Method for preparing different particle sizes of porous beta-TCP microspheres by oil-in-water type solid emulsification

An oil-in-water microsphere technology, which is applied in the preparation of microspheres, prostheses, and pharmaceutical formulations, can solve the problems of success rate, high cost, and complexity of introducing antigenic substances, and achieve good biocompatibility and operation Simple, Widely Applicable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

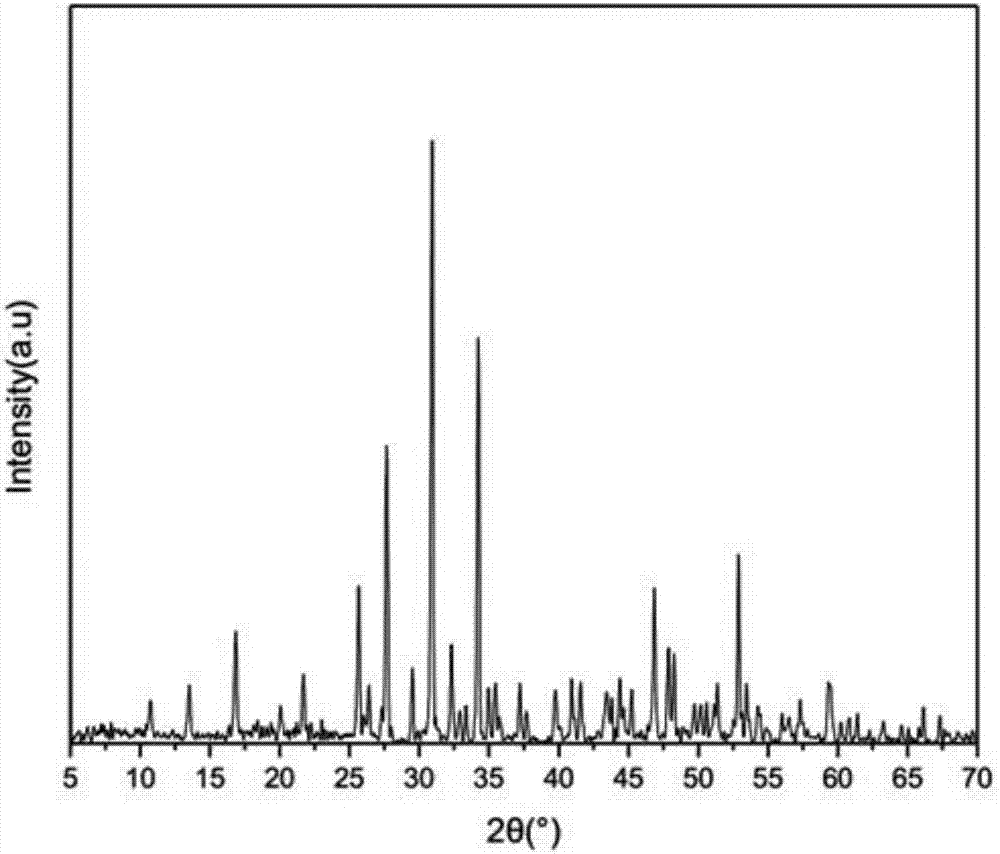

[0026] Weigh 3.9618g (NH4) 2 HPO 4 , 11.8075gCa (NO 3 ) 2 4H 2 Dissolve O in deionized water, and dilute to volume with a 100mL volumetric flask. 100mL(NH4) 2 HPO 4 The solution was slowly added dropwise to 90mL Ca(NO 3 ) 2 In the solution, the pH of the solution was adjusted to 7 with ammonia water. After the solution was aged for 24 hours, it was filtered, and the resulting precipitate was washed 5 times with deionized water, and the precipitate was placed in a refrigerator at -21°C for freeze-drying to obtain a nanoscale hydroxyapatite precursor. Weigh 0.5g of PVB and dissolve it in 10mL of dichloromethane solvent, stir for 12 hours, then weigh 1g of hydroxyapatite precursor and add it into the solution, and continue to stir for 3 hours to obtain a slurry. Dissolve 5g of PVA in 500mL of deionized water to obtain a PVA solution. Add the slurry dropwise to the PVA solution at 8°C and a rotation speed of 200rpm. After stirring for 3 hours, filter and wash with deioniz...

