry; The 5wt% sodium alginate of 8vol% of the total volume of the mixture is used as the curing agent, and then the 3M CaCl that accounts for 8vol% of the total volume of the mixture is added 2 As an initiator, a green body of a three-dimensional bone-like structure is made by using a three-dimensional stacked assembly method;

[0024] The specific preparation process of the stent material green body is as follows:

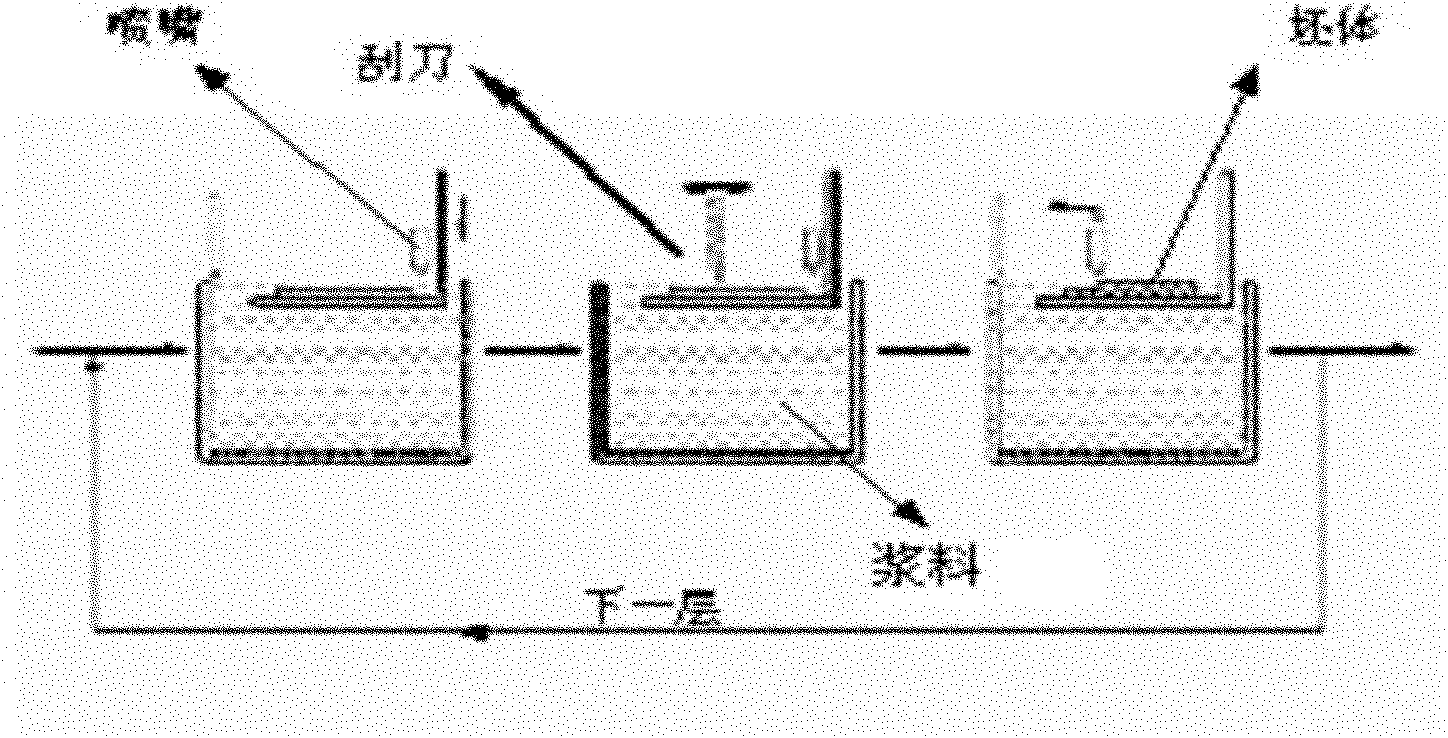

[0025] In order to reproduce the complex external contour and internal aperture of the three-dimensional structure of natural bone, the three-dimensional gel laminate molding system disclosed in the authorized announcement CN 98124402.5C (Patent No. ZL 98124402.5) is automatically formed to obtain the blank of the scaffold material, and the internal The pore size can be produced by fo...

Embodiment 2

[0047] (1) Add 30vol% hydroxyapatite, 0.1 gram of sodium lauryl sulfate and 0.5 gram of lauryl alcohol per 100 ml of deionized water, and stir evenly to obtain a ceramic mixed slurry; then add the mixture to the above ceramic mixed slurry The 5wt% sodium alginate of total volume 5vol% is used as curing agent, then adds the 3M CaCl that accounts for 5vol% of total mixture volume 2 As an initiator, a green body of a three-dimensional bone-like structure is made by using a three-dimensional stacked assembly method;

[0048] The specific preparation process of the stent material green body is shown in Example 1.

[0049] (2) Step (1) is made into a three-dimensional bone-like structure green body, dried at 37°C for 48 hours, and then sintered at 900°C for 6 hours to obtain a HA three-dimensional structure scaffold with a pore size of 300-600 μm; made into a 10mm x 10mm 10 x 2mm samples, 5 of which are used to test the compressive strength, and 5 are used to test the activity of a...

Embodiment 3

[0056] (1) Add 30vol% hydroxyapatite, 0.5 gram of sodium lauryl sulfate and 0.1 gram of lauryl alcohol per 100 ml of deionized water, and stir evenly to obtain a ceramic mixed slurry; then add the mixture to the above ceramic mixed slurry The 5wt% sodium alginate of total volume 10vol% is used as curing agent, then adds the 3M CaCl that accounts for the total volume of mixture 10vol% 2 As an initiator, a green body of a three-dimensional bone-like structure is made by using a three-dimensional stacked assembly method;

[0057] The specific preparation process of the stent material green body is shown in Example 1.

[0058] (2) Step (1) is made into a three-dimensional bone-like structure green body, dried at 37°C for 48 hours, and then sintered at 1000°C for 5 hours to obtain a HA three-dimensional structure scaffold with a pore size of 300-600 μm; made into a 10mm x 10mm 10 x 2mm samples, 5 of which are used to test the compressive strength, and 5 are used to test the activi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com