Structural flame-retardant functional composite material and preparation method thereof

A composite material and structural flame retardant technology, which is applied in the field of materials science and can solve the problems of damage to the interface structure of composite materials and mechanical decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

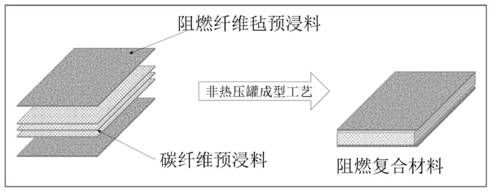

[0072] (3) Preparation of flame retardant structural material prepreg form

[0073] The flame-retardant structural material is a pure dry fiber mat. In the preparation of composite materials, it can be infiltrated with resin together with the reinforcements (fibers or particles) that are also in a dry state. It is suitable for traditional liquid molding processes (including resin transfer molding). RTM, vacuum induction technology). However, with the development of autoclave technology, prepregs made of fiber-reinforced resin prepregs have been widely used. Since the fiber reinforcement is already proportioned with the resin, the preparation does not require resin injection.

[0074] Therefore, the present invention proposes the form of a flame-retardant structure fiber mat prepreg. Through the fiber mat pre-impregnation process, the flame-retardant structure material is pre-impregnated with resin to make a flame-retardant structure material prepreg, which can not only be use...

Embodiment 2

[0120] Flame retardant structural material M2: disperse expanded graphite (60 parts), glass fiber (10 parts), mineral fiber (10 parts) and polyester (20 parts) in an aqueous solution, and stir at a uniform speed for 8 hours to obtain a uniformly dispersed suspension , after filtration through a screen, a fiber felt with a surface weight of 150g / ㎡ and a thickness of 0.5mm containing expanded graphite was obtained, which was dried in an oven at 60°C for 1 to 3 hours, and then cured at a temperature of 80°C to obtain flame retardant fiber mat. Then, the flame-retardant fiber mat is impregnated with epoxy resin through resin impregnation equipment to prepare a prepreg with a resin weight percentage of 50%, which is used for composite material preparation.

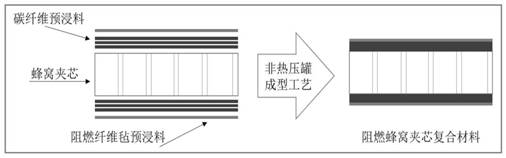

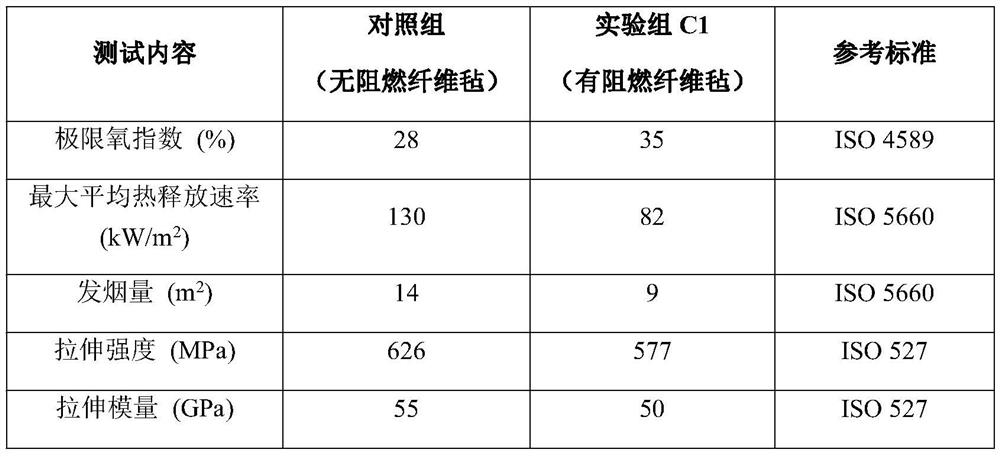

[0121] Composite material C2: as in Example 1, carbon fiber reinforced epoxy prepreg (resin weight percentage 50%) is used, and the flame retardant fiber mat is used as the surface layer of the composite material, and is placed...

Embodiment 3

[0126] Flame-retardant structural material M2: the material formula and preparation method are the same as those in the second embodiment

[0127] Composite material C3: use carbon fiber reinforced flame retardant epoxy prepreg (resin weight percentage of 50%), use flame retardant fiber felt as the surface layer of the composite material, and place it on the upper and lower surfaces of the prepreg as a whole. Tank forming process, forming at 120°C under vacuum pressure of 0.8bar. The flame-retardant fiber felt and the carbon fiber are combined by resin curing to become the protective layer on the upper and lower surfaces of the composite material. The material performance comparison is shown in Table 3. It can be seen that the M2 flame retardant material can effectively improve the flame retardant performance of the material. By comparing the requirements of the EN45545 standard, the composite material C3 has partially met the standard requirements and can be used for rail tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com