Embodiment 2

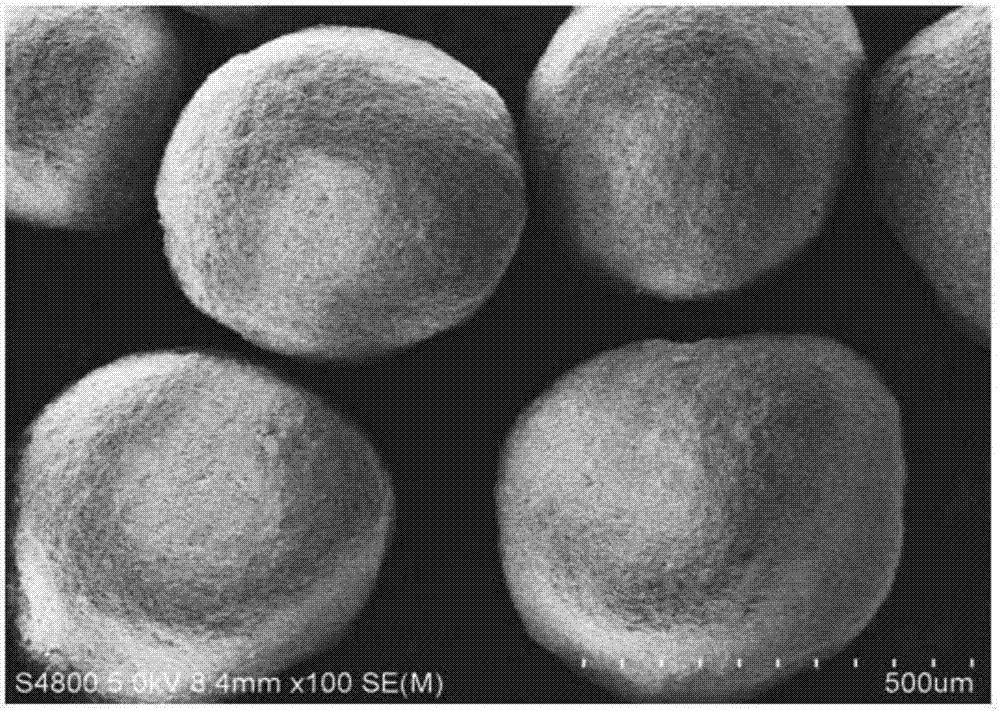

[0029] Weigh 0.5g of PVB and dissolve it in 15mL of dichloromethane solvent, stir for 12 hours, then weigh 1g of the hydroxyapatite precursor prepared in Example 1 and add it into the solution, stir for 3 hours to obtain a slurry. Dissolve 5g of PVA in 500mL of deionized water to obtain a PVA solution. Add the slurry dropwise to the PVA solution at 8°C and a rotation speed of 200rpm, stir for 3 hours, filter, wash with deionized water for 5 times, and freeze the obtained solid. After drying, precursor microspheres were obtained. The precursor microspheres were sintered in a muffle furnace to obtain porous β-TCP microspheres. The sintering procedure was as follows: from room temperature to 600°C, the heating rate was controlled at 2°C / min, kept at 600°C for 2 hours, and then heated at 5°C / min. The heating rate was raised from 600°C to 1100°C at a rate of min, kept at this temperature for 2 hours, and finally cooled to room temperature.

[0030] image 3 It is the SEM image of...

Embodiment 3

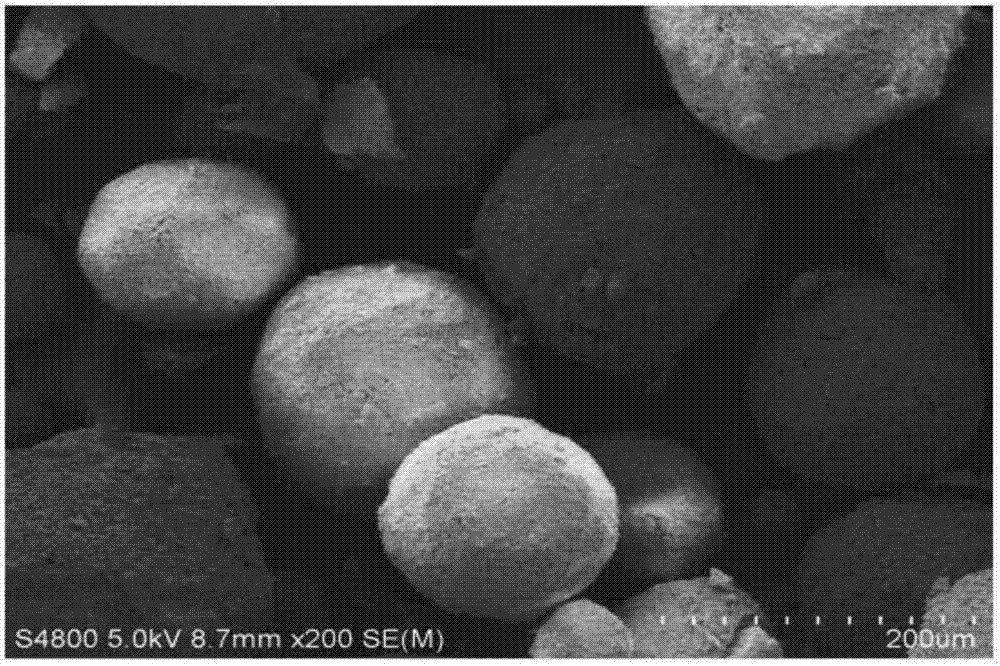

[0032] Weigh 0.5g of PVB and dissolve it in 10mL of dichloromethane solvent, stir for 12 hours, then weigh 1g of the hydroxyapatite precursor prepared in Example 1 and add it into the solution, stir for 3 hours to obtain a slurry. Dissolve 5g of PVA in 500mL of deionized water to obtain a PVA solution. Add the slurry dropwise to the PVA solution at 8°C and a rotation speed of 400rpm, stir for 3 hours, filter, wash with deionized water for 5 times, and freeze the obtained solid. After drying, precursor microspheres were obtained. The precursor microspheres were sintered in a muffle furnace to obtain porous β-TCP microspheres. The sintering procedure was as follows: from room temperature to 600°C, the heating rate was controlled at 2°C / min, kept at 600°C for 2 hours, and then heated at 5°C / min. The heating rate was raised from 600°C to 1100°C at a rate of min, kept at this temperature for 2 hours, and finally cooled to room temperature.

[0033] Figure 4 It is the SEM image of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com