Compound bone cement with high inorganic components as well as preparation method and application of compound bone cement

An inorganic component and composite technology, applied in the field of medical materials, can solve the problems of slow degradation rate of nano-hydroxyapatite, loosening between implant materials and host bone, and inflammatory response of surrounding tissues, and achieve a simple and feasible preparation method, Effect of enhancing biocompatibility and enhancing absorbability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

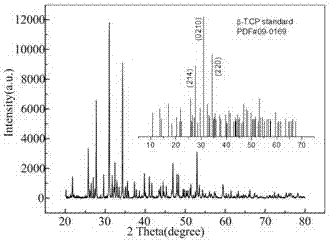

Image

Examples

Embodiment 1

[0033] Embodiment 1: raw material preparation:

[0034] 1. Synthesis of PMMA:

[0035] Dissolve 0.35g polyvinyl alcohol (PVA), 56ml MMA and 0.13g benzoyl peroxide (BPO) in 360ml deionized water, stir vigorously, raise the temperature to 80°C for 2 hours, then raise the temperature to 87°C for 2 hours , and finally raised the temperature to 95° C. for 2 hours to obtain a white granular product, which was washed twice with water and twice with alcohol, and then dried in vacuum. After the product is completely dry, use a ball mill to grind it, pass through a 100-mesh sieve to obtain white PMMA powder, and store it dry.

[0036] 2. Synthesis of P(MMA-co-MPS):

[0037] 2.1 Raw material purification

[0038] THF purification: Add calcium hydride to tetrahydrofuran (THF) and heat to 62°C for distillation. Add sodium potassium alloy to the liquid obtained after distillation and heat it to 62°C for distillation to obtain anhydrous THF with high purity.

[0039] MPS purification: A...

Embodiment 2

[0052] Example 2: Synthesis of Bone Cement:

[0053] At room temperature, the solid components and liquid components of bone cement were mixed in a ratio of 1:3 by mass to volume (W / V), stirred evenly, poured into the mold, and the samples were taken out after complete curing.

[0054] The solid phase components include PMMA, 0.3-nHA, β-TCP, BaSO 4 , BPO; liquid components include MMA, DMT. Among them, the molecular weight of PMMA is about 750,000. The raw material ratio of embodiment 2~4 is shown in table 1:

[0055] Table 1

[0056]

Embodiment 3

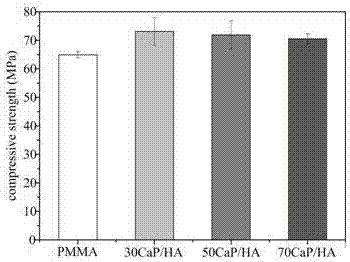

[0057] Example 3: Mechanical Properties Test

[0058] The mechanical property characterization of bone cement in Example 2 mainly chooses to test the compressive property of the finished product. The test method is as follows: the compression test bone cement sample is ground into a cylinder with a length of 12 mm and a diameter of 6 mm. Use a universal material testing machine (WD-5A) with a loading rate of 5 mm / min. Record the stress-deformation diagram of the sample, take the stress when the K value in the stress-deformation curve is 2%, and divide it by the cross-sectional area of the cylinder to obtain the compressive strength.

[0059] All mechanical property tests are carried out according to ISO 5833 international standard.

[0060] The mechanical properties of the CaP / HA-PMMA bone cement in the present invention are characterized by compressive strength. from figure 2 It can be seen that the compressive strength of CaP / HA-PMMA bone cement is increased compared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com